Page 1

Page 2

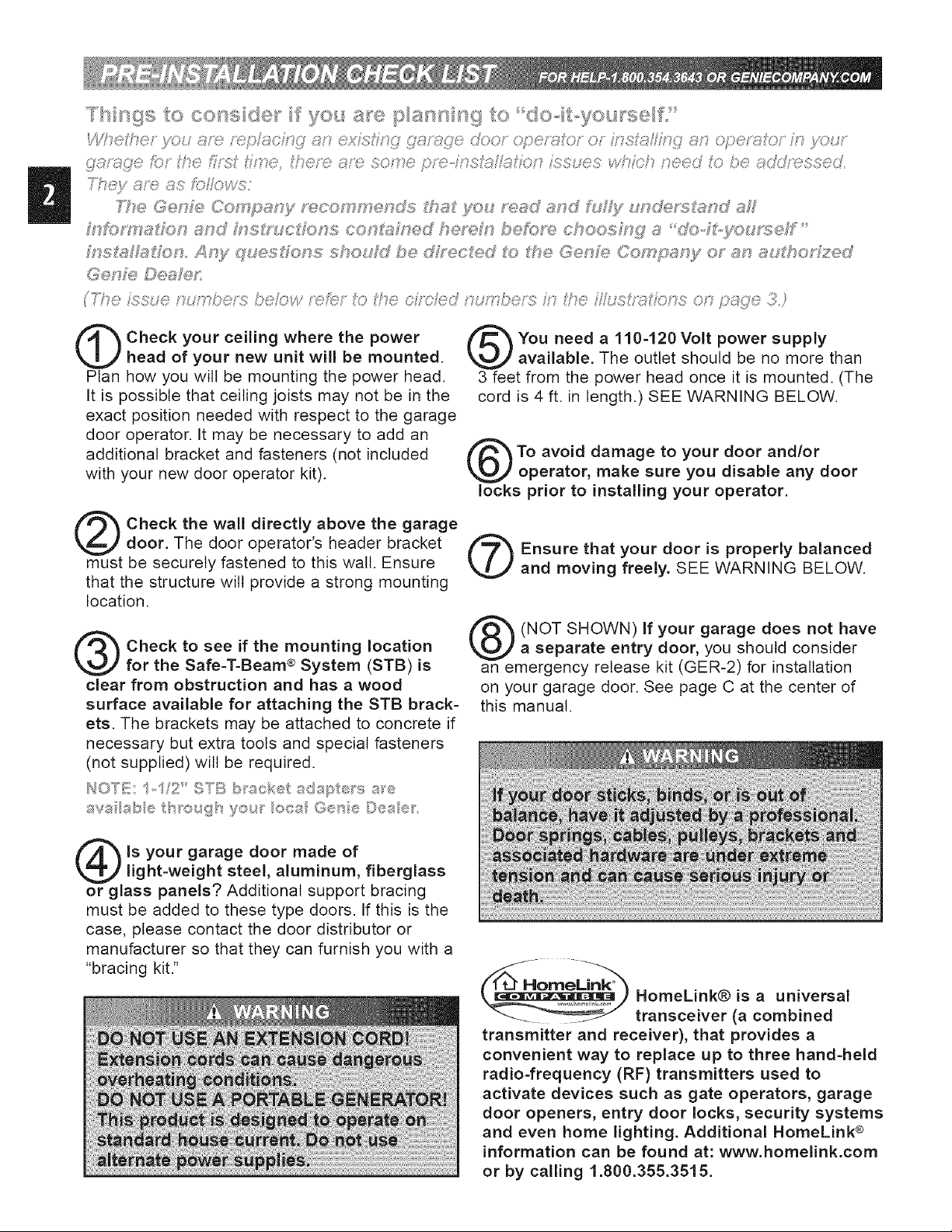

Check your ceiling where the power

head of your new unit will be mounted.

Plan how you wilt be mounting the power head.

It is possible that ceiling joists may not be in the

exact position needed with respect to the garage

door operator. It may be necessary to add an

additional bracket and fasteners (not included

with your new door operator kit).

Check the wall directly above the garage

door. The door operator's header bracket

must be securely fastened to this watt. Ensure

that the structure wilt provide a strong mounting

location.

Check to see if the mounting location

for the Safe-T-Beam ® System (STB) is

clear from obstruction and has a wood

surface available for attaching the STB brack-

ets. The brackets may be attached to concrete if

necessary but extra tools and special fasteners

(not supplied) will be required.

b_O'l" : 1-12 STB b_'_ck_:;£sd_;U_t_'s _;

You need a 110-120 Volt power supply

available. The outlet should be no more than

3 feet from the power head once it is mounted. (The

cord is 4 ft. in length.) SEE WARNING BELOW.

To avoid damage to your door and/or

operator, make sure you disable any door

locks prior to installing your operator.

Ensure that your door is properly balanced

and moving freely. SEE WARNING BELOW.

(NOT SHOWN) If your garage does not have

a separate entry door, you should consider

an emergency release kit (GER-2) for installation

on your garage door. See page C at the center of

this manual.

Is your garage door made of

light-weight steel, aluminum, fiberglass

or glass panels? Additional support bracing

must be added to these type doors. If this is the

case, please contact the door distributor or

manufacturer so that they can furnish you with a

"bracing kit."

, omeLink® is a universal

transceiver (a combined

transmitter and receiver), that provides a

convenient way to replace up to three hand-held

radio-frequency (RF) transmitters used to

activate devices such as gate operators, garage

door openers, entry door locks, security systems

and even home lighting. Additional HomeLink ®

information can be found at: www.homelink.com

or by calling 1.800.355.3515.

Page 3

36" POWER CORD

TO

120V GROUNDED

OUTLET

TYPICAL SECTIONAL DOOR iNSTALLATION

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

ADDED

HEADER BRACKET

MOUNTING BOARD

BRACES

SAFE=T-BEAM®

Page 4

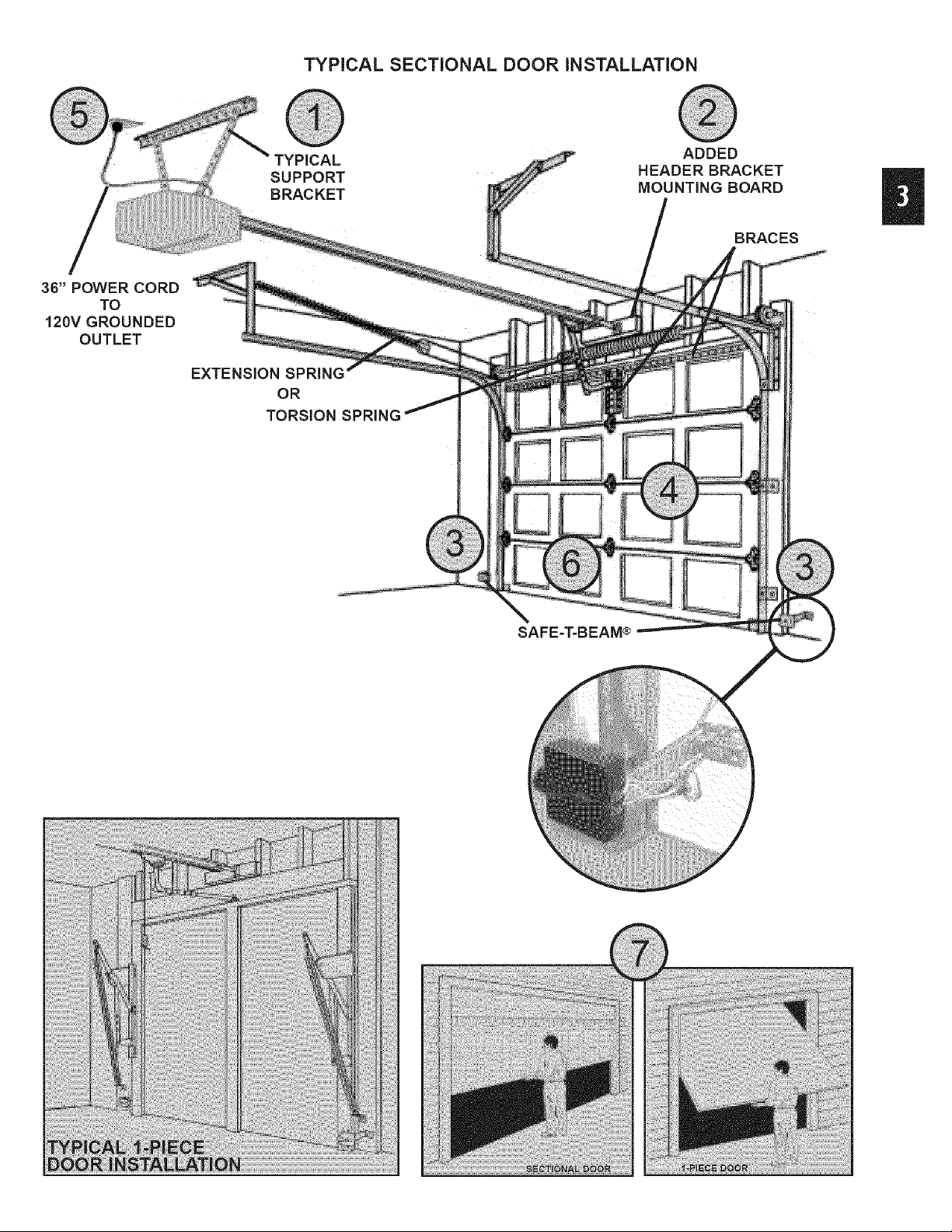

II

I {:D I[Z31@ I_1 (:_) I_DI O II

Carpenter's level

Adjustable wrench

Step ladder

Pencil

Wire strippers

5/32" Drill Bit

Phillips screwdriver

Ratchet

©

7/16" and 9/16" Sockets

Safe-T=Beam ® (STB} Non-Contact Reversing System

Places an invisible beam across door opening that reverses the door during down travel to the fully open

position if anything passes through beam.

Safe-T=Reverse ® Contact Reversing System

Automatically stops and reverses a closing door within 2 seconds of contact with an object.

Safe-T=Stop ® Timed Reversed System

Automatically opens a closing door, if door does not close within 30 seconds.

Force Guard ® Control

Used to set the force required for opening and closing door. For maximum safety, set the minimum force

required to fully open and close door.

Automatic Lighting System

Two light bulbs up to 60 Watts max. each are used for safer entries and exits. The light turns on when door is

activated and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually for emergencies or maintenance.

