Page 1

Operator’s Manual

First Edition

Sixth Printing

Part No. 35566

Page 2

Operator's Manual First Edition • Sixth Printing

Important

Read, understand and obey these safety rules and

operating instructions before operating this machine.

Only trained and authorized personnel shall be

permitted to operate this machine. If you have any

questions, call Genie Industries.

Contents

Page

Safety ......................................................................... 1

Legend ........................................................................ 6

Pre-operation Inspection ............................................. 8

Function Tests.......................................................... 10

Workplace Inspection................................................ 13

Operating Instructions............................................... 14

Battery & Charger Operating Instructions .................. 16

Transport Instructions ............................................... 17

Load Capacity Charts................................................ 18

Decals ...................................................................... 20

Specifications ........................................................... 22

Contact us:

Internet: http://www.genielift.com

e-mail: techpub@genieind.com

Copyright © 1995 by Genie Industries

First Edition: Sixth Printing, December 2004

"Genie" is a registered trademark of

Genie Industries in the USA and many other

countries.

Printed on recycled paper

Printed in U.S.A.

Genie Lift Part No. 35566

Page 3

Operator's ManualFirst Edition • Sixth Printing

Safety Rules

Warning

Failure to obey the instructions and

safety rules in this manual may

result in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation

inspection.

3 Always perform the function tests prior to

use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer's instructions and safety rules—

safety and operator's manuals and machine

decals.

You read, understand and obey employer's

safety rules and work site regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

Part No. 35566 Genie Lift 1

Page 4

Operator's Manual First Edition • Sixth Printing

SAFETY RULES

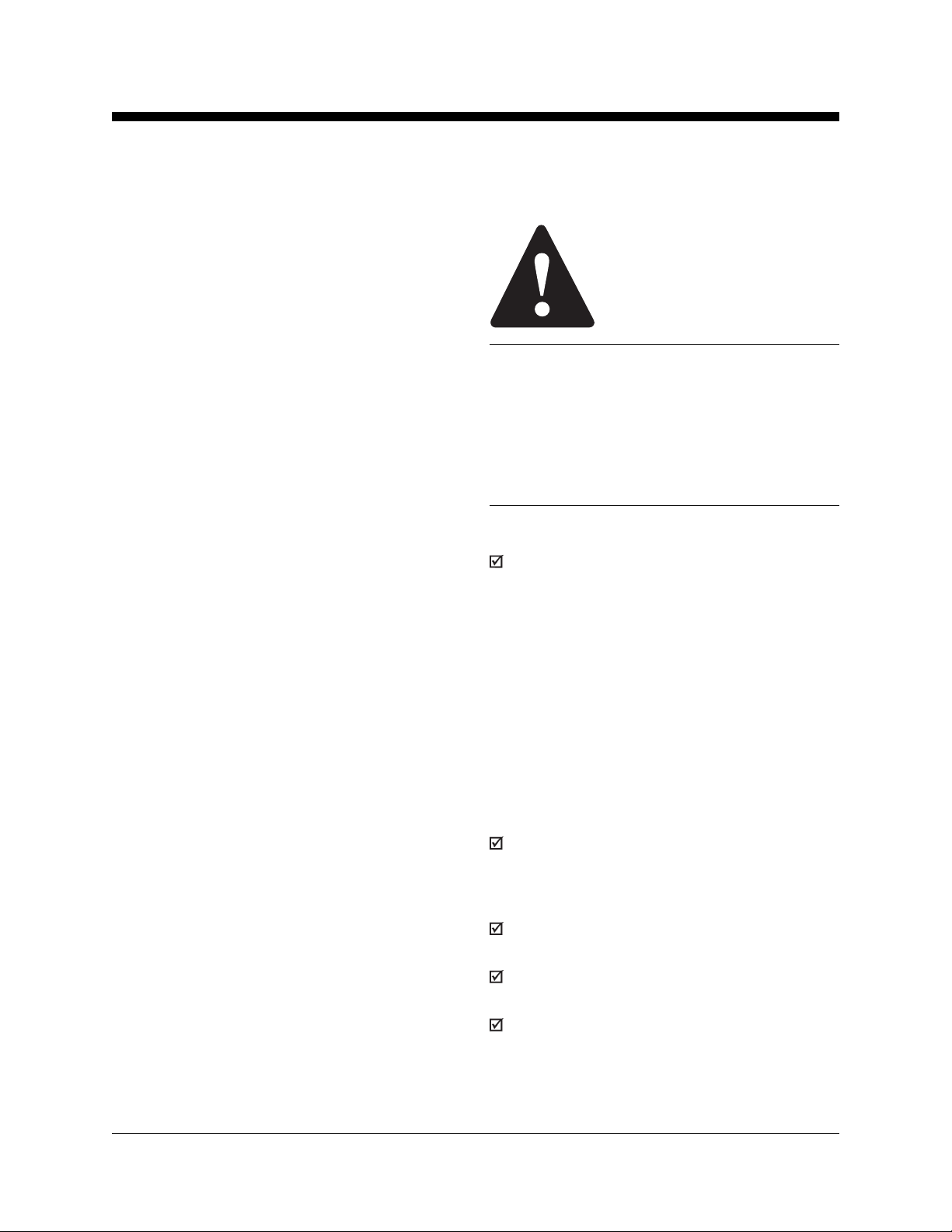

Fall Hazards

Do not use as a personnel

lifting platform or step.

