Page 1

Operator’s Manual

Serial number range

500L Loading Shovel.......from serial n: SHOV5DL15B-1001

800L Loading Shovel.......from serial n: SHOV8DL15B-1001

800L Loading Shovel.....from serial n: SHOV8CDL15B-1001

800L Loading Shovel..... from serial n: SHOV8RDL15B-1001

Brick-Holder Basket.......from serial n: BBSKETDL15B-1001

250L Mixing Bucket..........from serial n: MXBC2515B-1001

500L Mixing Bucket...........from serial n: MXBC515B-1001

500L Man. Conc. Bucket....from s/n: CB5MADL15B-1001

500L Hyd. Conc. Bucket....from s/n: CB5HYDL15B-1001

800L Man. Conc. Bucket....from s/n: CB8MADL15B-1001

800L Hyd. Conc. Bucket....from s/n: CB8HYDL15B-1001

Original Instructions

First Edition

Second Printing

Part No. 57.0303.5251

Page 2

December 2015

First Edition - Second Printing

Contents

Introduction ..........................................Page 3

Symbol and Hazard Pict.Definition ......Page 8

General Safety.....................................Page 9

Work Area Safety.................................Page 10

Safety Precautions............................ Page 11

Legend .................................................Page 13

Attachment Description .......................Page 14

Attachment Application Field ...............Page 17

Inspections ..........................................Page 18

Operating Instructions .........................Page 22

Parking and Storage ............................Page 31

Tansport and lifting instruction.............Page 32

Maintenance ........................................Page 42

Specification ........................................Page 46

Load Charts .........................................Page 52

Diagrams And Schemes ......................Page 66

EC Declaration of Conformity ..............Page 68

TEREX Global GmbH

Bleicheplatz 2

8200 Schaffhausen

Switzerland

Technical Assistance Service

Telephone: +39 075 9418129

+39 075 9418175

e-mail: UMB.Service@terex.com

2 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Copyright © 2015 by Terex Corporation

First Edition: Second Printing, December 2015

Genie is a registered trademark of Terex South

Dakota, Inc. in the U.S.A. and many other

countries. “GTH” is a trademark of Terex South

Dakota, Inc.

Page 3

First Edition - Second Printing December 2015

Introduction

About This Manual

Genie appreciates your choice of our machine for

your application. Our number one priority is user

safety, which is best achieved by our joint efforts.

This book is an operation and daily maintenance

manual for the user or operator of a Genie machine.

This manual should be considered a permanent part

of your machine and should remain with the machine

at all times. If you have any questions, contact Genie.

In this manual, the term "machine" can be referred

to both the attachment or the truck, according to

the context.

This manual shall be used in conjunction with the

user manual of the telehandler.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 3

Page 4

December 2015

Introduction

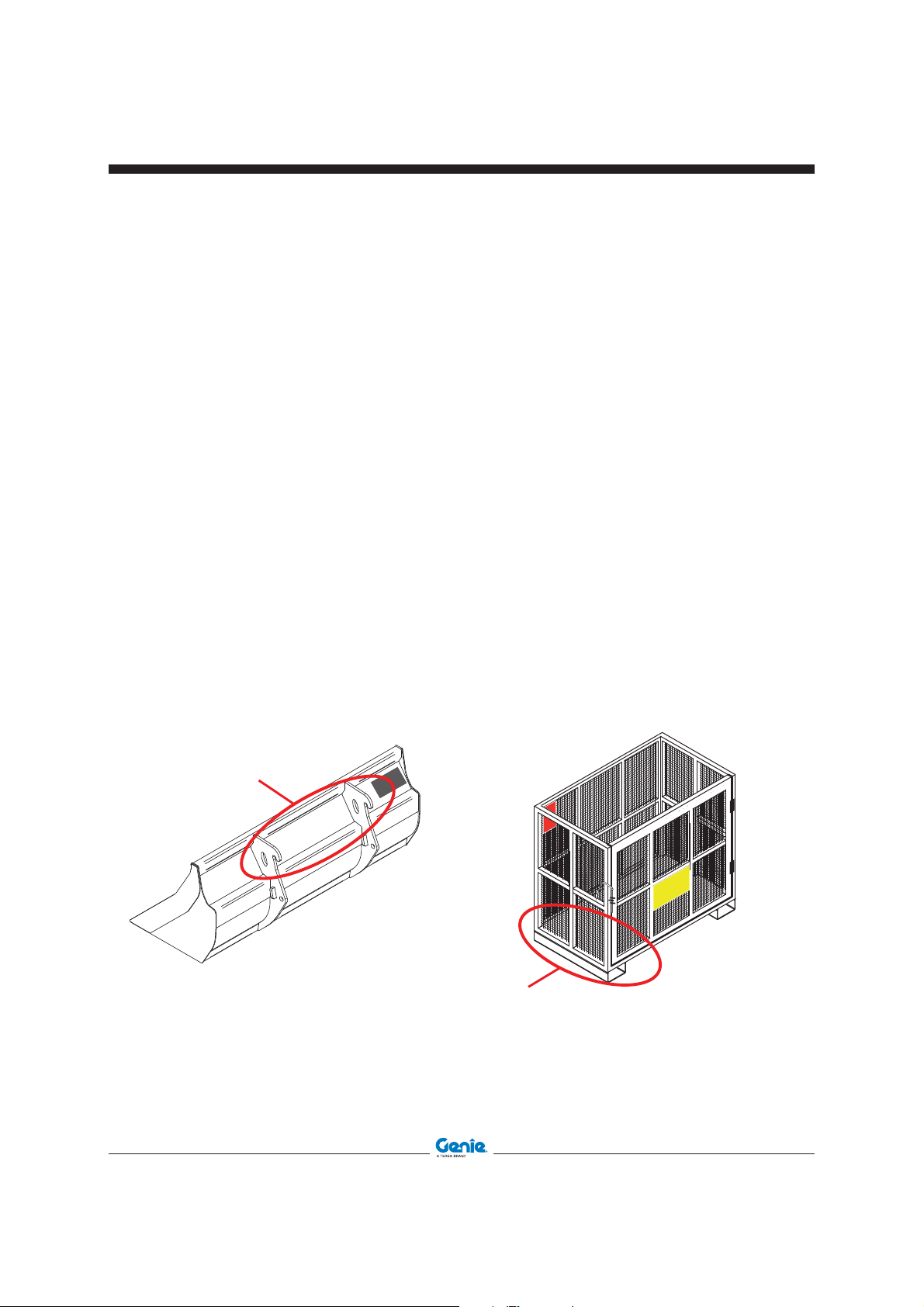

Product Identifi cation

The attachment serial number is located on the

serial label.

First Edition - Second Printing

• 500L Loading Shovel 59.0201.9019 GT

• 800L Loading Shovel 59.0201.9020 GT

• 800L Loading Shovel 59.0201.9021 GT

• 800L Loading Shovel 59.0201.9022 GT

• Brick-Holder Basket 59.0401.2032 GT

• 250L Mixing Bucket 59.0401.2018 GT

• 500L Mixing Bucket 59.0401.2016 GT

• 500L Man. Concrete Bucket 59.0401.2028 GT

• 500L Hyd. Concrete Bucket 59.0401.2029 GT

• 800L Man. Concrete Bucket 59.0401.2030 GT

• 800L Hyd. Concrete Bucket 59.0401.2031 GT

4 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Intended Use

The Loading Shovels and Mixing Bucket are designed

to move and to mix loose materials. Brick-Holder

Basket is designed to lift and lower loose materials.

Use of this product in any other way is prohibited

and contrary to its intended use.

Page 5

First Edition - Second Printing December 2015

Introduction

Bulletin Distribution and

Compliance

Safety of product users is of paramount importance

to Genie. Various bulletins are used by Genie

to communicate important safety and product

information to dealers and machine owners.

The information contained in the bulletins is tied to

specific machines using the machine model and

serial number.

Distribution of bulletins is based on the most current

owner on record along with their associated dealer,

so it is important to register your machine and keep

your contact information up to date.

To ensure safety of personnel and the reliable

continued operation of your machine, be sure to

comply with the action indicated in a respective

bulletin.

Contacting the Manufacturer

At times it may be necessary to contact Genie.

When you do, be ready to supply the model number

and serial number of your machine, along with your

name and contact information. At minimum, Genie

should be contacted for:

• Accident reporting

• Questions regarding product applications and

safety

• Standards and regulatory compliance information

• Current owner updates, such as changes in

machine ownership or changes in your contact

information. See Transfer of Ownership, below.

Transfer of Machine Ownership

Taking a few minutes to update owner information

will ensure that you receive important safety,

maintenance and operating information that applies

to your machine.

Please register your machine by visiting us on the

web at www.genielift.co.uk.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 5

Page 6

December 2015

Introduction

First Edition - Second Printing

Danger

Failure to obey the instructions and safety rules in

this manual will result in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

attachment operation contained in this operator’s

manual.

1. Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2. Always perform a pre-operation inspection.

