Page 1

Service and Repair Manual

Serial Number Range

GS™-2669 DC

from GS69F-18000

101

This manual includes:

Repair procedures

Fault Codes

Electrical and

Hydraulic Schematics

GS™-3369 DC

GS™-4069 DC

For detailed maintenance

procedures, refer to the

appropriate Maintenance

Manual for your machine.

Original Instructions

Part No. 1306585GT

Rev A1

August 2022

from GS69M-

Page 2

Service and Repair Manual August 2022

Introduction

Introductio n Introductio n

Important Inf or matio n

Important

Read, understand and obey the safety rules

and operating instructions in the appropriate

Operator's Manual on your machine before

attempting any procedure.

This manual provides troubleshooting and

repair procedures for qualified service

professionals.

Basic mechanical, hydraulic and electrical

skills are required to perform most procedures.

However, several procedures require

specialized skills, tools, lifting equipment and a

suitable workshop. In these instances, we

strongly recommend that maintenance and

repair be performed at an authorized Genie

dealer service center.

Compliance

Technical Publications

Genie has endeavored to deliver the highest

degree of accuracy possible. However,

continuous improvement of our products is a

Genie policy. Therefore, product specifications

are subject to change without notice.

Readers are encouraged to notify Genie of

errors and send in suggestions for

improvement. All communications will be

carefully considered for future printings of this

and all other manuals.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@terex.com

Find a Manual for this Model

Go to http://www.genielift.com

Machine Classification

Group A/Type 3 as defined by ISO 16368

Machine Design Life

Unrestricted with proper operation, inspection

and scheduled maintenance.

Use the links to locate Service Manuals,

Maintenance Manuals, Service and Repair

Manuals, Parts Manuals and Operator's

Manuals.

Copyright © 2020 by Terex Corporation

1306585GT Rev A, May 2021

Second Edition, First Printing

Genie is a registered trademark of Terex South Dakota,

Inc. in the U.S.A. and many other countries.

“GS” is a trademark of Terex South Dakota, Inc.

ii GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 3

August 2022 Service and Repair Manual

Section – Schematics, Legends and schematics

Introduction

Revision History

Revision History

Revision Date Section Procedure / Page / Description

A 5/2021

A1 8/2022 Fault Codes Update fault codes

Initial Release

Reference Examples:

