Genicom LA36 User Manual

G E N I C O M M a t r i x P r i n t er LA36

S e r v i c e M a n u a l

GENICOM CorporationGENICOM Corporation

GENICOM Corporation

GENICOM CorporationGENICOM Corporation

REVISION RECORD

Edition

001

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 2000 GENICOM Corporation.

No part of this manual may be reproduced in any form without permission.

Date published

FEB 2000

Page

–

First issue

Revised contents

PREFACE

This manual is for engineers who operate, install, or maintain the GENICOM Matrix Printer LA36N/LA36W.

The topics covered are:

Chapter 1: Printer specifications, performance, and configuration

Chapter 2: Unpacking, performance check, and connection

Chapter 3: Troubleshooting

Chapter 4: Maintenance

Chapter 5: Principles of operation

Chapter 6: Spare parts

CONTENTS

CHAPTER 1 PRINTER SPECIFICATIONS, PERFORMANCE, AND CONFIGURATION .............1-1

1.1 Overview ...................................................................................................................................................1-1

1.2 Equipment Structure .................................................................................................................................. 1-2

1.2.1 Overview ............................................................................................................................................. 1-2

1.2.2 Model configuration ........................................................................................................................... 1-2

1.2.3 Structure ..............................................................................................................................................1-3

(1) Upper cover assembly ................................................................................................................1-4

(2) Printing mechanism assembly ...................................................................................................1-5

(3) Lower cover assembly ............................................................................................................... 1-6

CHAPTER 2 UNPACKING, PERFORMANCE CHECK, AND CONNECTION.................................2-1

2.1 Overview ...................................................................................................................................................2-1

2.2 Notes on Installation .................................................................................................................................. 2-1

2.3 Unpacking .................................................................................................................................................2-2

2.4 Inspection after Unpacking ....................................................................................................................... 2-4

CHAPTER 3 TROUBLESHOOTING ........................................................................................................3-1

3.1 All Indicators Don’t Light .........................................................................................................................3-4

3.2 No Print Head Movement..........................................................................................................................3-6

3.3 Incorrect Printing due to Defective Nonvolatile RAM .............................................................................3-9

3.4 Printing Quality Abnormal ........................................................................................................................3-10

3.5 Forms Feed Abnormal ............................................................................................................................... 3-13

3.6 Error Display .............................................................................................................................................3-15

CHAPTER 4 MAINTENANCE ...................................................................................................................4-1

4.1 Overview ...................................................................................................................................................4-1

4.2 Notes on Use .............................................................................................................................................4-1

4.3 Maintenance Tools ....................................................................................................................................4-2

4.4 Maintenance Levels ................................................................................................................................... 4-2

4.5 Preventive Maintenance ............................................................................................................................4-2

4.6 Parts Drawings...........................................................................................................................................4-3

4.7 Parts That Must Not Be Disassembled ......................................................................................................4-4

4.8 Level 1 Maintenance .................................................................................................................................4-5

i

4.9 Level 2 Maintenance .................................................................................................................................4-6

4.9.1 Parts replacement ................................................................................................................................4-6

(1) Acoustic cover replacement ....................................................................................................... 4-7

(2) Tractor unit replacement ............................................................................................................4-8

(3) Cover replacement, including platen knob ................................................................................4-11

(4) Control panel replacement .........................................................................................................4-15

(5) Printing mechanism replacement ............................................................................................... 4-16

(6) Power supply and fuse replacement ..........................................................................................4-17

(7) RS-423 board replacement.........................................................................................................4-18

(8) ROM board (control board) replacement .................................................................................. 4-19

(9) Platen roll assembly replacement ..............................................................................................4-21

(10) Paper feed motor (LF motor) replacement ................................................................................ 4-22

(11) Space motor (SP motor) assembly replacement ........................................................................ 4-23

(12) Sensor T replacement.................................................................................................................4-24

(13) Carriage unit replacement ..........................................................................................................4-25

(14) Print head and ribbon feed assembly replacement ....................................................................4-27

(15) Gear assembly replacement ....................................................................................................... 4-28

(16) Paper feeder assembly replacement ...........................................................................................4-29

(17) Card guide replacement .............................................................................................................4-30

(18) Ribbon shift unit (color kit) replacement...................................................................................4-31

4.9.2 Adjustment ..........................................................................................................................................4-32

(1) Print head gap adjustment .......................................................................................................... 4-32

(2) Vertical alignment ......................................................................................................................4-34

(3) Top-of-forms adjustment (factory use) ...................................................................................... 4-36

4.9.3 Lubrication ..........................................................................................................................................4-37

(1) Ribbon drive assembly...............................................................................................................4-38

(2) Color ribbon shift motor (option) .............................................................................................. 4-39

(3) LF gear bearing and continuous/single lever ............................................................................. 4-40

(4) Back cover assembly .................................................................................................................4-41

(5) Paper feed roller shaft ................................................................................................................4-42

(6) Shaft ...........................................................................................................................................4-43

(7) Stay shaft .................................................................................................................................... 4-44

(8) Front and top covers (LA36N) ..................................................................................................4-45

(9) Front and top covers (LA36W)..................................................................................................4-46

(10) Sheet guide assembly ................................................................................................................4-47

ii

4.10 Diagnostics ..............................................................................................................................................4-48

4.10.1 Self-test printing................................................................................................................................4-48

(1) Starting self-test printing............................................................................................................4-48

(2) Checking printer performance ...................................................................................................4-49

(3) Stopping self-test printing .......................................................................................................... 4-49

4.10.2 Hex dump .......................................................................................................................................... 4-50

(1) Starting hex dump printing ........................................................................................................4-50

(2) Stopping hex dump printing ...................................................................................................... 4-50

4.10.3 Control panel maintenance functions initiated when power goes on ...............................................4-51

CHAPTER 5 PRINCIPLES OF OPERATION..........................................................................................5-1

5.1 Overview ...................................................................................................................................................5-1

5.2 Mechanical Operation ............................................................................................................................... 5-2

5.2.1 Print head drive ...................................................................................................................................5-2

5.2.2 Carriage drive......................................................................................................................................5-3

5.2.3 Ribbon feed .........................................................................................................................................5-4

5.2.4 Paper feed............................................................................................................................................5-5

(1) Continuous forms feeding..........................................................................................................5-6

(2) Cut-sheet feeding .......................................................................................................................5-8

(3) Paper selection ........................................................................................................................... 5-9

(4) Autoloading ...............................................................................................................................5-10

(5) Paper end detection ....................................................................................................................5-11

5.2.5 Print head gap control (paper thickness adjustment) ..........................................................................5-14

5.2.6 Color ribbon shift motor (option) ....................................................................................................... 5-15

5.2.7 Option detection mechanism...............................................................................................................5-16

5.3 Electrical Operation ...................................................................................................................................5-17

5.3.1 System configuration ..........................................................................................................................5-17

(1) Printer control board (ROM board) ...........................................................................................5-19

(2) Power supply unit ...................................................................................................................... 5-19

(3) Sensors .......................................................................................................................................5-19

(4) Control panel..............................................................................................................................5-19

5.3.2 Main controller....................................................................................................................................5-23

5.3.3 Interface control ..................................................................................................................................5-25

(1) Centronics parallel interface ...................................................................................................... 5-25

(2) RS-423 serial interface............................................................................................................... 5-26

5.3.4 Carriage motor control ........................................................................................................................ 5-27

5.3.5 Print head control ................................................................................................................................ 5-31

5.3.6 Paper feed control ...............................................................................................................................5-33

iii

5.3.7 Ribbon shift control ............................................................................................................................ 5-35

5.3.8 Fire check control ............................................................................................................................... 5-37

(1) Short-mode detection...............................................................................................................5-37

(2) Long-mode detection ............................................................................................................... 5-37

5.3.9 Control panel control .......................................................................................................................... 5-39

5.3.10 Power supply.....................................................................................................................................5-40

(1) Surge current prevention ......................................................................................................... 5-40

(2) Rectifying and smoothing........................................................................................................5-40

(3) Main voltage regulation switching ..........................................................................................5-42

(4) Protection ................................................................................................................................. 5-42

(5) External signal .........................................................................................................................5-44

5.4 Firmware Overview ...................................................................................................................................5-45

CHAPTER 6 RECOMMENDED SPARE PARTS.....................................................................................6-1

iv

ILLUSTRATIONS

Figure 1.1 LA36N and LA36W printers .........................................................................................................1-1