3. Always perform function tests prior to use.

4. Only use the machine as it was intended.

You read, understand and obey the manufacturer’s

instructions and the safety rules, the safety and

operator’s manuals, and the decals applied on

the machine.

You read, understand and obey the employer’s

safety rules and work-site regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

6 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 7

First Edition - Second Printing December 2015

Introduction

Hazard Classifi cation

Safety alert symbol: used to

alert you to potential personal

injury hazards. Obey all safety

messages that follow this

symbol to avoid possible injury

or death

DANGER

WARNING

CAUTION

NOTICE

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in minor or moderate injury.

Indicates a property damage

message.

Standards

The following standards and/or regulations apply to

this machine:

Directive

2006/42/EC Machinery Directive

Safety Sign Maintenance

Replace any missing or damaged safety signs.

Keep operator safety in mind at all times. Use mild

soap and water to clean safety signs. Do not use

solvent-based cleaners because they may damage

the safety sign material.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 7

Page 8

December 2015

First Edition - Second Printing

Symbol and Hazard Pictorials Defi nitions

Falling object

Hazard

No ride Brick

Holder

Basket

Close the gate Falling Hazard

Read the

operator's

manual

Crush Hazard

Fix brick holder with

Chain to Forks plate

Keep clear of

moving parts

8 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 9

First Edition - Second Printing December 2015

140 mm

General Safety

09.4618.1355

09.4618.1355

09.4618.1354 09.4618.1352

09.4618.1354

800 Kg

09.4618.1353

09.4618.1353

09.4618.1352

09.4618.0922

09.4618.0922

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 9

Page 10

December 2015

Work Area Safety

For work area safety, refer to the same section in

the telehandler operator's manual.

First Edition - Second Printing

10 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 11

First Edition - Second Printing December 2015

Safety Precautions

Requirements for Machine

Operators

Operators who use the machine regularly or

occasionally (i.e. for transport reasons) shall have

the following prerequisites:

health:

before and during any operation, operators shall

never take alcoholic beverages, medicines or other

substances that may alter their psycho-physical

conditions and, consequently, their working abilities.

physical:

good eyesight, acute hearing, good co-ordination and

ability to carry out all required operations in a safe

way, according to the instructions of this manual.

mental:

ability to understand and apply the enforced rules,

regulations and safety precautions. They shall be

careful and sensible for their own as well as for the

others’ safety and shall desire to carry out the work

correctly and in a responsible way.

emotional:

they shall keep calm and always be able to evaluate

their own physical and mental conditions.

training:

they shall read and be familiar with this handbook,

its enclosed graphs and diagrams, the identification

and hazard warning plates. They shall be skilled and

trained about the machine use.

Requirements for Service

Personnel

Personnel in charge of the machine maintenance

shall be qualified, specialised in the maintenance

of telehandlers, and shall have the following

prerequisites:

physical:

good eyesight, acute hearing, good co-ordination

and ability to carry out all required maintenance

operations in a safe way, according to this manual.

mental:

ability to understand and apply the enforced rules,

regulations and safety precautions. They shall be

careful and sensible for their own as well as for the

others’ safety and shall desire to carry out the work

correctly and in a responsible way.

training:

they shall read and be familiar with this handbook,

its enclosed graphs and diagrams, the identification

and warning plates. They shall be skilled and trained

about the machine functioning.

From a technical point of view, routine maintenance

of the machine is not a complex procedure and can

be carried out by the machine operator too, provided

he has a basic knowledge of mechanics.

The operator shall have a licence (or a driving

licence) when provided for by the laws enforced in

the country where the machine

ask the competent bodies. In Italy the operator must

be at least 18 year old.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 11

is operated. Please,

Page 12

December 2015

Safety Precautions

First Edition - Second Printing

Working clothes

During work, but especially when maintaining or

repairing the machine, operators must wear suitable

protective clothing:

• Overalls or any other comfortable garments.

Operators should not wear clothes with large

sleeves or objects that can get stuck in moving

parts of the machine.

• Protective helmet.

• Protective gloves.

• Working shoes.

Personal protective equipment

Under special working conditions, the following

personal protective equipment should be used:

• Breathing set (or dust mask).

• Ear-protectors or equivalent equipment.

• Goggles or facial masks.

Use only approved safety workwear in good

condition.

12 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 13

First Edition - Second Printing December 2015

Legend

Shovel, Bucket, Brick-Holder Basket main components

A. Fork Slots

B. Coupling Frame

C. Quick coupling (if any)

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 13

Page 14

December 2015

Attachment Description

First Edition - Second Printing

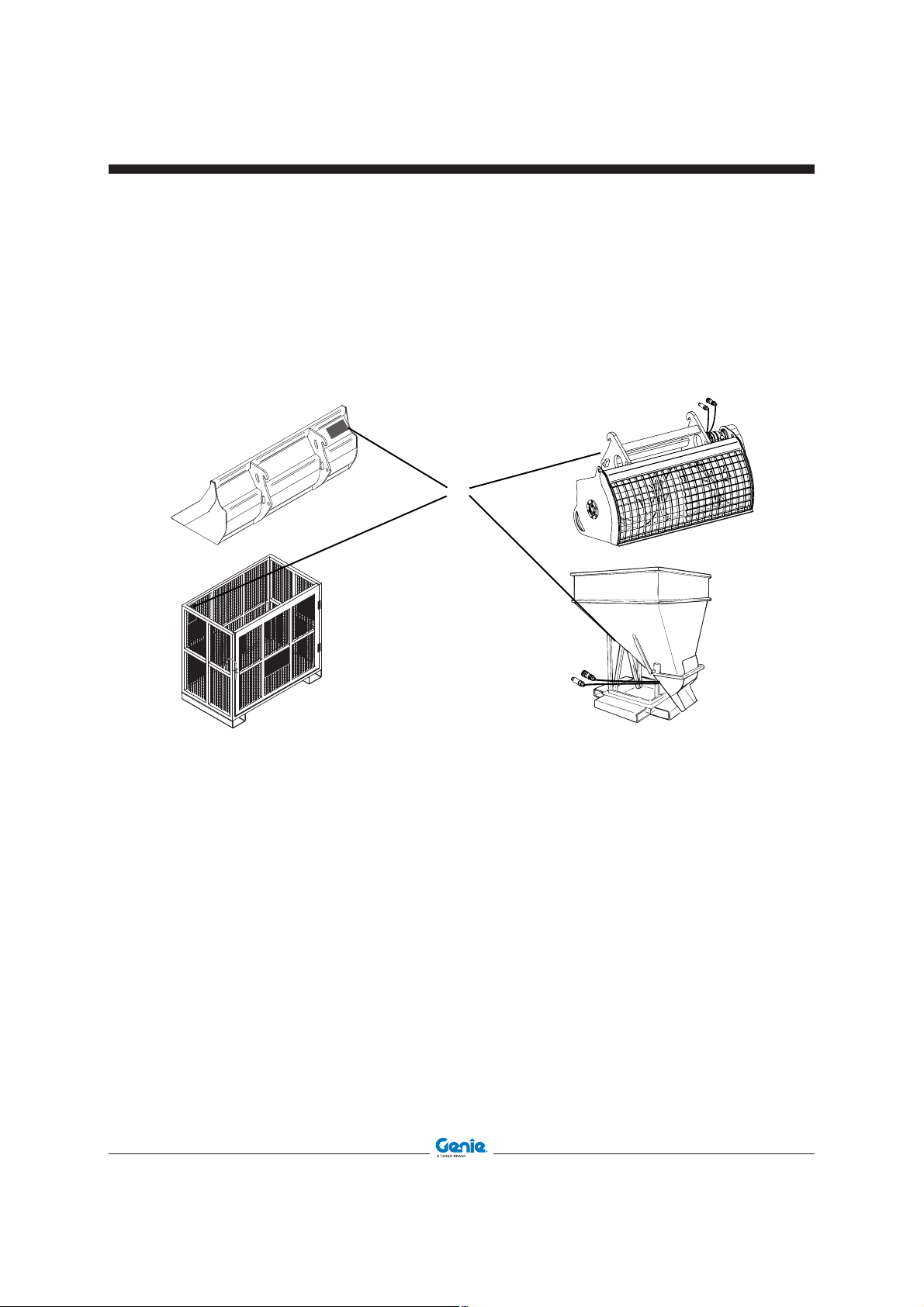

Shovel

The shovel consists of a welded concave shaped

steel structure designed to move and load loose

material such as soil, sand debris, inert material.

The main components of this structure are the front

blade, which works as the leading edge of the shovel

“cutting” the material volume and separating the part

which is gathered by the shovel itself, the central

concave shell, which provides the volume for the

material to be gathered, and the side walls, which

laterally close the useful volume of the shovel.

On the rear area of the shovel, there are two

shaped plates welded to its main structure and

designed to be coupled with the GTH telehandlers

standard attachment interface. Considering the

typical limitation in the maximum rotation of the

attachment articulation, the design of the shovel

and its mechanical interface with the attachments

articulation is optimized to provide the best

compromise in terms of material loading and

unloading capabilities.

Brick Holder Basket

This attachment is designed to handle bricks pallets,

and other materials and to place them where are

necessary in the construction working sites.

