Genie PCG700ML, PCG500ML, H2000, GCG350ML, GCG350L Owner’s Manual

...

il

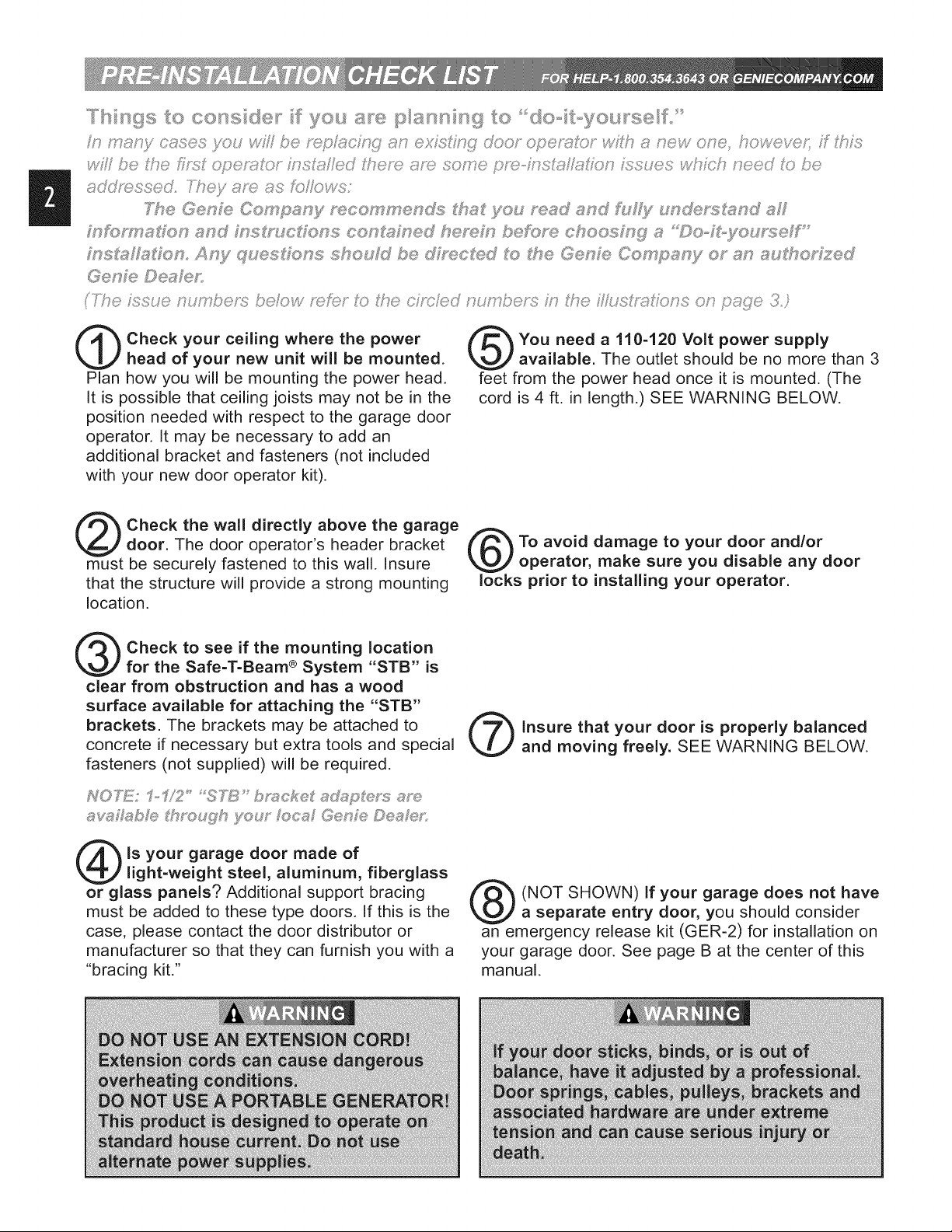

Check your ceiling where the power

head of your new unit will be mounted.

Plan how you will be mounting the power head.

It is possible that ceiling joists may not be in the

position needed with respect to the garage door

operator. It may be necessary to add an

additional bracket and fasteners (not included

with your new door operator kit).

