Page 1

3507535556

GPS-IC Series

PMX-IC B Series

Automatic

Chain Drive/Belt Drive

Garage Door Operator

System

Complete with Remote Control

and SERIES II Electronics

Operator MUST be installed with the included SERIES II Wall Control!

Self-diagnostic Electronic Sensory Protection System

(SAFE-T-BEAM SYSTEM) MUST Be Installed To Close Door!

Owner’s Manual

SAVE FOR FUTURE REFERENCE

Customer Service

CALL: 1-800-354-3643

VISIT: WWW.GENIECOMPANY.com

AUTOMATIC GARAGE DOOR OPERATOR SYSTEMS

HANG MANUAL NEAR YOUR WALL CONTROL

TABBLLEE OFF CONTTENTS

SECTIION PPAGE

SAFETYY IINFOORMATIION . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . . . . . . 2-44

PARTS IDENTIFIICATIONN .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . . . . . . 5-66

ASSSEEMBLLY

1 OPERATOR ASSEMMBLY .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . . 10-111

1A Chaannel and Power Head Assseemblly .. . .. . .. . .. . . . .100

1B Rail aand PPoweer Heaad Assembbly . .. . .. . . . . . . .

INNSTALLLATIION

22DDEETTEERRMMIINNEE DDDOOOORR TTYYPPEE AAAANNDDD MMOOUUNNTTIINNGG MMEETTTTHHOODD .. .. ...1111

22AA IInnsstttaallllaattiiooonnn oonn TTrrrraacccckk GGGGuuiiddeedd DDoooooorrss .... .. .... .. ... .. .. .. ..1122--1144

22BB IInnssttaalllllaattiioooonn oonn TTTTrraacckklllleessss DDoooorrss .. .... .. .... .. ... .. .. .. .. .. ..1155--1177

33SSAAAAFFEE--TT--BBEEAAAAM

SSeellff--ddiiaaaaggnnoossssttiicc ““SSTTBBB”” SSyyssttteeeemm TTTTrroouubbbblleessshhoooottiinngg .. .... .. ...1199

4 WAALL CCONTTROL INSSTALLATTION . . . . . .. . .. . .. . .. . .. . .. . .. . .. 200

5 CONNECTT OPERRATOOR TTO POWERR . . .

6 MAIN LIMIT SWWITTCH SEETTTINGGS . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. 222

OPPERATIOON

7 FORCE ADDJUUSTMENT . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 233

Conttaactt Reverrse . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 233

8 FINE LIMIT SWITTCH ADJUSTTMENTTS . . . . .. . .. . .. . .. . .. . .. . .. 244

99RREEMMOOOOTTEE CCOONNNNTTRROOLLSS .... .. .... .. .... .. .... .. .... .. .... .. .... .. ... .. .. .. .. .. .. .. .. .. ..

1100BBAATTTTTEERRYY && VVIIISSOOORRR CCLLIIPP IINNSSSSTTTTAALLLLAAAATTIIOOOONN .. .. .. .. .... .. .... .. .... .. .... .. ...2255

11 LIGHHT BULB AND LEENS IINSTALLLATTION . . . .. . .. . .. . .. . .. . .. 266

MAIINTEENANCE . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . .277

TRROUBBLESHHOOTIING GUIDDE . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 288

WIRRING DIIAGRRAMM . . . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . ..

ACCESSSORIES . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . .300

WARRANTY .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . . . . . . . .322

®

MM

(((SSSSTTBBB)) SSYYSSSSTTEEMM IINNSSTTAAALLLLAAAATTIIOOOONNN .... .. ... .. ..1188--1199

. . .. . .. . .. . .. . .. . .. . .. 211

.10-111

.. ..2244--2255

. .. . .. 299

11

44

77

99

99

55

55

Page 2

PPRREEEE----IIIINNNSSSSTTTTAALLLLLLAATTTTIIOOONNNN CCHHHHEECCKKK LLIIIISSTT

FORR HELP-11.8800.35544.336433 OR GEENIIECCOOMPPANYY.CCOM

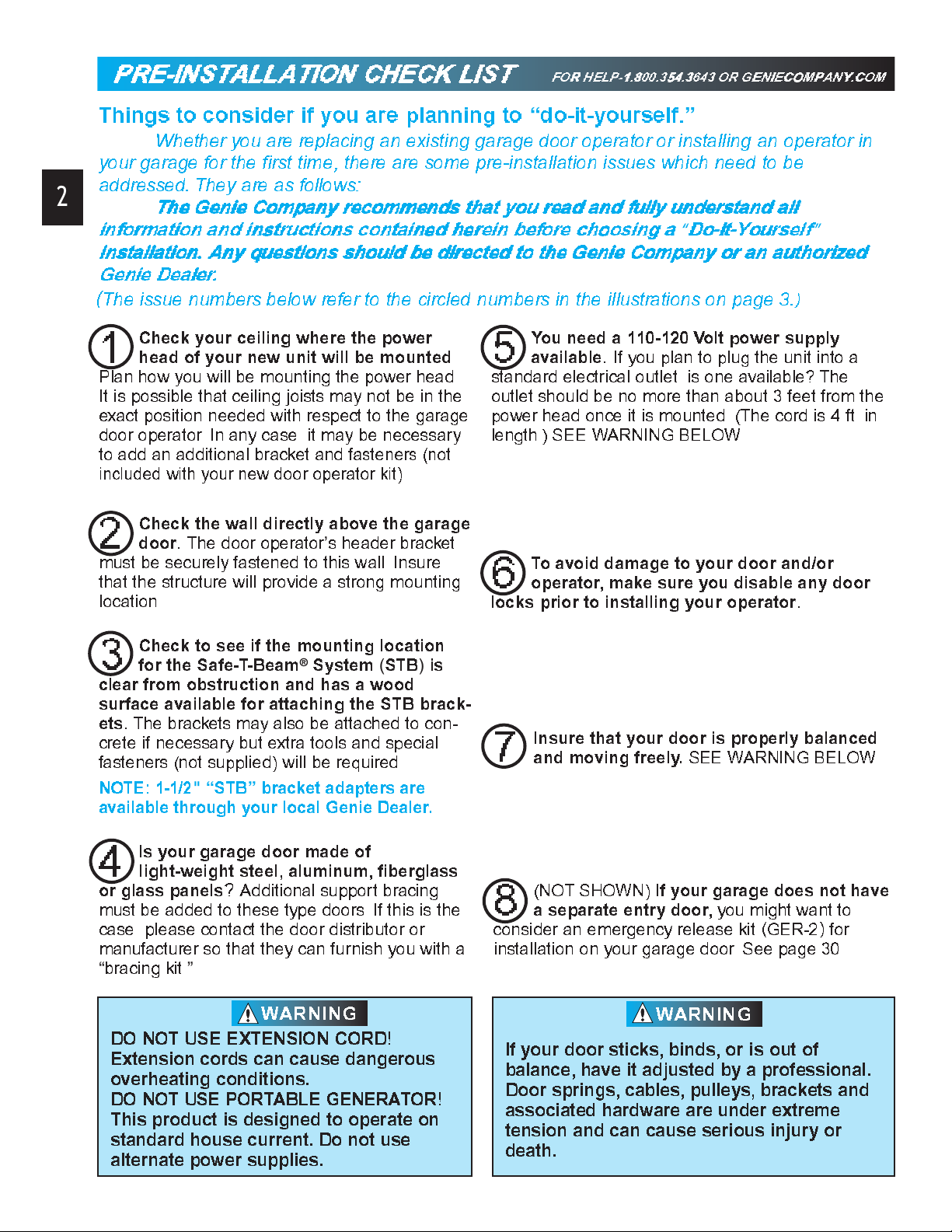

Things to consider if you are planning to “do-it-your se l f.

Whether you are replacing an existing garage door operator or installing an operator in

your garage for the first time, there are some pre-installation issues which need to be

addressed. They are as follows:

2

infforrmatiion and innssttrucctionns conttaainneedd hheerreinn beefforre cchhooosinngg aa “DDoo--IItt--Yoouursself

iinnssssttaallllaaaattiioonnnn.. AAnnnnyy qquuuueessssttttiioooonnss sssshhhoooouulldddd bbbeeee ddiiirrrreeeecctteedddd ttttooo tthhee GGGeenniieeee CCoooommpppaannyy oooorrr aann aauuuutthhoorrriizzzzeed

Genie DDealleerr.

(

The issue numbers below refer to the circled numbers in the illustrations on page 3.

1

P

It is possible that ceiling joists may not be in the

exact position needed with respect to the garage

door operator In any case it may be necessary

to add an additional bracket and

included with your new door operator kit)

2

must be securely fastened to this wall Insure

that the structure will provide a strong mounting

location

TThheeee GGeenniieeee CCoooommppppaannnnyy rreeccoooommmmmmeeennddddsss tthhaatt yyoouu rreeaaadddd aaanndddd ffuullllllyy uunnnnddeerrsssstttaanndd aallll

Check your ceiling where the power

head of your new unit will be mounted

lan how you will be mounting the power head

fasteners (not

Check the wall directly above the garage

door

. The door operator

’

s header bracket

You need a 110-120 Volt po wer suppl y

available

5

standard electr ical outlet is one available? The

outlet should be no more than about 3 feet from the

power head once it is mounted (The cord i s 4 f t in

length ) SEE WARNING BELOW

To avoid damage to your door and/or

6

operator, make sure you disable any door

locks prior to installing your operator

. I f you plan to plug the unit into a

”

”

d

)

.

Check to see if the mounting location

3

for the Safe-T-Beam

clear from obstruction and has a wood

surface available for attaching the STB brack-

ets

. The brackets may also be attached to con-

crete if nece s s ary but extra tools and special

fasteners (not supplied) will be required

NOTE: 1-1/2

available through your local Genie Dealer.

Is your garage door made of

light-weight steel, aluminum, fiberglass

4

or glass panels

must be added to these type doors If this is the

case please contact the door distributor or

manufacturer so that they can fur nish you with a

“

bracing kit

DO NOT USE EXTENSION CORD!

Extension cords can cause dangerous

overheating conditions.

DO NOT USE PORTABLE GENERATOR!

This product is designed to operate on

standard house current. Do not use

alternate power supplies.

" “

STB”bracket adapters are

? Additional support bracing

”

®

System (STB)is

WARNING

Insure that your door is properly balanced

7

and moving freely.

(NOT SHOWN)

a separate entry door,

8

consider an emergency release kit (GER-2)f

installation on your garage door See page 30

If your door sticks, binds, or is out o f

balance, have it adjusted by a professional.

Door springs, cables, pulleys, brackets and

associated hardware are under extreme

tension and can cause serious injury or

death.

