Genicom 5180, 5100, 5050 User Manual

Models

5050, 5100, 5180

User’s

Manual

GEK-99032

genicom

Line Printers

GENICOM Confidential

Duplication Prohibited

Without Written Authorization

GEK-99043

FCC COMPLIANCE STATEMENT (USA)

This equipment complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

! Reorient or relocate the receiving antenna.

! Increase the separation between the equipment and receiver.

! Connect the equipment to an outlet on a circuit different from

that to which the receiver is connected.

! Consult the dealer or an experienced radio/TV technician for

help.

FCC warning: Changes or modifications not expressly approved by

the party responsible for compliance could void the user’s authority

to operate the equipment.

Note the following:

! The use of a non-shielded interface cable with the referenced

device is prohibited.

! The length of the parallel interface cable must be 3 meters (10

feet) or less.

! The length of the serial interface cable must be 15 meters (50 feet)

or less.

! The length of the power cord must be 3 meters (10 feet) or less.

COMPLIANCE STATEMENT (CANADA)

This digital apparatus is in conformity with standard NMB-003 of

Canada.

Cet appareil numérique est conforme à la norme NMB-003 du

Canada.

COMPLIANCE STATEMENT (GERMANY)

Bescheinigung des Herstellers/Importeurs

Hermit wird bescheinigt, daß der/die/das

Machinenlärminformationsverordnung 3. GSGV, 18.01.1991: Der

höchste

Schalldruckpegel beträgt 70 dB (A) oder weniger gemäß EN27779-

1991.

GEK-99044 i Preface

COMPLIANCE STATEMENT (EUROPE)

Warning

This product meets the interference requirements of EN55022.

In a domestic environment, this product may cause radio

interference in which case, the user may be required to take

adequate measures.

Optional Interface Kits

If either of the Ethernet interface board, Token ring interface board,

IBM TX/CX interface board, or any variation of the Legacy parallel

board is installed in either or both of the interface expansion slots,

this equipment may produce additional radio frequency interference

in compliance with FCC Class A emissions.

Si des panneaux d’interface d’Ethernet, panneau de token ring,

panneau d’IBM TX/CX, ou n’importe quelle variation des panneaux

de parallèle de legs est installé dans l’un ou l’autre ou tous les deux

emplacements d’interface, ce matérial peut produire l’interférence

F.R. upplémentaire conformément ICES-003 aux émissions de la

classe A.

Falls Ethernet, Token ring, IBM TX/CX, Schnittstellenkarten oder

eine variation der herkoemmlicken Parallelscnittstellenkarten

(interface) in einer oder beiden steckbaren Erweiterungsschnittstellen

installiert sind, koennen moeglicherweise zusaetzliche

Funkfrequenzstoerungen erzeugt werden, unter Einhaltung der

EN55022 Klasse A Stoerstrahlungswerte.

ENERGY STAR

As an ENERGY STAR ® Partner, GENICOM has determined that this

product meets the ENERGY STAR ® guidelines for energy efficiency.

The International ENERGY STAR ® Office Equipment Program is an

international program that promotes energy saving through the use

of computers and other office equipment. The program backs the

development and dissemination of products with functions that

effectively reduce energy consumption. It is an open system in which

business proprietors can participate voluntarily. The targeted

products are office equipment such as computers, displays, printers,

facsimiles, and copiers. Their standards and logos are uniform among

participating nations.

INTERNATIONAL COMPLIANCE

EN5008-1:1993 EN55022:1994

EN50082-1:1997 EN61000-4-2:1995

EN61000-4-3:1994

EN61000-4-4:1995

EN61000-4-5:1995

EN61000-4-6:1994

5000 Series User’s Manual GEK-99044

ii

Trademark Acknowledgements

GENICOM is a registered trademark of GENICOM Corporation. The

following companies own the other trademarks used in this manual:

GENICOM Corporation: Centronics;

International Business Machines Corporation: IBM;

Epson Corporation: Epson;

All other product names mentioned in this manual may also be

trademarks of their respective companies.