It consists of a main basket made by welded steel

square shaped tubes and steel grids preventing any

debris exceeding small sizes that can accidentally

drop from the basket when this is operated at height.

A door is hinged on the right side of the basket

to make it easier to load and unload the pallets/

materials on/from the basket.

The door can be secured in the closed position by

a dedicated latch. The overall basket is installed

on a bottom structure having two rectangular

hollow shaped steel tubes working as slots for the

telehandlers forks.

The longitudinal movement of the basket, when

engaged with the forks, is controlled by a chain and

a shackle which must be secured before using the

basket to handle materials.

This equipment is coupled to the telehandler

through the coupling frame B

14 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

This equipment is coupled to the telehandler

through the forks slots A

Page 15

First Edition - Second Printing December 2015

Attachment Description

Mixing Bucket

This bucket is designed to produce limited volumes

of concrete by mixing its main components (cement,

aggregates, sand and water) and to discharge such

volumes (when the concrete is ready). It mainly

consists of a welded concave shaped steel structure

designed to gather from ground aggregates, cement

and sand, before the concrete mixing phase is

started, and then to mix these components with water

in order to produce concrete. The main components

of this welded structure are the front blade, which

works as the leading edge of the bucket “cutting”

the material volume and separating the part which

is gathered by the bucket itself, the central concave

shell, which provides the volume for the material to

be gathered and mixed, and the side walls, which

laterally close the useful volume of the bucket. To

mix the concrete components, a mixing blade made

by welded and shaped plates, is provided and

installed longitudinally to the main axis of the bucket.

This blade rotates on bearings installed on the side

walls of the bucket and is powered by a hydraulic

motor and a gear box which are located externally

of the right side wall of the bucket.

The concrete, after the mixing phase, can be

discharged through a dedicated door located on

the bottom of the bucket and activated through

a mechanism and a hydraulic cylinder. The

mixing blade and the concrete discharge door

are hydraulically powered through the hydraulic

auxiliary line available on the top of the boom. These

two functions are controlled by a dedicated radio

remote control device which can be operated also

by operators working outside of the machine cabin.

Before the concrete mixing phase is started, the top

of the bucket must be closed by a dedicated door,

made by a steel grid and hinged on the top of the

rear wall of the bucket, with the aim of protection

against moving parts. The steel grid allows the

operator to check when the concrete is ready for

discharge. On the rear area of the bucket, there are

two shaped plates welded to its main structure and

designed to be coupled with the GTH telehandlers

standard attachments interface.

This equipment is coupled to the telehandler

through the coupling frame B

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 15

Page 16

December 2015

Attachment Description

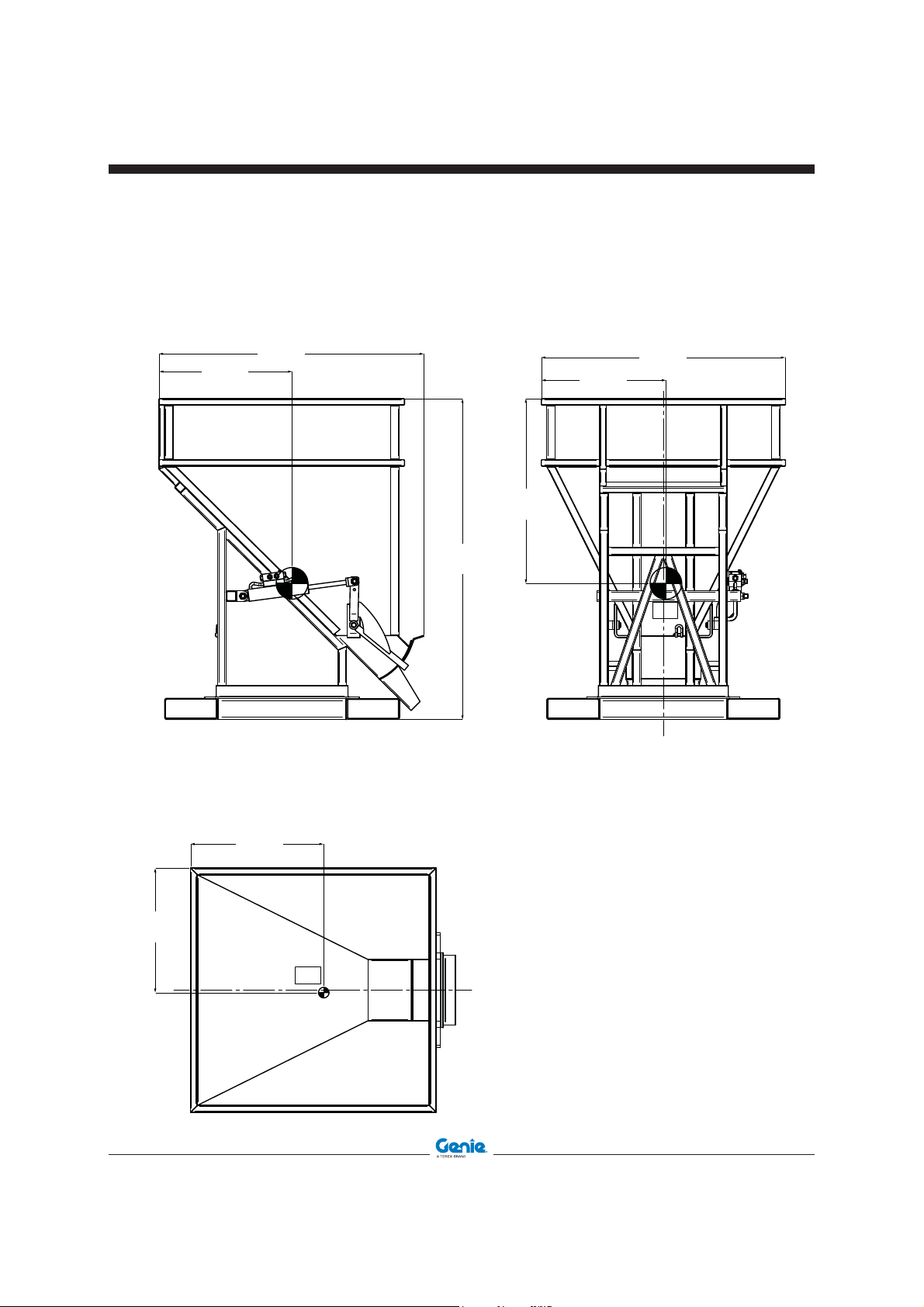

Concrete Bucket

The bucket mainly consists of a welded pyramid

shaped steel structure designed to handle limited

volumes of concrete from one place to another place

inside the typical construction working sites and to

discharge such volumes of concrete.

This pyramidal structure is open on the top to allow

the concrete to be easily loaded and has a section

regularly reducing towards the bottom to facilitate

the discharge of the concrete.

This discharge operation is allowed by a dedicated

steel door, located on the bottom of the bucket which

can be activated by a mechanical lever manually

moved by the operator or, according to the models

selected, by a mechanical articulation which is

hydraulically operated through the hydraulic auxiliary

line available on the top of the boom.

The overall bucket and door mechanism is installed

on a bottom structure having four rectangular

hollow shaped steel tubes working as slots for the

telehandlers forks.

The longitudinal movement of the bucket, when

engaged with the forks, is controlled by a chain and

a shackle which must be secured before using the

bucket to handle materials.

First Edition - Second Printing

This equipment is coupled to the telehandler

through the forks slots A

16 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 17

First Edition - Second Printing December 2015

Attachment Application Field

The following table represents the application field of attachment installed on Genie telehandlers

GTH-2506 GTH-4014 GTH-4018 GTH-4016R GTH-4018R GTH-5021R

500 L Loading

Shovel

800 L Loading

Shovel

Brick-Holder

Basket

250 L Mixing

Bucket

500 L Mixing

Bucket

500 L Manual

Concrete

Bucket

500 L

Hydraulic

Concrete

Bucket

800 L Manual

Concrete

Bucket

800 L

Hydraulic

Concrete

Bucket

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 17

Page 18

December 2015

Inspections

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual and in the telehandler one.

1. Avoid hazardous situations.

2. Always perform a pre-operation inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3. Always perform function tests prior to use.

4. Only use the machine as it was intended.

First Edition - Second Printing

Pre-operation Inspection

Fundamentals

It is the responsibility of the operator to perform a

pre-operation inspection and routine maintenance.

The pre-operation inspection is a visual inspection

performed by the operator prior to each work shift.

The inspection is designed to discover if anything

is apparently wrong with a telehandler and/or with

an equipment before the operator performs the

function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures are

required. Only routine maintenance items specified

in this manual may be performed by the operator.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

telehandler and/or the equipment must be tagged

and removed from service.

Repairs to the telehandler and/or the equipment

may only be made by a qualified service

technician, according to the manufacturer's

specifications. After repairs are completed, the

operator must perform a pre-operation inspection

again before going on to the function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications.

18 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 19

First Edition - Second Printing December 2015

Inspections

Pre-operation Inspection

Make sure the operator's manuals are intact,

legible and placed inside the telehandler.

