Page 1

¤

®

3452535348

®

Garage Door

Operator

Series

Includes Remote Control

and SERIES II Electronics

Included Wall Control MUST be installed prior to operation of this Garage

Door Operator

Safe-T-Beam®Safety Reverse System Must be installed to close door

NOTE: Your Residential Operator comes with a Rail Assembly which is

standard for up to a 7 foot 6 inch high door. An extension kit for an 8 foot

high door is available.

GCG

, PCG, H

For Answers and Assistance:

1.800.354.3643

or visit www.geniecompany.com

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

PRE-INSTALLATION CHECK LIST

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Things to consider if you are planning to do-it-yourself.

In many cases you will be replacing an existing door operator with a new one, however, if this

will be the first operator installed there are some pre-installation issues which need to be

addressed. They are as follows:

2

information and instructions contained herein before choosing a Do-it-yourself

installation. Any questions should be directed to the Genie Company or an authorized

Genie Dealer.

(

The issue numbers below refer to the circled numbers in the illustrations on page 3.

The Genie Company recommends that you read and fully understand all

)

Check your ceiling where the power

1

head of your new unit will be mounted.

Plan how you will be mounting the power head.

It is possible that ceiling joists may not be in the

position needed with respect to the garage door

operator. It may be necessary to add an

additional bracket and

with your new door operator kit).

Check the wall directly above the garage

2

must be securely fastened to this wall. Insure

that the structure will provide a strong mounting

location.

3

clear from obstruction and has a wood

surface available for attaching the STB

brackets

concrete if necessary but extra tools and special

fasteners (not supplied) will be required.

. The door operator s header bracket

door

Check to see if the mounting location

for the Safe-T-Beam

. The brackets may be attached to

fasteners (not included

®

System STB is

You need a 110-120 Volt power supply

5

available

feet from the power head once it is mounted. (The

cord is 4 ft. in length.) SEE WARNING BELOW.

To avoid damage to your door and/or

6

operator, make sure you disable any door

locks prior to installing your operator

Insure that your door is properly balanced

7

and moving freely. SEE WARNING BELOW.

. The outlet should be no more than 3

.

NOTE: 1-1/2" STB bracket adapters are

available through your local Genie Dealer.

Is your garage door made of

4

light-weight steel, aluminum, fiberglass

or glass panels

must be added to these type doors. If this is the

case, please contact the door distributor or

manufacturer so that they can furnish you with a

bracing kit.

DO NOT USE AN EXTENSION CORD!

Extension cords can cause dangerous

overheating conditions.

DO NOT USE A PORTABLE GENERATOR!

This product is designed to operate on

standard house current. Do not use

alternate power supplies.

? Additional support bracing

WARNING

(NOT SHOWN) If your garage does not have

8

a separate entry door, you should consider

an emergency release kit (GER-2)for installation on

your garage door. See page B at the center of this

manual.

WARNING

If your door sticks, binds, or is out of

balance, have it adjusted by a professional.

Door springs, cables, pulleys, brackets and

associated hardware are under extreme

tension and can cause serious injury or

death.

Page 3

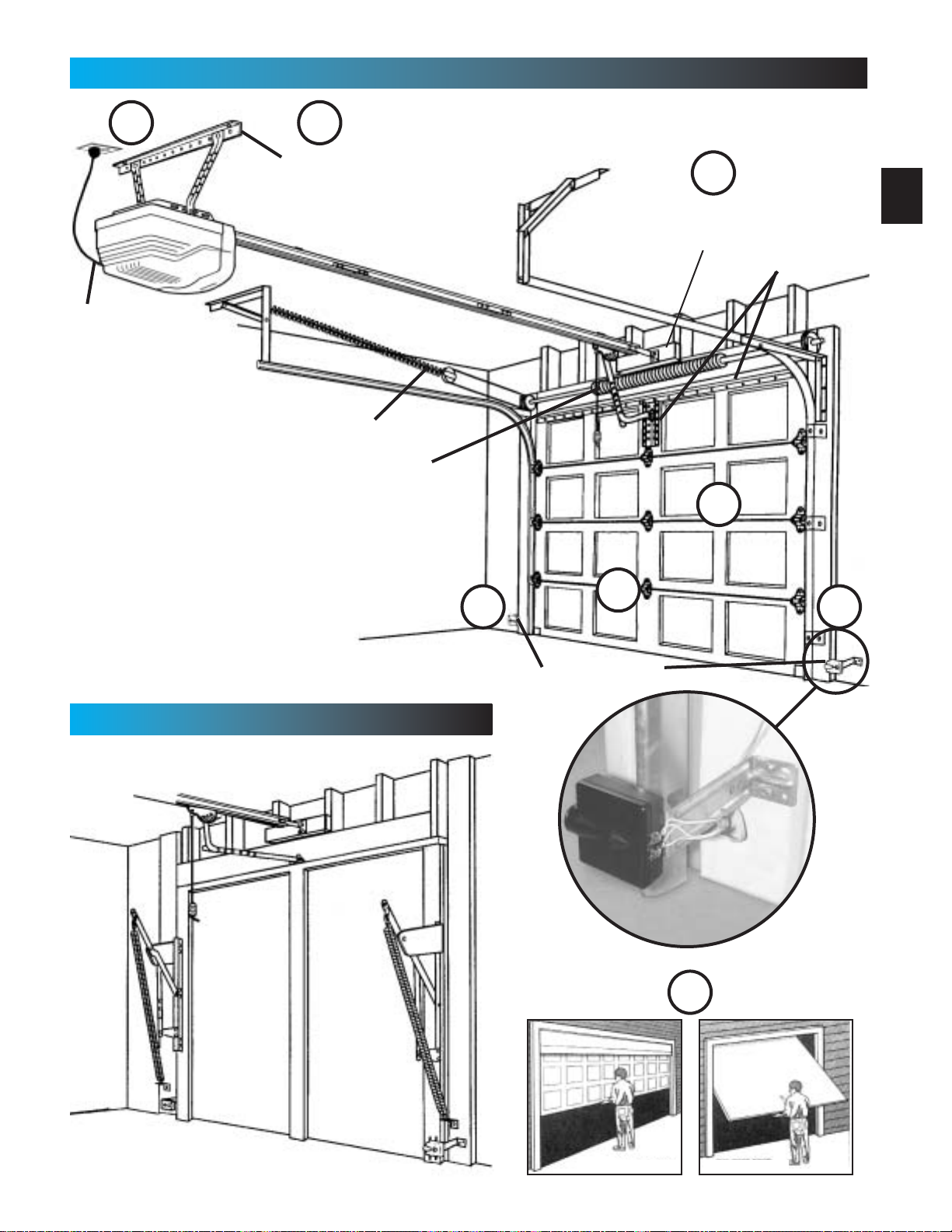

TYPICAL SECTIONAL DOOR INSTALLATION FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

5

48" POWER CORD

TO

120V GROUNDED

OUTLET

1

TYPICAL

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

2

ADDED

HEADER BRACKET

MOUNTING BOARD

4

3

BRACES

TYPICAL 1-PIECE DOOR INSTALLATION

3

6

SAFE-T-BEAM

3

®

7

SECTIONAL DOOR

1-PIECE DOOR

Page 4

TABLE OF CONTENTS

SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

PRE-INSTALLATION CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

OPERATOR FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4

TOOLS RECOMMENDED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

2 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

OPERATOR FEATURES

INTELLICODE®Rolling Code Security System.

An electronic rolling code system that enhances the security of

the door operator by continuously changing the access code

each time the remote control is used. The door operator

responds to each new code only once. An access code copied

from a working system and tried again will not control the door

operator.

INTELLICODE

with some models).

Operates 1, 2 or 3 garage doors from car.

Lighted Wall Button*.

Operates door operator from inside garage.

Lighted Wall Console* (included with some models).

Security vacation lock switch disables all controls. LED

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

®

3 SAFE-T-BEAM

4 WALL CONTROL INSTALLATION. . . . . . . . . . . . . . . . . . . . 17

SYSTEM INSTALLATION . . . . . . . . . . 15-16

Indicator shows whether system is locked or unlocked. Makes

console easy to find in dark. Controls door operator from inside

garage. Independent light control allows convenient manual

control of the automatic lighting system.

®

1, 2 or 3-Button Remote Control (included

5 CONNECT OPERATOR TO POWER . . . . . . . . . . . . . . . . . 18

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-21

6 LIMIT SWITCHES & FORCE ADJUSTMENT . . . . . . . . . . . 19.

CONTACT REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 PROGRAMMING REMOTE CONTROLS . . . . . . . . . . . 20-21

8 BATTERY/ VISOR CLIP INSTALLATION . . . . . . . . . . . . . . . 21

9 LIGHT BULB AND LENS INSTALLATION. . . . . . . . . . . . . . 21

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

MAINTENANCE & TROUBLESHOOTING . . . . . . . . . . . . . . . 22-24

®

SAFE-T-BEAM

OPERATOR / RADIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-B

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

NOTE: Your garage door operator may not come with all above

items included as standard equipment.

SAFETY FEATURES

Safe-T-Beam®(STB) Non-Contact Reversing System**.

Puts an invisible beam across the door opening. The door stops

and reverses to the full open position if anything passes

through the beam. Red and green LED indicators provide a self

diagnostic code if an operational problem exits.

Safe-T-Reverse

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop

Automatically opens a closing door if it fails to close completely

within 30 seconds.

Force Guard

Features adjustable open and close force settings. For

maximum safety, these must be set to the minimum force

required to fully open and close the door.

®

Contact Reversing System.

®

Timed Reversed System.

®

Control.

*Operator MUST be installed with the

included Wall Control.

**Safe-T-Beam®Safety Reverse System

MUST Be Installed To Close door.