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Electronic Version

Click on any content or proc edure in the Table of Contents to view

the update.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC iii

Page 4

Service and Repair Manual August 2022

Introduction

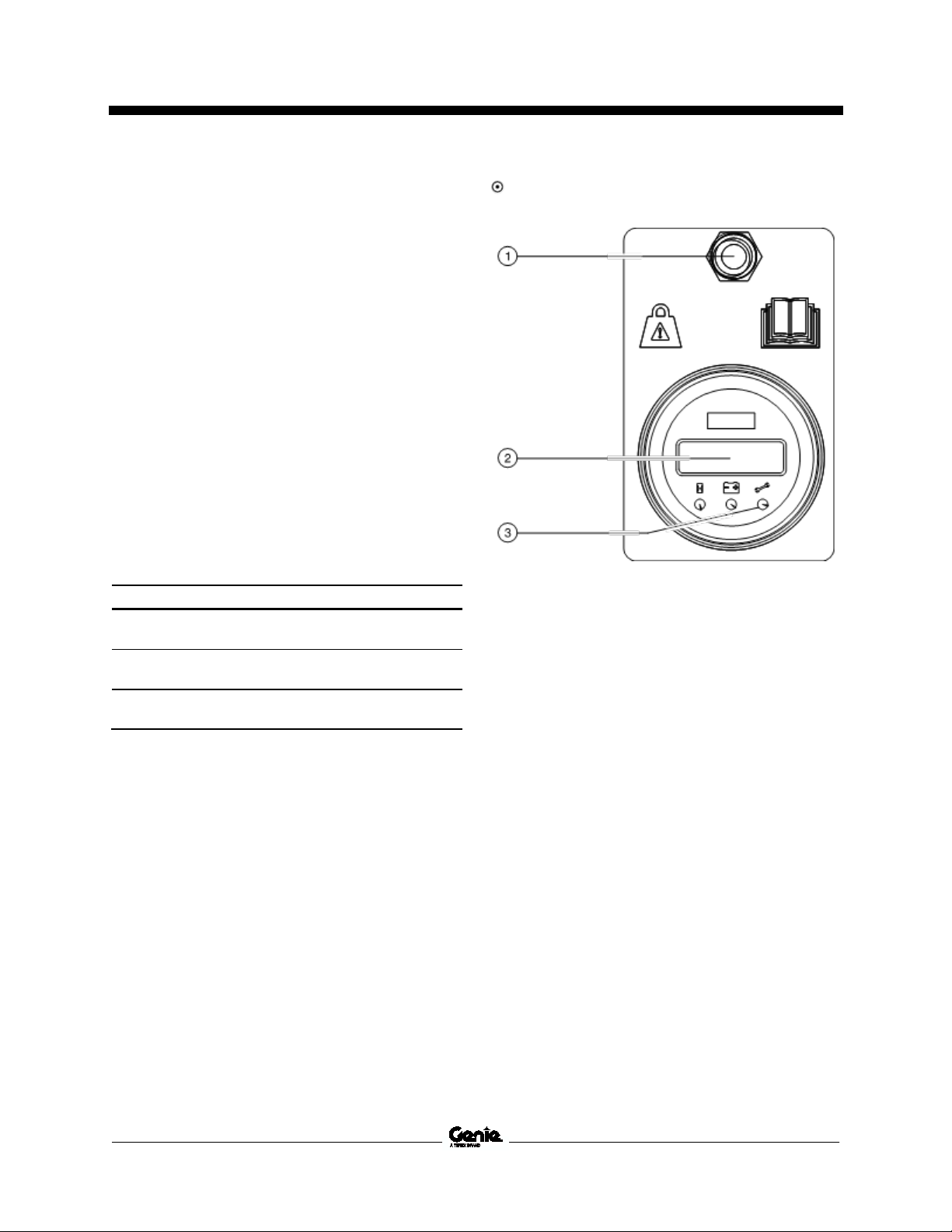

Serial Number Legend

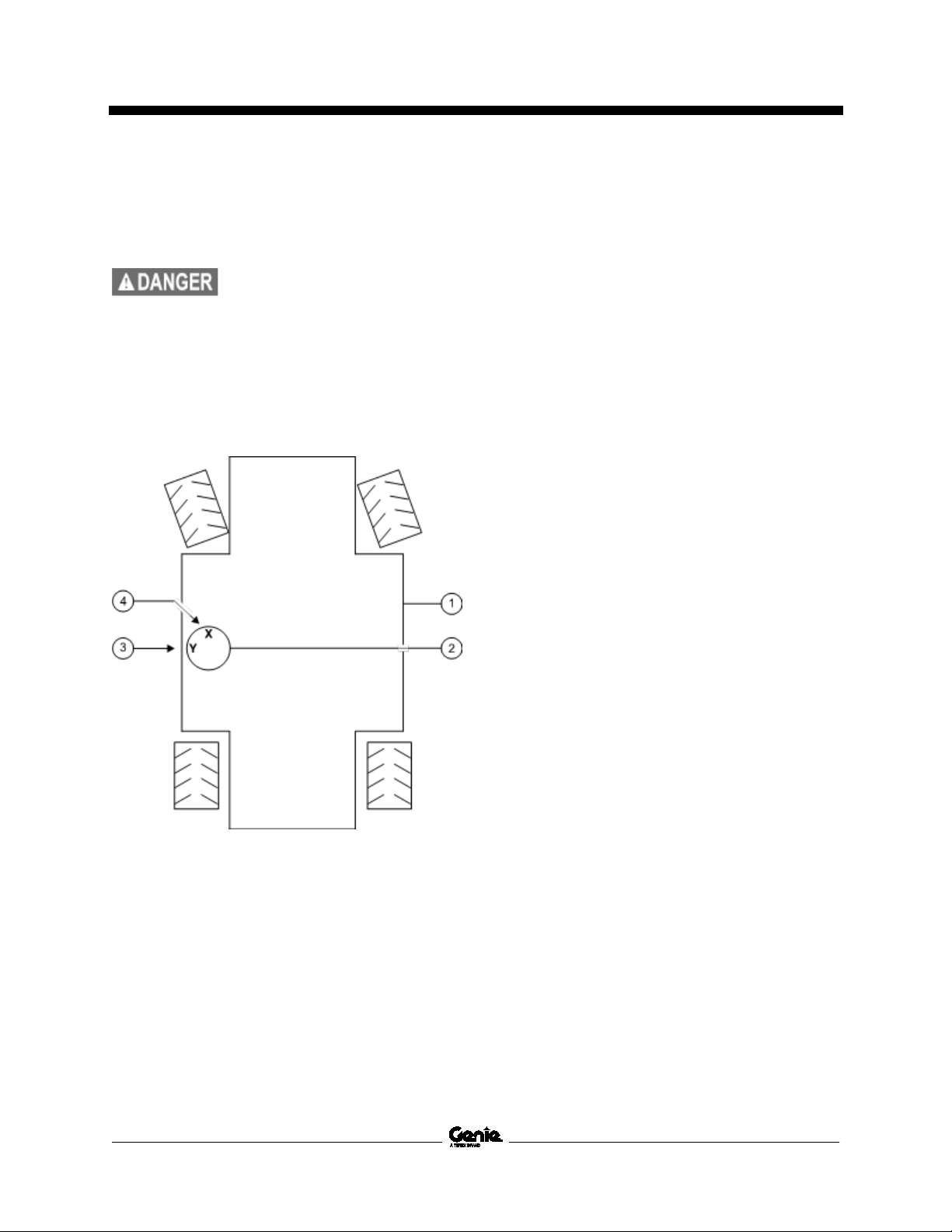

1 Model

2 Facility code

3 Sequence number

4 Serial label, ((located inside cover))

5 Serial number, ((stamped on chassis))

iv GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 5

August 2022 Service and Repair Manual

Safety Rules

Section 1 Safety Rules

General Saf ety Rul es

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when

maintenance and repair procedures are

performed.

Do not modify or alter a MEWP without prior

written permission from the manufacturer.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

• manufacturer's instructions and safety rules

• employer's safety rules and worksite

regulations

• applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC v

Page 6

Service and Repair Manual August 2022

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol

alert pers

personal injury hazards. Obey all

safety messages that follow this

symbol to avoid possible injury or

death.

Indicates a imminently hazardous

situation which, if not avoided,

will result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which,

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured

placing loads. Always wear approved

steel

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and workin

are properly maintained and ready for

use. Keep work surfaces clean and free

of debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of suppor

weight to be lifted. Use only chains or

straps that are in good condition and of

ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self

nuts) are not reused. These components

may fai

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

—used to

onnel to potential

Workplace Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

ting and stabilizing the

g areas

components when lifting or

-toed shoes.

vi GS

-locking

l if they are used a second time.

if not avoided,

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 7

August 2022

Table of Contents

Introduction Introduction ...................................................................................................... ii

Important Information ......................................................................................... ii

Find a Manual for this Model ............................................................................... ii

Revision History ................................................................................................ iii

Serial Number Legend ....................................................................................... iv

Section 1 Safety Rules ...................................................................................................... v

General Safety Rules ......................................................................................... v

Section 2 Specifications ................................................................................................... 1

Machine Specifications ....................................................................................... 1

Performance Specifications ................................................................................ 1

Hydraulic Oil Specifications ................................................................................ 2

Hydraulic Component Specifications ................................................................... 5

Manifold Component Specifications .................................................................... 5

Machine Component Weights ............................................................................. 6

Battery Specifications ......................................................................................... 6

Hydraulic Hose and Fitting Torque Specifications ............................................... 7

Torque Procedure .............................................................................................. 8

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC vii

Page 8

August 2022

Table of Contents

Section 3 Repair Procedures ......................................................................................... 10

Introduction ...................................................................................................... 10

Platform Controls ........................................................................................... 12

1-1 Circuit Board .............................................................................................. 13

1-2 Joystick ...................................................................................................... 14

1-3 Platfrom Controls Alarm ............................................................................. 14

1-4 Platfrom Emergency Stop Button................................................................ 15

Platform Components .................................................................................... 16

2-1 Platform ..................................................................................................... 16

2-2 Platform Extension Deck ............................................................................ 17

Scissor Components ..................................................................................... 19

3-1 Scissor Assembly, GS-2669 DC ................................................................. 20

3-2 Scissor Assembly, GS-3369 DC ................................................................. 23

3-3 Scissor Assembly, GS-4069 DC ................................................................. 27

3-4 Wear Pads ................................................................................................. 30

3-5 Lift Cylinders .............................................................................................. 32

3-6 Height Angle Sensor .................................................................................. 33

How to Replace the Height Angle Sensor .................................................... 33

Ground Controls ............................................................................................ 35

4-1 Software Revision Level ............................................................................. 36

4-2 Machine Setup ........................................................................................... 37

4-3 Auxiliary Platform Lowering ........................................................................ 38

4-4 Level Sensor - Models without Outriggers .................................................. 38

4-5 Level Sensor - Models with Outriggers ....................................................... 41

4-6 Service Override Mode............................................................................... 43

viii GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 9

August 2022

Table of Contents

Hydraulic Pump .............................................................................................. 45

5-1 Hydraulic Pump .......................................................................................... 45

How to Test the Hydraulic Pump .................................................................. 45

How to Remove the Hydraulic Pump............................................................ 45

How to Calibrate the Hydraulic Pump........................................................... 46

Manifolds ........................................................................................................ 48

6-1 Function Manifold Components .................................................................. 48

6-2 Valve Adjustments - Function Manifold ....................................................... 50

How to Check the System Proportional Relief Valve .................................... 50

How to Adjust the Oscillate Relief Valve ...................................................... 51

How to Adjust the Steer Relief Valve............................................................ 52

How to Adjust the Platform Up Relief Valve ................................................. 53

6-3 Outrigger Manifold Components ................................................................. 58

6-4 Valve Coils ................................................................................................. 59

Hydraulic Tank................................................................................................ 61

7-1 Hydraulic Tank ........................................................................................... 61

Steer Axle Components ................................................................................. 62

8-1 Yoke Assembly........................................................................................... 62

8-2 Steer Cylinder ............................................................................................ 64

8-3 Tie Rod ...................................................................................................... 64

8-4 Oscillate Cylinder ....................................................................................... 65

