Page 1

S

t

RL4 Vertical Mas

ervice Manual

Part No. 1266665

Rev A

August 2015

Page 2

Service Manual August 2015

Introduction

Introduction Introduction

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

maintenance procedure.

This manual provides detailed scheduled

maintenance information for the machine owner

and user. It also provides troubleshooting and

repair procedures for qualified service

professionals.

Basic mechanical, hydraulic and electrical skills are

required to perform most procedures. However,

several procedures require specialized skills, tools,

lifting equipment and a suitable workshop. In these

instances, we strongly recommend that

maintenance and repair be performed at an

authorized Terex dealer service center.

Technical Publications

Terex has endeavored to deliver the highest

degree of accuracy possible. However, continuous

improvement of our products is a Terex policy.

Therefore, product specifications are subject to

change without notice.

Readers are encouraged to notify Terex of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@terex.com

Compliance

Machine Design Life

Unrestricted with proper operation, inspection and

scheduled maintenance.

Copyright © 2015 by Terex Corporation

1266665 Rev A, August 2015

First Edition, First Printing

'Terex' and 'AWP' are registered trademarks of Terex USA, LLC

in the U.S.A. and many other countries.

ii RL4 Vertical Mast Part No. 1266665

Page 3

August 2015 Service Manual

Introduction

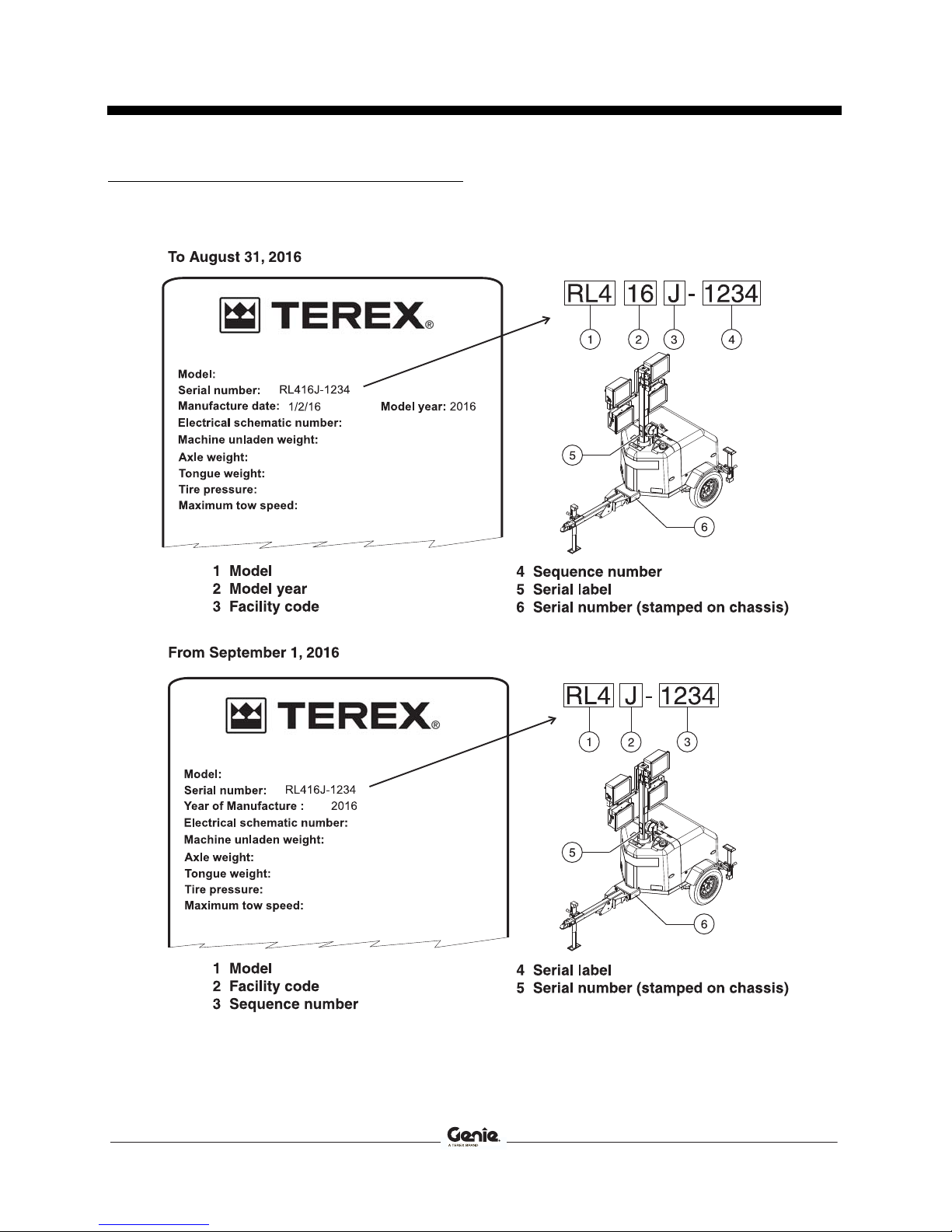

Serial Number Legend

Part No. 1266665 RL4 Vertical Mast iii

Page 4

Service Manual August 2015

Safety Rules

Section 1 Safety Rules

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when maintenance

and repair procedures are performed.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

manufacturer's instructions and safety rules

employer's safety rules and worksite

regulations

applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

iv RL4 Vertical Mast Part No. 1266665

Page 5

August 2015 Service Manual

NOTICE

Safety Rules

Workplace Safety

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol–used to alert

personnel to potential personal

DANGER

WARNING

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free of

debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or

straps that are in good condition and of

ample capacity.

CAUTION

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved

steel-toed shoes.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self-locking

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Part No. 1266665 RL4 Vertical Mast v

Page 6

August 2015

Table of Contents

Introduction Introduction .......................................................................................................... ii

Important Information .............................................................................................. ii

Serial Number Legend ........................................................................................... iii

Serial Number Legend ........................................................................................... iii

Section 1 Safety Rules ......................................................................................................... iv

General Safety Rules ............................................................................................. iv

Section 2 Specifications ....................................................................................................... 1

Machine Specifications .......................................................................................... 1

Performance Specifications ................................................................................... 1

Performance Specifications ................................................................................... 1

Kohler KDW1003GE Engine Specifications ......................................................... 1

Machine Specifications .......................................................................................... 2

Machine Torque Specifications .............................................................................. 4

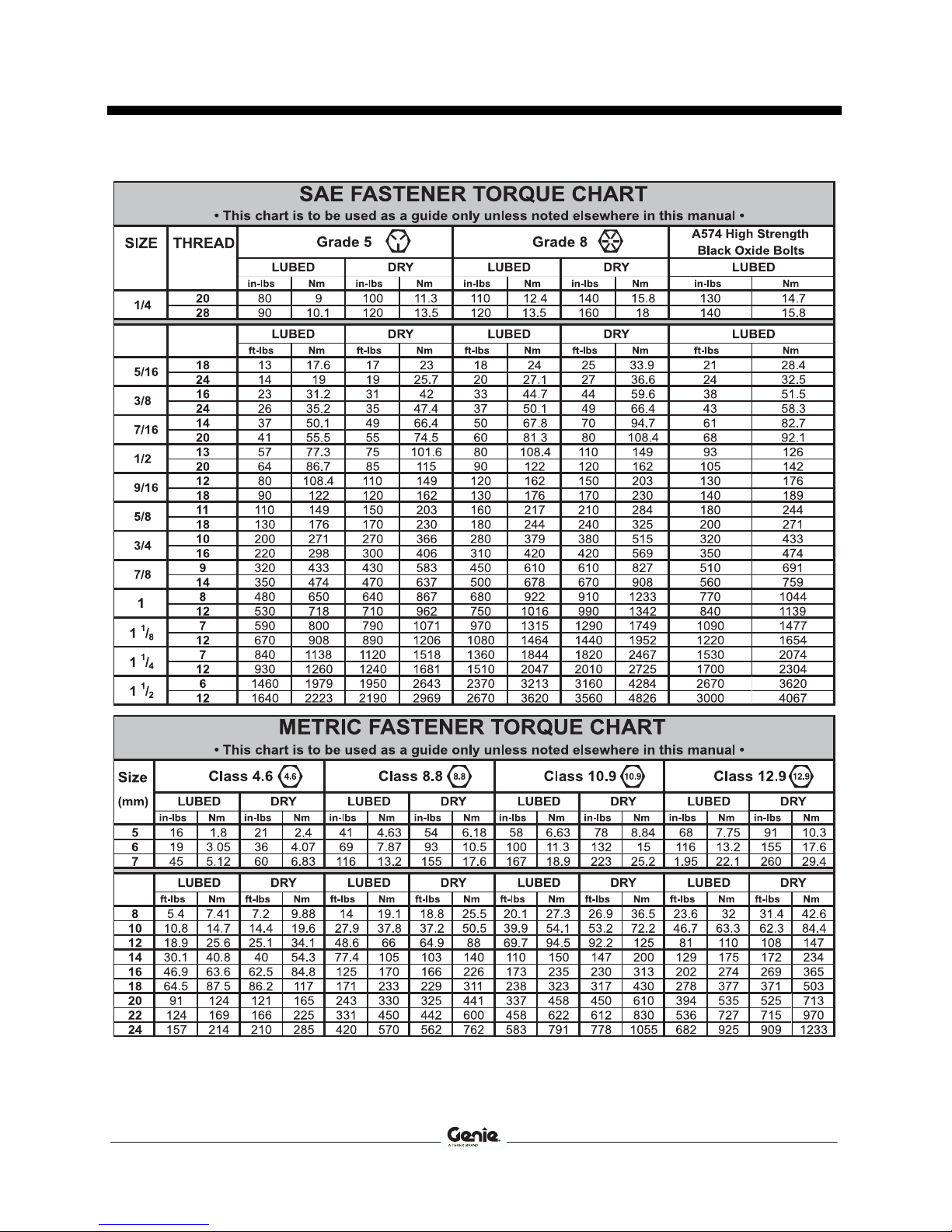

SAE and Metric Fasteners Torque Charts ............................................................. 5