Relay Monitoring System.

Automatically stops and reverses a closing door if the closing

relay malfunctions.

Watch Dog

®

Monitoring System.

Automatically stops and reverses a closing door if the

Safe-T-Beam System** has an operational problem.

Automatic Lighting System.

One bulb lighting supplies up to 100 Watts of light for safer

evening exits and entries. Turns on when door is activated and

automatically turns off 5 minutes later.

Manual Emergency Release.

Manually releases door from door operator. Use during a power

failure or other emergency to allow manual opening and closing

of door.

Page 5

RECOMMENDED TOOLS

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

Drill

Step ladder

PARTS IDENTIFICATION

33

#6 x 1-1/4" Pan

Head Phillips

Screw

7/32" Drill Bit

32

Wall console

Ratchet

7/16" and 9/16"

Sockets

-

Not Shown Full Size .

40

Safety Brochure

44

#10-16 x 1-1/4"

Machine Screw

Pencil

Tape measure

Single-button

remote control

Carpenter s level

Phillips screwdriver

OR

38

Multi-button

remote control

29

Wire

Adjustable wrench

5

Wire strippers

34

Entrapment Warning

Label

30

Insulated Staple

45

#4 x 1" Phillips

Flat Head Screw

FASTENERS

[9]

Bolt - 1/4"-20 x 5/8"

[

]

10

Nut - 1/4"-20

31

Wall button

-

Shown Full Size . See Parts List for description.

Source STB

(Red LED)

36

[

]

22

Lag screw - 1/4" x 2"

Cotter pin

[

]

25

Sensor STB

(Green LED)

35

Screw - #8-32 x 1"

[

]

28

Nut - 3/8"-16

[

]

39

37

STB Bracket

Wire clip

[

]

41

[

]

42

Self-drilling Screw

1/4"-20 x 3/4"

[24]

Clevis pin

[

]

27

Bolt - 3/8"-16 x 7/8"

[

]

46

Bolt - 5/16"-18 x 3/4"

[

]

47

Nut - 5/16"-18

Page 6

1-PIECE RAIL HARDWARE EXPLODED VIEW

[2]

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

6

11

15

16

25

1

10

13

39

9

22

41

47

14

39

9

3

23

28

26

22

42

20

24

17

25

27

48

10

12

18

3-PIECE RAIL HARDWARE EXPLODED VIEW

[4]

1

9

11

15

16

27

17

10

39

5

9

23

28

26

25

48

10

8

41

14

6

42

22

20

24

7

39

47

9

22

18

10

12

Page 7

PARTS LIST

Item Part Name Number Required

1 Power head assembly (box) 11

2 Rail assembly (1-piece)(box) 1

3 Rail (1-piece)(box) 1

4Rail assembly (3-piece)(items 5, 6, 7)(box) 1

5 First rail section (box) 1

6 Middle rail section (box) 1

7End rail section (box) 1

8 Rail clamp (blue bag) 4

9 1/4"-20 x 5/8" hex head bolt (blue bag) 412

10 1/4"-20 hex flange nut (blue bag) 412

11 Carriage assembly (box) 11

12 Rail strap (blue bag) 11

13 Limit switch OPEN (white wire)(green bag) 11

14 Limit switch CLOSE (brown wire)(green bag) 11

15 Release cord (green bag) 11

16 Release knob (green bag) 11

17 Emergency release tag (green bag) 11

18 Header bracket (orange bag) 11

20 Door bracket (orange bag) 11

22 1/4" x 2" lag screw (orange bag) 88

23 Straight door arm (box) 11

24 Clevis pin (yellow bag) 22

25 Cotter pin (yellow bag) 22

26 Curved door arm (box) 11

27 3/8"-16 x 7/8" hex head bolt (yellow bag) 22

28 3/8"-16 hex flange nut (yellow bag) 22

29 Wire (box) 11

30 Insulated staple (red bag) varies/model varies/model

31 Wall button (red bag) varies/model varies/model

32 Wall console (box) varies/model varies/model

33 No. 6 x 1-1/4" pan head phillips screw (red bag) varies/model varies/model

34 Entrapment WARNING label (manual) 11

35 Safe-T-Beam (STB) sensor (green LED)(box) 11

36 Safe-T-Beam (STB) source (red LED)(box) 11

37 Safe-T-Beam (STB) bracket (yellow bag) 22

38 Remote operator (box) 1 varies/model

39 #8-32 x 1" machine screw (green bag) 22

40 Safety & maintenance guide (manual) 11

41 Wire clip (green bag) 55

42 1/4"-20 x 3/4" self-drilling screw (orange bag) 33

44 #10-16 x 1-1/4" phillips hex head screw (yellow bag) 44

45 #4 x 1" Phillips head screw (red bag) varies/model varies/model

46 5/16"-18 x 3/4" hex head bolt (orange bag) 33

47 5/16"-18 hex flange nut (orange bag) 44

48 Mounting Straps (box) 22

1 pc. rail 3 pc. rail

1H

1B

49

POWER HEAD EXPLODED VIEW

Power Head Assembly

[1]

1P

1J

1N

1Q1G1D

1M

1F

POWER HEAD PARTS LIST (pre-assembled)

Item Part Name

1 Power head assembly

1A Cover (by series/model)

1B Front panel assembly

1D Motor parts

1E Circuit board assembly

1F Capacitor (by series/model)

1G Opto wheel (not shown)

1H Carriage slide

1J Chain

Item Part Name

1K Circuit board bracket

1L Drive module

1M Terminal strip

1N No. 8 x 3/4" hex washer head screw

1P Shock absorption stop (not shown)

1Q Motor mount bracket (not shown)

1X Chassis

49 Lens

1N

1X

1L

1E

1K

1D

1A

1N

7

1N

SAFETY INFORMATION

POTENTIAL

HAZARD

OVERVIEW OF

POTENTIAL HAZARDS

Garage doors are large, heavy objects that move with the help of springs under

high tension and electric motors. Since moving objects, springs under tension,

and electric motors can cause injuries, your safety and the safety of others

depend on the owner or user of this system to read, understand and implement

the information in this manual. If you have questions or

information presented, contact The Genie Company or an authorized Genie Dealer.

In this section and those that follow, the words Danger, Warning, and Caution

are used to emphasize important safety information. The word:

DANGER means that severe injury or death will result from failure to follow

instructions.

WARNING means that severe injury or death can result from failure to follow

instructions.

CAUTION means that property damage or injury can result from failure to

follow instructions.

The word NOTE is used to indicate important steps to be followed or

important considerations.

do not understand the

MOVING DOOR

ELECTRICAL

SHOCK

HIGH

SPRING

TENSION

EFFECT PREVENTION

Keep people clear of opening while door is

WARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

Serious Injury

or Death

moving.

Do Not allow children to play with the door

operator.

Do Not operate a door that jams or one

that has a broken spring.

Turn off power before removing operator

cover.

When replacing cover, make sure wires

are not pinched or near moving parts.

Operator must be properly grounded.

Do Not try to remove, repair or adjust

springs or anything to which door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made by

a trained professional service technician

using proper tools and instructions.

Page 8

8

OPERATOR ASSEMBLY

1

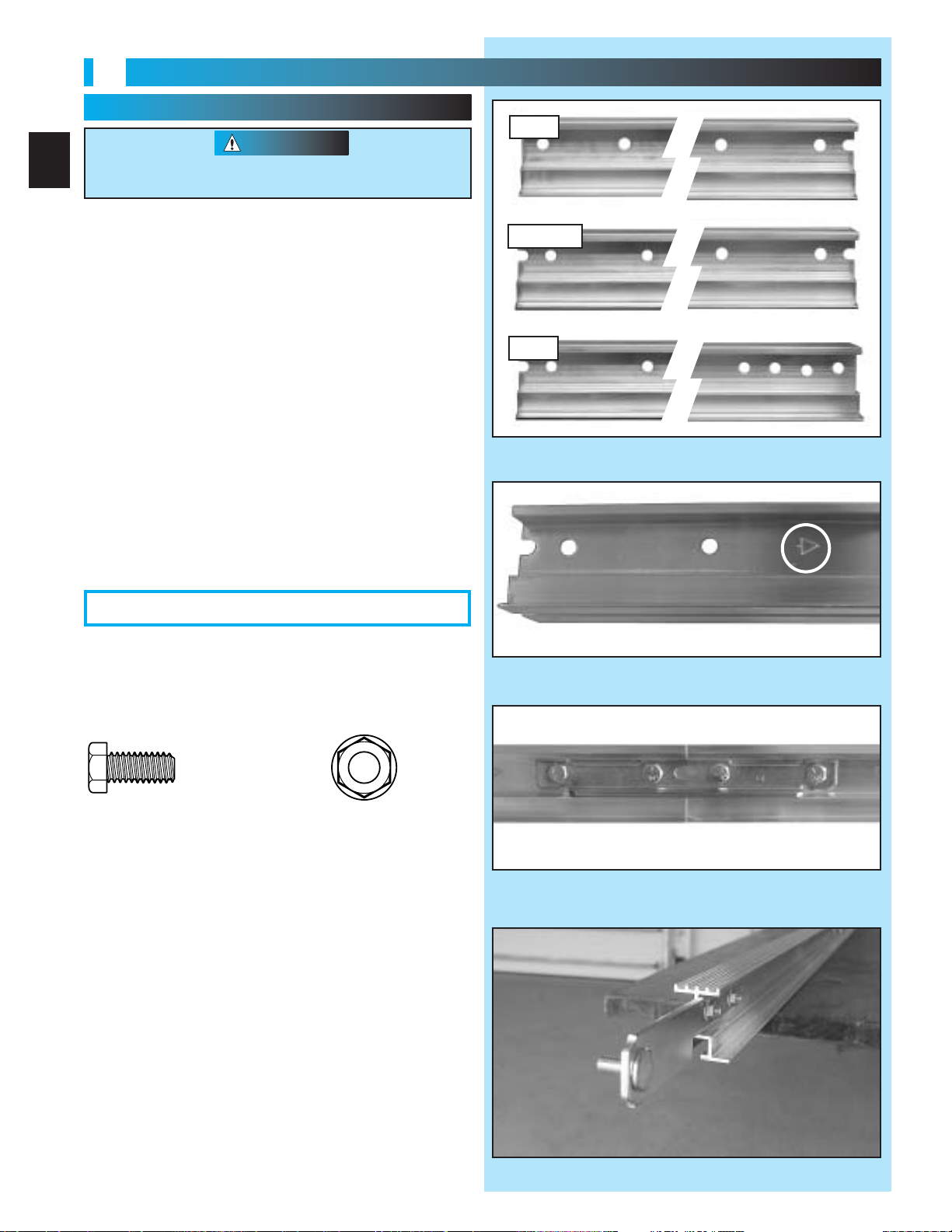

RAIL ASSEMBLY: Use a clean, flat surface.