8-5 Oscillate Hoses .......................................................................................... 65

8-6 Steer Angle Sensor .................................................................................... 67

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC ix

Page 10

August 2022

Table of Contents

Non-steer Axle Components ......................................................................... 72

9-1 Drive Motors .............................................................................................. 72

9-2 Drive Hub ................................................................................................... 74

Outrigger Components .................................................................................. 75

10-1 Outrigger Cylinder .................................................................................... 75

10-2 Outrigger Calibration ................................................................................ 76

Platform Overload Components .................................................................... 78

How to Calibrate the Platform Overload System .......................................... 78

11-2 Platform Overload Recovery..................................................................... 80

11-3 Down Limit Height .................................................................................... 82

How to Calibrate the Down Limit Height ...................................................... 82

x GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 11

August 2022

Table of Contents

Section 4 Fault Codes ..................................................................................................... 83

Introduction ...................................................................................................... 83

GCON I/O Map ................................................................................................. 86

Platform Overload Fault Codes...................................................................... 88

Operation Indicator Codes (OIC) ...................................................................... 93

Diagnostic Trouble Codes (DTC) ...................................................................... 93

Troubleshooting "HXXX" and "PXXX" Faults ..................................................... 94

Fault Inspection Procedure ............................................................................... 95

Type "HXXX" Faults ......................................................................................... 97

Type "PXXX" Faults ........................................................................................ 100

Type "UXXX" Faults ....................................................................................... 102

Type "FXXX" Faults ........................................................................................ 104

Type "CXXX" Faults ....................................................................................... 107

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC xi

Page 12

August 2022

Table of Contents

Section 5 Schematics ................................................................................................... 109

Introduction .................................................................................................... 109

Electrical Schematic Abbreviations and Wire Color Legends .......................... 110

Hydraulic Component Legend ........................................................................ 113

Electrical Symbols Legend ............................................................................. 114

Hydraulic Symbols Legend ............................................................................. 115

Limit Switch Legend ....................................................................................... 116

Fuse, Ground and Platform Control Boxes ................................................. 117

Fuse Box Layout, All Models .......................................................................... 118

Ground Control Box Layout ............................................................................ 119

Platform Control Box Layout ........................................................................... 121

Electrical Schematics .................................................................................. 123

Electrical Schematic ....................................................................................... 124

Hydraulic Schematics .................................................................................. 127

Hydraulic Schematic ...................................................................................... 128

xii GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 13

August 2022 Service and Repair Manual

Fluid capacities

Hydraulic tank

(maximum fill capacity)

allons

iters

Hydraulic system (including tank)

allons

iters

Drive hub

EP 9

gear oil API service classification GL5

unces

c

Tires and wheels

Wheel lugs

9 @ 5/8-18

Lug nut torque, dry

Rear

lbs

230 Nm

Lug nut torque, lubricated

Rear

lbs

176 Nm

Lug nut torque, dry

Front

lbs

122 Nm

Lug nut torque, lubricated

Front

lbs

92 Nm

Castle nut (steer end)

Castle nut torque

lbs

47.5 Nm

Tire size

12D380

Tire ply rating

8

Tire diameter

n

66 cm

Tire width

n

m

Weight, each

bs

g

Drive speed, maximum

Platform stowed

Forward direction

ph

m/h

ec

12.2 m / 6.1 sec

Platform stowed

Reverse direction

ph

m/h

ec

ec

Platform raised

ph

m/h

ec

ec

Braking distance, maximum

High range on paved

surface

t

m

Gradeability

See Operator's Manual

Function speed, maximum from platform controls

(with maximum rated load in platform)

Platform up

Platform down

econds

econds

GS-3369 DC

Platform up

Platform down

econds

econds

GS-4069 DC

Platform up

Platform down

econds

23 to 33 seconds

Outrigger leveling, maximum

Front

Back

Side to side

5.3°

4.2°

11.7°

Specifications

Section 2 Specificatio ns

Machine Specifi c atio ns

Machine Specifications

18 g

0 or SAE 90 multipurpose hypoid

Performance S peci f icati o ns

Performance Specifications

16.5 g

62.5 l

68.1 l

24.5 o

725 c

12.2 m / 9.1 s

170 ft-

130 ft-

90 ft-

68 ft-

GS-2669 DC

35 ft-

29 to 39 s

26 to 36 s

4.5 m

7.2 k

40 ft / 6.1 s

3.0 m

4.8 k

40 ft / 9.1 s

0.3 m

0.5 k

40 ft / 91 s

12.2 m / 91 s

3 f

0.9

Non-marking, foam filled, RT

26 x

For operational specifications, refer to the

Operator's Manual.

26 i

12 i

30 c

177.5 l

80.5 k

34 to 44 s

24 to 34 s

56 to 66 s

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 1

Page 14

Service and Repair Manual August 2022

Hydraulic Fluid Specifications

Genie specifications require hydraulic oils which are

designed to give maximum protection to hydraulic

systems, have the ability to perform over a wide

temperature range, and the viscosity index should

exceed 140. They should provide

oxidation prevention, corrosion inhibition, seal

conditioning, and foam and aeration suppression

properties.

Cleanliness level,

minimum

ISO 15/13

Water content,

maximum

pm

Recommended Hydraulic Fluid

Hydraulic oil type

Chevron Rando HD Premium

ISO Grade

32

Viscosity index,

maximum

200

Optional Hydraulic Fluids

Mineral based

Shell Tellus S2 V 32

Shell Tellus S2 V 46

Shell Tellus S4 VX 32

Shell Donax TG (Dexron III)

Chevron 5606A

Biodegradable

46

Fire resistant

5046

Optional fluids may not have

the same hydraulic lifespan and

may result in component

damage.

Do not top off with incompatible

hydraulic fluids. Hydraulic fluids

may be incompatible due to the

differences in base additive

chemistry. When incompatible

fluids are mixed, insoluble

materials may form and deposit

in the hydraulic system,

plugging hydraulic lines, filters,

control valves and may result in

component damage.

Specifications

Hydraulic Oi l Spec ific ations

Hydraulic Oil Specifications

excellent antiwear,

250 p

Petro Canada Environ MV

UCON Hydrolube HP-

Note: Genie specifications require additional

equipment and special installation instructions for

the approved optional fluids. Consult Genie

Product Support before use.

Note: Do not operate the machine when the

ambient air temperature is consistently above

120°F / 49°C.

Hydraulic Fluid Temperature

Range

Ambient air temperature

1 Chevron hydraulic oil 5606A

2 Petro-Canada Environ MV 46

3 UCON Hydrolube HP-5046D

4 Chevron Rando HD premium oil MV

Note: Extended machine operation can cause the

hydraulic fluid temperature to increase beyond its

maximum allowable range. If the hydraulic fluid

temperature consistently exceeds 200°F / 90°C an

optional oil cooler may be required.