Be sure that all decals are legible and in

place.

Check for Hydraulic oil leaks.

Checking the following components or areas for

damage, improperly installed or missing parts and

unauthorized modifications:

Hydraulic hoses and fittings

Nuts, bolts and other fastners

Check the entire structure for:

Cracks on welds or structural components

Dents or damage to the structure

Excessive rust, corrosion or oxidation

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 19

Page 20

December 2015

Inspections

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual and in the telehandler one.

1. Avoid hazardous situations.

2. Always perform a pre-operation inspection.

First Edition - Second Printing

Function Test Fundamentals

The function tests are designed to discover any

malfunctions before the machine is put into service.

The operator must follow the step-by-step instructions

to test all machine functions.

A malfunctioning machine must never be used. If

malfunctions are discovered, the machine must

be tagged and removed from service. Repairs

to the machine may only be made by a qualified

service technician, according to the manufacturer’s

specifications.

After repairs are completed, the operator must perform

a pre-operation inspection and function tests again

before putting the machine into service.

3. Always perform function tests prior to use.

Know and understand the function tests

before going on to the next section.

4. Only use the machine as it was intended.

20 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 21

First Edition - Second Printing December 2015

Inspections

Function Tests

Before getting started, refer to telehandler operator's

manual.

Test the Control Lever

(at every use)

• Using the control lever, momentarily lock and

unlock the attachment for those telehandlers

with hydraulic cylinder

Result: All the functions should operate

smoothly.

Test the correct open and close

movements of the concrete discharge

door (manually or hydraulically

powered).

(at every use)

• Using the function enable switch button A

move the functions joystick toward right or

left to open or close the door of the Concrete

Bucket.

• By the mechanical lever momentarily open

and close the door of the Concrete Bucket

Result: All the functions should operate

smoothly.

Test the Hydraulic movements for

Mixing bucket

(at every use)

• Using the dedicated switches on the control

panel, check the movement of the mixing

blade and the movement of the door.

Result: All the functions should operate

smoothly.

Test the lock system of the Brick-Holder

Basket gate.

(at every use)

• Move pin A upwards and open the basket

gate. Close the basket gate and move pin A

downwards through the hole.

Result: All the functions should operate

smoothly.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 21

Page 22

December 2015

Operating Instruction

First Edition - Second Printing

Fundamentals

The Operating Instructions section provides instructions for each aspects of machine operation.

It is the operator's responsability to follow all the

safety rules and instructions in the operator's safety and responsibilities manuals.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual and in the telehandler one.

1. Avoid hazardous situations.

2. Always perform a pre-operation inspection.

3. Always perform function tests prior to use.

4. Only use the machine as it was

intended.

Only trained and authorized personnel should be

permitted to operate a machine. If more than one

operator is expected to use a machine at different times in the same work shift, they must all be

qualified operators and are all expected to follow

all safety rules and instructions in the operator's,

safety and responsibilities manuals.

That means every new operator should perform

a pre-operation inspection, function test, and a

workplace inspection before using the machine.

Additionally, everyone working on or near the product also needs to be familiar with the applicable

safety precautions.

22 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 23

First Edition - Second Printing December 2015

Operating Instruction

Quick Attach Instructions

Version with mechanical locking

1 Drive to the place where you will release the

mounted attachment (when possible, a solid

and sheltered site).

2 Disconnect the quick connectors of the attachment

(if any).

3 Pull out the mechanical pin locking the attachment

after removing the safety split-pin at its end.

4 Rest the attachment flat on the ground.

5 Pitch the attachment holding frame forward and

lower the boom to release the attachment upper

lock.

6 Move back with the machine and drive to the new

attachment to be coupled.

7 Hold the frame pitched forward and hook the

upper lock of the new attachment.

8 Retract and raise the attachment a small distance.

It will center automatically on the quick coupling

frame.

9 Refit mechanical locking pin fixing it with its safety

split-pin.

10 Re-couple the connectors of the attachment (if

any).

Version with hydraulic locking (optional)

1. Drive to the place where you will release the

mounted attachment (when possible, a solid

and sheltered site).

2. Disconnect the quick connectors of the attachment

(if any).

3. Rest the attachment flat on the ground.

4. Press the Lock/Unlock Enabling Switch and keep

it pressed up to the end of Step 5.

5. Free the attachment moving the functions

joystick.

6. Pitch the attachment holding frame forward and

lower the boom to release the attachment upper

lock.

7. Move back with the machine and drive to the new

attachment to be coupled.

8. Hold the frame pitched forward and hook the

upper lock of the new attachment.

9. Retract and raise the attachment a small

distance. It will center automatically on the quick

coupling frame.

10. Coupling the attachment moving the functions

joystick with the Lock/Unlock Enabling Switch.

11. Re-couple the connectors of the attachment (if

any).

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 23

Page 24

December 2015

Operating Instructions

First Edition - Second Printing

Operation

Loading Shovel

500L Loading Shovel 59.0201.9019 GT

800L Loading Shovel 59.0201.9020 GT

800L Loading Shovel 59.0201.9021 GT

800L Loading Shovel 59.0201.9022 GT

• Couple the Shovel and hold it in position by means

of the attachment locking system (mechanical or

hydraulic)

• Engage materials slowly

• To remove the attachment, remove the

attachment locking system (mechanical or

hydraulic) then carefully tilt the attachment

forward, lower the boom resting the attachment

on the ground and retract the boom.

Mixing Bucket

250L Mixing Bucket 59.0401.2018 GT

500L Mixing Bucket 59.0401.2016 GT

• Couple the Mixing Bucket and hold it in

position by means of the attachment locking

system (mechanical or hydraulic)

• Connect the Hydraulic hoselines

• To remove the attachment, remove the

attachment locking system (mechanical or

hydraulic) then carefully tilt the attachment

forward, lower the boom resting the attachment

on the ground, disconnect the Hydraulic

hoselines, and retract the boom.

Once the attachment quick connectors have

been disconnected from the boom connectors,

take care to reconnect them to the proper rest

connectors that are present on the Mixing

Bucket, in order to prevent impurities from

entering the circuit. Carefully protect the rest

connectors with the provided plugs when they

are not used.

.

Brick-Holder Basket

Brick-Holder Basket 59.0401.2032 GT

• Couple the Brick-Holder Basket by the forks

slots.

• Using the chain and shackle, secure the

attachment to the Forks carriage.

• To remove the attachment rest the attachment

on the ground, remove the chain and shackle,

then reract the boom.

Concrete Bucket

500L Man. Concrete Bucket 59.0401.2028 GT

500L Hyd. Concrete Bucket 59.0401.2029 GT

800L Man. Concrete Bucket 59.0401.2030 GT

800L Hyd. Concrete Bucket 59.0401.2031 GT

• Couple the Concrete Bucket by the forks slots.

• Using the chain and shackle, secure the

attachment to the Fork carriage.

• Connect the Hydraulic hoselines.

• To remove the attachment, rest the

attachment on the ground, disconnect the

Hydraulic hoselines, remove the chain and

shackle, then retract the boom.

Load Limiting System control

panel

Refer to telehandler operator's manual.

Using The Load Chart

Refer to telehandler operator's manual

24 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 25

First Edition - Second Printing December 2015

Operating Instructions

Controller Movements - Functions

Joystick - Shovel

GTH-2506, GTH-4014 and GTH-4018

Refer to telehandler operator's manual

Before discharging the material, make sure that

nobody is within its working range.

Press and hold the function enable switch B and

move the joystick to the left to tilt the bucket up.

Press and hold the function enable switch B and

move the joystick to the right to tilt the bucket down.

Controller Movements - Functions

Joystick - Shovel

GTH-4016R, GTH-4018R and GTH-5021R

Refer to telehandler operator's manual

Before discharging the material, make sure that

nobody is within its working range.

WITH RIGHT JOYSTICK (Standard

Confi guration) and with LEFT JOYSTICK

(Optional Confi guration)

Functions joystick with enable

switch (B)

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 25

Functions joystick with enable switch

(B)

Page 26

December 2015

Operating Instructions

Controller Movements - Mixing

Bucket

For all the telehandler models

First Edition - Second Printing

Proceed as follow:

Set the Hydraulic Mixing Bucket Oil Direction

Switch A to position 0 and press the Mixing Bucket

Switch B to enable the movement of the internal

mixer of the bucket. Switch B has a block which

can be locked for continuous operation. Before

switching to another position, ensure the block is

unlocked at the top of switch B.

Setting switch A to position 2 or 1, regulates the

oil flow direction, to rotate the mixing blade either

clockwise or counterclowise.

To open the bucket door, set switch A to position

0 and press the Auxiliary Hydraulic Circuit Switch

. Then set switch A to position 1 or 2 to open or

C

close the bucket door.

To discharge the concrete, set switch A to position

0, set switch C to position 0, set switch A to

position 1 or 2, the mixer start to rotate clockwise

or counterclowise, pushing out the concrete.

Phase Switch Position

A 0 Stop Oil Flow

MIXING B 1 Enable Mix.