Do not stand or sit on the

forks, load platform or

boom.

Do not climb on the

machine.

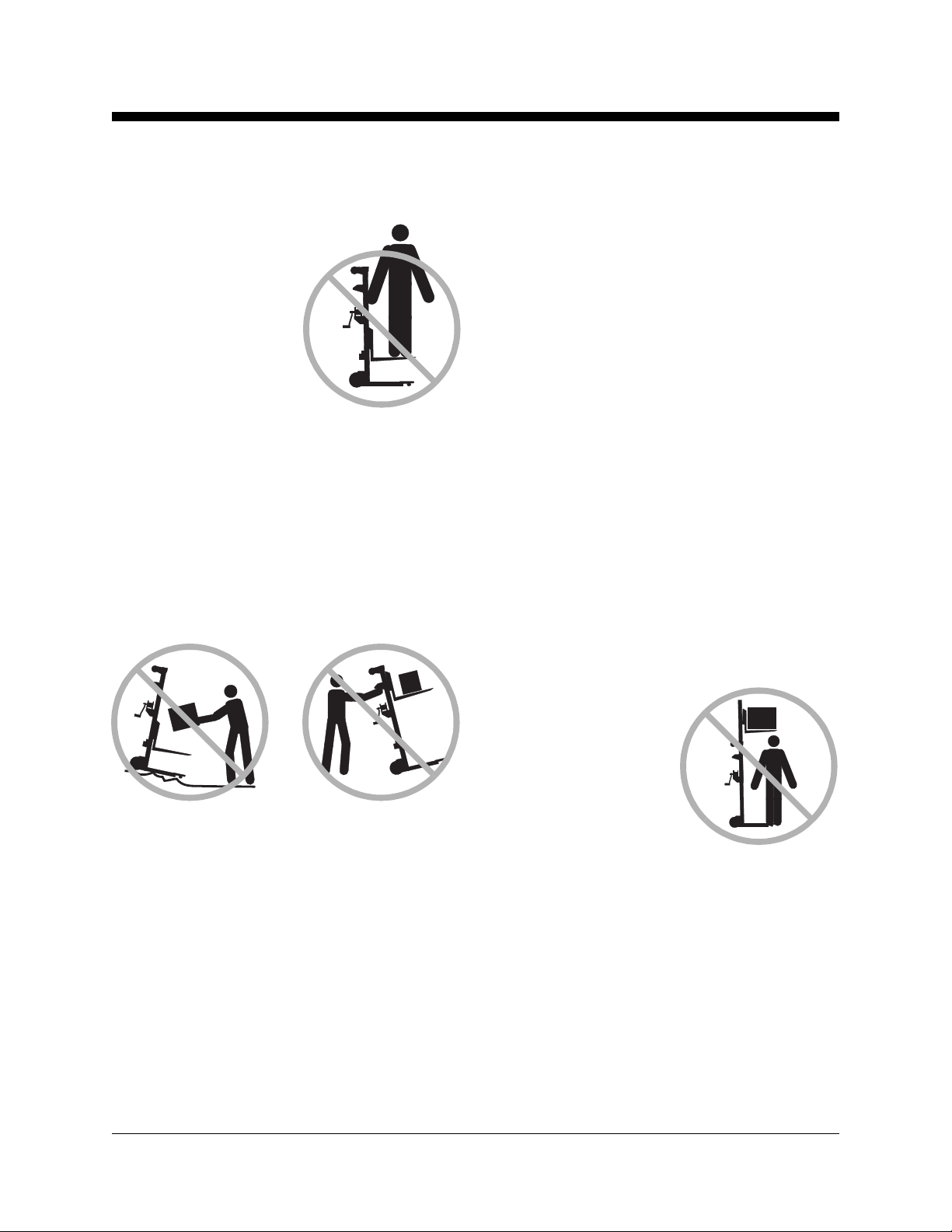

Tip-over Hazards

Do not exceed the rated load capacity. See Load

Capacity Charts section.

Do not raise the load unless the leg lock pins have

been properly inserted into the legs.

Do not raise the load unless the correct length legs

are properly installed.

Do not raise the load unless the machine is on a

firm, level surface.

Do not place ladders or scaffolding against any part

of the machine.

Do not operate the machine unless the

wheel/ leg/caster configuration is properly

installed.

Prior to use, check the work area for drop-offs,

holes, bumps, debris, unstable or slippery surfaces

or other possible hazardous conditions.

Avoid debris and uneven surfaces while rolling a

machine without the legs installed.

Do not replace machine parts critical to stability or

structure with items of different weight or

specification.

Do not cause a horizontal force or side load to the

machine by raising or lowering a fixed or

overhanging load.

Do not use the machine on a moving or mobile

surface or vehicle.

Collision Hazards

Do not raise if the load is not properly centered on

the forks or load platform.

Check the work area for

overhead obstructions or

other possible hazards.

Do not stand under or

allow personnel under the

machine when the load is

Do not move the machine with a raised load,

except for minor positioning.

Do not tilt the machine back with a raised load.

Do not use blocks to level the machine.

Do not operate the machine in strong or gusty

winds. Increasing the load surface area will

decrease machine stability in windy conditions.

2 Genie Lift Part No. 35566

raised.

Do not lower the load unless the area below is clear

of personnel and obstructions.

Use common sense and planning when transporting

the machine on an incline, slope or stairs.

