Page 1

Operator’s Manual

with Maintenance Information

CE Models

Third Edition

Second Printing

Part No. 97779

Page 2

Operator's Manual Third Edition • Second Printing

Important

Read, understand and obey these safety rules and

operating instructions before operating this machine.

Only trained and authorized personnel shall be

permitted to operate this machine. This manual

should be considered a permanent part of your

machine and should remain with the machine at all

times. If you have any questions, call Genie Industries.

Contents

Page

Safety Rules .............................................................. 1

Legend ....................................................................... 9

Controls .................................................................... 10

Pre-operation Inspection ........................................... 12

Maintenance ............................................................. 14

Function Tests .......................................................... 16

Workplace Inspection ................................................ 20

Operating Instructions ............................................... 21

Transport and Lifting Instructions .............................. 26

Decals ...................................................................... 28

Specifications ........................................................... 32

Contact us:

Internet: http://www.genielift.com

e-mail: techpub@genieind.com

Copyright © 2000 by Genie Industries

First Edition: Sixth Printing, October 2002

Second Edition: First Printing, August 2004

Third Edition: Second Printing, May 2005

"Genie" is a registered trademark of

Genie Industries in the U.S.A. and many other

countries. "Runabout" and "GR" are trademarks

of Genie Industries.

Printed on recycled paper

Printed in U.S.A.

2 GR-12 • GR-15 • GR-20 Part No. 97779

Page 3

Third Edition • Second Printing

Operator's Manual

Safety Rules

Danger

Failure to obey the instructions and

safety rules in this manual will

result in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

Know and understand the safety rules before

going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer's instructions and safety rules—

safety and operator's manuals and machine

decals.

You read, understand and obey employer's

safety rules and worksite regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

Part No. 97779 GR-12 • GR-15 • GR-20 1

Page 4

Operator's Manual Third Edition • Second Printing

SAFETY RULES

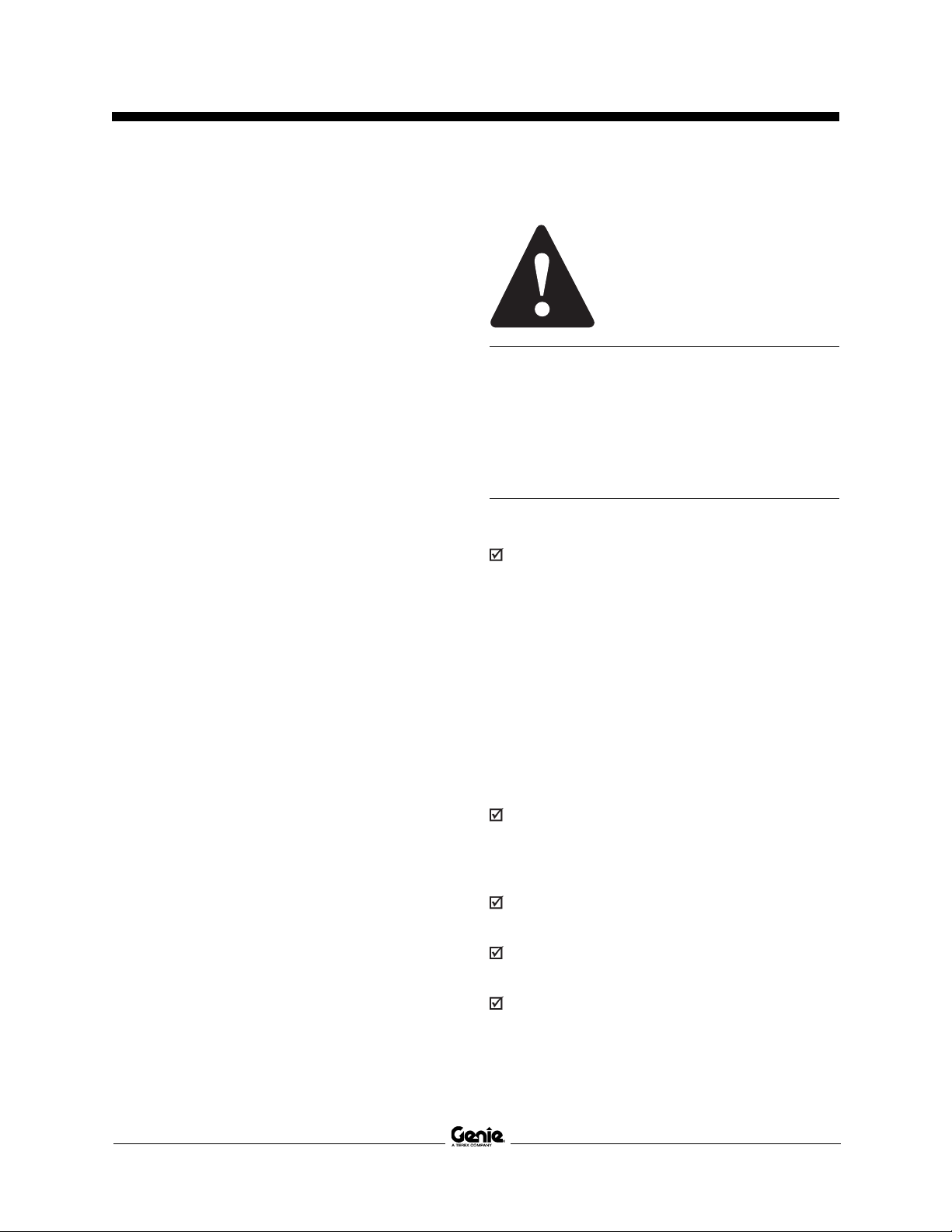

Electrocution Hazards

This machine is not electrically insulated and will

not provide protection from contact with or

proximity to electrical current.

Maintain safe distances from electrical power lines

and apparatus in accordance with applicable

governmental regulations and the following chart.

Voltage Minimum Safe

Phase to Phase Approach Distance

Meters

0 to 300V Avoid Contact

300V to 50KV 3.05

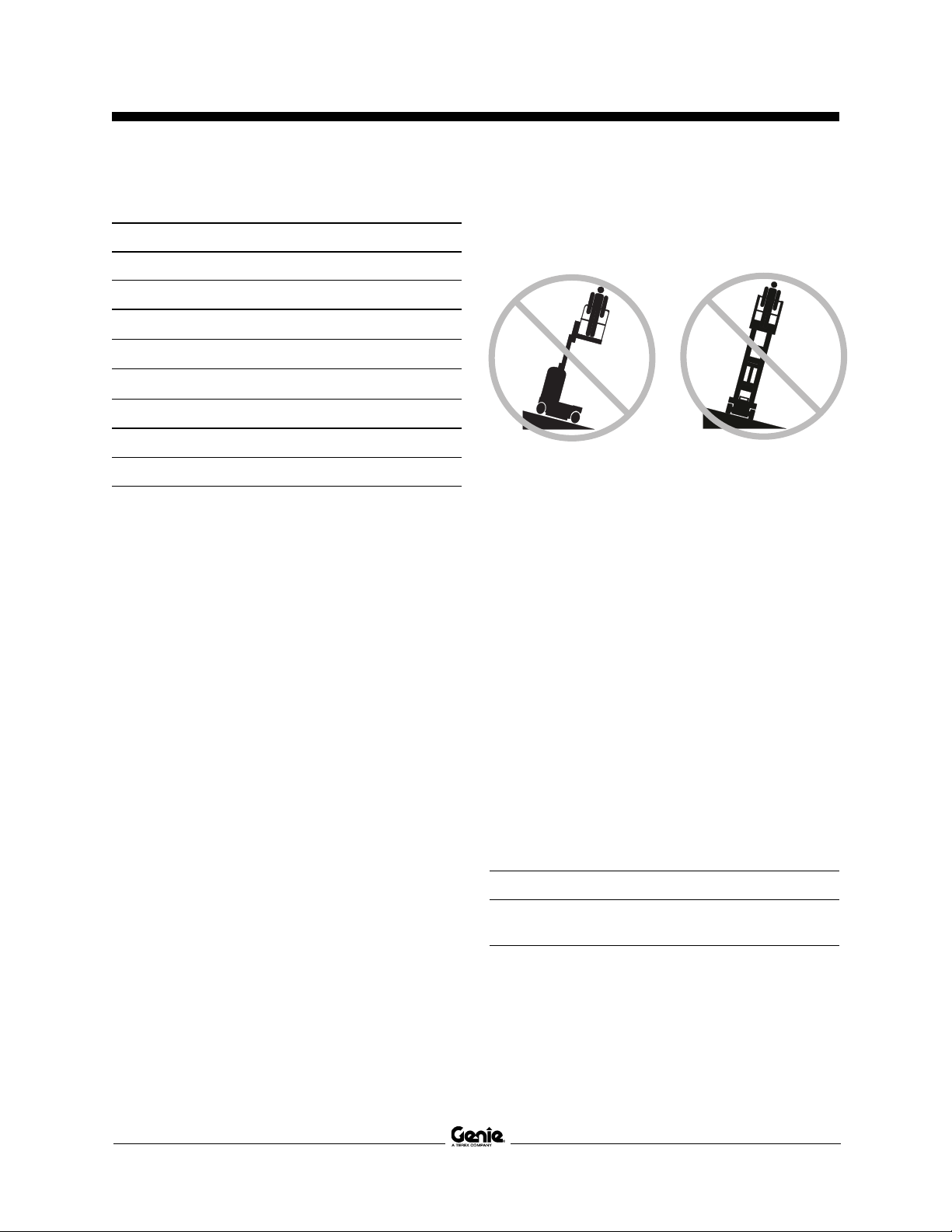

Tip-over Hazards

Occupants, equipment and materials must not

exceed the maximum platform capacity. Weight in

trays and in each bike rack is part of the total

platform load.