Tape measure

Page 5

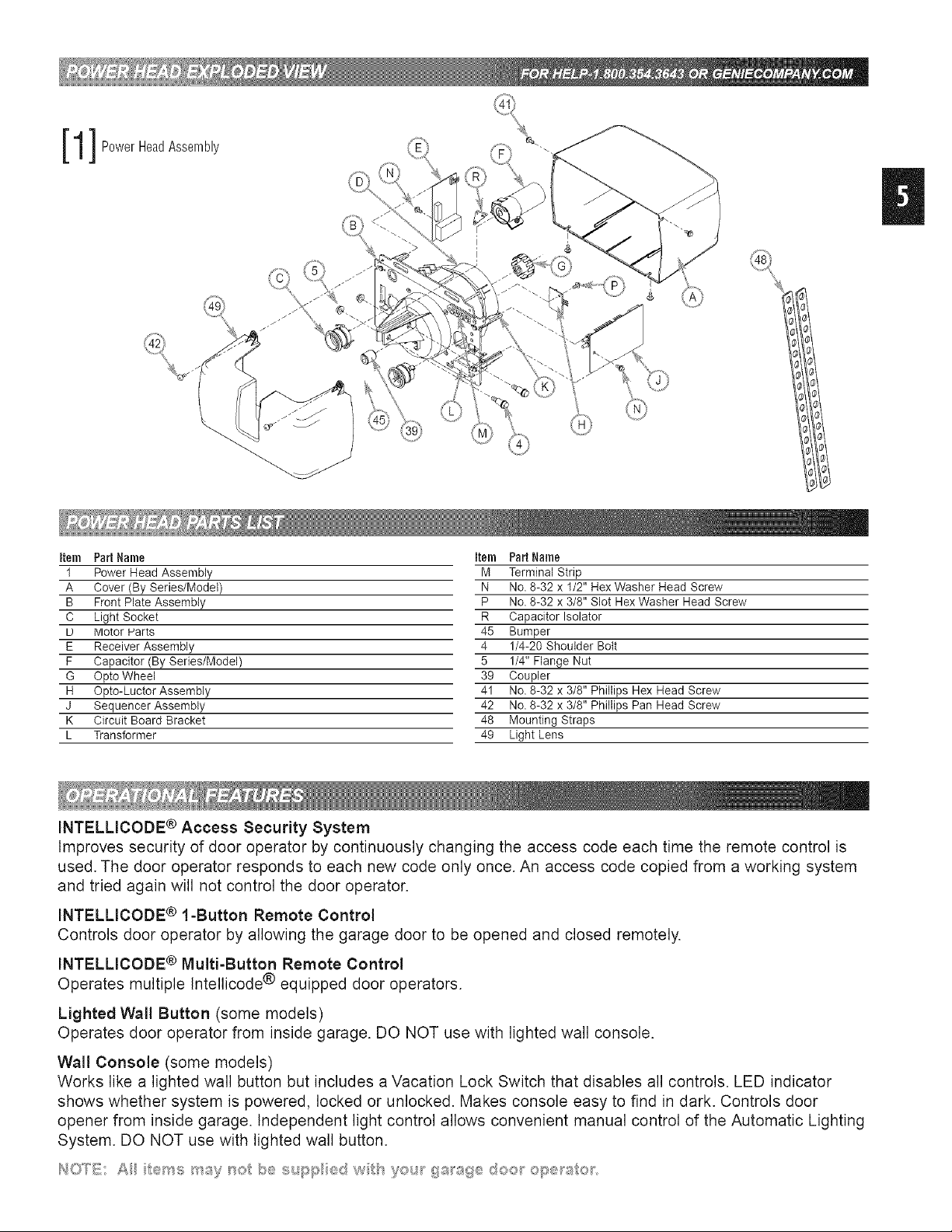

[1]P0werHeadAssemb,y

Item Part Name Item Part Name

1 Power Head Assembly M Terminal Strip

A Cover (By Series/Model) N No. 8-32 x 1/2" Hex Washer Head Screw

B Front Plate Assembly P No. 8-32 x 3/8" Slot Hex Washer Head Screw

C Light Socket R Capacitor Isolator

U Motor Harts 45 Bumper

E Receiver Assembly 4 1/4-20 Shoulder Bolt

F Capacitor (By Series/Model) 5 1/4" Flange Nut

G Opto Wheel 39 Coupler

H Opto-Luctor Assembly 41 No. 8-32 x 3/8" Phillips Hex Head Screw

J Sequencer Assembly 42 No. 8-32 x 3/8" Phillips Pan Head Screw

K Circuit Board Bracket 48 Mounting Straps

L Transformer 49 Light Lens

INTELLICODE ® Access Security System

Improves security of door operator by continuously changing the access code each time the remote control is

used. The door operator responds to each new code only once. An access code copied from a working system

and tried again will not control the door operator.

INTELLICODE ® l-Button Remote Control

Controls door operator by allowing the garage door to be opened and closed remotely.

INTELLICODE ® Multi-Button Remote Control

Operates multiple tntellicode ® equipped door operators.

Lighted Wall Button (some models)

Operates door operator from inside garage. DO NOT use with lighted wall console.

Wall Console (some models)

Works like a lighted wall button but includes a Vacation Lock Switch that disables all controls. LED indicator

shows whether system is powered, locked or unlocked. Makes console easy to find in dark. Controls door

opener from inside garage. Independent light control allows convenient manual control of the Automatic Lighting

System. DO NOT use with lighted wall button.

Page 6

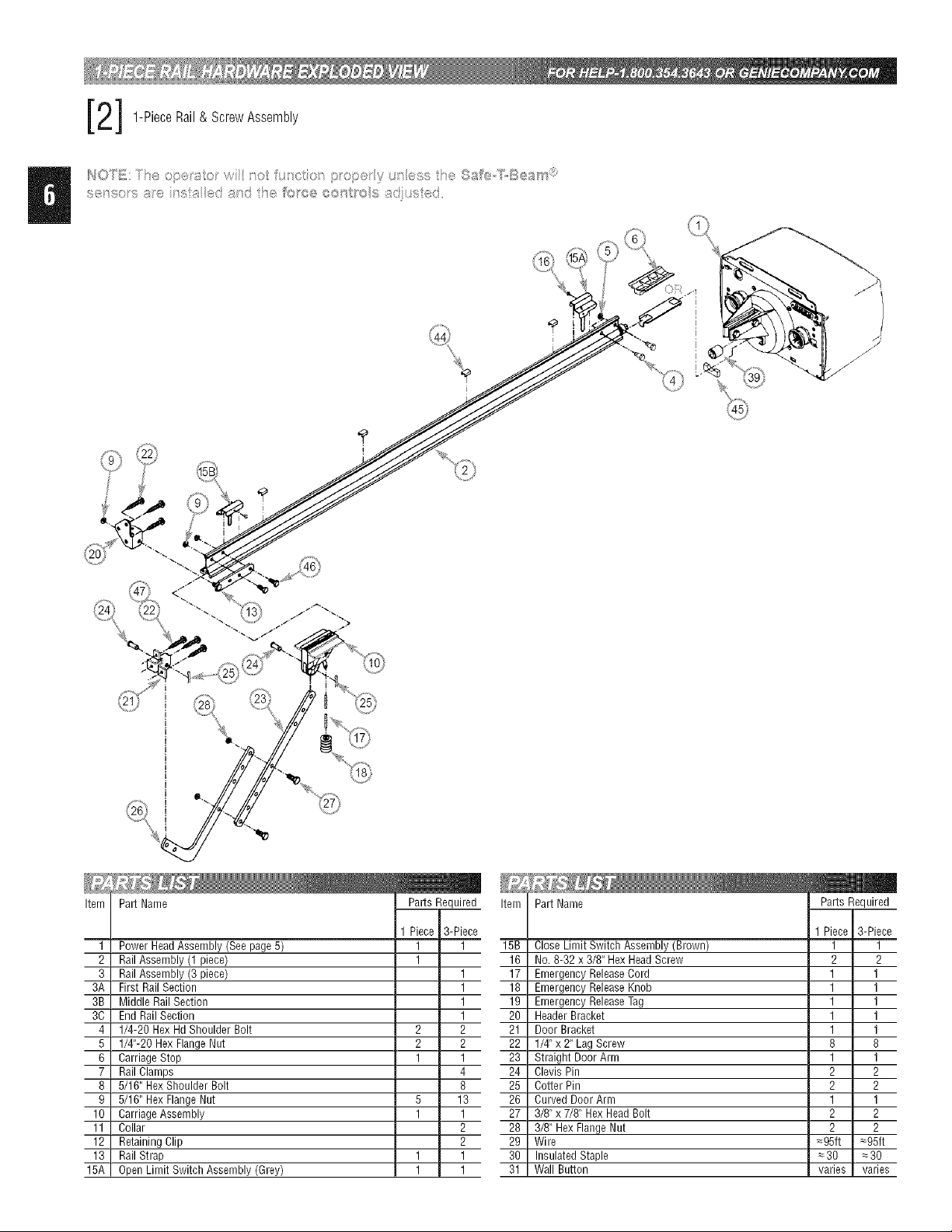

2]1-PieceRail& ScrewAssembly

,.,,, =.., =.., ,s*, Ii]I;,IIQIIII!CI....... = = ....... ........ ...........

Item

Part Name Item

3-Piece

1

PowerHeadAssembly(Seepage5) 1 1 15B

2

RailAssembly(1 piece) 1 16

3

RailAssembly(3 piece) 1 17

3A

FirstRailSection 1 18

3B

MiddleRailSection 1 19

3C

End RailSection 1 20

4

1/4-20 HexHdShoulderBolt 2 2 21

5

1/4"-20 HexFlangeNut 2 2 22

6

CarriageStop 1 1 23

7

RailClamps 4 24

8

5/16" HexShoulder Bolt 8 25

9

5/16" HexFlangeNut 5 13 26

10

CarriageAssembly 1 1 27

11

Collar 2 28

12

RetainingClip 2 29

13

RailStrap 1 1 30

15A

OpenLimit SwitchAssembly (Grey) 1 1 31

PartName

3-Piece

CloseLimit SwitchAssembly(Brown) 1 1

No.8-32x 3/8" HexHeadScrew 2 2

EmergencyReleaseCord 1 1

EmergencyReleaseKnob 1 1

EmergencyReleaseTag 1 1

HeaderBracket 1 1

DoorBracket 1 1

1/4"x 2"Lag Screw 8 8

Straight DoorArm 1 1

ClevisPin 2 2

Cotter Pin 2 2

CurvedDoorArm 1 1

3/8" x7/8"HexHeadBolt 2 2

3/8" HexFlangeNut 2 2

Wire _95ft =95ft

InsulatedStaple =30 _30

Wall Button varies varies

Page 7

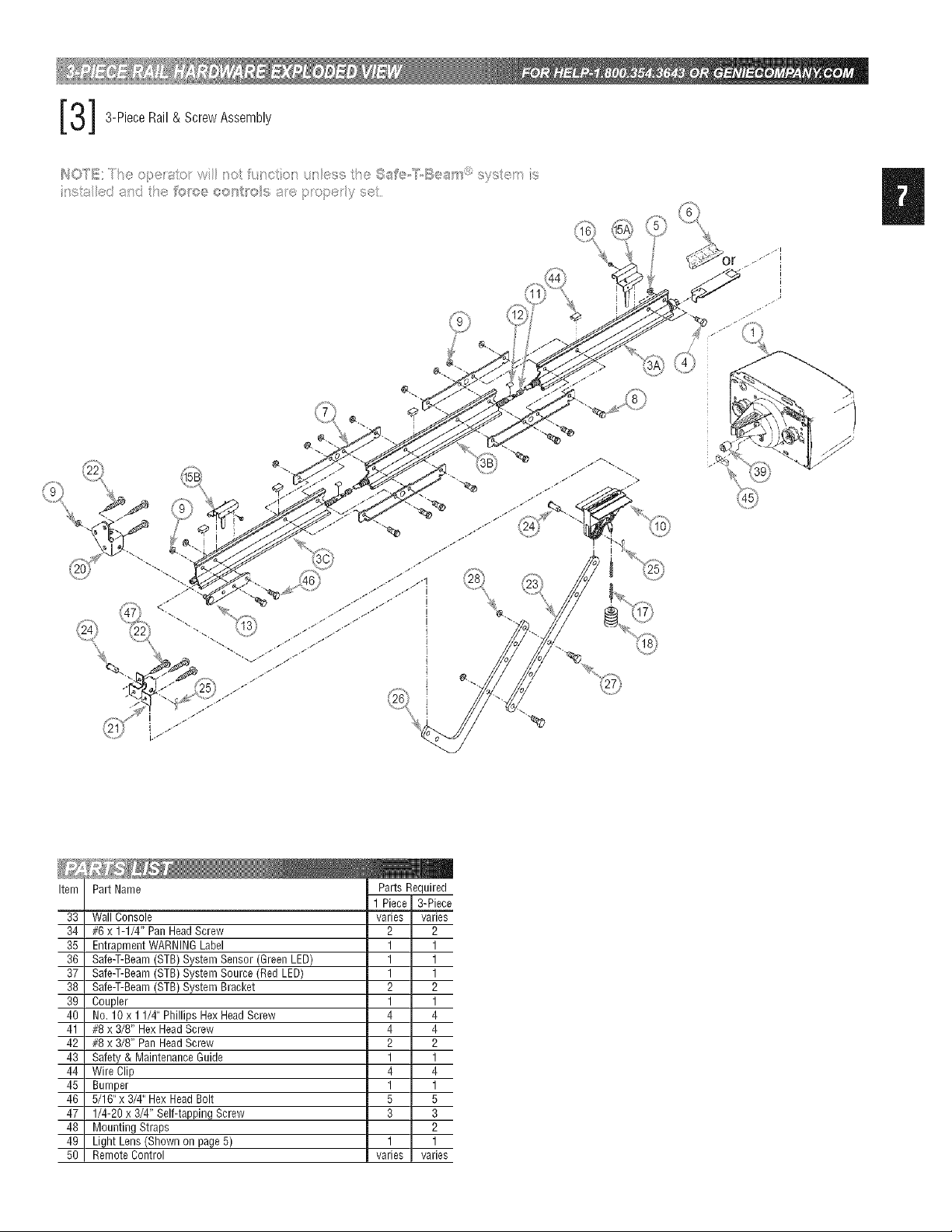

3]3-PieceRail&ScrewAssembly

8 _i ....... s.... w::; 8_;, >O>@Yd

Item

Part Name

33

WallConsole

34

#6 x 1-1/4" PanHeadScrew

35

EntrapmentWARNINGLabel

36

Safe-T-Beam(STB)SystemSensor (GreenLED)

37

Safe-T-Beam(STB)SystemSource (RedLED)

38

Safe-T-Beam(STB)System Bracket

39

Coupler

40

No. 10x11/4"Phillips HexHeadScrew

41

#8 x 3/8" HexHeadScrew

42

#8 x 3/8" PanHeadScrew

43

Safety& MaintenanceGuide

44

Wire Clip

45

Bumper

46

5/16"x 3/4"Hex HeadBolt

47

1/4-20x 3/4" Self-tappingScrew

48

MountingStraps

49

Light Lens (Shownon page5)

