Page 1

Installation Instructions

Software Update

Part No. 1300636GT

Rev. A

February 2020

Z ®-33

Page 2

Software Release Notes

REV A

Introduction

Glossary of Terms

TCON - Turntable controls (Ground controls)

PCON - Platform controls

Tools Required:

Computer or Laptop with 64 bit

Windows 7 or 10 operating system

Internet access

Plus+1 Service Tool

Note: The Plus+1 Service Tool must be

installed on your computer.

Programming cable

Genie part number 1267881GT

Programming harness

Genie part number 110803GT

Observe and Obey:

This procedure shall be completed by a

person trained and qualified on the repair of

this machine.

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Before Starting Installation:

Read, understand and obey the safety rules

and operating instructions in the appropriate

operator's manual.

Be sure that all necessary tools and parts are

available and ready for use.

Read this procedure completely and adhere

to the instructions. Attempting shortcuts may

produce hazardous conditions.

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

Note: These installation instructions only

apply to the Genie models listed on the front

cover.

If you have any further questions regarding these

instructions or need assistance, please contact

Genie Product Support at one of the following

telephone numbers:

United States: 800-536-1800

Canada: 425-881-1800

Europe: UK 0044 1476 584 333

France 0033 237 260 986

Germany 0049 421 3770 9890

Iberica 0034 935 725 090

Italy 0039 075 941 81 32

Scandinavia 0046 3157 5154

Other locations 0031 165 51 93 22

Middle East: 0097 143 391 800

or 0097 150 459 7937

Australia: 61 7 3456 4444

Brazil 000-800 031 0100

South America - other

locations 0056 9 6431 2110

All other locations 001-425-881-1800

2 Software Update Part No. 1300636GT

Page 3

Software Release Notes

REV A

Procedure

Plus+1® Service Tool Download

Note: If the Plus+1 Service Tool is installed

on your computer, proceed to Firmware Site

Download.

Note: Access to the internet and a valid email

account is required to perform this procedure.

1 Click on the Hyperlink below or open an

internet browser and copy and paste or type

the link into the address bar and press enter.

https://www2.powersolutions.danfoss.com/

l/38972/2016-05-30/525qvt

2 Fill out all fields of the request form and select

Request Plus+1 Service Tool.

Note: A link to the Plus+1 Service Tool Download will be sent to your email. This may take a few

minutes.

3 Select Plus+1 Service Tool Download.

4 Select Save As and save it to your desktop.

5 Close your internet browser.

6 Open the Plus1 Service Tool Setup.zip file

saved to your desktop. Select and run Plus+1

Service Tool Setup.exe file and follow the

prompts.

Software Version

Note: Before proceeding, verify the revision level

of software installed on your machine. Check the

firmware revisions on the Genie Firmware site to

verify whether the machine has the latest software

installed. Refer to the Firmware Site Download

section.

1 At the ground controls, turn the key switch

to platform controls and pull out the red

Emergency Stop button to the on position.

2 At the platform controls, pull out the red

Emergency Stop button to the on position.

Read and record the software revision level

installed on the machine shown on the LCD

screen

Note: Only record the revision level at the end of

the number sequence.

Example:123456A

revision level

part number

Software Revision

Part No. 1300636GT Software Update 3

Page 4

Software Release Notes

REV A

Procedure

Firmware Site Download

Note: Access to the internet is required to

perform this procedure.

1 Click on the Hyperlink below or open an

internet browser and copy and paste or type

the link into the address bar and press enter.

http://firmware.genielift.com

2 Select the model that is appropriate for your

machine under Machine Model. Select

Search.

3 Select the appropriate Firmware File to be

updated. Select I Accept. Select Save As and

save it to your desktop.

Note: Both the TCON and PCON firmware must

be downloaded to correctly update the machine

software.

4 Close your internet browser.

5 Locate the .zip files saved on your desktop.

Right click on the files and select Extract All.

Save the .lhx files to your desktop.

Updating the Software

Note: Before updating the machine software,

use the Navigation Menu at the platform controls

and the Options and Advanced Setup document

included with these instructions to read and record

the machine parameters. This information will be

required to configure the machine parameters

after the software update is complete.

Note: Perform this procedure on a firm, level

surface with the machine in the stowed position.

Note: Refer to the Harness Diagram for

connecting a computer to the Plus+1 module.