Maximum capacity - GR-12 and GR-15

Standard platform 227 kg

Work station tray (option) 22 kg

Parcel tray (option) 68 kg

Maximum occupants 1

Stock Picker platform 227 kg

Adjustable work station tray 68 kg

Parcel tray (option) 68 kg

Bike rack (option) (each) 20 kg

Maximum occupants 1

AWP and fiberglass platform 159 kg

Maximum occupants 1

50KV to 200KV 4.60

200KV to 350KV 6.10

350KV to 500KV 7.62

500KV to 750KV 10.67

750KV to 1000KV 13.72

Allow for platform movement, electrical line sway or

sag and beware of strong or gusty winds.

Keep away from the machine if it contacts

energized power lines. Personnel on the ground or

in the platform must not touch or operate the

machine until energized power lines are shut off.

Do not operate the machine during lightning or

storms.

Do not use the machine as a ground for welding.

2 GR-12 • GR-15 • GR-20 Part No. 97779

Page 5

Third Edition • Second Printing

Operator's Manual

SAFETY RULES

Maximum capacity - GR-20

Standard platform 159 kg

Maximum occupants 1

Stock Picker platform 159 kg

Adjustable work station tray 68 kg

Bike rack (option) (each) 20 kg

Maximum occupants 1

AWP and fiberglass platform 159 kg

Maximum occupants 1

Do not raise the platform unless the machine is on

a firm, level surface.

Do not depend on the tilt alarm as a level indicator.

The tilt alarm sounds only when the machine is on

a slope.

If the tilt alarm sounds:

Lower the platform immediately. Move the machine

to a firm, level surface. If the tilt alarm sounds

when the platform is raised, use extreme caution to

lower the platform.

Do not alter or disable the limit switches.

Do not drive over 0.8 km/h with the platform raised.

Use extreme care and slow speeds while driving

the machine in the stowed position across uneven

terrain, debris, unstable or slippery surfaces and

near holes and drop-offs.

Do not drive the machine on a slope that exceeds

the slope and side slope rating of the

machine.Slope rating applies to machines in the

stowed position.

Maximum slope rating, stowed position 30% (17°)

Maximum side slope rating,

stowed position 30% (17°)

Note: Slope rating is subject to ground conditions

and adequate traction.

Part No. 97779 GR-12 • GR-15 • GR-20 3

Page 6

Operator's Manual Third Edition • Second Printing

SAFETY RULES

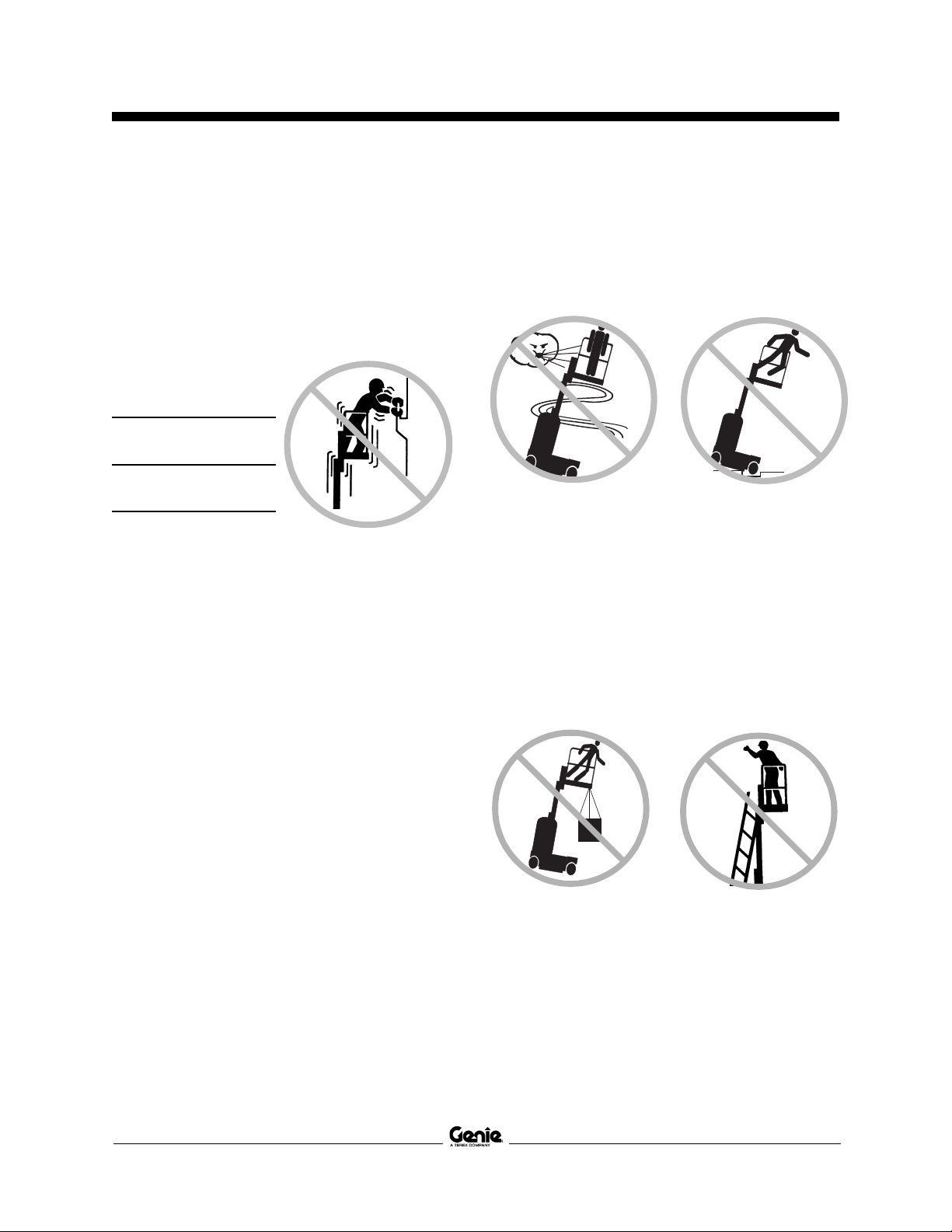

Do not use the platform controls to free a platform

that is caught, snagged or otherwise prevented

from normal motion by an adjacent structure. All

personnel must be removed from the platform

before attempting to free the platform using the

ground controls.

Do not push off or pull

toward any object

outside of the platform.

Maximum allowable

manual force

CE

200 N

Do not transport tools and materials unless they are

evenly distributed and can be safely handled by

person(s) in the platform.

Do not alter or disable machine components that in

any way affect safety and stability.

Do not modify or alter an aerial work platform

without prior written permission from the

manufacturer. Mounting attachments for holding

tools or other materials onto the platform, toeboards

or guard rail system can increase the weight in the

platform and the surface area of the platform or the

load.

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area exposed to

the wind will decrease machine stability.

Do not drive the machine on or near uneven terrain,

unstable surfaces or other hazardous conditions

with the platform raised.

Do not replace items critical to machine stability

with items of different weight or specification.

Do not use the machine on a moving or mobile

surface or vehicle.

Do not place or attach fixed or overhanging loads to

any part of this machine.

Do not raise the mast when wind speeds may

exceed 12.5 m/s. If wind speeds exceed 12.5 m/s

when the plaform is raised, lower the platform and

do not continue to operate the machine.

Do not place ladders or scaffolds in the platform or

against any part of this machine.

Be sure all tires are in good condition, castle nuts

are properly tightened and cotter pins are properly

installed.

4 GR-12 • GR-15 • GR-20 Part No. 97779

Page 7

Third Edition • Second Printing

Operator's Manual

SAFETY RULES

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh 28 kg.

Do not use the machine as a crane.

Do not push the machine or other objects with the

platform.

Do not contact adjacent structures with the

platform.

Do not tie the platform to adjacent structures.

Fall Hazards

The guard rail system provides fall protection. If

occupants of the platform are required to wear

personal fall protection equipment (PFPE) due to

job site or employer rules, PFPE equipment and its

use shall be in accordance with the PFPE

manufacturer’s instructions and applicable

governmental requirements.