CAUTION

Drive chain can slide out of rails. Do not run until operator is

fully assembled.

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

First

NOTE: For 1-piece rail skip to step 4.

1. Identify the rail sections (Fig. 1-1).

• First rail section (attaches to power head).

– 2 holes each end.

– Half-circle notch 1 end.

– Motor end has no notch.

• Middle rail section.

–

2 holes & half-circle notch each end.

• End rail section (attaches to door).

– Has 4 holes on door end.

NOTE: Rail assemblies are for 7 foot 6 inch high

door. An extension kit for an 8 foot high door is

available.

2. Arrange arrows on rail sections.

• Sections have arrows stamped into one side.

–

Aim all arrows toward door. (Fig. 1-2)

NOTE:

extension on an 8 foot high door, refer to the

instruction sheet included with the optional rail

extension at this point.

If installing a 3-piece rail assembly with an

OPEN BLUE PARTS BAG

3. Attach rail clamps to rail (Fig. 1-3).

• Use pair of clamps at both joints.

– Fasten each pair with 4 bolts (9) and nuts(10).

– Check rail sections aligned and level.

– Securely tighten bolts and nuts.

Middle

End

FIG. 1-1 Rail sections.

FIG. 1-2 Alignment arrows.

1/4"-20 x 5/8"

[9]

4.

Attach rail strap (Fig. 1-4).

• Place rail strap against rail so that projection on

strap mates with second hole from end of rail.

–

Place 2 bolts (9) through rail strap and rail.

–

Ignore fourth hole. (See NOTE)

–

Securely tighten bolts and nuts (10).

NOTE:

The hole furthest away from the end is for an

extension kit if needed.

Your rail has 4 holes in the rail strap end.

[

10

1/4"-20

]

FIG. 1-3 Attach rail clamps.

FIG. 1-4 Attach rail strap.

Page 9

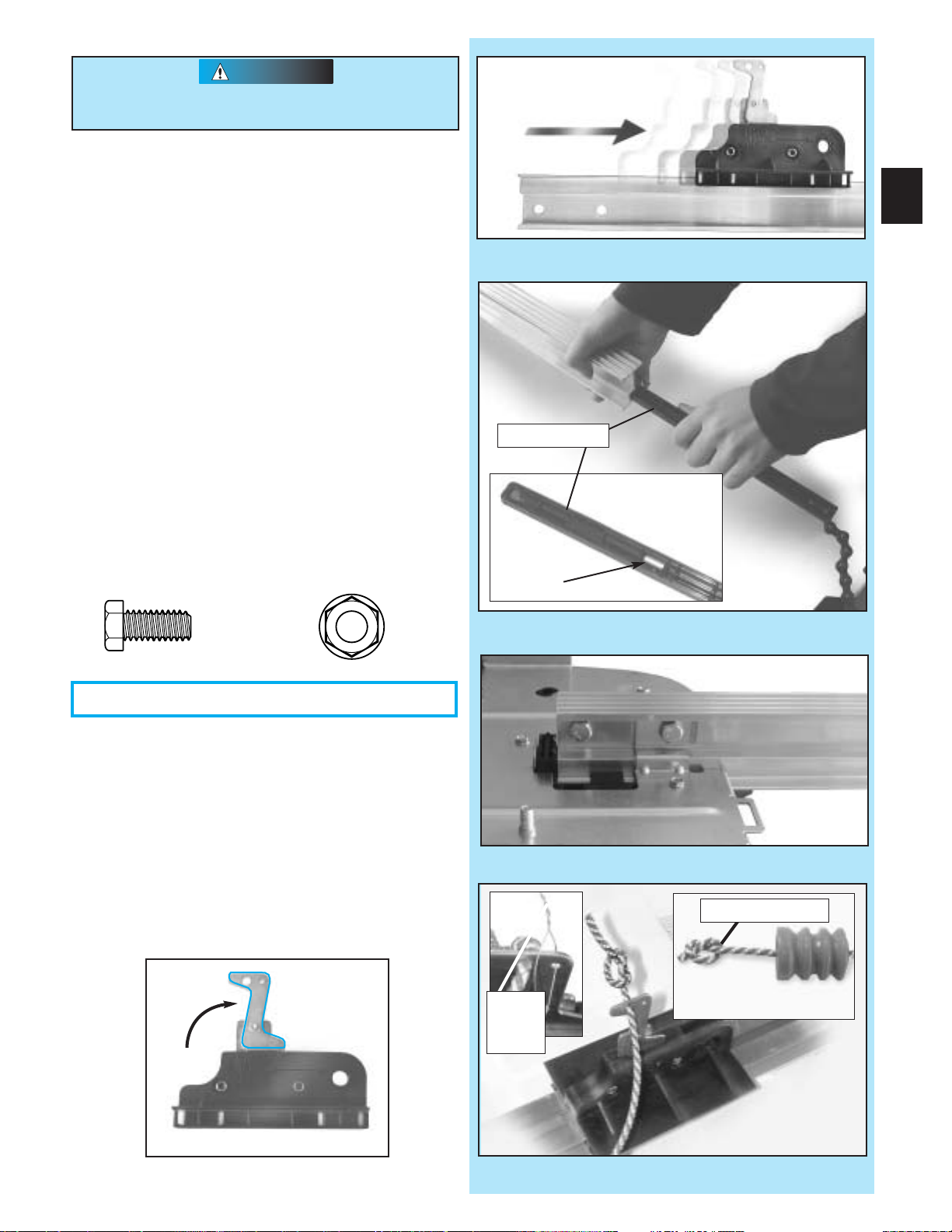

CAUTION

Make sure that the carriage magnet is in place in the

top of the carriage slide.

5.

Slip carriage into carriage slot of rail.

• Flip the rail assembly up side down.

• Place emergency release lever in release

position (See below).

– Check arrow on the side of carriage points

toward door end of rail.

– Slide carriage into rail at power head end

(Fig. 1-5).

– Flip rail assembly right-side up.

Rail is up-side down

9

FIG. 1-5 Align arrow.

6. Attach rail to power head

• Place rail in front of power head with rail strap at

opposite end.

• Support door end of rail (rail strap) at about same

height as power head.

–

Check if magnet is in place (Fig. 1-6 inset).Insert

carriage slide into rail (Fig. 1-6). (Carriage slide is

long straight piece attached to chain.)

–

Pull rail toward you as you feed chain into it.

(Fig. 1-6).

about 2 chain links of the power head, you can

then push it the rest of the way. (It is a snug fit.)

–

Securely fasten with 2 bolts (9) and nuts (10)

(Fig. 1-7).

When the end of the rail is within

1/4"-20 x 5/8"

[9]

.

[

]

10

1/4"-20

OPEN GREEN PARTS BAG

7. Attach emergency release cord, knob and tag.

• Tie overhand knot in 1 end of cord. Tighten knot.

(FIG. 1-8 inset A).

–

Slip opposite (no knot) end through knob

–

Slip through hole in emergency release lever

(Fig. 1-8).

–

Tie overhand knot in this end also. Tighten knot.

8. Attach emergency release tag

• Attach to hole in emergency release using metal

twist tie on tag. (Fig. 1-8 inset B).

.

.

carriage slide

magnet

FIG. 1-6 Slip carriage slide into rail.

FIG. 1-7 Attach rail to power head.

B

overhand knot

Lever in release position.

wire

twist

tie

FIG. 1-8 Attach emergency release cord & tag.

A

Page 10

9. Attach limit switches.

2 switches included, CLOSE limit switch (brown

wire) and OPEN limit switch (white wire)

(Fig. 1-10).

• Turn set screws (39) into threaded holes, just

enough so screw stays in place. (Fig. 1-10).

10

• Point arrow on top CLOSE limit switch toward

door end of rail.

–

Place CLOSE limit switch (Brown wire) on rail

about 12 from rail strap (Fig. 1-11).

–

Gently tighten set screw enough to keep switch

from moving.

• Point arrow on top OPEN limit switch toward

door end of rail.

–

Place OPEN limit switch (white wire) on rail

where chain attaches to carriage slide. (Near

the power head.)

–

Gently tighten set screw enough to keep switch

from moving.

[

39

#8-32 x 1"

]

FIG. 1-10 Identify limit switches / insert set screws.

FIG. 1-11 Place limit switches.

10.Attach limit switch wires

• Uncoil limit switch wires.

–

Place into channels located along top of rail

–

Run wires back to power head through hole in top

of power head (Fig. 1-12)

– Use wire clips to hold wires in place (Fig. 1-13).