Section 3 Scheduled Maintenance Procedures ................................................................. 7

Introduction ............................................................................................................ 7

Pre-Delivery Preparation Report .......................................................................... 10

Maintenance Inspection Report ........................................................................... 11

vi RL4 Vertical Mast Part No. 1266665

Page 7

August 2015

Table of Contents

Checklist A Procedures ..................................................................................... 13

A-1 Inspect the Manuals and Decals ................................................................... 13

A-2 Perform Pre-operation Inspection .................................................................. 14

A-3 Perform Function Tests ................................................................................. 14

A-4 Perform Engine Maintenance - Kubota ......................................................... 15

A-5 Perform Coupler Maintenance ....................................................................... 15

A-6 Test the Brakes (if equipped) ......................................................................... 16

A-7 Torque the Wheel Lug Nuts ........................................................................... 16

A-8 Perform Engine Maintenance - Kohler .......................................................... 17

A-9 Check the Tires and Wheels .......................................................................... 17

A-10 Inspect the Engine Air Filter ......................................................................... 18

A-11 Perform Generator Maintenance ................................................................. 19

A-12 Perform Engine Maintenance - Kubota ....................................................... 19

A-13 Perform Engine Maintenance - Kohler ........................................................ 20

A-14 Inspect the Cable and Cable Pulleys ........................................................... 20

A-15 Perform Engine Maintenance - Kubota ....................................................... 21

A-16 Perform Engine Maintenance - Kubota ....................................................... 22

A-17 Perform Generator Maintenance ................................................................. 22

A-18 Drain the Fuel Filter/Water Separator .......................................................... 23

A-19 Adjust the Brakes (if equipped) ................................................................... 24

A-20 Perform Engine Maintenance - Kohler ........................................................ 25

Checklist B Procedures ..................................................................................... 26

B-1 Inspect the Engine Start Battery .................................................................... 26

B-2 Inspect the Electrical Wiring .......................................................................... 27

B-3 Torque the Wheel Lug Nuts ........................................................................... 28

B-4 Perform Engine Maintenance - Kubota ......................................................... 28

B-5 Inspect and Lubricate the Winch ................................................................... 29

Part No. 1266665 RL4 Vertical Mast vii

Page 8

August 2015

Table of Contents

B-6 Lubricate the T-bolt ....................................................................................... 29

B-7 Inspect and Adjust the Brakes (if equipped) ................................................. 30

B-8 Inspect the Suspension ................................................................................. 32

B-9 Perform Engine Maintenance - Kohler .......................................................... 32

B-10 Perform Engine Maintenance - Kubota ....................................................... 33

Checklist C Procedures ..................................................................................... 34

C-1 Perform Engine Maintenance........................................................................ 34

C-2 Clean the Light Assemblies ........................................................................... 34

C-3 Grease the Wheel Bearings .......................................................................... 35

C-4 Inspect the Electric Brake Magnets .............................................................. 36

C-6 Perform Engine Maintenance - Kohler .......................................................... 37

C-6 Perform Engine Maintenance - Kubota ......................................................... 38

C-7 Perform Engine Maintenance - Kohler .......................................................... 38

C-8 Perform Generator Maintenance................................................................... 39

Checklist D Procedures ..................................................................................... 40

D-1 Perform Engine Maintenance - Kubota ......................................................... 40

D-2 Perform Generator Maintenance................................................................... 40

D-3 Perform Coupler Maintenance ...................................................................... 41

Checklist E Procedures ..................................................................................... 42

E-1 Inspect the Cable and Cable Pulleys ............................................................ 42

E-2 Perform Engine Maintenance - Kubota ......................................................... 43

E-3 Perform Engine Maintenance - Kubota ......................................................... 43

E-4 Perform Engine Maintenance - Kohler .......................................................... 44

E-5 Perform Engine Maintenance - Kohler .......................................................... 44

E-6 Perform Engine Maintenance - Kohler .......................................................... 45

E-7 Perform Generator Maintenance ................................................................... 45

E-8 Perform Generator Maintenance ................................................................... 46

E-9 Perform Generator Maintenance ................................................................... 46

viii RL4 Vertical Mast Part No. 1266665

Page 9

August 2015

Table of Contents

Section 4 Repair Procedures ............................................................................................. 47

Introduction ........................................................................................................... 47

Lighting ............................................................................................................... 49

1-1 How to Remove a Lamp ................................................................................. 49

1-2 How to Check Line Voltage ............................................................................ 49

Mast ..................................................................................................................... 50

2-1 How to Remove the Mast Assembly .............................................................. 50

2-2 How to Disassemble the Mast Assembly ....................................................... 50

2-3 How to Replace the Mast Lift Cables ............................................................. 52

2-4 How to Remove the Manual Winch ................................................................ 53

2-5 How to Remove the Electric Winch ................................................................ 54

2-6 How to Disengage the Tower Lock ................................................................ 55

Kohler KDW1003GE Engine .............................................................................. 57

3-1 Timing Adjustment-Kohler Engines ................................................................ 57

3-2 Glow Plugs-Kohler Engines ........................................................................... 57

3-3 Coolant Temperature and Oil Pressure Switches-Kohler Engines ................ 57

Kubota D1105-E4BG Engine ............................................................................. 58

4-1 Timing Adjustment-Kubota Engines ............................................................... 58

4-2 Glow Plugs-Kubota Engines .......................................................................... 58

4-3 Coolant Temperature and Oil Pressure Switches-Kubota Engines ............... 58

Generator ............................................................................................................ 59

5-1 Generator ....................................................................................................... 59

5-2 How to Check a Generator Capacitor ............................................................ 60

5-3 How to Check a Generator Diode .................................................................. 60

Light Ballast ........................................................................................................ 62

6-1 Ground Controls ............................................................................................. 62

6-2 Light Ballast .................................................................................................... 63

Fuel Tank ............................................................................................................. 64

7-1 Fuel Tank ....................................................................................................... 64

Part No. 1266665 RL4 Vertical Mast ix

Page 10

August 2015

Table of Contents

Section 5 Diagnostics ......................................................................................................... 65

Introduction .......................................................................................................... 65

Section 6 Schematics ......................................................................................................... 71

Introduction .......................................................................................................... 71

Wire Color Legend ............................................................................................... 72

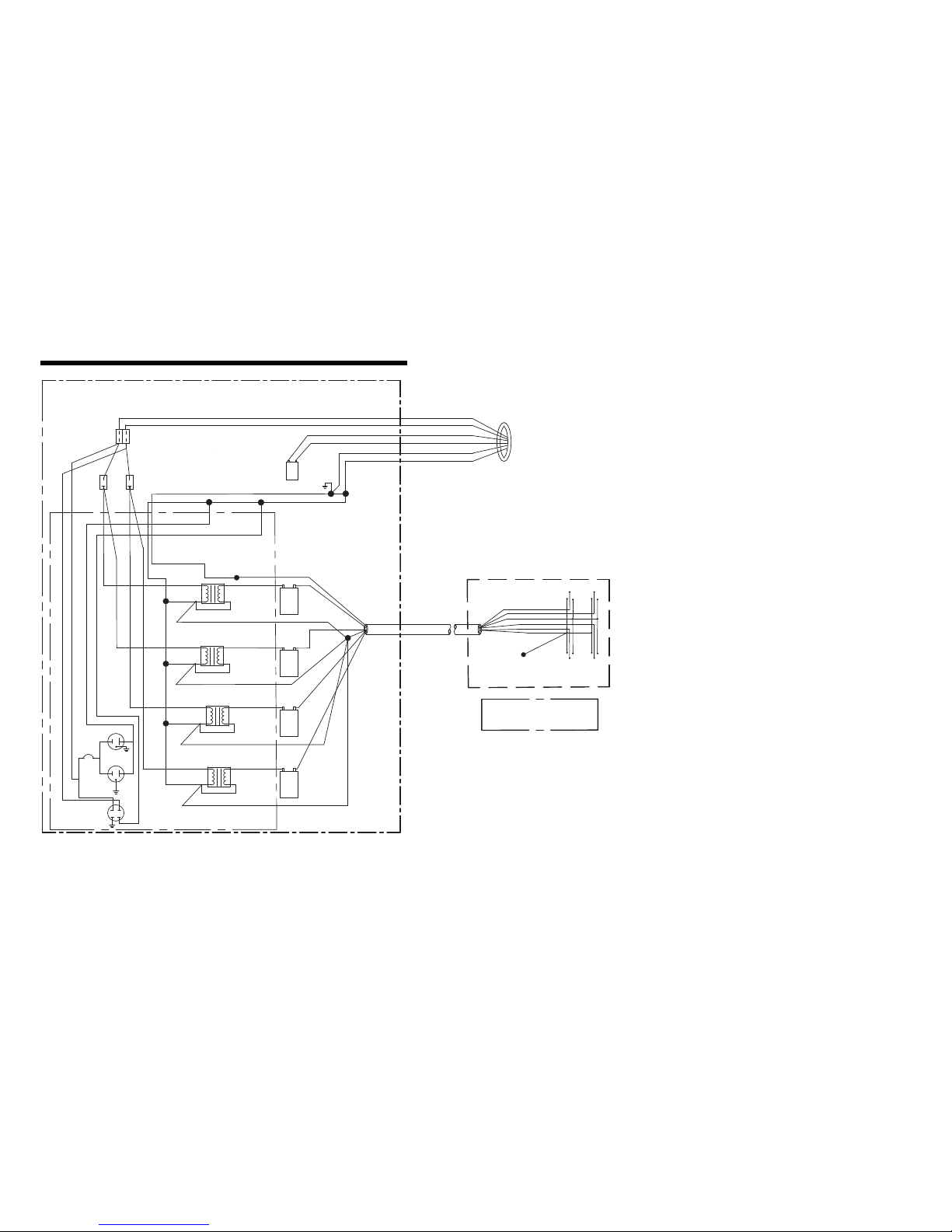

RL4 Control Box AC Voltage Wiring - Standard .................................................. 73