50

RemoteControl

varies

2

1

1

1

2

1

4

4

2

1

4

1

5

3

1

varies

3-Piece

varies

2

1

1

1

2

1

4

4

2

1

4

1

5

3

2

1

varies

Page 8

_m

U

@

@

®

@

.... y

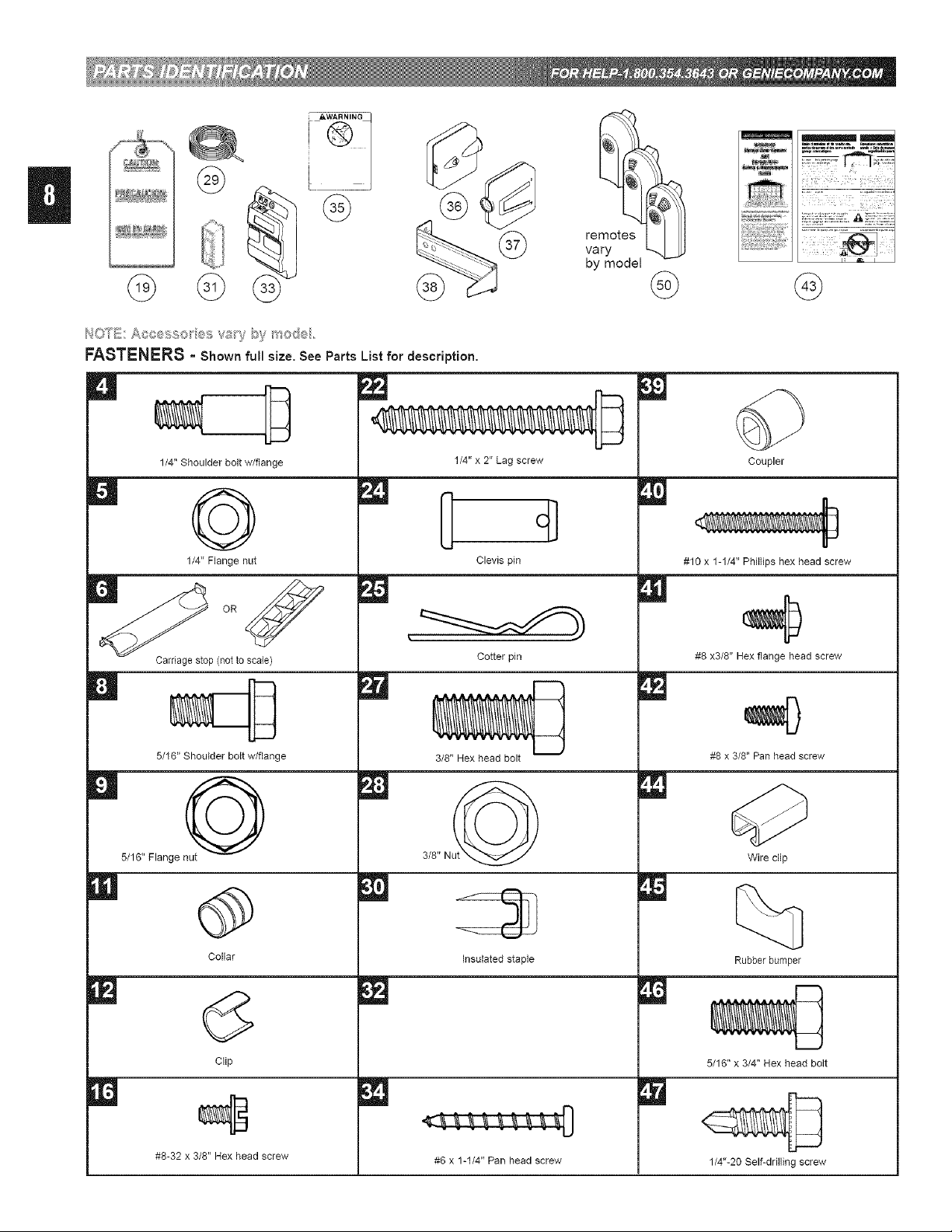

FASTENERS = Shown full size. See Parts List for description.

D

1/4" Shoulder bolt w/flange

.J l

q--

©

1/4" Flange nut

remotes

vary

by model

@

1/4" x 2" Lag screw Coupler

Clevis pin

#10 x 1-1/4" PhilHps hex head screw

..... _ .i}:..//,ii

Carriage stop (net to scale)

8/16" Shoulder bolt w/flange

g (8)

5/16" Flange nut

tn

@

Collar

Clip

Cotter pin

,21

3/8" Hex head bolt

N

N

3/8" Nut_

N

Insulated staple

NI Nt

#8 x3/8" Hex flange head screw

#8 x 3/8" Pan head screw

Wire clip

Rubber bumper

5/16" x 3/4" Hex head bolt

#8-32 x 3/8" Hex head screw

#6 x 1-1/4" Pan head screw

j_

1/4"-20 Self-drilling screw

Page 9

OVERVIEW OF

POTENTIAL HAZARDS

Garage doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs under

tension, and electric motors can cause injuries, your safety and the safety of

others depend on you reading the information in this manual, if you have

questions or do not understand the information presented, call your nearest

service representative.

in this section and those that foilow, the words Danger, Warning, and

Caution are used to emphasize important safety information.

The word:

,_ DANGER means that severe injury or death wilt result from failure

to follow instructions.

,_ WARNING means that severe injury or death can result from failure

to follow instructions.

,_ CAUTION means that property damage or injury can result from

failure to foliow instruction.

The word f40*__:is used to indicate important steps to be followed

or important considerations.

IMPORTANT

INSTALLATION

INSTRUCTIONS

Toreducethe risk of

severeinjuryordeath:

,

READ AND FOLLOW ALL SAFETY,

INSTALLATION AND OPERATION

INSTRUCTIONS. If you have any questions

or do not understand an instruction, call your

service representative.

,

Do Not install Opener on an improperly

balanced door. An improperly balanced

door may cause severe injury. Repairs and

adjustments to cables, spring assemblies,

and other hardware must be made by a

trained service person using proper tools

and instructions.

FILL THIS IN ATTIME OF INSTALLATIONFORYOUROWN

RECORDS,SOTHATITWILL

BE AVAILABLE IFYOU EVERNEEDTO CALL US.

Date Purchased / /

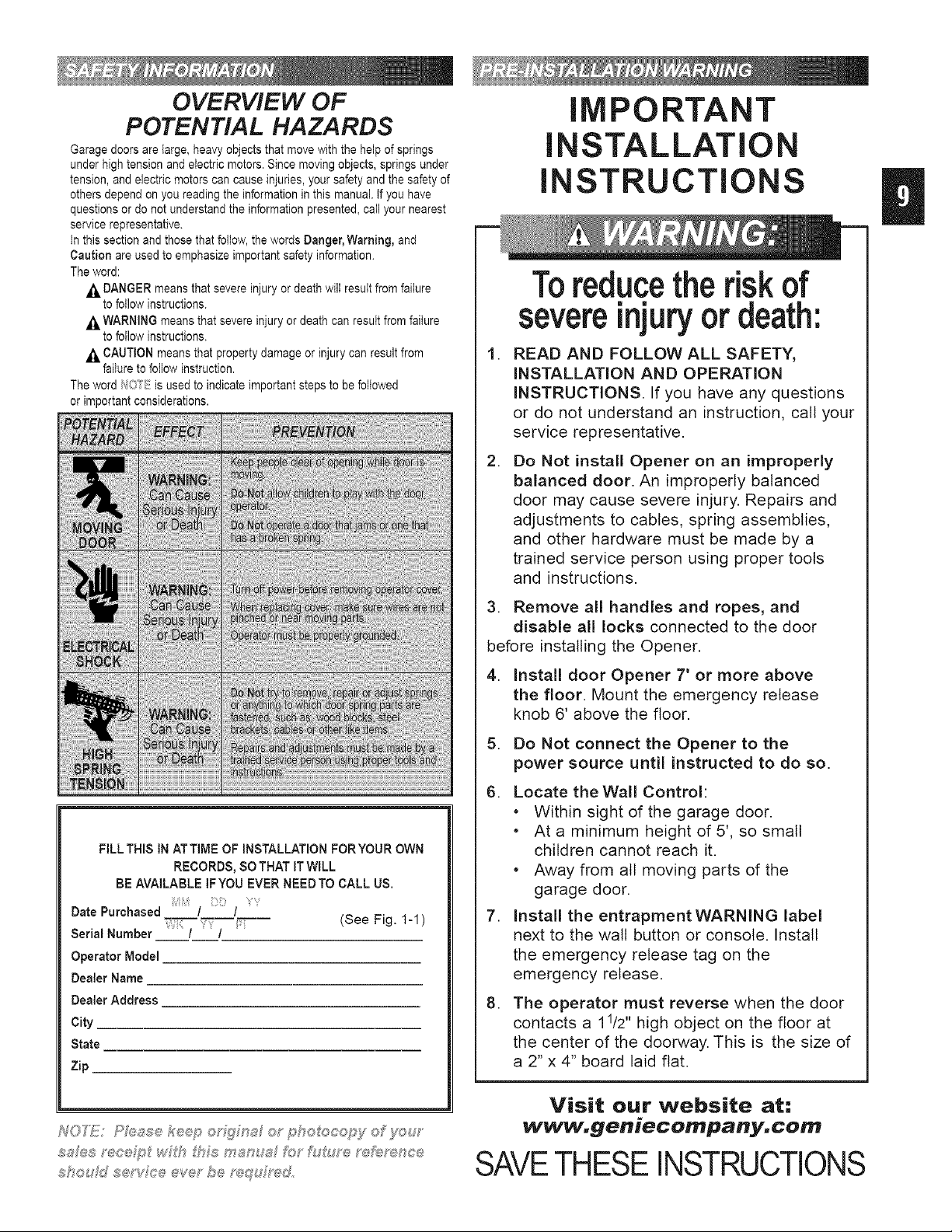

Serial Number / / (See Fig. 1-1 )

Operator Model

DealerName

DealerAddress

City

State

Zip

3. Remove all handles and ropes, and

disable all locks connected to the door

before installing the Opener.

4. Install door Opener 7' or more above

the floor. Mount the emergency release

knob 6' above the floor.

5. Do Not connect the Opener to the

power source until instructed to do so.

6. Locate theWall Control:

* Within sight of the garage door.

* At a minimum height of 5', so small

children cannot reach it.

* Away from all moving parts of the

garage door.

7. Install the entrapment WARNING label

next to the wall button or console. Install

the emergency release tag on the

emergency release.

8. The operator must reverse when the door

contacts a 11/2" high object on the floor at

the center of the doorway. This is the size of

a 2" x 4" board laid flat.

S'_ou d se vFo@eve" be ,u,_ dr_,d

Visit our website at:

www.geniecompany.com

SAVETHESEINSTRUCTIONS

Page 10

HO"I'E; 3,p ece ts assemby s Sc}__ doo_'s <p to

a/'_,d t_c_ d _g 7 f<i_ell6 _s@ses t}gt At_ ex/et_s et_

?o_'8?<:_et do®_'s says abe

1. Set power head so that front panel (with end

of shaft and rail attachment flange) is facing up.

Fig. 1-1.

I_O'TE: f yo_/_sve _/'t,s _y_:_e(it_w't _{_:_ Stop skp

tt,_p 2

2. Install bumper [45].

* Peel protective paper from glue side

of bumper.

* Stick bumper into position as shown.

Fig. 1-1.

3. Install coupler [39].

* Place coupler over end of shaft.

* Turn it as needed until it engages with shaft.

(it will drop down over end of shaft and will

no longer turn freely. Fig. 1-1.