SEE WARNING BELOW

If your garage does not have

you might want to

or

WARNING

Page 3

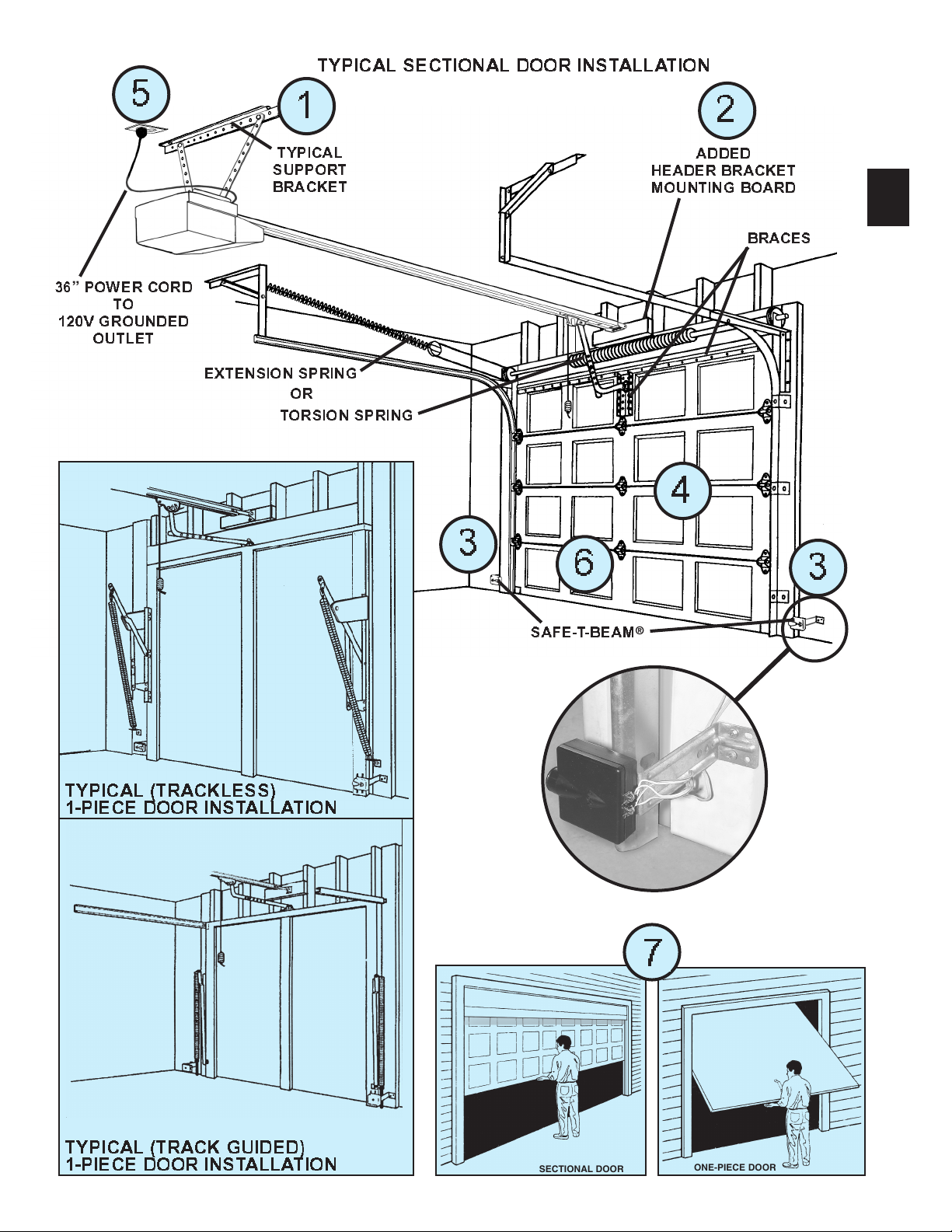

TYPICAL SECTIONAL DOOR INSTALLATION

5

36”POWER CORD

TO

120V GROUNDED

OUTLET

1

TYPICAL

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

3

6

2

ADDED

HEADER BRACKET

MOUNTING BOARD

3

BRACES

4

3

TYPICAL (TRACKLESS)

1-PIECE DOOR INSTALLATION

SAFE-T-BEAM

®

7

TYPICAL (TRACK GUIDED)

1-PIECE DOOR INSTALLATION

SECTIONAL DOOR

ONE-PIECE DOOR

Page 4

SAAFETTYY INNFORRMAATIOONN OPERRATOR IINNSTTAALLLLAATTIION

4

OVERVIEW OF

POTENTIAL HAZARDS

Garage doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs under

tension, and electric motors can cause injuries, your safety and the safety of

others depend on you reading the information in this manual. If you have

questions or do not understand the information presented, call your nearest

service representative

In this section and those that follow, the words

are used to emphasize important safety information.

ord:

The w

DANGER

o follow instructions.

t

W ARNING

o follow instructions.

t

CAUTION

to f

The word

r important considerations.

o

POTENTIAL

HAZARD

MOVING

DOOR

ELECTRICAL

SHOCK

HIGH

SPRING

TENSION

means that severe injury or death will result from failure

means that severe injury or death can result from failure

means that property damage or injury can result f r o m failure

ollow instruction.

NOTE

is used to indicate important step s to be followed

EFFECT PREVENTION

Keep people clear of opening while door is

W ARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

erious Injury

S

or Death

W ARNING:

Can Cause

Serious Injur

or Death

moving.

Do Not

allow children to play with the door

operator.

Do Not

operate a door that jams or one that

has a broken spring.

Turn off power before removing operator cover.

When replacing cover, make sure wires are not

pinched or near moving part s.

Operator must be properly grounded.

Do Not

try to remove, repair or adjust springs

or anything to which door spring parts are

fastened, such as, wood blocks, steel

brackets, cables or other like items.

y

Repairs and adjustments must be made by a

trained service person using proper tools and

instructions.

Dange

r,Warning,

and

Caution

IMPORTANT

INSTALLATION

INSTRUCTIONS

:

WWAAAARRNNNNIINNNGG

GG

:

To reduce the risk of

s evere injury or death:

1. READ AND FOLLOW ALL SAFETY,INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

operly balanced door could cause severe injury.Repairs

impr

and adjustments to cables, spring assembly, and other

hardware must be made by a trained service person using

proper tools and instructions.

3. Remove all ropes and disable all locks connected to the

or before installing operator.

do

4. Install door operator 7 feet or more above the floor.Mount

the emer

5. Do Not c

instructed to do so.

6. L

• Within sight of door.

• At a minimum height of 5 feet,so small children cannot

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall

button or c

next to, the emergency release

8. The operator must reverse when the door contacts a 1-1/2

inch high object on the flo

This is about the size of a 2” x 4” board laid flat.

gency release knob 6 feet above the floor.

onnect the operator to the source of power until

ocate the control button:

reach it.

onsole. Install the emergency release tag on, or

or at the center of the doorway.

SSAAAFFEETTYY FFEEAATTTTUUURRREES

S

((

((

vvvvaaaarrrriieess bbyy mmooddddeel

)

)

l

Safe-T -Beam®(STB) Non-Contact Reversing System

Places an invisible beam across door opening that reverses the door during down travel to the fully open

p

osition if anything passes through beam

Safe-T-Reverse

®

Contact Reversing System

Automatically stops and reverses a closing door within 2 seconds of contact with an object

Safe

-T-Stop®Timed Reversed System

Automatically opens a closing door if door does not close within 30 seconds

Force Guard

®

Control

Used to set the force required for opening and closing door For maximum safety set the minimum force

required to fully open and close door

Automatic Lighting System

One or two light bulbs (depending on model) up to 100 Watts max each ar e u se d for s afer entries and exits

The light tur

ns on when door is ac ti vated and automatically turns off 4 5 minutes later

Manual Emergency Release

Allow

s the garage door to be opened or closed manually for emergencies or maintenance

Page 5

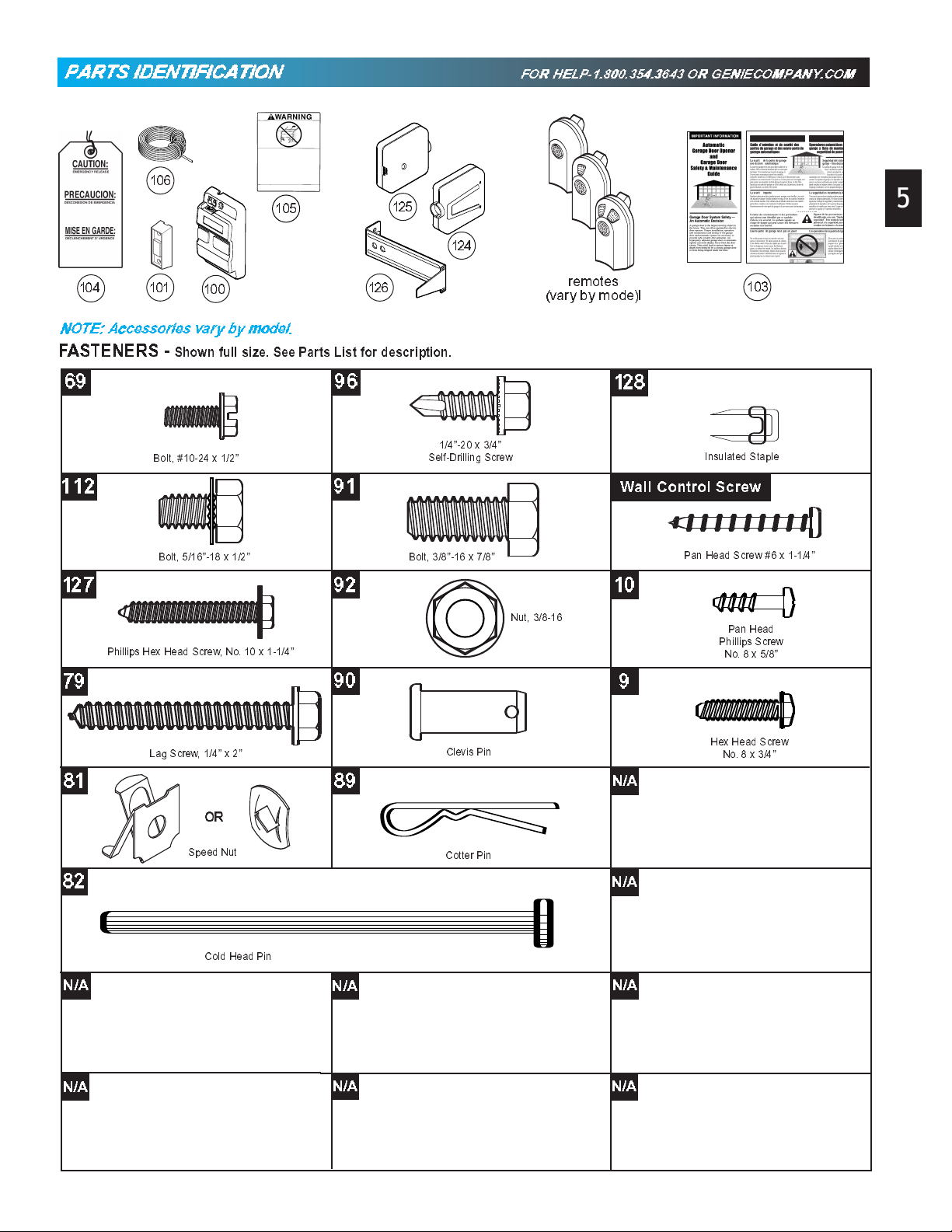

PPAAAARRTTSS IIIDDEEEENNTTTTIIIFFIICCAATTTIIOONN

106

105

125

FORR HEELP-1..8000.3544..33643 ORR GENNIECOMMPPAANNY..COMM

5

124

104

NOTEE:: Acccessories varyy by mmoodel

N

FASTENERS -

101

100

Shown full size. See Parts List for description.

69

Bolt, #10-24 x 1/2

”

112

Bolt, 5/16”-18 x 1/2

”

127

Phillips Hex Head Screw, No. 10 x 1-1/4

79

126

remotes

(vary by mode)l

103

.

96

1/4”-20 x 3/4

Self-Drilling Scre

”

w

91

Bolt, 3/8”-16 x 7/8

”

92

Nut, 3/8-16

”

90

128

Insulated Staple

Wall Control Screw

Pan Head Screw #6 x 1-1/4

10

Pan Head

Phillips Screw

No. 8 x 5/8

9

”

”

81

82

N/A

N/A

Lag Screw, 1/4”x 2

OR

Speed Nut

Cold Head Pin

C

”

89

levis Pin

N/A

Cotter Pin

Hex Head Screw

No. 8 x 3/4

”