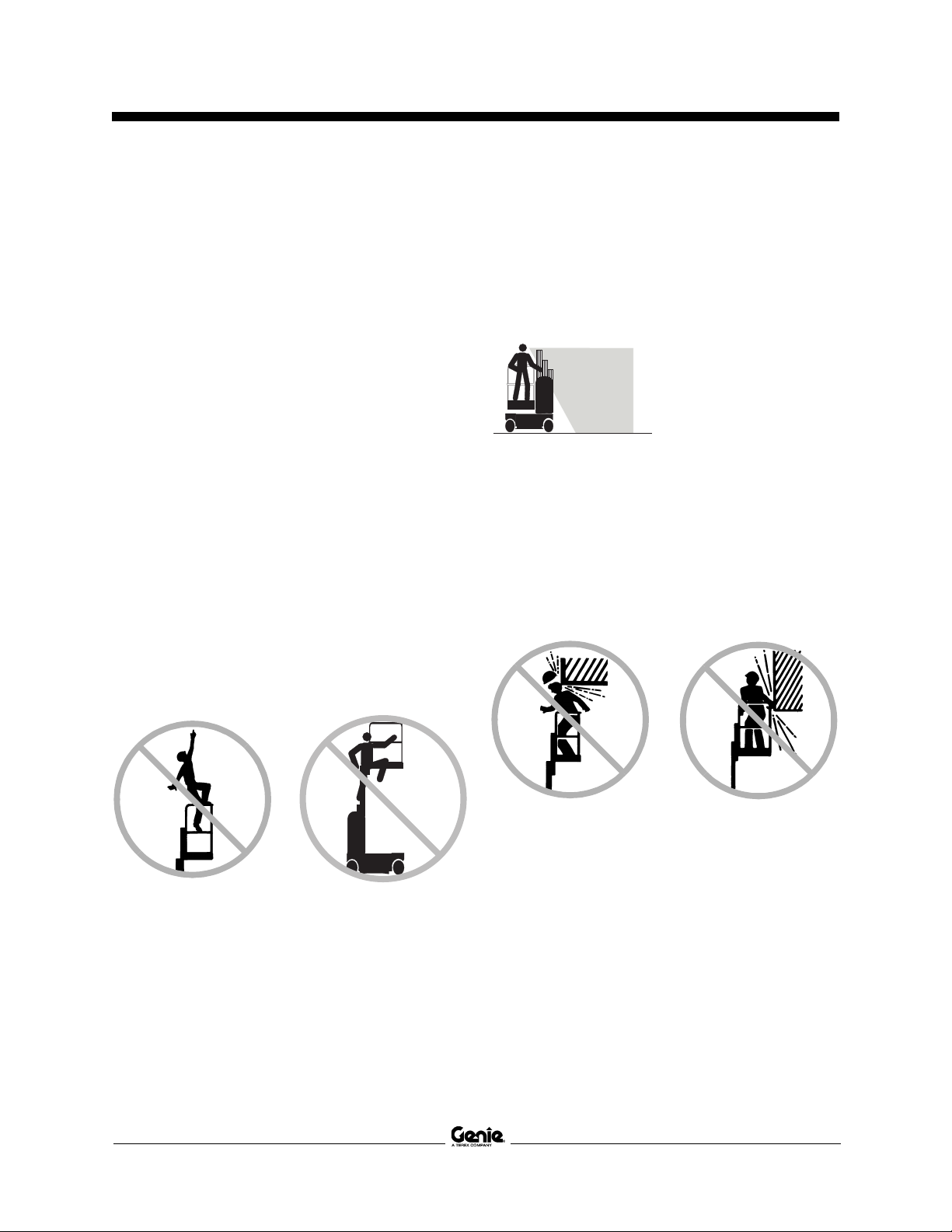

Do not sit, stand or climb on the platform guard

rails. Maintain a firm footing on the platform floor at

all times.

Collision Hazards

Be aware of limited sight distance and blind spots

when driving or operating.

Be aware of the

extended platform

position when moving

the machine.

Operators must comply

with employer, job site and governmental rules

regarding use of personal protective quipment.

Check the work area for overhead obstructions or

other possible hazards.

Be aware of crushing hazards when grasping the

platform guard rail.

Observe and use the color-coded direction arrows

on the platform controls and platform decal plate for

drive and steer functions.

No stunt driving or horseplay while operating a

Do not climb down from

the platform when raised.

Keep the platform floor clear of debris.

Lower the platform mid-rail bar or close the platform

entry gate before operating.

Part No. 97779 GR-12 • GR-15 • GR-20 5

machine.

Page 8

Operator's Manual Third Edition • Second Printing

SAFETY RULES

Do not lower the platform unless the area below is

clear of personnel and obstructions.

Limit travel speed according to the condition of the

ground surface, congestion, slope, location of

personnel, and any other factors which may cause

collision.

Do not operate a machine in the path of any crane

or moving overhead machinery unless the controls

of the crane have been locked out and/or

precautions have been taken to prevent any

potential collision.

Crushing Hazard

Use common sense and planning when operating

the machine with the controller from the ground.

Maintain safe distances between the operator, the

machine and fixed objects.

Component Damage Hazard

Do not use the machine as a ground for welding.

Explosion and Fire Hazard

Do not operate the machine or charge the battery in

hazardous locations or locations where potentially

flammable or explosive gases or particles may be

present.

Damaged Machine Hazards

Do not use a damaged or malfunctioning machine.

Conduct a thorough pre-operation inspection of the

machine and test all functions before each work

shift. Immediately tag and remove from service a

damaged or malfunctioning machine.

Be sure all maintenance has been performed as

specified in this manual and the appropriate service

manual.

Be sure all decals are in place and legible.

Be sure the operator’s, safety, and responsibilities

manuals are complete, legible and in the storage

container located on the platform.

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil or

air leak. An air leak or hydraulic leak can penetrate

and/or burn skin.

Improper contact with components under any cover

will cause serious injury. Only trained maintenance

personnel should access compartments. Access

by the operator is only advised when performing a

pre-operation inspection. All compartments must

remain closed and secured during operation.

6 GR-12 • GR-15 • GR-20 Part No. 97779

Page 9

Third Edition • Second Printing

Operator's Manual

SAFETY RULES

Battery Safety

Burn Hazards

Batteries contain acid. Always wear protective

clothing and eye wear when working with batteries.

Avoid spilling or contacting battery acid. Neutralize

battery acid spills with baking soda and water.

Do not expose the batteries or the charger to

water or rain during charging.

Explosion Hazards

Keep sparks, flames

and lighted tobacco

away from batteries.

Batteries emit an

explosive gas.

The battery tray should

remain open during the

entire charging cycle.

Component Damage Hazard

Do not use any battery charger greater than 24V to

charge the batteries.

Electrocution Hazards

Connect the battery charger to a

grounded, AC 3-wire electrical

outlet only.

Inspect daily for damaged cord,

cables and wires. Replace

damaged items before

operating.

Avoid electrical shock from contact with battery

terminals. Remove all rings, watches and other

jewelry.

Tip-over Hazard

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh 28 kg.

Lifting Hazard

Use the appropriate number of people and proper

lifting techniques when lifting batteries.

Do not contact the battery terminals or the cable

clamps with tools that may cause sparks.

Part No. 97779 GR-12 • GR-15 • GR-20 7

Page 10

Operator's Manual Third Edition • Second Printing

SAFETY RULES

Decal Legend

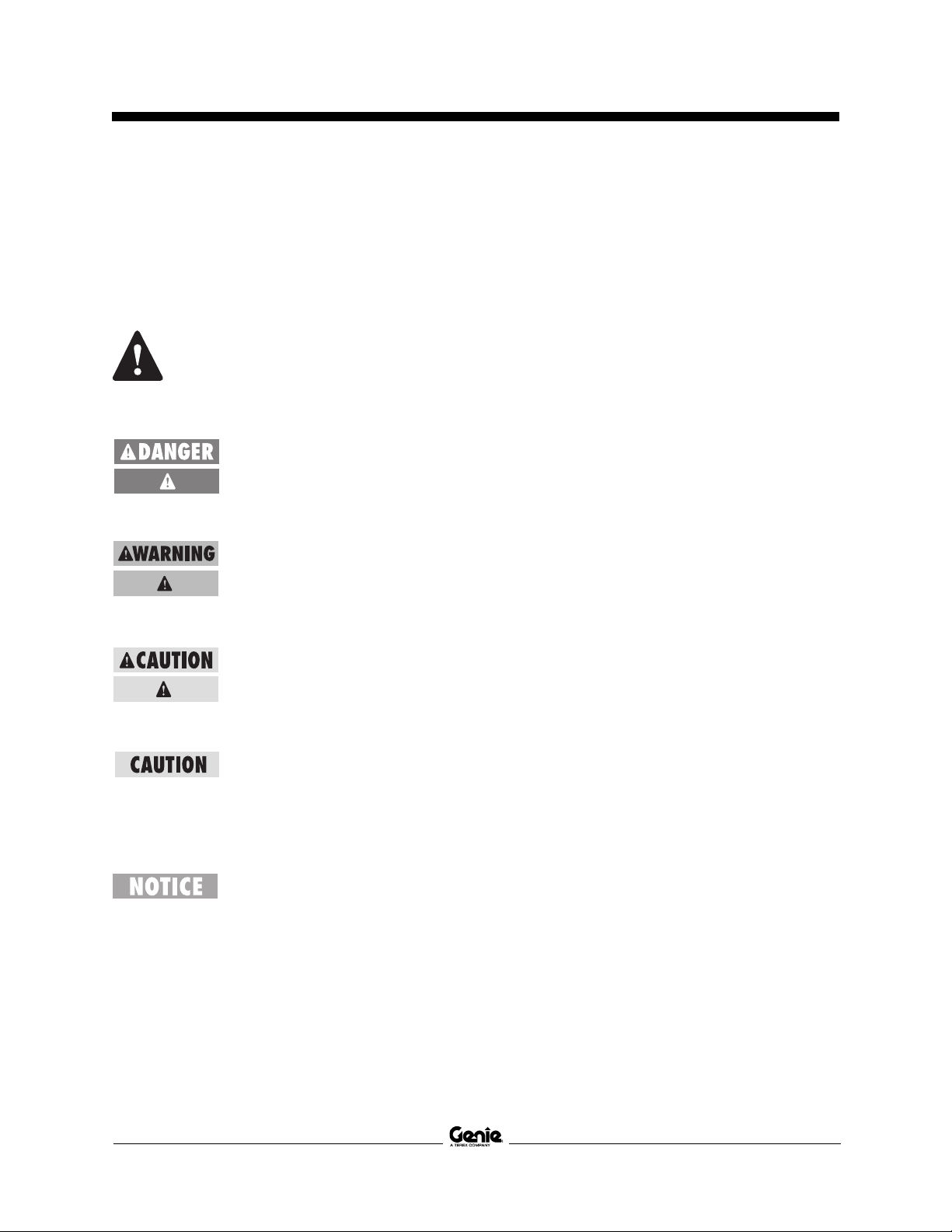

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—used to indicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Orange—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentially hazardous situation