4. Set power head on its bottom. Fig. 1-4.

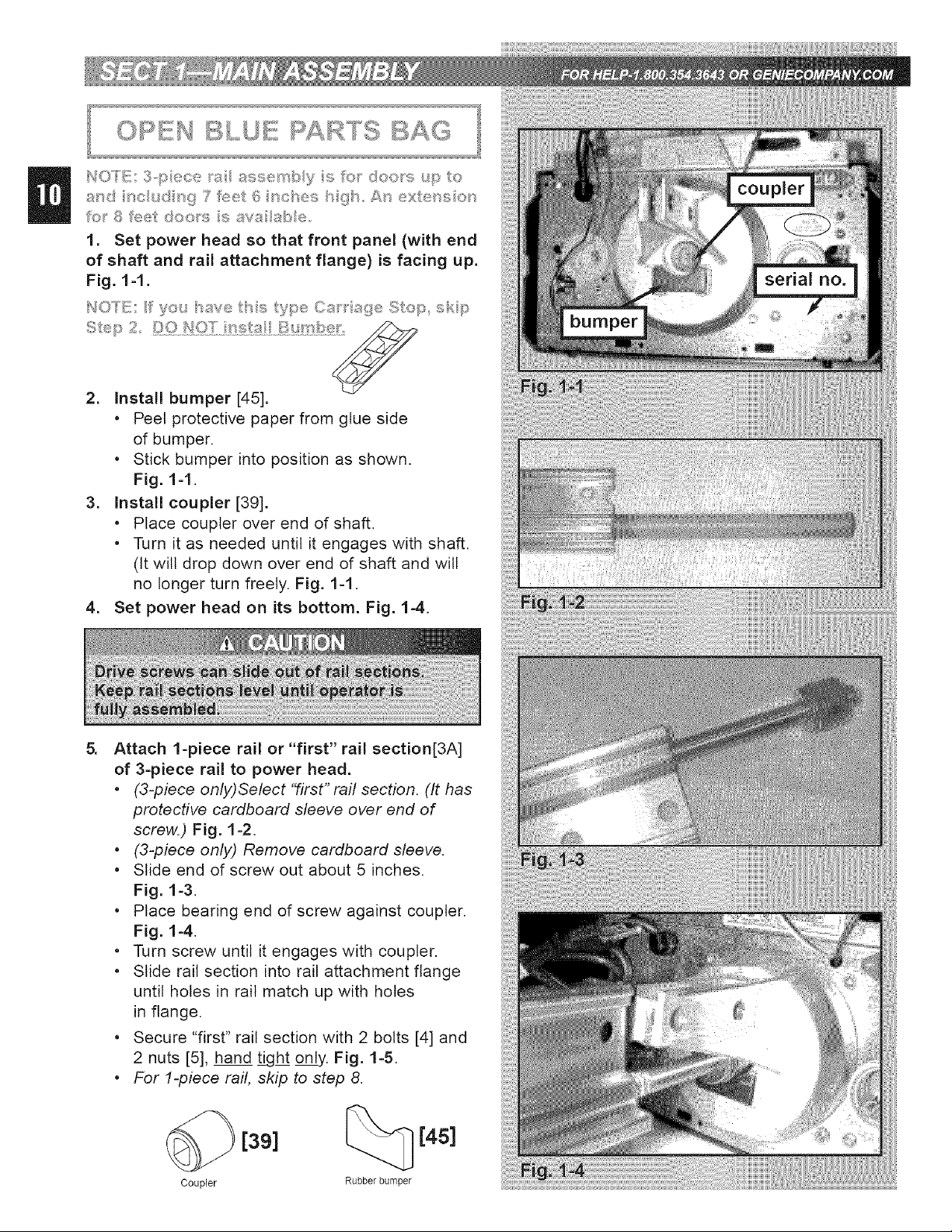

Attach 1-piece rail or "first" rail section[3A]

of 3-piece rail to power head.

* (3-piece only)Select "first" raft section. (It has

protective cardboard sleeve over end of

screw.) Fig. 1-2.

* (3-piece only) Remove cardboard sleeve.

* Slide end of screw out about 5 inches.

Fig. 1-3.

* Place bearing end of screw against coupler.

Fig. 1-4.

* Turn screw until it engages with coupler.

* Slide rail section into rail attachment flange

until holes in rail match up with holes

in flange.

* Secure "first" rail section with 2 bolts [4] and

2 nuts [5], hand tight only. Fig. 1-5.

* For 1-piece rail, skip to step 8.

Coupler

[39]

Rubber bumper

[4s]

Page 11

6_

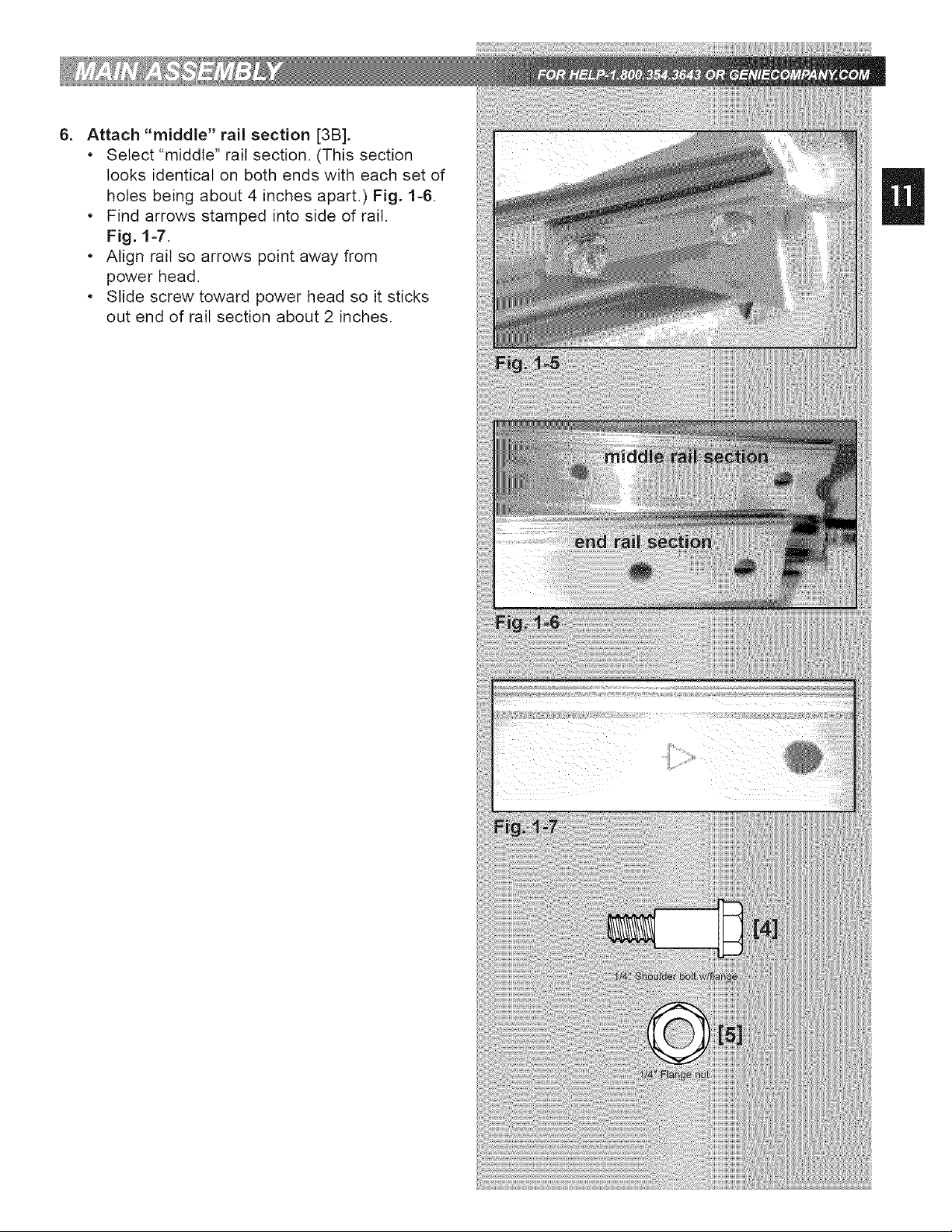

Attach "middle" rail section [3B].

• Select "middle" rail section. (This section

books identical on both ends with each set of

holes being about 4 inches apart.) Fig. 1-6.

• Find arrows stamped into side of rail.

Fig. 1-7.

• Align rail so arrows point away from

power head.

• Slide screw toward power head so it sticks

out end of rail section about 2 inches.

Page 12

• Slide a collar [11] over exposed end of

screw on "middle" rail as far as it wilt go.

Fig. 1-8.

• Engage "hook" on "middle" rail with "hook"

on "first" rail section. Fig. 1-9.

• Slide collar toward power head so that it

now covers hooks. Fig. 1-10.

• Snap a clip [12] onto screw behind collar to

hold collar in place. Fig. 1-11.

• Slide middle rail against first rail.

• Place rail clamp [7] on each side of joint

where rails meet. Match up holes in clamps

with holes in rail. (Edge with lip is bottom

of clamp.)

• Secure rail clamps with 4 bolts [8] and 4

nuts [9], hand tight only. Fig. 1-12.

[12]

Clip

5/16" Flange nut

5/16" Shoulder bolt w/flange

[8]

Page 13

7. Attach "end" rail section [3C].

• Attach "end" rail in same way as "middle" rail

(step 5). ("End" rail section screw has "hook"

on one end only.)

8. Flip power head/rail assembly over (upside

down), so that entire length of screw is visible

from above.

9. install carriage stop [6].

• With bent tabs facing up, slide carriage stop

into rail. Fig. 1-13.

• Slide carriage stop along rail until it rests

against power head.

10. install carriage [10].

• Place emergency release lever in released

position. Fig. 1-14.

• Make sure arrow on side of carriage

(Fig. 1-14) is pointing away from power

head. (Emergency release lever wilt be

facing power head.)

• Slide carriage into rail. Fig. 1-15.

NOFi_iJ!/Oa_%Q:e oa,,',,be t_;'ed_s s _:_mp®p;s_/

_?#L £V#c.®®me;s[?®oc}f ;,'<#_t_ssehive;" M ®g#g®d

11. Flip assembly right side up.

(Rail resting on carriage.)

12. Attach rail strap [13].

• Place rail strap against end of rail so that

attached stud passes in front of end of rail.

Fig. 1=16.

• Line up rail strap holes with rail holes.

• Secure with 2 bolts [46] and 2 nuts [9].

13. Make sure rail assembly is resting straight

and level.

• FULLY TIGHTEN ALL BOLTS AND NUTS IN

RAIL ASSEMBLY.

[91

5/16" Flange nut

[4S]

power

head

5/16" x 3/4" Hex head bolt

Page 14

14. Attach emergency release knob, cord

and tag.

• Tie an overhand knot in one end of

emergency release cord [17].

- Slide cord through center of knob [18].

Fig. 1=17.

- Slide cord through hole in emergency

release lever (on carriage).

- Tie a second knot in this end. Fig. 1-18.

- Slip wire of emergency release tag [19]

through hole in emergency release lever

and twist it around itself.

15. Attach limit switches.

• "CLOSE" limit switch [15B].

(Switches are identical.)

- Place "CLOSE" limit switch over top of rail

about 12 inches from rail strap. Fig. 1-19.

- Check that white lever is toward

power head.

- Insert set screw [16] into limit switch

hand tight only to temporarily hold switch

in place. Fig. 1-19A.

- Attach brown wire to switch. Fig. 1-19B.

- Leaving some slack in wire (Fig. 1=20),

run wire down inside groove in top of rail

back to power head.

- Use wire clip [44] to help maintain slack.

Fig. 1=20.

"OPEN" limit switch [15A].

- Place "OPEN" limit switch over top of rail

about 12 inches from power head. Fig. 1=21.

- Check that white lever is on side away from

power head. (This means limit switches

hang off opposite sides of rail. Check this

to help verify they are installed properly.)

- Insert set screw [16] into limit switch hand

tight only to temporarily hold switch in place.

- Attach grey wire to switch. Fig. 1=21.

- Leaving some slack in wire (Fig. 1=21),

run wire down inside groove in top of rail

back to power head.

- Use wire clip [44] to help maintain slack.

Fig. 1-21.

Coil excess wire and tape it to top of power

head. Fig. 1-21A.

[16] [44]

#8-32 x 3/8" Hex head screw Wire clip

Page 15

3"h®s® dJ_e?-enc®s a_'e _?t:_ Mn®d h_oudh®u

thh,_ sec ® Pk_ase noh_:__'hose ste_:¢s whFch a?-e

app icabF_ to .yo_,_-pa2'dcuF@2'd<:_oJ",

REFER TO PAGES 2 & 3.

There are two basic types of residential garage

doors. They are:

SECTIONAL DOORS--divided into a set of

narrow panels (usually four) connected by

hinges, so door can "bend" as it rides on a

curved track.

1-PIECE DOORS--consist of one barge

panel and swivel on large spring-loaded hinges

on each side of door.

Determining header bracket location.

• Find center of door from side to side.

- Measure overall width of door.

(example: 16 feet)

- Divide overall width by 2.

(example: 16+2 = 8 feet)

• Measure this distance from side of door and

draw a pencil line vertically from the top of

the door down approximately 1 foot. This is

the centerline. Fig. 2-1.

- Continue marking centerline on wall

above door from top of door up

approximately 1 foot. Fig. 2-1.

Page 16

2. Finding highest point of travel.

• Whileraisinggaragedoormanually,watch

topedge of door to see where it reaches its

highest point. This is called "highest point of

travel." Fig. 2-2.

• A locking pliers can be used to hold the

door in position by clamping it onto the rail.

(A stool, chair, table or any object that can

safely support door will also work.)

- With door held partly open (at its "highest

point"), measure distance from top edge

to the floor.

• Remove support and gently bower door.

• Mark "highest point of travel" at centerline

on watt above door. Fig. 2-3.

NOTE: Following step depends on type of door.

