Page 1

Automatic

Chain Drive/Belt Drive

Garage Door Operator

System

Owner’s Manual

SAVE FOR FUTURE REFERENCE

Customer Service

CALL: 1-800-354-3643

VISIT: WWW.GENIECOMPANY.com

3507535556

GPS-IC Series

PMX-IC B Series

AUTOMATIC GARAGE DOOR OPERATOR SYSTEMS

HANG MANUAL NEAR YOUR WALL CONTROL

Complete with Remote Control

and SERIES II Electronics

Operator MUST be installed with the included SERIES II Wall Control!

Self-diagnostic Electronic Sensory Protection System

(SAFE-T-BEAM SYSTEM) MUST Be Installed To Close Door!

TABLE OF CONTENTS

SECTION PAGE

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

ASSEMBLY

1 OPERATOR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

1A Channel and Power Head Assembly . . . . . . . . . . .10

1B Rail and Power Head Assembly . . . . . . . . . . . . .10-11

INSTALLATION

2 DETERMINE DOOR TYPE AND MOUNTING METHOD . . . 11

2A Installation on Track Guided Doors . . . . . . . . . 12-14

2B Installation on Trackless Doors . . . . . . . . . . . . 15-17

3 SAFE-T-BEAM®(STB) SYSTEM INSTALLATION . . . . . 18-19

Self-diagnostic “STB” System Troubleshooting . . . . 19

4WALL CONTROL INSTALLATION . . . . . . . . . . . . . . . . . . . . 20

5 CONNECT OPERATOR TO POWER . . . . . . . . . . . . . . . . . . 21

6 MAIN LIMIT SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . 22

OPERATION

7 FORCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contact Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 FINE LIMIT SWITCH ADJUSTMENTS . . . . . . . . . . . . . . . . . 24

9 REMOTE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

10 BATTERY & VISOR CLIP INSTALLATION . . . . . . . . . . . . . . 25

11 LIGHT BULB AND LENS INSTALLATION . . . . . . . . . . . . . . 26

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

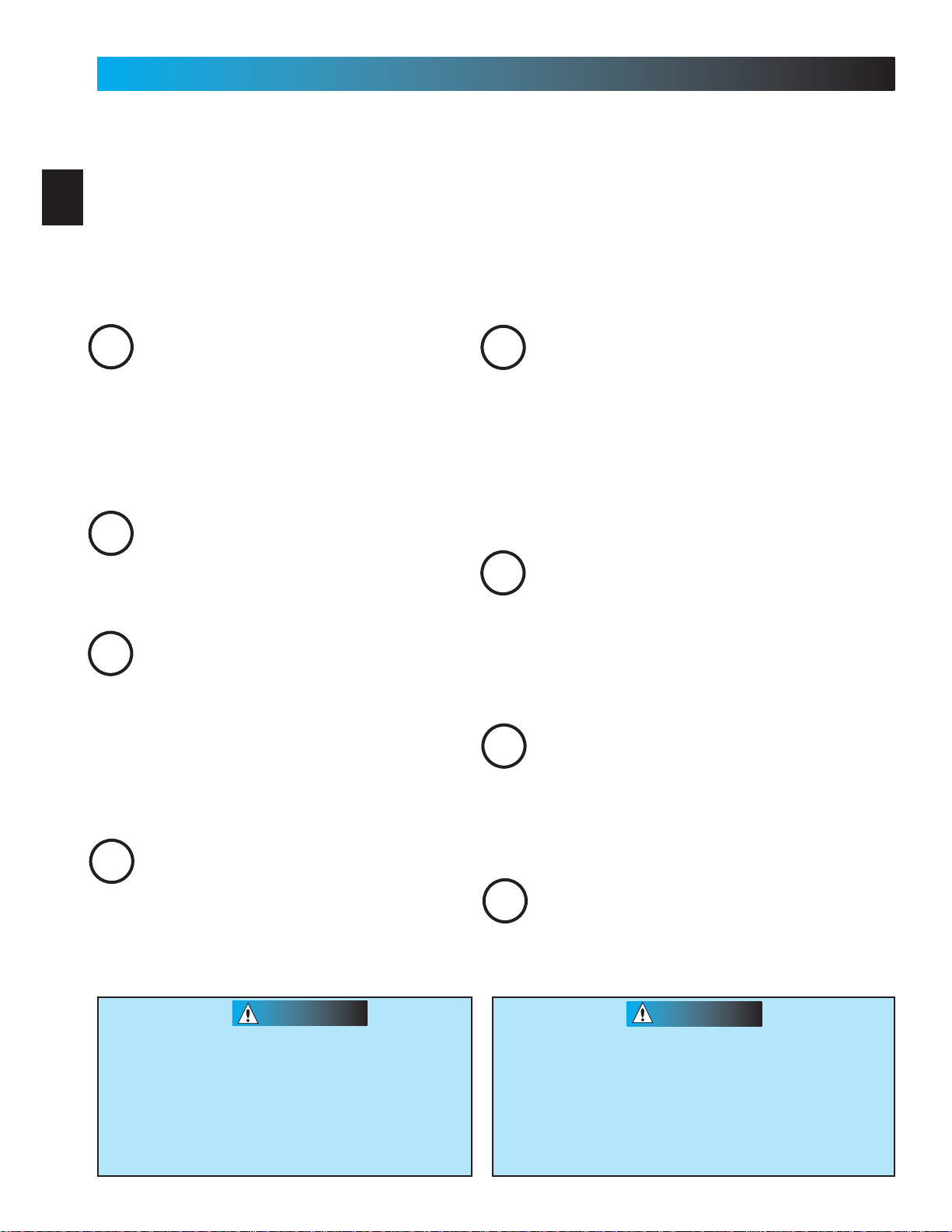

Page 2

Things to consider if you are planning to “do-it-yourself.”

Whether you are replacing an existing garage door operator or installing an operator in your

garage for the first time, there are some pre-installation issues which need to be addressed.

They are as follows:

The Genie Company recommends that you read and fully understand all

information and instructions contained herein before choosing a “Do-It-Yourself ”

installation. Any questions should be directed to the Genie Company or an authorized

Genie Dealer.

6

To avoid damage to your door and/or

operator, make sure you disable any door

locks prior to installing your operator

.

2

PRE-INSTALLATION CHECK LIST

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

1

Check your ceiling where the power

head of your new unit will be mounted.

Plan how you will be mounting the power head.

It is possible that ceiling joists may not be in the

exact position needed with respect to the garage

door operator. In any case, it may be necessary

to add an additional bracket and

fasteners (not

included with your new door operator kit).

2

Check the wall directly above the garage

door

. The door operator’s header bracket

must be securely fastened to this wall. Insure

that the structure will provide a strong mounting

location.

3

Check to see if the mounting location

for the Safe-T-Beam

®

System (STB) is

clear from obstruction and has a wood

surface available for attaching the STB

brackets

. The brackets may also be attached to

concrete if necessary but extra tools and special

fasteners (not supplied) will be required.

NOTE: 1-1/2" “STB” bracket adapters

are available through your local Genie Dealer.

4

Is your garage door made of

light-weight steel, aluminum, fiberglass

or glass panels

? Additional support bracing

must be added to these type doors. If this is the

case, please contact the door distributor or

manufacturer so that they can furnish you with a

“bracing kit.”

7

Insure that your door is properly balanced

and moving freely. SEE WARNING BELOW.

If your door sticks, binds, or is out of

balance, have it adjusted by a professional.

Door springs, cables, pulleys, brackets and

associated hardware are under extreme

tension and can cause serious injury or

death.

WARNING

(

The issue numbers below refer to the circled numbers in the illustrations on page 3.

)

8

(NOT SHOWN) If your garage does not have

a separate entry door, you might want to

consider an emergency release kit (GER-2)for

installation on your garage door. See page 30.

DO NOT USE EXTENSION CORD!

Extension cords can cause dangerous

overheating conditions.

DO NOT USE PORTABLE GENERATOR!

This product is designed to operate on

standard house current. Do not use

alternate power supplies.

WARNING

5

You need a 110-120 Volt power supply

available

. If you plan to plug the unit into a

standard electrical outlet, is one available? The

outlet should be no more than about 3 feet from the

power head once it is mounted. (The cord is 4 ft. in

length.) SEE WARNING BELOW.

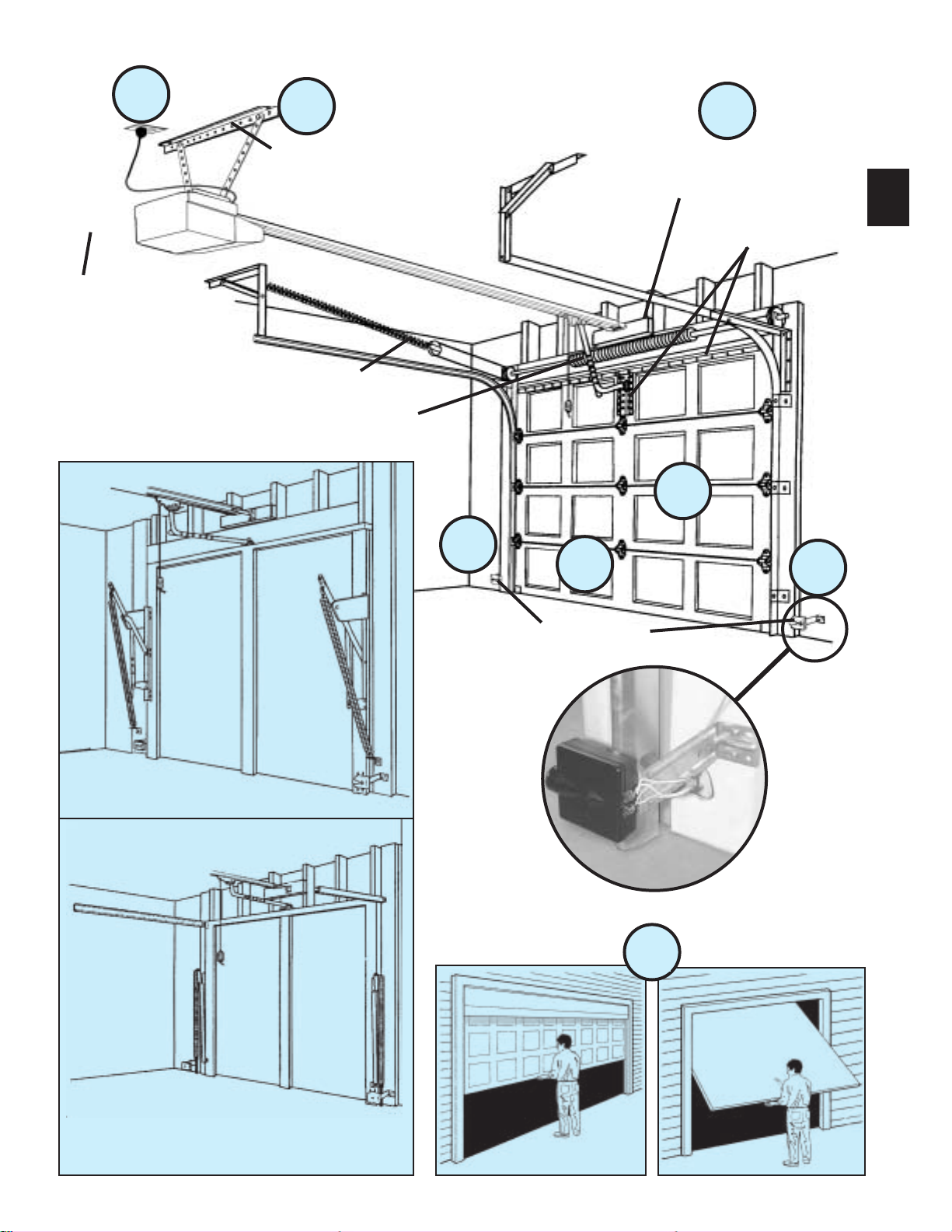

Page 3

3

TYPICAL SECTIONAL DOOR INSTALLATION

5

TYPICAL

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

SAFE-T-BEAM

®

BRACES

ADDED

HEADER BRACKET

MOUNTING BOARD

36” POWER CORD

TO

120V GROUNDED

OUTLET

6

4

3

1

2

3

TYPICAL (TRACK GUIDED)

1-PIECE DOOR INSTALLATION

7

SECTIONAL DOOR

ONE-PIECE DOOR

TYPICAL (TRACKLESS)