Bucket Circuit

A 1 or 2 Rotate the Mix

OPEN

DOOR

DISCHARGE C 0 Enable Mix. Blade

A 0 Stop Oil Flow

C 1 Enable Mix.

Bucket Door

A 1 or 2 Open/Close

Bucket Door

A 0 Stop Oil Flow

movements

A 1 or 2 Rotate Mix Blade

For the use of this equipment and its remote

control, please read the specific manual

26 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 27

First Edition - Second Printing December 2015

Operating Instructions

Controller movements - Functions

Joystick - Hydraulic Concrete

Bucket

GTH-2506, GTH-4014, and GTH-4018

Before discharging the concrete, make sure that

nobody is within its working range.

Press and keep switch A and B and move the Function

Joystick toward left to close the Bucket door or to the

right to open the Bucket door.

Functions joystick with enable switch

(B) and with white thumb switch (A)

Controller movements - Single

Functions Joystick - Hydraulic

Concrete Bucket

GTH-4016R, GTH-4018R, GTH-5021R

Controller movements - Dual

Functions Joystick - Hydraulic

Concrete Bucket

GTH-4016R, GTH-4018R, GTH-5021R

Functions joystick with enable switch

(B) and with white thumb switch (A)

Press and keep switch A and B on the Left

Control Joystick and move it toward ahead to

open the Bucket door or behind to close the

Bucket door.

Before discharging the concrete, make sure

that nobody is within its working range.

Press and keep switch A and B and move the Function

Joystick toward left to close the Bucket door or to

the right to open the Bucket door.

Functions joystick with enable switch

(B) and with white thumb switch (A)

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 27

Page 28

December 2015

Operating Instructions

First Edition - Second Printing

Loading Equipment

Loading the Shovel

• When using a shovel, load the material only

when the boom is completely retracted and push

against the heap with straight wheels.

• Approach the load to be handled perpendicularly

and check that the machine is level on the

inclinometer.

• Insert the shovel under the load and raise it some

centimetres.

• Pitch the load back to cradle the load.

• Engage materials slowly.

When loading round-shaped objects (as petrol

drums, etc) bind them with straps or ropes and

travel at reduced speed.

Loading the Brick-Holder Basket.

• Approach the place where

the material is stocked;

• lower the brick-holder

basket on the ground;

• open the gate;

• insert the material;

• close the gate and secure

it through the dedicated

pin 1.

09.4618.1355

Unsecured objects may fall out. Always ensure that the material is completely enclosed by

the basket and at the gate is secured prior to

lifting/lowering.

The brick-holder basket is designed to handle

bricks pallets and other materials. IT IS NOT

A MAN-PLATFORM. Don’t use for elevating or

transporting people!

Do not use for digging operations.

Don’t use the shovel for rising or transporting

people

09.4618.1352

28 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 29

First Edition - Second Printing December 2015

Operating Instructions

Loading the Concrete Bucket

• Approach the place where the material is

stocked;

• lower the concrete bucket on the ground;

• ensure that the discharge door is closed; if not,

move lever 2 clockwise for the manual version

or the functions joystick for the hydraulic one;

• introduce the concrete through the top end.

Loading the Mixing Bucket

For the use of this equipment please read the

specific manual.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 29

Page 30

December 2015

Operating Instructions

Trasporting the Loaded Material

First Edition - Second Printing

Once the material is loaded, operate as follow:

• identify any risks present on the route to be

travelled;

• raise the equipment to the transport height of

300-500mm from the ground;

• ensure that the load/attachment is high enough

to clear all objects before starting to move;

• avoid excessive rough terrain when travelling;

• consider that when transporting load permissible

gradients are 10% downhill, 15% uphill, 5% side;

• initiate movements of the load with the lowest

available speed;

• do not allow workers/bystanders to walk or work

under the load;

• do not leave the load unattended

• ensure that all personnel are out of the travel/

lifting hazard zones before operating;

;

• When driving on a rise with loaded material,

proceed in forward gear and travel with load in

the lowest possible position.

• When sloping downward with loaded material,

proceed into reverse.

• When driving on a rise with empty shovel, proceed into reverse.

• When sloping downward with empty shovel,

proceed in forward gear.

Load Landing

Before a load is lifted, a place should be prepared

where it is to be put down. The nature of the load will

determine the type of preparation necessary.

30 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 31

First Edition - Second Printing December 2015

Parking and Storage

Short inactivity and attachment

storage

To release the attachment from the telehandler:

• Approach the place where you will release the

equipment

• Lower the equipment on the ground.

• Stop the engine of the telehandler

• Disconnect the hydraulic pipes of the equipment

from the boom fittings.

• Restart the engine.

• Operate the joystick to release the equipment

from the quick coupling plate.

• Tilt the coupling plate forward and lower the

boom to release the upper look of the equipment.

• Move back with the telehandler.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 31

Page 32

December 2015

Transport and Lifting Instructions

First Edition - Second Printing

Moving the Equipment

When the equipment shall be moved, use only

means having a suitable capacity. The characteristic

data are detailed in the relevant chapter of this

manual and on the identification plate.

Shovels and Mixing Bukets shall be moved using

forks.

• Shovel 500L 59.0201.9019GT

10.5in/

268mm

21.2in/

541mm

38.5in/980mm

14.3in/

365mm

• Shovel 800L 59.0201.9020GT

11.3in/

289mm

31.8in/

810mm

32 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

11.9in/

303mm

25.9in/

658mm

46.25in/1175mm

10in/

254mm

17.28in/

439mm

37.1in/

943mm

Page 33

First Edition - Second Printing December 2015

Transport and Lifting Instructions

• Shovel 800L 59.0201.9021GT

37.0in/

8.77in/

223mm

11.4in/

292mm

940mm

23.8in/

607mm

42.1in/1070mm

15.8in/

403mm

• Shovel 800L 59.0201.9022GT

12.8in/

327mm

22.4in/

570mm

46.10in/

1170mm

25.8in/

656mm

44.88in/ 1140mm

16.6in/

422mm

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 33

Page 34

December 2015

Transport and Lifting Instructions

• Mixing Bucket 250L 59.0401.2018GT

12.4in/

315mm

First Edition - Second Printing

5.6in/

143mm

14.2in/

363mm

CoG of Mixing

Bucket

structure

33.0in/

840mm

13.0in/

331mm

7.5in/

192mm

59.4in/

1510mm

34.2in/

870mm

32.0in/

815mm

32.0in/

815mm

CoG of Mixing Bucket full of concrete

CoG of Mixing Bucket structure

13.5in/

344mm

CoG of Mixing Bucket

full of concrete

1.02in/

26mm

CoG of Mixing Bucket structure

13.5in/

345mm

17.3in/

441mm

31.2in/

795mm

36.2in/

920mm

2.4in/

62mm

35.0in/

890mm

34 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 35

First Edition - Second Printing December 2015

Transport and Lifting Instructions

• Mixing Bucket 500L 59.0401.2016GT

69.1in/

1630mm

CoG of Mixing Bucket structure

28.4in/

723mm

CoG of Mixing Bucket full of concrete

34.4in/

876mm

38.8in/

986mm

35.7in/

909mm

5in/

127mm

12.5in/

320mm

18.7in/

17.9mm

3.5in/

90mm

14.6in/

373mm

18.7in/

7.9mm

42.7in/

1086mm

17.1in/

436mm

18.7in/

477mm

14.4in/

367mm

CoG of Mixing

Bucket structure

CoG of Mixing

Bucket structure

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 35

Page 36

December 2015

Transport and Lifting Instructions

First Edition - Second Printing

• Brick-Holder Basket 59.0401.2032GT

Insert the forks into the dedicated lugs 1

• Concrete Bucket 500L

59.0401.2028GT

59.0401.2029GT

• Concrete Bucket 800L

59.0401.2030GT

59.0401.2031GT

Insert the forks into the dedicated lugs 1

36 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 37

First Edition - Second Printing December 2015

Transport and Lifting Instructions

• Brick-Holder Basket

59.0401.2032GT

23.8in/

605mm

15.8in/

402mm

23.2in/

590mm

28.9in/

736mm

47.6in/

1210mm

41.1in/

1046mm

45.2in/

1150mm

23.2in/

590mm

32.4in/

825mm

CoG of Busket full of bricks

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 37

Page 38

December 2015

Transport and Lifting Instructions

• Concrete Bucket 500 Manual Discharge

59.0401.2028GT

First Edition - Second Printing

24.7in/

629mm

24.76in/

629mm

49.21in/

1250mm

51.9in/

1320mm

26.49in/

673mm

23.14in/

588mm

45.27in/

1150mm

23.14in/

588mm

38 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 39

First Edition - Second Printing December 2015

Transport and Lifting Instructions

• Concrete Bucket 500 L Hydraulic Discharge

59.0401.2029GT

24.7in/

628mm

24.7in/

628mm

49.2in/

1250mm

51.9in/

1320mm

26.4in/

673mm

23.3in/

593mm

45.2in/

1150mm

23.3in/

593mm

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 39

Page 40

December 2015

Transport and Lifting Instructions

• Concrete Bucket 800L Manual Discharge

59.0401.2030G

First Edition - Second Printing

24.7in/

629mm

49.21in/

1250mm

59.8in/

1520mm

34.3in/

873mm

23.1in/

588mm

45.2in/

1150mm

24.7in/

629mm

23.1in/

588mm

40 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 41

First Edition - Second Printing December 2015

Transport and Lifting Instructions

• Concrete Bucket 800L Hydraulic Discharge

59.0401.2031GT

24.7in/

629mm

49.21in/

1250mm

59.8in/

1520mm

34.3in/

873mm

23.1in/

589mm

45.2in/

1150mm

24.7in/

629mm

23.1in/

589mm

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 41

Page 42

December 2015

Maintenance

Observe and Obey:

Only routine maintenance items specified in this

manual shall be performed by the operator.