N/A

N/A

N/A

N/A

N/A

Page 6

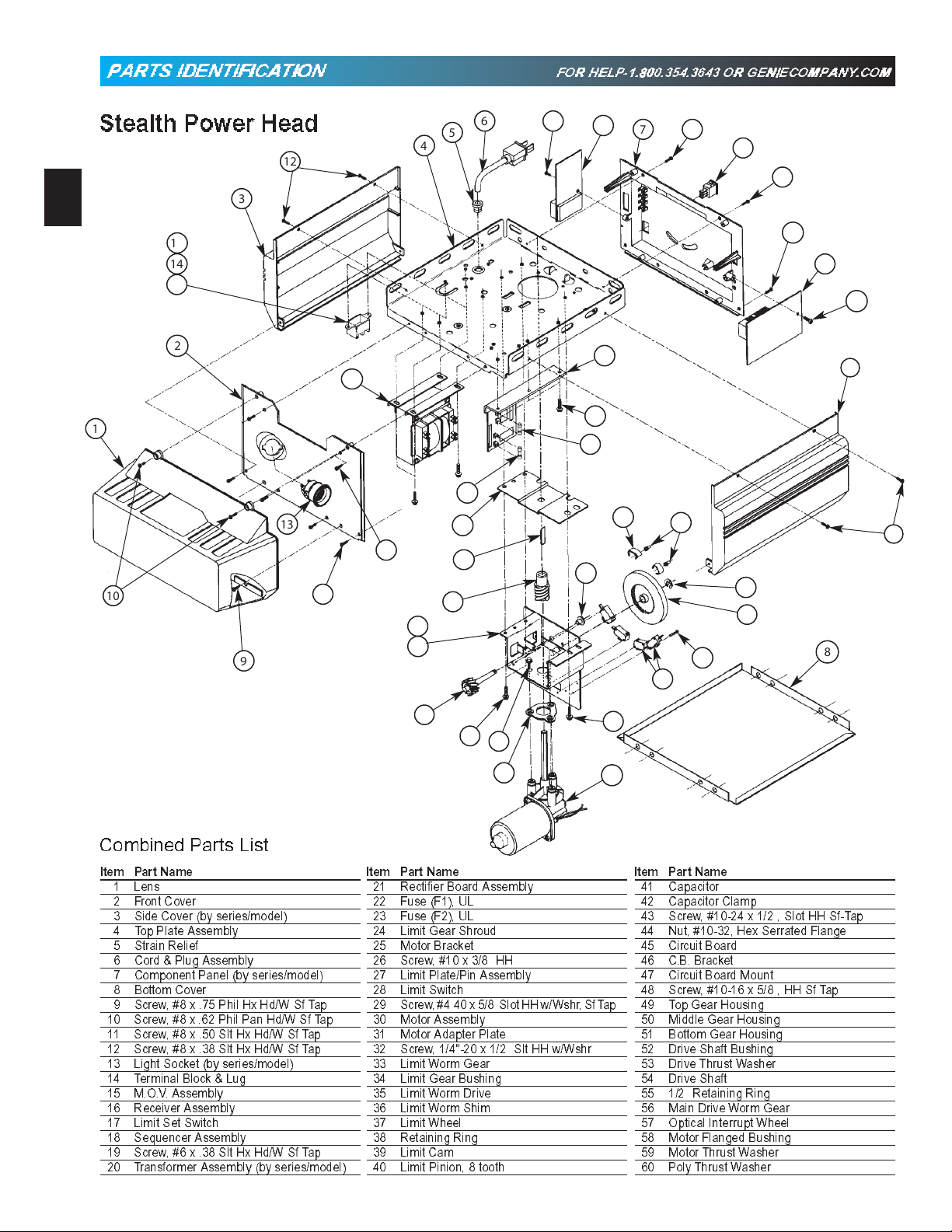

PARRTSS IDDENTIFFIICAATIIOON

P

FORR HEELP-1..88000.3544.33643 ORR GENNIIECOMMPPAANNY..COMM

Stealth Power Head

6

15

14

12

2

1

10

6

5

4

12

3

20

23

13

12

11

9

24

36

35

27

25

19

34

22

26

16

21

39

7

12

17

12

11

18

19

3

28

40

29

38

37

8

12

Combined Parts List

Item Part Name

1 Lens

2 Front Cover

3 Side Cover (by series/model)

4 Top Plate Assembly

5 Strain Relief

6 Cord & Plug Assembly

7 Component Panel (by series/model)

8 Bottom Cover

9 Screw, #8 x .75 Phil Hx Hd/W Sf Tap

10 Screw, #8 x .62 Phil Pan Hd/W Sf Tap

11 Screw, #8 x .50 Slt Hx Hd/W Sf Tap

12 Screw, #8 x .38 Slt Hx Hd/W Sf Tap

13 Light Socket (by ser ies/model)

14 Terminal Block & Lug

15 M.O.V. Assembly

16 Receiver Assembly

17 Limit Set Switch

18 Sequencer Assembly

19 Screw, #6 x .38 Slt Hx Hd/W Sf Tap

20 Transformer Assembly (by s eries/model)

33

26

32

31

Item Part Name

21 Rectifier Board Assembly

22 Fuse (F1), UL

23 Fuse (F2), UL

24 Limit Gear Shroud

25 Motor Bracket

26 Screw, #10 x 3/8”HH

27 Limit Plate/Pin Assembly

28 Limit Switch

29 Screw,#4 40 x 5/8”Slot HH w/Wshr,Sf Tap

30 Motor Assembly

31 Motor Adapter Plate

32 Screw, 1/4"-20 x 1/2”Slt HH w/Wshr

33 Limit Worm Gear

34 Limit Gear Bushing

35 Limit Worm Drive

36 Limit Worm Shim

37 Limit Wheel

38 Retaining Ring

39 Limit Cam

40 Limit Pinion, 8 tooth

26

30

Item Part Name

41 Capacitor

42 Capacitor Clamp

43 Screw, #10-24 x 1/2”, Slot HH Sf-Tap

44 Nut, #10-32, Hex Se r r ated Flange

45 Circuit Board

46 C.B. Bracket

47 Circuit Board Mount

48 Screw, #10-16 x 5/8”, HH Sf Tap

49 Top Gear Housing

50 Middle Gear Housing

51 Bottom Gear Housing

52 Drive Shaft Bushing

53 Drive Thrust Washer

54 Drive Shaft

55 1/2”Retaining Ring

56 Main Drive Worm Gear

57 Optical Interrupt Wheel

58 Motor Flanged Bushing

59 Motor Thrust Washer

60 Poly Thrust W asher

Page 7

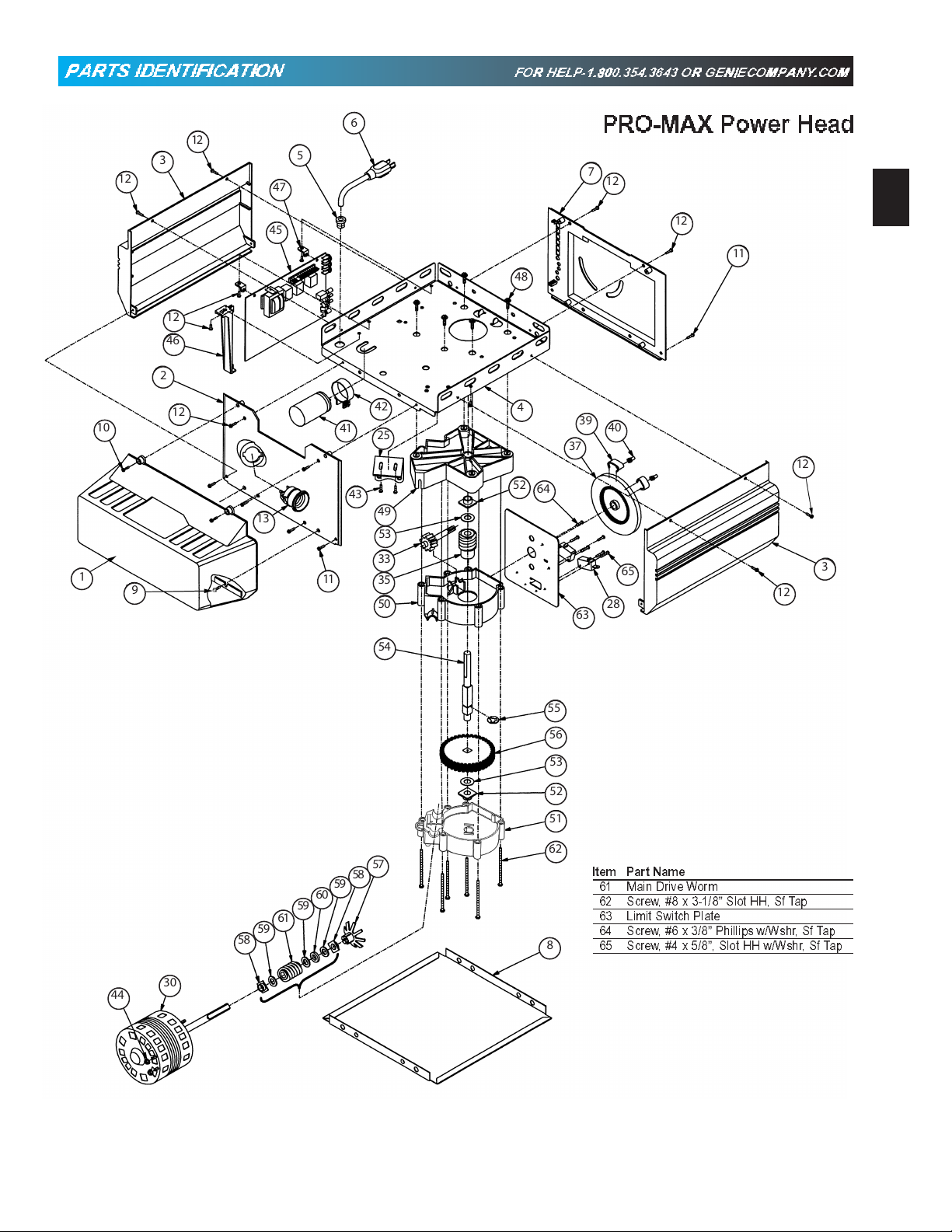

PARRTSS IDDENTIFFIICAATIIOON

P

FORR HEELP-1..88000.3544.33643 ORR GENNIIECOMMPPAANNY..COMM

12

6

12

3

5

47

P RO- MAX Power Head

7

12

7

45

48

12

46

2

12

10

13

1

9

11

42

41

25

43

49

53

33

35

50

52

4

64

39

40

37

65

28

63

12

11

12

3

12

44

30

54

55

56

53

52

51

57

58

59

60

59

61

59

58

62

8

Item Part Name

61 Main Drive Worm

62 Screw, #8 x 3-1/8”Slot HH, Sf Tap

63 Limit Switch Plate

64 Screw, #6 x 3/8”Phillips w/Wshr, Sf Tap

65 Screw, #4 x 5/8”, Slot HH w/Wshr, Sf Tap

Page 8

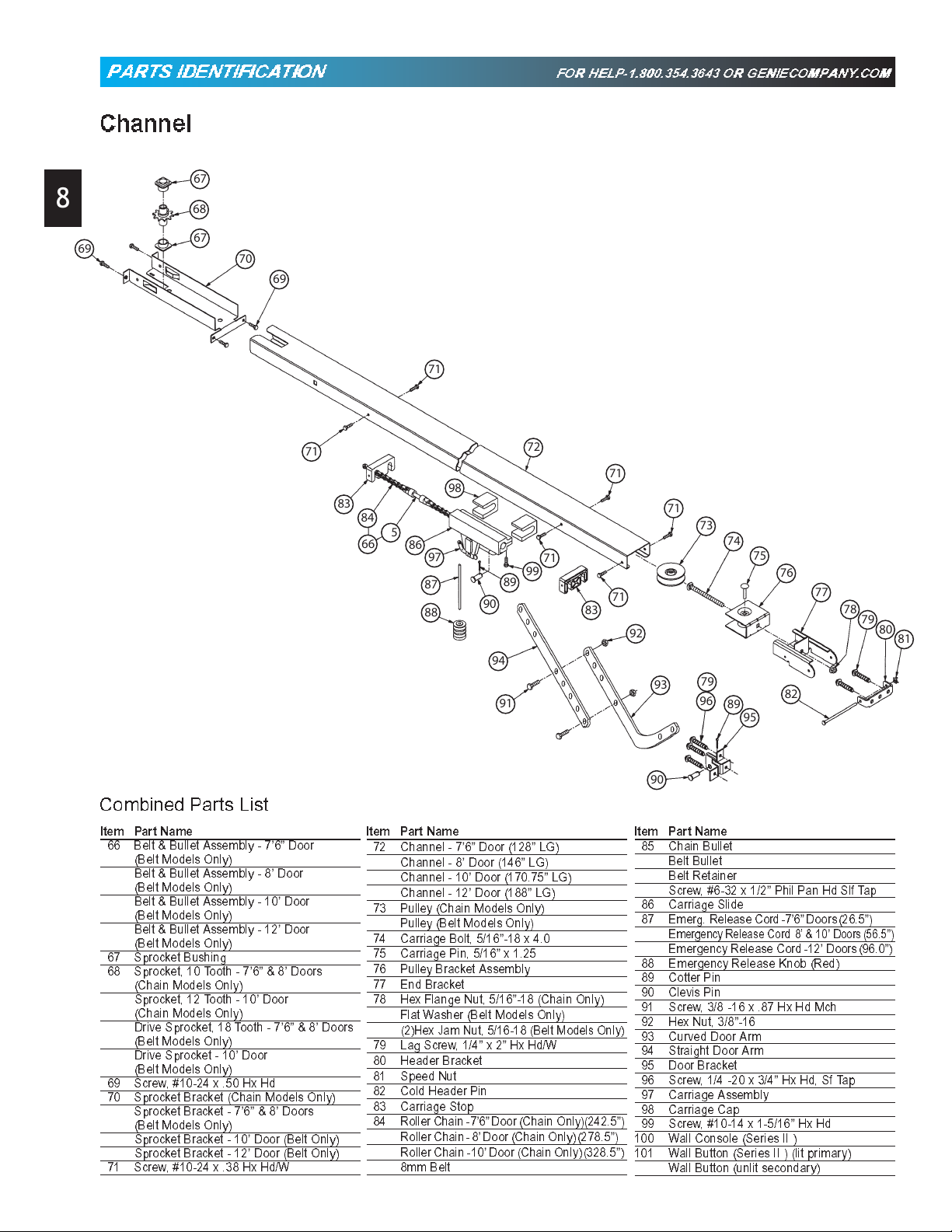

8

PARRTSS IDDENTIFFIICAATIIOON

P

Channel

67

68

FORR HEELP-1..88000.3544.33643 ORR GENNIIECOMMPPAANNY..COMM

69

67

70

69

71

83

84

66

85

86

87

88

71

97

98

90

94

91

89

99

72

71

83

71

71

92

93

71

96

73

79

74

89

95

75

76

82

77

78

79

80

81

Combined Parts List

Item Part Name

66 Belt & Bullet Assembly - 7’6”Door

(Belt Models Only)