which, if not avoided, may cause

minor or moderate injury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

8 GR-12 • GR-15 • GR-20 Part No. 97779

Page 11

Third Edition • Second Printing

Operator's Manual

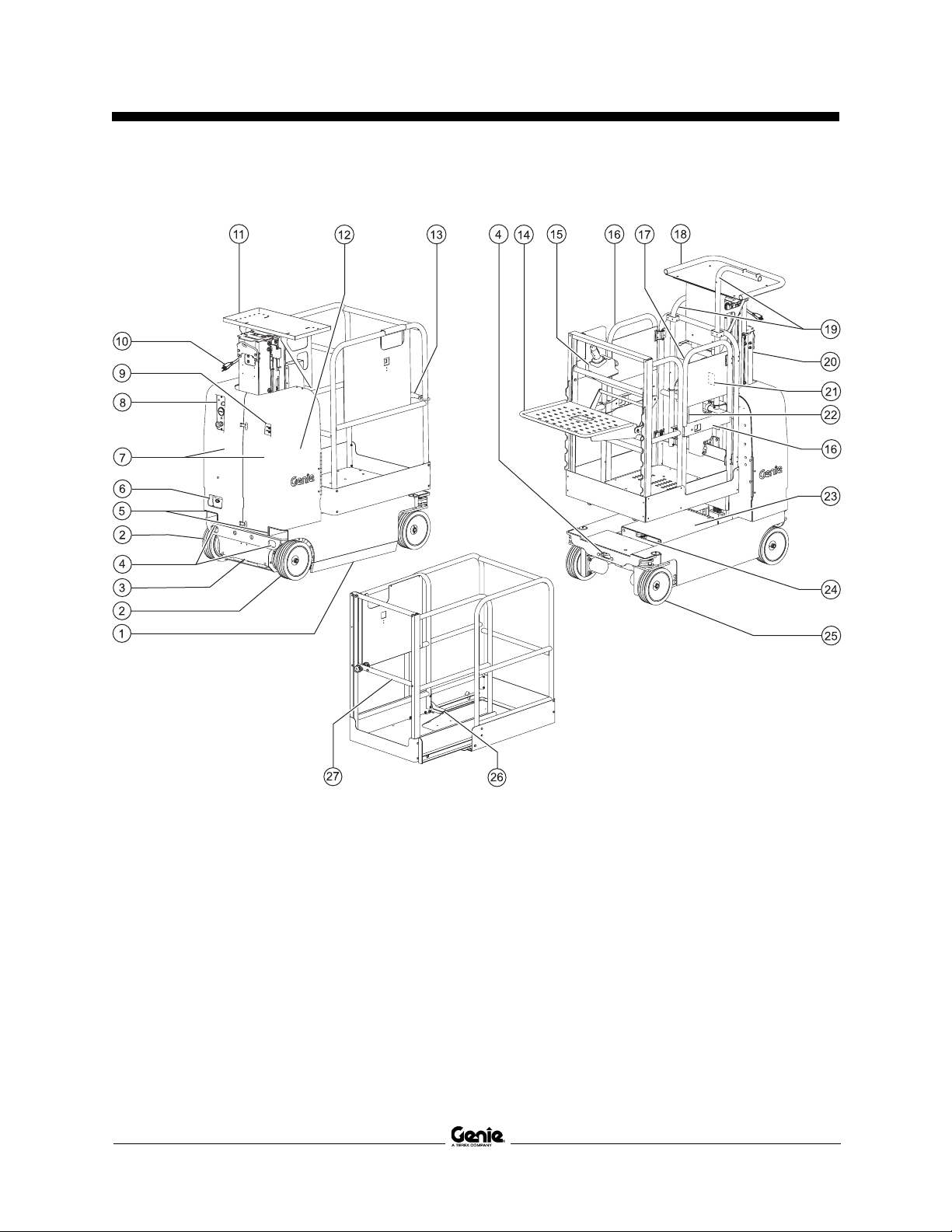

Legend

1 Pothole guard

2 Non-steer tire

3 Manual lowering valve

4 Transport tie-down

5 Forklift pocket

6 Battery charger display

7 Covers

8 Ground controls

9 Hydraulic oil level indicator

10 Power to platform/battery

charger connection for

optional inverter

Part No. 97779 GR-12 • GR-15 • GR-20 9

11 Work station tray

(if equipped)

12 Brake release pump knob

(under covers)

13 Mid-rail entry bar

14 Adjustable work station tray

15 Platform controls

16 Dual-entry gate

17 Lanyard anchorage

18 Parcel tray

(if equipped)