Check the wall directly above the garage

door. The door operator's header bracket

must be securely fastened to this wall. Insure

that the structure will provide a strong mounting

location.

Check to see if the mounting location

for the Safe-T-Beam ® System "STB" is

clear from obstruction and has a wood

surface available for attaching the "STB"

brackets. The brackets may be attached to

concrete if necessary but extra tools and special

fasteners (not supplied) will be required.

You need a 110-120 Volt power supply

available. The outlet should be no more than 3

feet from the power head once it is mounted. (The

cord is 4 ft. in length.) SEE WARNING BELOW.

To avoid damage to your door and/or

operator, make sure you disable any door

locks prior to installing your operator.

Insure that your door is properly balanced

and moving freely. SEE WARNING BELOW.

as<_flsb/@ tthrx>u£h you_" Iota[ Gen/® D®a @,:

Is your garage door made of

light-weight steel, aluminum, fiberglass

or glass panels? Additional support bracing

must be added to these type doors. If this is the

case, please contact the door distributor or

manufacturer so that they can furnish you with a

"bracing kit."

(NOT SHOWN) If your garage does not have

a separate entry door, you should consider

an emergency release kit (GER-2) for installation on

your garage door. See page B at the center of this

manual.

48" POWER

TO

120V GROUNDED

OUTLET

TYPICAL

SUPPORT

BRACKET

EXTENSION

®

@

ADDED

HEADER BRACKET

MOUNTING BOARD

BRACES

OR

TORSION SPRING'