RL4 Control Box AC Voltage Wiring - Standard .................................................. 74

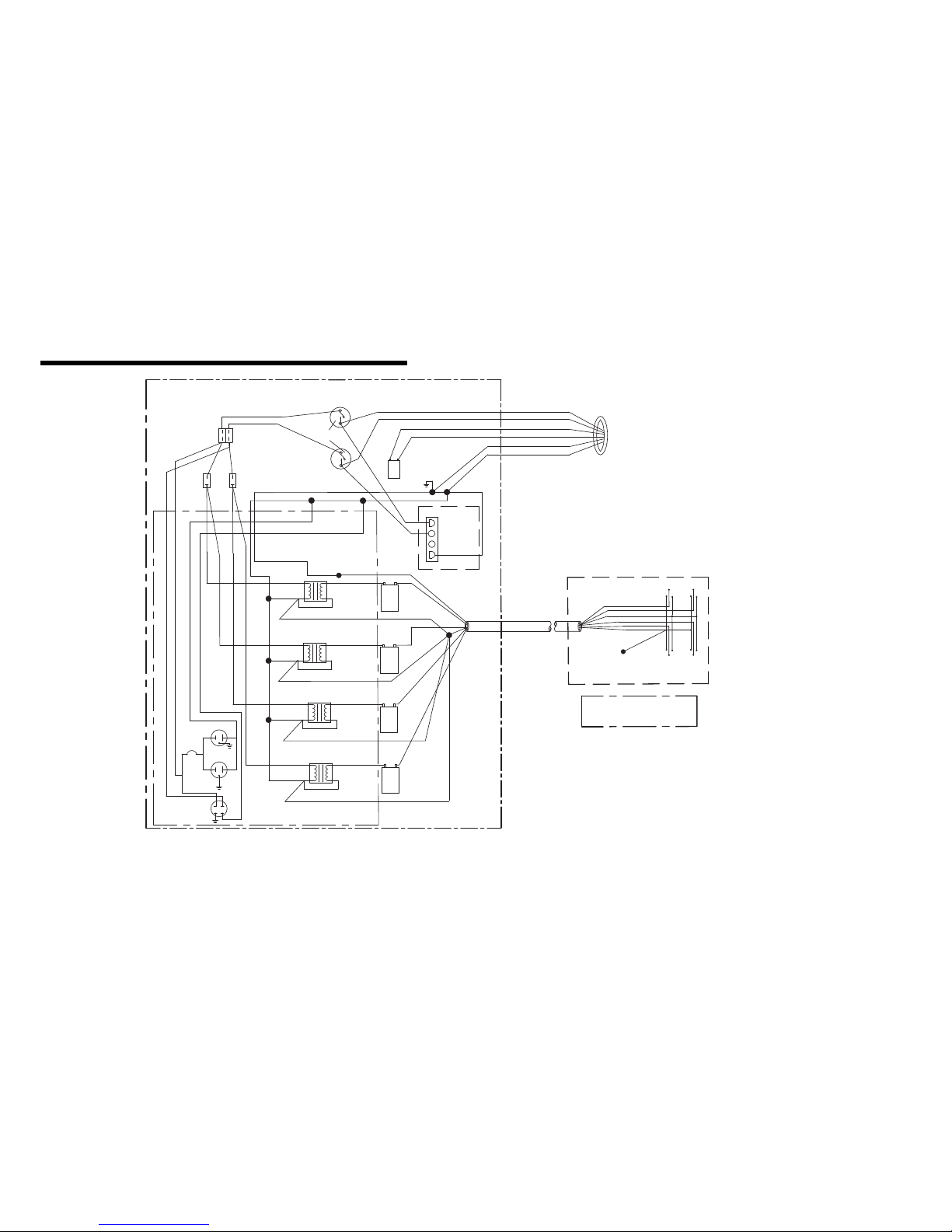

RL4 Control Box AC Voltage Wiring - Autostart .................................................. 75

RL4 Control Box AC Voltage Wiring - Autostart .................................................. 76

RL4 DC Control Box - Standard ........................................................................... 77

RL4 DC Control Box - Standard ........................................................................... 78

RL4 DC Engine Components - DynaGen Autostart ............................................. 79

RL4 DC Engine Components - DynaGen Autostart ............................................. 80

RL4 DC Engine Components - Kohler ................................................................. 81

RL4 DC Engine Components - Kohler ................................................................. 82

RL4 DC Engine Components - Kubota ................................................................ 83

RL4 DC Engine Components - Kubota ................................................................ 84

RL4 DC Control Box - Timed Oil Switch .............................................................. 85

RL4 DC Control Box - Timed Oil Switch .............................................................. 86

RL4 DC Control Box - Low Fuel Shut Down ........................................................ 87

RL4 DC Control Box - Low Fuel Shut Down ........................................................ 88

RL4 Running Lights - Front Fairing Section ......................................................... 89

RL4 Running Lights - Front Fairing Section ......................................................... 90

RL4 Running Lights - Rear Fairing Section ......................................................... 91

RL4 Running Lights - Rear Fairing Section ......................................................... 92

RL4 Electrical Winch Option ................................................................................ 93

RL4 Electrical Winch Option ................................................................................ 94

x RL4 Vertical Mast Part No. 1266665

Page 11

August 2015 Service Manual

Specifications

Section 2 Specifications

Machine Specifications

Total lighting wattage

Fuel capacities

Single tank

Tires and wheels

Tire size ST175/80D13

Load range C

Lug nut torque, dry

Lug nut torque, lubricated

4 x 1000 watts

45 gallons

170 liters

90 ft-lbs

122 Nm

67.5 ft-lbs

91.5 Nm

Performance Specifications

Tongue weight, maximum

With fuel (45 gallon tank)

Run time

45 gallon tank 90 hours

For operational specifications, refer to the

Operator's Manual.

Continuous improvement of our products is a

Genie policy. Product specifications are

subject to change without notice or obligation.

203 lbs

92 kg

Generator Options

Coliseum 6 kW 1CBC06-TX

Generator rpm @ full load 60Hz, 1800 rpm

Temperature, ambient maximum

Power 6 kW

Coliseum 7 kW 1CBC07-TX

Generator rpm @ full load 50 Hz, 1500 rpm

Temperature, ambient maximum

Power 7 kW

Coliseum 8 kW 1CBC08-TX

Generator rpm @ full load 60 Hz, 1800 rpm

Temperature, ambient maximum

Power 8 kW

For operational specifications, refer to the

Operator's Manual.

Continuous improvement of our products is a

Genie policy. Product specifications are

subject to change without notice or obligation.

104° F

40° C

104° F

40° C

104° F

40° C

Part No. 1266665 RL4 Vertical Mast 1

Page 12

Service Manual August 2015

Specifications

Kohler KDW1003GE Engine

Displacement

Number of cylinders

Bore and Stroke

Horsepower

Firing order

Compression ratio

Compression pressure

Engine speed

Governor

Valve Clearance, cold

Engine coolant

Capacity

Lubrication system

Oil pressure

Oil capacity (including filter)

2.95 x 3.1 inches

75 x 77.6 mm

10.7 @ 1800

412 to 469 psi

28.4 to 32.3 bar

0.00787402 in

28.8 to 50.6 psi

62.7 cu in

1.03 liters

8 kW

1 - 3 - 2

22.8:1

1800 rpm

centrifugal

mechanical

0.20 mm

4.5 quarts

4.3 liters

3 to 4.5 bar

5 quarts

4.7 liters

Oil pressure switch (engine

shutoff pressure)

Oil viscosity requirements

Unit ships with 10W-30. Extreme operating

3

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Injection system

Injection pump Bosch

Injection timing 9° BTDC

Injection pump pressure,

maximum

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Battery

Type 12V DC

Group 27TM

Quantity 1

Cold cranking ampere 500

Reserve capacity @ 75A rate 105 minutes

Alternator

Alternator output 45A, 12V DC

Fan belt deflection

1/4 to 3/8 inch

20 psi

2233 psi

155 bar

7 to 9 mm

2 RL4 Vertical Mast Part No. 1266665

Page 13

August 2015 Service Manual

Specifications

Kubota D1105-E4BG Engine

Displacement

Number of cylinders

Bore and Stroke

Horsepower

Firing order

Compression ratio

Compression pressure

Engine speed

Governor

Valve Clearance, cold

Engine coolant

Capacity

Lubrication system

Oil pressure

Oil capacity (including filter)

0.0057 to 0.0072 in

0.145 to 0.185 mm

68.53 cu in

3.07 x 3.09 inches

78 x 78.4 mm

13.6 @ 1800

397 to 454 psi

28.4 to 32.3 bar

mechanical

3.27 quarts

28 to 64 psi

1.93 to 4.41 bar

1.12 liters

10.1 kW

1 - 2 - 3

24:1

1800 rpm

centrifugal

3.1 liters

5.4 quarts

5.1 liters

Oil pressure switch (engine

shutoff pressure)

Oil viscosity requirements

Unit ships with 10W-30. Extreme operating

3

temperatures may require the use of alternative engine

oils. For oil requirements, refer to the Engine Operator

Manual for your engine.