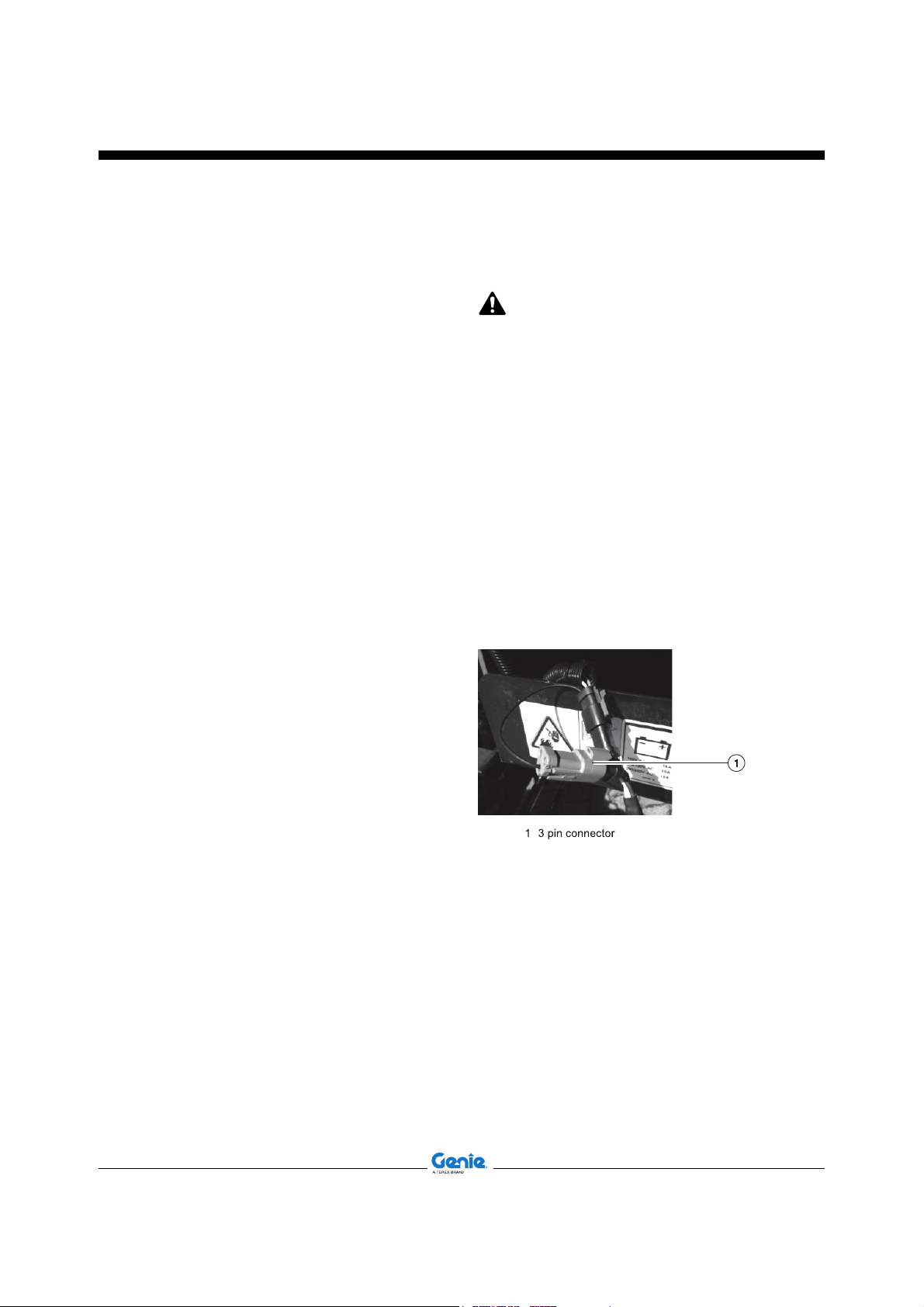

Updating the TCON firmware:

1 Disconnect the 3 pin harness connector

located below the ground control box.

2 Connect the program harness to both of the 3

pin harness connectors

Genie part number 110803GT

3 Connect the program harness to the

programming cable.

Genie part number 1267881GT

4 Connect the loose end of the programming

cable to a computer or laptop.

4 Software Update Part No. 1300636GT

Page 5

Software Release Notes

REV A

Procedure

5 Turn the key switch to ground control and pull

out the red Emergency Stop button to the on

position.

6 Select and run the 1261180.lhx firmware file

saved on your desktop.

Note: If Offline Mode is displayed at the bottom of

the screen, select the Communication tab at the

top of the screen and select Online Mode.