3. Final header bracket mounting location.

• For SECTIONAL DOORS--

add 2-1/2 inches to "highest point of travel"

and mark this height on centerline. Fig. 2-3.

• For ONE-PIECE DOORS--

add 6 inches to "highest point of travel" and

mark this height on centerline. Fig. 2-4.

Page 17

F,,. 11 @

( C_I OF s+,s. ;_ ........ @,,y s ,; o

_f@©/- ss #s

££ ....

4. Check mounting location for strength.

Header bracket must be attached to

framework of garage. Fig. 2-5.

• If final header bracket position is on garage

door header, continue with step 5.

• If final header bracket position is above

garage door header, a mounting plate must

be installed and mounting location must be

remarked before continuing with step 5.

Fig. 2-5.

• If your garage wall is finished (covered with

drywall), continue with step 5.

5. Mounting preparation.

• Hold bracket against wall where final header

bracket height crosses centerline.

• Make sure flange where rail strap attaches,

is on centerline. Fig. 2-6.

• Mark screw hole locations.

- If your walt is finished, take a small "finish

nail" and gently tap it through drywall

where you have marked screw holes to

find out if there is wood behind mounting

location. If your marked location is solid,

continue with step 6.

- If your marked mounting location is not

solid, a mounting plate must be installed

and mounting location remarked before

continuing. Fig. 2-7 and Fig. 2-5.

6. Mount header bracket [20].

• Drill 5/32 inch pilot holes at marked screw

hole locations.

• Fasten header bracket using 3 lag

screws [22].

TYPICAL FINISHED WALL

flange for

rail strap

1/4" x 2" Lag screw

[22]

Page 18

7. Attaching rail to header bracket.

• Gently set power head on garage floor while

leaning rail strap against header bracket. (It

is recommended that you place a piece of

cardboard or similar material between power

head and floor to prevent scrapes and

scratches to power head.)

NOTE: It may be necessary to support power

head above floor. As little as a few inches, or

as much as 5 or 6 feet depending on position

of torsion spring(s). Be sure to use a stable

support device, such as a ladder.

• Slide threaded stud of rail strap through hole

in flange of header bracket.

• Fasten with nut [9], finger tight only. Fig. 2-8.

Page 19

.

Mounting power head.

• Raise power head and support it high

enough that you can manually raise garage

door fully open.

• Line up power head and rail with center of

door. Fig. 2-9.

• Keeping power head centered, mount

to ceiling:

- at proper height;

a. for sectional doors rail should be level

with floor or slightly below level.

Fig. 2-10.

b. for 1-piece doors rail should clear

door by about 2 inches. Fig. 2-10.

SECTIONAL LEVEL OR SLIGHTLY BELOW LEVEL

1-PIECE MUST CLEAR DOOR BY 2 INCHES AT HIGHEST POINT OF TRAVEL

Fig. 2-10

- using one of the preferred methods

shown, Fig. 241, mount power head.

fit is possible to use other mounting

methods. The critical point to remember is

that the mounting assembly must be

solidly attached and able to support the

weight of the power head.) DO NOT

ATTACH TO DRY WALL OR

SUSPENDED CEILING. It must be

anchored to the framework of the garage.

Fully tighten rail strap nut.

2 II

Anc

FINISHED CEILING

Wood

Page 20

9_

Mounting door bracket [21].

• Center of bracket must be on centerline of

door and must be mounted as high as

possible. Fig. 2-12A & B.

• Hold bracket against door at preferred

location and mark screw holes.

- for wooden doors, drill 5/32 inch

pilot holes.

a. Fasten door bracket using

3 lag screws [22].

b. Check thickness of door against lag

screws. (It may be necessary to

mount door bracket on a 2" x 6",

etc. attached to inside of door to

prevent screws from coming out

other side of garage door.

Fig. 2-12A.

- for light=weight doors

CAUTION: In the case of sectional doors, the

door bracket must not be below the highest set

of rollers. Fig. 2-13.

- there are a wide variety of reinforcements

depending on manufacturer and some are

equipped with hardware that is intended

to be used in place of the door bracket.

Be sure to confirm proper use of

this hardware with your door

manufacturer. Unauthorized improper

use of these attachment systems

could void your warranty.

WHEREVER POSSIBLE--USE DOOR

BRACKET SUPPLIED WITH YOUR

GENIE OPERATOR.

a. Fasten door bracket using

3 self-drilling screws [47].

1/4" x 2" Lag screw

[22]

Page 21

10. Attach door arms [23] and [26].

• For sectional doors.

- Connect short leg of curved arm to

door bracket. Fig. 244.

- Use clevis pin [24] and cotter pin [25].

Fig. 2-14.

- Connect straight arm to carriage.

- Use clevis pin [24] and cotter pin [25].

- Overall length of arms together should be

as short as possible, but must not be so

short that they are vertical when the door

is fully closed. Fig. 2-14.

a. Move carriage as necessary to

adjust length.

b. Place bolts [27] and nuts [28] as far

apart as possible. Fig. 2-14.

c. Tighten bolts and nuts.

• For 1-piece doors.

- Connect short leg of curved arm to

carriage. Fig. 2-14.

- Use clevis pin [24] and cotter pin [25].

Fig. 2-14.

- Connect straight arm to door bracket.

- Use clevis pin [24] and cotter pin [25].

- Overall length of arms together should be

as long as possible. Fig. 2-14.

a. Move carriage as necessary to

adjust length.

b. Place bolts [27] and nuts [28] as

close together as possible. Fig. 2-14.

c. Tighten bolts and nuts.

11. Adjust emergency release knob height.

, Knob should hang approximately 6 feet from

the floor.

- adjust as necessary to clear vehicles yet

maintain height where it can be

easily reached.

• Pull cord through lever until knob is at

desired height.

• Tie a new knot at the lever.

• Cut off excess cord.

SECTIONAL DOOR

/

?

clevis & cotter pin

@--bolts/nuts (far apart as possible)

1-PIECE DOOR

i clevis & cotter pin

@--bolts/nuts (close as possible)

I

must be I I

:ffmi angle I I

c[] [24]

Clevis pin

, [2s]

Cotter pin

Page 22

1. Mounting brackets.

, Mark both sides of garage door frame or wall

5" above floor. Fig. 3=1.

, Hold bracket [38] against door frame or wall.

- Check if brackets extend out from wall far

enough, so tongue of bracket is beyond

door, tracks or any door hardware.

- If not:

a. STB bracket extensions are available

at local dealer.

b. Blocks of wood, etc. may be substituted

for extensions.

. Center bracket on your mark Fig. 3=2.

, Fasten each with 2 screws [40]. Fig. 3=2.

(Tongues should point toward each other.)

[4o]

#10-16 x 1-1/4"

2. Mounting STB source and sensor.

, If garage has only one garage door.

- Determine which side of garage receives

most direct sunlight Fig. 3=4, and place Red

LED here whenever possible Fig. 3-4.

. For multiple doors.

- Preventing crossed signals is critical.

- Place source and sensor modules on

adjacent doors facing in opposite directions

Fig. 3-4.

TWO DOOR

GARAGEGARAGE

• Slide source/sensor onto tongue of bracket

until it clicks into place Fig. 3-3.

=

Wiring.

, Route wire [29] using either method shown

Fig. 3-5.

, Securely fasten wires to ceiling and walls as

you go using insulated staples [30].

- Staples should be snug only. Staples which

are too tight can cut wires.

[30]

Insulated staple

THREE DOOR

GARAGE

Dashed Line = striped wire

Solid Line = white wire

I I

L

I

[]

Page 23

, Make wire attachments at STBs.

- Split and strip wire ends to be connected

as shown Fig. 3-6.

- Loosen terminal screws.

- Insert wire under flat plate and tighten screw.

It does not matter which wire, white or

striped, goes on which terminal Fig. 3-7.

, Make wire attachments at power head.

- STBs are connected to terminals #3 and

#4 on power head Fig. 3-8. tt does not

matter which wire, white or striped, goes on

which terminal.

4. Check the following.

, Ensure that no part of door or its hardware is

in path between lenses of source and sensor.

, Ensure that tops of lenses are between 5"-6"

above the floor Fig. 3=9. The brackets are

flexible, and can be adjusted slightly if needed.

(See Illustration on page 3 for a full view of

Safe-T-Beam ® location.)

Page 24

1. Run wire from power head to wall control

, Find location for wall control:

- In sight of door and away from moving parts.

- At least 5 feet from floor, so small

children cannot reach it.

• Route wire from wall control to power head.

• Use staples to fasten wire to ceiling and wall.

NON_!: Use only _J;_p e_; nc uded

2. Split wires at ends and remove 1!2 inch of

insulation from end of each Wire. Fig. 4=1.

3. Attach wires to terminals. Fig. 4=2, Fig. 4=3.

, Loosen (Do Not Remove) screws from

Terminals at power head and wall control

• Connect wires to power head

- White wire to terminal # 1

- Striped wire to terminal #2

- Tighten screws

• Connect wires to wall control

- Striped wire to terminal "B"

- White wire to terminal "W"

- Tighten screws

4. Mount wall control. Fig. 44.

. For Wall Console or Wall Button.

- Use pan head screws [34].

5. Mount entrapment warning label. Fig. 44.

. Remove protective backing.

• Stick label to wall next to wall control.

- Tacks or staples may be required on some

rough texture surfaces.

f<:,:y d®aFef' ONLY ONE OF YOUR _LL CON'f\POLS

_;_Y BE THE L GH'_) T'_'_E. f _m,_have a Z_h%_d

ws eet_f/_oh s :y'_:,:r add _;_'®t:_af¢ot:_g'oJs m_; be

Page 25

1. Wall console. Fig. 4-5.

A. Vacation locking switch.

- Lock disable all controls after door closes..

- Unlock allows all controls to work normally.

A

fockMg" swf_eh t_:_woTf_

B. Door control button.

- Opens and closes door from inside garage.

- Lights on shows system has power available

and vacation switch is not locked.

- Lights out shows either power is not

available or vacation locking switch is locked.

C. independent light control.

- Turns operator lights on and off without

moving door.

2. Wall Button

- Operates door from inside garage.

.

Install light bulbs.

. 2 bulbs.

- No more than 60 watts each.

- Do Not use short neck bulbs.

- Whenever possible, use bulbs rated for:

Rough service

Vibration

Appliances

.

Install lens.

. Hook bottom hinges into slots at bottom of

front plate. Fig. 5=1.

. Swing lens up over lights. Check for alignment

between the screw holes in the Lens and those

on the metal front plate.

. Lens will be fastened with 2 pan head screws.

([42] green parts bag). Fig. 5-2.

DO NOT FASTEN YET! Wait until you have

completed programming the Remote Controls.

C

B

Page 26

1. Check local building codes.

* Does building code require permanent wiring?

- If not, skip to step 9.

2. Remove power from circuit.

3. Remove motor cover (Fig. 64).

. Remove 4 screws [41] from cover and slide off

back of power head.

4. Remove and discard power cord.

. Cut off power cord inside power head.

. Remove and throw away power cord, strain

relief and knock-out.

5. Install suitable entrance bushing.

6. Connect permanent wiring to power head wires.

. Connect white supply line to white wire.

• Connect black supply line to black wire.

• Connect ground to green wire (ground).

NO_!!! U\se ®n_;/ U L_ ecoqn?_;,d wh-e nuJ_;

7. Replace motor cover.

. Slide motor cover back on.

• Replace and tighten 4 screws.

8. Reconnect power to circuit.

To correct the problem - the brackets are

flexible and can be adjusted slightly to bring

the system into alignment.

9. Plug in door operator.

. See warning above.

. Plug door operator into a grounded outlet.

. Perform STB ®alignment check (Fig. 6-2).

When the STBs are in alignment the red LED

will stop blinking and stay on.

Page 27

1. Set limit switch position.

, Check door fully closed.

- tf not, close door manually.

, Check carriage is between limit switches.

- If not, move "CLOSE" limit switch (brown wire)

to new position between door and carriage.

- Slide "CLOSE" limit switch back toward

carriage until lever is fully lifted. Fig. 7-1.

- Tighten limit switch set screw.

, Manually open door to fully open position..

, Check carriage is between limit switches.

- If not, move "OPEN" limit switch to new

position between power head and carriage.

- Slide "OPEN" limit switch back toward

carriage until lever is fully lifted. Fig. 7-1.

- Tighten limit switch set screw.

2. Adjust opening force.

, Engage Carriage by pulling Emergency

Release Lever toward Powerhead until

Lever snaps into engaged position.

, On front panel of power head--find adjusting

screw marked "CLOSE." Fig. 7-2.

• Turn screw gently counterclockwise until it stops.

. Run operator using wall control.

. Observe door runs to "CLOSE" limit switch.

- If not, increase closing force by turning

"CLOSE" adjusting screw clockwise slightly

(about 1/16 turn).

, Repeat until door runs to "CLOSE" limit switch.