2 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 15

August 2022 Service and Repair Manual

ISO Grade

32

Viscosity index, maximum

200

Kinematic

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

7.5

33.5

Brookfield Viscosity, maximum

cP @

cP @

1040

3310

Flash point

375°F / 190°C

Pour point

50°C

Maximum continuous operating

temperature

77°C

ISO Grade

15

Viscosity index, maximum

300

Kinematic Viscosity, maximum

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

cSt @

5.5

15.0

510

Flash point

180°F / 82°C

Pour point

-81°F / -63°C

Maximum continuous

temperature

124°F / 51°C

Continued use of Chevron

5606A

equivalent, when ambient

temperatures are consistently

above 32°F / 0°C may result in

component damage

ISO Grade

46

Viscosity index, maximum

154

Kinematic Viscosity, maximum

cSt @

cSt @ 104°F / 40°C

8.0

44.4

Flash point

482°F / 250°C

Pour point

45°C

Maximum continuous operating

temperature

180°F / 82°C

Specifications

Chevron Rando HD Premium Oil

MV Fluid Properties

Chevron 5606A Hydraulic Oil

Fluid Properties

Viscosity, maximum

-4°F / -20°C

-22°F / -30°C

-58°F / -

171°F /

Note: A hydraulic oil heating system is

recommended when the ambient temperature is

consistently below 0°F / -18°C.

Note: Do not operate the machine when the

ambient temperature is below -20°F / -29°C with

Rando HD Premium MV.

-40°F / -40°C

operating

Note: Use of Chevron 5606A hydraulic fluid, or

equivalent, is required when ambient temperatures

are consistently below 0°F / -17°C unless an oil

heating system is used.

hydraulic fluid, or

Petro-Canada Environ MV 46

Fluid Properties

Part No. 1306585GT GS

200°F / 100°C

-49°F / -

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 3

Page 16

Service and Repair Manual August 2022

ISO Grade

32

Viscosity index, maximum

300

Kinematic

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

9

33.8

Brookfield Viscosity, maximum

cSt @

cSt @

cSt @

481

702.4

2624

Flash point

>100

Pour point

60°C

Maximum continuous operating

temperature

103°F / 75°C

ISO Grade

46

Viscosity index, maximum

192

Kinematic Viscosity, maximum

cSt @ 149°F / 65°C

cSt @ 104°F / 40°C

cSt @ 0°F / -18°C

22

46

1300

Flash point

None

Pour point

63°C

Maximum continuous operating

temperature

189°F / 87°C

Specifications

Shell Tellus S4 VX Fluid

Properties

Viscosity, maximum

-4°F / -20°C

-13°F / -25°C

-40°F / -40°C

-76°F / -

UCON Hydrolube HP-5046 Fluid

Properties

-81°F / -

4 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 17

August 2022 Service and Repair Manual

Function Pump

Type

gear pump

Displacement

u in

c

Flow rate @ 310

pm

22.7 L/min

System relief valve pressure,

maximum

s

ari

Lift relief valve pressure

GS

si

ar

Lift relief valve pressure

GS

si

ar

Lift relief valve pressure

GS

si

ar

Steer relief valve

si

103 bar

Oscillate relief valve pressure

si

ar

Steer flow regulator

pm

7.6 L/min

Oscillate flow regulator

pm

4 L/min

Plug torque

SAE No. 2

lbs / 4 Nm

SAE No. 4

10 ft-lbs / 13 Nm

SAE No. 6

lbs / 19 Nm

SAE No. 8

lbs / 51 Nm

SAE No.10

lbs / 55 Nm

SAE No. 12

lbs / 76 Nm

Specifications

Hydraulic Com pon ent S p eci ficati ons

Hydraulic Component

Specifications

Manifold Co mpo nent Spec ific a tions

Manifold Component

Specifications

0 rpm

Function manifold

-2669 DC

-3369 DC

-4069 DC

pressure

0.4 c

6 g

3500 p

241 b

3300 p

1 g

3100 p

214 b

2900 p

200 b

2850 p

197 b

1500 p

228 b

2 g

6 c

36 in-

14 ft-

38 ft-

41 ft-

56 ft-

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 5

Page 18

Service and Repair Manual August 2022

Platform assembly

bs

425 kg

Link assembly (GS

bs

g

Link assembly (GS

bs

g

Link assembly (GS

bs

g

Outrigger assembly (if equipped)

bs

g

Chassis assembly (GS

(J10

bs

g

Chassis assembly (GS

(J10

bs

g

Chassis assembly (GS

(J30

bs

3281 kg

Chassis assembly (GS

(J30

bs

2408 kg

Chassis assembly (GS

(J30

bs

g

T105

Type

6v DC

Quantity

8

Capacity

225 AH

Reserve capacity @ 25A rate

inutes

Reserve capacity @ 75A rate

inutes

Weight, each

g

Weight (tray with batteries)

554 lbs / 251 kg

J305GH

Type

6V DC

Quantity

8

Capacity

315 AH

Reserve capacity @ 25A rate

inutes

Reserve capacity @ 75A rate

inutes

Weight, each

g

Weight (tray with batteries)

353.5kg

Specifications

Machine Co mponent Weight s

Machine Component Weights

Battery Speci ficat i ons

Battery Specifications

-4069)

-3369)

-2669)

5 battery option)

5 battery option)

5 battery option)

5 battery option)

5 battery option)

-3369)

-2669)

-4069)

-3369)

-2669)

936 l

3430 l

1556 k

2607 l

1183 k

2156 l

978 k

850 l

386 k

5084 l

2306 k

5623 l

2551 k

7233 l

5309 l

5848 l

2653 k

447 m

115 m

62 lbs / 28 k

678 m

175 m

88 lbs / 40 k

779 lbs /

6 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 19

August 2022 Service and Repair Manual

SAE Dash Size

Torque

-8

40 ft-lbs / 55 Nm

SAE Dash Size

Thread Size

Flats

-16

1 5/16-12

1

SAE Dash Size

Torque

-8

36 ft-lbs / 49 Nm

-4

ORFS / 37° (Adj)

-6

ORFS (Adj / Non-adj)

-16

(All types)

-20

(All types)

Specifications

Hydraulic Hos e and Fitti ng Tor que S p ecifi cati ons

Hydraulic Hose and Fitting

Torque Specifications

Your machine is equipped with Parker Seal-Lok™

ORFS or 37° JIC fittings and hose ends. Genie

specifications require that fittings and hose ends

be torqued to specification when they are removed

and installed or when new hoses or fittings are

installed.

Seal-Lok™ Fittings

(hose end - ORFS)

-4 18 ft-lbs / 25 Nm

-6 30 ft-lbs / 41 Nm

-10 60 ft-lbs / 81 Nm

-12 85 ft-lbs / 115 Nm

-16 110 ft-lbs / 150 Nm

-20 150 ft-lbs / 205 Nm

-24 230 ft-lbs / 315 Nm

SAE O-ring Boss Port

(tube fitting - installed into Aluminum)

(all types)

-4 14 ft-lbs / 19 Nm

-6 23 ft-lbs / 31,2 Nm

-10 62 ft-lbs / 84 Nm

-12 84 ft-lbs / 114 Nm

-16 125 ft-lbs / 169,5 Nm

-20 151 ft-lbs / 204,7 Nm

-24 184 ft-lbs / 249,5 Nm

Adjustable Fitting Non-adjustable fitting

1 jam nut

JIC 37° Fittings

(swivel nut or hose connection)

-4 7/16-20 2

-6 9/16-18 1 1/2

-8 3/4-16 1 1/2

-10 7/8-14 1 1/2

-12 1 1/16-12 1 1/4

-20 1 5/8-12 1

-24 1 7/8-12 1

SAE O-ring Boss Port

(tube fitting - installed into Steel)

SAE Dash Size Torque

15 ft-lbs / 20,3 Nm

ORFS (Non-adj)

37° (Non-adj)

37° (Adj / Non-adj)

ORFS (Adj / Non-adj)

-8

37° (Adj / Non-adj)

-10 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-12 (All types)

-24 (All types)

26 ft-lbs / 35,3 Nm

22 ft-lbs / 30 Nm

35 ft-lbs / 47,5 Nm

29 ft-lbs / 39,3 Nm

60 ft-lbs / 81,3 Nm

52 ft-lbs / 70,5 Nm

100 ft-lbs / 135,6 Nm

85 ft-lbs / 115,3 Nm

135 ft-lbs / 183 Nm

200 ft-lbs / 271,2 Nm

250 ft-lbs / 339 Nm

305 ft-lbs / 413,5 Nm

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 7

Page 20

Service and Repair Manual August 2022

Specifications

Torque Proce dur e

Torque Procedure

Seal-Lok™ fittings

1 Replace the O-ring. The O-ring must be

replaced anytime the seal has been broken.