7 Select Next. If prompted, enter MC024-120 into

the pop-up box and select Ok. Select Ok again.

8 Select Start Download.

Note: The software download may take a few

minutes.

9 After the download is complete, close the

service tool.

Part No. 1300636GT Software Update 5

Page 6

Software Release Notes

REV A

Procedure

Updating the PCON firmware:

1 Select and run the 1261181.lhx firmware file

saved on your desktop.

2 Select Next. If prompted, enter MC024-120

into the pop-up box and select Ok. Select Ok

again.

3 Select Start Download.

Note: The software download may take a few

minutes.

4 After Software download complete message

appears, push in the red Emergency Stop

button to the off position.

5 Disconnect the computer from the machine.

6 Calibrate the machine. Refer to Calibration

Process Steps.

6 Software Update Part No. 1300636GT

Page 7

Software Release Notes

REV A

Procedure

Calibration Process Steps

It is required to perform the calibration process

if system defaults have been reset or if new

software has been installed. Any deviation in

the order of these steps could result in improper

machine function and fault codes to display.

1 Set system defaults: Turn the machine on

at the ground controls and immediately move

and hold both the function enable and auxiliary

enable switches for 5 seconds.

Result: An alarm will sound indicating the

system has been restored to defaults

2 Use the Options and Advanced Setup

document to configure the machine

parameters.

Note: Calibration procedures can be found in the

Service and Repair Manual that is appropriate

for your machine. Download or print the following

procedures from the Genie website.

Link to Manuals

http://www.genielift.com/service-support/manuals/

index

3 Calibrate the pressure relief valve: Refer

to Repair Procedures, How to Adjust the

Proportional Relief Valve and Hydraulic

Pressure Sensor.

Note: Perform this procedure prior to calibrating

other hydraulic functions

4 Calibrate the steer angle sensor: Refer to

Repair Procedures, How to Calibrate the Steer

Angle Sensor.

5 Verify pump efficiency calibration: Refer to

Repair Procedures, How to Check the Function

Pump Calibration.

6 Set hydraulic valve thresholds for turntable

rotate, primary up/down, secondary up/down,

primary extend/retract, jib up/down, and

platform rotate: Refer to Repair Procedures,

How to Adjust the Joystick Threshold Setting.

7 Set low flow hydraulic valves for jib up/

down and platform rotate: Refer to Repair

Procedures, How to Adjust the Maximum

Speed Setting (Hydraulic Functions).

8 Set high flow hydraulic valves for primary

up/down, secondary up/down, primary extend/

retract and turntable rotate: Refer to Repair

Procedures, How to Adjust the Maximum

Speed Setting (Hydraulic Functions).

9 Clear the fault history: Refer to Repair

Procedure, How to Clear Fault History.

Part No. 1300636GT Software Update 7

Page 8

Software Release Notes

REV A

Procedure

Options and Advanced Setup

At the platform controls read and record or circle

the settings that are applicable to your machine.

Refer to the Options and Advanced Settings

Navigation Menus.

Important Information

Menu items with an (*) require an authorization

code. Using the joystick, enter:

<minus -><minus -><plus +><minus ->

Items in bold text are default settings.

Market Selection must be manually selected to

properly configure your machine

Options Settings

Language Select Language

Motion Alarm ON OFF

Travel Alarm ON OFF

Descent Alarm ON OFF

Low Voltage Cutout ON OFF

Power Save Alarm ON OFF

Advanced Setup

* LVI Level Cut Off 20 %

* Footswitch Time Out 120 sec

* Chassis Tilt Mode

ANSI Drive and tilt lift cutout

CE Drive tilt cutout

(OPT : Drive and tilt lift cutout)

AUS None

* Platform Level Cutout ON OFF

* Market Selection ANSI CE AUS

* Lift Drive Priority Mode

OFF Drive Priority+Tilt Cutout Drive Lockout

Drive Priority Only Tilt Cutout Only

Charger Interlock

OFF Disable Propel Lift + Propel All Functions

* Genie Telematics ON OFF

8 Software Update Part No. 1300636GT

Page 9

Software Release Notes

REV A

Harness Diagram

Part No. 1300636GT Software Update 9

Page 10

Software Release Notes

REV A

Navigation Menu

Option Settings

10 Software Update Part No. 1300636GT

Page 11

Part No. 1300636GT Software Update 11

Software Release Notes

REV A

Advanced Setup

Navigation Menu

Loading...

Loading...