1-PIECE DOOR INSTALLATION

Page 4

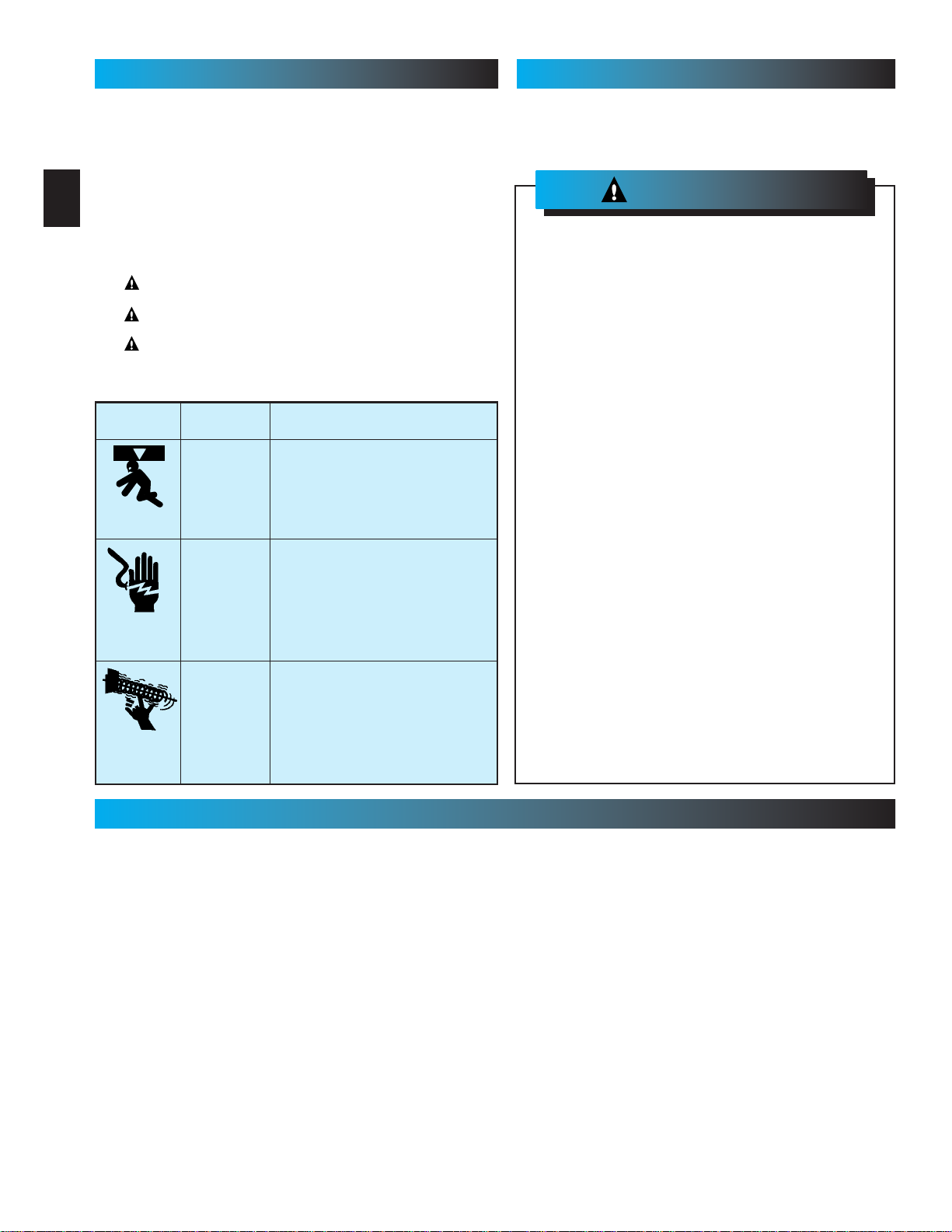

4

WARNING

:

Garage doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs under

tension, and electric motors can cause injuries, your safety and the safety of

others depend on you reading the information in this manual. If you have

questions or do not understand the information presented, call your nearest

service representative

In this section and those that follow, the words Danger, Warning, and

Caution are used to emphasize important safety information.

The word:

DANGER means that severe injury or death will result from failure

to follow instructions.

WARNING means that severe injury or death can result from failure

to follow instructions.

CAUTION means that property damage or injury can result from failure

to follow instruction.

The word NOTE is used to indicate important steps to be followed

or important considerations.

OVERVIEW OF

POTENTIAL HAZARDS

POTENTIAL

HAZARD

EFFECT PREVENTION

Keep people clear of opening while door is

moving.

Do Not allow children to play with the door

operator.

Do Not operate a door that jams or one that

has a broken spring.

MOVING

DOOR

WARNING:

Can Cause

Serious Injury

or Death

Turn off power before removing operator cover.

When replacing cover, make sure wires are not

pinched or near moving parts.

Operator must be properly grounded.

ELECTRICAL

SHOCK

WARNING:

Can Cause

Serious Injury

or Death

Do Not try to remove, repair or adjust springs

or anything to which door spring parts are

fastened, such as, wood blocks, steel

brackets, cables or other like items.

Repairs and adjustments must be made by a

trained service person using proper tools and

instructions.

HIGH

SPRING

TENSION

WARNING:

Can Cause

Serious Injury

or Death

Safe-T-Beam®(STB) Non-Contact Reversing System

Places an invisible beam across door opening that reverses the door during down travel to the fully open

position if anything passes through beam.

Safe-T-Reverse

®

Contact Reversing System

Automatically stops and reverses a closing door within 2 seconds of contact with an object.

Safe-T-Stop

®

Timed Reversed System

Automatically opens a closing door, if door does not close within 30 seconds.

Force Guard

®

Control

Used to set the force required for opening and closing door. For maximum safety, set the minimum force

required to fully open and close door.

Automatic Lighting System

One or two light bulbs (depending on model) up to 100 Watts max. each are used for safer entries and exits.

The light turns on when door is activated and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually for emergencies or maintenance.

IMPORTANT

INSTALLATION

INSTRUCTIONS

1. READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

improperly balanced door could cause severe injury. Repairs

and adjustments to cables, spring assembly, and other

hardware must be made by a trained service person using

proper tools and instructions.

3. Remove all ropes and disable all locks connected to the door

before installing operator.

4. Install door operator 7 feet or more above the floor. Mount the

emergency release knob 6 feet above the floor.

5. Do Not connect the operator to the source of power until

instructed to do so.

6. Locate the control button:

• Within sight of door.

• At a minimum height of 5 feet, so small children cannot

reach it.

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall button or

console. Install the emergency release tag on, or next to, the

emergency release

8. The operator must reverse when the door contacts a 1-1/2 inch

high object on the floor at the center of the doorway. This is about

the size of a 2” x 4” board laid flat.

To reduce the risk of

severe injury or death:

WARNING

:

SAFETY INFORMATION OPERATOR INSTALLATION

SAFETY FEATURES

(

varies by model

)

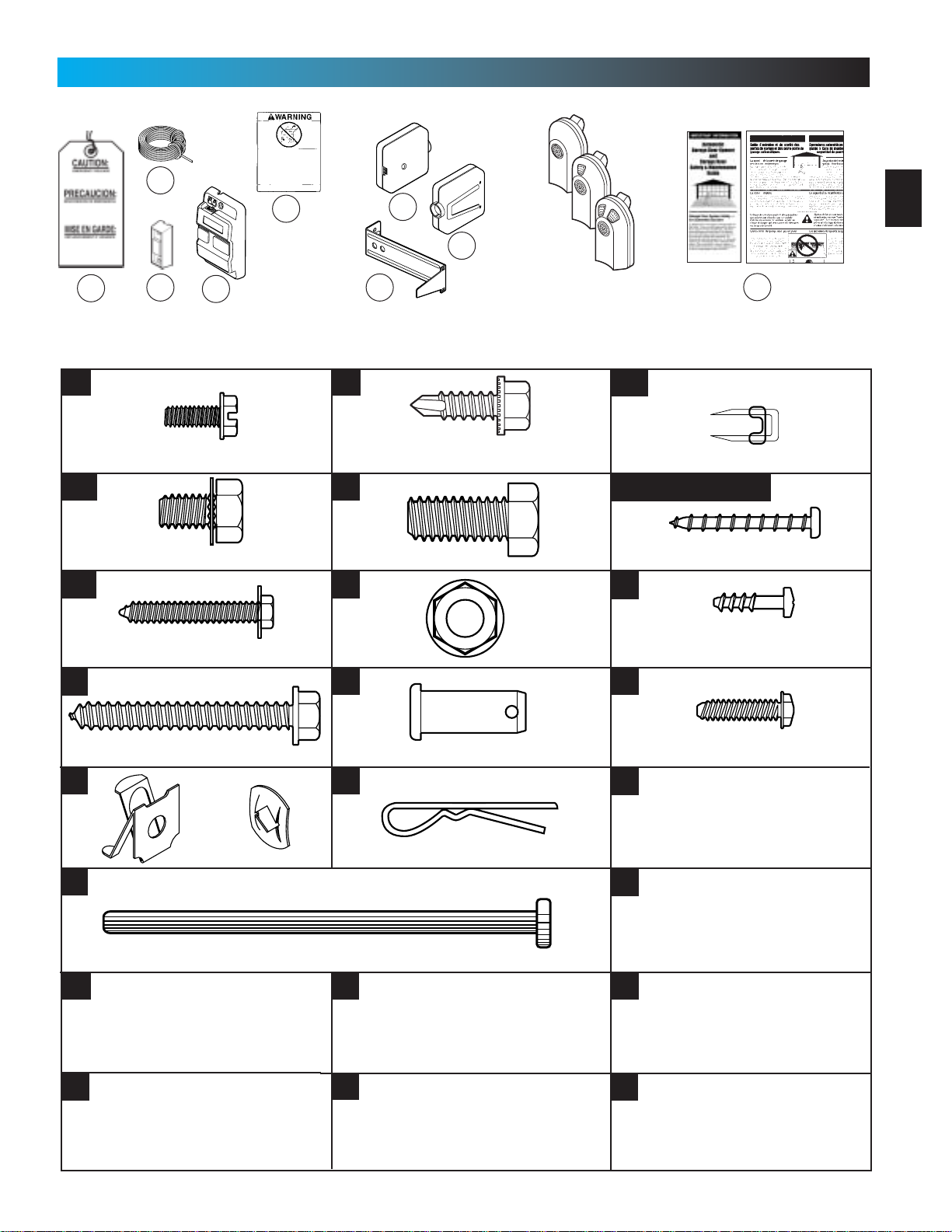

Page 5

NOTE: Accessories vary by model.

FASTENERS -

Shown full size. See Parts List for description.

105

10 4

103

101

106

12 6

12 4

12 5

Lag Screw, 1/4” x 2”

Cotter Pin

Clevis Pin

Bolt, 3/8”-16 x 7/8”

Phillips Hex Head Screw, No. 10 x 1-1/4”

Insulated Staple

Bolt, 5/16”-18 x 1/2”

10 0

69

112

79

81

82

127

N/A

N/A

96

91

92

90

89

Pan Head Screw #6 x 1-1/4”

128

N/A

10

PARTS IDENTIFICATION FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

9

N/A

Hex Head Screw

No. 8 x 3/4”

Cold Head Pin

Pan Head

Phillips Screw

No. 8 x 5/8”

Speed Nut

OR

N/A

N/A

Nut, 3/8-16

1/4”-20 x 3/4”

Self-Drilling Screw

Bolt, #10-24 x 1/2”