The O-ring cannot be re-used if the fitting or

hose end has been tightened beyond finger

tight.

Note: The O-ring in Parker Seal Lok™ fittings and

hose end are custom-size O-rings. They are not

standard size O-rings. They are available in the Oring field service kit (Genie part number 49612).

2 Lubricate the O-ring before installation.

3 Be sure the O-ring face seal is seated and

retained properly.

JIC 37° fittings

1 Align the tube flare (hex nut) against the nose

of the fitting body (body hex fitting) and

tighten the hex nut to the body hex fitting to

hand tight, approximately 30 in-lbs / 3.4 Nm.

2 Using a permanent ink marker, make a

reference mark on one the flats of the hex nut

and continue the mark onto the body of the

hex fitting. Refer to Illustration 1.

4 Position the tube and nut squarely on the face

seal end of the fitting, and tighten the nut

finger tight.

5 Tighten the nut or fitting to the appropriate

torque. Refer to the appropriate torque chart

in this section.

6 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

Illustration 1

1 hex nut

2 reference mark

3 body hex fitting

8 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 21

August 2022 Service and Repair Manual

Specifications

3 Working clockwise on the body hex fitting,

make a second mark with a permanent ink

marker to indicate the proper tightening

position. Refer to Illustration 2.

Note: Use the JIC 37° Fitting table in this section

to determine the correct number of flats, for the

proper tightening position.

Note: The marks indicate the correct tightening

positions have been determined. Use the second

mark on the body hex fitting to properly tighten the

joint after it has been loosened.

Illustration 2

1 body hex fitting

2 reference mark

3 second mark

4 Tighten the hex nut until the mark on the hex

nut is aligned with the second mark on the

body hex fitting.

5 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 9

Page 22

Service and Repair Manual August 2022

Repair Procedures

Section 3 Repair Proce dur es

Introductio n

Observe and Obey:

Repair procedures shall be completed by a

person trained and qualified on the repair of

this machine.

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Before Repairs Start:

Read, understand and obey the safety rules

and operating instructions in the appropriate

operator's manual on your machine.

Machine Configuration:

Unless otherwise specified, perform each

repair procedure with the machine in the

following configuration:

• Machine parked on a firm, level surface

• Key switch in the off position with the key

removed

• The red Emergency Stop button in the off

position at both the ground and platform

controls

• Wheels chocked

• All external AC power supply disconnected

from the machine

• Platform in the stowed position

Be sure that all necessary tools and parts are

available and ready for use.

Use only Genie approved replacement parts.

Read each procedure completely and adhere

to the instructions. Attempting shortcuts may

produce hazardous conditions.

10 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 23

August 2022 Service and Repair Manual

Safety alert symbol

lert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicat

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Repair Procedures

About This Section

Most of the procedures in this section should only

be performed by trained service professional in a

suitably equipped workshop. Select the

appropriate repair procedure after troubleshooting

the problem.

Symbols Legend

—used to a

Perform disassembly procedures to the point

where repairs can be completed. Then to reassemble, perform the disassembly steps in

reverse order.

es a potentially hazardous

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 11

Page 24

Service and Repair Manual August 2022

Code

Condition

LL Off

OL Platform Overload

CH Chassis Mode Operation

nd No Drive (option)

F053

DCON RR Thermal Protection

F054

DCON LR Thermal Protection

Ld Lifting Disabled

St Engine Start Delay

Platform Controls

Platfor m C on tr ols

Platform controls

The platform controls are used to operate the

machine from the platform.

Activating a function button sends a signal to the

Electronic Control Module (ECM). When the ECM

is in the function mode, the platform controls are

used to operate the various machine functions.

The platform controls consist of an Emergency

Stop button, electronic circuit board, proportional

control handle, drive/steer enable switch, alarm,

function buttons and LED display.

For further information or assistance, contact

Genie Product support.

Operational Indicator Codes

(OIC)

These codes are generated by the electrical

system to indicate machine operating status.

During normal operation a code will appear in the

platform controls LED readout if a condition such

as off-level, overload cutout, chassis mode

operation or pothole guards stuck occurs. These

codes are not indicators of a device malfunction in

the electrical system.

If the platform controls LED readout displays an

operational indicator code such as LL, the fault

condition must be repaired or removed before

resuming machine operation. Push in and pull out

the red Emergency Stop button to reset the

system.

Platform Controls LED Readout

-Level

1 red Emergency Stop button P2

2 platform controls circuit board U3

3 proportional control handle and drive/steer

enable switch JC9

4 alarm H1

Note: A code and a description of a code can also

(option)

be viewed at the ground controls LCD display.

12 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 25

August 2022 Service and Repair Manual

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Component damage hazard.

Electrostatic discharge (ESD)

can damage printed circuit board

components. Maintain firm

contact with a metal part of the

machine that is grounded at all

times when handling printed

circuit boards OR use a

grounded wrist strap.

Circuit board fastener torque specifications

Hand

lbs

< 0.6 Nm

Platform Controls

1-1 Circuit Bo ard

1-1

Circuit Board

8 Carefully disconnect all wire harness

connectors from the platform controls circuit

board.

How to Remove the Platform

Controls Circuit Board

1 Push in the red Emergency Stop button to the

off position at both the ground and platform

controls.

2 Disconnect the platform controls from the

control cable at the platform.

3 Remove the fasteners securing the platform

control box to the platform control bracket.

4 Remove the fasteners securing the bottom

cover to the platform control box. Open the

control box.

5 Remove the ties securing the wire harness.

6 Disconnect the red and black wires from the

alarm.

7 Carefully remove the alarm from the platform

control box.

9 Carefully remove the platform controls circuit

board fasteners.

10 Carefully remove the platform controls circuit

board from the platform control box.

11 Remove the transparent caps from the

platform controls circuit board and save.

Part No. 1306585GT GS

tighten until screw seats < 5 in-

Note: Before installing a circuit board, place the

transparent caps removed in step 11, over the

circuit board buttons.

Note: After installing the circuit board, check for

proper button operation. Excessive torque of the

circuit board fasteners will cause the buttons to

bind. Moderate torque of the circuit board

fasteners will not allow the buttons to engage.

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 13

Page 26

Service and Repair Manual August 2022

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

watches and other jewelry.

Component damage hazard.