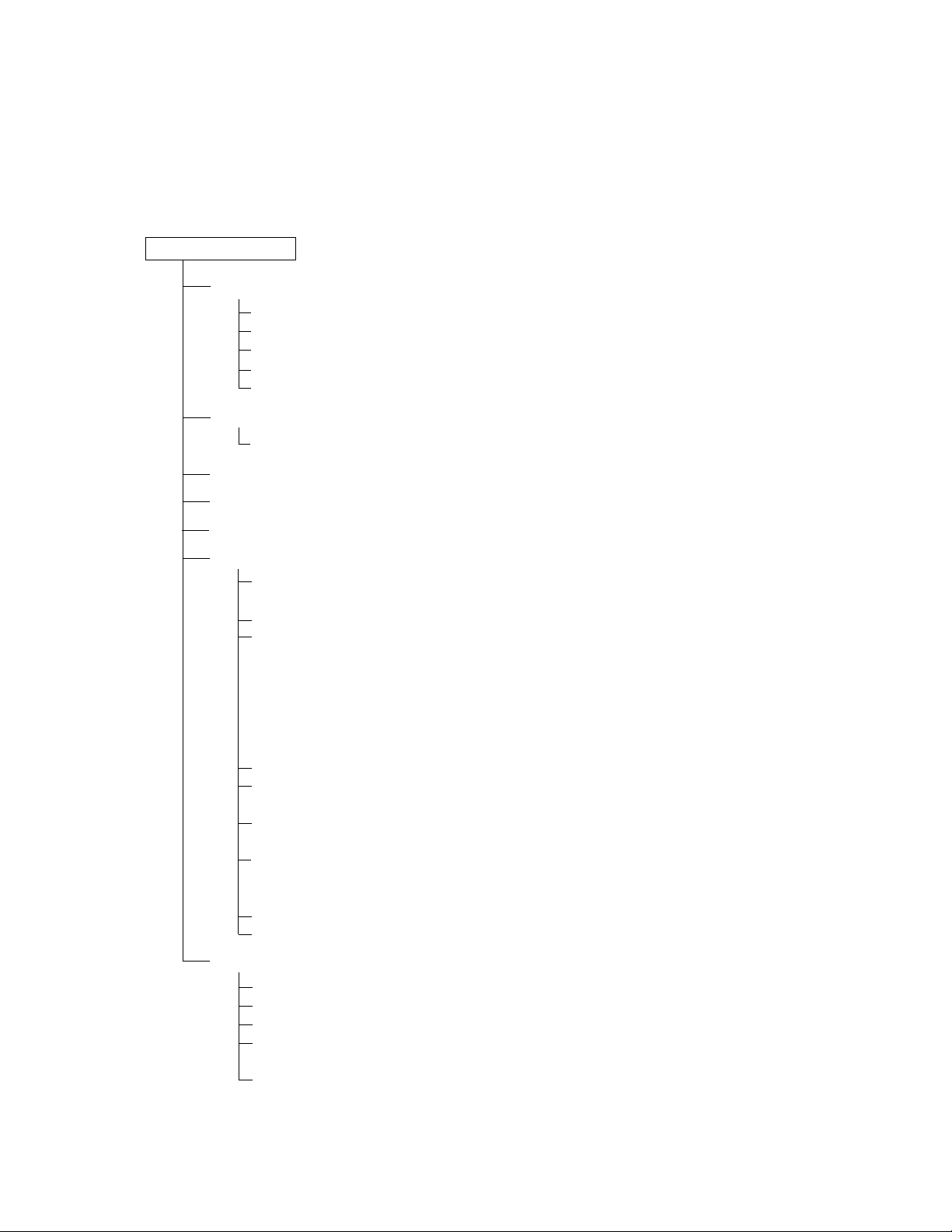

Figure 1.2 Printer component structure ........................................................................................................... 1-3

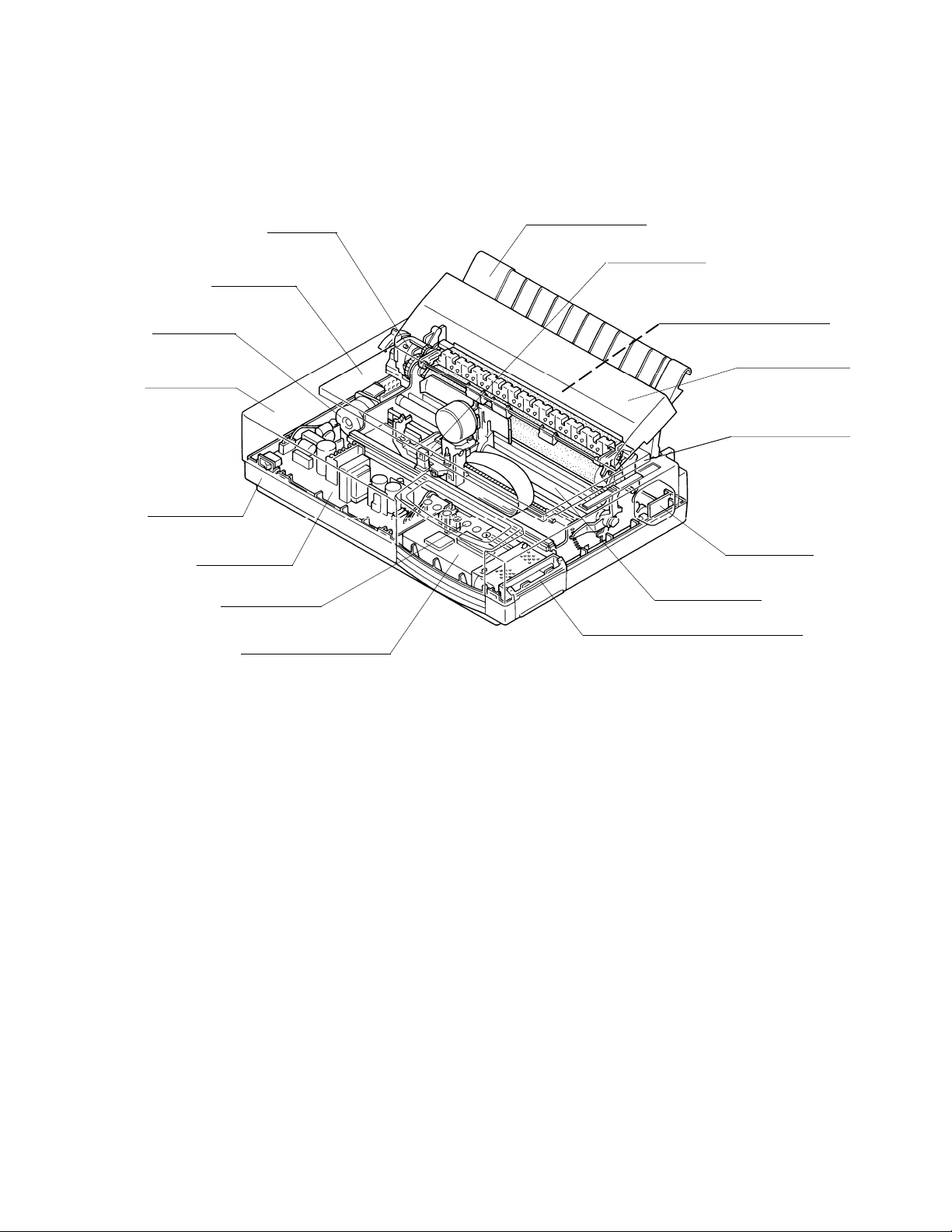

Figure 1.3 Upper cover assembly (LA36N) .................................................................................................... 1-4

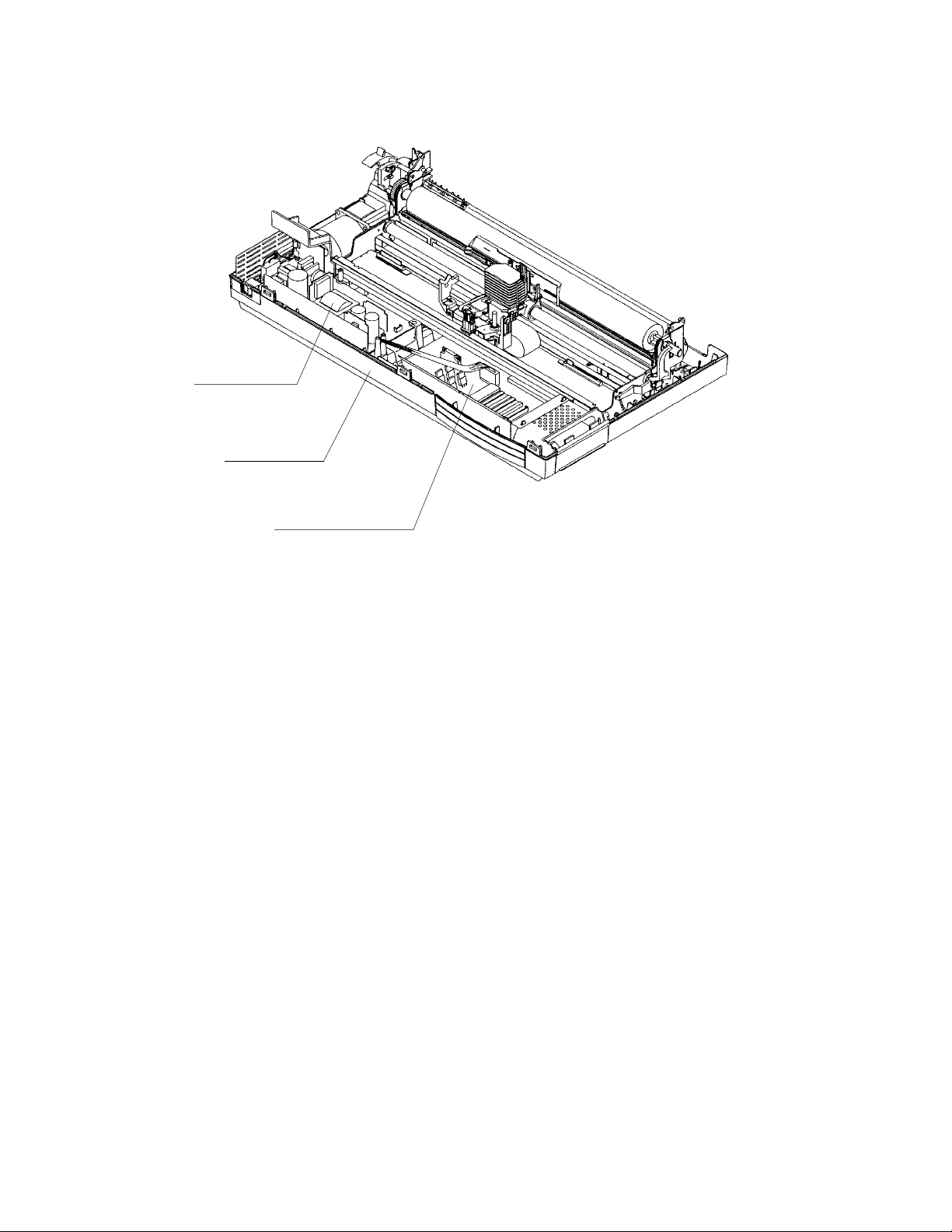

Figure 1.4 Printer lower assembly (LA36N) ................................................................................................... 1-6