Belt & Bullet Assembly - 8’Door

(Belt Models Only)

Belt & Bullet Assembly - 10’Door

(Belt Models Only)

Belt & Bullet Assembly - 12’Door

(Belt Models Only)

67 Sprocket Bushing

68 Sprocket, 10 Tooth - 7’6”& 8’Doors

(Chain Models Only)

Sprocket, 12 Tooth - 10’Door

(Chain Models Only)

Drive Sprocket, 18 Tooth - 7’6”& 8’Doors

(Belt Models Only)

Drive Sprocket - 10’Door

(Belt Models Only)

69 Screw, #10-24 x .50 Hx Hd

70 Sprocket Bracket (Chain Models Only)

Sprocket Bracket - 7’6”& 8’Doors

(Belt Models Only)

Sprocket Bracket - 10’Door (Belt Only)

Sprocket Bracket - 12’Door (Belt Only)

71 Screw, #10-24 x .38 Hx Hd/W

Item Part Name

72 Channel - 7’6”Door (128”LG)

Channel - 8’Door (146”LG)

Channel - 10’Door (170.75”LG)

Channel - 12’Door (188”LG)

73 Pulley (Chain Models Only)

Pulley (Belt Models Only)

74 Carriage Bolt, 5/16”-18 x 4.0

75 Carriage Pin, 5/16”x 1.25

76 Pulley Bracket Assembly

77 End Bracket

78 Hex Flange Nut, 5/16”-18 (Chain Only)

Flat Washer (Belt Models Only)

(2)Hex Jam Nut, 5/16-18 (Belt Models Only)

79 Lag Screw, 1/4”x 2”Hx Hd/W

80 Header Bracket

81 Speed Nut

82 Cold Header Pin

83 Carriage Stop

84

Roller Chain -7’6”Door (Chain Only)(242.5”)

Roller Chain - 8’Door (Chain Only)(278.5”)

Roller Chain -10’Door (Chain Only)(328.5”)

8mm Belt

90

Item Part Name

85 Chain Bullet

Belt Bullet

Belt Retainer

Screw, #6-32 x 1/2”Phil Pan Hd Slf Tap

86 Carriage Slide

87

Emerg. Release Cord-7’6”Doors(26.5”)

Emergency Release Cord 8’ & 10’Doors (56.5”)

Emergency Release Cord -12’Doors(96.0”)

88 Emergency Release Knob (Red)

89 Cotter Pin

90 Clevis Pin

91 Screw, 3/8”-16 x .87 Hx Hd Mch

92 Hex Nut, 3/8”-16

93 Curved Door Arm

94 Straight Door Arm

95 Door Bracket

96 Screw, 1/4”-20 x 3/4”Hx Hd, Sf Tap

97 Carriage Assembly

98 Carriage Cap

99 Screw, #10-14 x 1-5/16”Hx Hd

100 Wall Console (Ser ies II )

101 Wall Button (Ser ies II ) (lit primary)

Wall Button (unlit secondary)

Page 9

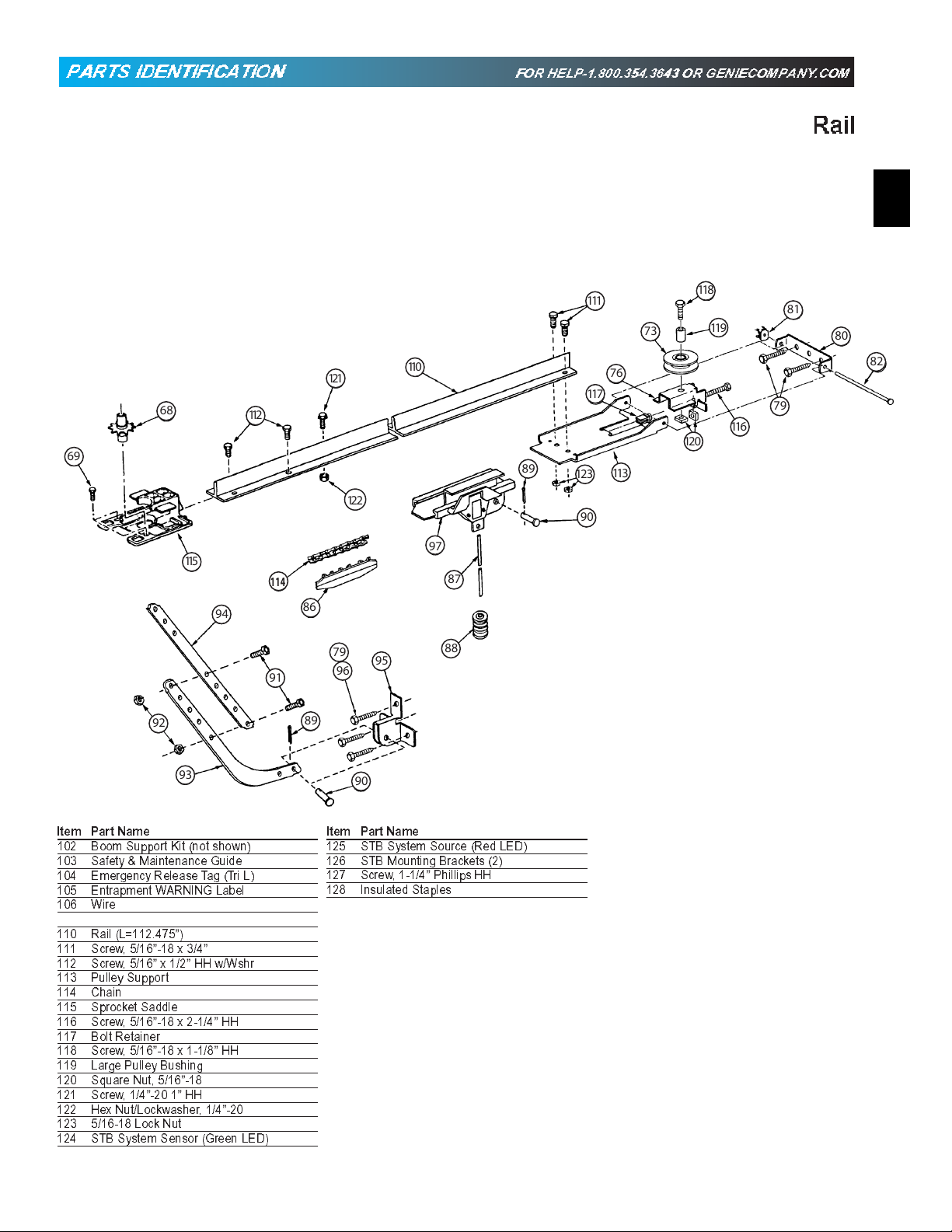

PAARTS IDEENTTIFICCATIONN

FFOOR HELP--1.800..3554.364433 OOR GENIEECOOMPANY.COOM

Rail

9

69

92

68

12 0

118

119

81

80

82

79

116

111

73

121

112

122

115

114

91

86

79

96

89

94

110

89

97

87

88

95

123

90

76

117

113

93

Item Part Name

102 Boom Support Kit (not shown)

103 Safety & Maintenance Guide

104 Emergency Release Tag (Tri L)

105 Entrapment WARNING Label

106 Wire

110 Rail (L=112.475”)

111 Screw, 5/16”-18 x 3/4

112 Screw, 5/16”x 1/2”HH w/Wshr

113 Pulley Support

114 Chain

115 Sprocket Saddle

116 Screw, 5/16”-18 x 2-1/4”HH

117 Bolt Retainer

118 Screw, 5/16”-18 x 1-1/8”HH

119 Large Pulley Bushing

120 Square Nut, 5/16”-18

121 Screw, 1/4”-20 1”HH

122 Hex Nut/Lockwasher, 1/4”-20

123 5/16-18 Lock Nut

124 STB System Sensor (Green LED)

”

90

Item Part Name

125 STB System Source (Red LED)

126 STB Mounting Brackets (2)

127 Screw, 1-1/4”Phillips HH

128 Insulated Staples

Page 10

..

11

.........

OOOPPEERRRRAAAATTTOOORR AAAASSSSSSEEMMMMBBLLYYY

FFOOR HELP--1.800..3554.364433 OOR GENIEECOOMPANY.COOM

10

OPEN BLUE PARTS BAG

Screws for attaching light cover are included in this

1. Attach emergency release knob cord (Fi g . 1-1).

•

•

•

•

Do Not

2. Attach emergency release tag (Fig. 1-1).

•

•

PLEASE NOTE THE ASSEMBLY PROCEDURES

ARE DIFFERENT FOR RAIL AND CHANNEL. BE

SURE T O FOLLOW THE APPLICABLE STEPS.

CCCCHHAANNNNNNEEEELL &&& PPPPOOOOWWWWEERRR HHHHEEAADD AASSSSSSSSEEEMMBBLLLLYY

Do Not

operator is fully assembled and attached to the door.

bag. Please set aside for use later.

Tie overhand knot in end of cord.

Thread cord through knob so knot is inside knob.

Thread cord through hole in carriage lever.

Tie overhand knot in other end of cord.

cut cord until after power head is mounted.

Thread wire through hole in carriage lever.

Wrap wire around itself, tie securely.

Y

CA UTION

attempt to run power head or to set limits until

Carriage

Emergency

Release

Tag

Hex Head Screws

[69]

Toward Door Towa rd Power Head

Emergency

Release

Cord

Emergency

Release

Knob

Fig. 1-1

“D”

-Shaft and Hole

3. Pl ace power head and channel on clean , flat surface.

4. Slide drive end of channel down over “D”-shaft on top of

p

ower head (Fig. 1-2).

•

Support header end of channel level with power head.

•

Slide carriage to align “D”-shaft with “D”-hole in sprocket.

•

Slide channel down “D”-shaft flush with power head.

5. Fasten c

•

•

NOOTTEE:: CChain iinnnnerr-sslidee oor bbeelltt buullett sshoouuld rremmaainn at

mid--traavel when aasssemblingg to power hheeaad to providee ppropeer

trraveel whhenn setttiinng lliimmiitts.

hannel to power head .

Align mounting holes in front and rear of power head frame.

Insert and securely tighten the four (4) No.10 x 1/2”hex

head scre

ws [69].

RRAIL && PPOOWEERR HHEEAAD ASSEMBLY

CA UTION

Do Not

operator is fully assembled and attached to the door.

3. Place power head and rail on clean, flat surface.

4. Slide drive end of rail down over “D”-shaft on top

attempt to run power head or to set limits until

o

f power head (Fig. 1-3).

•

Support header end of rail level with power head.