5

Wall Control Screw

N/A

remotes

vary by model

N/A

Page 6

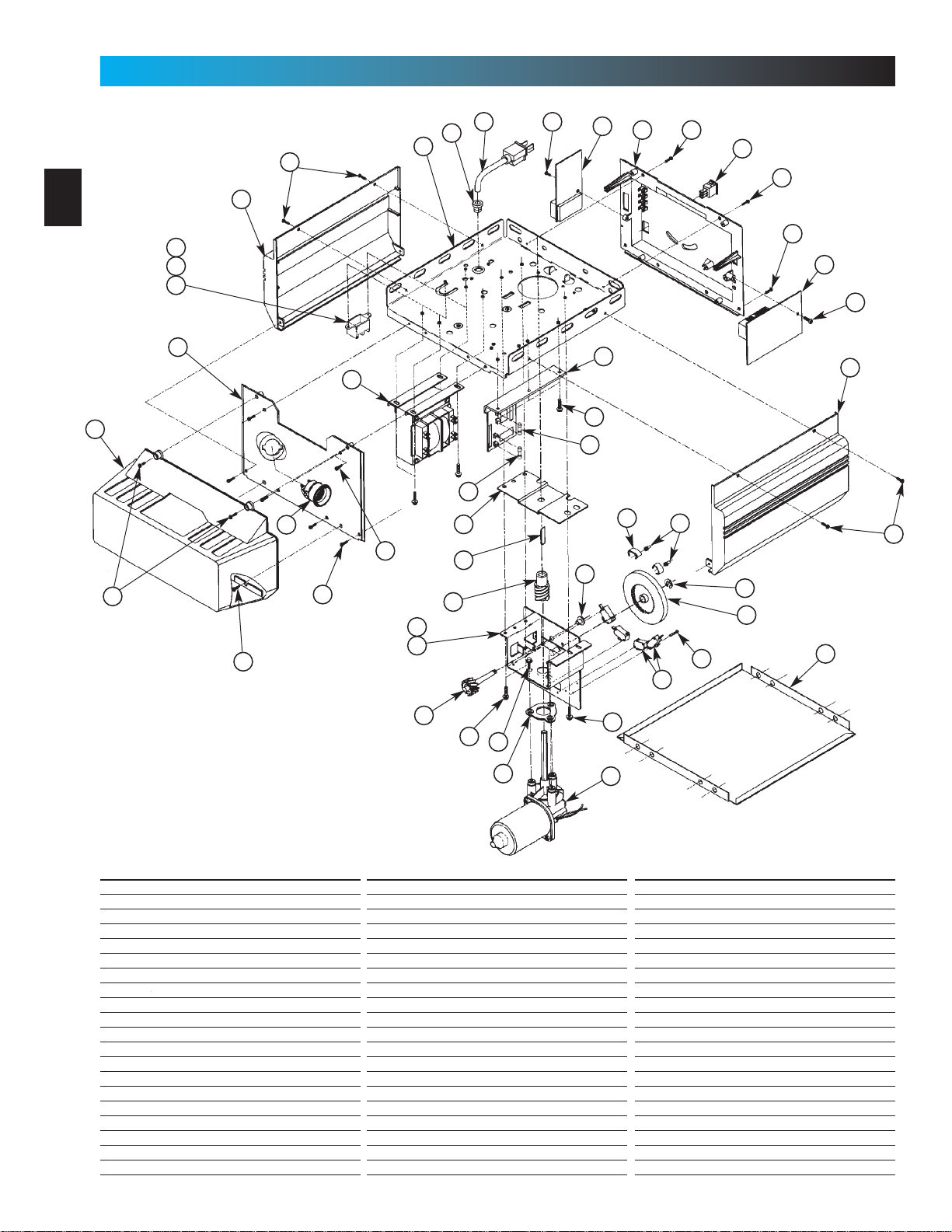

Stealth Power Head

2

3

4

5

6

7

8

9

10

1

12

13

14

15

16

17

18

19

20

11

22

23

24

25

26

27

28

29

30

21

32

33

34

35

36

37

38

39

31

40

12

12

12

12

11

19

3

12

26

26

Item Part Name

1 Lens

2Front Cover

3Side Cover (by series/model)

4Top Plate Assembly

5Strain Relief

6Cord & Plug Assembly

7Component Panel (by series/model)

8 Bottom Cover

9Screw, #8 x .75 Phil Hx Hd/W Sf Tap

10 Screw, #8 x .62 Phil Pan Hd/W Sf Tap

11 S crew, #8 x .50 Slt Hx Hd/W Sf Tap

12 Screw, #8 x .38 Slt Hx Hd/W Sf Tap

13 Light Socket (by series/model)

14 Terminal Block & Lug

15 M.O.V. Assembly

16 Receiver Assembly

17 Limit Set Switch

18 Sequencer Assembly

19 Screw, #6 x .38 Slt Hx Hd/W Sf Tap

20 Transformer Assembly (by series/model)

6

PARTS IDENTIFICATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Item Part Name

21 Rectifier Board Assembly

22 Fuse (F1), UL

23 Fuse (F2), UL

24 Limit Gear Shroud

25 Motor Bracket

26 Screw, #10 x 3/8” HH

27 Limit Plate/Pin Assembly

28 Limit Switch

29 Screw,#4-40 x 5/8”Slot HH w/Wshr,Sf Tap

30 Motor Assembly

31 Motor Adapter Plate

32 Screw, 1/4"-20 x 1/2” Slt HH w/Wshr

33 Limit Worm Gear

34 Limit Gear Bushing

35 Limit Worm Drive

36 Limit Worm Shim

37 Limit Wheel

38 Retaining Ring

39 Limit Cam

40 Limit Pinion, 8 tooth

Item Part Name

41 Capacitor

42 Capacitor Clamp

43 Screw, #10-24 x 1/2”, Slot HH Sf-Tap

44 Nut, #10-32, Hex Serrated Flange

45 Circuit Board

46 C.B. Bracket

47 Circuit Board Mount

48 Screw, #10-16 x 5/8”, HH Sf Tap

49 Top Gear Housing

50 Middle Gear Housing

51 Bottom Gear Housing

52 Drive Shaft Bushing

53 Drive Thrust Washer

54 Drive Shaft

55 1/2” Retaining Ring

56 Main Drive Worm Gear

57 Optical Interrupt Wheel

58 Motor Flanged Bushing

59 Motor Thrust Washer

60 Poly Thrust Washer

Combined Parts List

Page 7

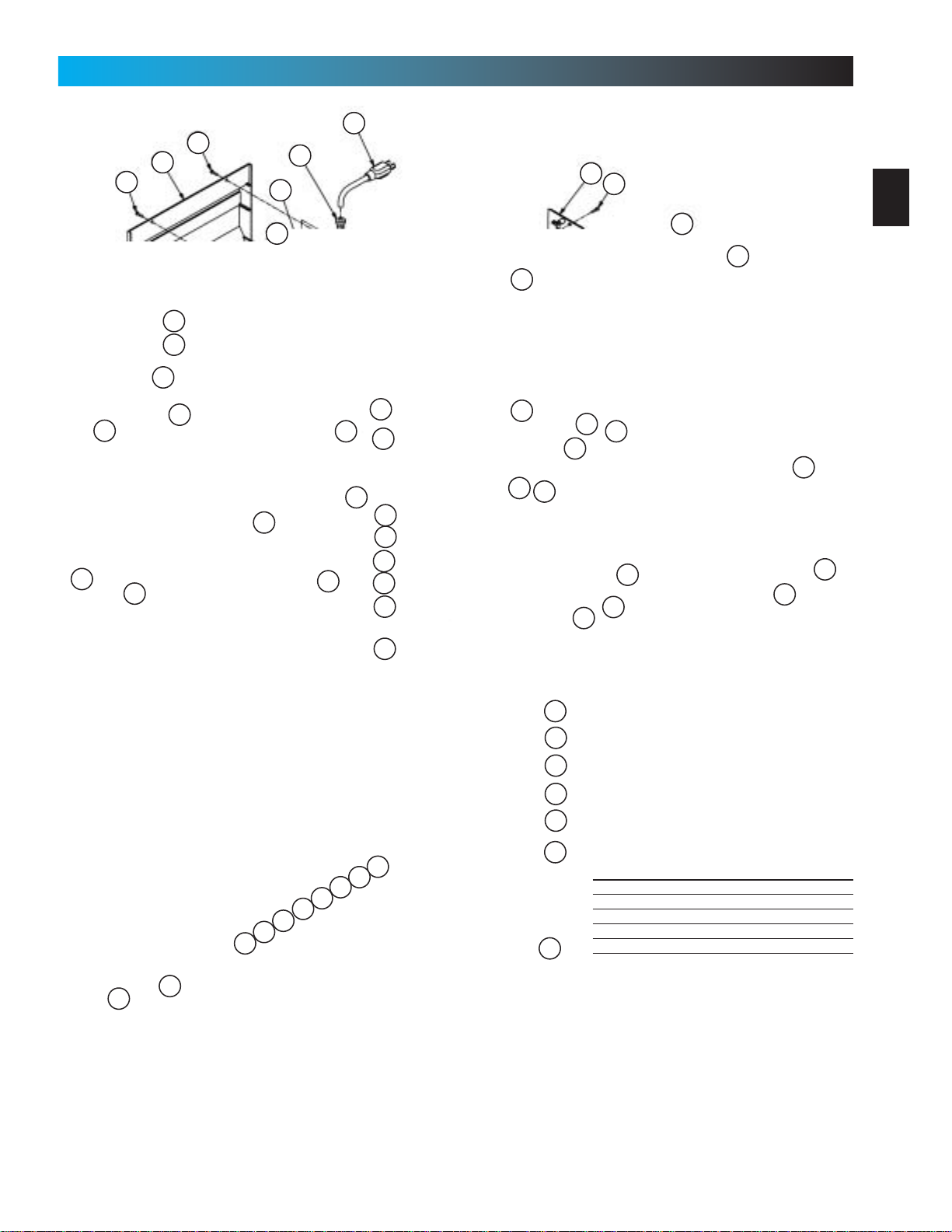

7

PARTS IDENTIFICATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Item Part Name

61 Main Drive Worm

62 Screw, #8 x 3-1/8” Slot HH, Sf Tap

63 Limit Switch Plate

64 Screw, #6 x 3/8” Phillips w/Wshr, Sf Tap

65 Screw, #4 x 5/8”, Slot HH w/Wshr, Sf Tap

2

10

12

46

12

12

3

12

45

47

5

6

7

12

48

12

11

12

40

39

37

4

52

64

3

12

65

28

63

41

42

25

43

13

11

49

53

33

35

50

54

57

58

59

60

59

61

59

58

30

44

8

62

51

52

53

56

55

1

9

PRO-MAX Power Head

Page 8

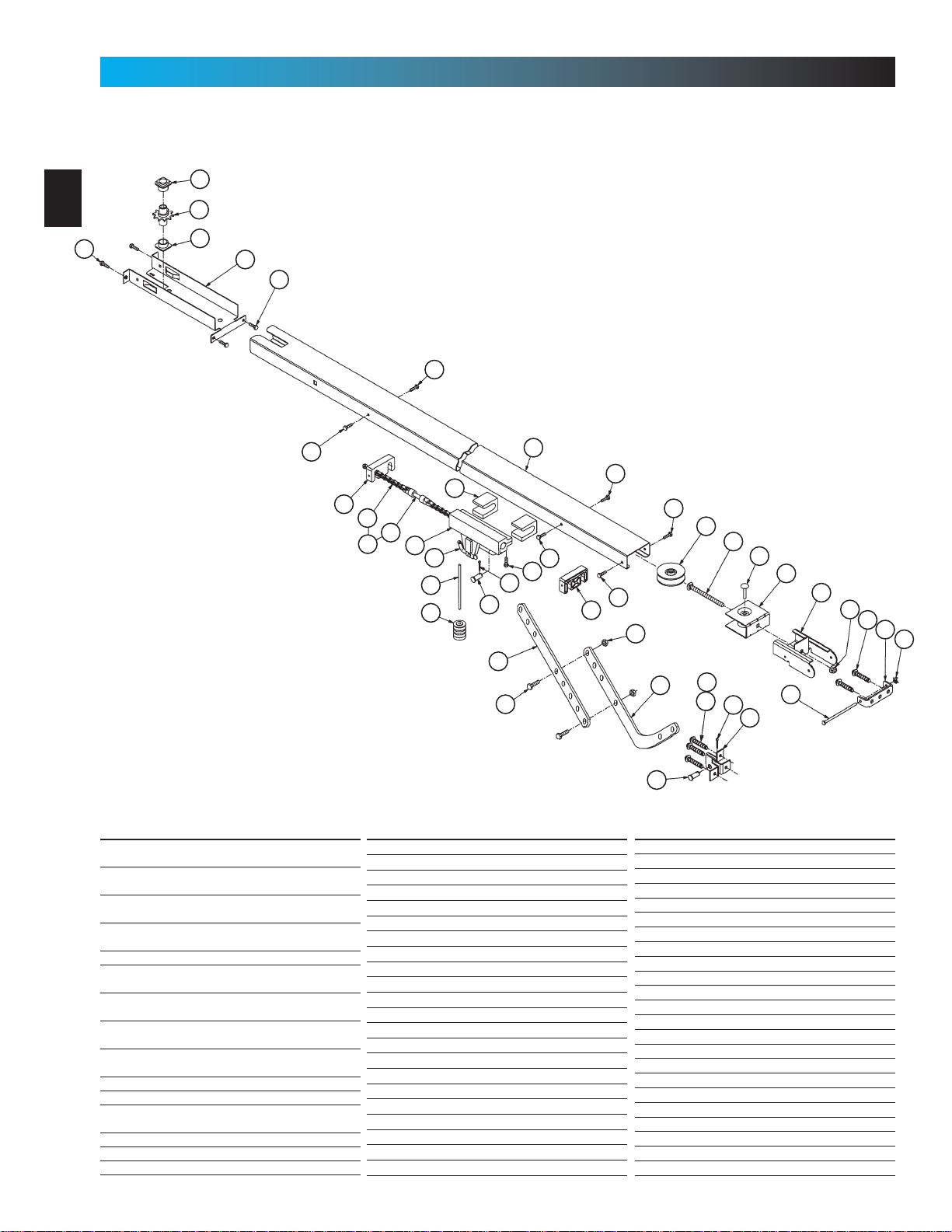

Channel

Item Part Name

66 Belt & Bullet Assembly - 7’6” Door

(Belt Models Only)