Injection system

Injection pump Bosch MD mini

Injection timing 16.5° BTDC

Injection pump pressure,

maximum

Fuel requirement

For fuel requirements, refer to the engine Operator

Manual for your engine.

Battery

Type 12V DC

Group 27TM

Quantity 1

Cold cranking ampere 500

Reserve capacity @ 75A rate 105 minutes

Alternator

Alternator output 30A, 12V DC

Fan belt deflection

1/4 to 3/8 inch

7 psi

1991 psi

137 bar

7 to 9 mm

Part No. 1266665 RL4 Vertical Mast 3

Page 14

Service Manual August 2015

Specifications

Machine Torque Specifications

Generator

Flex plate to flywheel

Generator case to bell housing

Generator isolators

Wheel lugs

Lug nut torque, lubricated

Lug nut torque, dry

Engine vibration isolators

Mounting bolts, dry

Mounting bolts, lubricated

25 ft-lbs

34 Nm

44 ft-lbs

60 Nm

37 ft-lbs

50.5 Nm

67.5 ft-lbs

91.5 Nm

90 ft-lbs

122 Nm

75 ft-lbs

102 Nm

57 ft-lbs

77 Nm

Continuous improvement of our products is a

Genie policy. Product specifications are

subject to change without notice or obligation.

4 RL4 Vertical Mast Part No. 1266665

Page 15

August 2015 Service Manual

Specifications

Part No. 1266665 RL4 Vertical Mast 5

Page 16

Service Manual August 2015

This page intentionally left blank.

6 RL4 Vertical Mast Part No. 1266665

Page 17

August 2015 Service Manual

Scheduled Maintenance Procedures

Section 3 Scheduled Maintenance Procedures

Observe and Obey:

Maintenance inspections shall be completed

by a person trained and qualified on the

maintenance of this machine.

Scheduled maintenance inspections shall be

completed daily, quarterly, semi-annually,

annually and every 2 years as specified of the

Maintenance inspection Report. The frequency

and extent of periodic examinations and tests

may also depend on national regulations.

WARNING

Failure to perform each

procedure as presented and

scheduled may cause death,

serious injury or substantial

damage.

Machine Configuration:

Unless otherwise specified, perform each

procedure with the machine in the following

configuration:

Machine parked on a firm, level surface

Mast in the stowed position

Key switch in the off position with the key

removed

The red Emergency Stop button in the off

position on the electrical control box

Wheels chocked

Light switches in the off position

All external AC power supply disconnected

from the machine

Boom in the stowed position

Turntable secured with the turntable rotation

lock

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Use only Terex approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Part No. 1266665 RL4 Vertical Mast 7

Page 18

Service Manual August 2015

NOTICE

Scheduled Maintenance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a description, safety

warnings and step-by-step instructions.

Symbols Legend

Safety alert symbol–used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

DANGER

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

8 RL4 Vertical Mast Part No. 1266665

Page 19

August 2015 Service Manual

Scheduled Maintenance Procedures

Maintenance Symbols Legend

Pre-delivery Preparation Report

Note: The following symbols have been used in this

manual to help communicate the intent of the

instructions. When one or more of the symbols

appear at the beginning of a maintenance

procedure, it conveys the meaning below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required to

perform this procedure.

Indicates that dealer service will be

required to perform this procedure.

Indicates that a cold engine will be

required to perform this procedure.

Indicates that a warm engine will be

required to perform this procedure.

The pre-delivery preparation report contains

checklists for each type of scheduled inspection.

Make copies for each inspection. Store completed

forms as required.

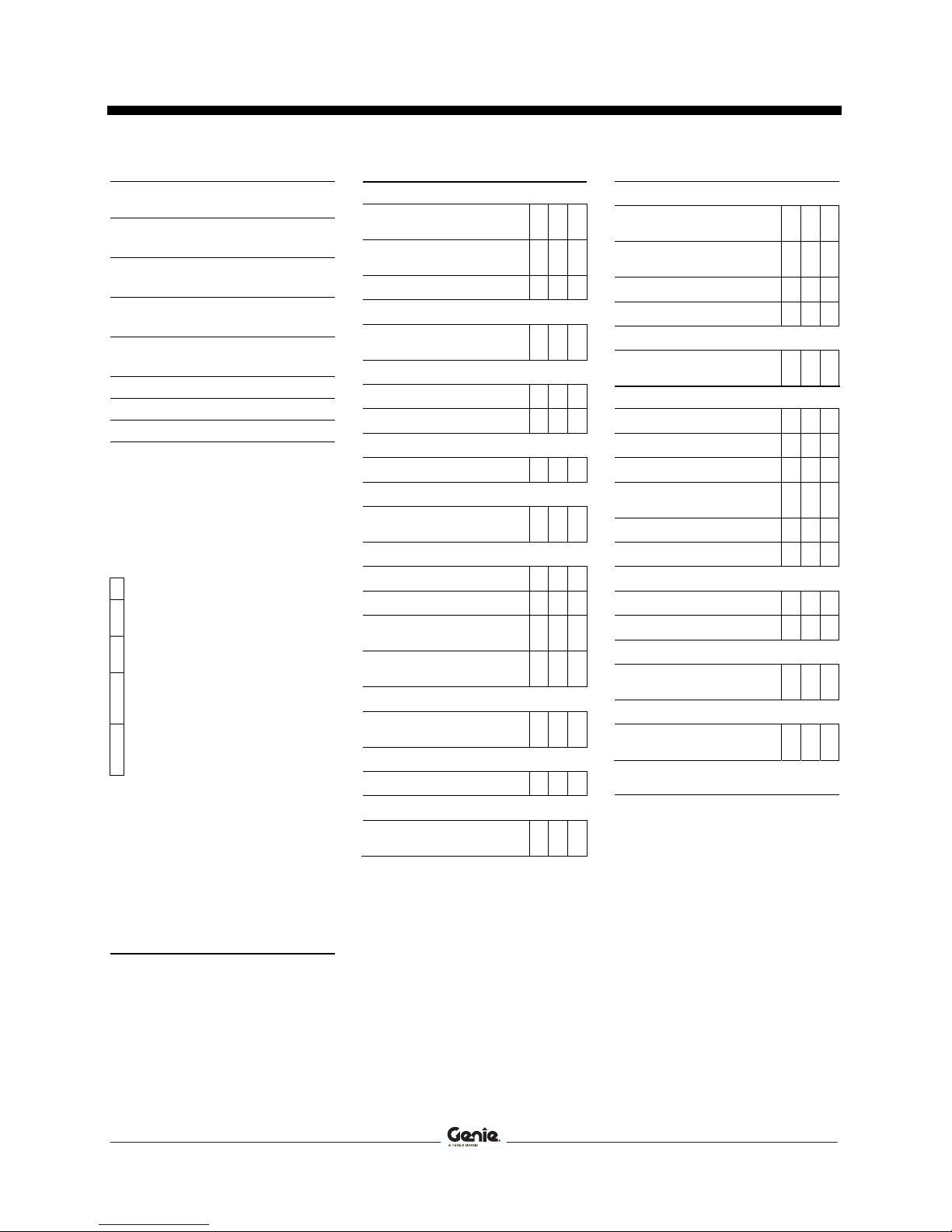

Maintenance Schedule

The Scheduled Maintenance Procedures section

and the Maintenance Inspection Report have been

divided into subsections. Use the following chart to

determine which group(s) of procedures are

required to perform a scheduled inspection.

Inspection Checklist

Daily or every 8 hours A

Quarterly or every 250 hours A + B

Semi-annually or every 500 hours A + B + C

Annually or every 1000 hours A + B + C + D

Two-year or every 2000 hours A + B + C + D + E

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with your employer, jobsite and governmental

regulations and requirements.

Part No. 1266665 RL4 Vertical Mast 9

Page 20

Service Manual August 2015

Pre-Delivery Preparation Report

Fundamentals

It is the responsibility of the dealer to perform the

Pre-delivery Preparation.

The Pre-delivery Preparation is performed prior to

each delivery. The inspection is designed to

discover if anything is apparently wrong with a

machine before it is put into service.

A damaged or modified machine must never be

used. If damage or any variation from factory

delivered condition is discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

Terex South Dakota, Inc USA

500 Oak Wood Road

PO Box 1150

Watertown, SD 57201-6150

(605) 882-4000

The Maltings, Wharf Road

Grantham, Lincolnshire

NG31- 6BH England

Genie UK

(44) 1476-584333

Instructions

Use the operator’s manual on your machine.

The Pre-delivery Preparation consists of

completing the Pre-operation Inspection, the

Maintenance items and the Function Tests.

Use this form to record the results. Place a check in

the appropriate box after each part is completed.

Follow the instructions in the operator’s manual.

If any inspection receives an N, remove the

machine from service, repair and re-inspect it. After

repair, place a check in the R box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

Comments

Pre-delivery Preparation

Pre-operation inspection completed

Maintenance items completed

Function tests completed

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Y N R

Page 21

August 2015 Service Manual

Maintenance Inspection Report

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

Make copies of this report to use for

each inspection.

Select the appropriate checklist(s) for

the type of inspection(s) to perform.

Daily or every 8 hours A

Quarterly or every

250 hours

Semi-annually or

every 500 hours

Annually or

every

1000 hours

Two-year or

every

2000 hours

Place a check in the appropriate box

after each inspection procedure is

completed.

Use the step-by-step procedures in

this section to learn how to perform

these inspections.

If any inspection receives an "N," tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the "R" box.