•

Slide carriage enough to align “D”-shaft with “D”-hole

in sproc

•

Slide rail down “D”-shaft flush with power head.

d

ket.

rags on the rail

5/16”x 1/2”Hex Head Screws

[

]

112

Carriage Stop

Fig. 1-2

[69]

No. 10 x 1/2”Hex Head Screw

No. 10-24 x 1/2”Hex Head Screws

[69]

Sprocket Saddle

Fig. 1-3

[

]

112

“D”

-Shaft and Hole

5/16”x 1/2”Hex Head Washer Screw

Page 11

5. Fasten rail to power head.

•

Align mounting holes of sprocket saddle, rail

a

nd power head frame.

• Insert the two (2) 5/16”x 1/2”hex head

s

crews[112], then two (2) No. 10-24 x 1/2”hex

head scre

•

Tighten screws.

ws [69].

NNOOTE: Innerr--ssliddee/bulllet shhoouulld remaiin att miidd--ttrraavel

wwhenn aasseembliing to powerr hheeadd tto pprroovvide pprrooppeer

ttrraaveel whheen settttiing limiitss.

6. Use adjusting bolt to set chain tension (Fig. 1-4)

•

Chain should sag slightly but not so much that it

d

rags on the rail.

OPEN ORANGE PARTS BAG

INSTTALLAATTIONN

...

2

I

2

IMPORTANT

INSTALLATION

INSTRUCTIONS

::

WWWWAAAARRRNNNIIINNGG

GG

::

To reduce the risk of

Adjusting

Bolt

Fig. 1-4

FOR HHEELLPP-1..8000.354..36643 OR GGENIECOMMPAANY.COMM

WWHHAAAATTT TTYYYPPPPEE OOOFF DDOOOOOORR DDDDOO YYOOOOUU HHAAVVVEE?

?

LLooooookk aatt tttthhee ddrrrraaawwwwiiinnnnggss bbeeeelllloooww.. TThheeeeyyy tttteelllllll yyyyoooouu wwhhheeerrrre

ttooo ffiinndddd tthheee iinnnnssttaallllaattiioonnnn iinnssttrrrruuuuccttiioonnnnss yyoouu nneeeed

Track Guided Doors

SEE SECTION 2A

Section Door With

Curved Track Hardware

1-Piece Door With

Horizontal Tr ack Hardwar e

d

11

e

severe injury or death:

1. READ AND FOLLOW ALL SAFETY,INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

improperly balanced door c

and adjustments to cables, spring assembly, and other

hardware must be made by a trained service person using

proper tools and instructions.

3. Remove all ropes and disable all locks connected to the

do

or before installing operator.

4. Install door oper

the emergency release knob 6 feet above the floor.

5. Do Not connect the operator to the source of power until

instr

ucted to do so.

6. Locate the control button:

• Within sight of door

• At a minimum height of 5 feet, so small children cannot

reach it.

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall

butt

on or console. Install the emergency release tag on, or

next to, the emergency release.

8. The opera

inch high object on the floor at the center of the doorway.

This is about the size of a 2” x 4” board laid flat.

ator 7 feet or more above the floor. Mount

tor must reverse when the door contacts a 1-1/2

ould cause severe injury.Repairs

.

Curved

ack

Tr

with

Vertical

Section

1-Piece Door

Jamb Type Hardware

(No Tr ack)

“H”

DOTTED LINE AT “H

INDICA TE S HIGHEST

POINT OF TRAV EL

Trackless Doors

SEE SECTION 2

“H”

“H”

B.

1-Piece Door

Pivot Type Hardware

Straight T rack

(Horizontal Only)

”

(No Track)

“H”

Page 12

12

AAlltteernatee Mouuntingg Meethodds

NOTE:

Materials for mounting are not included

Angle Iron Method Conduit Method

FFORR TRRAACCKK GUUIIDDEED DDOOORRSS

...

AA

2222AA

– FOR TRACKLESS DOORS GO TO PA GE 15 –

W ARNING

•

Do Not try to remove, repair or adjust

springs or anything to which door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made by

a trained service person using proper tools

and instructions.

•

Handles and other door projections can

catch clothing. Remov

hangers, decorative or security items

mounted to door.

•

Be sure Emergency Release Cor

catch on roof carrier or other vehicle parts.

e ropes, hooks,

d does not

Line“V

(Vertical Center Line

”

of Door)

Door

Header

Fig. 2-1

Line“H”Can Be

Drawn Above

Spring

Line“H

”

Inside of Door

Establish center line of door and header (Fig. 2-1).

1.

•

Close door.

•

Measure door width. Mark ce n t e r.

•

Use straight edge to draw ve

–

down door about 6”.

–

on top of door.

–

up header about 20”.

r tical line “V.

”

2. Establish Header Bracket position (Fig. 2-2).

•

Watch top edge of door as you raise it.

•

Stop door when top edge reaches highest point

avel.

of tr

•

Measure distance from top edge of door to floor.

•

Add 2-1/2”to this measurement.

•

Close door.

•

Mark header at this height.

•

If door spring is in the way

, mark header 2-1/2

”

above the spring.

•

Draw horizontal line “H”across line “V”at this

point (Fig 2-1).

NOTE: Heaaderr bbrraackket muusst be att lleaast 2--11/2”abovee

high poinntt of door travvel.. IIt cann bbee insttaalleed higherr iiff

door spprriing is iin the waay.. Doo NNott moovve the ssprinngg..

Mark

Header

Here

Or

Above

Spring

Header

Door

NOTE: Line “H”Can Be

Drawn Above Spring

Spring

Fig. 2-2

Line “H

”

Add 2-1/2

Minimum

Measure To Floor

”

High Point

Of Door Travel

Door Track

Page 13

CA UTION

Header brack

framing. Do Not fasten to drywall, particle

board, plaster or other such materials.

3. Install header bracket (Fig. 2-3)

•

Place bracket so:

–

center hole is on line “V.

–

all holes are on line “H.

•

Mark hole positions “A”and “B.

•

Drill 5/32”holes at marked positions.

•

Fasten bracket to header using two (2) 1/4”x 2

lag screws [79].

4. Attach channel/rail assembly to header

racket (Fig. 2-4).

b

•

Fasten header end of the channel/rail to the

eader bracket with cold header pin [82].

H

•

Install speed nut [81].

•

Support power head above floor, use:

–

rope.

–

ladder with cardboard packing.

–

wood.

5. Level rail assembly and pow e r head (Fig. 2-5).

•

Raise and suppor t power head above door tracks .

•

Open door.

•

Level channel/rail assembly and

upport temporarily.

s

•

Center channel/rail assembly and power head

on line “V”of door.

NNNNOOTTTEEE:: TThhee ccchhaannnneelll//rraaaaiill aaaassssseemmbbblllyy aannnndddd pppooowwweerrrr hhhheeeaadd

sssshhoouulldd bbee lleevvvveell iiiff ppoossssiibblleee.. IIffff nneeecceessssssaaaarryy,, pppooowwweerr

hhhheeeeaaddd mmmmaaaayy bbbbeeee mmoouunntteeddd lllloowweerrrr.... HHoowweevvvveerr mmmmoooouuuunnnntttteeeedd,

mmmmooovvviinnnggg dddoooooorrr mmmmuuuusssstt nnoott ttooouuuccchh cchhhhaaaannnneelll///rraaiiiill aasssssseemmbbllyy..

et must be fastened to garage

”

”

”

”

dd

rr

,

Line “V

Line“H

”

“A”

”

“B”

Header Bracket

13

Ve rtical

Centerline

of Door

Fig. 2-3

T-rail shown. Channel

attachment is same.

Speed nut

Header

Bracket

Header

[81]

Spring

..

Lag Screws

[82]

Cold header

pin

[79]

CA UTION

Mounting bracket must be fastened to garage

framing.

plaster or other such mater

Do Not

fasten to drywall, particle board,

ials.

6. Mount power head

(See Section 2 MOUNTING METHODS).

•

Be sure channel/rail assembly and power head

are on door center line (Line “V”).

•

Check the illustrations. Decide which mounting

ethod you will use. Materials for mounting are

m

not included.

•

After power head is installed, remove

upporting material.

s

•

Close door.

7. Install door braces (See CAUTION below).

CA UTION

Doors made of masonite, lightweight wood, fiber-

glass, and metal must be properly b r aced before

mounting Door Operator.

Contact door manufacturer o r distributor for bracing

instructions.

Door

Channel/Rail

Assembly

Support if

necessar

clear spring

y to

Fig. 2-4

Fig. 2-5

Power Head

Center Line

Page 14

Top of Door

orte

“V”

Top of Door

de la or t

“V”

“V”

Top of Door

OR

14

“V”

[96]

[96]

Sectional doors

8. Install door brack et (Fi g. 2-6).

•

Contact door manufacturer.

NOOTE: Sellf-ddrrilliing screwss arree intennddeed for use wwith

lliigggghhhhtttt--wweeeeiigghhtt ddoooorr oonnllyyyy,, wwhhhhiiiillee llllaagg ssccccrreewwwwss aarrreee mmeeaaaannt

for wood doors oonnlly.

BBecauusse ddoooorr desiigns vvarryy, mooddiifiicaations mmaay

be reequiredd and adddditionall matteerials nneeeddeed. Plleasse

contacct your door mmaanufacttuurreer witthh aany questions

concerninngg yyour doorr..

[79]

t

OPEN YELLOW P ARTS BAG

Fig. 2-6

“V”

[79]

[96]

One-piece doors

1/4”-20 x 3/4”Self-Drilling Screw

1/4”x 2”Lag Screw

14”MIN.

Clevis pin

Cotter pin

[90]

[89]

“V”

[79]

[96]

[79]

9. Install door arms (Fig. 2-7).

•

Attach straight door arm to carriage.

–

slip straight door arm into slot at bottom of

c

arriage as shown.

–

secure with clevis pin [90] and cotter pin [89] .

•

Attach short end of cur

ved door arm to door

bracket as shown.

–

slip short end of curv

ed door arm into slot in

door bracket.

–

secure with clevis pin and cotter pin.

•

Release carriage (See emergency release tag).

–

slide carriage tow

–

stop carriage 14”minimum from door.

ards closed door.

10. Join door arm sections (Fig. 2-8).

•

Use two (2) 3/8”x 7/8”hex bolts [91], and he

flange nuts [92].

–

use any two holes as far apart as possible.

–

slide carriage back and forth as needed to

align holes

•

Tighten hex

.

nuts securely.

11. Adjust emergency release cord length.

•

Mount the emergency release knob 6 feet from

the floor.

•

Retie overhand knot and trim exces s cord.

DO NOT plug power cord into outlet.

Go to Section 3-SAFE-T

-BEAM

®

SYSTEM INSTALLATION.

– PROCEED TO PAGE 18 –

x

Clevis pin

[90]

Cotter pin

[89]

Curved door arm

[91]

Bolt,

3/8-16 x 7/8”

Nut, 3/8-16

[92]

Curved door arm

Fig. 2-7

Straight door arm

Fig. 2-8

[91]

Bolt, 3/8”-16 x 7/8

Straight door arm

[92]

3/8-16 nut

”

Page 15

22BB

.

.....

FFFFOORRRR TTRRAACCKKLLEEEESSSSS DDDOOOORRS

S

W ARNING

•

Do Not

a

such as, wood blocks, steel br ackets, cables or

other like items.

Repairs and adjustments must be made by a

trained service person using proper tools

and instructions.

•

Handles and other door projections can catch

lothing. Remove ropes, hooks, hangers,

c

decorative or sec urity items mounted to door.

•

Be sure emergency release cord does not catch

o

Establish center line of door and header (Fig. 2-9).

1.

•

•

•

2. Determine door rise (Fig. 2-10).

•

•

•

TABLE A

try to remove, repair or adjust springs or

nything to which door spring par ts are fastened,

n roof carrier or other vehicle parts.

Close door.

Measure door width. Mark ce n t e r.

Use straight edge to dra

–

down door about 6.

–

on top of door.

–

up header about 20”.

”

w ver tical line “V.

”

Open door to highest point of travel.

Measure distance from top of door to floor.

Subtract the actual height of door.The remainder

is the door rise in inches as shown in TABLE A.

Door rise Locate header bracket above

in inches top edge of CLOSED door

Line“V

(Vertical centerline of door)

Door header

Door rise

”

Line “H

Highest point

of travel

”

Inside of door

Fig. 2-9

Highest point

of travel

See

T

ABLE A

Top of door

Door rise

15

Up to 4

4”to 8

8”to 12

”

”

”

Up to 10

10”to 15

15”to 20

”

”

”

3. Locate header bracket (Fi g . 2-9).

•

Use TABL E A to determine header

racket position.

b

•

Draw horizontal line “H”across line “H”at

this point.