Belt & Bullet Assembly - 8’ Door

(Belt Models Only)

Belt & Bullet Assembly - 10’ Door

(Belt Models Only)

Belt & Bullet Assembly - 12’ Door

(Belt Models Only)

67 Sprocket Bushing

68 Sprocket, 10 Tooth - 7’6” & 8’ Doors

(Chain Models Only)

Sprocket, 12 Tooth - 10’ Door

(Chain Models Only)

Drive Sprocket, 18 Tooth - 7’6” & 8’ Doors

(Belt Models Only)

Drive Sprocket - 10’ Door

(Belt Models Only)

69 Screw, #10-24 x .50 Hx Hd

70 Sprocket Bracket (Chain Models Only)

Sprocket Bracket - 7’6” & 8’ Doors

(Belt Models Only)

Sprocket Bracket - 10’ Door (Belt Only)

Sprocket Bracket - 12’ Door (Belt Only)

71 Screw, #10-24 x .38 Hx Hd/W

8

PARTS IDENTIFICATION FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Item Part Name

72 Channel - 7’6” Door (128” LG)

Channel - 8’ Door (146” LG)

Channel - 10’ Door (170.75” LG)

Channel - 12’ Door (188” LG)

73 Pulley (Chain Models Only)

Pulley (Belt Models Only)

74 Carriage Bolt, 5/16”-18 x 4.0

75 Carriage Pin, 5/16” x 1.25

76 Pulley Bracket Assembly

77 End Bracket

78 Hex Flange Nut, 5/16”-18 (Chain Only)

Flat Washer (Belt Models Only)

(2)Hex Jam Nut, 5/16-18 (Belt Models Only)

79 Lag Screw, 1/4” x 2” Hx Hd/W

80 Header Bracket

81 Speed Nut

82 Cold Header Pin

83 Carriage Stop

84

Roller Chain -7’6” Door (Chain Only)(242.5”)

Roller Chain - 8’Door (Chain Only) (278.5”)

Roller Chain -10’Door (Chain Only)(328.5”)

8mm Belt

Item Part Name

85 Chain Bullet

Belt Bullet

Belt Retainer

Screw, #6-32 x 1/2” Phil Pan Hd Slf Tap

86 Carriage Slide

87

Emerg. Release Cord -7’6”Doors(26.5”)

Emergency Release Cord -8’ & 10’ Doors (56.5”)

Emergency Release Cord -12’ Doors(96.0”)

88 Emergency Release Knob (Red)

89 Cotter Pin

90 Clevis Pin

91 Screw, 3/8”-16 x .87 Hx Hd Mch

92 Hex Nut, 3/8”-16

93 Curved Door Arm

94 Straight Door Arm

95 Door Bracket

96 Screw, 1/4”-20 x 3/4” Hx Hd, Sf Tap

97 Carriage Assembly

98 Carriage Cap

99 Screw, #10-14 x 1-5/16” Hx Hd

100 Wall Console (Series II )

101 Wall Button (Series II ) (lit primary)

Wall Button (unlit secondary)

Combined Parts List

81

69

71

71

71

73

74

75

76

77

78

79

80

83

71

92

93

90

96

89

95

82

66

85

98

86

97

87

88

90

89

99

71

94

91

70

71

83

84

69

67

68

67

79

72

Page 9

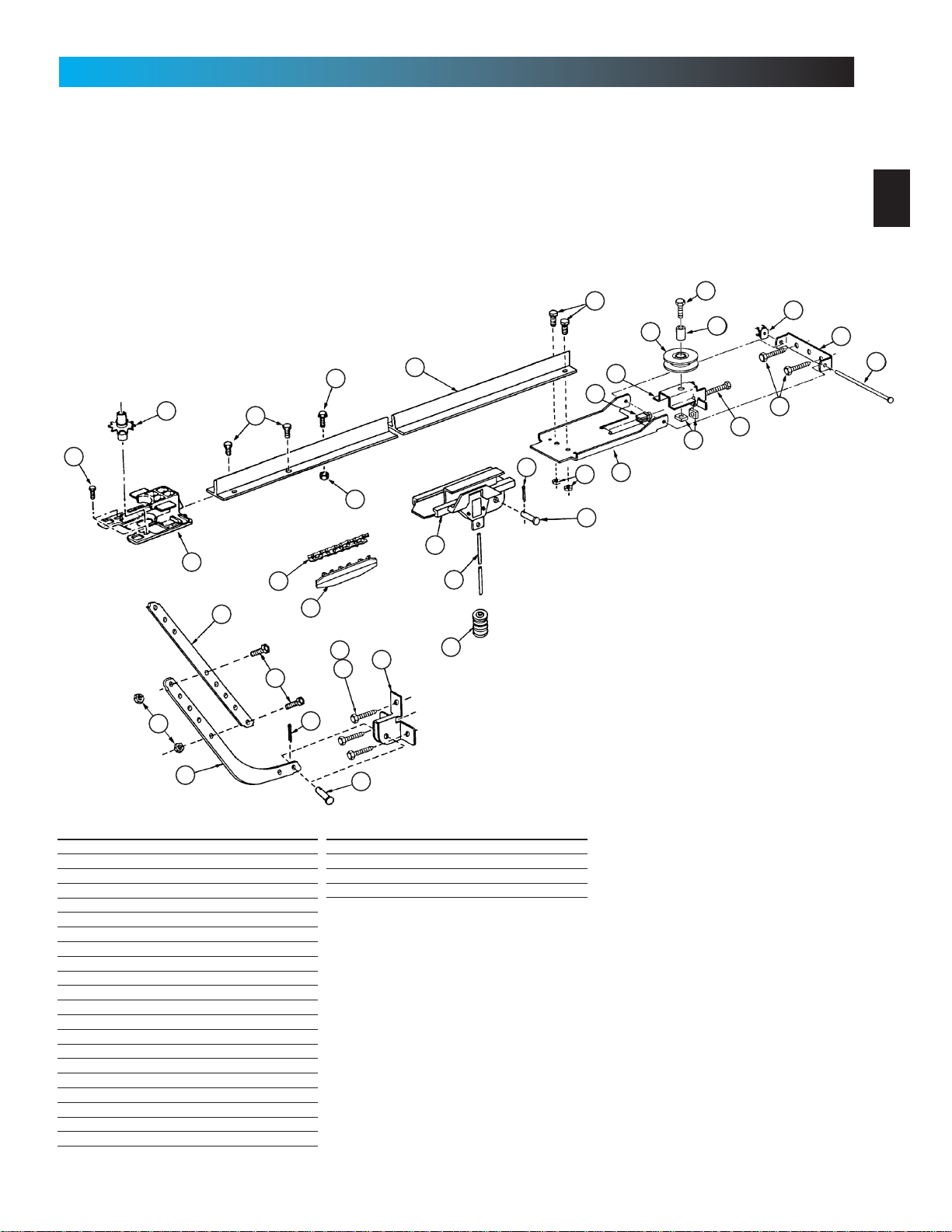

9

Rail

PARTS IDENTIFICATION FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Item Part Name

102 Boom Support Kit (not shown)

103 Safety & Maintenance Guide

104 Emergency Release Tag (Tri-L)

105 Entrapment WARNING Label

106 Wire

110 Rail (L=112.475”)

111 Scr ew, 5/16”-18 x 3/4”

112 Screw, 5/16” x 1/2” HH w/Wshr

113Pulley Support

114 Chain

115 Sprocket Saddle

116 Screw, 5/16”-18 x 2-1/4” HH

117 Bolt Retainer

118 Screw, 5/16”-18 x 1-1/8” HH

119 Large Pulley Bushing

120 Square Nut, 5/16”-18

121 Screw, 1/4”-20 1” HH

122 Hex Nut/Lockwasher, 1/4”-20

123 5/16-18 Lock Nut

124 STB System Sensor (Green LED)

68

88

90

95

96

89

93

91

92

115

94

114

86

110

122

121

112

69

73

76

117

12 0

113

123

90

89

97

87

82

80

79

116

81

119

118

111

Item Part Name

125 STB System Source (Red LED)

126 STB Mounting Brackets (2)

127 Screw, 1-1/4” Phillips HH

128 Insulated Staples

79

Page 10

Fig. 1-3

No. 10-24 x 1/2” Hex Head Screws

5/16” x 1/2” Hex Head Screws

“D” -Shaft and Hole

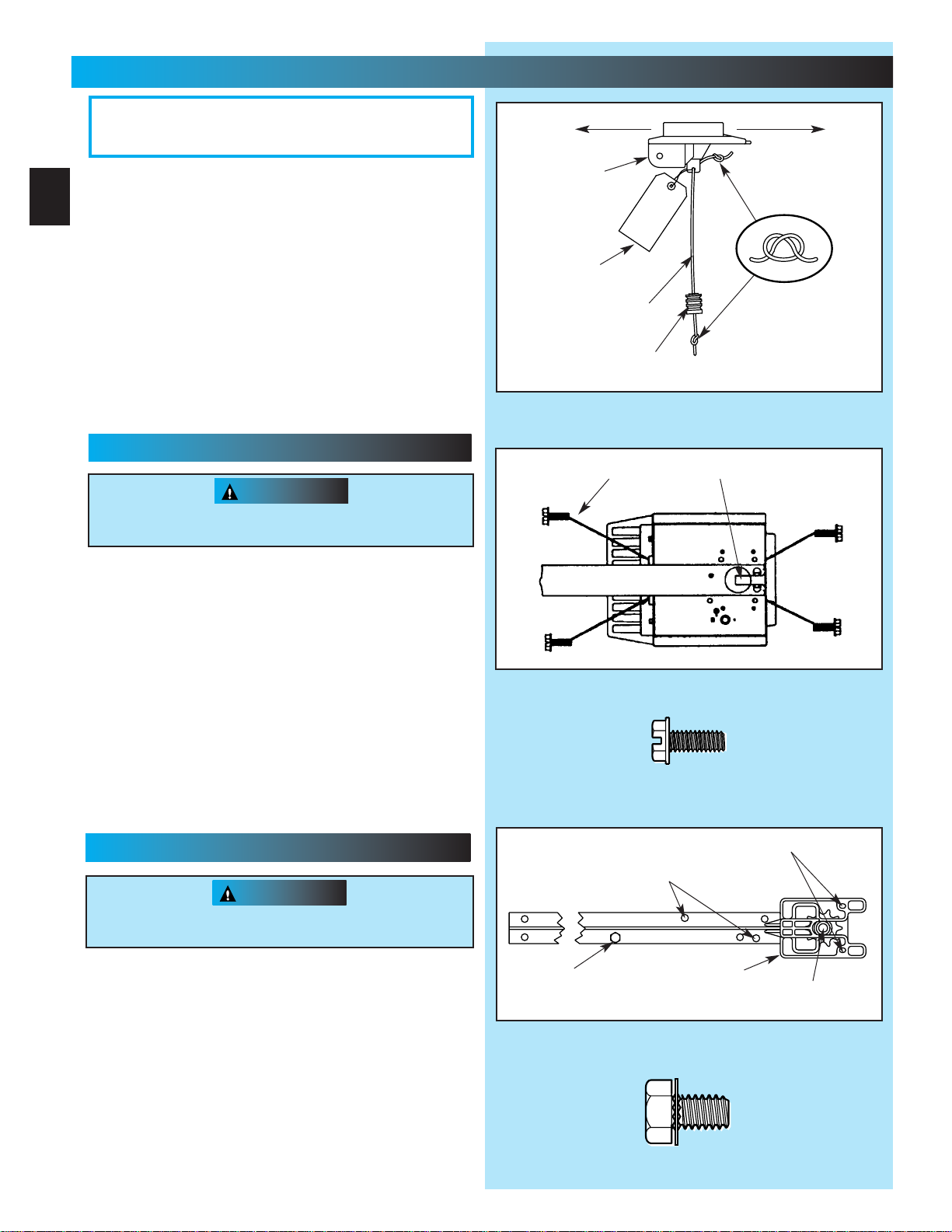

3. Place power head and channel on clean, flat surface.

4. Slide drive end of channel down over “D”-shaft on top of

power head (Fig. 1-2).