Maintain proper lubrication on the frame channels.

See the Pre-operation Inspection section.

Unlubricated frame channels can bind or stop

moving, which could result in the load shifting or

falling.

Page 5

Operator's ManualFirst Edition • Sixth Printing

SAFETY RULES

Electrocution Hazards

This machine is not electrically insulated and will

not provide protection from contact with or

proximity to electrical current.

Maintain safe distances away from electrical power

lines and apparatus in accordance with applicable

governmental regulations and the following chart.

Voltage Minimum Safe

Approach Distance

Phase to Phase Feet Meters

0 to 300V Avoid Contact

300V to 50KV 10 3.1

50KV to 200KV 15 4.6

200KV to 350KV 20 6.1

350KV to 500KV 25 7.6

500KV to 750KV 35 10.7

750KV to 1000KV 45 13.7

Allow for mast movement and electrical line sway

or sag, and beware of strong or gusty winds.

Keep away from the machine if it contacts

energized power lines. Personnel must not touch or

operate the machine until power lines are shut off.

Do not use the machine as a ground for welding.

Bodily Injury Hazards

Do not grasp the cable.

Improper Use Hazard

Never leave a machine unattended with a load.

Unauthorized personnel may attempt to operate the

machine without proper instruction, creating an

unsafe condition.

Damaged Machine Hazards

Do not use a damaged or

malfunctioning machine.

Do not use a machine with a

worn, frayed, kinked or damaged

cable.

Do not use a machine with less

than 4 wraps of cable on the

winch drum when the carriage is

fully lowered.

Conduct a thorough

pre-operation inspection prior to

each use.

Be sure that all decals are legible and in place.

Maintain proper lubrication on the winch. See

Genie Lift Parts and Service Manual

not allow oil or grease on braking surfaces.

for details. Do

Crushing Hazard

Maintain a firm grasp on the winch handle until the

brake is locked. The brake is locked when the load

will not cause the winch handle to turn.

Keep hands and fingers away from the pulleys,

carriage and other potential pinch points.

Do not place arms, hands or fingers through the

frame.

Part No. 35566 Genie Lift 3

Lifting Hazard

Use proper lifting techniques to load or tip the

machine, or move the machine on stairs.

Do not move the machine on stairs when the

machine is equipped with the 4 point caster option.

Page 6

Operator's Manual First Edition • Sixth Printing

SAFETY RULES

Ladder Safety

Fall Hazards

Do not use the ladder as scaffolding.

Do not sit on the ladder.

Do not over reach. Keep your body centered

between both side rails.

Do not use the top rung as a step.

Tip-over Hazards

Do not exceed the ladder's maximum capacity of

250 lbs / 113 kg.

Do not overload the ladder. Ladders are designed

for 1 person only.

Do not use the ladder unless it is properly set up.

Do not shift the ladder while on it. Avoid pushing or

pulling off to the side of the ladder.

Do not set up the ladder on slippery surfaces.

Do not use blocks to level the ladder.

Electric Winch Safety

Electrocution Hazard

Do not operate the DC battery charger unless using

a 3-wire grounded extension cord connected to a

grounded AC circit. Do not alter or disable the

3-wire grounded plugs.

Tip-over Hazards

Do not exceed the rated load capacity. See Load

Capacity Charts section.

Do not use the electric winch on models with the

standard base. The electric winch is designed for

use only on straddle base models.

Do not alter or disable the limit switch.

Battery and Charger Safety

- Electric Winch Models

Burn Hazards

Batteries contain acid.

Always wear protective

clothing and eyewear

when working with

batteries.

Avoid spilling or

contacting battery acid.

Neutralize battery acid

spills with baking soda

and water.

The battery pack must

remain in an upright

position.

4 Genie Lift Part No. 35566

Page 7

Operator's ManualFirst Edition • Sixth Printing

SAFETY RULES

Explosion Hazards

Batteries emit explosive

gas. Keep sparks, flames

and lighted tobacco away

from the battery.

Charge the battery in a

well-ventilated area.

Do not disconnect the charger DC output wires

from the battery when the charger is on.

Electrocution Hazards

Connect the charger to a

grounded AC circuit only.

Do not expose the battery

or charger to water or rain.

Before each use, inspect

for damage. Replace

damaged components

before operating.

Lifting Hazard

The battery pack weighs 80 lbs / 37 kg. Use the

appropriate number of people and proper lifting

techniques when lifting the battery pack.

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—used to indicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Orange—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentially hazardous situation