CA UTION

Header bracket must be fastened to garage

framing. Do Not fasten to drywall, particle board,

plaster or other such materials.

4. Install header bracket (Fig. 2-11).

•

Place header bracket so,

–

center hole is on line “V.

–

all holes are on line “H.

•

Mark hole positions (“A”and “B”).

•

Drill 5/32”holes at marked positions.

•

Fasten header bracket to header with two (2)

1/4”x 2”lag screws [79].

”

”

Line“H

Line “V

”

“A”

”

ertical centerline

V

of door

Floor Floor

Fig. 2-10

“B”

Header bracket

Lag screws

Fig. 2-11

[79]

Page 16

16

5. Install door braces

See CAUTION below).

(

Top of Door

CA UTION

de la rte

Doors made of masonite,

lightweight wood, fiberglass,

and metal must be properly

braced before mounting

an operator.

Contact door manufacturer

[96]

or distributor for

bracing instructions.

6. Install door bracket (Fig. 2-12).

•

Contact door manufacturer for proper installation.

NOOTE: Sellf-ddrriilliing scrrewss arree intennddeed for use wwith

ligghhtt-weeight door onlyy, whhiile llag sccrewws arree meaant

foorr wood doors oonnlly.

BBecauusse ddoooorr desiigns vvaryy, modiiffiicaatiions mmaay

be reequiredd aand addddiitionall matteerials nneeeddeed. Plleasse

contacct your door maanufaacttuurreer witthh aany quesstions

concerninngg yyour door..

7. Attach channel/rail assembly to h ea de r

bracket (Fig. 2-13).

•

Fasten header end of the channel/rail to the

eader bracket with pin.

h

•

Install speed nut onto pin (Fig, 2-14).

•

Place cardboard packing under power head. Use

additional support if needed.

Establish power head mounting height (Fig. 2-15).

8.

•

Power head should be at door height above floor

or higher.

mporarily support power head in this position.

•

Te

Use

–

rope.

–

ladder with cardboard packing.

–

wood.

Same arrangement applies

to channel (not shown)

“V”

“V”

[79]

Header bracket

Header

Door

br ket

OR

Door

bracket

Door

“V”

Top of Door

“V”

[96]

Fig. 2-12

Channel

Rail

Power head

(

Protected by cardboard

or packing)

Fig. 2-13

[79]

[81]

Speed

nut

[82]

Pin

Fig. 2-14

Critical height is point where the rail/channel attaches to power head.

r

Door height

Fig. 2-15

CORRECT

WRONG

Page 17

OPEN YELLOW P ARTS BAG

Str

fr Do Not fasten to drywall, particle board,

9. Mount po TERNATE

MOUNTING METHODS).

•

•

•

•

10. xactly as shown (Fig. 2-16).

•

•

•

11. Install assemb 2-17).

•

•

•

d_39905_38124_14.0

•

CA UTION

ket m ge

Be sure rail assembly and power head are on

door center line (line “V”).

Check the illustrations. Decide which mounting

ethod you will use. Materials for mounting are

m

not included.

After power head is installed, remove

upporting material.

s

Close door.

Overlap arms by two (2) holes.

Install two (2) 3/8”x 7/8”hex bolts, and hex

flange nuts.

Tighten hex nuts securely.

Attach straight end of assembled door arms to

door br

–

–

Release carriage (See emergency release tag).

Slide carriage toward door.

Attach short end of curved door ar

–

–

acket.

slip straight door arm into slot in door bracket.

secure with clevis pin [90] and cotter pin [89].

m to carriage.

slip curved door arm into slot in carriage.

secure with clevis pin and cotter pin.

3/8-16 nut

Clevis pin

[92]

[90]

[89]

Nut, 3/8-16

[92]

Fig. 2-16

Fig. 2-17

[91]

[91]

Bolt, 3/8-16 x 7/8”

Cur

Bolt, 3/8”-16 x 7/8

17

”

NOTE:: WWhheen openniing, door muusst not ppaasss levvell

posiitiion or if yoouu aare not abblle to clloosse tthhe dooorr after

coommppllettinngg pprreeviious stteep; a loonnggeer door arrm is

reqquuiiredd.. Ann eextteensioonn kkit caan be ppuurrcchassedd bbyy

caalliing the CCusttoommeer Seerviicce pphhoonnee number,

1..8000..3554..3643.

12. Adjust emergenc d length.

•

Mount the emergency release knob 6 feet from

the floor.

•

Retie overhand knot and trim exces s cord.

[90]

[89]

Clevis pin

Cotter pin

Page 18

SUN

ONE DOOR

GARAGE

THREE DOOR

GARAGE

RED

LED

RED

LED

GREEN

LED

RED

LED

GREEN

LED

GREEN

LED

GREEN

LED

RED

LED

RED

LED

RED

LED

GREEN

LED

GREEN

LED

TWO DOOR

GARAGE

18

SSAFE--TT--BBEEAAMM®IINNSSTAALLLAATTIONN

...

3

33

W ARNING

e-T -Beam®System

I

f you have plugged in the po d

—UNPLUG IT NOW.

NNNNOOTTTTEEEE::: TTTThhhheeee ooppeerrraaaattoorrr wwiilllllll nnoott cclloooossssee ttthhee dddooooooorrrr

aautomaticcalllly uunnllesss the SSaafe--T-Beaam

iis innsstalllledd..

1. kets

•

Mark both sides of garage door frame or wall 5

above floor

•

Hold bracket against door frame or wall.

–

Check if brackets extend out from wall far

enough, so tongue of br

.

(Fig. 3-1)

.

acket is beyond door,

tracks or any door hardware.

–

If not:

a

. STB bracket extensions are available at

local dealer.

b. Blocks of wood, etc. may be substituted

for extensions.

•

Center bracket on your mark

•

Fasten each with 2 screws [

[

127

]

#10-16 x 1-1/4

(Fig. 3-2)

].

127

®

Syystemm

S

FOR HEELPP-1..8000.354..36643 ORR GENNIECOMMPAANNY..COMM

”

FIG.

.

”

br ket

FIG. 3-2

kets

Attaching STB

(See directions on next page and

.

Figure 3-4 before attaching.)

.

F

IG. 3-3

tongue

’

kets

NOTE: Mountiing bracckettss caan be attttaachedd ttoo tthhee

floor usiing cooncrete aanchors (nnoott pprroovvidedd))..

2. Mounting STB source and sensor

•

If garage has only one garage door.

–

Determine which side of garage r ece ives

most direct sunlight

–

Red LED should always be on sunny side

whenever possible

•

For multiple doors.

–

Preventing crossed signals is critical.

–

Place source and sensor modules on

a

djacent doors facing in opposite directions

(Fig. 3-4)

.

(Fig. 3-4)

(Fig. 3-4)

.

.

.

NOTE:: Too hellp preevennt innterrffereence froom sun, SSTBB

sennssorrs((ggreeen LEED)) mayy bee plaaced ffuurrtherr awwayy

from tthhe ddoooor opening wwherre tthheey willl sspennd morree

timme iin shhadoowws..

•

Slide source/sensor onto tongue of bracket

until it clicks into place

(Fig. 3-3)

.

OPEN RED PARTS BAG

3.

•

•

.

Route wire using either method shown

Securely fasten wires to wall as you go.

–

Use insulated staples (included).

[

]

128

–

Staples should be snug only.

Insulated staple

(Fig. 3-5)

FIG. 3-4 STB locations

Dashed Line = striped wire

Solid Line = white wire

.

Green

Source

A

Sensor

Power

Head

FIG.

Red

B

Green

Source

.

Red

Sensor

Power

Head

.

Page 19

Staples whic

CA UTION

to stop wor When using the insulated

staples, ou fasten them only as tightly

ugly .

•

Make wire attachments at STB’s.

–

Splitting and stripping wire ends to be

wn

connected as sho

–

Loosen terminal screws.

–

Insert wire under flat plate and tighten screw. It

does not matter which wire

goes on which terminal

•

Make wire attachments at power head.

–

oMax

. STB’s are connected to terminals

#2 and #3 on pow

–

erminals #3 and #4 on power head

t

heck the following

4. C

•

Insure that no part of door or its hardw

. STB’s are connected to

path between lenses of

•

Insure that tops of lenses are between 5”-6

above the floor

(Fig. 3-9)

(Fig. 3-6)

er head

.

source

. The brack

, white or striped,

(Fig. 3-7)

(Fig. 3-8)

.

and

.

.

(Fig. 3-8)

are is in

sensor

ets are

.

.

”

Splitting and

flexible and can be adjusted slightly if needed.

NOTE: STB alignment check must be performed

following connection to electrical power (see page 21).

DO NOT PLUG IN YET!

FIG. 3-6

3

4

FIG. 3-8 (Stealth)

Attachments at

po

FIG. 3-7

Attachments

at STB.

.

2

3

FIG. 3-8 (ProMax)

Attachments at

po

top edge of lens between

5”- 6”above floor.

FIG. 3-9 Check lens height

.

19

.

Safe-T-Beam®Alignment Check

After turning the electrical power on, if the

STB’s are not in proper alignment, the red

LED (Source) will blink continuously.

To correct the problem – the brackets are

flexible and can be adjusted slightly to bring

the system into alignment.

When the STB’

will stop blinking and stay on.

STB

SOURCE (RED LED

2 BLINKS, PAUSE (REPEAT )

2 BLINKS, PAUSE (REPEAT )

3 BLINKS, PAUSE (REPEAT )

4 BLINKS, PA

NOTE

DOWN UNTIL DOOR IS CLOSED.(REMOTE CONTROL & WIRELESS KEYPAD WILL NOT WORK WITHOUT STB

SELF-DIAGNOSTIC TROUBLESHOOTING

ON

OFF

OFF

USE (REPEAT)

: IF OPERATING PROBLEM EXISTS, THE DOOR CAN BE CLOSED IF YOU:1. DISCONNECT THE STB SYSTEM FROM THE OPERATOR AND 2. HOLD WALL CONTROL BUTTON

s are in alignment the red LED

)

SENSOR (GREEN LED

ON

OFF

ON

ON

OFF

ON

ON

)

INDICATED CONDITION

NORMAL OPERATION

1.POWER HEAD NOT POWERED

2.WIRING FROM POWER HEAD BAD

1.WIRING TO SOURCE MISSING OR BAD

2.POWER HAS BEEN INTERRUPTED

1.BEAM NOT ALIGNED 2. BEAM OBSTRUCTED

3.SENSOR DEFECTIVE

1.WIRE TO SENSOR MISSING OR BAD

2.SENSOR DEFECTIVE

1.SENSOR RECEIVING INTERFERENCE

1.SOURCE NOT SENDING PULSES

2.SOURCE DEFECTIVE

REQUIRED ACTION

NONE REQUIRED

1.CHECK BREAKERS, FUSES, PLUGS

2.CHECK WIRING FOR OBVIOUS SHORTS

1.CHECK WIRING

2.REMOVE POWER AND REAPPLY

1.CHECK ALIGNMENT 2. CHECK FOR OBSTRUCTION

3.CALL CUSTOMER SERVICE

1.CHECK WIRING

2.CALL CUSTOMER SERVICE

1.

ATTEMPT TO DETERMINE SOURCE OF INTERFERENCE

2.CALL CUSTOMER SERVICE

1.CALL CUSTOMER SERVICE

2.CALL CUSTOMER SERVICE

)

CUSSTOMMEER SERRVIICCEE:: 1..8000.3544.336433 or wwww.ggeenniieccommpaanyy.ccom

Page 20

MORE

OPEN

PUSH

LMITS

TO SET

G4

Y3

2

W1

1

2

3

4

W

B

BW

1

2

3

4

NEC

1

2

3

4

5

6

MORE

FORCE

S

BE

LIM T

SET

OPEN

FOR E

CLO E

FOR E

RAD O

SIG AL

LEA N

CODE

CO

DO N T

USH

L M T S

UN E S

D OR I

A T C E

NO E

U E N Y

SERE CON ROLS

CLOSE

MORE

OPEN

MORE

SE OPEN

IMIT ADJUSTMENT

U S Patent o 5 243 784

5 21 869

1

2

3

W

B

BW

1

2

3

.