• Support header end of channel level with power head.

• Slide carriage to align “D”-shaft with “D”-hole in sprocket.

• Slide channel down “D”-shaft flush with power head.

5. Fasten channel to power head .

• Align mounting holes in front and rear of power head frame.

• Insert and securely tighten the four (4) No. 10 x 1/2” hex

head screws [69].

NOTE: Chain inner-slide or belt bullet should remain at

mid-travel when assembling to power head to provide proper

travel when setting limits.

1. Attach emergency release knob cord (Fig. 1-1).

• Tie overhand knot in end of cord.

• Thread cord through knob so knot is inside knob.

• Thread cord through hole in carriage lever.

• Tie overhand knot in other end of cord.

Do Not cut cord until after power head is mounted.

2. Attach emergency release tag (Fig. 1-1).

• Thread wire through hole in carriage lever.

• Wrap wire around itself, tie securely.

PLEASE NOTE THE ASSEMBLY PROCEDURES

ARE DIFFERENT FOR RAIL AND CHANNEL. BE

SURE TO FOLLOW THE APPLICABLE STEPS.

Fig. 1-2

Fig. 1-1

Do Not attempt to run power head or to set limits until

operator is fully assembled and attached to the door.

“D” -Shaft and Hole

Hex Head Screws

Carriage Stop

CAUTION

Do Not attempt to run power head or to set limits until

operator is fully assembled and attached to the door.

Toward Door Toward Power Head

Carriage

No. 10 x 1/2” Hex Head Screw

5/16” x 1/2” Hex Head Washer Screw

Emergency

Release

Tag

Emergency

Release

Cord

Emergency

Release

Knob

Sprocket Saddle

1

...

OPERATOR ASSEMBLY

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

10

CHANNEL & POWER HEAD ASSEMBLY

RAIL & POWER HEAD ASSEMBLY

3. Place power head and rail on clean, flat surface.

4. Slide drive end of rail down over “D”-shaft on top

of power head (Fig. 1-3).

• Support header end of rail level with power head.

• Slide carriage enough to align “D”-shaft with “D”-hole

in sprocket.

• Slide rail down “D”-shaft flush with power head.

drags on the rail

CAUTION

OPEN BLUE PARTS BAG

Screws for attaching light cover are included in this

bag. Please set aside for use later.

[

69

]

[

112

]

[69]

[69]

[

112

]

Page 11

Fig. 1-4

Adjusting

Bolt

WHAT TYPE OF DOOR DO YOU HAVE?

Look at the drawings below. They tell you where

to find the installation instructions you need

Track Guided Doors

SEE SECTION 2A

Trackless Doors

SEE SECTION 2B.

Section Door With

Curved Track Hardware

1-Piece Door With

Horizontal Track Hardware

Curved

Track

with

Vertical

Section

Straight Track

(Horizontal Only)

1-Piece Door

Jamb Type Hardware

(No Track)

1-Piece Door

Pivot Type Hardware

(No Track)

5. Fasten rail to power head.

• Align mounting holes of sprocket saddle, rail

and power head frame.

• Insert the two (2) 5/16” x 1/2” hex head

screws[112], then two (2) No. 10-24 x 1/2” hex

head screws [69].

• Tighten screws.

NOTE: Inner-slide/bullet should remain at mid-travel

when assembling to power head to provide proper

travel when setting limits.

6. Use adjusting bolt to set chain tension (Fig. 1-4)

• Chain should sag slightly but not so much that it

drags on the rail.

“H”

“H”

“H”

DOTTED LINE AT “H”

INDICATES HIGHEST

POINT OF TRAVEL

“H”

2

...

INSTALLATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

11

WARNING:

IMPORTANT

INSTALLATION

INSTRUCTIONS

1. READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

improperly balanced door could cause severe injury. Repairs

and adjustments to cables, spring assembly, and other

hardware must be made by a trained service person using

proper tools and instructions.

3. Remove all ropes and disable all locks connected to the door

before installing operator.

4. Install door operator 7 feet or more above the floor. Mount the

emergency release knob 6 feet above the floor.

5. Do Not connect the operator to the source of power until

instructed to do so.

6. Locate the control button:

• Within sight of door.

• At a minimum height of 5 feet, so small children cannot

reach it.

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall button or

console. Install the emergency release tag on, or next to, the

emergency release.

8. The operator must reverse when the door contacts a 1-1/2 inch

high object on the floor at the center of the doorway. This is about

the size of a 2” x 4” board laid flat.

To reduce the risk of

severe injury or death:

WARNING:

OPEN ORANGE PARTS BAG

Page 12

WARNING

• Do Not try to remove, repair or adjust

springs or anything to which door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made by

a trained service person using proper tools

and instructions.

• Handles and other door projections can

catch clothing. Remove ropes, hooks,

hangers, decorative or security items

mounted to door.

• Be sure Emergency Release Cord does not

catch on roof carrier or other vehicle parts.

1.

Establish center line of door and header (Fig. 2-1).

• Close door.

• Measure door width. Mark center.

• Use straight edge to draw vertical line “V.”

– down door about 6”.

– on top of door.

– up header about 20”.

2. Establish Header Bracket position (Fig. 2-2).

• Watch top edge of door as you raise it.

• Stop door when top edge reaches highest point

of travel.

• Measure distance from top edge of door to floor.

• Add 2-1/2” to this measurement.

• Close door.

• Mark header at this height.

• If door spring is in the way, mark header 2-1/2”

above the spring.

• Draw horizontal line “H” across line “V” at this

point (Fig 2-1).

NOTE: Header bracket must be at least 2-1/2” above

high point of door travel. It can be installed higher if

door spring is in the way. Do Not move the spring.

Fig. 2-2

Door

Header

Line “H”

Line “H” Can Be

Drawn Above

Spring

Fig. 2-1

Line “V”

(Vertical Center Line

of Door)

Inside of Door

Alternate Mounting Methods

NOTE: Materials for mounting are not included

Angle Iron Method Conduit Method

Page 13

CAUTION

CAUTION

Fig. 2-5

Mounting bracket must be fastened to garage

framing. Do Not fasten to drywall, particle board,

plaster or other such materials.

Power Head

Channel/Rail

Assembly

6. Mount power head

(See Section 2 MOUNTING METHODS).

• Be sure channel/rail assembly and power head

are on door center line (Line “V”).

• Check the illustrations. Decide which mounting

method you will use. Materials for mounting are

not included.

• After power head is installed, remove

supporting material.

• Close door.

7. Install door braces (See CAUTION below).

Fig. 2-4

Header

Bracket

Spring

Header

Door

Support if

necessary to

clear spring

Center Line

Doors made of masonite, lightweight wood, fiberglass, and metal must be properly braced before

mounting Door Operator.

Contact door manufacturer or distributor for bracing

instructions.

Header bracket must be fastened to garage

framing. Do Not fasten to drywall, particle

board, plaster or other such materials.

3. Install header bracket (Fig. 2-3)

• Place bracket so:

– center hole is on line “V.”

– all holes are on line “H.”

• Mark hole positions “A” and “B.”

• Drill 5/32” holes at marked positions.

• Fasten bracket to header using two (2) 1/4” x 2”

lag screws [79].

4. Attach channel/rail assembly to header

bracket (Fig. 2-4).

• Fasten header end of the channel/rail to the

Header bracket with cold header pin [82].

• Install speed nut

[81]

.

• Support power head above floor, use:

– rope.

– ladder with cardboard packing.

– wood.

5. Level rail assembly and power head (Fig. 2-5).

• Raise and support power head above door tracks.

• Open door.

• Level channel/rail assembly and

support temporarily.

• Center channel/rail assembly and power head

on line “V” of door.

NOTE: The channel/rail assembly and power head

should be level if possible. If necessary, power

head may be mounted lower. However mounted,

moving door must not touch channel/rail assembly.

Fig. 2-3

Line “V”

Line “H”

“A”

“B”

Header Bracket

Lag Screws

Vertical

Centerline

of Door

13

CAUTION

T-rail shown. Channel

attachment is same.

[79]

[81]

[82]

Speed nut

Cold header

pin

Page 14

8. Install door bracket (Fig. 2-6).

• Contact door manufacturer.

NOTE: Self-drilling screws are intended for use with

light-weight door only, while lag screws are meant

for wood doors only.

Because door designs vary, modifications may

be required and additional materials needed. Please

contact your door manufacturer with any questions

concerning your door.

9. Install door arms (Fig. 2-7).

• Attach straight door arm to carriage.

– slip straight door arm into slot at bottom of

carriage as shown.

– secure with clevis pin

[90]

and cotter pin [89] .

• Attach short end of curved door arm to door

bracket as shown.

– slip short end of curved door arm into slot in

door bracket.

– secure with clevis pin and cotter pin.

• Release carriage (See emergency release tag).

– slide carriage towards closed door.

– stop carriage 14” minimum from door.

10 . Join door arm sections (Fig. 2-8).

• Use two (2) 3/8” x 7/8” hex bolts

[91]

, and hex

flange nuts [92].

– use any two holes as far apart as possible.

– slide carriage back and forth as needed to

align holes.

• Tighten hex nuts securely.

11 . Adjust emergency release cord length.

• Mount the emergency release knob 6 feet from

the floor.

• Retie overhand knot and trim excess cord.

DO NOT plug power cord into outlet.

Go to Section 3-SAFE-T-BEAM

®

SYSTEM INSTALLATION.

– PROCEED TO PAGE 18 –

Fig. 2-8

Straight door arm

Curved door arm

Fig. 2-6

Fig. 2-7

14” MIN.

Straight door arm

Curved door arm

Top of Door

Dessus de la porte

Top of Door

Dessus de la porte

“V”

“V”

“V”

Page 15

CAUTION

WARNING

Header bracket must be fastened to garage

framing. Do Not fasten to drywall, particle

board, plaster or other such materials.

1.

Establish center line of door and header (Fig. 2-9).

• Close door.

• Measure door width. Mark center.

• Use straight edge to draw vertical line “V.”

– down door about 6.”

– on top of door.

– up header about 20”.

2. Determine door rise (Fig. 2-10).

• Open door to highest point of travel.

• Measure distance from top of door to floor.

• Subtract the actual height of door. The remainder

is the door rise in inches as shown in TABLE A.

• Do Not try to remove, repair or adjust springs or

anything to which door spring parts are fastened,

such as, wood blocks, steel brackets, cables or

other like items.

Repairs and adjustments must be made by a

trained service person using proper tools

and instructions.

• Handles and other door projections can catch

clothing. Remove ropes, hooks, hangers,

decorative or security items mounted to door.

• Be sure emergency release cord does not catch

on roof carrier or other vehicle parts.

4. Install header bracket (Fig. 2-11).

• Place header bracket so,

– center hole is on line “V.”

– all holes are on line “H.”

• Mark hole positions (“A” and “B”).

• Drill 5/32” holes at marked positions.

• Fasten header bracket to header with two (2)

1/4” x 2” lag screws

[79]

.

Fig. 2-11

Line “V”

Line “H”

“A”

“B”

Header bracket

Lag screws

Vertical centerline

of door

Fig. 2-9

Top of door

See

TABLE A

Line “H”

Inside of door

Door header

Line “V”

(Vertical centerline of door)

Door rise Locate header bracket above

in inches top edge of CLOSED door

Up to 4” Up to 10”

4” to 8” 10” to 15”

8” to 12” 15” to 20”

TABLE A

Fig. 2-10

Highest point

of travel

Door rise

Highest point

of travel

Floor Floor

3. Locate header bracket (Fig. 2-9).

• Use TABLE A to determine header

bracket position.

• Draw horizontal line “H” across line “H” at

this point.

Door rise

15

2B

...

FOR TRACKLESS DOORS

[79]

Page 16

CAUTION

6. Install door bracket (Fig. 2-12).

• Contact door manufacturer for proper installation.

NOTE: Self-drilling screws are intended for use with

light-weight door only, while lag screws are meant

for wood doors only.

Because door designs vary, modifications may

be required and additional materials needed. Please

contact your door manufacturer with any questions

concerning your door.

Doors made of masonite,

lightweight wood, fiberglass,

and metal must be properly

braced before mounting

an operator.

Contact door manufacturer

or distributor for

bracing instructions.

7. Attach channel/rail assembly to header

bracket (Fig. 2-13).

• Fasten header end of the channel/rail to the

header bracket with pin.

• Install speed nut onto pin (Fig, 2-14).

• Place cardboard packing under power head. Use

additional support if needed.

8.