which, if not avoided, may cause

minor or moderate injury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

Part No. 35566 Genie Lift 5

Page 8

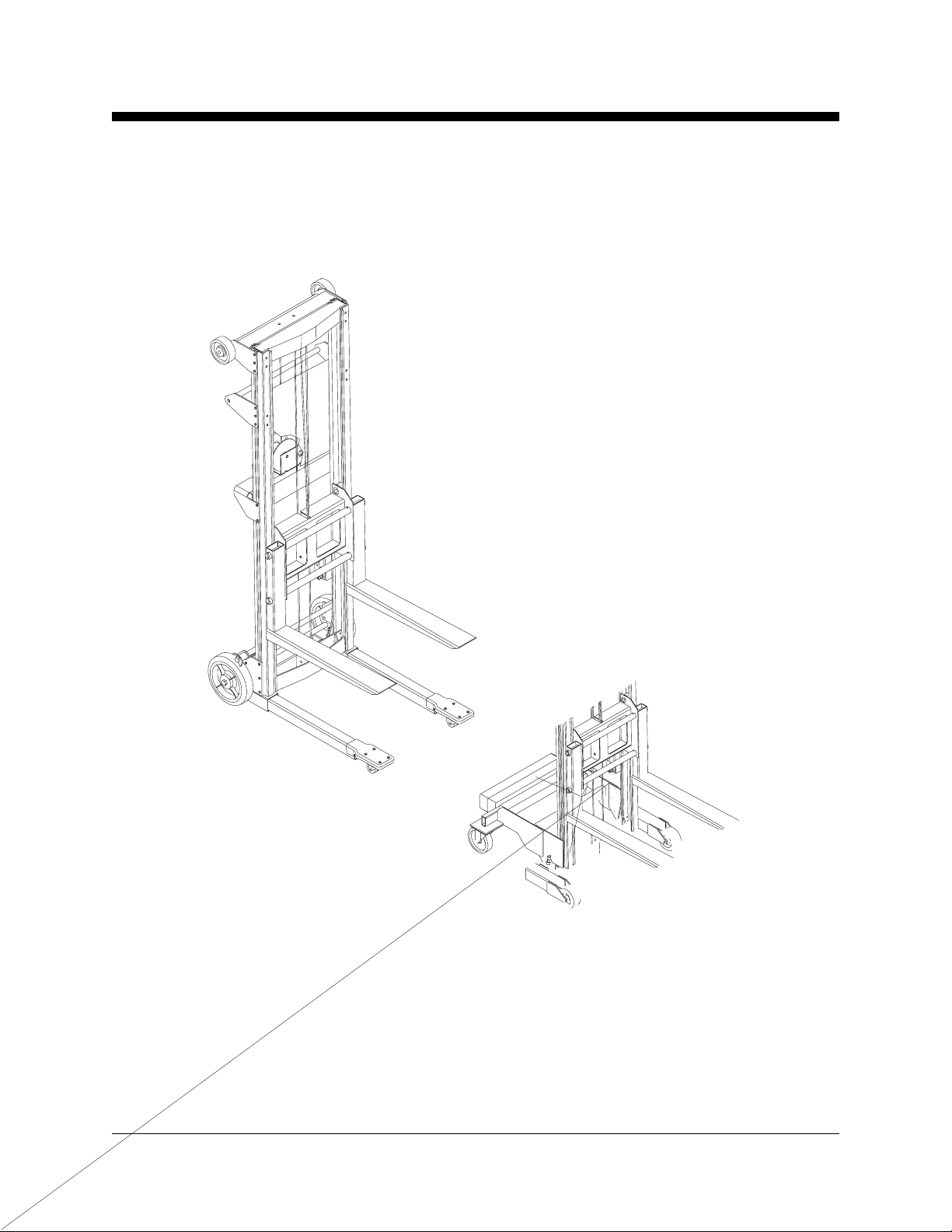

Operator's Manual First Edition • Sixth Printing

6 Genie Lift Part No. 35566

Page 9

Operator's ManualFirst Edition • Sixth Printing

LEGEND

Models with electric

winch option

Straddle Base with

4 Point Casters

24 Brake (option)

2 5 Fork lock pin

2 6 Winch mounting bracket

27 Winch

28 Boom (option)

29 Load platform (option)

3 0 Electric winch battery

Part No. 35566 Genie Lift 7

3 1 Electric winch charger

3 2 Electric winch (option)

3 3 Electric winch control

34 Electric winch limit switch

3 5 Red Emergency Stop button

3 6 Electric winch control up

button

3 7 Electric winch control down

button

3 8 Caster, 4 inch - option A

Caster, 5 inch - option B

3 9 Ladder snap pin

40 Ladder (option)

Page 10

Operator's Manual First Edition • Sixth Printing

Pre-operation Inspection

Fundamentals

The pre-operation inspection is a visual inspection

performed by the operator prior to each work shift.

This inspection is designed to discover if anything

is apparently wrong with a machine before the

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

operator tests it.

Refer to the list on the next page and check each

of the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a preoperation inspection again before testing the

machine functions.

8 Genie Lift Part No. 35566

Page 11

Pre-operation Inspection

Operator's ManualFirst Edition • Sixth Printing

PRE-OPERATION INSPECTION

o Be sure that the operator’s manual is complete,

legible and available for reference.

o Be sure that all decals are legible and in place.

See Decals section.

Check the following components or areas for

damage, improperly installed or missing parts and

unauthorized modifications:

o Winch and related components

o Base components

o Legs

o Roller wheels

o Inner and outer frames

o Glide buttons

o Carriage hold-down assembly

o Cable anchor

o Cable and pulleys

o Wheels and casters

o Forks

Check the entire machine for:

o Dents or damage

o Corrosion or oxidation

o Cracks in welds or structural components

o Be sure that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

o Inspect and clean the battery terminals and all

battery cable connections.

o Be sure there is a minimum of 4 wraps of cable

around the winch drum when the carriage is

fully lowered.

o Be sure the frame channels are properly

lubricated and free of debris. Lubricate the

channels with a dry silicone spray or silicone

wax (Genie part number 90337).

o Load platform and boom (if equipped)

o Nuts, bolts and other fasteners

o Cable (kinks, frays, abrasions)

o Ladder (if equipped)

o Brake system (if equipped)

o Limit switch (electric winch models)

o Electric winch and related components

(if equipped)

o Hand controls and wiring (electric winch

models)

Part No. 35566 Genie Lift 9

Page 12

Operator's Manual First Edition • Sixth Printing

Function T ests

Fundamentals

The function tests are designed to discover any

malfunctions before the machine is put into service.