, Check door is fully closed.

- If not, move "CLOSE" limit switch toward

door as necessary to achieve fully closed.

3. Adjust closing force.

, On front panel of power head--find adjusting

screw marked "OPEN." Fig. 7=2.

, Turn screw gently counterclockwise until it stops.

, Run operator using wall control.

, Observe door runs to "OPEN" limit switch.

- If not, increase opening force by turning

"OPEN" adjusting screw clockwise slightly

(about 1/16 turn).

, Repeat until door runs to "OPEN" limit switch.

, Check door is fully open.

- If not, move "OPEN" limit switch toward power

head as necessary to achieve fully open.

Page 28

Limit switch adjustments must be completed

before running contact reverse test.

, Test contact reverse.

. Open door using wall control.

. Lay 2" x 4" board* on floor in center of garage

door opening. Fig. 7-3.

. Close door using wall control.

- Door should stop and reverse

within 2 seconds of contacting the board.

- If door does not reverse properly:

a. Decrease closing force a small amount

by turning the "CLOSE" force adjustment

screw slightly counterclockwise.

b. Test contact reverse again.

c. Repeat steps a. and b. until contact

reverse works properly.

*If you don't have a 2" x 4" board handy, any object

1-1/2 inches high that can withstand being hit by the

garage door without sustaining damage is fine.

NOD!:!!: do_:y _ _!_:_?P_::_WX7bu_ _t_;__;t f_;W

'CLOSE _4_ _,_wfch mu_ be mov®d c_2_e' o

d%_oP:

1. Install/replace battery Fig. 8-1.

. Using a pen or similar object, gently push in

on tab.

. Cover snaps open. Remove old battery.

. Observe polarity markings (+,-)inside

battery compartment.

. Match new battery to polarity markings and

instal new SS_,EVEREAD_A23, 12 Volt battery.

• Replace battery cover.

2. Attach visor clip Fig. 6-1.

. Slide clip in slot on back of remote control.

- Snap in place.

Page 29

NOi"£_; £')Jc _et'_o_'edevce mus_ k_e

p_o_7 4s,mme_:Fse;_4s,sf#/e,y

h,!O_]]!_;Remo_e co '9"oFs w _'_e cos_, dec F

Learn Indicator

NO _#,]f: WG_e_puogms_ mm8 _emog,!:;c@'s_,!'e,;, must

1. Program one button remote.

• Lower lens cover.

. Locate learn code button and learn indicator on

power head Fig. 9-1.

• Press and release learn code button.

- Red learn indicator blinks 2 times per second.

• Press remote control button once within

30 seconds.

- Red learn indicator stays lit.

• Press remote control button again.

- Red indicator goes out and memory

is stored.

des per seeor:_d, p_ogx_;mmm£ ha s_o_p_ed,

2. Program multi-button remote.

= Repeat step 1 above "Program one-button

remote" for each button and operator.

sf_sFngFe does

3. Operating remote.

• Press button once:

- If door is at up or down limit, door will move

away from that limit.

- If door is stopped between limits, it will move

toward the limit where it was last stopped.

- tf door is moving, it will stop.

To erase all receiver memory, such as

following loss of remote, home sale or

tenant turn=over

• Press and hold learn code button for

10 seconds or until learn code

indicator goes out--memory is erased.

• Program remotes as before.

FCC and IC CERTIFIED

This device complies with FCC Part 15 and RSS

210 of Industry Canada. This equipment has been

tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide

reasonable protection against harmful interference

in a residential installation. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications. However,

there is no guarantee that interference will not

occur in a particular installation. If this equipment

does cause harmful interference to radio or

television reception, which can be determined by

turning the equipment off and on, the user is

encouraged to try to correct the interference by one

or more of the following measures:

• Re-orient or relocate the receiver antenna.

• Increase the separation between the operator

and receiver.

• Connect the operator into an outlet on a circuit

different from that towhich the appliance

is connected.

• Consult the dealer.

e/ose e}_;_;/#:,_,

Page 30

Transmitters comply with all United States and Canadian legal

requirements as of the date of manufacture. No warranty is

made that they comply with all legal requirements of any other

jurisdiction. If transmitters are to be used in another country,

the importer must determine compliance with any local laws

and regulations which may differ from United States and

Canadian requirements prior to use.

Toreducethe riskof

severeinjuryordeath:

READ AND FOLLOW ALL

INSTRUCTIONS.

Los transmisores cumplen con todas tas reglamentaciones

legales de los Estados Unidos y del Canad, en la fecha de

fabricaci n. Ninguna garant a se da que cumplan con todas las

reglamentaciones legates de ninguna otra jurisdicd n. Si los

transmisores se van a utilizar en otro pa s, el importador debe

determinar si cumplen con las reglamentaciones y leyes

locales que puedan ser diferentes alas reglamentadones

de los Estados Unidos y del Canad, antes de usar los mismos.

Les metteurs sent conformes la r glementation am ricaine

et canadienne compter de leur date de fabrication. Aucune

garantie nest stipule indiquant qu ils sent conformes toutes

les prescriptions juridiques d autres autodt s. Si les metteurs

sont utiNss dans d autres pays, il incombe I importateur d en

d terminer leur conformit aux lois et r gles locales pouvant

diff rer de ceNes des tats-Unis et du Canada avant toute

utitisation desdits metteurs.

Sendeger te entsprechen allen gesetziichen Bestimmungen in

den USA und Kanada zum Zeitpunkt der Herstetlung. Wir

bernehmen keine Gew hrleistung f rdie Einhaltung aller

gesetzlichen Bestimmungen in anderen L ndern. Soiten

Sendeger te in anderen L ndern eingesetzt werden, so muss

der Importeur vor dem Gebrauch sichersteNen, dass die

Sendeger te auch solchen Iokalen Bestimmungen entsprechen,

welche von den Bestimmungen der USA und

Kanadas abweichen.

Never let children operate or play with the

Door Controls. Keep the Remote Control

away from children.

Always keep the moving door in sight and

away from people and objects until the

door is completely closed. NO ONE

SHOULD CROSS THE PATH OF THE

MOVING DOOR.

NEVER GO UNDER A STOPPED,

PARTIALLY OPEN DOOR.

Test Opener monthly. The door MUST

reverse on contact with a 1-1/2" high

object (or a 2" x 4" board laid flat) at the

center of the doorway on the floor. After

adjusting either the Force or the Limit of

travel, retest the Door Opener. Failure to

adjust the Opener properly may cause

severe injury or death.

When possible use the Emergency

Release only when the door is closed.

Use caution when using this Release with

the door open. Weak or broken springs

are capable of increasing the rate of door

closure and increasing the risk of severe

injury or death.

_°=1__@l.-Jq._ _UlEt_OI 21El-C}_-__ xt_ll_,t _@_ 9 ° _o_

xl_°l _ _IIOil _q_tol_xl°l ot_ _st_ol _LIck

7 KEEP GARAGE DOORS PROPERLY

BALANCED. See Owner's Manual. An

improperly balanced door increases the

risk of severe injury or death. Have a

Genie Factory Authorized Dealer make

repairs to cables, spring assemblies, and

other hardware.

SAVETHESEINSTRUCTIONS.

Page 31

Door springs and hardware.

• Oil door rollers, bearings, and hinges.

- Use silicone lubricant or light oil.

NOTE: Do not operate door automatically or manually if

springs are broken. CONTACT A PROFESSIONAL FOR

SERVICE.

Balance door.

• Close door.

• Release carriage from rail assembly.

- Pull emergency release knob down.

• Raise door manually about 3 feet.

- Door should stay in that position.

NOTE: If door moves, HAVE DOOR SERVICED BY

A PROFESSIONAL.

• Reattach carriage to rail assembly.

- Pull emergency release knob toward power head.

• Close door

Contact reverse.

• Lay 2" x 4" board flat on the floor in the center of

garage doorway (See page 28).

• Close door using wall button or remote control.

NOTE: If door fails to reverse on contact with board. See

page 28, CONTACT REVERSE. If operator still fails,

replace operator or HAVE THE OPERATOR SERVICED BY

A PROFESSIONAL.

YEAR

Drive 8crew

• Lubricate drive screw.

- Use GENIE GLU3 lubricant.

Use only GENIE GLU3 lubricant, because other

lubricants may damage operator.

SOURCE (RED LED

0 ON

0 OFF

0 OFF

2 BLINKS, PAUSE(REPEAT)

2 BLINKS, PAUSE(REPEAT)

3 BLINKS, PAUSE(REPEAT)

4 BLINKS,PAUSE(REPEAT) 2.SOURCEDEFECTIVE 2.CALLCUSTOMERSERVICE

NOTE: IF OPERATING PROBLEM EXISTS, THE DOOR CAN BE CLOSED iF YOU: I DISCONNECT THE STB SYSTEM FROM THE OPERATOR AND 2 HOLD WALL CONTROL BUTTON

DOWN UNTIL DOOR IS CLOSED. (REMOTE CONTROL & WIRELESS KEYPAD WILL NOT WORK WITHOUT STB)

Q ON

0 OFF

0 ON

0 ON

0 OFF

• ON

0 ON

INDICATED CONDITION REQUIRED ACTIONSENSOR (GREEN LED

NORMAL OPERATION NONEREQUIRED

1.POWER HEAD NOT POWERED 1.CHECKBREAKERS,FUSES, PLUGS

2.WIRING FROMPOWER HEADBAD 2.CHECKWIRING FOR OBVIOUSSHORTS

1.WIRING TOSOURCE MISSING OR BAD 1.CHECKWIRING

2.POWER HAS BEENINTERRUPTED 2.REMOVE POWERAND REAPPLY

1.BEAM NOT ALIGNED 2. BEAMOBSTRUCTED 1.CHECKALIGNMENT 2. CHECKFOR OBSTRUCTION

3.SENSOR DEFECTIVE 3.CALL CUSTOMERSERVICE

1.WIRE TO SENSORMISSING OR BAD 1.CHECKWIRING

2.SENSOR DEFECTIVE 2.CALL CUSTOMERSERVICE

1.SENSOR RECEIVINGINTERFERENCE 1.ATTEMPTTO DETERMINESOURCEOFINTERFERENCE

1.SOURCENOTSENDINGPULSES 1.CALLCUSTOMERSERVICE

2.CALL CUSTOMERSERVICE

ii::

CUSTOMER SERVICE: 1.800.354.3643 or www.geniecompany.com

Page 32

Use this guide to correct problems with your door

operator. If these solutions do not work, call

Customer Service.

PROBLEM

Operator does not run

from wail control,

Door starts down, then

stops before it's closed.

Door will only run closed.

SOLUTIONS

Check lock switch on wall console (See section 4).

Check the power source.

• Plug a lamp into outlet used for power head. If lamp works, power source is OK. If not, check fuse

or circuit breaker.

• If power is OK:

- Check connections at power head terminals.

- Check connections at wall control.

- Motor protector may be open. Wait about 20 minutes for protector to reset.

Check CLOSE limit switch setting (See Section 7)

Check for shorted wires

Check OPEN limit switch for short and proper wiring.

Check force adjustment (See section 7).

Check for broken door spring.

Remote control has

less than 25 feet

operating range.

Operator runs, but door

does not move.

Noisy operation. Be sure all fasteners are tight.

Lights will not go out. Check wiring,

Relocate remote control inside car.

Point remote control at door.

Replace battery.

Do Not attempt to retune remote controls.

Make sure carriage is engaged.

Check force adjustment (See Section 7).

Be sure door is in good repair, properly lubricated and balanced (See Monthly Maintenance section).

Disconnect & reconnect wires on wall control.

Non-compatible wall control.

Page 33

PRIMARY

SEQUENCER

SECUENCIADOR

PRIMARIO

SEQUENCEUR

PRIMAIRE

WHITE

WHITE

CLOSE / CERRAR / FERMER

OPEN / ABRIR / OUVRIR

WHITE

POWER CORD

CORDON DE ALIMENTACION

CABLE D'ALIMENTATION

m

BLACK= NEGRO =NOIR

BLUE =AZUL= BLEU

BROWN= MARRON=BRUN

GREEN =VERDE=VERT

GREY= GRIS = GRIS

ORANGE = NARANJA = ORANGE

PURPLE= MORADO = POURPPRE

RED = ROJO = ROUGE

RED/WHITE=ROJO/BLANCO=ROUGE/BLANC

STRIPED = RAYAS = RAYE

YELLOW =AMARILLO =JAUNE

COLORLEGEND

"-,,--J I

LIGHTS

-UZES

-AMPESj

BLUE

TRANSFORMER

h BLACK BLACK

< < < RED

THERMAL PROTECTOR

PROTECTOR TERMICO

THERMIQUE

MOTOR

MOTOR

MOTEUR

Page 34

U

What is covered: Any defect in matedal and workmanship from

personal, normal household use in accordance with the

Owner's Manual

For how long:

H4000A-2 Series... Motor 10 years and all other parts 2 years.