Establish power head mounting height (Fig. 2-15).

• Power head should be at door height above floor

or higher.

• Temporarily support power head in this position.

Use

– rope.

– ladder with cardboard packing.

– wood.

5. Install door braces

(See CAUTION below).

Header bracket

Header

Door

Power head

(Protected by cardboard

or packing)

Door

bracket

Fig. 2-15

CORRECT

r

WRONG

Door height

Fig. 2-12

Fig. 2-14

Door

bracket

Pin

Speed

nut

Boom header end

Same arrangement applies

to channel (not shown)

Channel

Rail

16

Fig. 2-13

Critical height is point where the rail/channel attaches to power head.

Top of Door

Dessus de la porte

“V”

“V”

“V”

“V”

Top of Door

OR

Top of Door

Dessus de la porte

[79]

[96]

[79]

[96]

[82]

[81]

Page 17

CAUTION

Mounting bracket must be fastened to garage

framing. Do Not fasten to drywall, particle board,

plaster or other such materials.

9. Mount power head (See Section 2 ALTERNATE

MOUNTING METHODS).

• Be sure rail assembly and power head are on

door center line (line “V”).

• Check the illustrations. Decide which mounting

method you will use. Materials for mounting are

not included.

• After power head is installed, remove

supporting material.

• Close door.

10 . Join door arms exactly as shown (Fig. 2-16).

• Overlap arms by two (2) holes.

• Install two (2) 3/8” x 7/8” hex bolts, and hex

flange nuts.

• Tighten hex nuts securely.

11 . Install assembled door arms (Fig. 2-17).

• Attach straight end of assembled door arms to

door bracket.

– slip straight door arm into slot in door bracket.

– secure with clevis pin [90] and cotter pin [89].

• Release carriage (See emergency release tag).

• Slide carriage toward door.

• Attach short end of curved door arm to carriage.

– slip curved door arm into slot in carriage.

– secure with clevis pin and cotter pin.

NOTE: When opening, door must not pass level

position or if you are not able to close the door after

completing previous step; a longer door arm is

required. An extension kit can be purchased by

calling the Customer Service phone number,

1.800.354.3643.

12 . Adjust emergency release cord length.

• Mount the emergency release knob 6 feet from

the floor.

• Retie overhand knot and trim excess cord.

Fig. 2-17

Fig. 2-16

Straight door arm

Curved door arm

17

OPEN YELLOW PARTS BAG

[92]

[91]

Bolt, 3/8”-16 x 7/8”

Nut, 3/8-16

[92]

[91]

3/8-16 nut

Bolt, 3/8-16 x 7/8”

Clevis pin

[90]

Cotter pin

[89]

[90]

Clevis pin

[89]

Clevis pin

Page 18

NOTE: Mounting brackets can be attached to the

floor using concrete anchors (not provided).

2. Mounting STB source and sensor.

• If garage has only one garage door.

– Determine which side of garage receives

most direct sunlight (Fig. 3-4).

– Red LED should always be on sunny side

whenever possible (Fig. 3-4).

• For multiple doors.

– Preventing crossed signals is critical.

– Place source and sensor modules on

adjacent doors facing in opposite directions

(Fig. 3-4).

NOTE: To help prevent interference from sun, STB

sensors (green LED) may be placed further away

from the door opening where they will spend more

time in shadows.

• Slide source/sensor onto tongue of bracket

until it clicks into place (Fig. 3-3).

3. Wiring.

• Route wire using either method shown(Fig. 3-5).

• Securely fasten wires to wall as you go.

– Use insulated staples (included).

– Staples should be snug only.

WARNING

NOTE: The operator will not close the door

automatically unless the Safe-T-Beam®System

is installed.

1. Mounting brackets.

• Mark both sides of garage door frame or wall 5”

above floor (Fig. 3-1).

• Hold bracket against door frame or wall.

– Check if brackets extend out from wall far

enough, so tongue of bracket is beyond door,

tracks or any door hardware.

– If not:

a. STB bracket extensions are available at

local dealer.

b. Blocks of wood, etc. may be substituted

for extensions.

• Center bracket on your mark (Fig. 3-2).

• Fasten each with 2 screws [

12 7

].

There should be no electrical power to the

operator while installing Safe-T-Beam®System

wires. If you have plugged in the power cord

—UNPLUG IT NOW.

FIG. 3-1 Mark door frame.

FIG. 3-2

Mount brackets.

F

IG. 3-3

Attaching STB’s to brackets

.

(See directions on next page and

Figure 3-4 before attaching.)

tongue

mark

center of

bracket

#10-16 x 1-1/4”

FIG. 3-5 STB wiring methods.

Sensor

Source

Red

Green

Power

Head

Sensor

Source

Red

Green

Power

Head

A

B

Dashed Line = striped wire

Solid Line = white wire

FIG. 3-4 STB locations.

18

3

...

SAFE-T-BEAM®INSTALLATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

OPEN RED PARTS BAG

[

12 8

]

[

127

]

Insulated staple

RED

LED

ONE DOOR

GARAGE

GREEN

LED

THREE DOOR

GARAGE

SUN

GREEN

LED

RED

LED

RED

LED

GREEN

LED

TWO DOOR

GARAGE

GREEN

LED

RED

LED

RED

LED

GREEN

LED

GREEN

LED

RED

LED

Page 19

CAUTION

FIG. 3-8 (ProMax)

Attachments at

power head.

• Make wire attachments at STB’s.

– Splitting and stripping wire ends to be

connected as shown (Fig. 3-6).

– Loosen terminal screws.

– Insert wire under flat plate and tighten screw. It

does not matter which wire, white or striped,

goes on which terminal (Fig. 3-7).

• Make wire attachments at power head.

– For ProMax. STB’s are connected to terminals

#2 and #3 on power head (Fig. 3-8).

– For Stealth. STB’s are connected to

terminals #3 and #4 on power head (Fig. 3-8).

4. Check the following.

• Insure that no part of door or its hardware is in

path between lenses of source and sensor.

• Insure that tops of lenses are between 5”-6”

above the floor (Fig. 3-9). The brackets are

flexible and can be adjusted slightly if needed.

NOTE: STB alignment check must be performed

following connection to electrical power (see page 21).

DO NOT PLUG IN YET!

Staples which are too tight can cut or pinch wires.

Cut or pinched wires can cause the STB System

to stop working. When using the insulated

staples, make sure you fasten them only as tightly

as needed to hold the wire snugly.

FIG. 3-7

Attachments

at STB.

FIG. 3-9 Check lens height.

top edge of lens between

5” - 6” above floor.

FIG. 3-6

Splitting and

stripping.

2

3

FIG. 3-8 (Stealth)

Attachments at

power head.

3

4

19

STB

SELF-DIAGNOSTIC TROUBLESHOOTING

ON

ON

NORMAL OPERATION

NONE REQUIRED

OFF

OFF

1.POWER HEAD NOT POWERED

2.WIRING FROM POWER HEAD BAD

1.CHECK BREAKERS, FUSES, PLUGS

2.CHECK WIRING FOR OBVIOUS SHORTS

OFF

ON

1.WIRING TO SOURCE MISSING OR BAD

2.POWER HAS BEEN INTERRUPTED

1.CHECK WIRING

2.REMOVE POWER AND REAPPLY

2 BLINKS, PAUSE (REPEAT)

ON

1.BEAM NOT ALIGNED 2. BEAM OBSTRUCTED

3.SENSOR DEFECTIVE

1.CHECK ALIGNMENT 2. CHECK FOR OBSTRUCTION

3.CALL CUSTOMER SERVICE

1.WIRE TO SENSOR MISSING OR BAD

2.SENSOR DEFECTIVE

1.CHECK WIRING

2.CALL CUSTOMER SERVICE

OFF

ON

1.SENSOR RECEIVING INTERFERENCE

1.

ATTEMPT TO DETERMINE SOURCE OF INTERFERENCE

2.CALL CUSTOMER SERVICE

ON

1.SOURCE NOT SENDING PULSES

2.SOURCE DEFECTIVE

1.CALL CUSTOMER SERVICE

2.CALL CUSTOMER SERVICE

NOTE: IF OPERATING PROBLEM EXISTS, THE DOOR CAN BE CLOSED IF YOU: 1. DISCONNECT THE STB SYSTEM FROM THE OPERATOR AND 2. HOLD WALL CONTROL BUTTON

DOWN UNTIL DOOR IS CLOSED. (REMOTE CONTROL & WIRELESS KEYPAD WILL NOT WORK WITHOUT STB

)

SOURCE (RED LED

)

SENSOR (GREEN LED

)

INDICATED CONDITION

REQUIRED ACTION

2 BLINKS, PAUSE (REPEAT)

3 BLINKS, PAUSE (REPEAT)

4 BLINKS, PAUSE (REPEAT)

CUSTOMER SERVICE: 1.800.354.3643 or www.geniecompany.com

Safe-T-Beam®Alignment Check

After turning the electrical power on, if the

STB’s are not in proper alignment, the red

LED (Source) will blink continuously.

To correct the problem – the brackets are

flexible and can be adjusted slightly to bring

the system into alignment.

When the STB’s are in alignment the red LED

will stop blinking and stay on.

Page 20

CAUTION

WARNING

Wall console

Wall button

OR

Fig. 4-2

#6 x 1”

pan head screws

Fig. 4-3

1. Run wire from power head to wall control.

• Place the wall control:

– In sight of door.

– At least 5 feet from floor, so small children can

not reach it.

– Away from moving parts of door and

door hardware.

• Use staples to fasten wire to ceiling and wall.

2. Remove 1/2” insulation from each wire

(Fig. 3-6)(pg. 19).

3. Attach wires to terminals (Stealth Fig. 4-1a)

(MAX Fig. 4-1b).

• Loosen, but Do Not remove screw from terminal.

For Stealth.

– Connect striped wires to terminal “2” on power

head and “B” on wall control.

– Connect white wire to terminal “1” on power

head and “W” on wall control.

For MAX.

– Connect striped wires to terminal “1” on power

head and “B” on wall control.

– Connect white wire to terminal “2” on power

head and “W” on wall control.

4. Mount wall control (Fig. 4-2).

• Use two pan head screws.

5. Mount entrapment warning label.

• Remove protective backing and stick near

wall control.

• Use tacks or staples to permanently mount Label.

•

Make sure everyone reads and follows WARNINGS.

NOTE: Additional wall controls are available from your

dealer. ONLY ONE OF YOUR WALL CONTROLS MAY BE THE

LIGHTED TYPE. If you have a lighted wall control, all your

additional controls must be un-lighted. More than one

lighted wall control per operator will cause a malfunction.

Power cord must be unplugged before attaching

wires. Be sure wire ends do not touch each other

or other terminals.

• Use of any other wall control will cause the

light not to work and could cause door to

operate by surprise.

• Cut or pinched wires can cause door operator

to malfunction. Drive staples just tight enough

to hold wire.

Fig. 4-1a

1

2

3

4

W

B

BW

White

Striped

Wall

console

terminals

Wall

button

terminals

Power head

terminals

Back view

Back view

1

2

3

4

White

Striped

OR

Power

head

ferminals

Rear view of

power head

Fig. 4-1b

NEC

CLASS 2

1

2

3

4

5

6

MORE

FORCE

PUSH

BUTTON

SAFETY

BEAM

LIMIT

SET

OPEN

FORCE

CLOSE

FORCE

RADIO

SIGNAL

LEARN

CODE

COM

DO NOT

PUSH

LIMIT SET

UNLESS

DOOR IS

ATTACHED

NOTE:

USE ONLY WITH

SERIES II CONTROLS

CLOSE

MORE

OPEN

MORE

U.S. Patent No. 5,243,784

5,221,869

1

2

3

W

B

BW

Striped

White

Wall

console

terminals

Wall

button

terminals

Power head

terminals

power head

terminals

Back view

Back view

Front view of

power head

1

2

3

Striped

White

EITHER

20

4

...

WALL CONTROL INSTALLATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Independent Light Control

–

Controls door operator lights from inside garage

–

Energy-Saver shut-off turns off light 5 minutes after

door activation

Vacation Locking Switch

– LOCK disables controls after door is completely closed

– UNLOCK allows controls to work normally

Lighted Button

–

Shows system is powered

–

Lights when Security Lock

Switch is in UNLOCK position

–

Goes out when Security Lock

Switch is in LOCK position

Door Control Button

–

Open and closes door from

inside garage

1

4

3

2

MORE

OPEN

MENT

W1

B2

Y3

G4

PUSH

TO SET

LIMITS

Page 21

1. Disconnect the power cord from the branch

circuit mains.