A + B + C + D + E

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

A + B

A + B + C

A + B + C + D

Checklist A Y N R

A-1 Inspect the manuals

and decals

A-2 Pre-operation

inspection

A-3 Function tests

Perform after 8 hours:

A-4 Engine maintenance -

Kubota

Perform before towing:

A-5 Coupler

A-6 Brakes (if equipped)

Perform after 10 miles:

A-7 Lug nuts

Perform after 10 hours:

A-8 Engine maintenance -

Kohler

Perform weekly:

A-9 Tires and wheels

A-10 Engine air filter

A-11 Generator

maintenance

A-12 Engine maintenance -

Kubota

Perform after 50 hours:

A-13 Engine maintenance -

Kohler

Perform monthly:

A-14 Cables and pulleys

Perform every 100 hours:

A-15 Engine maintenance -

Kubota

Perform every 200 hours:

A-16 Engine maintenance -

Kubota

A-17 Generator

maintenance

A-18 Fuel/Water separator

A-19 Brakes (if equipped)

Perform every 250 hours:

A-20 Engine maintenance -

Kohler

Checklist B Y N R

B-1 Batteries

B-2 Electrical wiring

B-3 Lug nuts

B-4 Engine maintenance -

Kubota

B-5 Winch

B-6 T-bolt

Perform every 3000 miles:

B-7 Brakes (if equipped)

B-8 Suspension

Perform every 300 hours:

B-10 Engine maintenance -

Kohler

Perform every 400 hours:

B-11 Engine maintenance -

Kubota

Comments

Part No. 1266665 RL4 Vertical Mast 11

Page 22

Service Manual August 2015

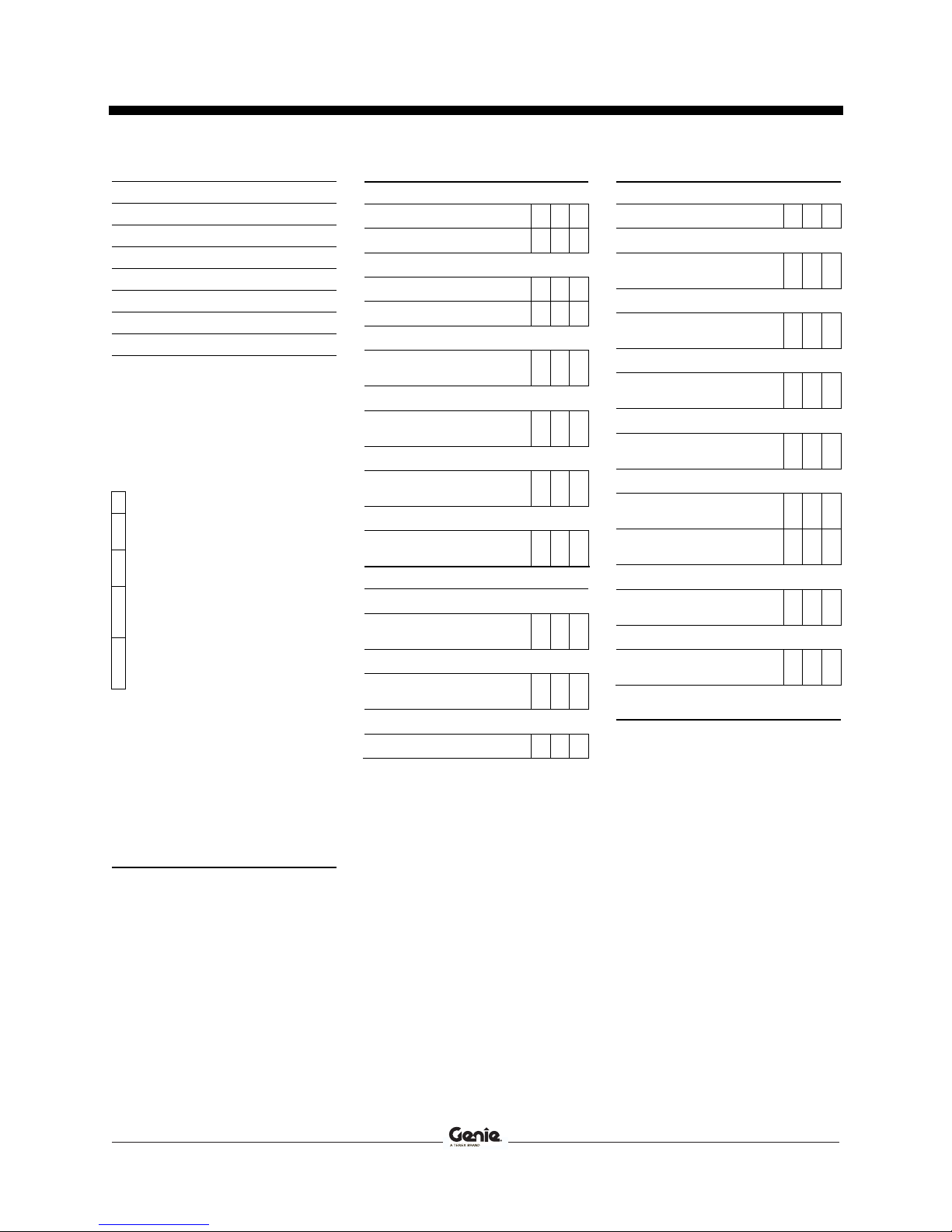

Maintenance Inspection Report

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

Make copies of this report to use for

each inspection.

Select the appropriate checklist(s) for

the type of inspection(s) to perform.

Daily or every 8 hours A

Quarterly or every

250 hours

Semi-annually or

every 500 hours

Annually or

every

1000 hours

Two-year or

every

2000 hours

Place a check in the appropriate box

after each inspection procedure is

completed.

Use the step-by-step procedures in

this section to learn how to perform

these inspections.

If any inspection receives an "N," tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the "R" box.

A + B + C + D + E

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

A + B

A + B + C

A + B + C + D

Checklist C Y N R

C-1 Engine maintenance

C-2 Lights

Perform every 6000 miles:

C-3 Wheel bearings

C-4 Brakes (if equipped)

Perform every 500 hours:

C-5 Engine maintenance -

Kohler

Perform every 800 hours:

C-6 Engine maintenance -

Kubota

Perform every 1000 hours:

C-7 Engine maintenance -

Kohler

Perform every 2000 hours:

C-8 Generator

maintenance

Checklist D Y N R

Perform every 1500 hours:

D-1 Engine maintenance -

Kubota

Perform every 8000 hours:

D-2 Generator

maintenance

Perform annually:

D-3 Coupler

Checklist E Y N R

E-1 Cable

Perform every 2000 hours:

E-2 Engine maintenance -

Kubota

Perform every 3000 hours:

E-3 Engine maintenance -

Kubota

Perform every 4000 hours:

E-4 Engine maintenance -

Kohler

Perform every 5000 hours:

E-5 Engine maintenance -

Kohler

Perform every 10,000 hours:

E-6 Engine maintenance -

Kohler

E-7 Generator

maintenance

Perform every 20,000 hours:

E-8 Generator

maintenance

Perform every 30,000 hours:

E-9 Generator

maintenance

Comments

12 RL4 Vertical Mast Part No. 1266665

Page 23

August 2015 Service Manual

Checklist A Procedures

A-1

Inspect the Manuals and Decals

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Maintaining the operator’s and safety manuals in

good condition is essential to safe machine

operation. Manuals are included with each

machine and should be stored in the container

provided in the platform. An illegible or missing

manual will not provide safety and operational

information necessary for a safe operating

condition.

In addition, maintaining all of the safety and

instructional decals in good condition is mandatory

for safe machine operation. Decals alert operators

and personnel to the many possible hazards

associated with using this machine. They also

provide users with operation and maintenance

information. An illegible decal will fail to alert

personnel of a procedure or hazard and could

result in unsafe operating conditions.

1 Check to make sure that the operator's and

safety manuals are present and complete in

the storage container inside the cabinet.

2 Examine the pages of each manual to be sure

that they are legible and in good condition.

Result: The operator's manual is appropriate

for the machine and all manuals are legible

and in good condition.

Result: The operator's manual is not

appropriate for the machine or all manuals are

not in good condition or is illegible. Remove

the machine from service until the manual is

replaced.

3 Open the operator's manual to the decals

inspection section. Carefully and thoroughly

inspect all decals on the machine for legibility

and damage.

Result: The machine is equipped with all

required decals, and all decals are legible and

in good condition.

Result: The machine is not equipped with all

required decals, or one or more decals are

illegible or in poor condition. Remove the

machine from service until the decals are

replaced.

4 Always return the manuals to the storage

container after use.

Note: Contact your authorized Terex distributor or

Terex if replacement manuals or decals are

needed.

Part No. 1266665 RL4 Vertical Mast 13

Page 24

Service Manual August 2015

Checklist A Procedures

A-2

Perform Pre-operation Inspection

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing a Pre-operation Inspection is essential

to safe machine operation. The Pre-operation

Inspection is a visual inspection performed by the

operator prior to each work shift. The inspection is

designed to discover if anything is apparently

wrong with a machine before the operator performs

the function tests. The Pre-operation Inspection

also serves to determine if routine maintenance

procedures are required.

Complete information to perform this procedure is

available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

A-3

Perform Function Tests

Terex specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing the function tests is essential to safe

machine operation. Function tests are designed to

discover any malfunctions before the machine is

put into service. A malfunctioning machine must

never be used. If malfunctions are discovered, the

machine must be tagged and removed from

service.

Complete information to perform this procedure is

available in the appropriate operator's manual.

Refer to the Operator's Manual on your machine.