19 Bike rack (if equipped)

20 Mast

21 GFCI outlet

22 Manual storage container

23 Battery compartment cover

24 Battery cover latch

25 Steer tire

26 Platform extension release

pedal

27 Platform extension entry gate

Page 12

Operator's Manual Third Edition • Second Printing

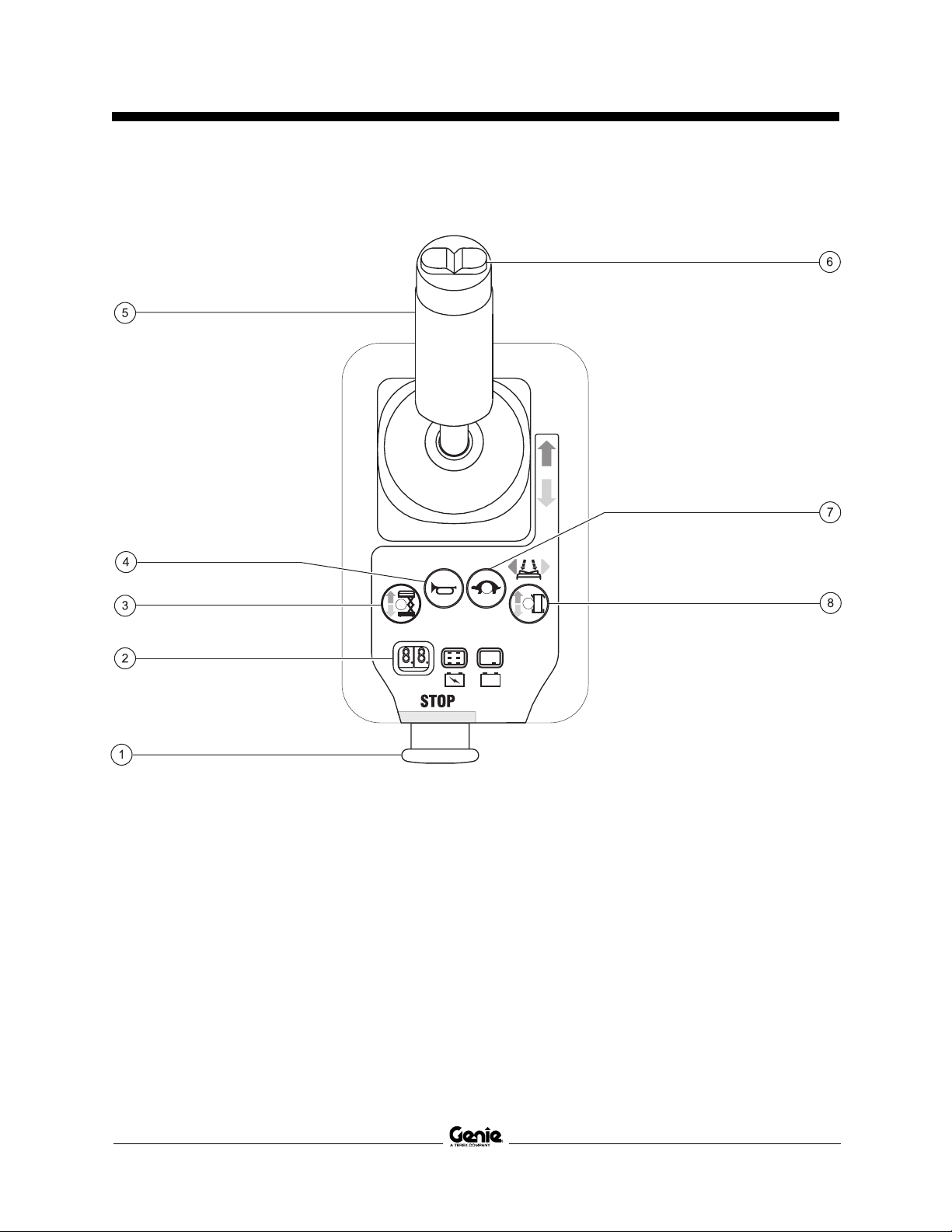

Controls

Platform Controls

1 Red Emergency Stop button

2 LED diagnostic readout / Platform overload

indicator / Battery charge indicator

3 Lift function select button

4 Horn button (if equipped)

10 GR-12 • GR-15 • GR-20 Part No. 97779

5 Proportional control handle and function enable

switch for lift and drive functions

6 Thumb rocker switch for steer functions

7 Drive speed button

8 Drive function select button

Page 13

Third Edition • Second Printing

1

2

Operator's Manual

CONTROLS

3

4

5

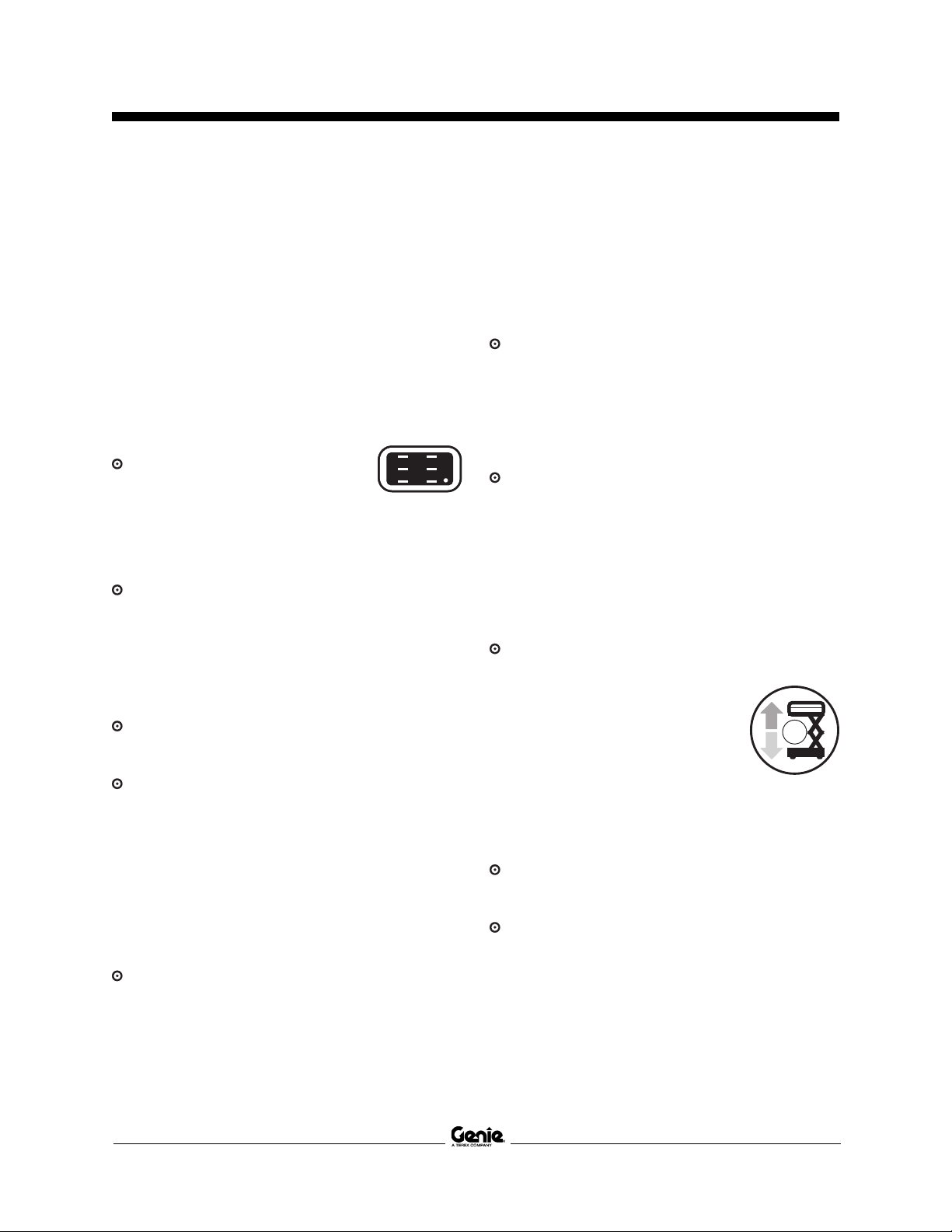

Ground Control Panel

1 7 amp breaker for electrical circuits

2 Key switch for platform/off/ground selection

3 Hour meter

4 Platform up/down toggle switch

5 Red Emergency Stop button

00009.9

STOP

Part No. 97779 GR-12 • GR-15 • GR-20 11

Page 14

Operator's Manual Third Edition • Second Printing

Pre-operation Inspection

Fundamentals

It is the responsibility of the operator to perform a

pre-operation inspection and routine maintenance.

The pre-operation inspection is a visual inspection

performed by the operator prior to each work shift.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

The inspection is designed to discover if anything

is apparently wrong with a machine before the

operator performs the function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures are

required. Only routine maintenance items specified

in this manual may be performed by the operator.

Refer to the list on the next page and check each

of the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a

pre-operation inspection again before going on to

the function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

12 GR-12 • GR-15 • GR-20 Part No. 97779

Page 15

Third Edition • Second Printing

Operator's Manual

PRE-OPERATION INSPECTION

Pre-operation Inspection

o Be sure that the operator's, safety and

responsibilities manuals are complete, legible

and in the storage container located on the

platform.

o Be sure that all decals are legible and in place.

See Decals section.

o Check for hydraulic oil leaks and proper oil level.

See Maintenance section.

o Check for battery fluid leaks and proper fluid

level. Add distilled water if needed. See

Maintenance section.

Check the following components or areas for

damage, improperly installed or missing parts and

unauthorized modifications:

o Electrical components, wiring and electrical

cables

o Hydraulic power unit, tank, hoses,

fittings, cylinders and manifolds

Check the entire machine for:

o Cracks in welds or structural components

o Dents or damage to the machine

o Be sure that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

o Battery pack and connections

o Drive motors

o Tires and wheels

o Limit switches and alarms

o Nuts, bolts and other fasteners

o Platform entry mid-rail bar or gate

o Sequencing cables and pulleys

o Platform extension (if equipped)

o Work trays and bike racks (if equipped)

o Mast columns and counterweight

o Platform controls

o Brake release components

Part No. 97779 GR-12 • GR-15 • GR-20 13

Page 16

Operator's Manual Third Edition • Second Printing

Maintenance

Check the Hydraulic Oil Level

Maintaining the hydraulic oil at the proper level is

essential to safe machine operation. Improper

hydraulic oil levels can damage hydraulic

components. Daily checks allow the inspector to

Observe and Obey:

Only routine maintenance items specified in this

manual shall be performed by the operator.

Scheduled maintenance inspections shall be

completed by qualified service technicians,

according to the manufacturer's specifications

and the requirements specified in the

responsibilities manual.

identify changes in oil level that might indicate the

presence of hydraulic system problems.

Perform this procedure with the

platform in the stowed position.

1 Visually inspect the hydraulic oil level through

the indicator at the back of the machine.

Result: The hydraulic oil level should be visible.

2 Add oil if necessary. Do not overfill.

Maintenance Symbols Legend

The following symbols have been

used in this manual to help

communicate the intent of the

instructions. When one or more of

the symbols appear at the

beginning of a maintenance

procedure, it conveys the meaning

below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be

required to perform this procedure.

Hydraulic oil specifications

Hydraulic oil type Chevron Rykon

Premium MV equivalent

14 GR-12 • GR-15 • GR-20 Part No. 97779

Page 17

Third Edition • Second Printing

Operator's Manual

MAINTENANCE

Check the Batteries

Proper battery condition is essential to good

performance and operational safety. Improper fluid

levels or damaged cables and connections can

result in component damage and hazardous

conditions.

This procedure does not need to

be performed on machines with

sealed or maintenance - free

batteries.

Electrocution hazard. Contact with

hot or live circuits could result in

death or serious injury. Remove all

rings, watches and other jewelry.

Bodily injury hazard. Batteries

contain acid. Avoid spilling or

contacting battery acid. Neutralize

battery acid spills with baking soda

and water.

7 Remove the battery vent caps.

8 Check the battery acid level. If needed,

replenish with distilled water to the bottom of the

battery fill tube. Do not overfill.

9 Install the vent caps.

10 Raise the platform and lower the cover.

Scheduled Maintenance

Maintenance performed quarterly, annually and

every two years must be completed by a person

trained and qualified to perform maintenance on this

machine according to the procedures found in the

service manual for this machine.

Machines that have been out of service for more

than three months must receive the quarterly

inspection before they are put back into service.

Perform this test after fully

charging the batteries.

1 Put on protective clothing and eye wear.

2 Raise the platform approximately 1.5 m.

3 Open the battery cover. Rest the cover against

the chassis.

4 Lower the platform until the mast just contacts

the battery cover.

Crushing hazard. Keep hands clear

of the battery cover when lowering

the platform.

5 Turn the key switch to the off position.

6 Be sure that the battery cable connections are

tight and free of corrosion.

Part No. 97779 GR-12 • GR-15 • GR-20 15

Page 18

Operator's Manual Third Edition • Second Printing

Function Tests

Fundamentals

The function tests are designed to discover any

malfunctions before the machine is put into service.

The operator must follow the step-by-step

instructions to test all machine functions.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to

use.

Know and understand the function tests

before going on to the next section.

4 Inspect the workplace.

5 Only use the machine as it was intended.

A malfunctioning machine must never be used. If

malfunctions are discovered, the machine must be

tagged and removed from service. Repairs to the

machine may only be made by a qualified service

technician, according to the manufacturer's

specifications.

After repairs are completed, the operator must

perform a pre-operation inspection and function

tests again before putting the machine into service.

16 GR-12 • GR-15 • GR-20 Part No. 97779

Page 19

Third Edition • Second Printing

Operator's Manual

FUNCTION TESTS

1 Select a test area that is firm, level and free of

obstruction.

2 Be sure the battery pack is connected.

At the Ground Controls

3 Pull out the platform and ground red Emergency

Stop buttons to the on position.

4 Turn the key switch to ground control.

5 Observe the diagnostic LED readout on the

platform controls.

Result: The LED should look

like the picture at right.

Test Emergency Stop

6 Push in the ground red Emergency Stop button

to the off position.

Result: No functions should operate.

7 Pull out the red Emergency Stop button to

the on position.

Test the Up/Down Functions

8 Activate the up function.

Result: The platform should raise.

At the Platform Controls

Test Emergency Stop

13 Push in the platform red Emergency Stop button

to the off position.

Result: No functions should operate.

Test the Horn

14 Pull out the red Emergency Stop button to

the on position.

15 Push the horn button.

Result: The horn should sound.

Test the Function Enable Switch

16 Do not press the function enable switch on the

control handle.

17 Slowly move the control handle in the direction

indicated by the blue arrow, then in the direction

indicated by the yellow arrow.

Result: No functions should operate.

Test the Up/Down Functions

18 Press the lift function select

button.

9 Activate the down function.

Result: The platform should lower. The descent

alarm should sound while the platform is

lowering.

Test Manual Lowering

10 Activate the up function and raise the platform

approximately 60 cm.

11 Pull the manual lowering knob located at the

base of the machine below the charger.

Result: The platform should lower. The descent

alarm will not sound.

12 Turn the key switch to platform control.

Part No. 97779 GR-12 • GR-15 • GR-20 17

19 Press and hold the function

enable switch on the control

handle.

20 Slowly move the control handle in the direction

indicated by the blue arrow.

Result: The platform should raise.

21 Release the control handle.

Result: The platform should stop raising.

Page 20

Operator's Manual Third Edition • Second Printing

FUNCTION TESTS

22 Press and hold the function enable switch.

Slowly move the control handle in the direction

indicated by the yellow arrow.