®

SECTmONAL DOOR I-PmECE DOOR

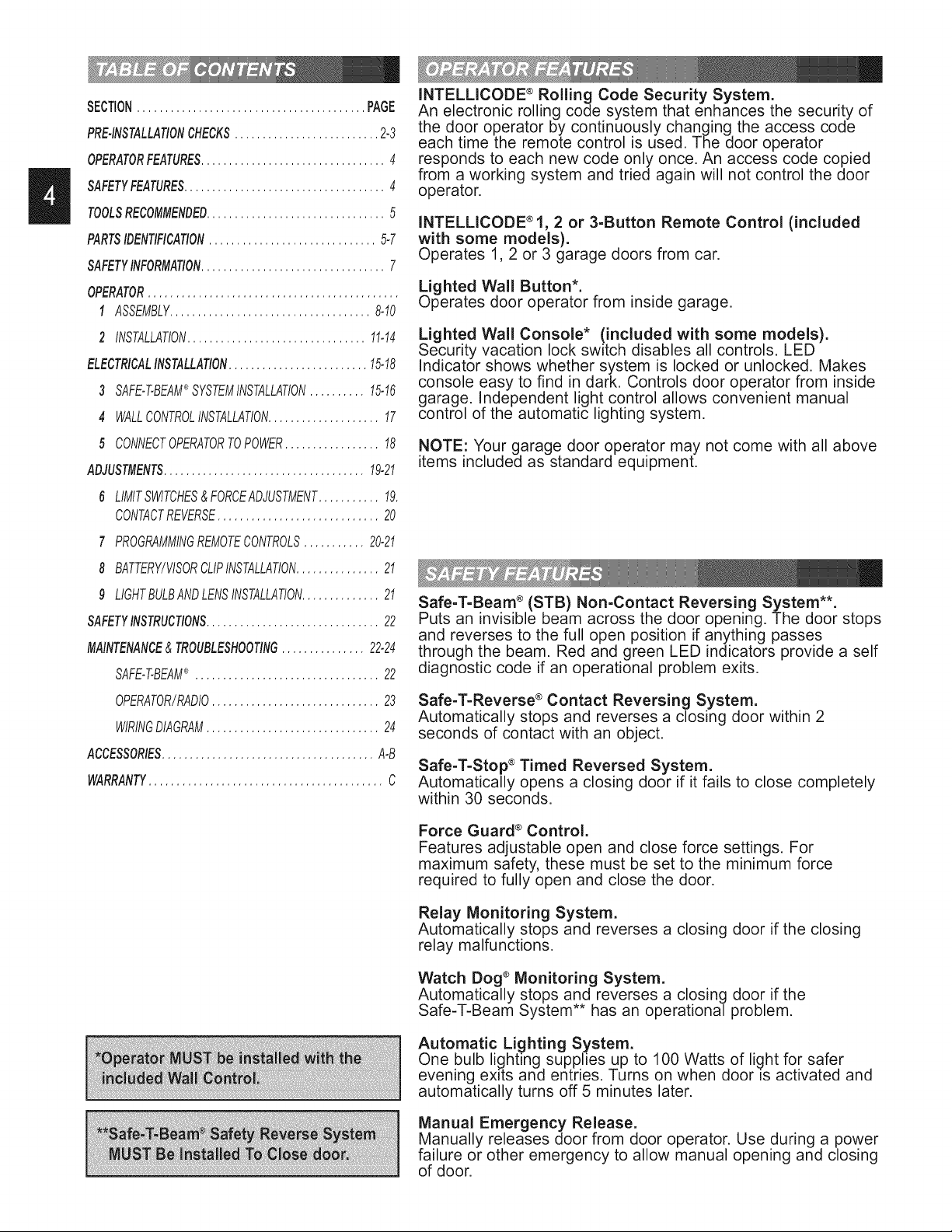

SECTION......................................... PAGE

PRE-INSTALLATIONCHECKS.......................... 2-3

OPERATORFEATURES................................. 4

SAFETYFEATURES.................................... 4

TOOLSRECOMMENDED................................ 5

PARTSIDENTIFICATION.............................. 5-7

SAFETYINFORMATION................................. 7

OPERATOR.............................................

1 ASSEMBLY.................................... 8-10

2 INSTALLATION................................ 11-14

ELECTRICALINSTALLATION......................... 15-18

3 SAFE-T-BEAM®SYSTEMINSTALLATION.......... 15-16

4 WALLCONTROLINSTALLATION.................... 17

5 CONNECTOPERATORTOPOWER................. 18 NOTE: Your garage door operator may not come with all above

ADJUSTMENTS.................................... 19-21 items included as standard equipment.

6 LIMITSWITCHES&FORCEADJUSTMENT........... 19.

CONTACTREVERSE............................. 20

7 PROGRAMMINGREMOTECONTROLS........... 20-21

8 BATTERY/VISORCLIPINSTALLATION............... 21

9 LIGHTBULBANDLENSINSTALLATION.............. 21

SAFETYINSTRUCT!ONS............................... 22

MAINTENANCE&TROUBLESHOOTING............... 22-24

SAFE-T-BEAM®................................. 22

OPERATOR/RADIO.............................. 23

WIRINGDIAGRAM............................... 24

ACCESSORIES...................................... A-B

WARRANTY.......................................... C

INTELLICODE ®Roiling Code Security System.

An electronic rolling code system that enhances the security of

the door operator by continuously changing the access code

each time the remote control is used. The door operator

responds to each new code only once. An access code copied

from a working system and tried again will not control the door

operator.

INTELLICODE ®1, 2 or 3-Button Remote Control (included

with some models).

Operates 1, 2 or 3 garage doors from car.

Lighted Wall Button*.

Operates door operator from inside garage.

Lighted Wall Console* (included with some models).

Security vacation lock switch disables all controls. LED

Indicator shows whether system is locked or unlocked. Makes

console easy to find in dark. Controls door operator from inside

garage. Independent light control allows convenient manual

control of the automatic lighting system.

Safe-T-Beam ®(STB) Non-Contact Reversing System**.

Puts an invisible beam across the door opening. The door stops

and reverses to the full open position if anything passes

through the beam. Red and green LED indicators provide a self

diagnostic code if an operational problem exits.

Safe-T-Reverse ®Contact Reversing System.

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop ®Timed Reversed System.

Automatically opens a closing door if it fails to close completely

within 30 seconds.

Force Guard ®Control.

Features adjustable open and close force settings. For

maximum safety, these must be set to the minimum force

required to fully open and close the door.

Relay Monitoring System.

Automatically stops and reverses a closing door if the closing

relay malfunctions.

Watch Dog ®Monitoring System.

Automatically stops and reverses a closing door if the

Safe-T-Beam System** has an operational problem.

Automatic Lighting System.