44

..........

WWAAAALLLLLL CCOONNNNTTTTRROOLLLL IIIINNSSTTAAALLLLLAAAATTTTIIOON

N

FORR HELP-11.8800.3544.336433 ORR GEENIIECCOMPPANNYY.CCOM

20

W ARNING

Po d must be unplugg ed befor hing

h each other

or

CA UTION

•

Use of an ol will cause the

light not to w

•

to malfunction. Dr

1. om po ol.

•

Place the wall control:

–

In sight of door.

–

At least 5 feet from floor, so small children can

not reach it.

–

Aw

door hardware.

•

Use staples to fasten wire to ceiling and wall.

emove 1/2”insulation from eac

2. R

(Fig. 3-6)

3. Attac 4-1a)

(MAX Fig.

•

Loosen, but Do Not remove screw fr om te rminal.

–

Connect striped wires to terminal “2”on power

head and “B”on wall control.

–

Connect white wire to terminal “1”on power

head and “W”on wall control.

or

.

.

ay from moving parts of door and

(pg. 19).

4-1b).

Rear view of

power head

Front view of

power head

Power head

terminals

ferminals

Power head

terminals

power head

Wall button

Powe r

head

terminals

Fig. 4-1a

Fig. 4-1b

White

Striped

White

Striped

Striped

White

EITHER

Striped

White

Wall console

Back view

OR

Back view

Back view

Back view

Wall

button

terminals

Wall

console

terminals

Wall

button

terminals

Wall

console

terminals

–

Connect striped wires to terminal “1”on power

head and “B”on wall control.

–

Connect white wire to terminal “2”on power

OR

head and “W”on wall control.

4. Mount wall control (Fig. 4-2).

•

Use two pan head screws.

#6 x 1

-1/4

5.

•

Remove protective backing and stick near

NOTE: Additional wall controls are available from your

dealer. ONLY ONE OF YOUR WALL CONTROLS MAY BE

THE LIGHTED TYPE. If you have a lighted wall control, all

your additional controls must be un-lighted. More than one

lighted wall control per operator will cause a malfunction.

all control.

w

•

Use tacks or staples to permanently mount Label.

Make sure everyone reads and follows WARNINGS.

•

Vacation Locking Switch

–

LOCK

–

disables controls after door is completely closed

UNLOCK

allows controls to work normally

Independent Light Control

–

Controls door operator lights from inside garage

–

Energy-Saver shut-off tu rns off light 5 minutes aft e r

door activation

1

4

Fig. 4-3

Lighted Button

2

3

”

ws

Fig. 4-2

–

Shows system is powered

–

Lights when Security Lock

Switch is in UNLOCK position

–

Goes out when Security Lock

Switch is in LOCK position

Door Control Button

–

Open and closes door from

inside garage

Page 21

..

55

.....

CCOONNNNNEECCCTTTT OOOOPPEEEERRAATTOORRR TTOOOO PPPPOOWWWWEEEER

W ARNING

To reduce the risk of electrical shock, this equipment

has a grounding type plug that has a third

(grounding) pin. This plug will only fit into a grounding

type outlet. If the plug does not fit into the outlet,

contact a qualified electrician to install the proper

outlet. Do Not change the plug in any way.The door

operator must be properly grounded to prevent

personal injury and damage to the components.

The ELECTRICAL POWER to the door op e rator

MUST BE TURNED OFF when power head cover is

removed. Electrical power must remain off while mak-

ing electrical connections.

1. Check local building codes.

•

Some building codes require direct wiring to a

ranch circuit. If direct wir ing is NOT required,

b

plug door operator into grounded outlet

(Fig. 6-1)

2. Return to Section 3 for SAFE-T-BEAM

alignment and troubleshooting.

NNOOTTEE::: IIffff ppppeeeerrmmaannnneeeenntt wwiirrrriiiinngg iiss rreeqquuiirrrreeeedd,, hhhaaavvee aaa

pprrooffeessssssiioooonnnnaaaall eelleeccccttrriicciiiiaann iinnnnssssttaallllll cciirrrrcccuuiittt aannnddd wwiirrreeee

ddoooorr ooppeerraattoorr..

.

.

R

®

System

FFOOR HELLP--1.8000.3354.36443 OOR GGENIECOMPANY.COM

Grounded

outlet

Operator

power cord

Fig. 5-1

21

INNSTRRUCTTIONSS FOOR ELEECCTRIICIIAN

PPPPEERRMMAAAANNNNEEEENNTTT WWWWIIIIRRIIINNGGG

1. Disconnect the po wer cord from the branc h

circuit mains.

2. Remove bottom cover from power head.

•

Remove four (4) hex head screws from front

and rear co

•

Slide bottom cover off.

emove existing power cord from power head.

3. R

•

Disconnect three power cord wires.

•

Remove and discard po

•

Remov

•

Install a suitable entrance bushing.

4. Install permanent wiring to power head.

For Stealth—connect permanent wiring to

internal terminal b

•

Connect white supply line to silver ter minal.

•

Connect black supply line to brass terminal.

•

Connect ground wire to green wire location

(GROUND).

For ProMax—connect permanent wiring.

•

Make connections with UL recognized wire nuts.

•

Connect white supply line to white wire.

•

Connect black supply line to b

•

Connect ground wire to g

(GROUND).

•

Wires inside operator are to be a minimum of

6 inches

5. Replace power head bottom cover.

•

Replace and tighten four (4) hex head s crews.

NNOOTTEE::::

CCiirrccccuuiitttt bbbbooaarrrddddsss aarree llliiggghhhhttt sseennssiiiittiivvee..

ccoovveerr iissss oonn ppoowweeeerr hheeaaaadd bbeeffffooorrreeee

vers.

e 7/8”diameter knock-out plug.

.

lock.

wer cord.

lack wire.

reen wire location

ooooppppeerraaaattiioooonnnn.

MMaakkkkee ssuurrrree

.

ee

Page 22

MORE MORE

LMIT ADJUSTMENT

CLO E

O EN

PUSH

LIMTS

TO SET

4

3

2

1

CLASS 2

NEC

OEN

CO E

TO SET

LIMITS

PUSH

NEC

CLASS 2

1

2

3

4

5

6

MORE

FORCE

PUSH

BUT ON

SAF TY

BEAM

LIM T

SET

OPEN

FOR E

CLO E

FOR E

RAD O

SIG AL

LEA N

CODE

COM

DO N T

USH

L M T S

U LE S

D OR I

TT C E

NOTE

U E ONLY W TH

SERE CON ROL

CLOSE

MORE

OPEN

MORE

CLOSE OPEN

IMIT ADJUSTMENT

S Patent No 5 243 784

5 221 869

C

5

6

MORE

FORC

LIMIT

SET

OPEN

FORCE

LOSE

E

SE

NLESS

DOOR IS

ATTACHED

22

..

66

.....

MMAAAAIIIINNNN LLIIIIMMMIITTTT SSSSWWIITTCCCCHHHH SSEEEETTTTTIINNGGSS

SS

W ARNING

Door opens rapidly.

•

Keep path clear.

•

Position ladder to the side of power head so it

s clear of all moving parts of door and

i

operator.

Set door operator so minimum force is needed

to operate door.

FFFFOOOORR HHEELLLPP----11..8800000...3335544..3366444433 OOOORR GGEENNIIEEECCOOMMPPAANNYY..CCOOOM

STEALTH

M

Before star ting main limit switch settings, LOCK car-

riage onto rail assembly (See emerg ency

release tag).

1. Raise the door until the carriage engages with

the inner-slide/bullet.

2. Set “OPEN”limit switch (Fig 6-1).

•

Locate limit set switch on back of power head.

•

Push and hold limit set switch until door moves

to the fully open position.

–

release the limit set switch.

–“

OPEN”limit switch is set.

NNOOTTEE:::: IIffff ddddoooooooorrrr ssssttooppss aannnndddd rrrreeeffuusseeess ttoo mmoovveeee uupp,, aadddjjjuusst

OOPPEEEENN FFOORRRRCCCCEE

“

E

(((SSSSeeee SSeeccccttiioonn 77--FFFOORRCCEE

”

AADDJJJUUSSTTMMEEEENNTTTT)))) aaaanndd tthheenn rreeppeeaatttt sssseettttiinnnngggg lllliimmiitttt ssswwiittttccchh.

t

.

3. Set “CLOSE”limit switch (Fig. 6-1).

•

Push and hold limit set switch until door contacts

he ground and stops.

t

–

release limit set switch.

–“

CLOSE”limit is set.

NOTE:: Iff ddoooorr sstops anndd rrefusees to movee downn,,

addjjustt

CCLLOOSEE FORRCE”((SSeee SSectiion 7--FFOORCEE

“

ADJUUSSTMEENT) annd thenn reppeat seetting llimiit swwittcch.

NOTE:: Do Not ppuussh the liimit seet swiitch aggaain, yyour

liimits aare sset. SSllight addjjusttmeent may bbee neeededd llaterr

Seecttiion 8--FFIINEE LIMIT SSWWITCH ADJJUSTMENTS).

(S

eee S

OR

PRO MAX

Fig. 6-1

Page 23

NEC

CLASS 2

1

2

3

4

5

6

MORE

FORCE

USH

UTT N

AFE Y

EAM

IMIT

ET

PEN

OR

LOS

ORCE

ADIO

IGN L

EARN

ODE

OM

O N T

P SH

L M T

N E S

O R I

A T C E

NOTE

USE O LY W TH

ERE CON RO S

CLOSE

MORE

OPEN

MORE

CLOSE OPEN

LIMIT ADJUSTMENT

U S Pa ent No 5 243 7 4

5 221 869

MO E MORE

LMIT ADJUSTMENT

C OSE

OPEN

PUSH

LIMTS

TO SET

4

3

2

1

CLASS 2

NEC

OPN

CLSE

MORE

FORCE

LIMIT

SET

OPEN

FORCE

CLOSE

FORCE

RADIO

SIGNAL

LEARN

CODE

FOORCEE AADDJJUSTTMEENT

......

77

77

W ARNING

Adjust your door operator so that minimum force

is needed to operate door.

Position ladder to the side of the power head so

that it is clear of all moving parts of th e p ower

head, rail assemb ly a n d d o or.

During the following steps, the motor protector may

pen. Wait about 20 minutes for protector to reset.

o

NNOOTE:

CCLLOOSEED posiitioonn beffoorree starttiing

aaaaddjjuuusstttmmmeenntttt..

1. Adjust the “OPEN”Force (Fig. 7-1).

NNOOTE:: LLiittlee effffoortt isrreequuiired too tturn aadjuusstinng sccreew.

NNOTTE:: Seett minimmum foorce requiireed tto make doooroopen.

2. Adjust the “CLOSE FORCE”(Fig. 7-1).

NNOOTE:: LLiittlee effffoortt isrreequuiired too tturn aadjuusstinng sccreew.

NNOTE: Sett the mminimmuumm foorrcce rreequirreed to makke the

ddoooorr cloosse.. Smalllerr tthhee numberr thhee smmaalller the

ffffoooorrrccee.

Usse wall ccontroll to run ddoooor to the fuullyy

OOPEEN FOORCE

“

.

•

Locate sc rew on back of power head marked

“

OPEN FORCE.

•

Gently turn sc rew counterclockwise until it stops.

•

Operate door using wall control.

•

If door does not completely open, turn “OPEN

”

FORCE”screw clockwise slightly.

•

Activate door using wall control.

•

Repeat force adjustment until door will

completely open.

•

Close door, use wall control.

Use wall

control to run door to the fully OPEN position

before start ing “CLOSE FORCE”adjustment.

•

Locate screw on back of power head marked

“

CLOSE FORCE.

•

Gently turn sc rew counterclockwise until it stops.

•

Operate door using wall control.

•

If door does not completely close, turn “CLOSE

FORCE”screw clockwise slightly

•

Operate door using wall control.

•

Repeat force adjustment until door will

completely close

.

”

.

.

”

FOR HELP-1.800..3554.36433 OR GENIEECCOOMPANY.CCOOM

F

STEALTH

OR

PRO MAX

Fig. 7-1

23

3. (Fig. 7-2)

Fine adjustments for limit switches (see Section 8)

CONT ACT REVERSE

MUST BE completed before starting CONTACT

REVERSE.