Result: The platform should lower. The descent

alarm should sound while the platform is

lowering.

Test the Steering

Note: When performing the steer and drive function

tests, stand in the platform facing the steer end of

the machine.

23 Press the drive function select

switch.

24 Press and hold the function enable

switch on the control handle.

25 Press the thumb rocker switch on top of the

control handle in the direction indicated by the

blue triangle on the control panel.

Result: The steer wheels should turn in the

direction that the blue triangle points on the

control panel.

Test Drive and Braking

27 Press and hold the function enable switch on the

control handle.

28 Slowly move the control handle in the direction

indicated by the blue arrow on the control panel

until the machine begins to move, then return

the handle to the center position.

Result: The machine should move in the

direction that the blue arrow points on the

control panel, then come to an abrupt stop.

29 Slowly move the control handle in the direction

indicated by the yellow arrow on the control

panel until the machine begins to move, then

return the handle to the center position.

Result: The machine should move in the

direction that the yellow arrow points on the

control panel, then come to an abrupt stop.

Note: The brakes must be able to hold the machine

on any slope it is able to climb.

Test the Tilt Sensor Operation

26 Press the thumb rocker switch in the direction

indicated by the yellow triangle on the control

panel.

Result: The steer wheels should turn in the

direction that the yellow triangle points on the

control panel.

Note: Perform this test from the ground with the

platform controller. Do not stand in the platform.

30 Press the lift function select button.

31 Fully lower the platform.

32 Place a 2x4 or similar piece of wood in front of

each wheel on one side of the machine.

33 Press the drive function select button.

34 Drive the machine up onto both pieces of wood.

35 Press the lift function select button.

18 GR-12 • GR-15 • GR-20 Part No. 97779

Page 21

Third Edition • Second Printing

Operator's Manual

FUNCTION TESTS

36 Raise the platform.

Result: Before the platform is raised

approximately 30 cm, the lift

function should stop, an alarm

should sound and the LED

readout should display LL.

37 Press the drive function select button.

38 Press and hold the function enable switch and

slowly move the control handle in the direction

indicated by the blue arrow, then in the

direction indicated by the yellow arrow.

Result: The drive function should not work in

either direction.

39 Lower the platform and drive the machine off

both pieces of wood.

Test Limited Drive Speed

40 Press the lift function select button.

41 Press and hold the function enable switch on

the control handle. Raise the platform

approximately 60 cm from the ground.

42 Press the drive function select button.

43 Press and hold the function enable switch on

the control handle. Slowly move the control

handle to the full drive position.

Test the Pothole Guards

Note: The pothole guards should automatically

deploy when the platform is raised. The pothole

guards activate another limit switch which allows

the machine to continue to function. If the pothole

guards do not deploy, an alarm sounds and the

machine will not drive.

44 Raise the platform.

Result: When the platform is raised 1.2 m from

the ground, the pothole guards should deploy.

45 Press on the pothole guards on one side, and

then the other.

Result: The pothole guards should not move.

46 Lower the platform.

Result: The pothole guards should return to the

stowed position.

47 Place a 2x4 or similar piece of wood under a

pothole guard. Raise the platform.

Result: Before the platform is raised 2.1 m from

the ground, an alarm should sound and the drive

function should not work.

48 Lower the platform and remove the 2x4.

Result: The maximum achievable drive speed

with the platform raised should not exceed

20 cm per second.

If the drive speed with the platform raised exceeds

20 cm per second, immediately tag and remove

the machine from service.

Part No. 97779 GR-12 • GR-15 • GR-20 19

Page 22

Operator's Manual Third Edition • Second Printing

Workplace Inspection

Workplace Inspection

Be aware of and avoid the following hazardous

situations:

· drop-offs or holes

· bumps, floor obstructions or debris

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

Know and understand the workplace

inspection before going on to the next

section.

· sloped surfaces

· unstable or slippery surfaces

· overhead obstructions and high voltage

conductors

· hazardous locations

· inadequate surface support to withstand all load

forces imposed by the machine

· wind and weather conditions

· the presence of unauthorized personnel

· other possible unsafe conditions

5 Only use the machine as it was intended.

Fundamentals

The workplace inspection helps the operator

determine if the workplace is suitable for safe

machine operation. It should be performed by the

operator prior to moving the machine to the

workplace.

It is the operator's responsibility to read and

remember the workplace hazards, then watch for

and avoid them while moving, setting up and

operating the machine.

20 GR-12 • GR-15 • GR-20 Part No. 97779

Page 23

Third Edition • Second Printing

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Operator's Manual

Operating Instructions

Fundamentals

The Operating Instructions section provides

instructions for each aspect of machine operation.

It is the operator's responsibility to follow all the

safety rules and instructions in the operator's,

safety and responsibilities manuals.

Using the machine for anything other than lifting

personnel, along with their tools and materials, to

an aerial work site is unsafe and dangerous.

Only trained and authorized personnel should be

permitted to operate a machine. If more than one

operator is expected to use a machine at different

times in the same work shift, they must all be

qualified operators and are all expected to follow all

safety rules and instructions in the operator's,

safety and responsibilities manuals. That means

every new operator should perform a pre-operation

inspection, function tests, and a workplace

inspection before using the machine.

Part No. 97779 GR-12 • GR-15 • GR-20 21

Page 24

Operator's Manual Third Edition • Second Printing

OPERATING INSTRUCTIONS

Emergency Stop

Push in the red Emergency Stop button to the off

position at the ground or platform controls to stop

all machine functions.

Repair any function that operates when either red

Emergency Stop button is pushed in.

Auxiliary Lowering

1 Pull the auxiliary lowering knob.

Operation From Ground

1 Turn the key switch to ground control.

2 Pull out both ground and platform red

Emergency Stop buttons to the on position.

3 Be sure the battery pack is connected before

operating the machine.

To Position Platform

1 Move the up/down toggle switch according to

the markings on the control panel.

Drive and steer functions are not available from the

ground controls.

Operation From Platform

1 Turn the key switch to platform control.

2 Pull out the ground and platform red Emergency

Stop buttons to the on position.

3 Be sure the battery pack is connected before

operating the machine.

To Position Platform

1 Press the lift function select

button.

2 Press and hold the function enable

switch on the control handle.

3 Move the control handle according to the

markings on the control panel.

To Steer

1 Press the drive function select

button.

2 Press and hold the function enable

switch on the control handle.

3 Turn the steer wheels with the thumb rocker

switch located on the top of the control handle.

To Drive

1 Press the drive function select button.

2 Press and hold the function enable switch on the

control handle.

3 Increase speed: Slowly move the control handle

off center.

Decrease speed: Slowly move the control

handle toward center.

Stop: Return the control handle to center or

release the function enable switch.

Use the color-coded direction arrows on the

platform controls and on the platform to identify the

direction the machine will travel.

Machine travel speed is restricted when the

platform is raised.

22 GR-12 • GR-15 • GR-20 Part No. 97779

Page 25

Third Edition • Second Printing

Operator's Manual

OPERATING INSTRUCTIONS

To Reduce Drive Speed

The drive controls can operate in two different drive

speed modes. When the drive speed button light is

on, slow drive speed mode is active. When the

button light is off, fast drive speed mode is active.

Press the drive speed button to select

the desired drive speed.

Driving on a slope

Determine the slope and side slope ratings for the

machine and determine the slope grade.

Maximum slope rating, stowed

position: 30% (17°)

Maximum side slope rating,

stowed position: 30% (17°)

Note: Slope rating is subject to ground conditions

and adequate traction.

Press the drive speed button to the fast drive

speed mode.

To determine the slope grade:

Measure the slope with a digital inclinometer OR

use the following procedure.

You will need:

carpenter’s level

straight piece of wood, at least 1 m long

tape measure

Lay the piece of wood on the slope.

At downhill end, lay the level on the top edge of the

piece of wood and lift the end until the piece of

wood is level.

While holding the piece of wood level, measure the

distance from the bottom of the piece of wood to

the ground.

Divide the tape measure distance (rise) by the

length of the piece of wood (run) and multiply by

100.

Example:

run

rise

Run = 3.6 m

Rise = 0.3 m

0.3 m ÷ 3.6 m = 0.083 x 100 = 8.3%

If the slope exceeds the maximum slope or side

slope rating, the machine must be winched or

transported up or down the slope. See Transport

and Lifting section.

Part No. 97779 GR-12 • GR-15 • GR-20 23

Page 26

Operator's Manual Third Edition • Second Printing

OPERATING INSTRUCTIONS

Error Indicator display

If the LED diagnostic readout

displays an error code, such as LL,

push in and pull out the red

Emergency Stop button to reset the

system.

To Extend and Retract Platform

(if equipped)

1 Step on the platform extension release pedal.

2 Grasp the platform guard rails carefully and push

to extend the platform.

3 Step on the platform extension release pedal

and pull the guard rails to retract the platform.

Operation From Ground with

Controller

Maintain safe distances between the operator,

machine and fixed objects.

Be aware of the direction the machine will travel

when using the controller.

Battery Level Indicator

Full Low

Use the LED diagnostic readout to determine the

battery level.

Fall Protection

Personal fall protection equipment (PFPE) is not

required when operating this machine. If PFPE is

required by job site or employer rules, the following

shall apply:

All PFPE must comply with applicable

governmental regulations and must be inspected

and used in accordance with the manufacturer’s

instructions.

After Each Use

1 Select a safe parking location—firm level

surface, clear of obstruction and traffic.

2 Lower the platform.

Platform Overload

Flashing OL in the LED diagnostic

readout indicates the platform is

overloaded and no functions will

operate. An alarm will sound.

1 Push in the Red Emergency stop button to the

off position.

2 Remove the weight from the platform.

3 Pull out the Red Emergency stop button to the

on position.

24 GR-12 • GR-15 • GR-20 Part No. 97779

3 Turn the key switch to the off position and

remove the key to secure from unauthorized

use.