One bulb lighting supplies up to 100 Watts of light for safer

evening exits and entries. Turns on when door _sactivated and

automatically turns off 5 minutes later.

Manual Emergency Release.

Manually releases door from door operator. Use during a power

failure or other emergency to allow manual opening and closing

of door.

Drill

Ratchet

Pencil

Carpenter's level

Adjustablewrench

Stepladder

#6 x 1-1t4" Pan (32)

Head Phillips

Screw Wall console

r_

5/32"DrillBit

©

7/16"and 9/16"

Sockets

@

Safety Brochure

#10-16 x 1-1t4"

Machine Screw

%

Tape measure

Phillipsscrewdriver

oRI

Single-button Multi-button

remote control remote control

Q

@

Wire

Wire strippers

,&WARNING

@

EntrapmentWarning

Label

ii

#6 x 1-1/4" Pan

Head Phillips

Screw Wallbutton

[9]

Bolt - 1/4"-20 x 5/8"

0

[10]

Nut - 1/4'L20

SourceSTB SensorSTB

(Red LED) (Green LED)

[22]

Lag screw - 1/4" x 2"

[25]Cotter0in

@

[28]

Nut - 3/8"-16

[39]

Screw -#8-32 x 1"

STBBracket

lnsu_taple

[41]Wirec'i0

[42]

Self-drilling Screw

1/4'L20x 3/4"

[24]C,evispin

[27]

Bolt - 3/8"-16 x 7/8"

[46]

Bolt - 5/16"-18 x 3/4"

[47]