2. Remove bottom cover from power head.

• Remove four (4) hex head screws from front

and rear covers.

• Slide bottom cover off.

3. Remove existing power cord from power head.

• Disconnect three power cord wires.

• Remove and discard power cord.

• Remove 7/8” diameter knock-out plug.

• Install a suitable entrance bushing.

4. Install permanent wiring to power head.

For Stealth—connect permanent wiring to

internal terminal block.

• Connect white supply line to silver terminal.

• Connect black supply line to brass terminal.

• Connect ground wire to green wire location

(GROUND).

For ProMax—connect permanent wiring.

• Make connections with UL recognized wire nuts.

• Connect white supply line to white wire.

• Connect black supply line to black wire.

• Connect ground wire to green wire location

(GROUND).

• Wires inside operator are to be a minimum of

6 inches.

5. Replace power head bottom cover.

• Replace and tighten four (4) hex head screws.

NOTE:

Circuit boards are light sensitive.

Make sure

cover is on power head before

operation.

1. Check local building codes.

• Some building codes require direct wiring to a

branch circuit. If direct wiring is NOT required,

plug door operator into grounded outlet

(Fig. 6-1).

2. Return to Section 3 for SAFE-T-BEAM

®

System

alignment and troubleshooting.

NOTE: If permanent wiring is required, have a

professional electrician install circuit and wire

door operator.

Fig. 5-1

Operator

power cord

Grounded

outlet

To reduce the risk of electrical shock, this equipment

has a grounding type plug that has a third

(grounding) pin. This plug will only fit into a grounding

type outlet. If the plug does not fit into the outlet,

contact a qualified electrician to install the proper

outlet. Do Not change the plug in any way. The door

operator must be properly grounded to prevent

personal injury and damage to the components.

The ELECTRICAL POWER to the door operator

MUST BE TURNED OFF when power head cover is

removed. Electrical power must remain off while

making electrical connections.

5

...

CONNECT OPERATOR TO POWER

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

21

PERMANENT WIRING

INSTRUCTIONS FOR ELECTRICIAN

WARNING

Page 22

WARNING

Fig. 6-1

TO SET

LIMITS

PUSH

OR

5

6

MORE

FORCE

LIMIT

SET

OPEN

FORCE

CLOSE

FORCE

PUSH

LIMIT SET

UNLESS

DOOR IS

ATTACHED

PRO MAX

Before starting main limit switch settings, LOCK

carriage onto rail assembly (See emergency

release tag).

1. Raise the door until the carriage engages with

the inner-slide/bullet.

2. Set “OPEN” limit switch (Fig 6-1).

• Locate limit set switch on back of power head.

• Push and hold limit set switch until door moves

to the fully open position.

– release the limit set switch.

–“OPEN” limit switch is set.

NOTE: If door stops and refuses to move up, adjust

“OPEN FORCE” (See Section 7-FORCE

ADJUSTMENT) and then repeat setting limit switch.

3. Set “CLOSE” limit switch (Fig. 6-1).

• Push and hold limit set switch until door contacts

the ground and stops.

– release limit set switch.

–“CLOSE” limit is set.

NOTE: If door stops and refuses to move down,

adjust “CLOSE FORCE” (See Section 7-FORCE

ADJUSTMENT) and then repeat setting limit switch.

NOTE: Do Not push the limit set switch again, your

limits are set. Slight adjustment may be needed later

(See Section 8-FINE LIMIT SWITCH ADJUSTMENTS).

Door opens rapidly.

• Keep path clear.

• Position ladder to the side of power head so it

is clear of all moving parts of door and

operator.

Set door operator so minimum force is needed

to operate door.

STEALTH

6

...

MAIN LIMIT SWITCH SETTINGS

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

22

1

2

NEC

CLASS 2

3

OPEN

CLOSE

CLOSE

LIMIT ADJUSTMENT

MORE MORE

4

PUSH

TO SET

OPEN

LIMITS

NEC

CLASS 2

PUSH

1

BUTTON

COM

2

NOTE:

SAFETY

USE ONLY WITH

3

BEAM

SERIES II CONTROLS

4

DO NOT

PUSH

LIMIT SET

UNLESS

5

DOOR IS

ATTACHED

6

LIMIT

SET

OPEN

MORE

5,221,869

OPEN

FORCE

MORE

CLOSE

FORCE

FORCE

RADIO

SIGNAL

LEARN

CODE

CLOSE

MORE

CLOSE OPEN

LIMIT ADJUSTMENT

U.S. Patent No. 5,243,784

Page 23

WARNING

CONTACT REVERSE

Fine adjustments for limit switches (see Section 8)

MUST BE completed before starting CONTACT

REVERSE.

• Open door, use wall control.

• Place a 2 by 4 board laid flat in center of doorway.

• Close door.

• Door MUST stop and reverse to open position. If it

does not, repeat fine adjustments for down limit

switch and “CLOSE FORCE” adjustment until the

door will reverse to the open position.

NOTE: Set minimum force required to make door close.

If door does not reverse, decrease “CLOSE FORCE”

until door reverses.

During the following steps, the motor protector may

open. Wait about 20 minutes for protector to reset.

NOTE:

Use wall control to run door to the fully

CLOSED position before starting “OPEN FORCE”

adjustment.

1. Adjust the “OPEN” Force (Fig. 7-1).

• Locate screw on back of power head marked

“OPEN FORCE.”

• Gently turn screw counterclockwise until it stops.

NOTE: Little effort is required to turn adjusting screw.

• Operate door using wall control.

• If door does not completely open, turn “OPEN

FORCE” screw clockwise slightly.

• Activate door using wall control.

• Repeat force adjustment until door will

completely open.

NOTE: Set minimum force required to make door open.

• Close door, use wall control.

2. Adjust the “CLOSE FORCE” (Fig. 7-1).

Use wall

control to run door to the fully OPEN position

before starting “CLOSE FORCE” adjustment.

• Locate screw on back of power head marked

“CLOSE FORCE.”

• Gently turn screw counterclockwise until it stops.

NOTE: Little effort is required to turn adjusting screw.

• Operate door using wall control.

• If door does not completely close, turn “CLOSE

FORCE” screw clockwise slightly.

• Operate door using wall control.

• Repeat force adjustment until door will

completely close.

NOTE: Set the minimum force required to make the

door close. Smaller the number the smaller the

force.

3. (Fig. 7-2)

Adjust your door operator so that minimum

force is needed to operate door.

Position ladder to the side of the power head so

that it is clear of all moving parts of the power

head, rail assembly and door.

Fig. 7-2

1 1/2” Object

(or a 2 x 4

laid flat)

CONTACT REVERSE

Fig. 7-1

OR

6

MORE

FORCE

LIMIT

SET

OPEN

FORCE

CLOSE

FORCE

RADIO

SIGNAL

LEARN

CODE

PRO MAX

STEALTH

7

...

FORCE ADJUSTMENT

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

23

NEC

CLASS 2

OPEN

CLOSE

CLOSE

LIMIT ADJUSTMENT

MORE MORE

PUSH

OPEN

TO SET

LIMITS

CLOSE

OPEN

MORE

MORE

CLOSE OPEN

LIMIT ADJUSTMENT

U.S. Patent No. 5,243,784

5,221,869

NOTE:

USE ONLY WITH

SERIES II CONTROLS

1

2

3

4

NEC

CLASS 2

PUSH

1

BUTTON

COM

2

SAFETY

3

BEAM

4

DO NOT

PUSH

LIMIT SET

UNLESS

5

DOOR IS

ATTACHED

6

LIMIT

SET

OPEN

FORCE

MORE

CLOSE

FORCE

FORCE

RADIO

SIGNAL

LEARN

CODE

Page 24

WARNING

During the following steps, the motor protector may

open. Wait about 20 minutes for protector to reset.

1. Adjusting the “OPEN” limit switch (Fig. 8-1).

• Run door to open position by pushing wall control.

• Locate curved “OPEN” limit adjustment slot on

back of power head.

• Look into slot for pinion screw.

• Insert a screwdriver and turn pinion screw.

– clockwise to open more.

– counterclockwise to open less.

2. Test door operator. Use wall control to run

door open and close.

3. Repeat step as necessary to properly set

“OPEN” limit switch.

4. Adjust the “CLOSE” limit switch (Fig. 8-1).

• Run door fully closed by pushing wall control.

• Locate curved “CLOSE” limit adjustment slot on

back of power head.

• Look into slot for pinion screw.

• Insert a screwdriver and turn pinion screw.

– counterclockwise to close more.

– clockwise to close less.

5. Test door operator. Use wall control to run door

open and close

6. Repeat step as necessary to properly set

“CLOSE” limit switch

7. Perform CONTACT REVERSE

Moving door can cause serious injury or death

•

Keep people clear of opening while door is moving.

• Do Not allow children to play with remote controls.

If safety reverse does not work properly:

• Close door and disconnect operator using

emergency release.

• Do not use door operator or remote controls

• Refer to door and door operator owner’s

Manuals before attempting any repairs

NOTE: Factory sets different codes for each remote

control.

Remote controls will not work if STB’s malfunction

When programming remote control keep at least 24

inches away from antenna.

1. Program one-button remote (Fig. 9-1)

• Locate learn code button and learn indicator on

power head.

– Remove lens cover on back of power head.

• Press and release learn code button on

power head.

– LED on power head blinks 2 times per second.

One-Button Remote Control*

Multi-Button Remote Control*

Complete with

Battery

Actual picture may vary by model

STEALTH

PRO-MAX

Fig. 9-1

24

8

...

FINE LIMIT SWITCH ADJUSTMENT

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

LIMIT ADJUSTMENT

CLOSE

MORE

OPEN

MORE

Fig. 8-1

9

...

REMOTE CONTROLS

* Remotes vary depending on model. Your operator will

have one or the other.

(continued on next page)

1

2

NEC

CLASS 2

3

4

MORE MORE

CLOSE

LIMIT ADJUSTMENT

PUSH

OPEN

TO SET

LIMITS

1

2

NEC

CLASS 2

3

4

MORE MORE

PUSH

CLOSE

OPEN

TO SET

LIMITS

LIMIT ADJUSTMENT

PUSH

BUTTON

COM

NOTE:

SAFETY

USE ONLY WITH

BEAM

SERIES II CONTROLS

LIMIT SET

UNLESS

DOOR IS

ATTACHED

LIMIT

SET

OPEN

CLOSE

OPEN

FORCE

MORE

MORE

CLOSE

FORCE

RADIO

SIGNAL

CLOSE OPEN

LEARN

CODE

LIMIT ADJUSTMENT

U.S. Patent No. 5,243,784

5,221,869

DO NOT

PUSH

NEC

CLASS 2

1

2

3

4

5

6

MORE

FORCE

Page 25

1. Turn remote control upside down (Fig. 10-1)

2. Battery replacement (your remote control is

battery powered).

• Gently push straight IN on tab as shown

(Fig. 10-1).

– use ball point pen, coin or small screwdriver.

– battery cover snaps open.

• Install new battery in same position.

– use A23, 12 Volt battery.

3. Attach visor clip to remote control (Fig. 10-2)

• Slide visor clip into back of case until it snaps

into place.

4. Remote control operation

• Point remote control at the garage door and

press the button. Door will move.

• Press remote control button again and door

will stop.

• Press remote control button again and the door

will move the other way. The door automatically

stops at the end of the open or close cycle.

Fig. 10-1

Fig. 10-2

Visor clip

Battery

Battery

cover

+

–

Fig. 9-1

Learn

code

button

Radio

signal

indicator

MORE MORE

LIMIT ADJUSTMENT

CLOSE

OPEN

PUSH

LIMITS

TO SET

4

3

2

1

CLASS 2

NEC

NEC

CLASS 2

1

2

3

4

5

6

MORE

FORCE

PUSH

BUTTON

SAFETY

BEAM

LIMIT

SET

OPEN

FORCE

CLOSE

FORCE

RADIO

SIGNAL

LEARN

CODE

COM

DO NOT

PUSH

LIMIT SET

UNLESS

DOOR IS

ATTACHED

NOTE:

USE ONLY WITH

SERIES II CONTROLS

CLOSE

MORE

OPEN

MORE

CLOSE OPEN

LIMIT ADJUSTMENT

U.S. Patent No. 5,243,784

5,221,869

STEALTH

PRO-MAX

• Press and release a remote control button.

– LED on power head stops blinking.

• Press and release same remote button again.

– LED goes out. Remote is now programmed.

2. Program multi-button remote control

• Repeat step 1 (“program one-button remote” for

each button).

NOTE: Each button on a multi-button remote control

is for a different operator.