Electrostatic discharge (ESD)

can damage printed circuit board

components. Maintain firm

contact with a metal part of the

machine that is grounded at all

times when handling printed

circuit boards OR use a

grounded wrist strap.

Torque specifications

Joystick fasteners

lbs

1 Nm

Electrocution/burn hazard.

Contact with electrically charged

circuits could

serious injury. Remove all rings,

watches and other jewelry.

Component damage hazard.

Electrostatic discharge (ESD)

can damage printed circuit board

components. Maintain firm

contact with a metal part of the

machine that is

times when handling printed

circuit boards OR use a

grounded wrist strap.

Platform Controls

1-2 Joystick

1-2

Joystick

1-3 Platfrom Con t rols A larm

1-3

Platform Controls Alarm

How to Remove the Joystick

1 Push in the red Emergency Stop button to the

off position at both the ground and platform

controls.

2 Disconnect the platform controls from the

control cable at the platform.

3 Remove the fasteners securing the platform

control box to the platform control bracket.

4 Remove the fasteners securing the bottom

cover to the platform control box. Open the

control box.

5 Remove the ties securing the joystick wire

harness.

6 Carefully disconnect the joystick wire harness

from the platform controls circuit board.

How to Remove the Platform

Controls Alarm

1 Push in the red Emergency Stop button to the

off position at both the ground and platform

controls.

2 Disconnect the platform controls from the

control cable at the platform.

3 Remove the fasteners securing the platform

control box to the platform control bracket.

4 Remove the fasteners securing the bottom

cover to the platform control box. Open the

control box.

5 Disconnect the red and black wires from the

alarm.

result in death or

7 Carefully remove the joystick fasteners.

8 Carefully remove the joystick from the

platform control box.

14 GS

grounded at all

6 Carefully remove the alarm from the platform

control box.

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

9 in-

Page 27

August 2022 Service and Repair Manual

Electrocution/burn hazard.

Contact with electrically charged

ci

serious injury. Remove all rings,

watches and other jewelry.

Component damage hazard.

Electrostatic discharge (ESD)

can damage printed circuit board

components. Maintain firm

contact with a metal part of the

machine that is grounded at all

times when handling printed

circuit boards OR use a

grounded wrist strap.

Platform Controls

1-4 Platfrom E me rgenc y St o p Butt on

1-4

Platform Emergency Stop Button

How to Remove the Platform

Controls Emergency Stop Button

1 Push in the red Emergency Stop button to the

off position at both the ground and platform

controls.

2 Disconnect the platform controls from the

control cable at the platform.

3 Remove the fasteners securing the platform

control box to the platform control bracket.

4 Remove the fasteners securing the bottom

cover to the platform control box. Open the

control box.

5 Disconnect the white wires from the

Emergency Stop base.

6 Carefully remove the Emergency Stop base

from the Emergency Stop button.

7 Carefully remove the retaining ring from the

Emergency Stop button.

8 Carefully remove the Emergency Stop button

from the platform control box.

rcuits could result in death or

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 15

Page 28

Service and Repair Manual August 2022

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these

skills and tools could result in

death or serious injury and

significant component damage.

Dealer service is strongly

recommended.

Component damage hazard. Be

sure not to cut the power to the

platform wiring.

Component damage hazard.

The platform controls wiring can

be

pinched.

Electrocution/burn hazard.

Contact with electrically charged

circuits could result in death or

serious injury. Remove all rings,

wa

Platform Components

Platfor m C ompo ne nts

2-1 Platform

2-1

Platform

How to Remove the Platform

Note: This procedure will require an overhead

supporting device capable of supporting 1000 lbs /

454 kg.

1 Remove the cable ties that secures the power

to platform wiring to the bottom of the

platform.

5 Remove the cover from the AC outlet. Tag

and disconnect the wiring from the outlet.

tches and other jewelry.

6 Models with air line to platform option:

Disconnect the air line from the platform. Pull

the air line free of the platform.

7 Attach a sling chain from the overhead lifting

device to the four lifting points on the platform.

2 Remove the clamp that secures the platform

controls cable to the platform.

3 Disconnect the platform controls cable from

the connector located under the platform.

4 Remove the platform controls from the

platform.

16 GS

damaged if it is kinked or

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

8 Remove the two carriage bolts that secure the

platform to the platform pivot at the steer end

of the machine.

Page 29

August 2022 Service and Repair Manual

Crushing hazard. The platform

will become unbalanced and fall

it not properly

Platform Components

9 Carefully lift the platform enough to clear the

platform pivot.

10 Slide the platform towards the non-steer end

of the machine until the slider blocks are

visible underneath the slider block channel.

11 Carefully lift the platform off of the machine

and place it on a structure capable of

supporting it.

2-2 Platform E xten si on D eck

2-2

Platform Extension Deck

How to Remove the Platform

Extension Deck

1 Remove the retaining fasteners from the deck

catch and remove the deck catch.

2 Remove the retaining fasteners from the deck

stop and remove the deck stop.

3 Repeat steps 1 and 2 for the other side of the

platform.

supported.

Note: Note the position of the slider blocks before

the platform is removed so that when the platform

is installed they will be in the correct position.

1 deck catch

2 deck stop

4 Remove the platform controls from the

platform.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 17

Page 30

Service and Repair Manual August 2022

Crushing hazard. The platform

extension will become

unbalanced and fall when

removed from the machine if not

properly

to the forklift.

Platform Components

5 Release the four rail spacers by pulling the

retaining pin and turn them in a downward

position.

1 rail spacer

6 Position a forklift at the steer end of the

machine with the forks even with the bottom

of the platform extension.

9 Carefully slide the platform extension out and

away from the platform and place it on a

structure capable of supporting it.

supported and secured

7 Carefully slide the platform extension out until

the platform extension makes contact with the

carriage on the forklift.

8 Secure the platform extension deck railings to

the carriage of the forklift to support the

platform extension deck.

18 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 31

August 2022 Service and Repair Manual

Scissor Components

Scissor C omp one nt s

Steer End

1 Platform pivot

2 Number 3 outer arm

3 Lift cylinder rod-end pivot pin

4 Number 3 pivot pin (steer end)

5 Number 2 center pivot pin (Qty. 2)

6 Number 2 pivot pin (steer end)

7 Number 1 center pivot pin (Qty. 2)

(ANSI/CSA)

8 Number 1 center pivot pin (Qty. 1) (AS/CE)

9 Number 1 inner arm

Part No. 1306585GT GS

Non-steer End

10 Chassis pivot

11 Slider block (Qty. 2)

12 Number 3 inner arm

13 Number 3 center pivot pin (Qty. 2)

14 Number 3 pivot pin (non-steer end)

15 Number 2 inner arm

16 Number 2 outer arm

17 Number 2 pivot pin (non-steer end)

18 Lift cylinder barrel-end pivot pin

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 19

19 Number 1 outer arm

Page 32

Service and Repair Manual August 2022

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these

skills and tools could result in

death or serious injury and

signifi

Dealer service is strongly

recommended.

Component damage hazard

Cables can be damaged if they

are kinked or pinched.

Crushing haz

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

3-1 Scissor Assembly, GS-2669 D C

3-1

Scissor Assembly, GS-2669 DC

4 Using a suitable supporting device, attach a

strap to the rod end of the lift cylinder. Do not

apply pressure.