•

Open door, use wall control.

•

Place a 2 by 4 board laid flat in center of doorway.

•

Close door.

•

Door

MUST

does not, repeat fine adjustments for down limit

stop and reverse to open position.

switch and “CLOSE FORCE”adjustment until the

oor will reverse to the open position.

d

NNOTTE:: Set miniimuum ffoorce rrequiired tto make ddooor cloose..

If door does not reverse, decrease “CLOSE FORCE

until door reverses.

”

If it

1 1/2”Object

(or a 2 x 4

laid flat)

CONTACT REVERSE

Fig. 7-2

Page 24

N C

C ASS 2

1

2

3

4

5

6

E

U H

U T

A E

E M

I IT

ET

P N

O CE

L

O

N L

E RN

E

OM

OTE:

E E C T O

LO E

ORE

OP N

MO E

CL S

PEN

LI IT ADJUST ENT

5 2 3 7 4

5 21 6

MRE MRE

LMT A J S ME T

LS

N

PSH

L IS

O ST

CA S 2

NC

24

MORE MORE

LMIT ADJUSTMENT

CLOSE

OPEN

PUSH

LMITS

TO SET

4

3

2

1

CLASS 2

NEC

LIMIT ADJUSTMENT

CLOSE

MORE

OPEN

MORE

FINNEE LLIMIITT SSWITTCH ADJUSTTMEENT

....

88

8

During the following steps, the motor protector may

open. Wait about 20 minutes for protector to reset.

1. Adjusting the “OPEN”limit switch (Fig. 8-1).

•

Run door to open position by pushing wall control.

•

Locate curved “OPEN”limit adjustment slot on

ack of power head.

b

•

Look into slot for pinion screw.

•

Insert a screwdriver and turn pinion screw.

–

clockwise to open more.

–

counterclockwise to open less.

2. Test door operator. Use wall control to run

door open and c

lose.

3. Repeat step as necessary t o p r operl y se t

“

OPEN”limit switch.

. Adjust the “CLOSE”limit switch (Fig. 8-1).

4

•

Run door fully closed by pushing wall control.

•

Locate curved “CLOSE”limit adjustment slot on

ack of power head.

b

•

Look into slot for pinion screw.

•

a screwdriver and turn pinion screw.

Insert

–

counterclockwise to close more.

–

clockwise to close less.

5. Test door operator. Use wall control to run doo r

open and cl

ose

6. Repeat step as necessary t o p r operl y se t

“

CLOSE”limit switch

. Perform CONTACT REVERSE

7

FFOOR HELLP--1.8000.3354.36443 OOR GENIEECOMPANY.COOM

Fig. 8-1

Actual picture may vary by model

....

99

RREEMMOOTTEEEE CCCCOOOONNTTRROOLLLS

S

W ARNING

Moving door can cause serious injur y or death

Keep people clear of opening while door is moving.

•

•

Do Not allow children to play with remote controls.

If safety reverse does not work properly:

•

Close door and disconnect operator using

mergency release.

e

•

Do not use door operator or remote controls

•

Refer to door and door operator owner’s

anuals before attempting any repairs

M

NNOOTE: Facttoorryy seets diffffeerent cooddees ffoorr eeach remootte

ccontrol..

RReemote coonnttrroolls wiill nnoott wwork iff SSTTBB

WWhenn pprrooggrraammiinngg remootte control kkeeep att leeasst 24

iinchhees awayy from anntteenna..

1. Program one-button remote (Fig. 9-1)

s mmaalffunctiion

’

•

Locate learn

code button and learn indicator on

power head.

–

On back of power head.

•

Press and release learn code b

power head.

–

LED on power head blinks 2 times per second.

utton on

(continued on next page)

Complete with

One-Button Remote Control*

STEALTH

* Remotes vary depending on model. Your operator will

have one or the other.

Battery

Fig. 9-1

Multi-Button Remote Control*

PRO-MAX

Page 25

M RE ORE

IMT AD US MENT

LOE

OEN

PU H

IMTS

TO SET

CLA S 2

N C

N C

LASS 2

1

2

3

4

5

6

M RE

RC

SH

T O

F T

AM

M T

E

R

O

R

D

A

N

D

M

NO E

UE N W H

SR O O

CLO E

MORE

PEN

ORE

CLOS PEN

LIMIT ADJUSTMENT

US P t t N 5 437 4

52 1 869

•

Press and release a remote control button.

–

LED on power head stops blinking.

•

Press and release same remote button again.

–

LED goes out. Remote is now programmed.

2. Program multi-button remote control

•

Repeat step 1 (“program one-button remote” for

ach button).

e

NOOTE: Eacch butttoonn oonn aa multi-button remote ccontrol

is ffoorr aa differeent ooppeerattoorr..

3. Operate remote control

•

Point remote control at door

–

Door moves

•

Press button again

–

Door stops

•

Press button again

–

Door reverses

NOOTE: Dooorr automattiicallly sstops att eend of open or

cloose cyclee.

4. Erasing all receiver memory

•

Press and hold learn code button on

ower head

p

–

10 seconds or until light goes out

–

Memory is er

•

Program door operator again

•

Press remote control button once within

ased

30 seconds

–

LED on power head stays lit

•

Press remote control button again

–

LED on power head goes out and remote

control is prog

rammed

NOOTE: Iff LEDD bliinkss approoxximatteely 4 timmees ppeer

seccond, pprrooggrraamminngg hhaas sstopped. IIf pprogrammmiing

stops,, reppeeatt above ssteppss.

STEALTH

Learn

code

button

Radio

signal

indicator

Radio

signal

indicator

Learn

code

button

Fig. 9-1

25

PRO-MAX

......

1100

BBAATTTTTTEERRRRYYYY //// VVVVIISSOOOORR CCCLLLIIPPP IIIINNNNSSSSTTAAAALLLLLLAAAATTTTIIOONN

1. Turn remote control upside do w n ( F i g. 10-1)

2. Battery replacement

y powered).

batter

•

Gently push straight IN on tab as shown

(your remote control is

(Fig. 10-1).

–

use ball point pen, coin or small screwdriver.

–

battery co ver snaps open.

•

Install new battery in same position.

–

use A23, 12 Volt battery.

3. Attach visor clip to remote control (Fig. 10-2)

•

Slide visor clip into back of case until it snaps

into place

.

4. Remote control operation

•

Point remote control at the garage door and

ress the bu tton. Door will move.

p

•

Press remote control button again and door

will stop.

•

Press remote con t r o l b utton again and the door

ill move the other way.The door automatically

w

stops at the end of the open or close cycle.

NN

Fig. 10-1

Visor clip

Battery

cover

Battery

–

+

Fig. 10-2

Page 26

11

111111

LIIGHHTT BBUULLB AANNDDLLENNSS IINSSTAALLLAATTIONN

......

FOR HELP-1.800..3554.36433 OR GEENIEECCOOMPANY.CCOOM

F

26

1. Install light bulb(s) into socket(s).

Do Not

•

•

use shor t neck bulb(s).

Use bulb(s) rated for:

–

rough service

–

vibration

–

appliances

100 watt maximum

2. Bend two (2) slotted tabs up.This will activate

the ”living hinge”of the lens (Fig. 11-1).

NNNOOOOTTEE:: TThhee ffoolllllloowwiinnnggg ssstteeeppss uuuussssee tthhee ssssccrrrreeeewwss fffrrrroooommmm tthhhhee

BBBlllluuee PPaaaarrttss BBBBaagggg tthhhhaaaatt wweeerree ssseett aasssiiddddeeee eeaarrlliieeeerr.

.

3. Start two (2) No. 8 x 3/4”hex head screws into

bottom holes of panel (Fig. 11-2).

•

Slide slotted tabs up behind hex head screws.

•

Tighten hex head scre ws .

4. Align lens holes and holes of panel.

•

Insert and tighten a No. 8 x 5/8”pan head

crew into each round lens hole and tighten,

s

NNOOTE: Scrreew hheeads fiit compplleetelly innttoo rreecess ooff

llennss tabb..

Bend tabs up (2)

Slotted tabs

ee

Fig. 11-1

[10]

Pan head

screws

[9]

[10]

Hex head

screws

Fig. 11-2

Hex Head Screw

No. 8 x 3/4

Pan Head

Phillips Screw

No. 8 x 5/8

”

”

Bend tabs up

[9]

Page 27

MAAINNTEENAANNCCEE

FOOR HHELLPP--1.8000.3354.36443 OOR GGENIECOMPANY.COM

MMMMOONNTTHHLLYY MMAAAAIIINNNTTEEENNNNAAAANNCCE

DOOR SPRINGS and DOOR HARDW ARE

•

Do not operate garage door automatically or

anually if springs are broken. CONTACT A

m

PROFESSIONAL FOR SERVICE.

•

Oil door rollers, bearings, and hinges monthly.

se silicone lubricant or light oil.

U

DOOR BALANCE

•

Close door. Pull red emergency release knob

own and toward power head to release door

d

from rail assembly.

•

Raise door manually approximately 3 feet. Door

should sta

DOOR SERVICED BY A PROFESSIONAL.

•

Close door. Pull red emergency release knob to

eattach door t o rail/channel assembly.

r

y in that position. If door moves, HAVE

IMPORTANT

SAFETY INSTRUCTIONS

WARNING

E

CONT A

Safe-T -Beam

CT REVERSE

•

Close door on a 2 by 4 board laid flat on the floor

in the center of the gar

•

Close door by using wall button or remote control.

•

If door fails to reverse on contact with the board,

see Section7-CONTACT REVERSE.

•

If operator still fails, replace operator or HAVE

HE DOOR SERVICED BY A PROFESSIONAL.

T

•

Use self-diagnostic Safe-T-Beam

troubleshooting information to maintain safe

operation.

(See Section3-STB SYSTEM INSTALLATION.)

®

STB SYSTEM

Transmitter Compliance Statement

age doorway.

®

System

27

To reduce the risk of

severe injury or death:

1 READ AND FOLLOW ALL INSTRUCTIONS.

2 Never let children operate or play with the Door

Controls. Keep the Remote Control away

from children.

3 Always keep the moving door in sight and away

from people and objects until the door is completely

closed. NO ONE SHOULD CROSS THE PATH OF

THE MOVING DOOR.

4 NEVER GO UNDER A STOPPED, PARTIALLY

OPEN DOOR.

5 Test Opener monthly. The door MUST reverse on

contact with a 1-1/2" high object (or a 2" x 4" board

laid flat) at the center of the doorway on the floor.

After adjusting either the Force or the Limit of travel,

retest the Door Opener. Failure to adjust the

Opener properly may cause severe injury or death.

6 When possible use the Emergency Release only

when the door is closed. Use caution when using

this Release with the door open. Weak or broken

springs are capable of increasing the r ate of door

closure and increasing the risk of severe injury

or death.

7 KEEP GARAGE DOORS PROPERLY BALANCED.

See Owner's Manual. An improperly balanced door

increases the risk of severe injury or death. Have a

Genie Factory Authorized Dealer make repairs to

cables, spring assemblies, and other hardware.

8

S AVE THESE INSTRUCTIONS

.

Page 28

28

TRROOUBLEESHHOOOTTING GUUIIDE

Use this guide to correct problems with your door

operator. If these solutions

Customer Ser

vice.

do not

work, call

CA UTION

Use only with included SERIES II wall control

U

se of any other wall control can cause the door

to operate unexpectedly and the light not to work.

PROBLEM SOLUTIONS

Operator does not run

from wall control.

Check lock switch on wall console (See section4).

heck the power source.

C

•

Plug a lamp into outlet used for power head. If lamp works, power source is OK. If not, chec k fuse

or circuit break

•

If power is OK:

-

Check connections at power head terminals.

-

Check connections at wall control.

-

Motor protector may be open. Wait about 20 minutes for protector to reset.

er.

FFOOR HELP--1.8000.3354.36443 OOR GENIEECOMPANY.COOM

Door starts for no reason.

Door starts down, then

stops before it’s closed.

Door starts down, t h e n

stops and goes back

Door will only run closed.

Door will only run open.

Remote control has

less than 25 f

operating range.

Door starts up, but

stops before it’s

completely open.

Operator runs, but door

does not move

Operator works fr

control, but not from

remote control.

Noisy operation.

STB System malfunction.