H6000A-2K Series. Motor 15 years and all other parts 3 years.

18525 Series ...... Motor 2 yearsand all other parts 2 years.

18550-1 Series .... Motor 7 years and all other parts 2 years.

18550-2 Series .... Motor 10 years and all other parts 2 years.

ISS50-2X Series... Motor 12 years and all other parts 2 years.

18850-2M Series... Motor Lifetime* and all other parts 3 years.

18900-1 Series .... Motor 10 years and all other parts 2 years.

18900-2 Series .... Motor Lifetime* and all other parts 2 years.

18920 Series ..... Motor Lifetime* and all other parts 2years.

ISL9S0 Series .... Motor Lifetime* and all other parts 3 years.

ISL900 Series ..... Motor and all other parts Lifetime*.

CM7600 Series.... Motor 10 years and all other parts 0 years.

CM8600 Series.... Motor Lifetime and all other parts 5 years.

PRO 95 Series..... Motor and all other parts Lifetime*.

*Lifetime l,varranty- warranted for as long asyou own your home

Who Gets the Warranty: The warranty ie limited to the

consumer who originally purchased the product.

Geographic Scope: This warranty applee only to Genie

products purchased in the United Statee and Canada.

What we wig do: If your Genie product is defective, we wil

send replacement parts or, at our option, replace it at no charge

to you. if we send replacement parts for your Genie product, we

may uee new or reconditioned replacement parts. If we choose

to replace your Genie product, we may replace it with a new or

reconditioned one of the same or eirnlar design.

LimitaDons: iMPLiEDWARRANTIES,INCLUDINGTHOSEOF

FITNESSFORA PARTICULARPURPOSEANDMERCHANTABILITY

(AN UNWRITTENWARRANTYTHATTHE PRODUCTIS FITFOR

ORDINARYUSE)ARELIMITEDTOONEYEARFROMDATEOF

PURCHASE.GENIEWiLL NOTPAYFOR;LOSSOFUSEOF

YOURGENIEPRODUCTOR PROPERTYDAMAGECAUSEDBY

YOURGENIEPRODUCTOR ITSFAILURETOWORK;ANY

SPECIAL,INCIDENTALORCONSEQUENTIALDAMAGES;ANY

DAMAGESRESULTINGFROMMISUSEORMODiFiCATiONOF

YOURGENIEPRODUCT.

Some statesand provincesdo notalow lirngationeon howlong

an impled warrantylaetsorthe exclusionof incidentalor

consequentialdamages,so theaboveexclusionemaynot apply.

Dewto getWarranty Service: To getwarranty servicefor your

Genieproduct, youmust provide proofof date, and placeof

purchaseof the product.

1. Do-it-Yonrself-Service:CallGenieConsumerComlectiontoll

free at1-800-354-3643. TrainedGenierepresentativeswil assist

in diagnosingthe problem andwill arrangetosupply you with

requiredpartsfor do-g-yoursel repairs.Trainedservice

representativesareavailable Monday-Friday,8:00AM - 11:00

PM, and on Saturday,11:00 AM-8:00 PMEasternTime

(subjoGto holidays.)

2. Service FromAethorizedDealers:Youcanobtainthe nameof

a Genieauthorizeddealerby callingtheGenieConsumer

Connectionat1-800-654-3643.g an authorizeddealer provides

warrantyservice, Geniewil not reimburseyouor otherwisebe

responeiblefor thosecharges.

Your choice of anyone of the abovedescribedservice optionsis

your remedy underthis warranty.

WhatThis Warranty DoesNotCover: Thiswarranty doesnot

cover batteries (which areconsideredreplaceableparts,)

instalation, commercial use,defects resulting from accidents,

damagewhile intransitto our servicelocation or damage

reeugingfromagerations,misuseor abuse,lackof proper

maintenance,unauthorizedrepairor modilcatione of the

product, affixing of anyattachment notprovided with the

product, programmingof the RemoteControlDevices,

Safe-T-Beam®adiustment/Meaning,stapleethrougll wiring,

pinchedor broken wires,Carriagedisengaged,ForceControl

adjustments, doorout ofbalance, brokensprings or cables,

power outages,ueeof extensioncords, rniesingor damaged

parts ondiscounted, Mearanced,final sale or taped cartons,

phantom operations(labor is notcoveredif Openeris

functioning properly whfe teelmicianis in garage),fire, Iced,

actsof God, orfafure to follow the Owner'sManual

This warranty is Die only one we wig give off yoor Genie

prodact, and it sets forth all oer responsibilities regarding

yoor Genie prodact. There are no other express warranties.

State and Province Rights: This warranty gives you specific

legal rights, and you may also have other rights that vary from

state to state add province to province.

Lo qne estd cuhierto: todo defeeto en matedales y mane de obra en el

usedomGstieo personal y normal deacuerdo con el Manual del

PropietaNo.

DuraciSn:

Sede H4000A-2... Motor 10 ales y todas las demos piezas 2 ales.

Sede H6000A-2K.. Motor 15 aSosy todas las demos piezas 3a£os.

Sede IS525 ...... Motor 2 a£os y todas las demos piezas 2 a£os.

Sede IS550-1 ..... Motor 7aSos y todas las demos piezas 2 aSos.

Sede IS550-2 ..... Motor 10 ales y todas las dem£s piezas 2 ales.

Sede IS550-2X.... Motor 12 ales y todas los dem£s piezas 2 ales.

Sede IS850-2M... Motor Vgale[a y todas las demos piezas0 ales.

Sede IS900-1 ..... Motor 10ales y todas las demos piezas 2 ales.

Sede IS900-2 ..... Motor Vgale[a* y todas los demos piezas 2 ales.

Sede IS920 ...... Motor Vgale[a* y todas las dem£s piezas2 a£os.

Sede ISL950 ..... Motor Vgale[a* y todas las demos piezas0 a£os.

Sede ISL980 ..... Motor y todas los dem£s piezas Vgalicia.

Sede CM7600 .... Motor 10ales y redes los demos piezas 3ales.

Sede CM8600 .... Motor Vgale[a* y redes las demos piezas 5 ales.

Sede PRO95 ..... Motor y todas las demds piezas Vitalicia*.

*Garantfa Vitaticia = se garantiza mientras usted sea el propietario de

su ease

zQuidn ohDene lagarantia? La garantia est£ limitada al consumidor

que eompr0 originalmente el produeto.

Aleaace geogr_fice: Esta garanla seap]ica sGIoa los produetos Genie

eomprados en los Estados Unidos y Canada.

Lo gee haremos: Si su produeto Genie es defectuoso, mandaremos el

reemplazo los partes o, aope[Gn nuestra, Io reereplazaremos sin cargo

alguno para usted. Si mandamos el reemplazo las partessu producto

Genie, podemos user piezas de reereplazo nuevas o reacondicionadas.

Si optamos per cambiar su producto Genie, podemos camhiarlo per

uno nuevo o reacondicionado del mismo diseio o similar.

Limita¢ienee: LASGARANTJAS IMPL[CITAS, INCLUYENDO

AQUELLAS DECONVENIENCIAPARA UNPROPOSITO PARTICULARY

COMERCIABILIDAD (UNA GARANTiANO ESCRITAQUE EL

PRODUCTOESAPR_OPIADOPARAUSO ORDINARIO) ESTAN

LIMITADAS A UNANO A PARTIR DE LA FECHADECOMPRA.GENIE

NOPAGAR,_POR PERDIDA DEL use DESU PRODUCTOGENIE0

POR DAi/OS DE PROPIEDADCAUSADOSPOR SU PRODUCTOGENIE

O POR LAFALLA DE TRABAJAR; POR DA%S CUALESQUIERA

ESPECIALES,INCIDENTALES0 EMERGENTES;PeR DANOS

RESULTANTESDELMAL USO 0 LA MODIFICACIONDE SU

PRODUCTOGENIE.

AIgunos estados y provine[as no permiten limitaciones del tiempo que

dura la garantia implega o la exclusion de dales ine[dentales o

e[rcunstane[ales, entonees puede que los limitaciones de ardba no se

aplquen.

CSmo obtener servieio de garaoDa: Para obtener swvie[o de garantia

paresu producto Genie,usted debe proporeionar prueba de la fecha y

lunar de laeompra delprodueto.

1. Servicio de hHcelaje: Llamar sin cargoala conexiGndelcensumider

de Genie,mamandee]1-000-354-3643. Representantesentrenades de

Geniele adstir_n endiagnoslcar e]prebiema y har£narregles pare sum-

inistrade ]aspiezasnecesadaspara los reparacienes debdcelaie e seaque

ustedmismo haga.Los representanfesde servicio entrenadosest_n

disponibJesde Noes aviemes, de 0:00a.m. a11:00 p.m. y loss£bades

de 11:00a.m. a8:00 p.m. hera del Este(sujete aferiades).

2. 8ervicio de distrihoidoree autorizados: Usted puede obtener el

hombre del distNhuidor autodzado de Genie lamando ala eonexiSn de[

eonsumidor de Genie, mareando el 1-800-654-3643. Si (in

distNhuider autodzado exlende una garantia de servicio, Genie no le

reemholsar£ austed ni ser_responsable per esos cargos.

Su elecciOn de cualesquiera de los opciones de los servieios descNtos

ardba es el reeurso que tiene baio esta garantia.

Qn6 Eeta Garantia no Cnhre: Esta garantia no cubre baterias

(que coneidera lae partes reemplazables,) la instalaci0n, el use

de la propagaHda, los defeetos resultando de aeeidentes, el

dale mientrae en tr_nsito a nuestra ubieaciSn de[ eervieio o

resugar de dale de modgicacionee, el magrato o el abuse, la

faga de la coneervacion apropiada, la reparaeiGn o las

modgieaeiones no autodzadas del producto, porter de ninguna

fijaci0n no proporcion8 con el producto, programar de los

Diepositivoe del Mando a distancia, de T de Rayo Segura® el

ajuste/lirnpiar, Los alambres pelizcados o rotes, el Coche sonG,

los ajustee del Control de la Fuerza, la puerta fuera de

equlibdo, los pDmaveras o los cables rotes, lee fallas del poder,

el use de cuerdae de exteneion, perdiendo o lae partes daladas

en descontado, Mearanced, la venta final o los cartones

grabados, las operaciones fantasmales (el trabajo no se cubre

s[ el Abrelatae funciona apropiadamente ngentras tGcnieo eet_

en el garaje), el fuego, la inundaciGn, los actoe de la naturaleza,

o el fra.

Esta gaiantia es ]a uoiea que daremes a so prodnctoGenie, y

esgpula tedas nnestras respensahilidades con respeetoa sn

prodocto Genie. No hay otrasgaranDas expresas.

Dereches de estados y previocias: Esta garantia leotorga dereehos

legales especgicos y puede que usted tenga tambidn otros dereehos

que varian de estado a eetade y de previncia a provincia.

Ce gu'eRe eenwe: toute dGfectuosit6 de matGNauet tout d_faut de fab-

rication constaf_s pendant Rdilsation norman du produit par un indi-

vidu 8 son domicile en conformed avec le Manuel de I'utilisateur.

Peedaot cemhien detemps:

SGNeH4000A-2... Moteur 10 anset toutes les autres pi_ces 2 ans.

SdNe H6000A-2K.. Moteur 15 anset toutes los autres pi_ces 3 ans.

SdNe 18525....... Moteur 2 anset toutes los autres pi_ces2 ans.

SGNe18550-1 ..... Moteur 7 anset routes los autres pi_ces2 ans.

SdNe 18550-2 ..... Moteur 10 anset routes los autres pi_ces 2 ans.

SdNe 18550-2X.... Moteur 12 anset toutes los autres pi_ces 2 ans.

SGNe18850-2M ... Moteur _ vie* et routes los autres pihces 3 ans.

SdNe 18900-1 ..... Moteur 10 anset toutes leeautres pi_ces 2 ans.

SGNe18900-2 ..... Moteur _ vie*et teutes los autres pi_ees 2 ans.

SGNe18920....... Moteur _vie*et teutes los autres pi_ees 2ans.

SdNe ISLES0...... Moteur 8 vieet toutes los autres pi_ees 3ans.

SGNeISLg80 ...... Moteur et toutes los autres pihees & vie'.

SdNeCM7600 ..... Moteur 10 anset routes los autres pi_ces 3 ans.

SdNeCM8600 ..... Moteur 8vieet toutes los autres pi_ees5 ans.

SGNePRO95 ..... Moteur et toutes los autres pihees 8 vie'.

*GarantieD vie= Garanti rant que vous restez propri_taire de votm

habitation

BGnGficiaire de la garantie: La garantie est limitGe au client qui a

acheth ingialement le produit.

Pays converts: Cette garantie s'app]ique eeulement aex produgs

Genie aehetGsaux htats-Unis et Canada.