The operator must follow the step-by-step

instructions to test all machine functions.

A malfunctioning machine must never be used. If

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

malfunctions are discovered, the machine must be

tagged and removed from service. Repairs to the

machine may only be made by a qualified service

technician, according to the manufacturer's

specifications.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

Know and understand the function tests

before going on to the next section.

4 Inspect the workplace.

5 Only use the machine as it was intended.

After repairs are completed, the operator must

perform a pre-operation inspection and function

tests again before putting the machine into service.

10 Genie Lift Part No. 35566

Page 13

Operator's ManualFirst Edition • Sixth Printing

FUNCTION TESTS

Function Tests

1 Select a test area that is firm, level and free of

obstructions.

Setup

1 Tilt the machine back.

2 Slide each fork onto the carriage and secure it

with the fork lock pins.

3 Slide each leg into

a base socket until

the leg lock pin

snaps into the leg.

4 Stand the machine up.

5 Remove the winch handle, reverse the handle

and install it. The handle grip should face the

operator.

6 Straddle base: Adjust to desired width. Be sure

the leg lock pin snaps into the leg.

7 Rotate the hold-down bar off of the carriage.

Boom

Load Platform

1 Lay the load platform onto the forks.

2 Lift the front of the load platform and push it

toward the carriage until the back angle is under

the lower fork mounting tube.

3 Rotate the load platform down until it locks into

place over the forks.

Ladder Setup (if equipped)

1 Position the machine.

2 Pull the snap pins on both sides of the ladder.

3 Pull the ladder down into the lowered position.

Be sure to support the ladder until it is fully

lowered.

To store the ladder: Raise the ladder to the stowed

position and be sure the snap pins lock into place.

1 Hold the boom in a vertical position.

2 Place the top of the boom plate under the upper

fork mounting tube and lift up.

3 Rotate the boom down until it locks into place.

4 Attach the lifting shackle to the desired hole on

the boom.

Part No. 35566 Genie Lift 11

Page 14

Operator's Manual First Edition • Sixth Printing

FUNCTION TESTS

Test the Brake Operation

(if equipped)

1 Press down on the foot pedal to lock the brake.

2 Push the machine.

Result: The wheels should not roll.

3 Pull up on the foot pedal to release the brake.

4 Push the machine.

Result: The machine should move.

Test the Winch Operation

Note: The Genie Lift 4 does not have an inner

frame.

1 Rotate the winch handle clockwise to raise the

carriage.

Result: The carriage should raise to the top of

the inner frame and then the inner frame should

raise. The carriage and inner frame should

move smoothly, free of hesitation and binding.

2 Rotate the winch handle counterclockwise to

lower the carriage.

Test Electric Winch Operation

(if equipped)

Note: The Genie Lift 4 does not have an inner

frame.

1 Connect the battery pack.

2 Pull out the red Emergency Stop button to the

on position.

3 Push the up button on the hand controls.

Result: The carriage should raise to the top of

the inner frame and then the inner frame should

raise. The carriage and inner frame should

move smoothly, free of hesitation and binding.

The winch should turn off when the carriage

reaches maximum height.

4 Push in the red Emergency Stop button to the

off position.

5 Push the down button, then the up button.

Result: The up/down function should not

operate.

Result: The inner frame should lower into the

outer frame, and then the carriage should lower

into the inner frame. The carriage and inner

frame should move smoothly, free of hesitation

and binding.

Note: If the carriage and inner frame do not move

freely, the channels may need to be lubricated with

a dry silicone spray or silicone wax.

12 Genie Lift Part No. 35566

Page 15

Operator's ManualFirst Edition • Sixth Printing

Workplace Inspection

Be aware of and avoid the following hazardous

situations:

· drop-offs or holes

· bumps and floor obstructions

· debris

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

Know and understand the workplace

inspection before going on to the next

section.

5 Only use the machine as it was intended.

Fundamentals

The workplace inspection helps the operator

determine if the workplace is suitable for safe

machine operation. It should be performed by the

operator prior to moving the machine to the

workplace.

· overhead obstructions and high voltage

conductors

· hazardous locations

· sloped surfaces

· unstable or slippery surfaces

· inadequate surface support to withstand all

load forces imposed by the machine

· wind and weather conditions

· all other possible unsafe conditions

It is the operator's responsibility to read and

remember the workplace hazards, then watch for

and avoid them while moving, setting up and

operating the machine.

Part No. 35566 Genie Lift 13

Page 16

Operator's Manual First Edition • Sixth Printing

Operating Instructions

Setup

Select an area that is firm, level and free of

obstructions.

Follow the Setup procedures in the Function Tests

section.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Raising and Lowering Load Manual Winch

1 Center the load on the forks or load platform.

2 Raise the load by firmly grasping the winch

handle and rotating it clockwise. Do not allow

the cable to wind unevenly onto the winch

drum.

3 Lower the load by firmly grasping the winch

handle and rotating it counterclockwise. After

lowering to the desired position, turn the winch

handle clockwise (raise the load) 1/4 turn to set

the brake.