Nut - 5/16"-18

@

/

\

\

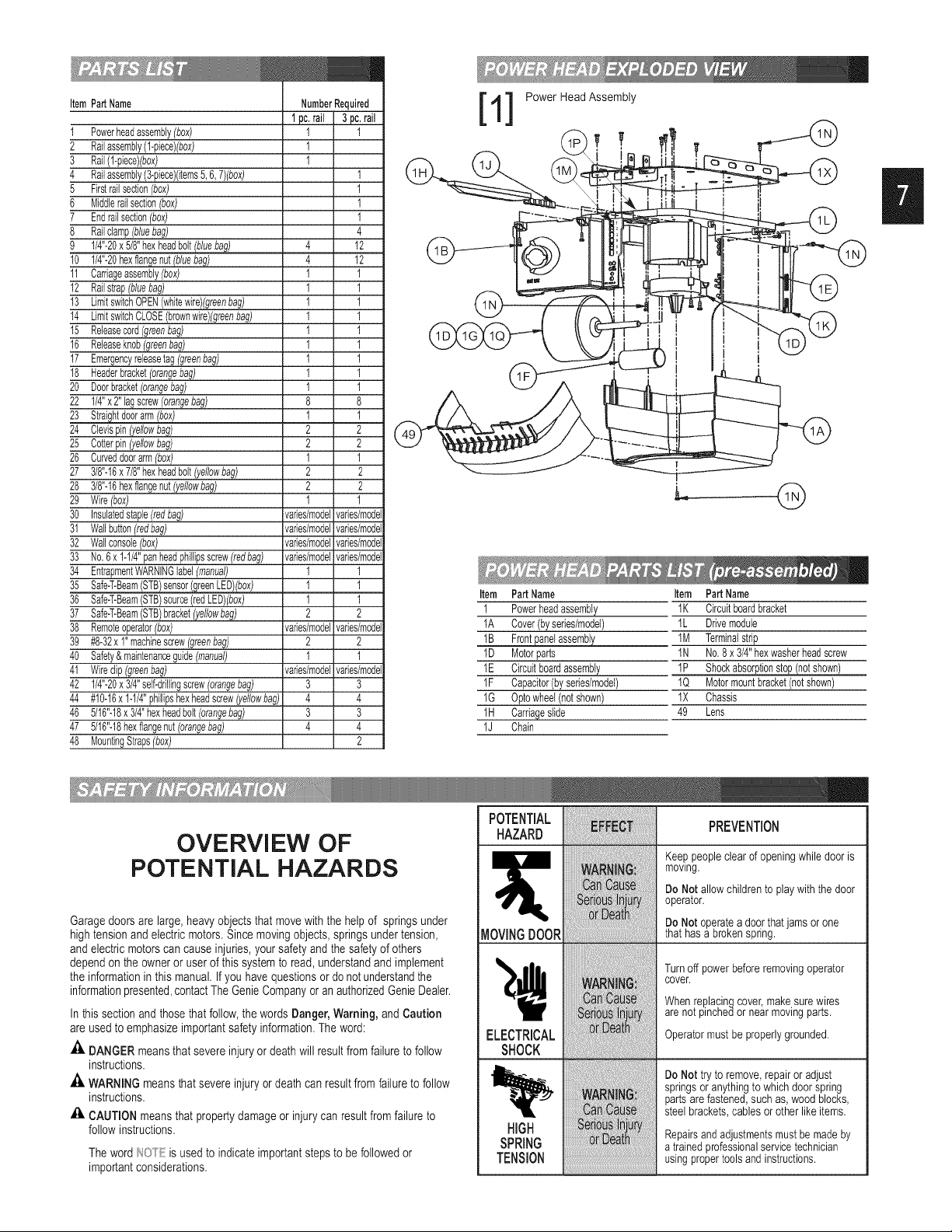

ItemPartName

Powerheadassembly(box) 1 1

Railassembly(1-piece#box) 1

Rail(1-piece)(box) 1

Railassembly(3-piece)(items5,6,7)(box) 1

Firstrailsection(box) 1

Middlerailsection(box) 1

Endrailsection(box) 1

Railclamp(bluebag) 4

1/4"-20x5/8"hexheadbolt(blueba@) 4 12

10 1/4"-20hexflangenut(bluebag) 4 12

11 Carriageassembly(box) 1 1

12 Railstrap(bluebag) 1 1

13 LimitswitchOPEN(whitewire)(greenbag) 1 1

14 LimitswitchCLOSE(brownwire)(greenbag) 1 1

15 Releasecord(greenbag) 1 1

16 Releaseknob(greenbag) 1 1

17 Emergencyreleasetag(greenbag) 1 1

18 Headerbracket(orangebag) 1 1

!0 Doorbracket(orangebag) 1 1

!2 1/4"x2"lagscrew(orangebag) 8 8

!3 Straightdoorarm(box) 1 1

!4 Clevispin(yellowbag) 2 2

!5 Cotterpin(yellowbag) 2 2

!6 Curveddoorarm(box) 1 1

!7 3/8"-16x 7/8"hexheadbolt(yellowbag) 2 2

!8 3/8"-16hexflangenut(yellowbag) 2 2

!9 Wire(box) 1 1

30 Insulatedstaple(redbag) varies/modelvaries/model

31 Wallbutton(redbag) varies/modelvaries/model

32 Wallconsole(box) varies/modelvaries/model

33 No.6x 1-1/4"panheadphillipsscrew(redbag) varies/modelvaries/model

34 EntrapmentWARNINGlabel(manual) 1 1

35 Safe-T-Beam(STB)sensor(greenLEa)(box) 1 1

36 Safe-T-Beam(STB)source(redLEa)(box) 1 1

37 Safe-T-Beam(STB)bracket(yellowbag) 2 2

38 Remoteoperator(box) varies/modelvaries/model

39 #8-32x 1"machinescrew(greenbag) 2 2

_0 Safety&maintenanceguide(manual) 1 1

H Wireclip(greenbag) varies/modelvaries/model

$2 1/4"-20x3/4"self-drillingscrew(orangebag) 3 3

N #10-16x1-1/4"phillipshexheadscrew(yellowbag) 4 4

_6 5/16"-18x 3/4"hexheadbolt(orangebag) 3 3

$7 5/16"-18hexflangenut(orangebag) 4 4

$8 MountingStraps(box) 2

NumberRequired

1pc,rail 3pc,rail

1] Power Head Assembly

Item PartName

I Powerheadassembly

1A Cover(byseries/model)

IB Frontpanelassembly

1D Motorparts

1E Circuitboardassembly

1F Capacitor(byseries/model)

1G Optowheel(notshown)

IH Carriageslide

lJ Chain

I

Item PartName

IK Circuitboardbracket

1L Drivemodule

1M Terminalstrip

1N No.8x3/4"hexwasherheadscrew

IP Shockabsorptionstopn(notshow_

1Q Motormountbracket(notshown)

1X Chassis

49 Lens

OVERVIEW OF

POTENTIAL HAZARDS

Garagedoors are large, heavyobjectsthat movewith the helpof springs under

high tension andelectric motors.Since movingobjects, springs under tension,

andelectric motors can causeinjuries,your safety andthe safety of others

dependon the owneror userof this system to read, understandand implement

theinformation in this manual. If you have questionsor do not understandthe

informationpresented,contactThe GenieCompany or anauthorizedGenieDealer.