4 Chock the wheels.

5 Charge the batteries.

Page 27

Third Edition • Second Printing

Operator's Manual

OPERATING INSTRUCTIONS

Standard Batteries

1 Put on protective clothing and eye wear.

2 Raise the platform approximately 1.5 m.

3 Open the battery cover. Rest the cover against

the chassis.

Battery and Charger Instructions

Observe and Obey:

Do not use an external charger or booster

battery.

Charge the battery in a well-ventilated area.

Use proper AC input voltage for charging as

indicated on the machine.

Use only a Genie authorized battery and

charger.

To Charge Batteries

Maintenance - free batteries

1 Connect the battery charger to a grounded AC

circuit.

2 The charger will indicate when the battery is fully

charged.

4 Lower the platform until the mast just contacts

the battery cover.

Crushing hazard. Keep hands clear

of the battery cover when lowering

the platform.

5 Turn the key switch to the off position.

6 Be sure that the battery cable connections are

tight and free of corrosion.

7 Remove the battery vent caps and check the

battery acid level. If necessary, add only

enough distilled water to cover the plates. Do

not overfill prior to the charge cycle.

8 Replace the battery vent caps.

9 Connect the battery charger to a grounded AC

circuit.

10 The charger will indicate when the battery is fully

charged.

11 Check the battery acid level when the charging

cycle is complete. Replenish with distilled water

to the bottom of the fill tube. Do not overfill.

12 Raise the platform and lower the cover.

Part No. 97779 GR-12 • GR-15 • GR-20 25

Page 28

Operator's Manual Third Edition • Second Printing

Transport and Lifting Instructions

Brake Release Operation

1 Chock the wheels to prevent the machine from

rolling.

2 Be sure the winch line is properly secured to the

drive chassis tie points and the path is clear of

Observe and Obey:

Common sense and planning must be applied to

control the movement of the machine when

lifting it with a crane or forklift.

The transport vehicle must be parked on a level

surface.

The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

Be sure the vehicle capacity, loading surfaces

and chains or straps are sufficient to withstand

the machine weight. See the serial plate for the

machine weight.

all obstructions.

3 Push in the black brake release knob to open

the brake valve.

4 Pump the red brake release pump knob

After the machine is loaded:

1 Push in both ground and platform red

Emergency Stop buttons to the off position.

2 Turn the key switch to the off position.

3 Chock the wheels to prevent the machine from

rolling.

4 Push the brake release switch closed to reset

the brakes.

The machine must be on a level surface or

secured before releasing the brakes.

Do not drive the machine on a slope that

exceeds the slope or side slope rating. See

Driving on a Slope in the Operating Instructions

section.

If the slope of the transport vehicle bed exceeds

the maximum slope rating, the machine must be

loaded and unloaded using a winch as

described.

Brake Release Switch

26 GR-12 • GR-15 • GR-20 Part No. 97779

Page 29

Third Edition • Second Printing

Operator's Manual

TRANSPORT AND LIFTING INSTRUCTIONS

Loading the Machine With

a Crane

Use the lifting eye mounted on the rear mast

column.

Make sure the mast is fully lowered.

Inspect the machine and remove any loose or

unsecured items.

Always place the lifting hook through the lifting eye

so that it points away from the machine.

Securing to Truck or Trailer for

Transit

Always chock the machine wheels in preparation

for transport.

Turn the key switch to the off position and remove

the key before transporting.

Inspect the entire machine for loose or unsecured

items.

Securing the Chassis

Use the tie-down points on the chassis for

anchoring down to the transport surface.

Use chains or straps of ample load capacity.

Use a minimum of 4 chains.

Adjust the rigging to prevent damage to the chains.

Truck bed

1

3

2

Part No. 97779 GR-12 • GR-15 • GR-20 27

4

Page 30

Operator's Manual Third Edition • Second Printing

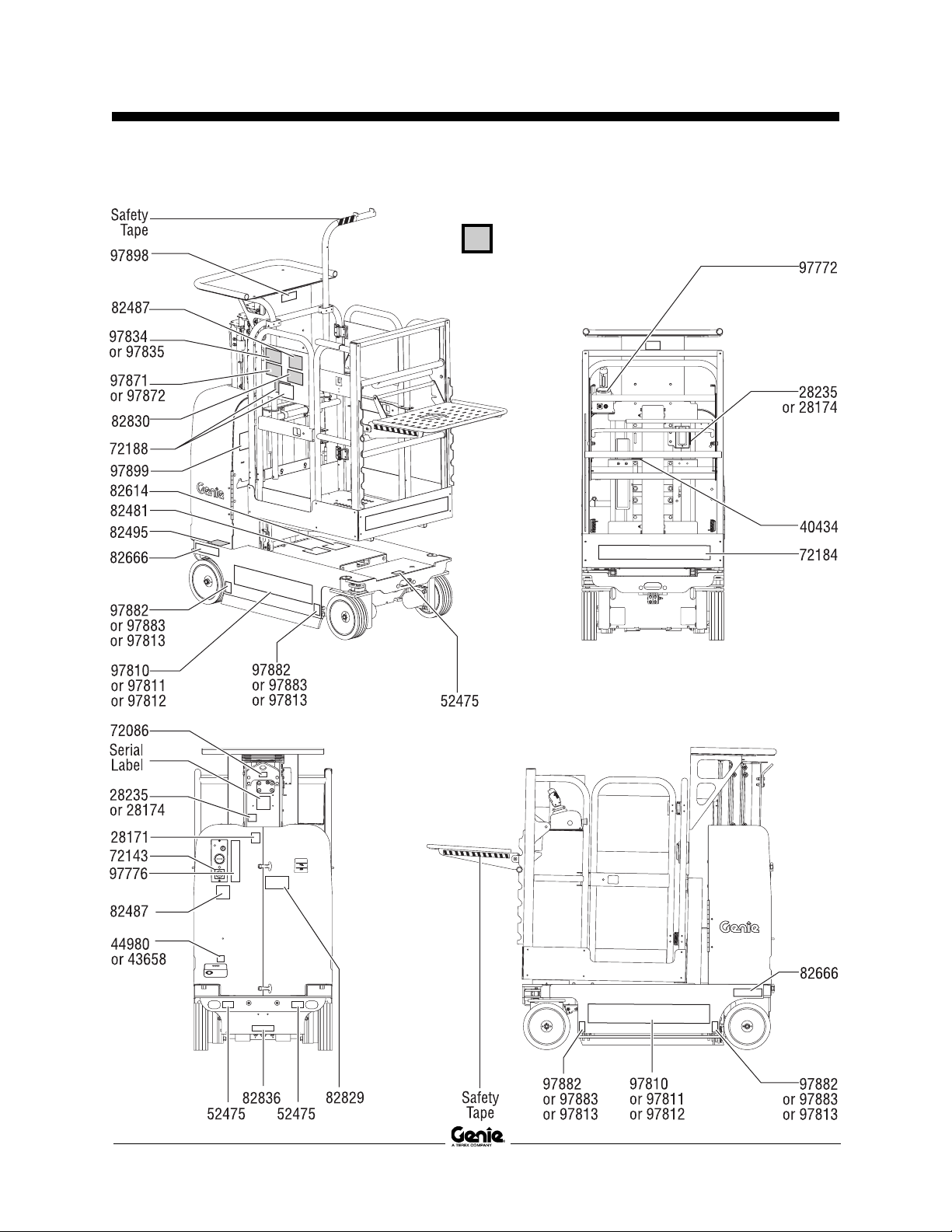

Decals

Inspection for Decals with

Symbols

Standard and AWP Platforms

Determine whether the decals on your machine

have words or symbols. Use the appropriate

inspection to verify that all decals are legible and in

place.

Part No. Description Quantity

28171 Label - No Smoking 1

28174 Label - Power to Platform, 230 V 2

28235 Label - Power to Platform, 115 V 2

40434 Label - Lanyard Anchorage 1

43658 Label - Power to Charger, 230 V 1

44980 Label - Power to Charger, 115 V 1

52475 Label - Transport Tie-down 3

72086 Label - Lifting Eye 1

72143 Label - Emergency Stop 1

72184 Cosmetic - Genie Runabout 2

72188 Label - Directional Arrows 2

82481 Danger - Battery Safety 1

82487 Label - Read the Manual 2

82495 Danger - Brake Release Safety &

Operating Instructions 1

82614 Danger - Collision Hazard 1

82666 Label - Forklift Pocket 2

82829 Danger - Electrocution Hazard 1

82830 Danger - Max Side Force 200 N 1

82835 Danger - Max Capacity 159 kg

(models with AWP and fiberglass platform) 1

Part No. Description Quantity

82836 Label - Manual Lowering 1

97772 Overlay - Platform Controls 1

97776 Ground Control Panel 1

97810 Cosmetic - Genie GR-12 2

97811 Cosmetic - Genie GR-15 2

97812 Cosmetic - Genie GR-20 2

97813 Label - Wheel Load, GR-20 4

97815 Label - Lower Midrail

(models with sliding midrail entry option) 1

97832 Danger - Max Capacity 227 kg,

GR-12, GR-15 (standard platform) 1

97833 Danger - Max Capacity 159 kg, GR-20 1

97873 Danger - Max Capacity, Workstation Tray

22 kg, GR-12, GR-15 1

97882 Label - Wheel Load, GR-12 4

97883 Label - Wheel Load, GR-15 4

97898 Danger - Max Capacity, Parcel Tray

68 kg, GR-12, GR-15 1

97899 Danger - Safety Chock 1

28 GR-12 • GR-15 • GR-20 Part No. 97779

Page 31

Third Edition • Second Printing

Operator's Manual

DECALS

Shading indicates

decal is hidden from

view, i.e., under covers.

Note: Platform decals

may be in diffferent

locations on optional

AWP and fiberglass

platforms.