• Attach limit switch wires to terminals on power

head (Fig. 1-14)

–

White wire ( OPEN ) to terminals #4 and #5.

–

Brown wire ( CLOSE ) to terminals #5 and #6.

• Bundle extra wire and lay it on top of power head

(Fig. 1-14 inset).

.

[

41

.

.

.

]

hole

FIG. 1-12 Run wire to power head.

FIG. 1-13 Wire clips.

4

5

Bundle

Wire

FIG. 1-14 Attach wire at power head terminals.

6

Page 11

INSTALLATION

2

IMPORTANT

WARNING :

To reduce the risk of severe injury or death:

1.

READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS.

do not understand an instruction, call The Genie

Company or an authorized Genie Dealer.

2. Do Not install operator on an improperly balanced door.

An improperly balanced door could cause severe injury.

Repairs and adjustments to cables, spring assembly, and

other hardware must be made by a professionally trained

service technician using proper tools and instructions.

3. Remove all ropes and disable all locks connected to the

door before installing operator.

4. Install door operator 7 feet or more above floor. Mount

emergency release knob 6 feet above floor.

HEADER AND DOOR

MOUNTING BRACKETS:

CAUTION

Header bracket must be fastened to garage framing.

Do Not fasten to drywall, particle board, plaster or other

such materials.

1. Finding header bracket mounting location.

• Close garage door.

–Use a pencil.

a. Mark center of garage door (one-half overall

width) with 6 vertical line at top edge of door.

b. Continue this line on wall above door for

about 12" (Fig. 2-1).

• Raise garage door until top edge of door

reaches its maximum height

• Place door at highest point.

Measure height from top edge of door to floor.

–

• Close door again.

• Mark height measurement on wall above door.

–Make your mark across vertical line

made earlier.

If you have questions or

(Fig. 2-2)

.

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

5. Do Not connect the operator to the source of power

until instructed to do so.

6. Locate the control button:

• Within sight of door.

• At minimum height of 5 feet above the highest floor

level, so small children cannot reach it.

• Away from all moving parts of the door.

7. Install the Entrapment WARNING Label next to the wall

button or wall console. Install the emergency release

tag on, or next to, the emergency release.

8. The operator must reverse when the door contacts a

1-1/2 inch high object on the floor at the center of the

doorway. This is the size of a 2 x 4 board laid flat.

from here to

floor

FIG. 2-1 Finding highest point of travel

(sectional).

from here to

floor

11

• Marking final height.

THE 2 BASIC TYPES OF GARAGE DOOR

MECHANISMS ARE:

Sectional doors–have rollers on each side

in tracks to guide the door up and down.

One-Piece doors–swivel on large spring loaded

hinges as the door opens and closes.

• For sectional – add 2-1/2" to height mark

just made on

header bracket.

NOTE: If spring or its shaft is in way, measure

2-1/2" above spring or shaft and mark this height

as your location for header bracket.

• For one-piece –

just made on the wall. This is location for

header bracket.

wall. This is location for

add 6"- 12 to your height mark

which ride

final height

mark

FIG. 2-2 Finding highest point

of travel (1-piece).

top of door

FIG. 2-3 Final height mark.

Page 12

NOTE: If header bracket location needs to be

above header for garage door opening, you

need to add a mounting surface. A 2" x 6"

board securely attached (fasteners not included)

across wall studs on either side of your mark is

sufficient (Fig. 2-4).

OPEN ORANGE PARTS BAG

12

2. Mounting the header bracket.

NOTE: Although header bracket may be oriented

several ways, method 1 is preferred if possible

because of added strength over other methods

(Fig. 2-5).

• Hold header bracket against wall

–

Place left edge on vertical line.

–

Bottom edge on final height line.

•

Mark screw hole locations on wall.

• Drill 7/32" pilot holes at each screw hole mark.

–

Fasten header bracket with 3 lag screws (22)

(Fig. 2-5).

(Fig. 2-5).

bolted to studs in wall

FIG. 2-4 Adding mounting surface.

preferred

22

1/4" x 2"

]

FIG. 2-5 Header bracket in place (3 methods)

[

DOOR BRACKET:

CAUTION

Doors made of masonite, lightweight wood, fiberglass, and

sheet metal must be properly braced before mounting door

operator. Contact door manufacturer or distributor for a

bracing kit. The Genie Company is not responsible for

damage caused due to improperly braced door (Fig. 2-6).

3. Finding door bracket mounting location.

• Door bracket is mounted as high on

possible along vertical centerline.

NOTE: In the case of sectional type doors, door

bracket must be mounted NO LOWER THAN top

set of rollers (Fig. 2-7).

For 1-piece doors, door bracket must be mounted

at top edge of door.

4. Mounting the door bracket.

• Proper bracing should be verified at this point.

–

Align door bracket centered on your

vertical centerline.

–

Attach using 3 self-drilling screws (42) for

sheet metal or other light weight material.

–

Use lag screws (22) for solid wooden doors.

door as

FIG. 2-6 Examples of door bracing.

FIG. 2-7 Mounting door Bracket (sectional)

1

even with or

above top roller

2

3

.

.

1/4"-20 x 3/4"

[

]

42

[

]

22

1/4" x 2"

NOTE: For solid wood doors, carriage bolts

WITHOUT

also be used for attaching door bracket.

SLOTTED HEADS (not included) may

on top edge

FIG. 2-7B Mounting door Bracket (one-piece)

at top of back

.

Page 13

MOUNTING THE OPERATOR:

1. Getting Started.

• Position rail/power head assembly (Fig. 2-7).

Rail strap leaning on wall next to header bracket.

–

–Place material on floor under power head to

protect from scratching. (A box, stool, or similar

device may be needed to clear a torsion

spring, as shown.)

2. Mounting the assembly.

• Attach rail strap to header bracket using nut (47)

.

(Fig. 2-7 inset)

FINGER TIGHT ONLY.

13

[

]

47

5/16"-18

• Support power head on step-ladder.

NOTE: Before final attachment to ceiling, insure

that assembly is in proper alignment (Fig. 2-9).

• Attach mounting straps to ceiling using lag

bolts (22) (Fig. 2-10).

• Set height of power head according to following:

–Track guided doors

a.

Rail must clear door at highest point of travel

b. Be level or, power head slightly below level.

–Trackless doors

a.

Rail must clear door at highest point of travel

by 1" to 1-1/2".

• Securely tighten power head mounting bolts (46)

and nuts (47).

• Lower door.

• Fully tighten rail strap nut.

• DO NOT PLUG UNIT IN YET!

3. Adjusting length of emergency release cord.

• Check emergency release knob height.

–Low enough you can reach it.

–High enough to clear your vehicle, but

NO HIGHER THAN 6 FEET ABOVE FLOOR.

• Tie a new overhand knot where desired

–Cut off any extra cord.

[

]

22

1/4" x 2"

.

.

.

FIG. 2-7 Position assembly.

HEADER BRACKET

DOOR

90°

VIEW FROM ABOVE

(not to scale)

N

O

FIG. 2-9 Operator must be aligned.

YES

O

N

ANGLE IRON ON FINISHED CEILING

DRYWALL

Attach angle iron to beams

UNFINISHED OR OPEN BEAM

Extra framing

[22]

not needed

Mounting Straps

[22]

[46 & 47]

[46 & 47]

[

]

46

5/16"-18 x 3/4"

[

]

47

5/16"-18

Extra framing

NEEDED

FIG. 2-10 Mounting the power head.

Page 14

14

INSTALL DOOR ARMS: Sectional doors

OPEN YELLOW PARTS BAG

1. Attach the arms.

• Fasten curved door arm to door bracket using

clevis pin (24) and cotter pin (25) (Fig. 2-10).

• Straight arm to carriage using clevis pin (24) and

cotter pin (25) (Fig. 2-10).

[

]

25

[24]

2. Connecting the arms.

•

Slide carriage back and forth to adjust arm length.

–Overlap arms as much as possible.

–Make overall length as short as possible.

• Fasten arms together using 2 bolts (27) and

nuts (28) (Fig. 2-10). (Place the bolts as far

apart as possible.)

[

[

]

27

3/8"-16 x 7/8"

28

3/8"-16

clevis & cotter pins

short as possible

]

FIG. 2-10 Attaching door arms (sectional doors)

clevis &

cotter

pins

.

NOTE: Whenever possible, it is recommended

that the door arms assembly be angled away

from the door to prevent putting downward force

on the door and door bracket. (Fig. 2-11).

Additionally, where possible, the straight door

arm may be eliminated.

INSTALL DOOR ARMS: 1-piece doors

OPEN YELLOW PARTS BAG

1. Attach the arms.

• Straight arm to door bracket using clevis pin (24)

and cotter pin (25) (Fig. 2-12).

• Curved arm to carriage using clevis pin (24)

and cotter pin (25) (Fig. 2-12).

[

]

25

[24]

2. Connecting the arms.

•

Slide carriage back and forth to adjust arm length.

–Overlap arms as little as possible

–Make overall length as long as possible.

• Fasten arms together using 2 bolts (27) and

nuts (28) (Fig. 2-12).

[

]

27

3/8"-16 x 7/8"

.

[

]

28

3/8"-16

angle

door arms

door

FIG. 2-11 Door arms at angle to door.

clevis &

cotter

pins

long as possible

FIG. 2-12 Attaching door arms (1-piece doors)

REMINDER: If you have no access to your

garage from the outside other than your

garage door, please consider a GER-2

emergency release kit shown on page B in

center of manual

Call Customer Service at 1.800.354.3643, or

visit www

.

geniecompany.com

.

.

.

Page 15

SAFE-T-BEAM®SYSTEM INSTALLATION

3

WARNING

There should be no electrical power to the operator

while installing Safe-T-Beam System®wires. If you

have plugged in the power cord UNPLUG IT NOW.