Fundamentals

The Operating Instructions section provides

instructions for each aspect of machine operation.

It is the operator's responsibility to follow all the

safety rules and instructions in the operator's

manual.

Using the machine for any purpose other than lifting

material is unsafe.

If more than one operator is expected to use a

machine at different times in the same work shift,

each operator is expected to follow all safety rules

and instructions in the operator's manual. That

means every new operator should perform a preoperation inspection, function tests and a

workplace inspection before using the machine.

Raising and Lowering Load Electric Winch

1 Center the load on the forks or load platform.

2 Connect the battery pack.

3 Pull out the red Emergency Stop button to the

on position.

4 Push the up or down button on the hand controls

for the desired direction of travel.

14 Genie Lift Part No. 35566

Page 17

Operator's ManualFirst Edition • Sixth Printing

OPERATING INSTRUCTIONS

Moving Machine with a Load

It is best to move the machine on the work site with

no load. Moving a raised load should be restricted

to positioning for loading and unloading. If it is

necessary to move the machine with a raised load,

understand and obey the following safety rules:

· Make sure the area is level and clear of

obstructions.

· Make sure the load is centered on the forks or

load platform.

· Avoid sudden starts and stops.

· Travel with the load in the lowest possible

position.

· Keep personnel away from the machine and

load.

· Do not tilt the machine back with a raised

load.

Moving Machine on Stairs

It is best to move the machine on stairs using the

optional stair glides. Moving the machine on stairs

without the use of stair glides is not recommended.

If it is necessary to move the machine on stairs,

understand and obey the following safety rules:

After Each Use

To prepare the machine for storage, remove the

forks and legs and reverse the winch handle. Refer

to the Setup procedure.

Select a safe storage location - firm level surface,

weather protected, clear of obstruction and traffic.

Models with electric winch: Recharge the battery.

· Do not move the machine on stairs when the

machine is equipped with the 4 point caster

option.

· Fully lower the load.

· Ease the machine over each stair. Maintain a

firm grasp on the handle.

· Do not allow the machine to become

unbalanced.

· Continue carefully up or down the stairs.

· Use the appropriate number of people and

proper lifting techniques with heavy loads.

· Models with electric winch: Remove the

battery pack.

Part No. 35566 Genie Lift 15

Page 18

Operator's Manual First Edition • Sixth Printing

OPERATING INSTRUCTIONS

9 Charger models equipped with manual/auto

selector switch: If the ampere meter indicates

that the battery is not being charged, set the

power switch to the MANUAL position until the

ampere meter begins to move up the scale.

Then set the power switch to the AUTO position.

Battery and Charger Instructions

Observe and Obey:

Do not use an external charger or booster

battery.

Charge the battery in a well-ventilated area.

Use proper AC input voltage for charging as

indicated on the charger.

Use only a Genie authorized battery and

charger.

To Charge Battery

1 Open the battery pack lid to access the battery.

2 Remove the battery vent caps and check the

battery acid level. If necessary, add only

enough distilled water to cover the plates. Do

not overfill prior to the charge cycle.

3 Replace the battery vent caps.

4 If equipped: Set the power switch to the OFF

position. Be sure that the DC output cord is

properly connected to the battery (black to

negative, red to positive).

5 Connect the battery charger to a grounded AC

circuit.

6 If equipped: Set the AC Selector switch to the

proper voltage.

10 The charger will turn off automatically when the

battery is fully charged. If equipped: Set the

power switch to the OFF position, then

disconnect from the AC supply.

11 Check the battery acid level when the charge

cycle is complete. Replenish with distilled water

to the bottom of the fill tube. Do not overfill.

Dry Battery Filling and

Charging Instructions

1 Remove the battery vent caps and permanently

remove the plastic seal from the battery vent

openings.

2 Fill each cell with battery acid (electrolyte) until

the level is sufficient to cover the plates.

Do not fill to maximum level until the battery charge

cycle is complete. Overfilling can cause the battery

acid to overflow during charging. Neutralize battery

acid spills with baking soda and water.

3 Install the battery vent caps.

4 Charge the battery.

5 Check the battery acid level when the charging

cycle is complete. Replenish with distilled water

to the bottom of the fill tube. Do not overfill.

7 Set the power switch to the AUTO position.

8 Monitor the ampere meter for the correct charge

rate. The initial charge rate should be

approximately 10A. The charge rate will

decrease as the battery reaches full charge.

16 Genie Lift Part No. 35566

Page 19

Transport Instructions

Operator's ManualFirst Edition • Sixth Printing

OPERATING INSTRUCTIONS

Lifting Instructions

The number of people required to load and unload a

machine is dependent on a number of factors,

including but not limited to:

· the physical condition, strength and

disabilities or prior injuries of the people

involved

Observe and Obey:

Be sure the vehicle capacity and loading

surfaces are sufficient to support the machine

weight. See the serial plate for the machine

weight.

The transport vehicle must be parked on a level

surface.

Remove the load from the forks, boom or load

platform before loading for transport.

The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

The machine must be securely fastened to the

transport vehicle.

· the vertical and horizontal distances the

machine has to be moved

· the number of times the machine will be

loaded or unloaded

· the stance, posture and grip used by the

people involved

· the lifting techniques used

· the site conditions and weather in which the

activity is being performed (i.e., slippery, icy,

raining)

The appropriate number of people and proper

lifting techniques must be used to prevent physical

injury.