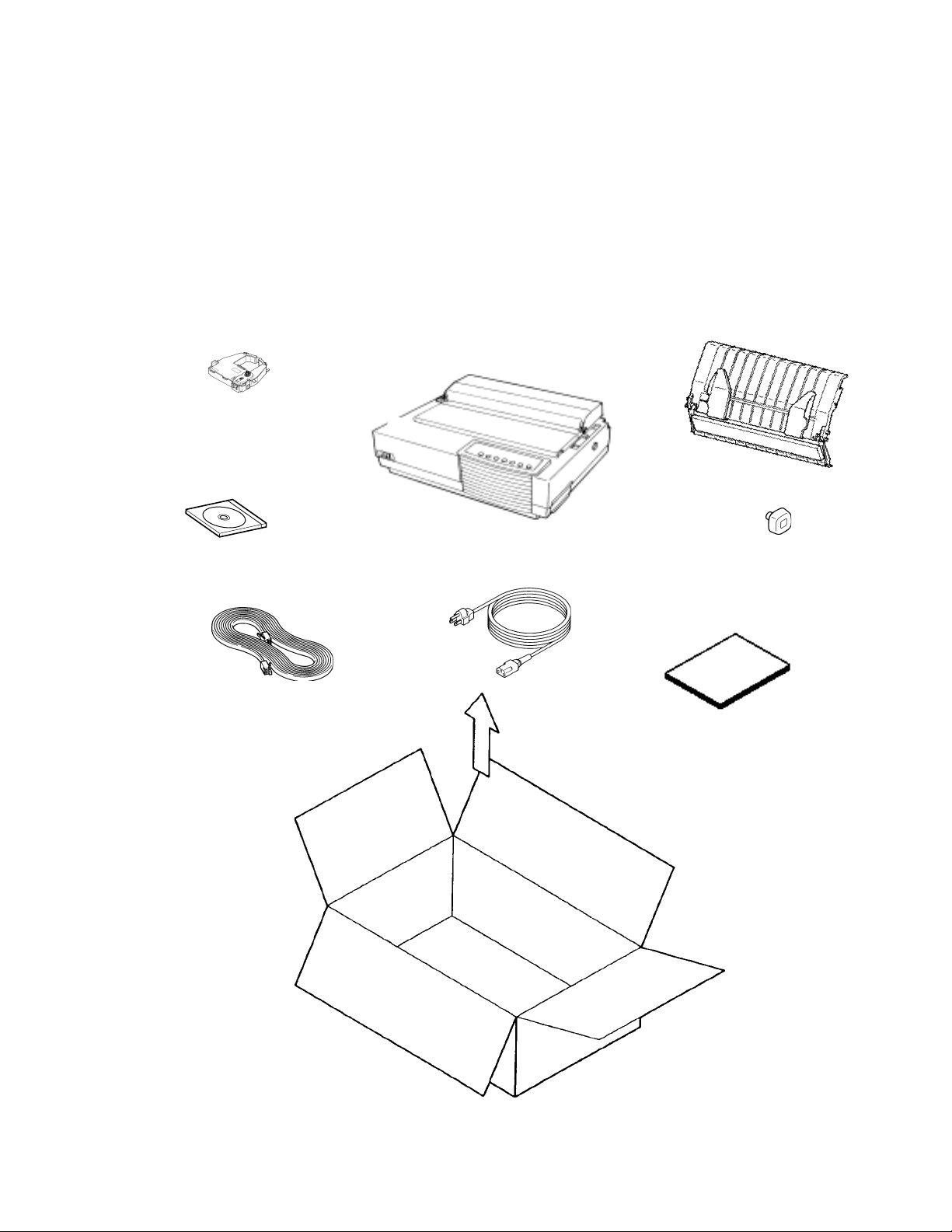

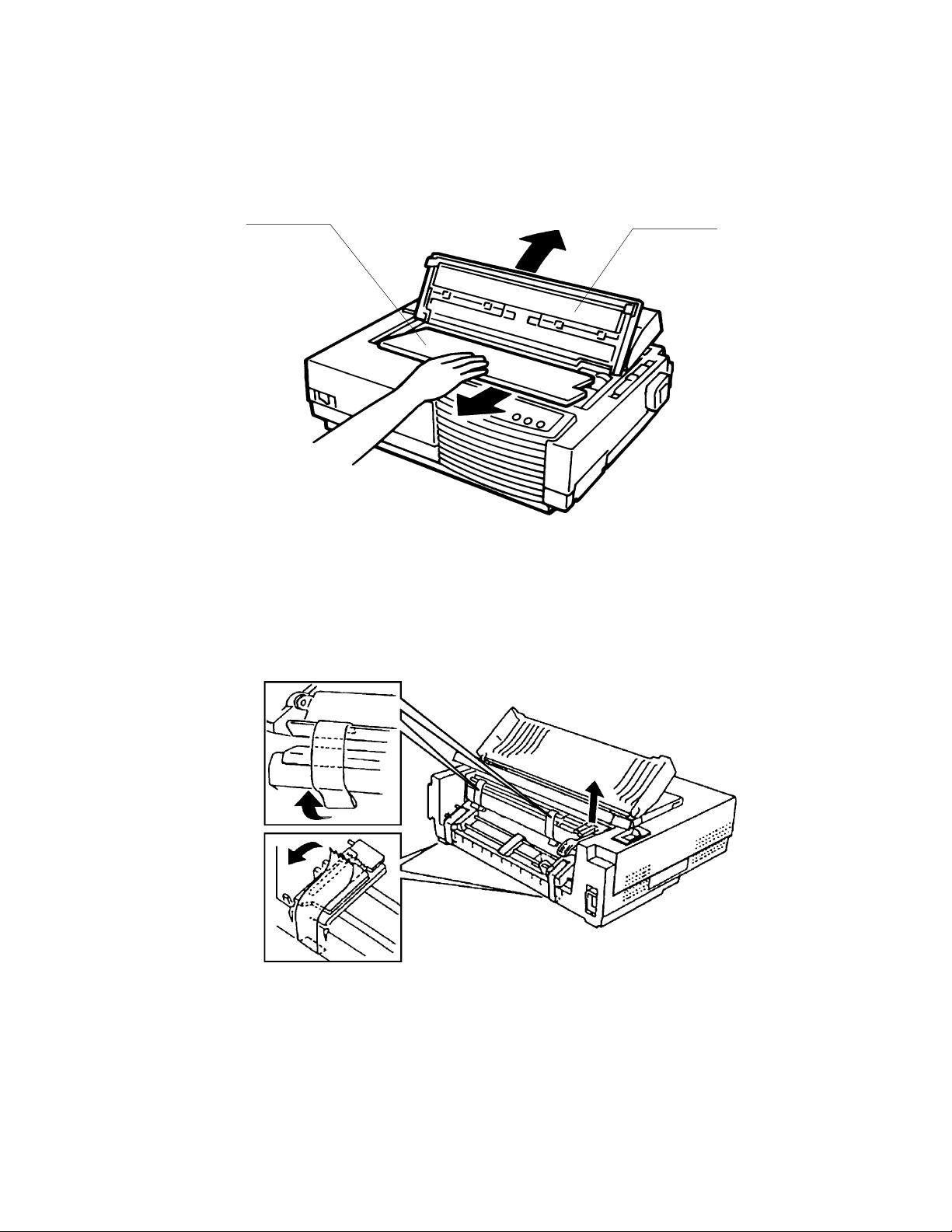

Figure 2.1 Unpacking the printer and accessories...........................................................................................2-2

Figure 2.2 Removing the print head shipping restraint (cardboard) ...............................................................2-3

Figure 2.3 Removing the bail stopper and four tapes ..................................................................................... 2-3

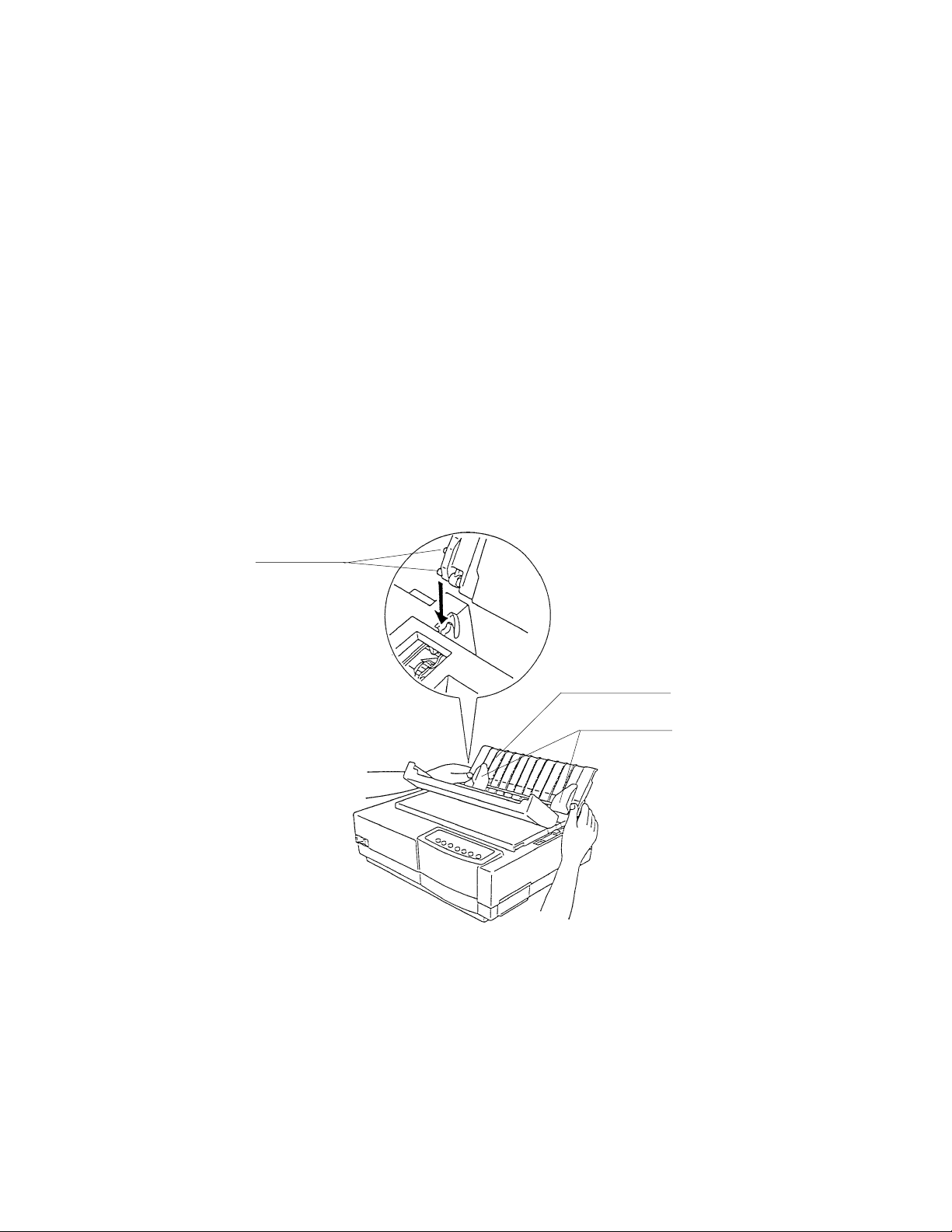

Figure 2.4 Installing the cut-sheet stand..........................................................................................................2-4