NOTE: The operator will not close the door

automatically unless the Safe-T-Beam

installed.

1. Mounting brackets.

• Mark both sides of garage door frame or wall 5"

above floor.

(Fig. 3-1).

• Hold bracket against door frame or wall.

–Check if brackets extend out from wall far

enough, so tongue of bracket is beyond door,

tracks or any door hardware.

–If not:

a. STB bracket extensions are available

at local dealer.

b. Blocks of wood, etc. may be substituted for

extensions.

• Center bracket on your mark (Fig. 3-2).

• Fasten each with 2 screws (44) (Fig. 3-2).

®

System is

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

FIG. 3-1 Mark door frame

center of

bracket

FIG. 3-2 Mount

brackets

.

mark

.

tongue

FIG. 3-3 Attaching

STB’s to brackets

15

.

#10-16 x 1-1/4"

[44]

NOTE: Mounting brackets can be attached to the

floor using concrete anchors (not provided).

2. Mounting STB source and sensor.

• If garage has only one garage door.

–Determine which side of garage receives most

direct sunlight (Fig. 3-4).

–Red LED should always be on sunny side

whenever possible (Fig. 3-4).

• For multiple doors.

–Preventing crossed signals is critical.

–Place source and sensor modules on adjacent

doors facing in opposite directions (Fig. 3-4).

NOTE: To help prevent interference from sun, ST B

sensors (Green LED) may be placed further away from

the door opening where they will spend more time

in shadows.

FIG. 3-4 STB locations

• Slide source/sensor onto tongue of bracket until

it clicks into place (Fig. 3-3).

3. Wiring.

• Route wire (29) using either method shown

(Fig. 3-5).

• Wires along rail are held in place with wire clips.

RED

LED

ONE DOOR

GARAGE

GREEN

LED

THREE DOOR

GARAGE

Green

Source

SUN

GREEN

LED

RED

LED

RED

LED

GREEN

LED

TWO DOOR

GARAGE

GREEN

LED

RED

LED

RED

LED

GREEN

LED

.

Dashed Line = striped wire

Solid Line = white wire

Red

Sensor

Green

Source

GREEN

LED

RED

LED

Red

Sensor

[41]

–Wires can be slipped under the wire clips

already in place.

Power

Head

A

B

FIG. 3-5 STB wiring methods

Power

Head

.

Page 16

OPEN RED PARTS BAG

3. Wiring (cont ).

• Securely fasten wires to wall as you go.

16

–Use insulated staples (included).

[30]

–Staples should be snug only.

CAUTION

Staples which are too tight can cut or pinch wires. Cut or

pinched wires can cause the STB System to stop working.

When using the insulated staples, make sure you fasten

them only as tightly as needed to hold the wire snuggly.

• Make wire attachments at “STB’s.”

–Splitting and stripping wire ends to be

connected as shown (Fig. 3-6).

–Loosen terminal screws.

–Insert wire under flat plate and tighten screw.

It does not matter which wire, white or

striped, goes on which terminal (Fig. 3-7).

• Make wire attachments at power head.

–“STB’s” are connected to terminals #2 and #3

on power head (Fig. 3-8).

4. Check the following.

• Insure that no part of door or its hardware is

in path between lenses of source and sensor.

• Insure that tops of lenses are between 5"-6"

above the floor (Fig. 3-9). The brackets are

flexible, and can be adjusted slightly if needed.

FIG. 3-6 Splitting and stripping

FIG. 3-7 Terminal attachments at STB

.

.

2

3

NOTE: Safe-T-Beam® alignment check must be

performed following connection to electrical

power (see page 18). DO NOT PLUG IN YET!

FIG. 3-8 Terminal attachments at power head

top edge of lens

between 5" - 6"

above floor.

FIG. 3-9 Check lens height

.

.

Page 17

WALL CONTROL INSTALLATION

4

WARNING

Verify there is no power to the operator before

installing wall control wires.

CAUTION

Use of any wall control other than the type

supplied will prevent the light from working and

could cause the door to operate on its own.

Cut or pinched wires can cause the wall control to

stop working. When using the insulated staples,

make sure you only pound them in as far as

needed to hold the wire snugly.

1. Finding the mounting location.

• Pick a convenient location for mounting

wall control.

–Location you choose should be in direct sight

of door.

–It should be at least 5’ above floor to prevent

small children from operating door.

–It must be away from any moving parts. (You

should not be able to reach the door while

standing at wall control.)

2. Wiring.

• Run wire from power head to wall control.

• Securely fasten to ceiling using insulated

staples provided.

• Split and strip ends of wire (Fig. 4-5).

• On power head:

–Attach the striped wire to terminal #1 and

white wire to terminal #2 (Fig. 5-1).

• On back of wall control:

–Attach striped wire to terminal B , and

white wire to terminal W. (Fig. 5-2).

3. Mounting.

• Fasten wall control to wall with 2 screws

(wall button use 33) (console use 45)

(Fig. 5-3).

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

FIG. 5-1 Terminal attachments at power head.

button

FIG. 5-2 Wall control wire attachment.

console

1

17

2

33

45

#6 x 1-1/4"

]

#4 x 1"

]

[

[

• Remove protective backing from entrapment

warning label (Fig. 5-4).

–Stick label on wall near wall control.

NOTE: Additional wall controls are available from

your dealer. ONLY ONE OF YOUR WALL

CONTROLS MAY BE THE LIGHTED TYPE. If you

have a lighted wall control, all your additional

controls must be un-lighted. More than one

lighted wall control per operator will cause

a malfunction.

FIG. 5-3 Mounting wall control.

FIG. 5-4 Entrapment warning label.

Page 18

18

CONNECTING TO POWER

5

WITH GROUNDED PLUG:

WARNING

To reduce the risk of electrical shock, this

equipment has a grounded type plug that includes

a third (grounding) pin. This plug will only fit a

grounded type outlet. If you do not have a

grounded outlet, contact a qualified electrician to

install one. DO NOT alter the plug in any way. The

door operator must be properly grounded in order

to prevent personal injury and damage to

the components.

CAUTION

Check local building codes to make sure that you

are not required to have your garage door operator

permanently wired, with circuit breaker protection.

If permanent wiring is required, have this installed

by a qualified electrician.

1. Plug the operator into a properly grounded

electrical outlet.

2. Check Safe-T-Beam

®

alignment (Fig. 6-3).

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

screw

FIG. 6-1 Removing motor cover.

knock-out plug

WITH PERMANENT WIRING:

WARNING

The electrical power to the door operator MUST

BE turned off when the motor cover is removed.

Electrical power must remain off while making

electrical connections.

1. Instructions for electrician.

• Remove power from circuit.

• Remove motor cover (Fig. 6-1)

–Removing hex head screw located in center

on bottom of cover.

–Slide cover down and off.

• Remove and throw away existing power cord.

• Remove 7/8" knockout plug (Fig. 6-2).

–Install a suitable entrance bushing.

• Connect permanent wiring to power head

–

White to white/black to black / ground to green

–Use only UL recognized wire nuts.

• Wires inside power head must be at least 6"

in length.

.

.

CAUTION

The circuit board is light sensitive. Make sure

the motor cover has been replaced prior to

re-energizing the circuit.

• Replace motor cover and re-energize

the circuit.

2. Check Safe-T-Beam

®

alignment (Fig. 6-3).

FIG. 6-2 Knock-out plug.

Safe-T-Beam®Alignment Check

After turning the electrical power on, if the

STB’s are not in proper alignment, the red

.

LED (Source) will blink continuously.

To correct the problem — the brackets are

flexible and can be adjusted slightly to bring

the system into alignment.

When the STB’s are in alignment the red

LED will stop blinking and stay on.

FIG. 6-3

NOTE: The Genie Company is not responsible

for charges resulting from work performed by an

independent electrician.

NOTE: If a problem exists with the STB that is

preventing the door from closing, the door can be

closed by holding the wall control button in until the

door is fully closed. (The remote control will not work.)

Page 19

LIMIT SWITCH / FORCE ADJUSTMENT

6

WARNING

DOOR OPENS RAPIDLY

Keep the path clear

Position the ladder to the side of the power head

so it is clear of all moving parts of the operator

and door.

Always set the door operator to the minimum

force required to operate the door

NOTE: During operator cycling for force

adjustment, the motor protector may shut off

power to the operator. If this occurs, wait about

20 minutes to allow the motor protector to reset.

1. Adjusting limit switches.

• Locate force control knobs on power head

(Fig. 7-1).

–Gently turn both control knobs

counter-clockwise until they stop.

• Verify emergency release lever in disengaged

position.

• Verify OPEN limit switch at point where chain

attaches to carriage slide

• Manually close door.

• Move the CLOSE limit switch:

–Loosen set screw.

–

Slide limit switch along rail to align front edge

of switch with back edge of carriage (Fig. 7-3).

–Gently tighten set screw.

• Press wall control button.

–Carriage slide will move toward power head

and stop at the OPEN limit switch.

• Manually open door.

• Move the OPEN limit switch:

–Loosen set screw.

–

Slide limit switch along rail to align front edge

of switch with back edge of carriage (Fig. 7-4).

–Gently tighten set screw.

–Manually close door.

• Place emergency release lever in engaged

position.

• Press wall control button.

–Carriage slide will move toward door, engage

with carriage and stop at CLOSE limit switch.

2. Adjusting OPEN force.

• Press wall control button.

–

Door should open and stop at OPEN limit.

• Door does not fully open.

–Press wall control button.

–Door should close and stop at CLOSE limit.

–Turn

–Press wall control button.

3. Adjusting CLOSE force.

• Door is not fully closing.