14 RL4 Vertical Mast Part No. 1266665

Page 25

August 2015 Service Manual

Checklist A Procedures

A-4

Perform Engine Maintenance Kubota

Engine specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Engine oil level — check

Coolant level — check/add

Fuel system filter/water separator — drain

Engine tightness — check for leaks

Exhaust system — check for leaks

Loose or missing fasteners

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

A-5

Perform Coupler Maintenance

Coupler specifications require that this procedure

be performed before towing.

Maintaining the coupler in good condition is

essential to safe operation and good performance.

Coupler failure could result in a machine tip-over

during transport, and component damage may also

result if problems are not discovered and repaired

in a timely fashion.

1 Check vehicle, mounting bracket, hitch ball

and coupler for signs of wear or damage and

that the coupler handle opens and closes

freely.

Result: if coupler and/or mounting bracket is

deformed or damaged, replace complete

coupler and mounting bracket. Replace bent,

broken or worn parts before use.

2 Close coupler securely by ensuring that the

hitch ball is fully seated in the coupler ball

pocket and the pin is inserted behind the collar

or latch.

3 Check mounting bracket hardware for wear

and proper tightness.

Result: Replace bent, broken or worn

hardware.

Part No. 1266665 RL4 Vertical Mast 15

Page 26

Service Manual August 2015

Checklist A Procedures

A-6

Test the Brakes (if equipped)

Axle specifications require that this procedure be

performed before towing.

Maintaining the axle brakes in good condition is

essential to safe operation and good performance.

Brakes which are out of adjustment can result in

longer stopping distances and excessive brake

wear on the towing vehicle. Component damage

may also result if problems are not discovered and

repaired in a timely fashion.

Test the brakes for proper function. Repair or

replace any faulty components as needed.

A-7

Torque the Wheel Lug Nuts

Axle specifications require that this procedure be

performed initially at 10, 25 and 50 miles of use, or

after reinstallation of a tire.

Maintaining the wheel lug nuts at proper torque is

essential to safe operation and good service life of

the tires, wheel and axle.

1 Check each lug nut for proper torque. Refer to

Specifications, Machine Specifications.

16 RL4 Vertical Mast Part No. 1266665

Page 27

August 2015 Service Manual

Checklist A Procedures

A-8

Perform Engine Maintenance Kohler

Engine specifications require that this procedure be

performed every 10 hours or daily, whichever

comes first.

Engine oil level — check

Coolant level — check/add

Radiator — clean

Air filter

fuel line

Alternator/Fan Belt - Inspect Tension

Required maintenance procedures and additional

engine information is available in the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

A-9

Check the Tires and Wheels

Axle specifications require that this procedure be

performed weekly.

Maintaining the tires and wheels in good condition

and the tires at the correct pressure is essential to

safe operation and good performance. Tire and/or

wheel failure could result in a machine tip-over.

Component damage may also result if problems

are not discovered and repaired in a timely fashion.

WARNING

WARNING

1 Check tire surface and sidewalls for cuts,

cracks, punctures and unusual wear.

2 Check each wheel for damage, bends and

cracks.

Bodily injury hazard. An

over-inflated tire can explode

and could cause death or serious

injury.

Tip-over hazard. Do not use

temporary flat tire repair

products.

3 Check the pressure in each air-filled tire. Refer

to Specifications, Machine Specifications.

Part No. 1266665 RL4 Vertical Mast 17

Page 28

Service Manual August 2015

Checklist A Procedures

A-10

Inspect the Engine Air Filter

Terex specifications require that this procedure be

performed every 40 hours or weekly, whichever

comes first.

Maintaining the engine air filter in good condition is

essential to good engine performance and service

life. Failure to perform this procedure can lead to

poor engine performance and component damage.

Note: Perform this procedure with the engine off.

1 Open the engine side cover. Empty the dust

discharge valve by pressing together the sides

of the discharge slot. Clean the discharge slot

as needed.

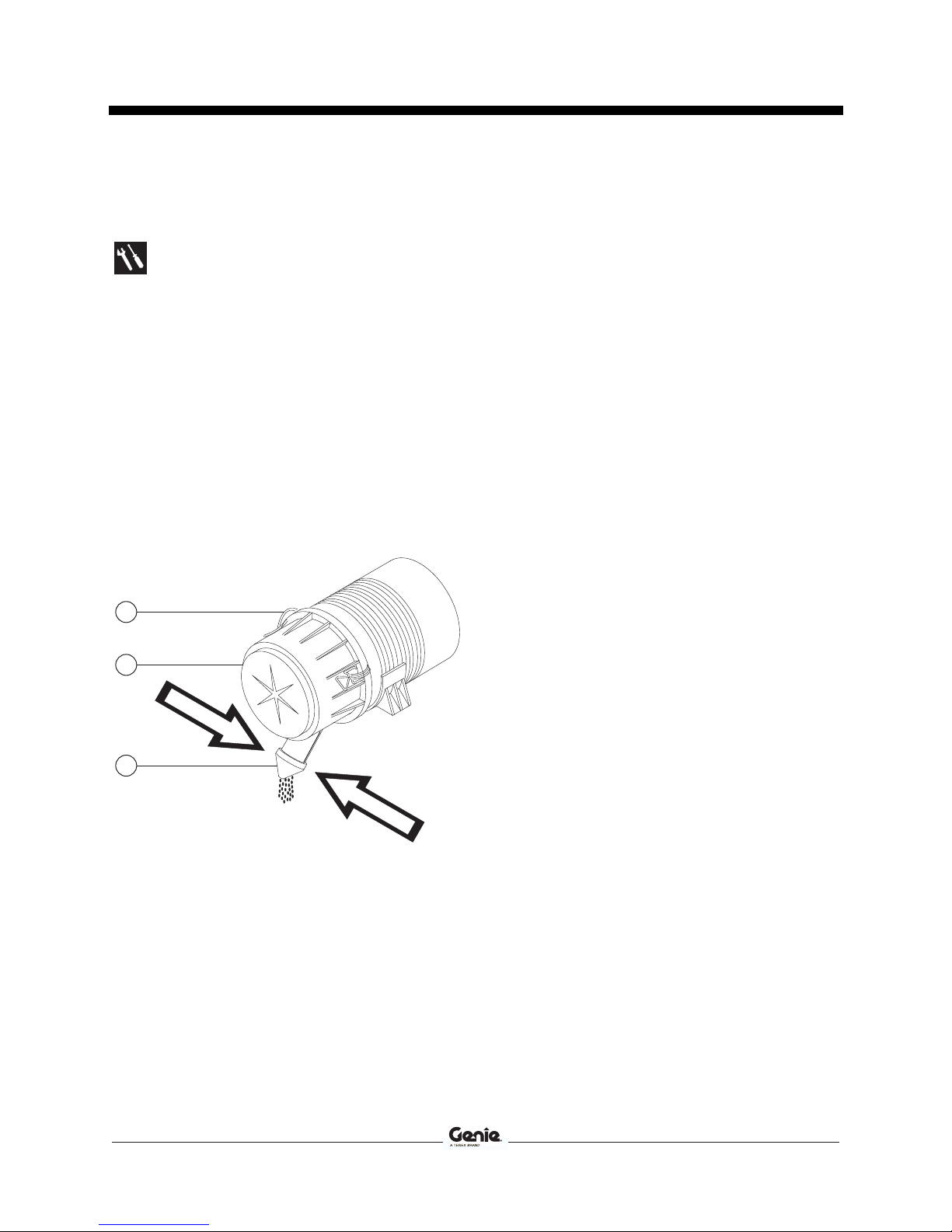

1

2 Release the latches on the air cleaner cap.

Remove the end cap from the air cleaner

canister.

3 Remove the filter element.

4 Use a damp cloth to wipe the filter sealing

surface and the inside of the outlet tube. Make

sure that all contaminant is removed before

the filter is inserted.

5 Check new filter element gasket for damage

before installing.

6 Install the new filter element.

7 Install the end cap on the canister and secure.

Note: Be sure the discharge slot is pointing down.

2

3

1 clamp

2 cannister end cap

3 dust discharge valve

18 RL4 Vertical Mast Part No. 1266665

Page 29

August 2015 Service Manual

Checklist A Procedures

A-11

Perform Generator Maintenance

Generator specifications require that this

procedure be performed every 40 hours or weekly,

whichever comes first.

Clean and inspect the generator exterior

Clean and replace the generator air filters -

(if equipped)

Coliseum Manual

Genie part number 1268770

A-12

Perform Engine Maintenance Kubota

Engine specifications require that this procedure be

performed every 100 hours.

Check fuel lines and clamps

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Part No. 1266665 RL4 Vertical Mast 19

Page 30

Service Manual August 2015

Checklist A Procedures

A-13

Perform Engine Maintenance Kohler

Engine specifications require that this procedure be

performed after 50 hours.

Engine oil and filter — change

Required maintenance procedures and additional

engine information is available in the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

A-13

Inspect the Cables and Cable

Pulleys

Terex specifications require that this procedure be

performed monthly.

Detection of damage to the cables or pulleys is

essential for safe machine operation. An unsafe

working condition exists if these components are

damaged and do not operate smoothly. Regular

inspection of this system allows the inspector to

identify changes in the operating condition that may

indicate damage.

1 Visually inspect the electric winch and cable

pulleys for the following:

broken or damaged pulleys

unusual or excessive pulley wear

Result: A pulley is broken or damaged, or

shows unusual or excessive pulley wear. The

pulley must immediately be replaced.

2 Put on protective leather gloves and eye wear.

3 Fully unwind the cable from the winch.

4 Wearing leather gloves, run a hand up and

down a length of the cable, inspecting the

cable and components for the following:

frayed or broken wire strands

Result: In any given one-foot of cable length

there are 4 or more broken wires on any 2 or

more strands. The cable must immediately be

replaced.