How to Disassemble the Scissor

Assembly

cant component damage.

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications, Hydraulic Hose and Fitting Torque

Specifications.

Note: This procedure will require an overhead

supporting device capable of supporting 1000 lbs /

454 kg.

1 Remove the platform. Refer to Repair

Procedure, How to Remove the Platform.

2 Remove the retaining fasteners that attach

the ladder to the drive chassis. Remove the

ladder and set aside.

5 Remove the lift cylinder rod end pivot pin

retaining fasteners.

6 Using a soft metal drift, remove the pivot pin.

7 Lower the lift cylinder and remove the strap.

8 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

3 inner arm. Make the chains tight but do not

apply lifting pressure.

ard. The linkage

9 Remove the retaining fasteners from the

number 3 pivot pins.

Note: Do not remove the external snap ring.

10 Using a soft metal drift, remove the pivot pins

and set aside.

11 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

12 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

2 inner arm. Make the chains tight but do not

apply lifting pressure.

3 Remove the cables from the linkage

assembly.

20 GS

.

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 33

August 2022 Service and Repair Manual

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil

gradually. Do not allow oil to

squirt or spray.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

13 Remove the retaining fasteners from the

number 2 pivot pins.

Note: Do not remove the external snap ring.

14 Using a soft metal drift, remove the pivot pins

and set aside.

15 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

16 Tag and disconnect the harness from the lift

cylinder valve block.

17 Tag and disconnect the hydraulic hoses from

the lift cylinder. Plug the hoses and cap the

fittings.

20 Remove the two carriage bolts that secure the

inner arm and chassis pivot to the steer end

of the drive chassis.

21 Move the linkage towards the non-steer end

of the machine until the slider feet are clear of

the slider channel.

22 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

Separate the link sets:

1 Using an overhead supporting device attach a

4 hook sling chain to the ends of the inner

arm. Make the chains tight but do not apply

lifting pressure.

pressure to dissipate

18 Remove the hose clamps and hoses from the

number 1 inner arm.

19 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

1 inner arm. Make the chains tight but do not

apply lifting pressure.

2 Remove the retaining fasteners from the

center pivot pins.

Note: Do not remove the external snap ring.

3 Using a soft metal drift, remove the center

pivot pins and set aside.

4 Carefully lift and separate the linkage

assembly apart and place it on a structure

capable of supporting it.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 21

Page 34

Service and Repair Manual August 2022

Scissor Components

Steer End

1 Platform pivot

2 Number 4 center pivot pin (Qty. 2)

3 Number 4 pivot pin (steer end)

4 Number 3 center pivot pin (Qty. 2)

5 Lift cylinder rod-end pivot pin

6 Number 3 pivot pin (steer end)

7 Number 2 center pivot pin (Qty. 2)

8 Number 2 pivot pin (steer end)

9 Number 1 outer arm

10 Number 1 center pivot pin (Qty. 2)

(ANSI/CSA)

11 Number 1 center pivot pin (Qty. 1) (AS/CE)

12 Number 1 inner arm

Non-steer End

13 Chassis pivot

14 Slider block (Qty. 2)

15 Number 4 inner arm

16 Number 4 outer arm

17 Number 4 pivot pin (non-steer end)

18 Number 3 inner arm

19 Number 3 outer arm

20 Number 3 pivot pin (non-steer end)

21 Number 2 inner arm

22 Number 2 outer arm

23 Number 2 pivot pin (non-steer end)

24 Lift cylinder barrel-end pivot pin

25 Number 1 outer arm

22 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 35

August 2022 Service and Repair Manual

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these

skills and tools could result in

death or serious injury and

significa

Dealer service is strongly

recommended.

Component damage

Cables and hoses can be

damaged if they are kinked or

pinched.

Crushing

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

3-2 Scissor Assembly, GS-3369 D C

3-2

Scissor Assembly, GS-3369 DC

How to Disassemble the Scissor

Assembly

4 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

4 inner arm. Make the chains tight but do not

apply lifting pressure.

hazard. The linkage

nt component damage.

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications, Hydraulic Hose and Fitting Torque

Specifications.

Note: This procedure will require an overhead

supporting device capable of supporting 1000 lbs /

454 kg.

1 Remove the platform. Refer to Repair

Procedure, How to Remove the Platform.

2 Remove the retaining fasteners that attach

the ladder to the drive chassis. Remove the

ladder and set aside.

5 Remove the retaining fasteners from the

number 4 pivot pins.

Note: Do not remove the external snap ring.

6 Using a soft metal drift, remove the pivot pins

and set aside.

7 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

8 Using a suitable supporting device, attach a

strap to the rod end of the lift cylinder. Do not

apply pressure.

9 Remove the lift cylinder rod end pivot pin

retaining fasteners

10 Using a soft metal drift, remove the pivot pin.

11 Lower the lift cylinder and remove the strap.

12 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

3 inner arm. Make the chains tight but do not

apply lifting pressure.

3 Remove the cables from the linkage

assembly.

Part No. 1306585GT GS

hazard.

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 23

Page 36

Service and Repair Manual August 2022

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Bodily injury hazard. Spraying

hydraulic oil can p

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or spray.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

13 Remove the retaining fasteners from the

number 3 pivot pins.

Note: Do not remove the external snap ring.

21 Tag and disconnect the hydraulic hoses from

the lift cylinder. Plug the hoses and cap the

fittings.

14 Using a soft metal drift, remove the pivot pins

and set aside.

15 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

16 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

2 inner arm. Make the chains tight but do not

apply lifting pressure.

17 Remove the retaining fasteners from the

number 2 pivot pins.

Note: Do not remove the external snap ring.

18 Using a soft metal drift, remove the pivot pins

and set aside.

19 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

20 Tag and disconnect the harness from the lift

cylinder valve block.

enetrate and

22 Remove the hose clamps and hoses from the

number 1 inner arm.

23 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

1 inner arm. Make the chains tight but do not

apply lifting pressure.

24 Remove the two carriage bolts that secure the

inner arm and chassis pivot to the steer end

of the drive chassis.

25 Move the linkage towards the non-steer end

of the machine until the slider feet are clear of

the slider channel.

26 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

24 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 37

August 2022 Service and Repair Manual

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

Separate the link sets:

1 Using an overhead supporting device attach a

4 hook sling chain to the ends of the inner

arm. Make the chains tight but do not apply

lifting pressure.

2 Remove the retaining fasteners from the

center pivot pins.

Note: Do not remove the external snap ring.

3 Using a soft metal drift, remove the center

pivot pins and set aside.