–Cycle door, turning CLOSE force knob

OPEN

clockwise direction.

a. Continue step 2 until door opens completely.

clockwise slightly each time until door reaches

fully closed.

force control knob slightly in

.

.

.

(Fig. 7-2).

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

19

FIG. 7-1 Force adjustment screws.

FIG. 7-2 Place “Open” limit switch.

FIG. 7-3 Align “CLOSE” limit switch.

FIG. 7-4 Align “OPEN” limit switch.

Page 20

CONTACT REVERSE TEST

The force adjustments and limit switch

settings MUST BE COMPLETED before testing

contact reverse.

1. Testing.

20

2. Adjustment.

7

SINGLE BUTTON REMOTE

1. Programming.

• Locate learn code button and indicator LED

• Press and release learn code button.

• Within 30 seconds, push remote control

• Press remote control button again.

2. Operating.

• Press remote button once.

• Press button again.

• Press button again.

The door will stop automatically at the fully

open or fully closed position.

• Open garage door using wall control.

–Place a 2" x 4" board (laid flat) under center

of garage door opening (Fig. 7-5).

–Close door using wall control.

• When door hits board, it must stop and

reverse (within 2 seconds) to open position.

• Door does not properly reverse.

–Check to see if door is at close limit.

–It should not have reached limit switch

before hitting board.

• Door is at close limit switch.

–Move limit switch closer to door.

• Test again. Repeat as necessary.

• Door is not reaching close limit, but

still does not reverse.

–Decrease CLOSE FORCE setting

slightly (turn it counter-clockwise).

• Test again. Repeat as necessary.

PROGRAMMING REMOTE CONTROLS

on front of power head (under force

adjustment screws) (Fig. 8-1).

–Indicator LED will blink at a rate of twice

per second.

button once.

–Indicator LED will stop blinking and stay on.

–LED will go out. Remote is now programmed.

–Door will move.

–Door will stop.

–Door will move in opposite direction.

FIG. 7-5 2 x 4 under center of door opening

FCC and IC CERTIFIED

This device complies with FCC Part 15 and RSS

210 of Industry Canada. This equipment has been

tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide

reasonable protection against harmful interference

in a residential installation. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in

accordance with the instructions, may cause

harmful interference to radio communications.

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause harmful interference to

radio or television reception, which may be

determined by turning the equipment off and on,

the user is encouraged to try to correct the

interference by one or more of the following

measures:

Re-orient or relocate the receiver antenna.

Increase the separation between the operator

and receiver.

Connect the operator into an outlet on a circuit

different from that to which the receiver is

connected.

Consult your local dealer.

FIG. 8-1 Learn code button and LED

Page 21

MULTI-BUTTON REMOTE

1. Programming.

NOTE: Each button on a multi-button remote is

designed for use with 1 door. You cannot program 2 buttons to operate the same door, nor

can you program 1 button to operate 2 doors.

• For each button

–Program each button separately.

–Follow single button remote procedure

(previous page) for each button.

2. Operating.

• Same as single button remote.

.

LOST OR STOLEN REMOTE

1. Clear memory.

• Press and hold learn code button (on power

head) for 10 seconds or until Indicator LED

goes out.

• Program remaining or new remote controls as

done previously. Your door operator will no

longer recognize any signal received from the

missing remote control, or any other which has

not been reprogrammed.

21

FIG. 9-1 Open battery cover.

+ polarity marks

REMOTE CONTROL

8

BATTERY REPLACEMENT AND

VISOR CLIP INSTALLATION

1. Battery replacement.

• Use coin, ball-point pen or similar device.

–Gently push straight in on battery cover lock

tab as shown (Fig. 9-1).

• Flip open battery cover.

–Remove old battery.

• Make sure new battery is facing proper direction

(Match battery polarity with symbols inside

battery cover) (fig. 9-2).

–Recommended replacement battery is

Eveready A-23, 12 volt.

• Slip new battery into place.

–Snap battery cover shut.

• Operate remote to make sure it is working

properly. (No re-programming is needed.)

2. Visor clip.

• Slide visor clip into back of remote control.

–It will snap into place (Fig. 9-3).

LIGHT BULB/ LENS INSTALLATION

9

1. Light bulb.

• Recommendations.

–Do not use a short neck bulb.

–Light bulb should be no more than 100 Watts.

–Use a heavy duty service bulb for longer life.

• Screw bulb into socket.

2. Lens.

• Slide hinges into slots on motor cover (Fig. 10-1).

• Swing lens up.

–Fit tabs into slots provided on power head.

FIG. 9-2 Match battery polarity.

FIG. 9-3 Attach visor clip.

FIG. 10-1 Slide hinges into motor cover.

FIG. 10-2 Fasten lens.

Page 22

22

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of severe injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with the door controls. Keep the remote control away from children.

3. Always keep the moving door in sight and away from people and objects until the door is completely

closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4. NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

5. Test operator monthly. The door MUST reverse on contact with a 1

board laid flat) at the center of the doorway on the floor. After adjusting either the force or the limit of

travel, retest the door Opener. Failure to adjust the Opener properly may cause severe injury or death.

6. When possible, use the emergency release only when the door is closed. Use caution when using this

release with the door open. Weak or broken springs are capable of increasing the rate of door closure

and increasing the risk of severe injury or death.

7. KEEP DOORS PROPERLY BALANCED. See Owner’s Manual. An improperly balanced door increases

the risk of severe injury or death. Have a qualified service person make repairs to cables, spring

assemblies, and other hardware.

SAVE THESE INSTRUCTIONS.

8.

1

/2" high object (or a 2" x 4"

MAINTENANCE

10

ROUTINE MONTHLY MAINTENANCE

1. Door springs and hardware.

• Do not operate garage door automatically or

manually if springs are broken.

–

CONTACT A PROFESSIONAL FOR SERVICE.

2. Door balance.

• Close the door.

• Pull emergency release knob down to release

door from carriage assembly.

• Raise door manually approximately 3 feet.

–

Door should stay in that position or close

very slowly.

–

If door moves quickly, HAVE DOOR SERVICED

BY A PROFESSIONAL.

• Close the door.

• Pull emergency release knob toward power

head to place release lever in engaged position.

–

Operate door using remote.

–

Door will re-attach itself to carriage assembly.

3. Contact reverse.

• Place a 2" x 4" board laid flat on floor.

–

In center of garage door opening.

• Close door by using wall button or

remote control.

–

Door fails to reverse on contact with board see

Section 7 CONTACT REVERSE

–

Operator still fails CONTACT A

SERVICE PROFESSIONAL.

.

4. Safe-T-Beam®System.

• Use Self-Diagnostic STB system Troubleshooting

information to maintain safe operation (Below).

TROUBLESHOOTING GUIDE

Use This Guide To Correct Problems With Door Operator.

SOURCE

RED LED

ON

OFF

OFF

2 BLINKS, PAUSE

(REPEAT)

2 BLINKS, PAUSE

(REPEAT)

3 BLINKS, PAUSE

(REPEAT)

4 BLINKS, PAUSE

(REPEAT)

NOTE: IF OPERATING PROBLEM EXISTS, THE DOOR CAN BE CLOSED IF YOU:

•DISCONNECT THE STB SYSTEM FROM THE OPERATOR

• HOLD WALL CONTROL BUTTON DOWN UNTIL DOOR IS CLOSED

(REMOTE CONTROL & WIRELESS KEYPAD WILL NOT WORK WITHOUT STB)

For Answers: CALL CUSTOMER SERVICE

If These Solutions Do Not Work,

Call Customer Service at 1.800.35.GENIE

SELF-DIAGNOSTIC

STB SYSTEM TROUBLESHOOTING

SENSOR

GREEN LED

ON

OFF

ON

ON

OFF

ON

ON

INDICATED

CONDITION

NORMAL OPERATION

1. POWER HEAD NOT

POWERED

2. WIRING FROM

POWER HEAD BAD

1. WIRING TO

SOURCE MISSING

OR BAD

2. POWER HAS BEEN

INTERRUPTED

1. BEAM NOT ALIGNED

2. BEAM OBSTRUCTED

3. SENSOR DEFECTIVE

1. WIRE TO SENSOR

MISSING OR BAD

2. SENSOR DEFECTIVE

1. SENSOR RECEIVING

INTERFERENCE

1. SOURCE NOT

SENDING PULSES

2. SOURCE DEFECTIVE

REQUIRED

ACTION

NONE REQUIRED

1. CHECK BREAKERS,

FUSES, PLUGS

2. CHECK WIRING FOR

OBVIOUS SHORTS

1. CHECK WIRING

2. REMOVE POWER

AND REAPPLY

1. CHECK ALIGNMENT

2. CHECK FOR

OBSTRUCTION

3. CALL CUST. SERV.

1. CHECK WIRING

2. CALL CUST. SERV.

1. ATTEMPT TO

DETERMINE SOURCE

OF INTERFERENCE

2. CALL CUST. SERV.

1. CALL CUST. SERV.

2. CALL CUST. SERV.

at 1.800.35.GENIE

Page 23

TROUBLESHOOTING GUIDE (CONTINUED)

FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

CAUTION

Use wall control supplied with operator. Any other wall control can cause

the operator to operate unexpectedly and light not to work.

Operator does

not run from

wall control

.

Door operator

starts for

no reason

.

• Check lock switch on wall console.

• Check power source.

–

Plug a lamp into outlet used for power

head If lamp works, power source is OK.

–

If not, check fuse or circuit breaker.

• Power is OK.

–

Check connections at power head

terminals.

–

Check connections at wall control.

• Check wires to ensure they are not cut.

Staples can cut insulation and short wires. If

wire is cut, replace it.

• Was a remote control lost or stolen?