In this section and those that follow,the words Danger, Warning, and Caution

are usedto emphasizeimportant safety information.The word:

DANGER meansthat severe injuryor death will resultfrom failure tofollow

instructions.

_. WARNING meansthat severe injury or death can result from failure to follow

instructions.

£i. CAUTION means that property damageor injury can resultfrom failure to

follow instructions.

Theword/_2Oi'Eis used to indicate importantstepsto befollowed or

importantconsiderations.

POTENTIAL

HAZARD

ELECTRICAL

SHOCK

HiGH

SPRING

TENSION

PREVENTION

Keeppeopleclearof openingwhiledooris

mowng.

Do Not allowchildrento playwith thedoor

operator.

Do Not operatea doorthatjamsorone

thathasa brokenspring.

Turnoff powerbeforeremovingoperator

cover.

Whenreplacingcovermakesurewires

arenotpinchedor nearmovingparts.

Operatormustbeproperlygrounded.

De Net tryto remove,repairoradjust

iiiiiiiiii!iiiii!ii i iii!iiii!!i!iii!!iii!

springsoranythingtowhichdoorspring

partsarefastened,suchas,wood blocks,

steelbrackets,cablesorotherlike items.

Repairsandadjustmentsmustbemadeby

atrainedprofessionalservicetechnician

usingpropertoolsandinstructions.