Figure 3.1 Printer functional block diagram ................................................................................................... 3-2

Figure 4.1 Basic components .......................................................................................................................... 4-3

Figure 4.2 Cleaning and lubrication ................................................................................................................4-5

Figure 5.1 Function sequence..........................................................................................................................5-1

Figure 5.2 Print head ....................................................................................................................................... 5-2

Figure 5.3 Carriage drive.................................................................................................................................5-3

Figure 5.4 Ribbon feed .................................................................................................................................... 5-4

Figure 5.5 Paper feed path...............................................................................................................................5-5

Figure 5.6 Continuous form feeding (push-feed tractor) ................................................................................5-6

Figure 5.7 Continuous form feeding (pull-feed tractor)..................................................................................5-7

Figure 5.8 Cut-sheet feeding ...........................................................................................................................5-8

Figure 5.9 Paper selection ...............................................................................................................................5-9

Figure 5.10 Autoloading ................................................................................................................................. 5-10

Figure 5.11 Paper end detection (cut sheet) ....................................................................................................5-11

Figure 5.12 Paper end detection (continuous forms via push-feed tractor) ....................................................5-12

Figure 5.13 Paper end detection (continuous forms via pull-feed tractor) ..................................................... 5-13

Figure 5.14 Print head gap control ..................................................................................................................5-14

Figure 5.15 Color ribbon shift motor ..............................................................................................................5-15

Figure 5.16 Option detection mechanism .......................................................................................................5-16

Figure 5.17 System configuration ...................................................................................................................5-17

Figure 5.18 Connection diagram .....................................................................................................................5-18

Figure 5.19 Controller block diagram .............................................................................................................5-20

Figure 5.20 MB90706 block diagram .............................................................................................................5-21

Figure 5.21 MBCU20050 block diagram........................................................................................................5-22

Figure 5.22 Memory configuration .................................................................................................................5-23

Figure 5.23 Centronics parallel interface signal timing .................................................................................. 5-25

Figure 5.24 RS-423 serial interface signal timing...........................................................................................5-26

Figure 5.25 Stepping motor drive circuit ........................................................................................................5-27

v

Figure 5.26 Phase switching and carriage drive direction ..............................................................................5-28

Figure 5.27 Relationship between carriage drive speed and phase excitation ................................................5-29

Figure 5.28 Carriage drive 1/2-phase excitation at low speed ........................................................................5-30

Figure 5.29 Carriage drive 2-phase excitation at high speed ..........................................................................5-30

Figure 5.30 Print head pin magnet drive circuit .............................................................................................. 5-31

Figure 5.31 Print timing .................................................................................................................................. 5-32

Figure 5.32 Phase switching and paper feed direction .................................................................................... 5-33

Figure 5.33 Paper feed speed .......................................................................................................................... 5-34

Figure 5.34 1/2-phase excitation of paper feed ...............................................................................................5-34

Figure 5.35 Phase switching and ribbon shift direction ..................................................................................5-35

Figure 5.36 Ribbon shift speed........................................................................................................................5-36

Figure 5.37 Ribbon shift phase excitation ....................................................................................................... 5-36

Figure 5.38 Fire check circuits ........................................................................................................................5-38

Figure 5.39 Control panel block diagram........................................................................................................5-39

Figure 5.40 Surge current prevention circuit .................................................................................................. 5-40

Figure 5.41 Power supply block diagram........................................................................................................5-41

Figure 5.42 PWSTOP signal ........................................................................................................................... 5-44

Figure 5.43 Firmware configuration ............................................................................................................... 5-45

vi

TABLES

Table 3.1 Errors indicated by the Fault indicator and the buzzer ................................................................... 3-15

Table 3.2 Alarms that turn power off ..............................................................................................................3-15

Table 4.1 Maintenance tools ...........................................................................................................................4-2

Table 4.2 Parts not to be disassembled............................................................................................................4-4

Table 4.3 Cleaning ..........................................................................................................................................4-5

Table 4.4 Power-on-initiated maintenance......................................................................................................4-51

Table 5.1 Memory address map ......................................................................................................................5-24

Table 5.2 Voltage regulation switching control ..............................................................................................5-42

Table 5.3 Overcurrent protection ....................................................................................................................5-43

Table 5.4 Overvoltage protection .................................................................................................................... 5-43

vii

CHAPTER 1CHAPTER 1

CHAPTER 1

CHAPTER 1CHAPTER 1

PRINTER SPECIFICATIONS,PRINTER SPECIFICATIONS,

PRINTER SPECIFICATIONS,

PRINTER SPECIFICATIONS,PRINTER SPECIFICATIONS,

PERFORMANCE, ANDPERFORMANCE, AND

PERFORMANCE, AND

PERFORMANCE, ANDPERFORMANCE, AND

CONFIGURATIONCONFIGURATION

CONFIGURATION

CONFIGURATIONCONFIGURATION

1.11.1

1.1

1.11.1

This manual is for maintenance engineers, and covers overall maintenance of the Matrix Printers LA36N and

LA36W, together with detailed information such as troubleshooting and component replacement.

The information in this manual applies both to the Matrix Printer LA36N (80-column printer) and to the Matrix

Printer LA36W (136-column printer). However, illustrations are of Matrix Printer LA36N unless otherwise

stated.

Recommended references are:

• GENICOM Matrix Printer LA36 Illustrated Parts Breakdown

• GENICOM Matrix Printer LA36 User Guide ( CD-ROM )

The former contains information on location and order number of all parts needed for printer maintenance. The

latter contains general information on printer operation.

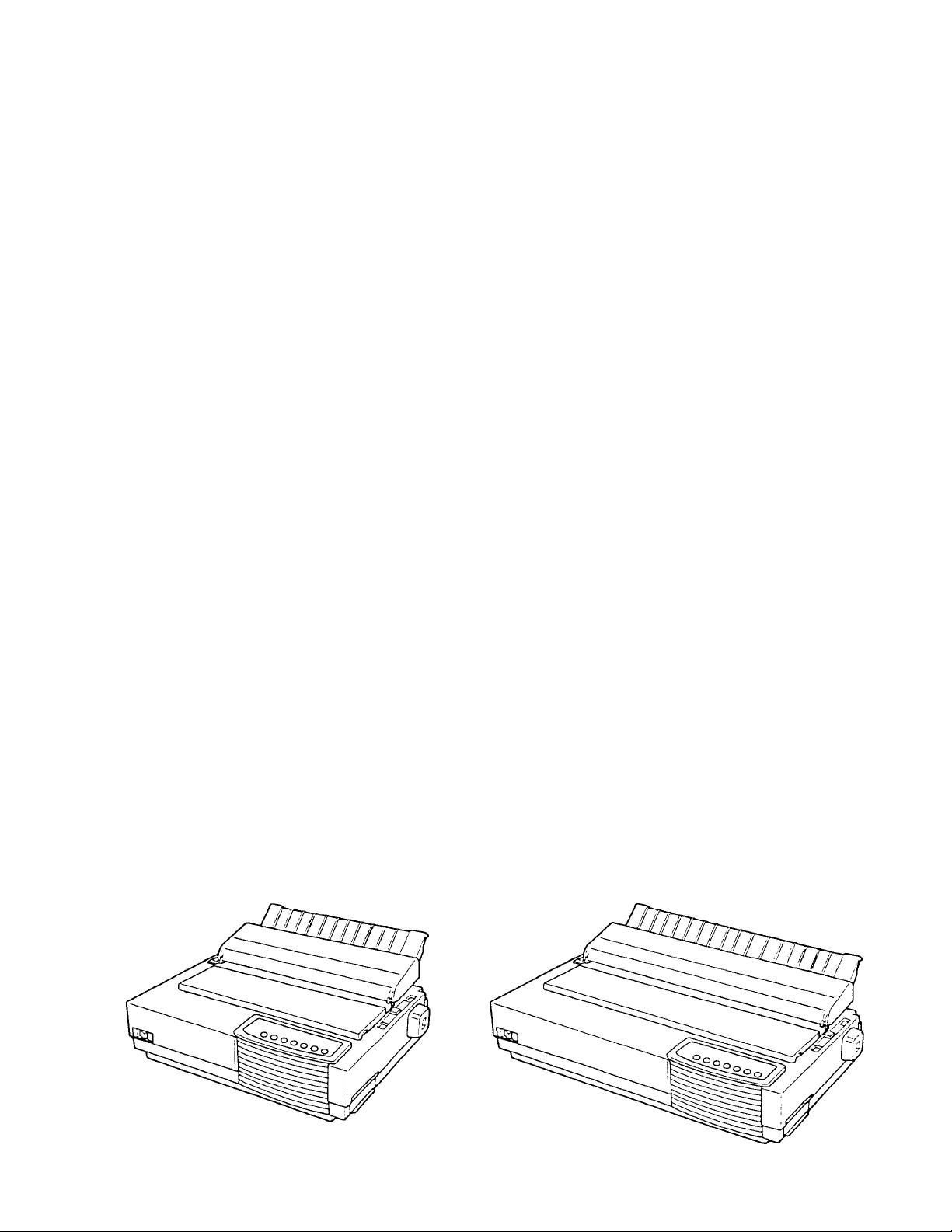

The main difference between the LA36N and the LA36W is the “ print span”. The LA36N is an 80-column

printer and the LA36W a 136-column printer. As shown in the figures below, the physical specifications are

thus different (size, weight, ...). Some minor differences concern mechanical internal parts that do not impact

the general maintenance of the printer (top cover hinges, bail rollers mechanism, ...). The only visible difference

concerns the accurate location of the notch scale of the paper thickness lever.