First Edition - Second Printing

Maintenance Symbols Legend

The following symbols have been used in this

manual to help communicate the intent of the

instructions. When one or more of the symbols

appear at the beginning of a maintenance

procedure, it conveys the meaning below.

Indicates that tools will be required to

perform this procedure.

Scheduled maintenance inspections shall be

completed by qualified service technicians,

according to the manufacturer’s specifications

and the requirements specified in the

responsibilities manual.

Indicates that new parts will be

required to perform this procedure.

Indicates that a cold engine will be

required to perform this procedure.

42 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 43

First Edition - Second Printing December 2015

Maintenance

Scheduled Maintenance

Machines that have been out of service for more

than three months must receive the quarterly

inspection before they are put back into service.

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

· Make copies of this report to use for each inspection.

· Select the appropriate checklist(s) for the type of inspection

to be performed.

Daily or 8 hours

Inspection: A

Checklist A Y N R

A-1 Manuals and decals

A-2 Pre-operation inspect

A-3 Function tests

A-4 Checking the Chains

· Place a check in the appropriate box after each inspection

procedure is completed.

· Use the step-by-step procedures in this section to learn how

to perform these inspections.

· If any inspection receives an “N”, tag and remove the machine

from service, repair and re-inspect it. After repair, place a

check in the “R” box.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 43

Page 44

December 2015

Maintenance

A-1

Inspect the Manuals and Decals

First Edition - Second Printing

Genie specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Maintaining the operator’s and safety manuals in

good condition is essential to safe machine operation.

Manuals are included with each machine and should

be stored in the container provided in the operator's

compartment. An illegible or missing manual will not

provide safety and operational information necessary

for a safe operating condition.

In addition, maintaining all of the safety and

instructional decals in good condition is mandatory for

safe machine operation. Decals alert operators and

personnel to the many possible hazards associated

with using this machine. They also provide users

with operation and maintenance information. An

illegible decal will fail to alert personnel of a procedure

or hazard and could result in unsafe operating

conditions.

1 Check to make sure that the operator's and safety

manuals are present and complete in the storage

container in the operator's compartment.

3 Open the operator's manual to the decals

inspection section. Carefully and thoroughly

inspect all decals on the machine for legibility

and damage.

Result: The machine is equipped with all required

decals, and all decals are legible and in good

condition.

Result: The machine is not equipped with all

required decals, or one or more decals are

illegible or in poor condition. Remove the

machine from service until the decals are

replaced.

4 Always return the manuals to the storage

container after use.

Note: Contact your authorized Genie distributor or

Genie Industries if replacement manuals or decals

are needed.

2 Examine the pages of each manual to be sure

that they are legible and in good condition.

Result: The operator's manual is appropriate for

the machine and all manuals are legible and in

good condition.

Result: The operator's manual is not appropriate

for the machine or all manuals are not in good

condition or is illegible. Remove the machine

from service until the manual is replaced.

44 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 45

First Edition - Second Printing December 2015

Maintenance

A-2

Perform Pre-operation Inspection

Genie specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing a Pre-operation Inspection is essential to

safe machine operation. The Pre-operation Inspection

is a visual inspection performed by the operator

prior to each work shift. The inspection is designed

to discover if anything is apparently wrong with a

machine before the operator performs the function

tests. The Pre-operation Inspection also serves to

determine if routine maintenance procedures are

required.

A-3

Perform Function Tests

Genie specifications require that this procedure be

performed every 8 hours or daily, whichever comes

first.

Completing the function tests is essential to safe

machine operation. Function tests are designed to

discover any malfunctions before the machine is put

into service. A malfunctioning machine must never

be used. If malfunctions are discovered, the machine

must be tagged and removed from service.

A-4

Check the Chains

Check the Chains and shackles used to fix the

Concrete Buckets and Brick-Holder Basket to the

fork carriage.