GEK-99044 iii Preface

Operating Precautions

Read this section and remember these instructions to ensure user

safety and the printer’s correct performance. Follow the cautions and

notices labeled on the printer or marked in the manual. Save this

manual for future reference.

! Use only the power cord furnished with the printer and a properly

grounded outlet. Do not use an extension power cord.

! Confirm that the rated voltage of the printer matches the voltage

of the power outlet where the printer will be connected.

! The maximum wattage of these printers is as follows:

Model 5050 printer: 400 watts.

Model 5100 printer: 524 watts.

Model 5180 printer: 1167 watts.

! Turn off the printer and disconnect the power cord before

beginning maintenance.

! Disconnect the power cord from the outlet when the printer is not

used over an extended period of time.

! Disconnect the power cord from the outlet whenever

thunderstorms are nearby. Leaving the power cord connected

may damage the printer or other property.

! Do not put the printer in direct sunlight, near a heater, or near

water. Leave adequate space around the printer.

! Use only a shielded interface cable 3 meters (10 feet) or less for

the parallel interface, 15 meters (50 feet) or less for the serial

interface, 100 meters (328 feet) or less for Ethernet interface

10Base-T connection, and 185 meters (607 feet) or less for the

Ethernet interface 10Base-2 connection.

! Be sure the printer is turned off before connecting any interface.

! Do not turn the printer off while it is printing.

! Do not disassemble or remove any components unless instructed

in the maintenance procedures.

! Keep the printer unit upright when removing or installing it.

! Do not drop small objects, such as paper clips, into the printer.

! Do not set page margins off the physically printable page area.

! Turn off the printer and disconnect the power cord immediately if

an abnormal condition occurs: for instance, if the printer emits

smoke, prints abnormally, becomes wet, or falls. For additional

information, contact the GENICOM authorized dealer, where the

printer was purchased.

5000 Series User’s Manual GEK-99044

iv

TABLE OF CONTENTS

FCC COMPLIANCE STATEMENT (USA).......................................................................................................i

C

OMPLIANCE STATEMENT (CANADA

COMPLIANCE STATEMENT (GERMANY

COMPLIANCE STATEMENT (EUROPE

) ...................................................................................................................i

) .................................................................................................................i

)................................................................................................................... ii

Optional Interface Kits.................................................................................................................................. ii

E

NERGY STAR

I

NTERNATIONAL COMPLIANCE

.................................................................................................................................................... ii

........................................................................................................................... ii

Trademark Acknowledgements..................................................................................................................... iii

Operating Precautions ..................................................................................................................................iv

TABLE OF CONTENTS.....................................................................................................................................v

CHAPTER 1.INTRODUCTION .................................................................................................................... 1-1

R

EFERENCE USAGE

O

RGANIZATION OF THIS MANUAL

:......................................................................................................................................... 1-2

.................................................................................................................... 1-2

CHAPTER 2.GETTING STARTED.............................................................................................................. 2-1

P

REPARING THE PRINTER FOR OPERATION

C

ONNECTING THE POWER CORD

C

ONNECTING THE INTERFACE CABLE

..................................................................................................................... 2-1

...................................................................................................... 2-1

.............................................................................................................. 2-2

I/O Interface Card Options available......................................................................................................... 2-3

D

ESCRIPTION OF THE CONTROL PANEL

........................................................................................................... 2-3

Beeper......................................................................................................................................................... 2-4

Display........................................................................................................................................................ 2-5

Pushbuttons ................................................................................................................................................ 2-5

O

PERATION OF THE CONTROL PANEL

.............................................................................................................. 2-5

Data Entry .................................................................................................................................................. 2-6