20 RL4 Vertical Mast Part No. 1266665

Page 31

August 2015 Service Manual

Checklist A Procedures

5 Visually inspect the winch cable for the

following:

nicks (partial strand cut through)

kinks in the cable (permanent bends)

A-15

Perform Engine Maintenance Kubota

weld splatter

Result: Nicks, kinks in the cable or weld

splatter are. The cable must immediately be

replaced.

6 Visually inspect the winch cable for the

following:

crushed spot on the cable

Result: A crushed spot on the cable

measuring 125% of the cable diameter or

more is found OR there is a broken wire at the

crush point. The cable must immediately be

replaced.

7 Wind cable onto the winch, ensuring that the

cable is correctly installed onto each of the

pulleys.

Engine specifications require that this procedure be

performed every 100 hours.

Clean air filter

Clean the fuel filter

Inspect fan belt

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Part No. 1266665 RL4 Vertical Mast 21

Page 32

Service Manual August 2015

Checklist A Procedures

A-16

Perform Engine Maintenance Kubota

Engine specifications require that this procedure be

performed every 200 hours.

Change engine oil

Replace oil filter

Inspect radiator hoses and clamps

Inspect air intake hose

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

A-17

Perform Generator Maintenance

Generator specifications require that this

procedure be performed every 200 hours or

quarterly, whichever comes first.

Clean and inspect the generator exterior

Check for loose or damaged wires and

components.

WARNING

Coliseum Manual

Genie part number 1268770

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

a

a generator

22 RL4 Vertical Mast Part No. 1266665

Page 33

August 2015 Service Manual

Checklist A Procedures

A-18

Drain the Fuel Filter/Water

Separator

Terex specifications require that this procedure be

performed every 200 hours or monthly, whichever

comes first.

Proper maintenance of the fuel filter/water

separator is essential for good engine performance.

Failure to perform this procedure can lead to poor

engine performance and component damage.

2 Loosen the drain plug located at the bottom of

the bowl. Allow the water to drain into a

suitable container until fuel starts to come out.

Immediately tighten the drain plug.

a

b

c

DANGER

Explosion and fire hazard.

Engine fuels are combustible.

Perform this procedure in an

open, well-ventilated area away

from heaters, sparks, flames and

lighted tobacco. Always have an

approved fire extinguisher within

easy reach.

1 Locate the fuel filter/water separator and

loosen the vent plug located on the fuel

filter/water separator head.

d

e

a head bolt

b vent plug

c separator head

d filter bowl

e drain plug

3 Tighten the vent plug and clean up any spills

or wet surfaces.

Note: If the fuel bowl is completely drained,

you must prime, or bleed, the fuel filter/water

separator before starting the engine. See step

5.

4 Start the engine from the electrical control

panel and check the fuel filter/water separator

for leaks.

Part No. 1266665 RL4 Vertical Mast 23

Page 34

Service Manual August 2015

Checklist A Procedures

Bleed the fuel system:

5 Loosen the vent plug/screw located on the

filter head.

6 Operate the hand primer until fuel, free of air,

flows from the vent plug/screw. Tighten the

vent plug/screw on the filter head.

7 Loosen the vent screw, located on top of the

fuel injection pump.

8 Operate the hand primer until fuel, free of air,

flows from the vent plug/screw. Tighten the

vent plug/screw on the injection pump.

9 Clean up any fuel that may have spilled.

10 Attempt to start the engine using the starter

motor for a maximum of 15 seconds, resting

the starter for 30 seconds before trying again.

11 Inspect the fuel filter/water separator for leaks.

DANGER

Note: Required maintenance procedures and

additional engine information is available in the

Kubota D1105-E and V1505-E Operator's Manual

(Kubota 16683-89169 part number ) OR the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Explosion and fire hazard. If a

fuel leak is discovered, keep any

additional personnel from

entering the area and do not

operate the machine. Repair the

leak immediately.

A-19

Test the Brakes (if equipped)

Axle specifications require that this procedure be

performed initially at 200 miles of use.

Maintaining the axle brakes in good condition is

essential to safe operation and good performance.

Brakes which are out of adjustment can result in

longer stopping distances and excessive brake

wear on the towing vehicle. Component damage

may also result if problems are not discovered and

repaired in a timely fashion.

Note: Perform this procedure with the machine on

a firm, level surface with the machine in the stowed

position.

1 Select a wheel. Chock the front and rear of the

tire at the opposite side of the machine.

2 Place a lifting jack under the axle near the

brake to be adjusted. Lift the axle until the

wheel is off the ground and place a jack stand

under the axle. Lower the axle onto the jack

stand.

3 Working from the back side of the wheel at the

brake backing plate, locate and remove the

small rubber plug from the lower side of the

backing plate to access the star-shaped brake

adjuster wheel. Set the plug to the side.

4 Insert a brake adjuster tool into the opening of

the brake backing plate, engaging it with the

teeth of the brake adjuster wheel. Move the tip

of the adjuster tool in an upwards direction to

tighten the brakes.

Note: It may be helpful to use a flashlight when

locating the brake adjuster wheel.

24 RL4 Vertical Mast Part No. 1266665

Page 35

August 2015 Service Manual

Checklist A Procedures

5 Repeatedly move the tip of the adjuster tool in

an upwards direction to tighten the brakes until

the wheel locks up and will no longer turn.

Note: This centers the brake shoes on the brake

drum, ensuring the shoes are positioned correctly.

A-20

Perform Engine Maintenance Kohler

6 Move the tip of the adjuster tool in a

downwards direction 3 to 5 clicks to loosen the

brakes only until the wheel spins freely with

little drag.

7 Securely install the small rubber plaug into the

brake backing plate.

8 Check the wheel bearing wear by attempting

to move wheel hub side to side, then up and

down.

There is no side to side or up and down

movement. The bearing is good.

There is side to side or up and down

movement. The bearing must be adjusted or

replaced. See B-8, Inspect and Adjust the

Brakes (if equipped).

9 Lift the axle slightly. Remove the jack stand

and lower the machine to the ground. Chock

the front and rear of the tire.

10 Repeat this procedure, beginning with step 2,

for the other wheel.

Engine specifications require that this procedure be

performed every 200 hours.

Inspect radiator hoses and clamps

Inspect air intake hose

Change engine oil - add oil if necessary

Replace fuel filter

Required maintenance procedures and additional

engine information is available in the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

Part No. 1266665 RL4 Vertical Mast 25

Page 36

Service Manual August 2015

Checklist B Procedures

B-1

Inspect the Engine Start Battery

Terex specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Proper battery condition is essential to good engine

performance and operational safety. Improper fluid

levels or damaged cables and connections can

result in engine component damage and

hazardous conditions.

WARNING

WARNING

Note: Fully charge the batteries and allow the

batteries to rest 24 hours before performing this

procedure to allow the battery cells to equalize.

1 Open the side covers.

2 Be sure that the battery cable connections are

free of corrosion.

Note: Adding terminal protectors and a corrosion

preventative sealant will help eliminate corrosion

on the battery terminals and cables.

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Bodily injury hazard. Batteries

contain acid. Avoid spilling or

contacting battery acid.

Neutralize battery acid spills with

baking soda and water.

3 Be sure that the battery retainers and cable

connections are tight.

4 Be sure that the battery separator wire

connections are tight (if equipped).

Models without maintenance-free or sealed

batteries:

5 Put on protective clothing and eye wear.

6 Remove the battery vent caps and check the

specific gravity of each battery cell with a

hydrometer. Note the results.

7 Check the ambient air temperature and adjust

the specific gravity reading for each cell as

follows:

Add 0.004 to the reading of each cell for

every 10° F / 5.5° C above 80° F / 26.7° C.

Subtract 0.004 from the reading of each cell

for every 10° F / 5.5° C below 80° F / 26.7°

C.

Result: All battery cells display an adjusted

specific gravity of 1.277 or higher. The battery

is fully charged. Proceed to step 11.

Result: One or more battery cells display a

specific gravity of 1.276 or below. Proceed to

step 8.

8 Perform an equalizing charge OR fully charge

the battery(s) and allow the battery(s) to rest at

least 6 hours.

9 Remove the battery vent caps and check the

specific gravity of each battery cell with a

hydrometer. Note the results.

26 RL4 Vertical Mast Part No. 1266665

Page 37

August 2015 Service Manual

Checklist B Procedures

10 Check the ambient air temperature and adjust

the specific gravity reading for each cell as

follows:

Add 0.004 to the reading of each cell for

every 10° F / 5.5° C above 80° F / 26.7° C.

B-2

Inspect the Electrical Wiring

Subtract 0.004 from the reading of each cell

for every 10° F / 5.5° C below 80° F / 26.7°

C.

Result: All battery cells display a specific

gravity of 1.277 or greater. The battery is fully

charged. Proceed to step 11.

Result: One or more battery cells display a

specific gravity from 1.218 to 1.269. The

battery is still usable, but at a lower

performance. The battery will need to be

recharged more often. Proceed to step 11.

Result: One or more battery cells display a

specific gravity from 1.217 to 1.173. The

battery is approaching the end of it's life.

Proceed to step 11.

Result: The difference in specific gravity

readings between cells is greater than 0.1 OR

the specific gravity of one or more cells is less

than 1.177. Replace the battery.

11 Check the battery acid level. If needed,

replenish with distilled water to 1/8 inch / 3 mm

below the bottom of the battery fill tube. Do not

overfill.

12 Install the vent caps and neutralize any

electrolyte that may have spilled.

13 Close the side covers.

Terex specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Maintaining electrical wiring in good condition is

essential to safe operation and good machine

performance. Failure to find and replace burnt,

chafed, corroded or pinched wires could result in

unsafe operating conditions and may cause

component damage.