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 45

Page 46

December 2015

Specifi cation

First Edition - Second Printing

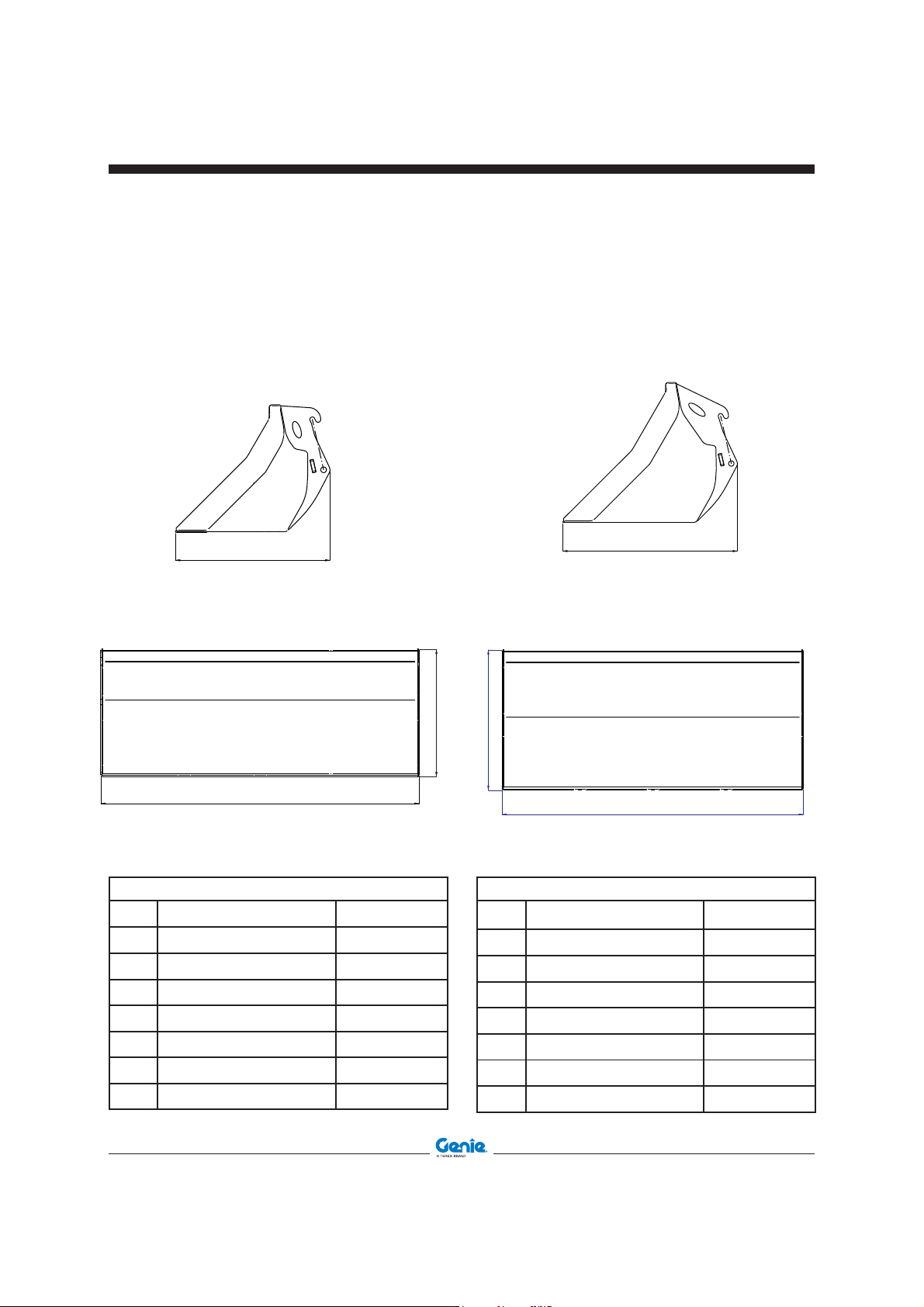

Loading Shovel 500L

part number 59.0201.9019GT

for GTH-2506

Loading Shovel 800L

part number 59.0201.9020GT

for GTH-2506

TECHNICAL DATA

46 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Width 2024

Height 810 mm

Length 980 mm

Weight 355 Kg

Payload 500 L

CoG Width 1012 mm

CoG Height 268 mm

CoG Length 541 mm

Width 2024 mm

Height 940 mm

Length 1175 mm

Weight 420 kg

Payload 800 L

Cog Width 1012 mm

CoG Height 303 mm

CoG Length 658 mm

TECHNICAL DATA

Page 47

First Edition - Second Printing December 2015

Specifi cation

Loading Shovel 800L

part number 59.0201.9021GT

for GTH-4014,GTH-4018, GTH-5021R

Loading Shovel 800L

part number 59.0201.9022GT

for GTH-4016R, GTH-4018R

TECHNICAL DATA

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 47

Width 2435

Height 940 mm

Length 1070 mm

Weight 450 Kg

Payload 800 L

CoG Width 1217.5 mm

CoG Height 292 mm

CoG Length 607 mm

Width 2435 mm

Height 1170 mm

Length 1140 mm

Weight 510 Kg

Payload 800 L

CoG Width 1217.5 mm

CoG Height 327 mm

CoG Length 656 mm

TECHNICAL DATA

Page 48

December 2015

Specifi cation

First Edition - Second Printing

Mixing Bucket 250L

part number 59.0401.2018GT

for GTH-2506

Mixing Bucket 500L

part number 59.0401.2016GT

for GTH-4014, GTH-4018

TECHNICAL DATA

48 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Width 1510 mm

Height 840 mm

Length 795 mm

Weight 460 Kg

Payload 250 L

CoG Width 953 mm

CoG Height 344 mm

CoG Length 363 mm

Width 1650 mm

Height 990 mm

Length 880 mm

Weight 550 Kg

Payload 500 L

CoG Width 723 mm

CoG Height 456 mm

CoG Length 373 mm

TECHNICAL DATA

Page 49

First Edition - Second Printing December 2015

Specifi cation

Brick-Holder Basket

part number 59.0401.2032GT

for all the range.