Erase all remote control codes from

receiver memory and reprogram

(See section ).

7

• Button stuck on wall control.

Check CLOSE limit switch setting

•

(See section ).

•

Wires shorted.

6

Door starts up,

but stops before

its completely

open

.

Operator runs,

but door does

not move

.

Remote control

has less than

25 feet

operating range

• Be sure door, operator, and springs are in

good repair, properly lubricated and balanced

(See maintenance section).

• Check OPEN limit switch setting

(See section ).

6

• Check OPEN FORCE adjustment

(See section ).

6

• Make sure carriage is engaged to

carriage slide.

— Place carriage lever in lock position.

• Check force adjustment (See section ).

6

Door operator will NOT run more than

30 seconds each way if door does

not move.

• Relocate remote control inside car.

• Point remote control at garage door.

• Replace battery (See section ).

.

• Reposition door operator antenna.

8

• DO NOT attempt to retune remote controls.

23

Door starts down,

then stops before

its closed.

Door starts

down, then stops

and goes

back up

.

Door will only

run closed

.

Door will only

run open

• Check CONTACT REVERSE

(See section ).

6

• Check STB system for beam obstruction

or misalignment of lenses (See section ).

Check STB diagnostic code.

•

3

• Check CLOSE FORCE adjustment

(See section ).

6

• Check OPEN limit switch for short and

proper wiring.

• Check OPEN FORCE adjustment

(See section ).

6

• Check door condition and door spring.

Check STB system (See self-diagnostic

•

STB Troubleshooting Chart).

Check CLOSE limit switch for short and

•

proper wiring.

Check CLOSE FORCE adjustment

•

(See section ).

6

Operator works

from wall

control, but

not from

remote control

Noisy operation

Safe-T-Beam

®

system

malfunction

Program remote control code into

•

receiver memory.

Replace remote control battery with good

•

(See section ).

one.

(See section ).

8

7

.

• Be sure all fasteners are tight.

.

• Be sure door and operator is in good repair,

properly lubricated and balanced (See

monthly maintenance section).

If an operational problem exists, and operator

will not run closed. The operator can be forced

to close as follows (See section ).

5

• Disconnect the STB system from

the operator.

• Hold the wall control button down until door is

completely closed.

Use self-diagnostic STB system Troubleshooting

information to maintain safe operation.

Lights will not go

out

Disconnect and reconnect wires on wall control

•

(See section ).

4

• Check wiring.

• Incompatible wall control.

If you have any questions, please do not hesitate to

contact customer service at:

1.800.354.3643

Page 24

24

WIRING DIAGRAM FOR HELP-1.800.354.3643 OR GENIECOMPANY.COM

TRANSMITTER COMPLIANCE STATEMENT

Transmitters comply with all United States and Canadian legal requirements as of the date of manufacture. No warranty is made

that they comply with all legal requirements of any other jurisdiction. If transmitters are to be used in another country, the importer

must determine compliance with any local laws and regulations which may differ from United States and Canadian requirements

prior to use.

Los transmisores cumplen con todas las reglamentaciones legales de los Estados Unidos y del Canadá, en la fecha de fabricación.

Ninguna garantía se da que cumplan con todas las reglamentaciones legales de ninguna otra jurisdicción. Si los transmisores se

van a utilizar en otro país, el importador debe determinar si cumplen con las reglamentaciones y leyes locales que puedan ser

diferentes a las reglamentaciones de los Estados Unidos y del Canadá, antes de usar los mismos.

Les émetteurs sont conformes à la réglementation américaine et canadienne à compter de leur date de fabrication. Aucune garantie

n’est stipulée indiquant qu’ils sont conformes à toutes les prescriptions juridiques d’autres autorités. Si les émetteurs sont utilisés

dans d’autres pays, il incombe à l’importateur d’en déterminer leur conformité aux lois et règles locales pouvant différer de celles

des États-Unis et du Canada avant toute utilisation desdits émetteurs.

Sendegeräte entsprechen allen gesetzlichen Bestimmungen in den USA und Kanada zum Zeitpunkt der Herstellung. Wir

übernehmen keine Gewährleistung für die Einhaltung aller gesetzlichen Bestimmungen in anderen Ländern. Sollen Sendegeräte in

anderen Ländern eingesetzt werden, so muss der Importeur vor dem Gebrauch sicherstellen, dass die Sendegeräte auch solchen

lokalen Bestimmungen entsprechen, welche von den Bestimmungen der USA und Kanadas abweichen.

Page 25

Garage Door Operator Accessories

Accesorios para abridores de garajes

Accessoires pour ouvre-porte de garage

Prices on reverse

Precio en dorso

Prix sur oppos

AVAILABLE AT YOUR LOCAL GENIE®DISTRIBUTOR

(GIT-1) Deluxe Remote Control with Intellicode®. - Allows remote operation of one garage door.

Controlador remoto de lujo con Intellicode

Télécommande de luxe avec Intellicode®. - Permettre opération élogin de un porte de garage.

(GIT-2BL) 2-Button Remote Control with Intellicode

Controlador remoto de 2 funciones con Intellicode

Télécommande à 2 fonctions avec Intellicode®.- Permettre opération élogin deux portes de garage.

(GIT-3BL) 3-Button Remote Control with Intellicode

Controlador remoto de 3 funcione con Intellicode

Télécommande à 3 fonctions avec Intellicode®. - Permettre opération élogin trios portes de garage.

(GMIC90-2BL) 2-Button Mini Remote Control with Intellicode

Minicontrolador remoto de 2 funciones con Intellicode

Mini télécommande à 2 fonctions avec Intellicode®- se glisse dans la poche de veston ou le sac à main.

(GPWC-2WLB) 3-Function Wall Console - Operates garage door. Independent light control. Security vacation lock.

Consola de pared de 3 funciones - Acciona la puerta del garaje. Control de luz independiente. Cerradura de seguridad para vacaciones.

Console murale à trois fonctions - Actionne la porte de garage. Commande d’éclairage indépendante. Interrupteur de verrouillage de sécurité.

(GWKIC) Wireless Keypad Entry System - Operates Intellicode

Sistema de entrada por teclado numérico inalámbrico - Acciona los abridores de puertas de garaje Intellicode

Système d’ouvre-porte de garage à clavier sans fil - Actionne les ouvre-porte de garage avec Intellicode

(GWB) Universal Wall Button - Provides convenient inside operation of door.

Botón de pared universal - Proporciona operación conveniente de la puerta desde el interior.

Bouton mural universel - Actionne l’ouvre-porte de l’intérieur du garage.

(GPS-5BL) Perfect Stop

Stop

®

Perfecto - Asegura el estacionamiento perfecto.

®

- Ensures perfect parking.

Butoir Perfect Stop®- Permet de stationner à la perfection dans le garage.

(LCGX-8) Chain Glide™ Extension Kit - An 18 inch extension to increase the travel of a Chain Glide™ operator to accommodate an 8 foot door.

Juego de extensión deslizante - Una extensión de 18 pulgadas para aumentar la carrera de un abridor deslizable de cadena, para acomodar una puerta de 8 pies (2,43 m.).

Nécessaire de rallonge du Chain Glide™- Rallonge de 30 dm (18 po) prolongeant la course de l’ouvre-porte Chain Glide pour une porte de 2,4 m (8 pi) de hauteur.

(GIRU-1T) Universal Conversion Kit - Converts any garage door operator to a secure radio signal system. Kit includes a remote control, receiver and transformer.

Juego de conversión universal - Convierte cualquier abridor de puerta de garaje a un sistema de señal de radio seguro. El juego incluye un control remoto de abridor,

receptor y transformador.

Nécessaire de conversion universel - Transforme tout ouvre-porte de garage en système de sécurité à signal radio. Comprend une télécommande, un récepteur et

60 WATT Light Bulb - Ensures proper equipment compatability.

Bombilla de 60 Vatios - Asegura componente correcto de sistema.

Éclairage de 60 WATT - Garantir componant exact par systéme.

(GER-2) Emergency Release Kit - Provides access to garage from outside in the event of an electrical power failure.

Juego de pica-porte de pestillo - Permitir entrtada desde por fuera de garaje porque corte de eléctrico.

Nécessaires de Déclenchement de secours - Le nécessaire de déclenchement de secours est conçupour vous permettre d’accéder à votre garage depuis l’extérieur en cas

de panne de courant et lorsqu’il.

STB Bracket Extensions - Provides additional bracket length where it may be needed for clearance.

Exttesión de Cartelas de STB - Adiciónal extensión de las cartelas de sistema de STB.

Extension de Support du STB - Pourvoir étendue de plus de support du systéme STB.

®

.- Proporciónar operación remoto de uno puerta del garaje.

®

. - Allows remote operation two garage doors.

®

. - Proporciónar operación remoto de dos las puerta del garaje.

®

. - Allows remote operation of three garage doors.

®

. - Proporciónar operación remoto de tres las puerta del garaje.

®

- Fits easily into pocket or purse.

®

- Cave fácilmente en el bolsillo o cartera.

®

garage door operators without remote control or key.

®

sin control remoto o llave.

®

sans télécommande ni clé.

A

No C.O.D. shipments. Please include check or

money order, do not send cash.

TEAR ALONG DOTTED LINE /ARRANCAR EN LA LºNEA DE PUNTOS / ARRACHER LA LIGNE EN POINTILLE

Allow 3-4 weeks for delivery. We accept Visa or

Mastercard phone orders.

1.800.354.3643. Please have part number and credit

card ready.

Please add local sales tax if you reside in one of

the states listed.