Part No. 97779 GR-12 • GR-15 • GR-20 29

Page 32

Operator's Manual Third Edition • Second Printing

DECALS

Inspection for Decals with

Symbols

Stock Picker Platform

Determine whether the decals on your machine

have words or symbols. Use the appropriate

inspection to verify that all decals are legible and in

place.

Part No. Description Quantity

28171 Label - No Smoking 1

28174 Label - Power to Platform, 230 V 2

28235 Label - Power to Platform, 115 V 2

40434 Label - Lanyard Anchorage 1

43658 Label - Power to Charger, 230 V 1

44980 Label - Power to Charger, 115 V 1

52475 Label - Transport Tie-down 3

72086 Label - Lifting Eye 1

72143 Label - Emergency Stop 1

72184 Cosmetic - Genie Runabout 1

72188 Label - Directional Arrows 2

82481 Danger - Battery Safety 1

82487 Label - Read the Manual 2

82495 Danger - Brake Release Safety &

Operating Instructions 1

82614 Danger - Collision Hazard 1

82666 Label - Forklift Pocket 2

82829 Danger - Electrocution Hazard 1

82830 Danger - Max Side Force 200 N 1

Part No. Description Quantity

82836 Label - Manual Lowering 1

97772 Overlay - Platform Controls 1

97776 Ground Control Panel 1

97810 Cosmetic - Genie GR-12 2

97811 Cosmetic - Genie GR-15 2

97812 Cosmetic - Genie GR-20 2

97813 Label - Wheel Load, GR-20 4

97834 Danger - Max Capacity, 227 kg,

GR-12, GR-15 1

97835 Danger - Max Capacity, 159 kg, GR-20 1

97871 Danger - Max Capacity, Bike Rack,

GR-12, GR-15 1

97872 Danger - Max Capacity, Bike Rack,

GR-20 1

97882 Label - Wheel Load, GR-12 4

97883 Label - Wheel Load, GR-15 4

97898 Danger - Max Capacity, Parcel Tray

68 kg, GR-12, GR-15 1

97899 Danger - Safety Chock 1

30 GR-12 • GR-15 • GR-20 Part No. 97779

Page 33

Third Edition • Second Printing

Operator's Manual

DECALS

Shading indicates

decal is hidden from

view, i.e., under covers.

Part No. 97779 GR-12 • GR-15 • GR-20 31

Page 34

Operator's Manual Third Edition • Second Printing

Specifications

GR-12

Height, working maximum 5.31 m

Height, platform maximum 3.48 m

Height, stowed maximum 1.72 m

Height, stowed maximum 1.62 m

standard platform with work station tray

Height, stowed maximum 1.62 m

stock picker platform with work station tray

Height, stowed maximum 1.60 m

stock picker platform with bike racks

Width 75 cm

Length, stowed 1.35 m

Length with standard platform 1.85 m

optional platform extension extended

Length with stock picker platform 1.87 m

including adjustable tray

Length with stock picker platform 1.91 m

including adjustable tray and work station tray

Maximum capacity, 227 kg

standard platform

Maximum capacity, 159 kg

AWP and fiberglass platform

Maximum capacity, 227 kg

stock picker platform

Maximum wind speed 12.5 m/s

Turning radius (inside) 0 cm

Power source 4 Batteries, 6V 225AH

Controls Proportional

AC outlet in platform Standard

Tire size 25.4 x 7.6 x 2.5 cm

Airborne noise emissions 70 dB

Maximum sound level at normal operating workstations

(A-weighted)

Maximum slope rating, stowed position 30% (17°)

Maximum side slope rating 30% (17°)

Note: Slope rating is subject to ground conditions and

adequate traction.

Drive speeds

Stowed, maximum 4.0 km/h

12.2 m/10.9 sec

Platform raised, maximum 0.8 km/h

12.5 m/55 sec

Floor loading information

Tire load, maximum 464 kg

Tire contact pressure 11.06 kg/cm

1085 kPA

Occupied floor pressure 936 kg/m

9.18 kPA

Note: Floor loading information is approximate and

does not incorporate different option configurations.

It should be used only with adequate safety factors.

2

2

Turning radius (outside) 78.7 cm

Weight See Serial Label

(Machine weights vary with option configurations)

Continuous improvement of our products is a Genie

policy. Product specifications are subject to change

without notice or obligation.

32 GR-12 • GR-15 • GR-20 Part No. 97779

Page 35

Third Edition • Second Printing

Operator's Manual

SPECIFICATIONS

GR-15

Height, working maximum 6.30 m

Height, platform maximum 4.47 m

Height, stowed maximum 1.72 m

Height, stowed maximum 1.62 m

standard platform with work station tray

Height, stowed maximum 1.62 m

stock picker platform with work station tray

Height, stowed maximum 1.97 m

stock picker platform with bike racks

Width 75 cm

Length, stowed 1.35 m

Length with standard platform 1.85 m

optional platform extension extended

Length with stock picker platform 1.87 m

including adjustable tray

Length with stock picker platform 1.91 m

including adjustable tray and work station tray

Maximum capacity, 227 kg

standard platform

Maximum capacity, 159 kg

AWP and fiberglass platform

Maximum capacity, 227 kg

stock picker platform

Maximum wind speed 12.5 m/s

Turning radius (inside) 0 cm

Power source 4 Batteries, 6V 225AH

Controls Proportional

AC outlet in platform Standard

Tire size 25.4 x 7.6 x 2.5 cm

Airborne noise emissions 70 dB

Maximum sound level at normal operating workstations

(A-weighted)

Maximum slope rating, stowed position 30% (17°)

Maximum side slope rating 30% (17°)

Note: Slope rating is subject to ground conditions and

adequate traction.

Drive speeds

Stowed, maximum 4.0 km/h

12.2 m/10.9 sec

Platform raised, maximum 0.8 km/h

12.5 m/55 sec

Floor loading information

Tire load, maximum 606 kg

Tire contact pressure 14.4 kg/cm

1418 kPA

Occupied floor pressure 1210 kg/m

11.87 kPA

Note: Floor loading information is approximate and

does not incorporate different option configurations.

It should be used only with adequate safety factors.

2

2

Turning radius (outside) 78.7 cm

Weight See Serial Label

(Machine weights vary with option configurations)

Continuous improvement of our products is a Genie

policy. Product specifications are subject to change

without notice or obligation.

Part No. 97779 GR-12 • GR-15 • GR-20 33

Page 36

Operator's Manual Third Edition • Second Printing

SPECIFICATIONS

GR-20

Height, working maximum 7.90 m

Height, platform maximum 6.07 m

Height, stowed maximum 1.98 m

Height, stowed maximum 1.60 m

stock picker platform with bike racks

Width 80 cm

Length, stowed 1.42 m

Length with standard platform 1.92 m

optional platform extension extended

Length with stock picker platform 1.94 m

including adjustable tray

Maximum capacity, 159 kg

standard platform

Maximum capacity, 159 kg

AWP and fiberglass platform

Maximum capacity, 159 kg

stock picker platform

Maximum wind speed 45 km/h

Turning radius (inside) 0 cm

Turning radius (outside) 78.7 cm

AC outlet in platform Standard

Tire size 25.4 x 7.6 x 2.5 cm

Airborne noise emissions 70 dB

Maximum sound level at normal operating workstations

(A-weighted)

Maximum slope rating, stowed position 30% (17°)

Maximum side slope rating 30% (17°)

Note: Slope rating is subject to ground conditions and

adequate traction.

Stowed, maximum 4.0 km/h

12.2 m/10.9 sec

Platform raised, maximum 0.8 km/h

12.5 m/55 sec

Floor Loading Information

Tire Load, maximum 553 kg

Tire Contact Pressure 13 kg/cm

1292.76 kPA

Occupied Floor Pressure 1180 kg/m

11.57 kPA

Note: Floor loading information is approximate and

does not incorporate different option configurations.

It should be used only with adequate safety factors.

2

2

Weight See Serial Label

(Machine weights vary with option configurations)

Power source 4 Batteries, 6V 225AH

Controls Proportional

Continuous improvement of our products is a Genie

policy. Product specifications are subject to change

without notice or obligation.

34 GR-12 • GR-15 • GR-20 Part No. 97779

Page 37

Third Edition • Second Printing

Platform dimensions, all models (length x width)

Standard platform 88 x 75 cm

Standard platform 1.4 m x 75 cm

with extension

Stock picker platform 88 x 73 cm

Stock picker platform 1.4 m x 73 cm

including adjustable tray

Standard AWP platform 69 x 51 cm

Narrow AWP platform 66 cm x 51 cm

Standard fiberglass 74 x 67 cm

platform

Narrow fiberglass platform 66 x 56 cm

Operator's Manual

SPECIFICATIONS

Part No. 97779 GR-12 • GR-15 • GR-20 35

Page 38

GenieNorthAmerica

Phone

TollFree

425.881.1800

USAandCanada

800.536.1800

Fax

425.883.3475

GenieAustraliaPtyLtd.

Phone+

Fax+

61733751660

61733751002

GenieScandinavia

Phone+

Fax+

4631575100

4631579020

GenieFrance

Phone+

33(0)237260999

Fax+

33(0)237260998

GenieIberica

Phone+

Fax+

34935795042

34935795059

GenieGermany

Phone+

49(0)420288520

Fax+

49(0)42028852-20

GenieU.K.

Phone+

44(0)1476584333

Fax+

44(0)1476584334

GenieMexicoCity

Phone+

525556665242

Fax+

525556663241

GenieChina

Phone+

Fax+

862153852570

862153852569

GenieMalaysia

Phone+

Fax+

6598480775

6567533544

GenieJapan

Phone+

Fax+

81334536082

81334536083

GenieKorea

Phone+

Fax+

8225587267

8225583910

GenieBrasil

Phone+

551141665755

Fax+

551141665754

GenieHolland

Phone+

Fax+

31183581102

31183581566

Loading...

Loading...