OverviewOverview

Overview

OverviewOverview

LA36N LA36W

Figure 1.1 LA36N and LA36W printers

1-1

1.21.2

1.2

1.21.2

Equipment StructureEquipment Structure

Equipment Structure

Equipment StructureEquipment Structure

1.2.1 Overview

This section outlines printer structure and features.

1.2.2 Model configuration

There are two basic models. The LA36N is an 80-column printer and the LA36W a 136-column printer.

Each model has two optional components: power supply and color kit (color ribbon shift mechanism).

Power supply: factory option

Color kit (consisting of a color ribbon shift mechanism and ribbon): user option

The model configuration varies with the combination of the three options, as follows:

Print span

80 columns

(LA36N)

Basic models

136 columns

(LA36W)

The monochrome model prints in color when the optional color kit is installed.

Each model has three emulations: Digital PPL2, IBM Proprinter X24E and XL24E, and Epson ESC/P2.

Each model is equipped with a dual interface: Centronics parallel and RS-423 serial (to be exact, IEEE 1284

parallel and DEC-423 serial).

Input voltage

100 to 120 VAC

220 to 240 VAC

100 to 120 VAC

220 to 240 VAC

Color

No color kit

Color kit

No color kit

Color kit

No color kit

Color kit

No color kit

Color kit

1-2

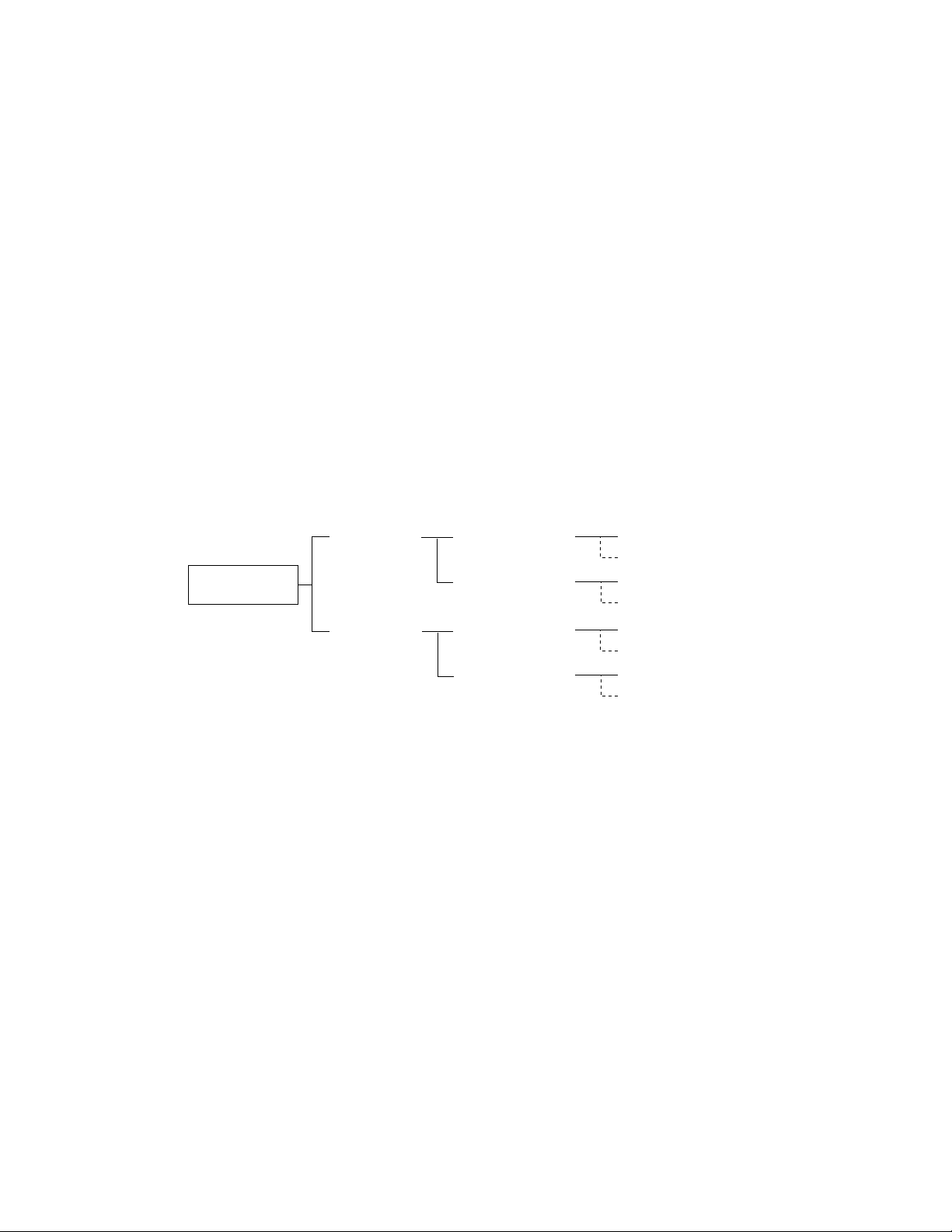

1.2.3 Structure

Major printer components are organized as shown below. Items in boldface are recommended spare parts (see

Chapter 6) that can be replaced in the field by maintenance service engineers. Replacement and adjustment are

detailed in Chapter 4.

LA36N/W printer

Upper cover assy

Upper cover

Front cover

Top cover (bail rollers are built in for LA36W)

Acoustic cover [soundproof cover]

Control panel [OP board]

Cut-sheet stand [sheet guide sub assy]

Back cover

Bail roller unit (LA36N only)

Platen knob

Tractor unit

Printing mechanism [printer mecha assy]

Frame assy

Platen assy [platen roll assy]

Carriage unit [carrier unit]

SP motor assy [space motor assy]

Stay shaft assy

Sensors

Gear assy (paper feed gear system)

Print head (consumables)

Ribbon cartridge (black or four-color, consumables)

Printer lower assy

Note:

[ ] indicates a name referred to in the

Recommended Spare Parts List.

( ) shows additional information.

Paper feeder assy (contains feed roller assy)

Card guide assy (plastic print guide)

Ribbon feed assy

Ribbon shift assy (color kit, option)

Timing belt

Carrier cable assy

Relay cable assy

Copy control lever (linked to paper thickness lever )

Sensor T assy (for cut-sheet paper end)

Paper feed motor [LF motor]

Paper select lever [change lever]

Bottom cover

ROM board [main board with ROM] (also called control board)

RS-423 board

Power supply [power unit] (also called power supply board)

(100-120 or 220-240VAC)

AC inlet assy

Figure 1.2 Printer component structure

1-3

(1) Upper cover assembly

The screws (two for the LA36N and three for the LA36W) on the back, fasten the upper cover to the bottom

cover. The upper cover assembly consists of the upper, front, and top covers, an acoustic cover, and a control

panel –– all plastic, lightweight, and sturdy. The cut-sheet stand is mounted on this assembly.

Front cover

Space motor

Upper cover

Bottom cover

Power supply

Gear assy

Control panel

Printer control board

Cut-sheet stand

Carriage unit

Tractor unit (not visible)

Acoustic cover

Top cover assy

Platen knob

Stay shaft assy

Interface connectors (not visible)

Figure 1.3 Upper cover assembly (LA36N)

a. Upper cover

The interface cable connector is located to the right side, as seen from the front of the upper cover, so that it

does not obstruct the paper feed path.

b. Front cover

The front cover is opened when the ribbon cartridge is installed.

c. Top cover

The separator directs the printed paper to the cut-sheet stand. The separator of the LA36W has bail rollers.

d. Acoustic cover

The acoustic cover helps reduce printing noise.

e. Control panel

The control panel consists of an LSI, 7 switches, 16 LEDs, and a buzzer. The switches control operations

such as forms loading and feeding, font selection, and conditions selected in setup mode. The LEDs display

printer statuses, the selected font, and a setup menu number. The buzzer sounds to indicate operating and

printer statuses.

1-4

f. Cut-sheet stand

The cut-sheet stand catches printed pages ejected by the printer. It must be raised while printing cut sheets

and laid down while printing continuous forms. It must also be raised while printing paper-stapled continuous forms in push-tractor mode.

g. Back cover

The back cover, which is installed on the cut-sheet stand, is opened to set continuous forms on the tractor

unit from the back of the printer. It must be closed while the printer is operating.

(2) Printing mechanism assembly

The two hooks on the bottom cover hold the printing mechanism in place and the two screws fasten it to the

bottom cover.

a. Frame assembly

The frame assembly consists of metal plates, a rack rail for ribbon feeding and a paper feed assembly.

b. Carriage unit

The carriage unit supports the removable 24-wire print head and endless inked-ribbon cartridge (black or

four-color), and slides back and forth on the stay shaft. The ribbon feeder (gear system) moves the ribbon in

one direction regardless of carriage movement. The color kit, consisting of a color selection shift motor and

four-color ribbon, is installed on the cartridge. One of the two sensors detects left, right, top, and bottom

edges of paper and the other detects the left end of cartridge movement and information on installed options.

c. Space motor and stay shaft assemblies

The main stay shaft and guide rail support the carriage unit, which the space motor moves horizontally

through the timing belt. The paper thickness lever rotates the eccentric main stay shaft that adjusts the gap

between the print head and platen.

d. Sensors

Three of four sensors detect paper outages and the other detects the paper select lever.

e. Forms feed mechanism

The paper feed motor drives the platen and/or the tractor unit via gears in feeding paper. The paper select

lever switches power transmission to the tractor unit.

f. Tractor unit

The convertible tractor unit is used on the back of the printer as a push tractor and on top of the printer as a

pull tractor.