WARNING

1 Inspect the following areas for burnt, chafed,

corroded pinched and loose wires:

Ground controls

Battery

Engine

Mast

Lighting junction box

Trailer lighting wire harness

2 Inspect for a liberal coating of dielectric grease

in the following locations:

Lighting junction box

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Part No. 1266665 RL4 Vertical Mast 27

Ground controls

All wire harness connectors

Page 38

Service Manual August 2015

Checklist B Procedures

B-3

Torque the Wheel Lug Nuts

Axle specifications require that this procedure be

performed initially at 10, 25 and 50 miles of use, or

after reinstallation of a tire.

Maintaining the wheel lug nuts at proper torque is

essential to safe operation and good service life of

the tires, wheel and axle.

1 Check each lug nut for proper torque. Refer to

Specifications, Machine Specifications.

B-4

Perform Engine Maintenance Kubota

Engine specifications require that this procedure be

performed every 250 hours or six months,

whichever comes first.

Inspect alternator and fan belts

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

28 RL4 Vertical Mast Part No. 1266665

Page 39

August 2015 Service Manual

Checklist B Procedures

B-5

Inspect and Lubricate the Winch

Terex specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Maintaining the winch is essential to good machine

performance and safe operation. An unsafe

working condition exists if the winch has excessive

wear and/or does not operate smoothly, free of

hesitation and binding.

1 Carefully lubricate the winch.

B-6

Lubricate the T-bolt

Terex specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Maintaining the T-bolt is essential to good machine

performance and safe operation. An unsafe

working condition exists if the T-bolt has excessive

wear and/or does not operate smoothly, free of

hesitation and binding.

1 Using the illustration as a guide, locate the

T-bolt at the bottom of the mast assembly.

Remove the T-bolt from the mast.

2 Remove all dust, dirt and copper anti-seize

from the threaded surfaces of the T-bolt, and

apply a few drops of light oil or copper

anti-seize lubricant onto the threaded

surfaces.

3 Fully install the T-bolt into the mast.

Part No. 1266665 RL4 Vertical Mast 29

a

a T-bolt

Page 40

Service Manual August 2015

NOTICE

Checklist B Procedures

B-7

Inspect and Adjust the Brakes (if

equipped)

Axle specifications require that this procedure be

performed every 3000 miles or quarterly,

whichever comes first.

Maintaining the axle brakes in good condition is

essential to safe operation and good performance.

Brakes which are out of adjustment can result in

longer stopping distances and excessive brake

wear on the towing vehicle. Component damage

may also result if problems are not discovered and

repaired in a timely fashion.

Note: Perform this procedure with the machine on

a firm, level surface with the machine in the stowed

position.

1 Select a wheel. Chock the front and rear of the

tire at the opposite side of the machine.

2 Loosen the wheel lug nuts. Do not remove

them.

3 Place a lifting jack under the axle near the

wheel to be removed. Lift the axle until the

wheel is off the ground and place a jack stand

under the axle. Lower the axle onto the jack

stand and remove the wheel.

4 Remove the dust cap from the hub. Remove

the cotter pin from the castle nut.

5 Remove the castle nut and washer.

6 Pull the hub off of the spindle. The washer and

outer bearing should fall loose from the hub.

7 Inspect the brake lining for wear (if equipped).

Result: the thickness of the brake lining is

greater than 1/16 inch / 1.6 mm. The brake

shoes are good.

Result: the thickness of the brake lining is

1/16 inch / 1.6 mm or less. The brake shoes

must be replaced and the brake drums must

be inspected for wear, scoring and other

damage.

Note: The maximum bore of a good brake drum

shall not be greater than 0.090 inch / 2.29 mm in

excess of the drum diameter.

Note: If drum resurfacing is required, the brake

drum should be resurfaced to a 120 micron finish.

Note: If replacing the brake shoes, apply a light

coat of grease or anti-seize compound to the

anchor pin, arm bushing and pin, and areas of the

backing plate which contact the magnet arm and

brake shoes frame. Apply a small amount of lube to

the actuating cam at the top of the magnet arm. Do

not allow grease or oil to contact the brakes shoes

or the inside of the drum.

8 Slide the hub onto the yoke spindle.

Component damage hazard. Do

not apply excessive force or

damage to the lip of the seal may

occur.

9 Place the outer bearing into the hub.

10 Install the washer and the castle nut.

11 Tighten the castle nut to 50 ft-lbs / 68 Nm to

seat the bearings.

12 Fully loosen the castle nut. Do not rotate the

hub.

30 RL4 Vertical Mast Part No. 1266665

Page 41

August 2015 Service Manual

Checklist B Procedures

13 Finger tighten the castle nut until snug.

14 Install a new cotter pin. Bend the cotter pin to

lock it in place.

Note: Always replace the cotter pin with a new one

when removing the castle nut.

15 Install the dust cap, then the tire and wheel

assembly. Torque the wheel lug nuts to

specification. Refer to Section 2,

Specifications.

16 Working from the back side of the wheel at the

brake backing plate, locate and remove the

small rubber plug from the lower side of the

backing plate to access the star-shaped brake

adjuster wheel. Set the plug to the side.

17 Insert a brake adjuster tool into the opening of

the brake backing plate, engaging it with the

teeth of the brake adjuster wheel. Move the tip

of the adjuster tool in an upwards direction to

tighten the brakes.

Note: It may be helpful to use a flashlight when

locating the brake adjuster wheel.

19 Move the tip of the adjuster tool in a

downwards direction 3 to 5 clicks to loosen the

brakes only until the wheel spins freely with

little drag.

20 Securely install the small rubber plug into the

brake backing plate.

21 Check the wheel bearing wear by attempting

to move wheel hub side to side, then up and

down.

There is no side to side or up and down

movement. The bearing is good.

There is side to side or up and down

movement. The bearing must be adjusted or

replaced. See B-8, Inspect and Adjust the

Brakes (if equipped).

22 Lift the axle slightly. Remove the jack stand

and lower the machine to the ground. Chock

the front and rear of the tire.

23 Repeat this procedure, beginning with step 2,

for the other wheel.

18 Repeatedly move the tip of the adjuster tool in

an upwards direction to tighten the brakes until

the wheel locks up and will no longer turn.

Note: This centers the brake shoes on the brake

drum, ensuring the shoes are positioned correctly.

Part No. 1266665 RL4 Vertical Mast 31

Page 42

Service Manual August 2015

Checklist B Procedures

B-8

Inspect the Suspension

Axle specifications require that this procedure be

performed every 3000 miles or quarterly,

whichever comes first.

Maintaining the axle suspension in good condition

is essential to safe operation and good

performance. Towing the machine with worn or

damaged suspension components could result in a

tip-over. Component damage may also result if

problems are not discovered and repaired in a

timely fashion.

1 Working with a flashlight or in a well lit shop,

carefully inspect all suspension components

and fasteners. Replace as necessary.

B-9

Perform Engine Maintenance Kohler

Engine specifications require that this procedure be

performed every 300 hours.

Inspect radiator hoses and clamps

Inspect air intake hose

Inspect alternator and fan belts

Required maintenance procedures and additional

engine information is available in the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

32 RL4 Vertical Mast Part No. 1266665

Page 43

August 2015 Service Manual

Checklist B Procedures

B-10

Perform Engine Maintenance Kubota

Engine specifications require that this procedure be

performed every 400 hours or semi-annually,

whichever comes first.

Replace oil filter

Replace fuel filter

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number )

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

Part No. 1266665 RL4 Vertical Mast 33

Page 44

Service Manual August 2015

NOTICE

Checklist C Procedures

C-1

Perform Engine Maintenance

Engine specifications require that this procedure be

performed every 500 hours.

Kohler engine only:

Check valve clearance

Kubota engine only:

Replace fan belts

Flush coolant system

Clean fuel tank

Required maintenance procedures and additional

engine information is available in the Kubota

D1105-E and V1505-E Operator's Manual (Kubota

16683-89169 part number ) OR the Kohler

KDW1003 Engine Owner's Manual (Kohler part

number ED0053028440).

Kohler KDW1003 Engine Owner's Manual

Genie part number 1268769

Kubota D-1105 and V-1505 Operator's Manual

Genie part number 893020

C-2

Clean the Light Assemblies

Terex specifications require that this procedure be

performed every 500 hours or semi-annually,

whichever comes first.

Maintaining the light assemblies is essential to

good machine performance. Failure to regularly

clean the light assemblies may result in less light

than expected and, over time, could result in

damage to the machine.

Note: Perform this procedure with the light

assemblies out of direct sunlight and cool to the

touch.

1 Use clean, cool water to rinse the surface of

each light assembly.

2 Clean each light assembly using a soft cloth,

water and a mild dishwashing detergent.

Component damage hazard.

Harsh checmcals and cleaning

agents will damage the surface

of the light assembly. Do not

allow harsh cleaning agents to

make contact with the light

surface..

34 RL4 Vertical Mast Part No. 1266665

3 Thoroughly rinse, then dry with a soft cloth.

Page 45

August 2015 Service Manual

NOTICE

Checklist C Procedures

C-3

Grease the Wheel Bearings

Axle specifications require that this procedure be

performed every 6,000 hours or semi-annually,

whichever comes first.

Maintaining the axle wheel bearings is essential to

safe machine operation and service life. Operating

a machine with loose or worn wheel bearings may

cause an unsafe operating condition and continued

use may result in component damage. Extremely

wet or dry conditions or regular steam cleaning and

pressure washing of the machine may require that

this procedure be performed more often.

Note: Perform this procedure with the machine on

a firm, level surface with the machine in the stowed

position.

9 Inspect the hub for wear. Replace if

necessary.

10 Place the large inner bearing into the rear of