1

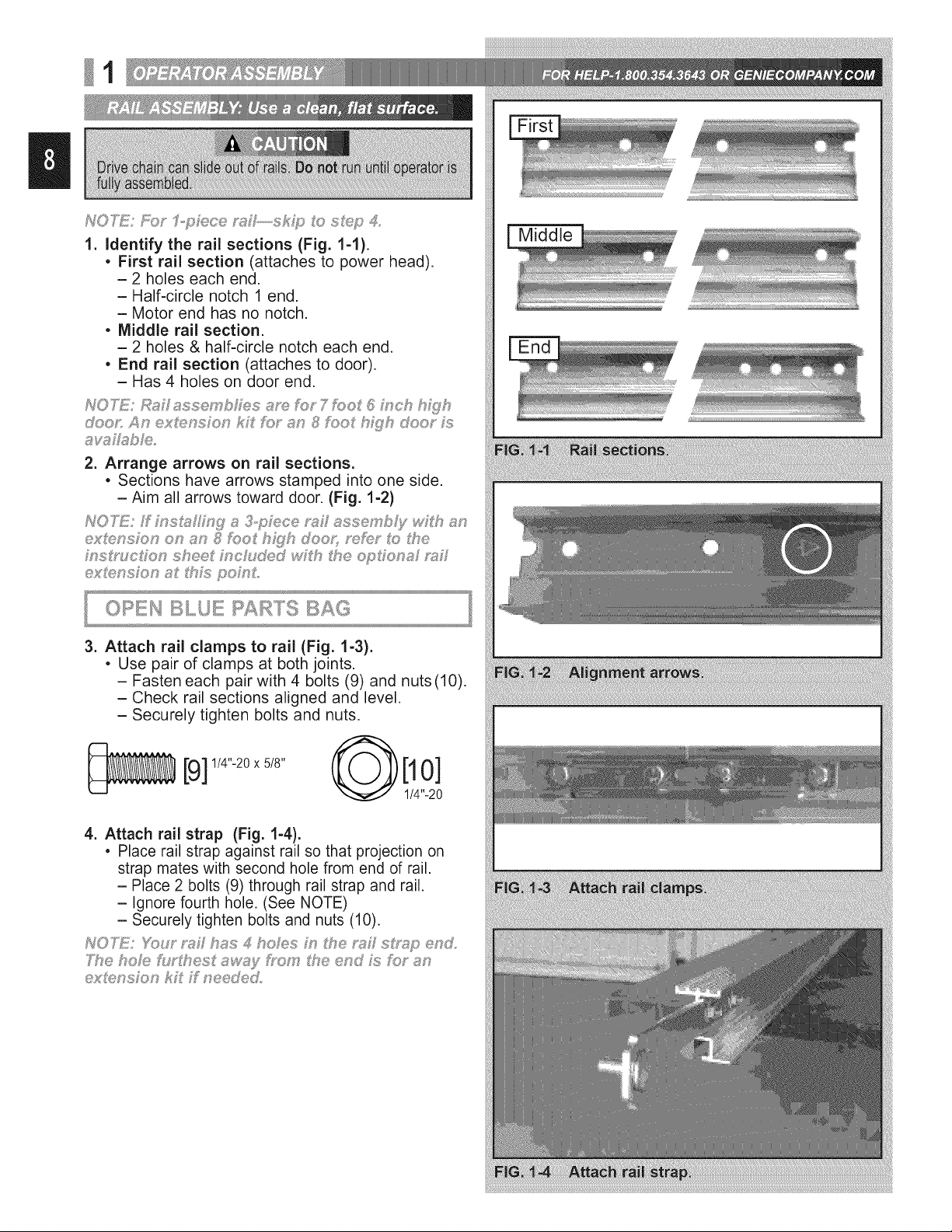

1. Identify the rai! sections (Fig. 1-1).

• First rail section (attaches to power head).

- 2 holes each end.

- Half-circle notch 1 end.

- Motor end has no notch.

• Middle rail section.

- 2 holes & half-circle notch each end.

• End rail section (attaches to door).

- Has 4 holes on door end.

2. Arrange arrows on rail sections.

• Sections have arrows stamped into one side.

- Aim all arrows toward door. (Fig. 1-2)

ex_ensFon on an _ foot h_yh doox_ _f_;_ t_f:_the

3. Attach rail clamps to rail (Fig. 1-3).

• Use pair of clamps at both joints.

- Fasten each pair with 4 bolts (9) and nuts(10).

- Check rail sections aligned and level.

- Securely tighten bolts and nuts.

Middle

[9] 114''-20x518" @[10]

4. Attach rail strap (Fig. 1-4).

• Place rail strap against rail so that projection on

strap mates with second hole from end of rail.

- Place 2 bolts (9) through rail strap and rail.

- Ignore fourth hole. (See NOTE)

- Securely tighten bolts and nuts (10).

cxUf:,nsFon kF Ffneede&

1/4"-20

5. Slip carriage into carriage slot of rail.

• Flip the rail assembly up side down.

• Place emergency release lever in "release"

position (See below).

- Check arrow on the side of carriage points

toward door end of rail.

- Slide carriage into rail at power head end

(Fig. 1-5).

- Flip rail assembly right-side up.

6. Attach rail to power head.

* Place rail in front of power head with rail strap at

opposite end.

* Support door end of rail (rail strap) at about same

height as power head.

- Check if magnet is in place (Fig. 1-6 inset). Insert

carriage slide into rail (Fig. 1-6). (Carriage slide is

long straight piece attached to chain.)

- Pull rail toward you as you feed chain into it.

(Fig. 1-6). When the end of the rail is within

about 2 chain links of the power head, you can

then push it the rest of the way. (It is a snug fit.)

- Securely fasten with 2 bolts (9) and nuts (10)

(Fig. 1-7).

9] 1/4"-20x 5/8"

7. Attach emergency release cord, knob and tag.

* Tie overhand knot in 1 end of cord. Tighten knot.

(FIG. 1-8 inset A).

- Slip opposite (no knot) end through knob.

- Slip through hole in emergency release lever

(Fig. 1-8).

- Tie overhand knot in this end also. Tighten knot,

8. Attach emergency release tag.

* Attach to hole in emergency release using metal

twist tie on tag. (Fig. 1-8 inset B).

[10]

1/4"-20

B

overhand knot ]

Lever in release position.

Loading...

Loading...