Bail roller unit (LA36N only)

The bail rollers hold down paper on the platen. For the LA36W, the bail rollers are built in the top cover.

1-5

(3) Lower cover assembly

Power supply

Bottom cover

Printer control board

Figure 1.4 Printer lower assembly (LA36N)

a. Bottom cover

The bottom cover supports the printer mechanism.

b. Printer control board

The printer control board controls the host interface, control panel, and printing mechanism, using an MPU

and an LSI. Memory holds resident character patterns and firmware, including resident emulation programs. This board has drivers and receivers for other components. Sensor receivers convert signals from

sensors. Drivers supply power to motors, print head wires, and other components. It also has a Centronics

parallel interface controller and RS-423 serial interface controller.

c. Power supply

The power supply at the front of the printer outputs a constant voltage, regardless of fluctuation in input AC

line voltage, between 100 and 120 VAC or 220 and 240 VAC. It includes an AC line switch and noise

filter.

1-6

CHAPTER 2CHAPTER 2

CHAPTER 2

CHAPTER 2CHAPTER 2

The contents of this chapter are briefly reproduced from the Setting the Installation Guide for reference in

maintenance although the contents are originally for users of the LA36N and LA36W printers.

UNPACKING, PERFORMANCE CHECK,UNPACKING, PERFORMANCE CHECK,

UNPACKING, PERFORMANCE CHECK,

UNPACKING, PERFORMANCE CHECK,UNPACKING, PERFORMANCE CHECK,

AND CONNECTIONAND CONNECTION

AND CONNECTION

AND CONNECTIONAND CONNECTION

2.12.1

2.1

2.12.1

The LA36N and LA36W printers come packed for transportation.

After unpacking and before installation, the printer must undergo self-test printing. Installation requires minimum time and expense.

2.22.2

2.2

2.22.2

For best results, note the following points when installing the printer:

• Place the printer on a level, vibration-free surface.

• Keep the printer away from sunlight and heaters.

• Be sure printer ventilation ports are not blocked.

• Do not operate the printer in a humid or dusty environment.

• Use an outlet that is separated from noise-generating equipment such as motors.

• Use the correct AC voltage to avoid unexpected problems.

• Be sure the platen knob is able to turn freely during printer operation. Obstructions may cause incorrect

OverviewOverview

Overview

OverviewOverview

Notes on InstallationNotes on Installation

Notes on Installation

Notes on InstallationNotes on Installation

printing.

2-1

2.32.3

2.3

2.32.3

Unpack the printer as follows (Figure 2.1):

1. Open the carton and remove accessories — the Installation guide, CD-ROM, cut-sheet stand, platen knob,

2. Lift out the printer together with its packing cushions (not shown in the figure). Remove cushions and place

UnpackingUnpacking

Unpacking

UnpackingUnpacking

power cord (100 –120 or 220 –240 VAC), serial interface cable, and ribbon cartridge.

the printer carefully on a level, vibration-free surface.

Ribbon

cartridge

CD-ROM

(User guide &

Printer driver)

Serial interface

cable

Shipping

carton

Printer

(LA36N)

Power cord

Cut-sheet stand

Platen

knob

Installation

guide

Figure 2.1 Unpacking the printer and accessories

2-2

3. Remove tape securing the acoustic cover. Adhesive tape is applied along the front edge of the acoustic

cover. For LA36W printers, two adhesive tapes are applied at the back of the acoustic cover.

4. Open the front cover and remove the print head shipping restraint (cardboard).

Cardboard

Front cover

Figure 2.2 Removing the print head shipping restraint (cardboard)

5. At the back of the printer, remove the two tractor unit securing adhesive tapes [A]. For LA36N printers,

remove also the bail unit shipping restraints (two adhesive tapes [B] and a cardboard [C]).

B

C

A

Figure 2.3 Remove the bail stopper and four tapes (LA36N)

6. Store the original shipping carton and packaging materials for future use, for example, in moving or

shipping the printer to another location.

2-3

2.42.4

2.4

2.42.4

1. Carefully check the printer and the accessories for visible damage.

2. Install the cut-sheet stand (Figure 2.4). The cut-sheet stand enables smooth feeding of not only cut sheets

3. Install the platen knob.

4. Install the ribbon cartridge. See the Installation Guide for details.

5. Check the rated voltage for the printer and AC power outlet, then connect the AC power cord between the

6. Close the front cover.

7. Turn on the power switch.

8. Load a cut sheet or continuous forms as explained in the Installation Guide.

Inspection after UnpackingInspection after Unpacking

Inspection after Unpacking

Inspection after UnpackingInspection after Unpacking

but continuous forms, and its paper guides position cut sheets for printing.

printer and AC power outlet.

Check printing performance and quality using self-test printing, detailed in Section 4.10.1 “Self-test printing”.

Mounting pins

Cut-sheet stand

Paper guides

Figure 2.4 Installing the cut-sheet stand

2-4

CHAPTER 3CHAPTER 3

CHAPTER 3

CHAPTER 3CHAPTER 3

This chapter helps pinpoint the causes of problems with the printer.

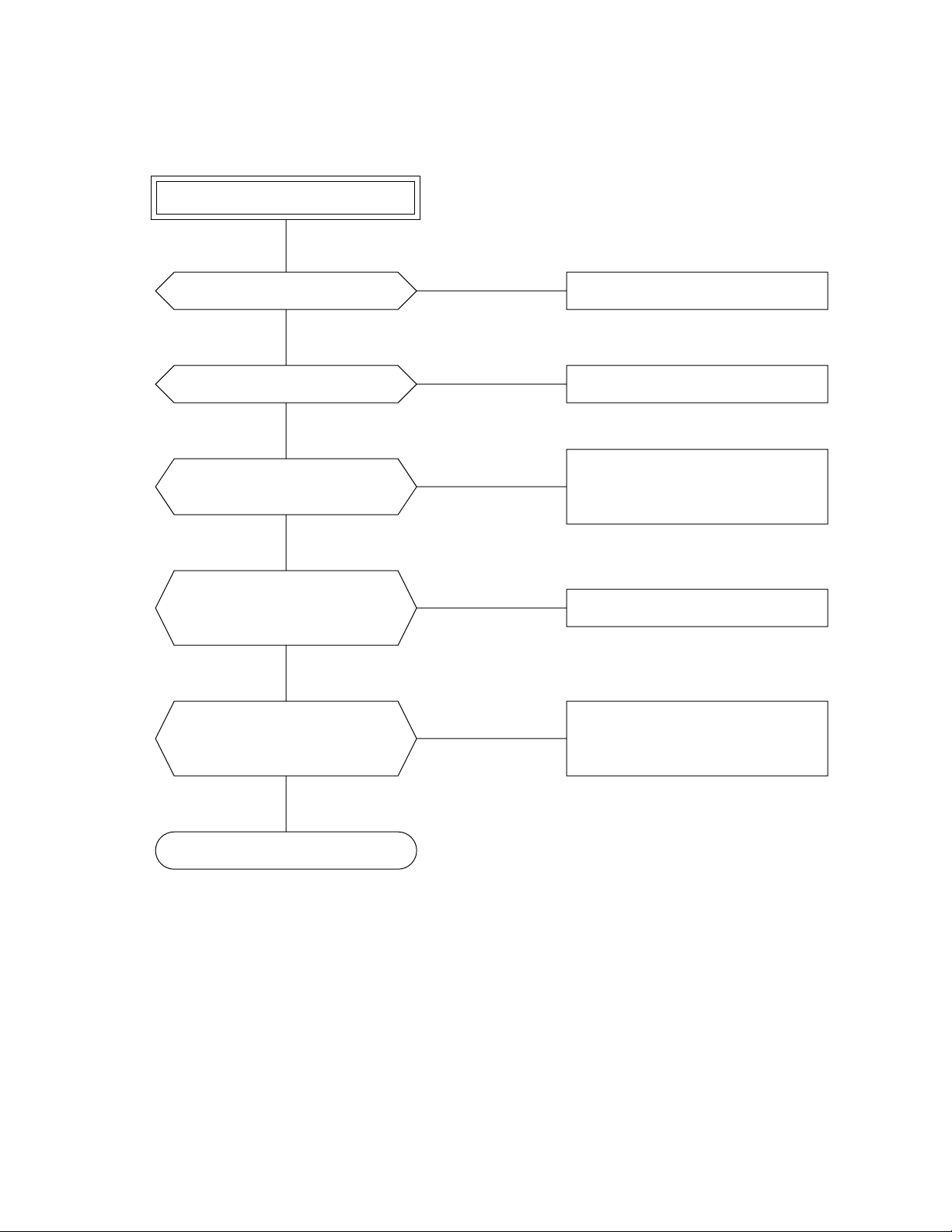

Sections 3.1 to 3.5 are troubleshooting diagrams. The flowcharts show how to determine what is wrong with the

printer and what to do to correct the problem.

Section 3.6 explains error displays on the control panel that help clarify the cause of a problem.

For replacement and adjustment after recovery, see Chapter 4.