3. Operate remote control

• Point remote control at door

– Door moves

• Press button again

– Door stops

• Press button again

– Door reverses

NOTE: Door automatically stops at end of open or

close cycle.

4. Erasing all receiver memory

• Press and hold learn code button on

power head

– 10 seconds or until light goes out

– Memory is erased

• Program door operator again

• Press remote control button once within

30 seconds

– LED on power head stays lit

• Press remote control button again

– LED on power head goes out and remote

control is programmed

NOTE: If LED blinks approximately 4 times per

second, programming has stopped. If programming

stops, repeat above steps.

Radio

signal

indicator

Learn

code

button

25

10

...

BATTERY / VISOR CLIP INSTALLATION

Page 26

1. Install light bulb(s) into socket(s).

Do Not use short neck bulb(s).

• Use bulb(s) rated for:

– rough service.

– vibration.

– appliances.

• 100 watt maximum.

2. Bend two (2) slotted tabs up. This will activate

the ”living hinge” of the lens (Fig. 11-1).

NOTE: The following steps use the screws from the

Blue Parts Bag that were set aside earlier.

3. Start two (2) No. 8 x 3/4” hex head screws into

bottom holes of panel (Fig. 11-2).

• Slide slotted tabs up behind hex head screws.

• Tighten hex head screws.

4. Align lens holes and holes of panel.

• Insert and tighten a No. 8 x 5/8” pan head

screw into each round lens hole and tighten,

NOTE: Screw heads fit completely into recess of

lens tab.

Fig. 11-2

Fig. 11-1

Pan head

screws

Bend tabs up

Slotted tabs

Bend tabs up (2)

Hex head

screws

11

...

LIGHT BULB AND LENS INSTALLATION

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

26

[10]

[10]

[9]

Hex Head Screw

No. 8 x 3/4”

Pan Head

Phillips Screw

No. 8 x 5/8”

[9]

Page 27

MONTHLY MAINTENANCE

DOOR SPRINGS and DOOR HARDWARE

• Do not operate garage door automatically or

manually if springs are broken. CONTACT A

PROFESSIONAL FOR SERVICE.

• Oil door rollers, bearings, and hinges monthly.

Use silicone lubricant or light oil.

DOOR BALANCE

• Close door. Pull red emergency release knob

down and toward power head to release door

from rail assembly.

• Raise door manually approximately 3 feet. Door

should stay in that position. If door moves, HAVE

DOOR SERVICED BY A PROFESSIONAL.

• Close door. Pull red emergency release knob to

reattach door to rail/channel assembly.

CONTACT REVERSE

• Close door on a 2 by 4 board laid flat on the floor

in the center of the garage doorway.

• Close door by using wall button or remote control.

• If door fails to reverse on contact with the board,

see Section 7-CONTACT REVERSE.

• If operator still fails, replace operator or HAVE

THE DOOR SERVICED BY A PROFESSIONAL.

Safe-T-Beam

®

STB SYSTEM

• Use self-diagnostic Safe-T-Beam

®

System

troubleshooting information to maintain safe

operation.

(See Section 3-STB SYSTEM INSTALLATION.)

IMPORTANT

SAFETY

INSTRUCTIONS

1 READ AND FOLLOW ALL INSTRUCTIONS.

2Never let children operate or play with the Door

Controls. Keep the Remote Control away

from children.

3Always keep the moving door in sight and away

from people and objects until the door is completely

closed. NO ONE SHOULD CROSS THE PATH OF

THE MOVING DOOR.

4 NEVER GO UNDER A STOPPED, PARTIALLY

OPEN DOOR.

5Test Opener monthly. The door MUST reverse on

contact with a 1-1/2" high object (or a 2" x 4" board

laid flat) at the center of the doorway on the floor.

After adjusting either the Force or the Limit of travel,

retest the Door Opener. Failure to adjust the

Opener properly may cause severe injury or death.

6When possible use the Emergency Release only

when the door is closed. Use caution when using

this Release with the door open. Weak or broken

springs are capable of increasing the rate of door

closure and increasing the risk of severe injury

or death.

7 KEEP GARAGE DOORS PROPERLY BALANCED.

See Owner's Manual. An improperly balanced door

increases the risk of severe injury or death. Have a

Genie Factory Authorized Dealer make repairs to

cables, spring assemblies, and other hardware.

8

SAVE THESE INSTRUCTIONS.

WARNING

To reduce the risk of

severe injury or death:

27

MAINTENANCE

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Transmitters comply with all United States and Canadian legal

requirements as of the date of manufacture. No warranty is made that

they comply with all legal requirements of any other jurisdiction. If

transmitters are to be used in another country, the importer must

determine compliance with any local laws and regulations which may

differ from United States and Canadian requirements prior to use.

Los transmisores cumplen con todas las reglamentaciones legales de

los Estados Unidos y del Canad , en la fecha de fabricaci n. Ninguna

garant a se da que cumplan con todas las reglamentaciones legales de

ninguna otra jurisdicci n. Si los transmisores se van a utilizar en otro

pa s, el importador debe determinar si cumplen con las

reglamentaciones y leyes locales que puedan ser diferentes a las

reglamentaciones de los Estados Unidos y del Canad , antes de usar

los mismos.

Sendeger te entsprechen allen gesetzlichen Bestimmungen in den USA

und Kanada zum Zeitpunkt der Herstellung. Wir bernehmen keine

Gew hrleistung f r die Einhaltung aller gesetzlichen Bestimmungen in

anderen L ndern. Sollen Sendeger te in anderen L ndern eingesetzt

werden, so muss der Importeur vor dem Gebrauch sicherstellen, dass

die Sendeger te auch solchen lokalen Bestimmungen entsprechen,

welche von den Bestimmungen der USA und Kanadas abweichen.

Les metteurs sont conformes la r glementation am ricaine et

canadienne compter de leur date de fabrication. Aucune garantie

n est stipul e indiquant qu ils sont conformes toutes les prescriptions

juridiques d autres autorit s. Si les metteurs sont utilis s dans d autres

pays, il incombe l importateur d en d terminer leur conformit aux lois

et r gles locales pouvant diff rer de celles des tats-Unis et du Canada

avant toute utilisation desdits metteurs.

Transmitter Compliance Statement

Page 28

CAUTION

Door starts for no reason. Check staples on wire from power head to wall control. If they cut into insulation, they can short wires.

If wire is cut, replace it.

Was a remote control lost or stolen? Erase all remote control codes from receiver memory and reprogram.

Wall control button sticking. Check operation of buttons.

Door starts down, then

stops before it’s closed.

Check CLOSE limit switch setting (See Section 8)

Check for shorted wires

Door starts down, then

stops and goes back up.

Check force adjustment (See Section 7).

Check CONTACT REVERSE (See Section 7).

Check for light beam obstruction or misalignment of Safe-T-Beam

®

(See Section 3).

Check STB self-diagnostic code.

Door will only run closed. Check OPEN limit switch for short and proper wiring.

Check force adjustment (See section 7).

Check for broken door spring.

Door will only run open.

Check Safe-T-Beam

®

System(See section 3).

Check CLOSE limit switch for short and proper wiring.

Check force adjustment (See Section 7).

Remote control has

less than 25 feet

operating range.

Relocate remote control inside car.

Point remote control at door.

Replace battery.

Do Not attempt to retune remote controls.

Door starts up, but

stops before it’s

completely open.

Be sure door is in good repair, properly lubricated and balanced.

Check OPEN limit switch setting (See section 8).

Check force adjustment (See section7).

Check for broken door spring.

Operator runs, but door

does not move.

Make sure carriage is engaged.

Check force adjustment (See Section 7).

Operator works from wall

control, but not from

remote control.

Program remote control code into receiver memory (See section 9).

If one remote control works and another does not, check battery, remote control type (Series II ) and

frequency of non-working unit (See section 9) .

Noisy operation. Be sure all fasteners are tight.

Be sure door is in good repair, properly lubricated and balanced (See Monthly Maintenance section).

STB System malfunction. Use self-diagnostic STB System troubleshooting information to maintain safe operation

(See section 3).

Use this guide to correct problems with your door

operator. If these solutions do not work,

call Customer Service.

Use only with included SERIES II wall control

Use of any other wall control can cause the door

to operate unexpectedly and the light not to work.

PROBLEM SOLUTIONS

Operator does not run

from wall control.

Check lock switch on wall console (See section 4).

Check the power source.

• Plug a lamp into outlet used for power head. If lamp works, power source is OK. If not, check fuse

or circuit breaker.

• If power is OK:

-

Check connections at power head terminals.

-

Check connections at wall control.

-

Motor protector may be open. Wait about 20 minutes for protector to reset.

Lights will not go out. Check wiring.

Disconnect & reconnect wires on wall control.

Non-compatible wall control.

Innerslide jammed into

power head.

Remove motor cover and rotate opti-wheel.

TROUBLESHOOTING GUIDE

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

28

Page 29

CAUTION

(

Stealth Motor

)

Opening cover could cause electrical shock.

WIRING DIAGRAM

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

29

(

ProMax Motor

)

Page 30

30

No C.O.D. shipments. Please include check or money

order, made payable to The Genie Company. Do not

send cash.Allow 3-4 weeks for delivery.

1-800-354-3643. Please have part number and credit

card ready. Mail Order Form to: Genie Company,

Alliance, Ohio 44601.We accept Visa or Mastercard

on phone orders only.

Please add local sales tax if you reside in one of the states listed.

California, Connecticut, Florida, Georgia, Illinois, Indiana,

Maryland, Massachusetts, Michigan, New Jersey, New York,

Ohio, Tennessee, Virginia, Wisconsin

TOTAL ORDER $

SHIPPING & HANDLING $ 5.00

STATE SALES TAX $

GRAND TOTAL $

Pas d’expédition contre remboursement.Veuillez inclure un

chèque ou un mandat bancaire, le payable fait à The Genie

Company. N’envoyez pas d’argent comptant.Accordez de 3 à

4 semaines pour la livraison. 1-800-354-3643. Ayez sous la

main le numéro de la pièce et celui de la carte de crédit. Mettre

à la poste le arrngement à: Genie Company, Alliance, Ohio

44601. Nous acceptons les commandes par téléphone avec

paiement par carte de crédit Visa ou Mastercard.

Veuillez indiquer les taxes de vente locales si vous résidez dans l’un

des états répertoriés ci-dessous.

COMMANDE TOTALE $

MANUTENTION ET EXPÉDITION $ 5.00

TAXE DE VENTE $

TOTAL GLOBAL

$

No se aceptan pedidos de pago contra entrega (COD).

Sírvase incluir su cheque o giro postal, la cuenta

pagadera hecha a The Genie Company. No envíe

dinero en efectivo.Concédanos 3 a 4 semanas para la

entrega. 1-800-354-3643. Sír vase tener listos los

números del modelo y de la tarjeta de crédito.Enviar

hacer un pedido de mercancia a: Genie Company,

Alliance, Ohio 44601.Aceptamos pedidos telefónicos de

Visa o Mastercard.

Sírvase agregar el impuesto de ventas local si usted reside en

uno de los siguientes estados:

TOTAL DEL PEDIDO $

FLETE Y MANEJO $ 5.00

IMPUESTO DE VENTAS ESTATAL $

GRAN TOTAL

$

Ordering Instructions

Las Instrucciones que Ordenan

Instructions Commandant

3

DEFDEF

1

2

4 5 6

7

8

9

0

GHIGHI

JKLJKL

MNOMNO

PQRSPQRS

TUVTUV

WXYZWXYZ

9V9V

Garage Door Opener Accessories Order Form

Formulario de pedido de accesorios para abridores de puertas de garaje

Formulaire de commande des accessoires pour ouvre-porte de garage

Page 31

INSTALLATION NOTES

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

CONTACT NUMBERS

NAME COMPANY NUMBER

NAME COMPANY NUMBER

NAME COMPANY NUMBER

NAME COMPANY NUMBER

NAME COMPANY NUMBER

NAME COMPANY NUMBER

31

Page 32

SAVE THESE INSTRUCTIONS

Manufactured under one or more of the following U.S. patents: 3,898,582 / 4,041,259/ 4,048,630 /4,064,487 / 4,103,238/ 5,222,403

Other Patents applied for

22790 Lake Park Blvd. • Alliance, Ohio USA • 44601

Customer Service

1. 800.35 GENIE

CORRESPONDENCE WITH FACTORY MUST INCLUDE DATE / MFG. NO.

(LOCATED UNDER LENS OF POWER HEAD)

__________________________________

FILL THIS IN AT TIME OF INSTALLATION FOR YOUR OWN RECORDS,

SO THAT IT WILL BE AVAILABLE IF YOU EVER NEED TO CALL US