Loading for T ransport

1 Fully lower the carriage.

2 Rotate the carriage hold-down bar over the

carriage. Be sure the lock pin snaps into place.

3 Remove the winch handle, reverse the handle

and install it. The handle grip should face the

carriage.

4 Models with electric winch: Remove the battery

pack.

Part No. 35566 Genie Lift 17

Page 20

Operator's Manual First Edition • Sixth Printing

Load Capacity Charts

Forks

Load Positioning Instructions

1 Determine the weight of the load and the

location of its load center.

2 Measure to the load center from the side of the

Observe and Obey:

Failure to properly position the load may result

in death or serious injury.

Verify that the load you wish to raise does not

exceed the maximum load for your load center.

See the load capacity charts on the next page.

Tip-over hazard. Raising a load

that exceeds the machine capacity

may result in death or serious

injury.

load that will be closest to the carriage.

3 Refer to the chart on the next page to determine

if the machine is capable of lifting the weight at

the location on the forks.

4 Place the load so that it rests on the forks, as

close to the carriage as possible.

5 Position the load so that the load center is

within the load center zone.

A load center is defined as the balancing point

(center of gravity) of a load and must be

positioned within the load center zone.

Tip-over hazard. Failure to

position the load center within the

load center zone may result in

death or serious injury.

measure to the load center

18 Genie Lift Part No. 35566

Page 21

Forks Load Capacity Chart

inches

cm

Model

GL-4 500 500

GL-8 400 400

GL-10 350 350

GL-12 350 350

lbs

kg

lbs

kg

lbs

kg

lbs

kg

Boom

12 14

30 35

227 227

181 181

159 159

159 159

Operator's ManualFirst Edition • Sixth Printing

LOAD CAPACITY CHARTS

Maximum Load Centers

(measure from front of carriage)

Forks: 14 in 35 cm

Load Platform: 14 in 35 cm

Boom: 20 in 51 cm

Load Positioning Instructions

1 Determine the weight of the load and the

location of its load center.

2 Refer to the chart below to determine if the

machine is capable of lifting the weight at the

location on the boom.

3 Attach the lifting shackle to the desired hole on

the boom.

Boom Load Capacity Chart

Model Front Rear

Hole Hole

GL-4 lbs 300 500

kg 136 227

Rear

mounting hole

Front

mounting hole

GL-8 lbs 240 400

kg 109 181

GL-10 lbs 210 350

kg 95 159

GL-12 lbs 210 350

kg 95 159

Part No. 35566 Genie Lift 19

Page 22

Operator's Manual First Edition • Sixth Printing

52982

35577

or 35578

or 35579

82959

33468

97529

37049

35574

35567

43022

43021

35577 or

35578 or

35579

37120

37111

37111

37084

35575

20 Genie Lift Part No. 35566

Page 23

Operator's ManualFirst Edition • Sixth Printing

52982

97511

or 97512

or 97513

97539

97532

82962

Serial

Plate

97539

82487

97536

82481

82487

97511 or

97512 or

97513

97533

97540

97540

82487

82487

97510

Part No. 35566 Genie Lift 21

Page 24

Operator's Manual First Edition • Sixth Printing

Specifications

Model GL-4 GL-8 GL-10 GL-12

Height, maximum lift 5 ft 11 in 10 ft 1/2 in 11 ft 8 in 13 ft 91/2 in

Forks up 1.8 m 3.1 m 3.6 m 4.2 m

Height, maximum lift 4 ft 11/2 in 8 ft 3 in 9 ft 101/2 in 12 ft

Forks down 1.2 m 2.5 m 3 m 3.7 m

Height, minimum lift 31/2 in 31/2 in 2 in 2 in

Forks down 8.9 cm 8.9 cm 5.1 cm 5.1 cm

Lift capacity 500 lbs 400 lbs 350 lbs 350 lbs

at 12 in / 30.5 cm load center 227 kg 181 kg 159 kg 159 kg

Machine weight See specification chart on next page.

Height, stowed* 5 ft 71/2 in 5 ft 71/2 in 6 ft 51/2 in 7 ft 63/4 in

1.7 m 1.7 m 2 m 2.3 m

Ground clearance*

3

/4 in

1.9 cm 1.9 cm 1.9 cm 1.9 cm

Standard base

3

Width 24

/4 in 243/4 in NA NA

62.9 cm 62.9 cm

Length - stowed 12 in 12 in NA NA

30.5 cm 30.5 cm

Length - operating 343/4 in 343/4 in NA NA

88.3 cm 88.3 cm

Straddle base

3

Width - stowed 28

/4 in 283/4 in 283/4 in 283/4 in

73 cm 73 cm 73 cm 73 cm

Width - extended 431/2 in 431/2 in 431/2 in 431/2 in

1.1 m 1.1 m 1.1 m 1.1 m

Length - stowed 191/4 in 191/4 in 191/4 in 191/4 in

48.9 cm 48.9 cm 48.9 cm 48.9 cm

Length - operating 43 in 43 in 43 in 43 in

1 m 1 m 1 m 1 m

Counterweighted base

3

Width - stowed 28

/4 in 283/4 in 283/4 in NA

73 cm 73 cm 73 cm

Width - extended 431/2 in 431/2 in 431/2 in N A

1.1 m 1.1 m 1.1 m

Length - operating 281/2 in 281/2 in 281/2 in NA

72.4 cm 72.4 cm 72.4 cm

Airborne noise emissions by machinery

Maximum sound level at normal operating workstations (A-weighted)

Manual winch 90 dB 90 dB 90 dB 90 dB

Electric winch 95 dB 95 dB 95 dB 95 dB

* The 10 inch pneumatic rear wheel option will add 1 inch / 2.5 cm to these specifications.