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

3-1

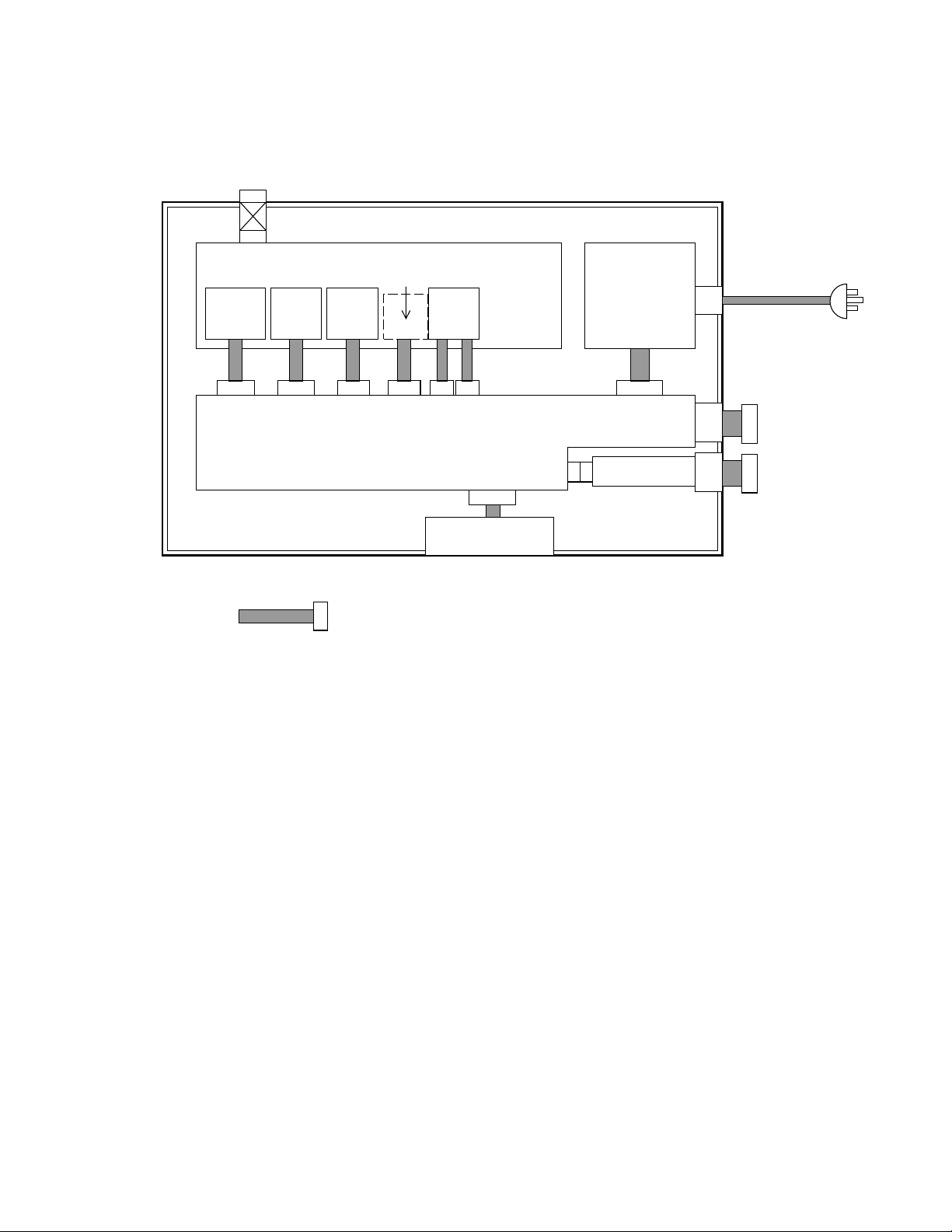

Figure 3.1 shows printer functional components and connecting cables without showing their names since

locating the connectors is easy.

Printer

Gears

Printing mechanism Color ribbon

shift motor

Sensors

LF

motorSPmotor

Printer control board

Note:

indicates a cable and connector.

Figure 3.1 Printer functional block diagram

Print

head

Control panel

100-120 VAC or

220-240 VAC

Power supply

Centronics (parallel)

To computer

RS-423 board

RS-423 (serial)

a. Printing mechanism

The printing mechanism consists of the print head and carriage, carriage drive, forms feed mechanism,

sensors, and print head gap adjustment mechanism. The carriage includes ribbon feed and other sensors.

The printing mechanism has two motors, for driving the carriage and feeding forms.

b. Printer control board

The printer control board consists of a main controller, memory, drivers, sensor receivers, and Centronics

parallel interface controller. This board governs the computer interface, control panel, and printing mechanism using the main controller and memory that holds resident character patterns and firmware, including

resident emulation programs.

c. RS-423 board

The RS-423 board controls the RS-423 (DEC-423) serial interface.

d. Control panel

The control panel is used by the operator for operations such as changing or feeding forms, resetting the

printer, and selecting operating conditions in setup mode. The panel displays the printer status via a buzzer

and LEDs.

3-2

e. Power supply

The power supply provides power for operating the printer. Its specifications depend on the input AC

voltage.

f. Color ribbon shift motor (user option)

The color ribbon shift motor, installed on the print head cartridge, enables printing in seven colors, if

supported by software. It uses either four-color cartridges or black ribbon cartridges.

3-3

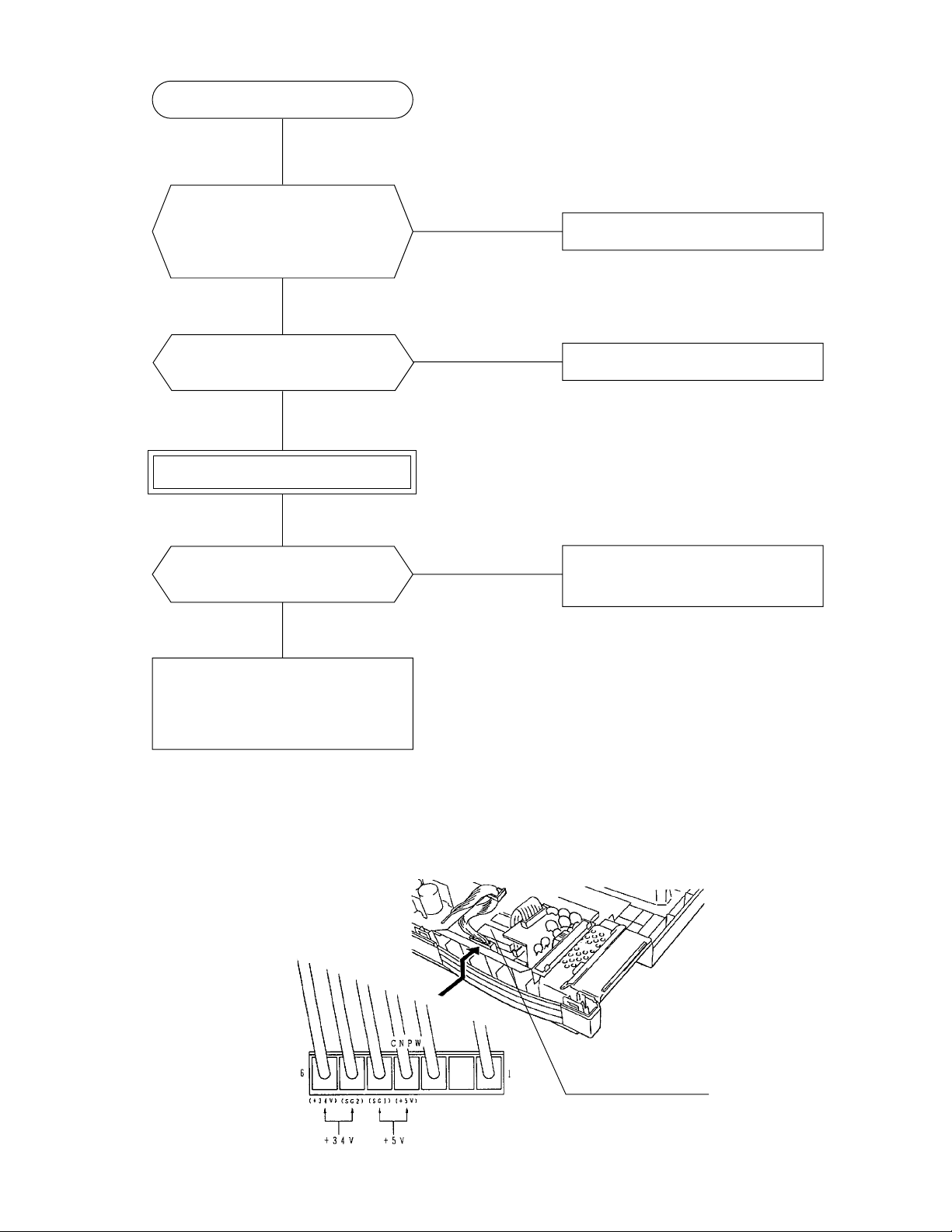

3.13.1

3.1

3.13.1

The flowchart below shows what to do if all indicators don’t light.

All Indicators Don't LightAll Indicators Don't Light

All Indicators Don't Light

All Indicators Don't LightAll Indicators Don't Light

All indicators don’t light.

Does the mechanism move?

No

Is the power switch turned on?

Yes

Is the power plug disconnected

from the receptacle?

No

Turn off the power switch, and then

remove the AC fuse.

Is the fuse blown?

No

Is the AC output voltage from the

receptacle to the printer power inlet

correct? (Check the AC voltage.)

Yes

No

Yes

Yes

No

The control panel is defective.

Turn on the power switch.

Turn off the power switch, then

insert the power plug into the

receptacle.

Replace the AC fuse.

Correct the problem and make the

output live, or plug the printer into

a different receptacle.

Yes

To the next page

3-4

Continued from the previous page

Unplug the AC input cord from

the printer power connector, then

check again AC voltage supplied

to the printer. Is it correct?

Yes

Are all connectors to the printer

control board connected?

Yes

Do voltage check.

Is DC output voltage of the power

supply board correct?

No

No

No

Yes

Replace the AC power cord.

Connect connectors.