California

Connecticut

Florida

Georgia

Illinois

TOTAL ORDER $

SHIPPING & HANDLING $ 5.00

STATE SALES TAX $

GRAND TOTAL $

Indiana

Maryland

Massachusetts

Michigan

New Jersey

New York

Ohio

Tennessee

Virginia

Wisconsin

No se aceptan pedidos de pago contra entrega (COD).

Sírvase incluir su cheque o giro postal; no envíe dinero

en efectivo.

Concédanos 3 a 4 semanas para la entrega.

Aceptamos pedidos telefónicos de Visa o Mastercard.

1.800.354.3643. Sírvase tener listos los números del

modelo y de la tarjeta de crédito.

Sírvase agregar el impuesto de ventas local si

usted reside en uno de los siguientes estados:

California

Connecticut

Florida

Georgia

Illinois

TOTAL DEL PEDIDO $

FLETE Y MANEJO $ 5.00

IMPUESTO DE VENTAS ESTATAL $

GRAN TOTAL $

Indiana

Maryland

Massachusetts

Michigan

New Jersey

New York

Ohio

Tennessee

Virginia

Wisconsin

Pas d’expédition contre remboursement. Veuillez

inclure un chèque ou un mandat bancaire. N’envoyez

pas d’argent comptant.

Accordez de 3 à 4 semaines pour la livraison. Nous

acceptons les commandes par téléphone avec

paiement par carte de crédit Visa ou Mastercard.

1.800.354.3643. Ayez sous la main le numéro de la

pièce et celui de la carte de crédit.

Veuillez indiquer les taxes de vente locales si vous

résidez dans l’un des états répertoriés ci-dessous.

California

Connecticut

Florida

Georgia

Illinois

COMMANDE TOTALE $

MANUTENTION ET EXP DITION $ 5.00

TAXE DE VENTE $

TOTAL GLOBAL $

Indiana

Maryland

Massachusetts

Michigan

New Jersey

New York

Ohio

Tennessee

Virginia

Wisconsin

Page 26

Garage Door Operator Accessories Order Form

21

A

B

C

3

D

E

F

56

M

N

O

J

K

L

4

G

H

I

8

0

9

W

X

Y

T

U

V

7

P

R

S

S

E

N

D

P

R

O

G

Formulario de pedido de accesorios para abridores de puertas de garaje

Formulaire de commande des accessoires pour ouvre-porte de garage

B

MODEL DESCRIPTION PRODUCT CODE PRICE (US$)* QTY. TOTAL

MODELO D ESCRI PCI N C DIG O PRECIO* CANTIDAD TOTAL

MODØLE DESCRIPTION CODE DU PRODUIT PRIX ($ US)* Q T TOTAL

Deluxe Remote Control with Intellicode

GIT-1 Controlador remoto de lujo con Intellicode®33069R $34.95

Télécommande de luxe avec Intellicode

2-Button Remote Control with Intellicode

GIT-2BL Controlador remoto de 2 funciones con Intellicode®33142S $44.95

Télécommande à 2 fonctions avec Intellicode

3-Button Remote Control with Intellicode

GIT-3BL Controlador remoto de 3 funciones con Intellicode®33142T $49.95

Télécommande à 3 fonctions avec Intellicode

2-Button Mini Remote Control with Intellicode

GMIC90-2BL

Minicontrolador remoto de 2 funciones

con Intellicode

®

Mini télécommande à 2 fonctions avec Intellicode

®

®

®

®

®

®

®

32433R.S $44.10

®

Lighted Wall Console

GPWC-2WBL Consola de pared encender 34292R $35.00

Console murale avec éclairage

Wireless Keypad Entry System

GWKIC Sistema de entrada por teclado numérico inalámbrico 00001033 $50.00

Système d’ouvre-porte de garage à clavier sans fil

Universal Wall Button (unlit)

GWB Botón de pared universal (unlit) 32569R $03.75

Bouton mural universel (unlit)

Perfect Stop

GPS-5BL Stop Perfecto

Butoir Perfect Stop

®

®

®

00001200 $04.00

*Prices subject to change without notice

*El precio est sujeto a cambios sin aviso

* Les prix peuvent subir des modifications

sans pr avis

Chain Glide™ Extension Kit

LCGX-8

Juego de extensión de cadena deslizable

Nécessaire de prolongement du

00001085 $30.00

coulisseau

Universal Conversion Kit

GIRU-1T Juego de conversión universal 33154R $50.00

Nécessaire de conversion universel

60 WATT Light Bulb

Bombilla de 60 Vatios 26210A.S $2.50

Éclairage de 60 WATT

Emergency Release Kit

GER-2 Juego de pica-porte de pestillo 32561R $20.00

Nécessaires de d’clenchement de secours

STB Bracket Extensions

Extensión de Cartelas de STB 34439R.S $04.00

Extension du Support de STB

SHIP ORDER TO:

NAME / NOMBRE / NOM

ENVIAR MERCANCIA

CON:

ADDRESS / DIRECCIóN / ADRESSE

CITY / CIUDAD / VILLE

EXPÉDIER MARCHANDISE

POUR:

STATE / ESTADO / éTAT ZIP / CóDIGO POSTAL / CODE POSTAL

TEAR ALONG DOTTED LINE /ARRANCAR EN LA LºNEA DE PUNTOS / ARRACHER LA LIGNE EN POINTILLE

MAIL ORDER

FORM TO:

The Genie Company

22790 Lake Park Blvd.

Alliance, Ohio 44601

Page 27

The Genie Company Professional Access Systems

LIMITED WARRANTY

What is covered: Any defect in material and product workmanship from personal,

normal household use in accordance with the Owner s Manual.

For how long:

H2000C-1 Series - 3 years on Motor, and 1 year on all other parts.

350L- 1 Series - 3 years on Motor, and 1 year on all other parts.

350L - 2 Series - 5 years on Motor, and 2 years on all other parts.

350L-2WKC Series - Lifetime* on Motor, 2 years on all other parts.

350L-2C Series - 5 years on Motor, 2 years on all other parts.

350L-2WK Series - 5 years on Motor, 2 years on all other parts.

500ML Series - 5 years on Motor, and 3 years on all other parts.

700ML Series - Lifetime* on Motor, 3 years on all other parts.

*Lifetime warranty - warranted for as long as you own your home.

Who gets the warranty: This warranty is limited to the consumer who originally

purchased the product.

Geographic scope: This warranty applies only to Genie products purchased in

the United States and Canada.

What we will do: If your Genie product is defective, we will repair it or, at our

option, replace it at no charge to you. If we repair your Genie product, we may use

new or reconditioned replacement parts. If we choose to replace your Genie

product, we may replace it with a new or reconditioned one of the same or

similar design.

Limitations:

IMPLIED WARRANTIES, INCLUDING THOSE OF FITNESS FOR A PARTICULAR

PURPOSE AND MERCHANTABILITY (AN UNWRITTEN WARRANTY THAT THE

PRODUCT IS FIT FOR ORDINARY USE), ARE LIMITED TO ONE YEAR FROM

THE DATE OF PURCHASE. GENIE WILL NOT PAY FOR: LOSS OF TIME;

INCONVENIENCE; LOSS OF USE OF YOUR GENIE PRODUCT OR PROPERTY

DAMAGE CAUSED BY YOUR GENIE PRODUCT OR ITS FAILURE TO WORK;

ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES; OR ANY

DAMAGES RESULTING FROM MISUSE OR MODIFICATION OF YOUR GENIE

PRODUCT.

Some states and provinces do not allow limitations on how long an implied

warranty lasts or the exclusion of incidental or consequential damages, so the

above exclusions may not apply to you.

How to get warranty service: To obtain warranty service for your Genie

product, you must provide proof of the date and place of purchase of the product.

1. Do-It-Yourself-Service. Call the Genie Consumer Connection toll free at

1.800.354.3643 to speak in person to a trained Genie representative for

assistance in diagnosing the problem and arranging to supply you with the

required parts for do-it-yourself repairs. Trained service representatives are

available Monday-Friday, 8:00 a.m. - 11:00 p.m., Eastern Time, and on Saturday,

11:00 p.m. to 8:00 p.m., Eastern Time (subject to holidays) You may also get the

information you need at www.geniecompany.com.

2.Service From Authorized Dealers.

You also may obtain warranty service from Genie authorized dealers listed in the

enclosed directory. Please note that this listing is subject to change without

notice; we recommend that you verify the dealer s status by calling the Genie

Consumer Connection at 1.800.654.3643 or by visiting www.geniecompany.com

before reaching any agreement on service. If warranty service is provided by an

authorized dealer, Genie will provide all required parts under warranty at no

charge to you, but the dealers are independent business people and may render

a bench or service call charge for their services. Genie will not reimburse you or

otherwise be responsible for those charges.

We suggest that you retain your original packing material in the event you need

to ship your Genie product. Be sure to include your name, address, telephone

number, proof of date and place of purchase and a description of the operating

problem. After repairing or, at our option, replacing, your Genie product, we will

ship it to your home at no cost to you for parts and labor, but you will have to pay

a minimum of $8.00 for shipping and handling charges.

Your choice of either one of the above-described service options is your

exclusive remedy under this warranty.

What this warranty does not cover: This warranty does not cover batteries

(which are considered replaceable parts), installation, commercial use, defects

resulting from accidents, damage while in transit to our service location or damage

resulting from alterations, misuse or abuse, lack of proper maintenance,

unauthorized repair or modification of the product, affixing of any attachment not

provided with the product, programming of the Remote Control Devices,

Safe-T-Beam® adjustment/cleaning, staples through wiring, pinched or broken

wires, Carriage disengaged, Force Control adjustments, door out of balance,

broken springs or cables, power outages, use of extension cords, missing or

damaged parts on discounted, clearanced, final sale or taped cartons, phantom

operations (labor is not covered if Opener is functioning properly while technician