4 Carefully lift and separate the linkage

assembly apart and place it on a structure

capable of supporting it.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 25

Page 38

Service and Repair Manual August 2022

Scissor Components

Steer End

1 Platform pivot

2 Number 5 center pivot pin (Qty. 2)

3 Number 5 pivot pin (steer end)

4 Number 4 center pivot pin (Qty. 2)

5 Number 4 inner arm

6 Number 4 pivot pin (steer end)

7 Number 3 center pivot pin (Qty. 2)

8 Lower lift cylinder rod-end pivot pin

9 Number 3 inner arm

10 Number 3 pivot pin (steer end)

11 Number 2 center pivot pin (Qty. 2)

12 Number 2 pivot pin (steer end)

13 Number 1 center pivot pin (Qty. 2)

(ANSI/CSA) OR

Number 1 center pivot pin (Qty. 1) (AS/CE)

14 Number 1 inner arm

15 Chassis pivot

Non-steer End

16 Slider block (Qty. 2)

17 Number 5 inner arm

18 Number 5 outer arm

19 Number 5 pivot pin (non-steer end)

20 Upper lift cylinder rod-end pivot pin

21 Number 4 outer arm

22 Number 4 pivot pin (non-steer end)

23 Upper lift cylinder barrel-end pivot pin

24 Number 3 outer arm

25 Number 3 pivot pin (non-steer end)

26 Number 2 inner arm

27 Number 2 outer arm

28 Number 2 pivot pin (non-steer end)

29 Lower lift cylinder barrel-end pivot pin

30 Number 1 outer arm

26 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 39

August 2022 Service and Repair Manual

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting

this procedure without these

skills and tools could result in

death or serious injury and

significant component

Dealer service is strongly

recommended.

Component damage hazard.

Cables and hoses can be

damaged if they are kinked or

pinched.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The li

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

3-3 Scissor Assembly, GS-4069 D C

3-3

Scissor Assembly, GS-4069 DC

How to Disassemble the Scissor

Assembly

4 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

4 inner arm. Make the chains tight but do not

apply lifting pressure.

damage.

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications, Hydraulic Hose and Fitting Torque

Specifications.

Note: This procedure will require an overhead

supporting device capable of supporting 1000 lbs /

454 kg.

1 Remove the platform. Refer to Repair

Procedure, How to Remove the Platform.

2 Remove the retaining fasteners that attach

the ladder to the drive chassis. Remove the

ladder and set aside.

5 Remove the retaining fasteners from the

number 5 pivot pins.

Note: Do not remove the external snap ring.

6 Using a soft metal drift, remove the pivot pins

and set aside.

7 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

8 Using a suitable supporting device, attach a

strap to the rod end of the upper lift cylinder.

Do not apply pressure.

9 Remove the upper cylinder rod end pivot pin

retaining fasteners.

10 Using a soft metal drift, remove the pivot pin.

11 Lower the lift cylinder and remove the strap.

12 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

4 inner arm. Make the chains tight but do not

apply lifting pressure.

3 Remove the cables from the linkage

assembly.

Part No. 1306585GT GS

nkage

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 27

Page 40

Service and Repair Manual August 2022

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to

squirt or s

Component damage hazard.

Cables and hoses can be

damaged if they are kinked or

pinched.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Scissor Components

13 Remove the retaining fasteners from the

number 4 pivot pins.

Note: Do not remove the external snap ring.

14 Using a soft metal drift, remove the pivot pins

and set aside.

15 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

16 Tag and disconnect the harness from the

upper lift cylinder valve block.

17 Tag and disconnect the hydraulic hoses from

the upper lift cylinder. Plug the hoses and cap

the fittings.

22 Using a soft metal drift, remove the pivot pin.

23 Lower the lift cylinder and remove the strap.

24 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

3 inner arm. Make the chains tight but do not

apply lifting pressure.

25 Remove the retaining fasteners from the

number 3 pivot pins.

Note: Do not remove the external snap ring.

26 Using a soft metal drift, remove the pivot pins

and set aside.

pray.

18 Remove the cables and hoses from the

linkage assembly.

19 Using a suitable supporting device remove

the retaining fasteners from the upper lift

cylinder. Remove the cylinder.

20 Using a suitable supporting device, attach a

strap to the rod end of the lower lift cylinder.

Do not apply pressure.

21 Remove the lower cylinder rod end pivot pin

retaining fasteners.

27 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

28 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

2 inner arm. Make the chains tight but do not

apply lifting pressure.

29 Remove the retaining fasteners from the

number 2 pivot pins.

Note: Do not remove the external snap ring.

30 Using a soft metal drift, remove the pivot pins

and set aside.

28 GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 41

August 2022 Service and Repair Manual

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to

gradually. Do not allow oil to

squirt or spray.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported when

removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supp

removed from the machine.

Scissor Components

31 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

32 Tag and disconnect the harness from the

lower lift cylinder valve block.

33 Tag and disconnect the hydraulic hoses from

the lower lift cylinder. Plug the hoses and cap

the fittings.

dissipate

34 Remove the hose clamps and hoses from the

number 1 inner arm.

35 Using an overhead supporting device attach a

4 hook sling chain to the ends of the number

1 inner arm. Make the chains tight but do not

apply lifting pressure.

Separate the link sets:

1 Using an overhead supporting device attach a

4 hook sling chain to the ends of the inner

arm. Make the chains tight but do not apply

lifting pressure.

orted when

2 Remove the retaining fasteners from the

center pivot pins.

Note: Do not remove the external snap ring.

3 Using a soft metal drift, remove the center

pivot pins and set aside.

4 Carefully lift and separate the linkage

assembly apart and place it on a structure

capable of supporting it.

36 Remove the two carriage bolts that secure the

inner arm and chassis pivot to the steer end

of the drive chassis.

37 Move the linkage towards the non-steer end

of the machine until the slider feet are clear of

the slider channel.

38 Carefully lift the linkage assembly off of the

machine and place it on a structure capable of

supporting it.

Part No. 1306585GT GS

™

-2669 DC • GS™-3369 DC • GS™-4069 DC 29

Page 42

Service and Repair Manual August 2022

Crushing hazard. The ladder

could fall if not properly

supported when the fasteners

are removed from the machine.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not

properly supported.

Scissor Components

3-4 Wear Pads

3-4

Wear Pads

2 Remove the fasteners securing the ladder to

the chassis. Remove the ladder from the

machine and set aside.

How to Replace the Scissor Arm

Wear Pad

Platform Scissor Arm Slider Blocks:

1 Remove the platform. Refer to Repair

Procedure, How to Remove the Platform.

2 Remove the slider blocks and discard.

3 Install the slider blocks.

Note: When installing the platform the drill holes in

the slider blocks must be on the top and bottom.

3 Using an overhead lifting device attach a

strap to the #1 inner arm at the non-steer end

of the machine.

Note: The overhead lifting device and strap must

be capable of supporting 5000 lbs / 2268 kg.

4 Install the platform.

Chassis Scissor Arm Wear Pads:

1 Attach a lifting strap from a suitable lifting

device to the ladder at the non-steer end of

the machine. Support the ladder. Do not apply

lifting pressure.

30 GS

4 Raise the linkage assembly slightly with the

overhead lifting device just enough to take

pressure off of the slider feet.

™

-2669 DC • GS™-3369 DC • GS™-4069 DC Part No. 1306585GT

Page 43

August 2022 Service and Repair Manual

Scissor Components

5 Remove the retaining fasteners from the

slider feet pivot pins and set aside.

9 Using a hard rubber mallet, secure the upper

and lower wear pads to the slider feet.

1 Slider foot assembly

2 pivot pin

3 retaining fasteners

6 Using a soft metal drift, remove the pivot pins

and set aside.

7 Remove the slider feet by sliding them out of

the slider channel.

8 Remove the upper and lower wear pads and

discard.

1 upper wear pads

2 slider foot

3 lower wear pad

10 Install the slider feet into the slider channel

and secure them to the linkage assembly with

the pivot pins.

11 Securely tighten the pivot pin retaining

fasteners.

12 Securely install the ladder onto the machine.