Defective PC board

• Defective printer control board

• Defective control panel

Defective PC board

• Defective printer control board

• Defective control panel

• Defective power supply unit

$ Note:

To check DC voltage, use the output connector to the printer control board. Pin assignment of voltages

are as follows:

Output connector

Printer control board

3-5

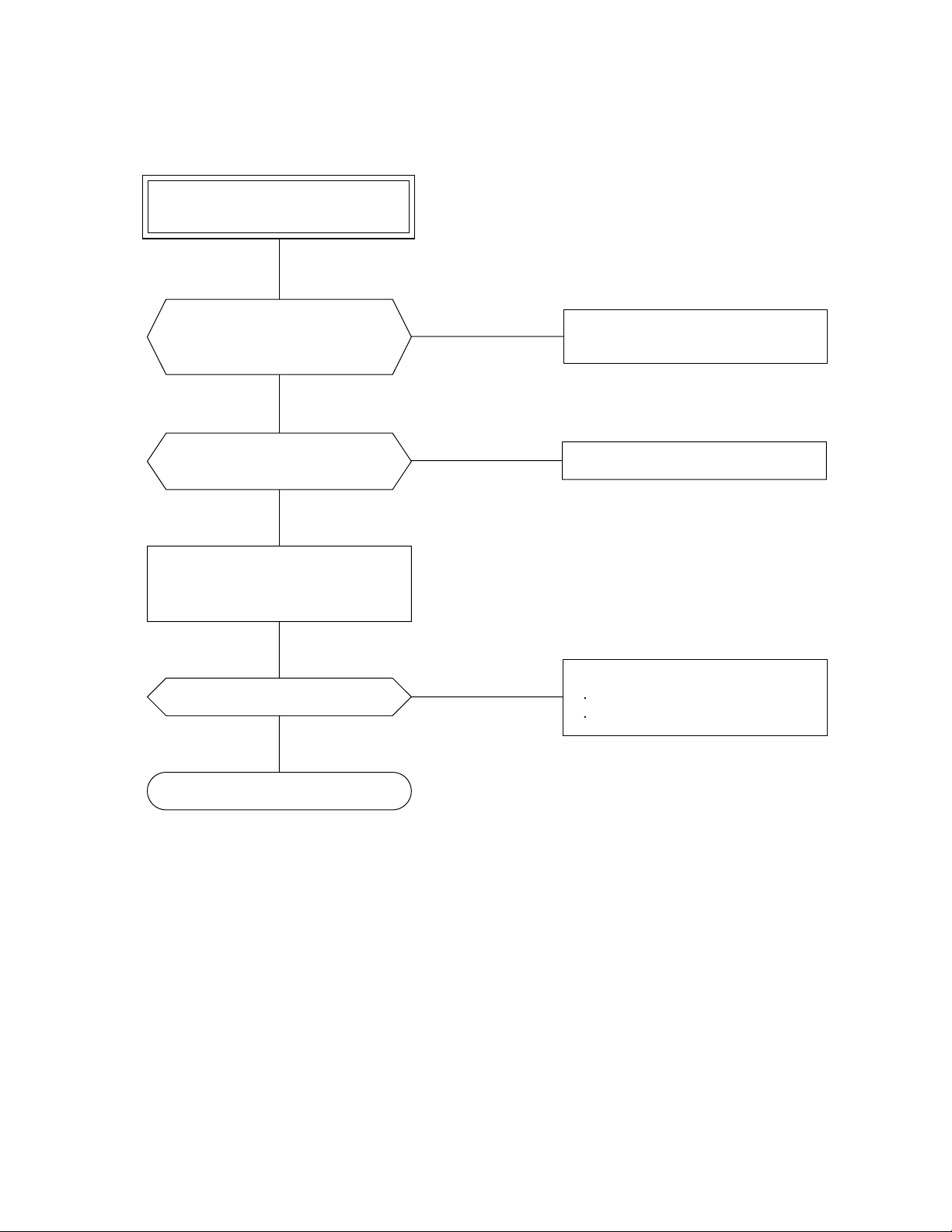

3.23.2

3.2

3.23.2

The flowchart below shows what to do if the print head does not move even though certain indicators light.

No Print Head MovementNo Print Head Movement

No Print Head Movement

No Print Head MovementNo Print Head Movement

The Fault indicator lights but

the print head does not move.

Does the buzzer sound continuously?

No

Are all connectors to the printer

control board connected?

Yes

Turn off the power switch, unplug

the interface cable, and turn on the

power switch again.

Does the print head move?

No

Yes

No

Yes

Defective printer control board

(ROM/RAM error)

Connect connectors.

Defective host

Defective host computer

Defective interface cable

See page 3-5, DC voltage check.

3-6

The Fault indicator lights and the buzzer sound once.

Are continuous forms in the printer?

No

Set continuous forms in the printer

and press the FF/Load button.

Is the Fault indicator off?

No

Push and release the paper end feeler

equipped on the right-hand tractor.

Yes

Yes

Recovered

Does the sensor shield lever move

up and down?

Yes

Are the paper end sensor block

dusty with paper particles?

No

See page 3-5, DC voltage check.

No

Yes

Replace the paper end detection

link mechanism.

Clean the sensor block.

3-7

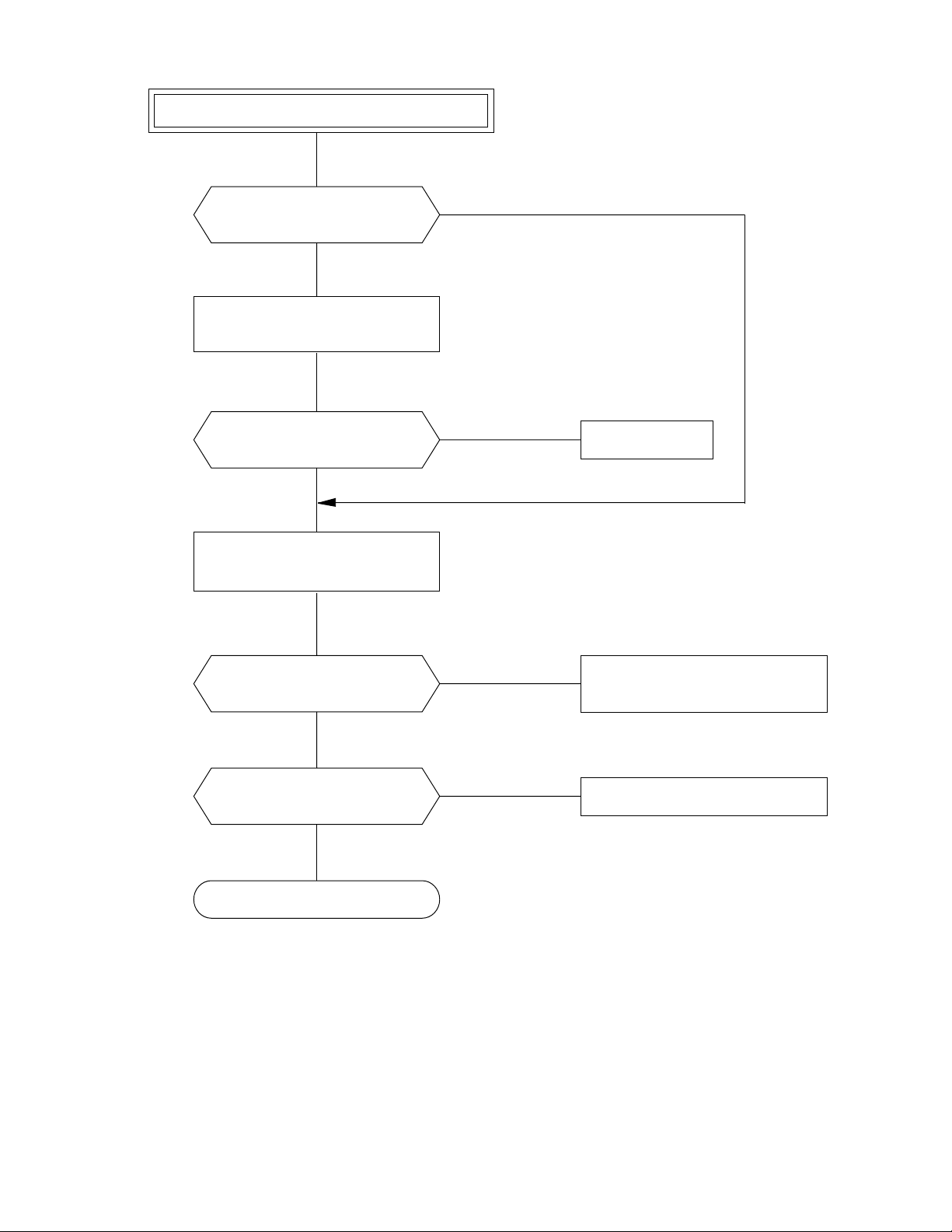

No printing online

Is the interface cable connected?

Yes

Is the interface cable OK?

Yes

Is the RS-423 interface used?

Yes

Is the selected protocol OK?

Yes

Is the selected baud rate OK?

Yes

No

Connect the interface cable.

No

Replace the interface cable.

No (Centronics)

See page 3-5, DC voltage check.

No

Use the correct protocol.

No

Use the correct baud rate.

Is the selected data length OK?

Yes

Is the selected data format OK?

Yes

See page 3-5, DC voltage check.

No

Use the correct data length.

No

Use the correct data format.

3-8

3.33.3

3.3

3.33.3

If the printer uses defective nonvolatile RAM or the contents of nonvolatile RAM are written incorrectly,

unexpected phenomena will occur. For example:

• Printing is not performed even though no error is apparently detected. This may be caused when the interface

• Printing is not done in specified columns. This may be caused when setup parameters are mistakenly

For the above cases, do as follows:

1. Restore the factory defaults into the RAM. See Section 4.10.3.

2. If the printer still does not operate correctly, replace the control board (ROM board).

Incorrect Printing due to Defective Nonvolatile RAMIncorrect Printing due to Defective Nonvolatile RAM

Incorrect Printing due to Defective Nonvolatile RAM

Incorrect Printing due to Defective Nonvolatile RAMIncorrect Printing due to Defective Nonvolatile RAM

type specified is the Centronics parallel, but the RS-423 serial interface is mistakenly selected internally.

changed internally for the character pitch.

3-9

Loading...

Loading...