Nee cendiDens: Sile produg Genie est dhtectueux, noue enverrons

los parties de replacement ou, solon notre choix, de le remplacer

sane Trois de notre part. Si nous envoyons lee parties de

replacement du produg, il est possiMe que nous uRlieions des

pidces de remplacement neuves ou reeondgionnhes. Si noue

dGe[donede rempiacer le produg Genie, il est possible que nous le

remp]ae[ons avec un produg neut ou recondgionnd de conception

semblable.

Limites: LES GARANTIES IMPLJCITES, Y COMPRIS LES

GARANTIES D'A-DAP-TA-TION A UN USA-GE PAR-TI-CU-LIER ET

LA GA-RAN-TIE DE VALIDITE MAR-CHAN-DE (UNE GARANTIE

TACITE QUE LE PRODUIT EST ADAPTE A L'USAGE) SeNT

LIMITEES A UN ANA COMPTER DE LA DATE D'ACHAT. GENIE

DECLINE TOUTE RESPONSABILITE ENCAS DE PERTE

D'UTILISATION DU PRODUIT OU DE DOMMAGES MATERIELS

CAUSES PAR LE PRODUIT GENIE OU PAR UN FONCTIONNEMENT

DEFECTUEUX ; DE DOMMAGES ACCIDENTELS OU INDIRECTS ;

DEDOMMAGES ISSUS DEL'UTILISATION INCORRECTE OU DE

LA MODiFICATiON DU PRODUIT GENIE.

Certains 6tats et provinces n'autodsent pas los limites de durhe

des garantiee impiicites ou I'exclusion des dommages aecidentels

ou indirects. Dane ce cos, los exclusions ci-dessue ne

s'appliquent pae.

Comment hGnhfieier dn service offert par la gerantie: Pour

pouvoir enbGnhficier, il veus Taut fournir une justifieatiw_ de la

date et du lieu de I'achat.

1, Service pont eflectner los r_peretiene soi-mhme: Appeler le

numGro saus trais du service a la clenthle Genie 1-800-354-3643.

Des agents Genie spdcialsGs vous aideront a diagnoetiquer le

probl_me et prendront lee dispositions n_ceesaires pour vous

lournir los piGces requises are que vous puiss[ez effectuer los

rGparations par vous-m£me. Voue pouvez joindre ce service de

lundi au vendredi, de 8 h _ 23 het leeamedi, de 11 h a 20 h,

heure de I'Est (saul louts fdriGs)

2, Service effeetn_ par dee teehnieiens egreds: Appeler leservice

8 la c]ientGle Genie au 1-800-654-3643 qui vous communiquera le

nora d'un technicien agrGh. Sile technicien agrGh ottre un service

de garantie, lee trais encourus ne seront pas rwobours6s par Genie

et Genie ne serapas tenu responsable du rGglement des frais.

Le choix de I'une des options de service dGcdte cbdessus eet le

recours dent vous disposez sous cette garantie.

Que Cette Garantie Poe Couverture: Cette garantie pas piles

couverture (qui sontdls considhr6 des parties rempia_ablee,)

instalation, usage, dGfauts Rayon rGsuiter de accidents,

dommages dans travers_e _ notre enlplacenlent service ou

pas domrnagee qui rhsuge de ehangements, ou abus, is/anque

d'entretien propre, rhparation ou modgieations inautorisGe du

produg, apposant d'attachement cot foum[ avee le produg,

programmant de H, de T de Rayon SQr® ajustement

nettoyage,Fis pincGs ou casshs, I'Attelage a dGcienchh, los

aiustements de ContrOle de Force, la porte d'hqulibre, lee

reeeort ou lee c£bles caesGe, lee coupuree de courant, I'ueage

de ralonges, manquant oua endommagh des parties sur

escomptG, Mearanced, la vente finale ou a enregistrh des boles,

les opGrations fantSmes (la main-d'oeuvre n'eet pae couverte e[

I'Ouvre-botte fonctionne convenablement pendant que le

technicien est dane le garage), le feu, I'inondation, lee dhsastres

naturels, ou i'Gchec pour suivre le Manuel du Proprihtaire.

Cette garantie est la seole garanDe fonrnie poor le prednit et fait

valoir tontes los responsahgg£s qni vens incemhent cencernant

le produit Genie. R n'y e pas d'eotres garanties expresses.

Dregs pour los £tats et les provinces: Cette garantie vous donne

des droits jeddiques spGcgiques; los autree dregs peuvent vader

d'un atat a I'autre et d'une province a I'autre.

Page 35

Z

o

Garage Door Operator Accessories Order Form

Formulario de pedido de accesorios pare abridores de puertas de garaje

Formutaire de commande des accessoires pour ouvre=porte de garage

AVAILABLEATYOURLOCALDISTRIBUTOR=DISPONIBLEPORSUDISTRIBUIBORLOCAL=BISPONIBLEAUPRESBEVOTREDISTRIBUTEURLOCAL

==

2

o

=o

t_

,,=,

Z

o

GIRU-1T uncontrolremotodeabddordepuertadegaraje,receptorytransformador. _ 33154R $49.95

LIDHTBULBBombdlade60Vatios-Aseguracomponentecorrectodesistema. _ 26210A.S $2.95

ADAPTERBRACKETBrasadaptadorporSTB(2)-UsadoconbrasnormalpotSTB,proveerespacioadicionak _ _ .........'_a,_'_Q_£ $4.95 ..........................................................

S

NoC.O.D.shipments.Pleaseincludecheckormoneyorder,donotsendcash.

Allow3-4weeksfordelivery.WeacceptVisaorMastereardphoneorders.

1.800.354.3643.Pleasehavepartnumberandcreditcardready

,,=,

Noseaceptanpedidosdepagecentreentrega(COD).Sirvaseincluirsuchequeo

Direpostal;noenviedineroenetedivo.Concedanos3a 4semanasparalaentrega.

Aceptamospedidostelef0nicosdeVisaoNastercard.1.800.3£4.3643.Sirvasetoner

o

listoslosndmerosdelmodeloydelatarjetadecredito.

Pasd'expeditioncentreremboumement.Veuillezinclureunchequeouunmandat

2

bancaire.N'envoyezpasd'argentcomptant.Accordezde3a4semainespourla

w

livraison.Nousacceptonsloscommandospartelephoneavecpaiementparcartede

creditVisaouNastercard.1.800.354.3643.Ayezsouslamainlenumerodelapieceet

o

celuidelacartedecredit.

w

SHIPORDERTO:/ ENVIARMERCANCiACON:/ EXPI_DIERMARCHANDISEPOUR:

DeLuxeRemoteContrdwithIntdlicode÷-ALlowsremoteoperationofgaragedoor.

GIT-1 ControladorremotodeLujoconLntdLicode÷-ProporoibnaroperacibnremotodeLapuertaddgaraje. 33069R $34.95

T_l_commandedeluxeavecIntdlicode÷-Permettraopdration_Loign"deportedegarage.

2-ButtonRemoteControlwithIntdlJcode_-AHowsremoteoperationof2garagedoors.

GIT-2 Controladorremotode2fundonesconIntellicode÷-Proporcidnaroperacidnremotodedoslaspuertaadelgaraie. 33069S $44.95

Td_commande_2fonctionsavecIntellicode÷-Permdtraopdration_Loign"deuxportesdegarage.

3-ButtonRemoteControlwithIntdlicode'_-Allowsremoteoperationofggaragedoors.

GIT-3 Controladorremotode3funcionesconIntdlicode÷-Proporcienaroperacienremotodetreslaspuertasdelgaraie. 33069T $49.95

Td_commandea3fonctionsavecIntellicode÷-Permdtraoperationdoign'troisportesdegarage.

LightedWaLlConsole-OperatesGarageDoor.independentlightcontroL.Securityvacationlock.

GPWC" Consoledeparedde3 funciones-Acetonelapuertaddgaraie.Controldeluzindependiente.Cerraduradeseguddadparevacaciones. _ 34292R $34.95

2WLB Consolemurale_troisfonctions-Actionnelaportedegarage.Commandod'_dairageinddpendante.InterrapteurdeverroudLagedesdcudtd.

3-ButtonMiniRemoteControl/dtbIntdlicode_- Fitseadlyintopocketorpurse.

6MI-3 Minicontrdadorremotode3funcionesconIntellicode÷-Cavefdcdmenteenelbdsdloocartera. _ 34909R $39.95

Minitdldcommande_3fonctJonsavecInteJiicode- segJissedanslapochedevestonoulesac&main.

WirelessKeypadEntrySystem-OperatesIntdLicodeGarageDoorOperatorswithoutRemoteContrdorkey.

DWKP Sistemadeentradapottedado .......... _ ' 35282R $49.95numenoomaLambnoo-AcolonaLosabndorasdepuertasdegaraIeLntelhcodesincontrdremotooLLave.

Systemedouvra-portedegarageaclaviersanshi-Actlonneleeouvra-portedegarageavecletdhcodesanstdeoommandenlole.

(3)1/4oz.tubesScrewGrease-Ensuresproperequipmentwearprotection.

DW-3 (3)1/4oncelubdcantedetomiHoaccionar-Aseguracomponentecorrectoprotectionpordetedoro. 35164R $1.95

Laonza1/4lubdcantdelavis(3)-Garantircomponentexactparsyst_med_fenseversuser.

UniveraalWallButton-ProvidesadditionalconvenientinsideoperationofDoor.

GWB Botbndepareduniversal-Proporcionaoperacibnconvenientedelapuertadesdeelinterior. 34960R $ 4.95

Boutonmuraluniverael-ActionneI'ouvra-portedeI'intdrieurdugarage.

PerfectStop÷-Ensuresperfectparking. _jf_-

6PS-5 StopPerfecto_-Aseguraelestacionamientoperfecto. _ _ 34964R $ 4.95

ButoirPerfectStop_-Permetdestationner_laperfectiondenslegarage.

ScrewDriveExtensionKit-EighteeninchExtensiontoincreasetravdofScrewDriveOperatortoaccommodateeightfootdoor.

JuegodeextensigndedizantedeScrewDrive-Unaextensiende18pulgadaspareaumentarlacameradeunabddordeslizabledetornHIo_.................................................................

DSX-8 pareacomodarunapuertade8 pies(2,43m.). _ $34.95

NdcessairaderaLIongeduScrewDrive-RaLIongede30dm(18pc)prdongeantlacoursedePouvra-porteScrewDrivepouruneporte_=_-_ 33523R

de2,4m(8pi)dehauteur.

UniversalConversionKit-ConvertsanyGarageDoorOperatortoesecureradiosignalsystem.KitincludesaRemoteControl,ReceiverandTransformec.

Juegodeconversibnuniveraal-Conviertecualquierabddordepuertadegaraiea unsietemadesebalderadioseguro.Eliuegoincluye

Ndcessairadeconversionuniversal-Transformetoutouvra-portedegarageensyst_medes_cudt__signalradio.Comprendune

td_commanded'ouvre-portedegarage,unr_cepteuretuntransformateuc

60WATTEnhanced/RoughServiceLightBuLb-Ensuresproperequipmentcompatability.

Edairagede60WATT-Garantiroomponantexadparsyst_me.

EmergencyReleaseKit-Providesaccesstogaragefromoutsideintheeventofanelectricalpowerfailure.

Juegodepica-portedepestillo- Permitirentrtadadesdeporfueradegaraieporquecortedeel_ctdc.o

DER-2 N_cessairasdeD_clencbementdesecoura-Len_cessaireded_clenchementdesecoursestcon_upourvouspermettrad'acc_der 34963R $29.95

votragaragedepuisI'extddeurencasdepannedecourantetIoraqu'ik

STBAdapterBrackets(2)-UsedinconiundionwithstandardSTBmountingbrackets,theyprovideadditionalcleerancealongwith,_mountingoptions.

SupportsraccordduSTB(2)-SeservirencompagniedesupportsnormalduSTB,assurerespacesuppl_mentaira. -¢_

. %

TOTAL ORDER/ TOTAL DEL PEDIDO / COMMANDE TOTALE

SHiPPiNG & HANDLING IFLETE Y MANEJO IMANUTENTION ET EXPEDITION

STATE SALES TAX IIMPUESTO DE VENTAS ESTATAL ITAXE DE VENTE

GRAND TOTAL / GRAN TOTAL / TOTAL GLOBAL

Please add local sales tax if you reside in one of the states listed.

California Georgia Maryland New York

Connecticut illinois Massachusetts Ohio

Florida indiana New Jersey Tennessee

MAILORDERFORMTO:

ENVIARHACERUNPEDIDODEMERCANCIAA:

METTREA LA POSTELE ARRANGEMENT/_:

Virginia

Wisconsin

8

o

=o

Prices subiect to change without notice * El precio esta suieto a carnbios sin awso * Les prix peuvef_t subir des modifications sans preavis i

Loading...

Loading...