I

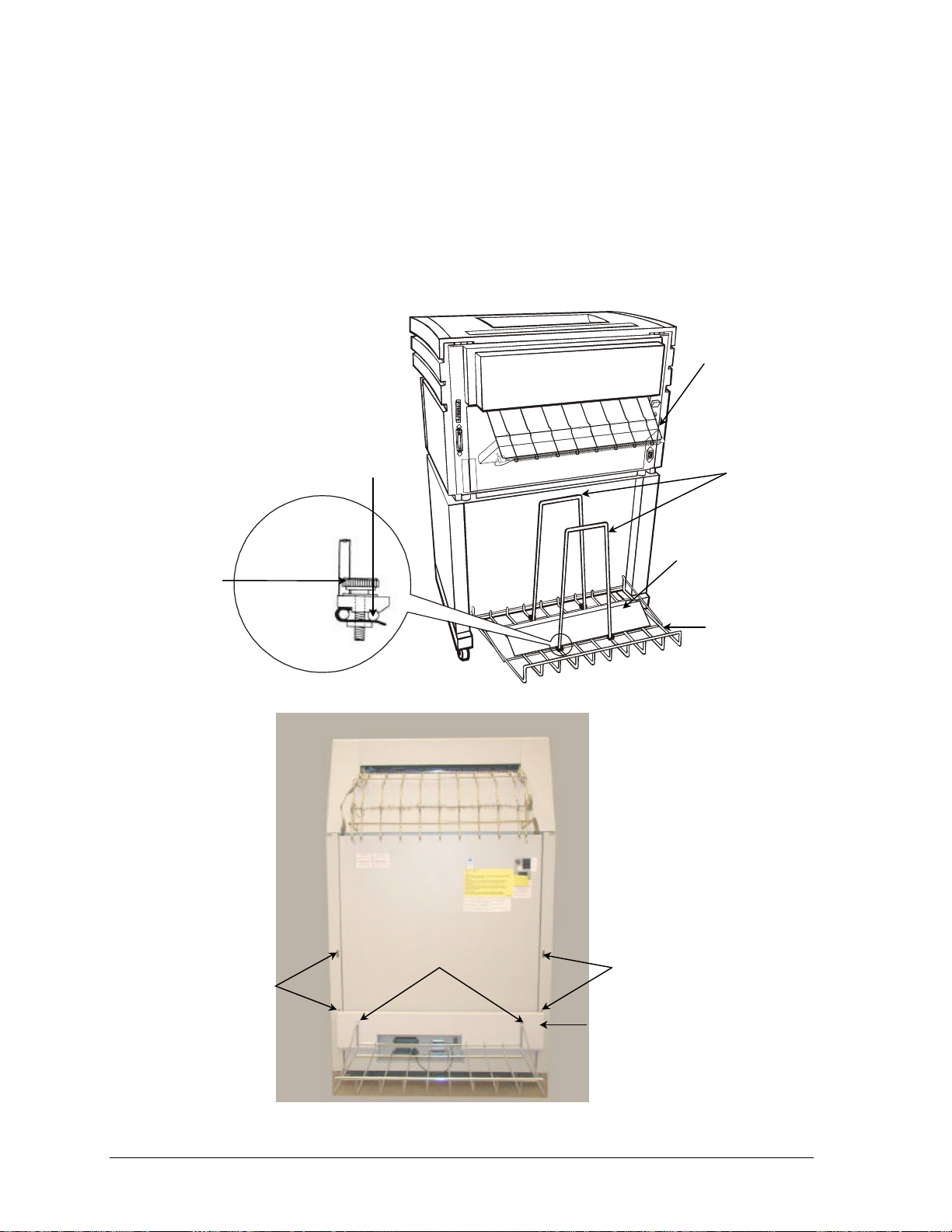

NSTALLING THE PAPER HANDLING SYSTEM

(55

OR

60

DBA

CABINET

MODELS

) ............................................................................................................... 2-8

................................................................................................... 2-8