TECHNICAL DATA

Width 1210 mm

Height 1150 mm

Length 825 mm

Weight 120 Kg

Payload 500 L

CoG Width 605 mm

CoG Height 590 mm

CoG Length 402 mm

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 49

Page 50

December 2015

Specifi cation

First Edition - Second Printing

500L Manual Concrete Bucket

part number 59.0401.2028GT

for all the range

500L Hydraulic Concrete Bucket

part number 59.0401.2029GT

for all the range

TECHNICAL DATA

50 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Width 1110 mm

Height 1320 mm

Lenght 1110 mm

Weight 230 Kg

Payload 500 L

CoG Width

CoG Height 673 mm

CoG Length 629 mm

588 mm

Width 1110 mm

Height 1320 mm

Lenght 110 mm

Weight 244 Kg

Payload 500 L

CoG Width

CoG Height 673 mm

CoG Length 628 mm

TECHNICAL DATA

593 mm

Page 51

First Edition - Second Printing December 2015

Specifi cation

800L Manual Concrete Bucket

part number 59.0401.2030GT

for GTH-4014, GTH-4018, GTH-4016R, GTH4018R

800L Hydraulic Concrete Bucket

part number 59.0401.2031GT

for GTH-4014, GTH-4018, GTH-4016R, GTH4018R

TECHNICAL DATA

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 51

Width 1110 mm

Height 1520 mm

Lenght 1110 mm

Weight 250 Kg

Payload 800 L

CoG Width 588 mm

CoG Height 873 mm

CoG Length 629 mm

Width 1110 mm

Height 1520 mm

Lenght 1110 mm

Weight 264 Kg

Payload 800 L

CoG Width 589 mm

CoG Height 873 mm

CoG Length 629 mm

TECHNICAL DATA

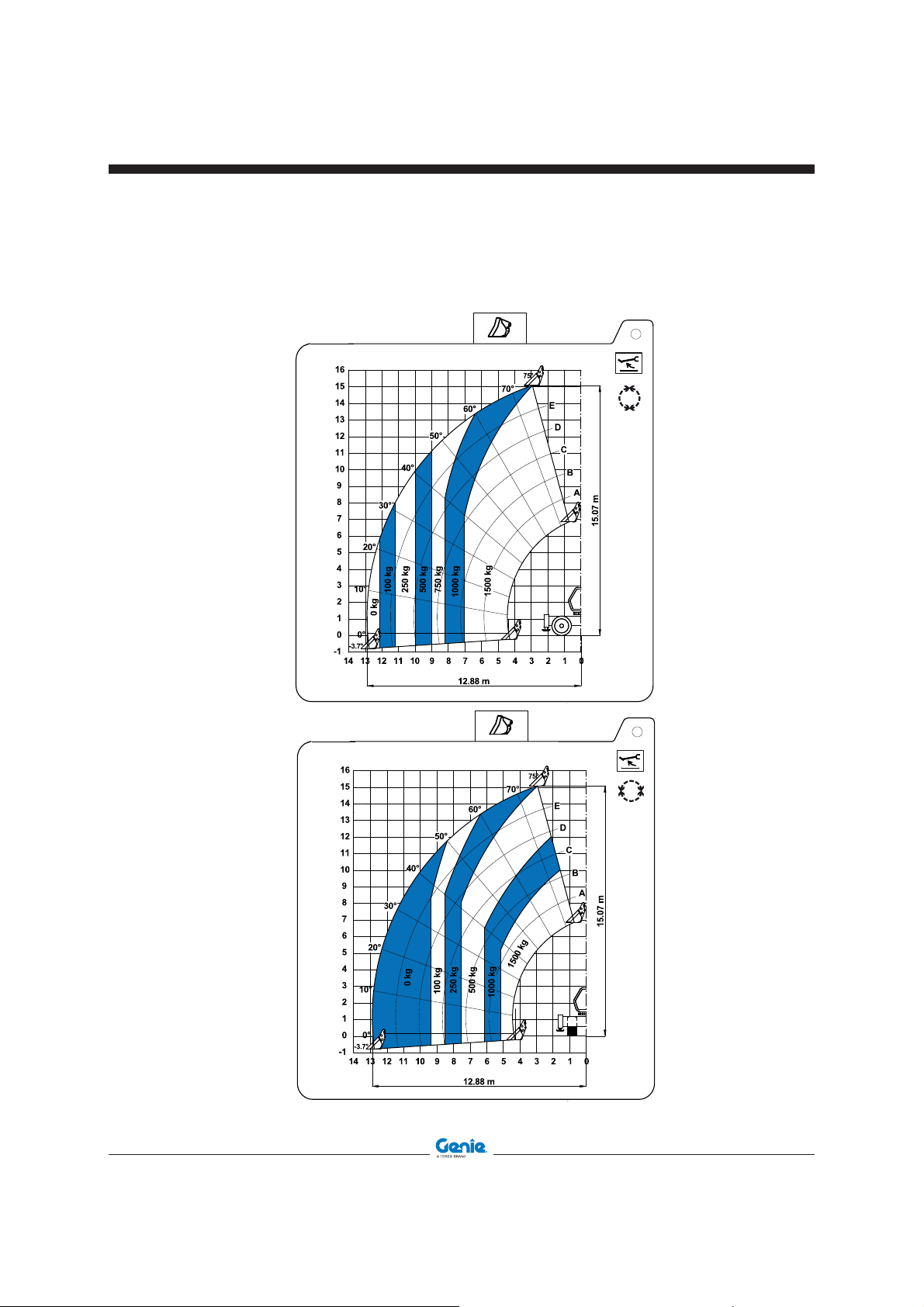

Page 52

December 2015

Load Charts

First Edition - Second Printing

GTH-2506, Loading Shovel and Mixing Bucket 250L

GTH-2506

09.4618.1426

52 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 53

First Edition - Second Printing December 2015

Load Charts

GTH-4014

09.4618.1752

GTH-4014, Loading Shovel and Mixing Bucket 500L

GTH-4014

09.4618.1751

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 53

Page 54

December 2015

GTH-4018

09.4618.1724

Load Charts

GTH 4018, Loading Shovel and Mixing Bucket 500L

First Edition - Second Printing

GTH-4018

09.4618.1725

54 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 55

First Edition - Second Printing December 2015

Load Charts

GTH-4016R, Loading Shovel and Mixing Bucket

GTH-4016 R

0°

180°

GTH-4016 R

09.4618.1942

±90°ĈĈĈ

09.4618.1941

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 55

Page 56

December 2015

Load Charts

GTH-4016R, Loading Shovel and Mixing Bucket

GTH-4016 R

First Edition - Second Printing

0°

180°

GTH-4016 R

09.4618.1940

±90°ĈĈĈ

09.4618.1939

56 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 57

First Edition - Second Printing December 2015

Load Charts

GTH-4018R, Loading Shovel and Mixing Bucket

GTH-4018 R

0°

180°

GTH-4018 R

±90°ĈĈĈ

GTH-4018 R

09.4618.1854

09.4618.1852

±90°ĈĈĈ

180°

0°

09.4618.1853

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 57

Page 58

December 2015

Load Charts

GTH-5021R, Loading Shovel and Mixing Bucket

GTH-5021 R

First Edition - Second Printing

GTH-5021 R

180°

0°

GTH-5021 R

09.4618.1708

±90°ĈĈĈ

09.4618.1709

09.4618.1710

58 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 59

First Edition - Second Printing December 2015

Load Charts

GTH-2506, Brick-Holder Basket and Concrete Bucket

GTH-2506

09.4618.1637

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 59

Page 60

December 2015

Load Charts

GTH-4014

09.4618.1639

First Edition - Second Printing

GTH-4014, Brick-Holder Basket and Concrete Bucket

GTH-4014

09.4618.1641

60 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 61

First Edition - Second Printing December 2015

GTH-4018

09.4618.1715

Load Charts

GTH-4018, Brick-Holder Basket and Concrete Bucket

GTH-4018

09.4618.1714

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 61

Page 62

December 2015

Load Charts

First Edition - Second Printing

GTH-4016R, Brick-Holder Basket and Concrete Bucket

GTH-4016 R

0°

180°

09.4618.1925

GTH-4016 R

16

15

14

13

12

11

10

9

8

7

6

20°

5

4

10°

3

2

1

0°

0

-1

-3.7°

-2

50°

40°

30°

0 kg

250 kg

60°

500 kg

13.35 m

70°

1000 kg

75°

E

D

C

B

A

0.6 m

g

k

0

0

0

2

±90°ĈĈĈ

15.31 m

0123456789101112131415

09.4618.1926

62 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 63

First Edition - Second Printing December 2015

Load Charts

GTH-4016R, Brick-Holder Basket and Concrete Bucket

GTH-4016 R

16

15

14

13

12

11

10

9

8

7

6

20°

5

4

10°

3

2

1

0°

0

-1

-3.7°

-2

50°

40°

30°

1000 kg

1500 kg

700 kg

60°

2500 kg

2000 kg

13.35 m

70°

75°

E

D

C

B

A

0.6 m

g

k

0

0

0

4

3000 kg

0123456789101112131415

09.4618.1923

15.42 m

180°

0°

GTH-4016 R

16

15

14

13

12

11

10

9

8

7

6

20°

5

4

10°

3

2

1

0°

0

-1

-3.7°

-2

30°

450 kg

50°

40°

750 kg

1000 kg

60°

1500 kg

13.35 m

70°

75°

E

D

kg

C

0

0

5

2

300

2000 kg

B

kg

0

A

0.6 m

g

k

0

0

0

4

±90°ĈĈĈ

15.42 m

0123456789101112131415

09.4618.1924

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 63

Page 64

December 2015

Load Charts

First Edition - Second Printing

GTH-4018R, Brick-Holder Basket and Concrete Bucket

GTH-4018 R

0°

180°

GTH-4018 R

±90°ĈĈĈ

GTH-4018 R

09.4618.1849

09.4618.1850

180°

±90°ĈĈĈ

0°

09.4618.1851

64 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

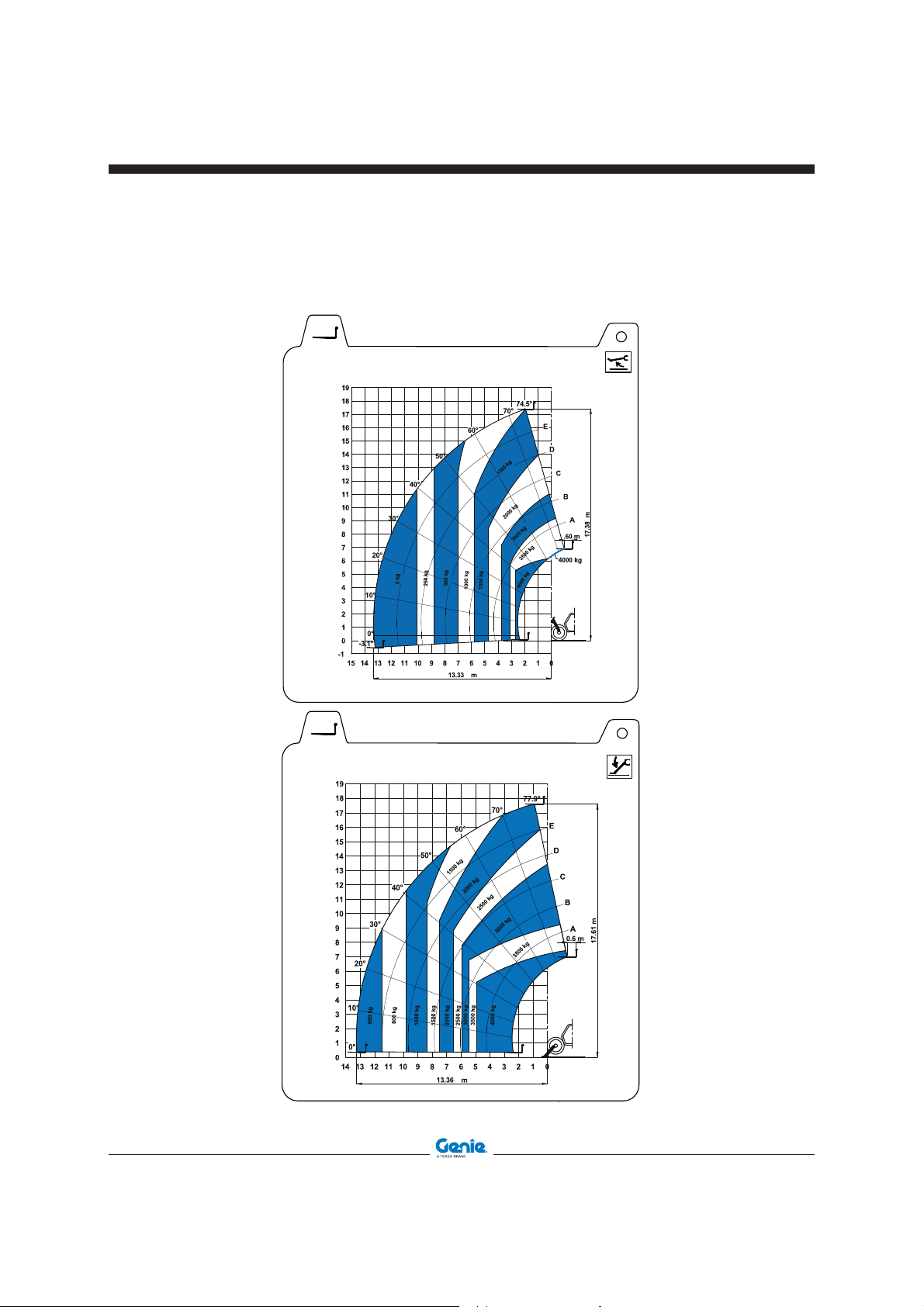

Page 65

First Edition - Second Printing December 2015

Load Charts

GTH-5021 R

0°

180°

A

B

C

D

E

70°

60°

50°

40°

30°

20°

0°

77.50°

10°

-3.50°

012345678910111213141516

171819

0

-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

-2

16

17

18

19

20

21

22

18.24 m

20.64 m

4000 kg

3000 kg

2000 kg

1500 kg

1000 kg

750 kg

500 kg

0 kg

250 kg

0.60 m

09.4618.1642

GTH-5021 R

A

B

40°

30°

20°

0°

10°

-3.50°

012345678910111213141516

171819

0

-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

-2

18.24 m

20.64 m

2500 kg

1500 kg

1000 kg

500 kg

0 kg

250 kg

0.60 m

C

D

E

70°

60°

50°

77.50°

15

16

17

18

19

20

21

22

±90°ĈĈĈ

09.4618.1644

GTH 5021R, Brick-Holder Basket and Concrete Bucket

GTH-5021 R

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-1

-2

40°

30°

20°

750 kg

10°

475 kg

0°

-3.50°

171819

1000 kg

60°

50°

2500 kg

1500 kg

2000 kg

18.24 m

3000 kg

77.50°

70°

E

D

C

B

A

0.60 m

5000 kg

4000 kg

012345678910111213141516

20.86 m

09.4618.1643

±90°ĈĈĈ

180°

0°

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 65

Page 66

December 2015

Diagrams and Schemes

Hydraulic Diagram

only for Hydraulic Concrete Bucket

First Edition - Second Printing

66 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 67

First Edition - Second Printing December 2015

Diagrams and Schemes

Hydraulic Diagram

Only for Mixing Bucket

Part No. 57.0303.5251 SHOVEL - BUCKET - BASKET 67

Page 68

December 2015

First Edition - Second Printing

Content of the EC Declaration of Conformity

TEREX Global GmbH hereby declares that the machinery described below complies with the provisions

of the following Directives:

1. EC Directive 2006/42/EC, Machinery Directive.

The machinery described below is suitable for Genie telehandlers, models specified in the user manual.

Model/Type:

Description:

Serial Number:

Manufacture Date:

Country of Manufacture:

Manufacturer:

TEREX Global GmbH

Bleicheplatz 2

8200 Schaffhausen

Switzerland

European representative:

Genie UK LTD

The Maltings

Wharf Road, Grantham, Lincolnshire

NG31 6BH United Kingdom

Empowered signatory:

Place of issue:

Date of issue:

68 SHOVEL - BUCKET - BASKET Part No. 57.0303.5251

Page 69

www.genielift.com

:yB detubirtsiD

Loading...

Loading...