* The 4 point caster option B will add 1

inch / 2.5 cm to these specifications.

* The counterweight base will add 1 inch / 2.5 cm to these specifications.

3

/4 in

3

/4 in

3

/4 in

22 Genie Lift Part No. 35566

Page 25

Operator's ManualFirst Edition • Sixth Printing

SPECIFICATIONS

Model GL-4 GL-8 GL-10 GL-12

Forks

Length 22

Width 20

Load Platform

Length 23 in 23 in 23 in 23 in

Width 22 in 22 in 22 in 22 in

1

/2 in 221/2 in 221/2 in 221/2 in

57.2 cm 57.2 cm 57.2 cm 57.2 cm

1

/2 in 201/2 in 201/2 in 201/2 in

52.1 cm 52.1 cm 52.1 cm 52.1 cm

58.4 cm 58.4 cm 58.4 cm 58.4 cm

55.9 cm 55.9 cm 55.9 cm 55.9 cm

Machine Configurations

Base: Standard Base

GL-4 and GL-8

*Wheel and Casters:

Pneumatic option

Front: 2

Rear: 10 inch pneumatic wheels

Base: Straddle Base

GL-4, GL-8, GL-10 and GL-12

*Wheel and Casters:

Pneumatic option

Front: 2

Rear: 10 inch pneumatic wheels

4 point caster option A

Front: 2 inch dual wheel swivel

Rear: 4 inch swivel casters

4 point caster option B

Front: 2

Rear: 5 inch swivel casters with

Base: Counterweight

GL-4, GL-8, GL-10

**Wheel and Casters:

Front: 4 inch fixed wheel

Rear: 5 inch swivel casters with

*Machines with standard or straddle base ship standard

with 8 inch rear wheels and 2 inch dual wheel front

swivel casters.

**Machines with counterweight base ship standard with

5 inch rear swivel casters with side brakes and 4 inch

front fixed wheels.

1

/2 inch swivel casters

1

/2 inch swivel casters

casters

1

/2 inch swivel casters

side brakes and

4 point rotational locks

side brakes

Machine Weights

Genie Lift 4

Base: Caster Option: Weight:

Standard Standard 113 lbs / 51 kg

Standard Pneumatic 117 lbs / 53 kg

Straddle Standard 126 lbs / 57 kg

Straddle Pneumatic 130 lbs / 59 kg

Straddle 4 point caster A 137 lbs / 62 kg

Straddle 4 point caster B 139 lbs / 63 kg

Counterweight Standard 392 lbs / 178 kg

Genie Lift 8

Base: Caster Option: Weight:

Standard Standard 132 lbs / 60 kg

Standard Pneumatic 136 lbs / 62 kg

Straddle Standard 145 lbs / 66 kg

Straddle Pneumatic 149 lbs / 68 kg

Straddle 4 point caster A 156 lbs / 71 kg

Straddle 4 point caster B 158 lbs / 72 kg

Counterweight Standard 411 lbs / 186 kg

Genie Lift 10

Base: Caster Option: Weight:

Straddle Standard 149 lbs / 68 kg

Straddle Pneumatic 153 lbs / 69 kg

Straddle 4 point caster A 160 lbs / 73 kg

Straddle 4 point caster B 162 lbs / 73 kg

Counterweight Standard 415 lbs / 188 kg

Genie Lift 12

Base: Caster Option: Weight:

Straddle Standard 154 lbs / 70 kg

Straddle Pneumatic 158 lbs / 72 kg

Straddle 4 point caster A 165 lbs / 75 kg

Straddle 4 point caster B 167 lbs / 76 kg

The electric winch option will add an additional

103 lbs / 47 kg to the above machine weights.

Part No. 35566 Genie Lift 23

Page 26

Genie North America

Phone 425.881.1800

Toll Free USA and Canada

Genie Australia Pty Ltd.

800.536.1800

Fax 425.883.3475

Phone +61 7 3375 1660

Fax +61 7 3375 1002

Genie Scandinavia

Phone +46 31 575100

Fax +46 31 579020

Genie France

Phone +33 (0)2 37 26 09 99

Fax +33 (0)2 37 26 09 98

Genie Iberica

Phone +34 93 579 5042

Fax +34 93 579 5059

Genie Germany

Phone +49 (0)4202 88520

Fax +49 (0)4202 8852-20

Genie U.K.

Phone +44 (0)1476 584333

Fax +44 (0)1476 584334

Genie Mexico City

Phone +52 55 5666 5242

Fax +52 55 5666 3241

Genie China

Phone +86 21 53852570

Fax +86 21 53852569

Genie Malaysia

Phone +65 98 480 775

Fax +65 67 533 544

Genie Japan

Phone +81 3 3453 6082

Fax +81 3 3453 6083

Genie Korea

Phone +82 25 587 267

Fax +82 25 583 910

Genie Brasil

Phone +55 11 41 665 755

Fax +55 11 41 665 754

Genie Holland

Phone +31 183 581 102

Fax +31 183 581 566

Distributed By:

Loading...

Loading...