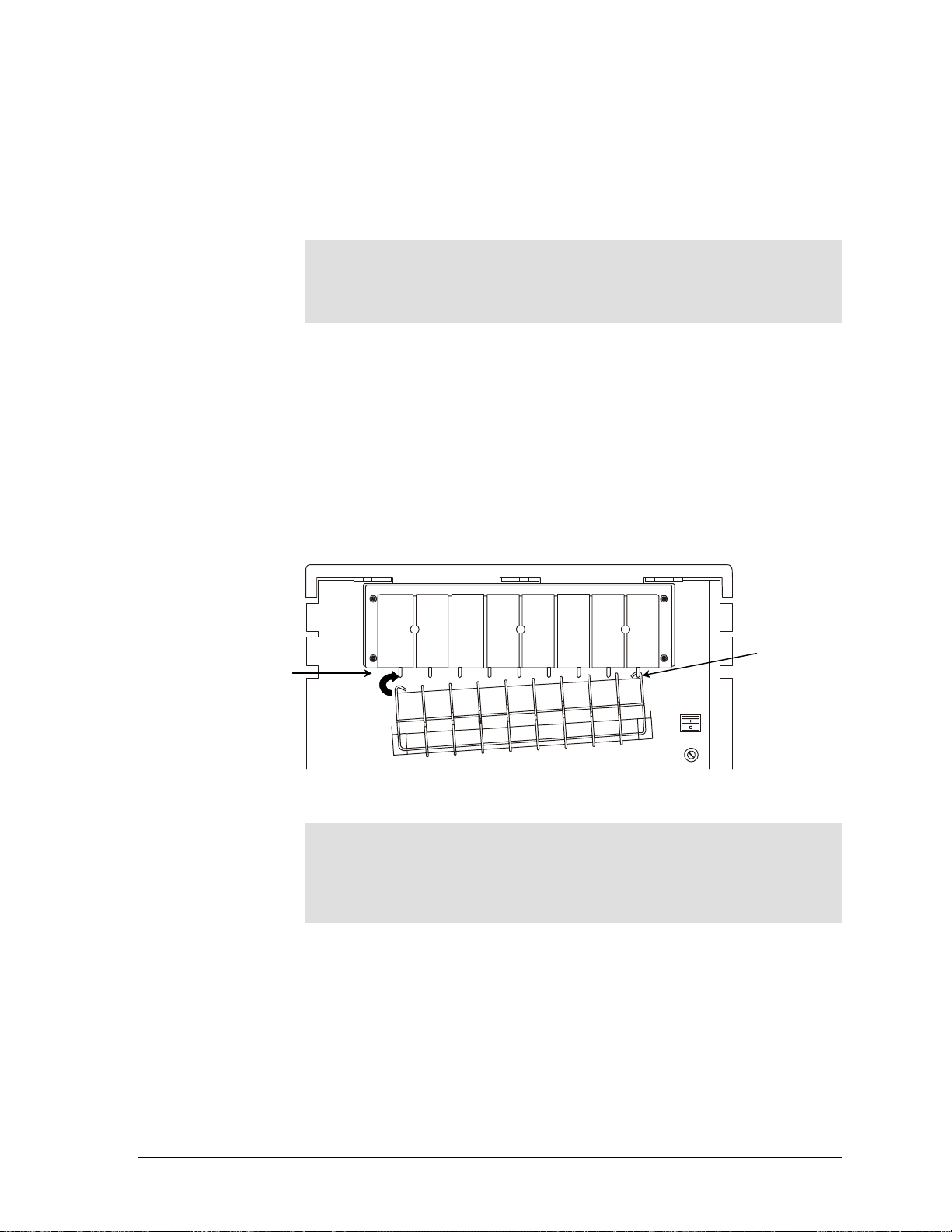

Paper Handling Aids (55 dBa) Cabinet Models....................................................................................... 2-11

S

ELECTING THE PAPER PATH

5050/5100 (55

60 DBA) CABINET M

AND

......................................................................................................................... 2-11

ODEL ONLY

............................................................................... 2-11

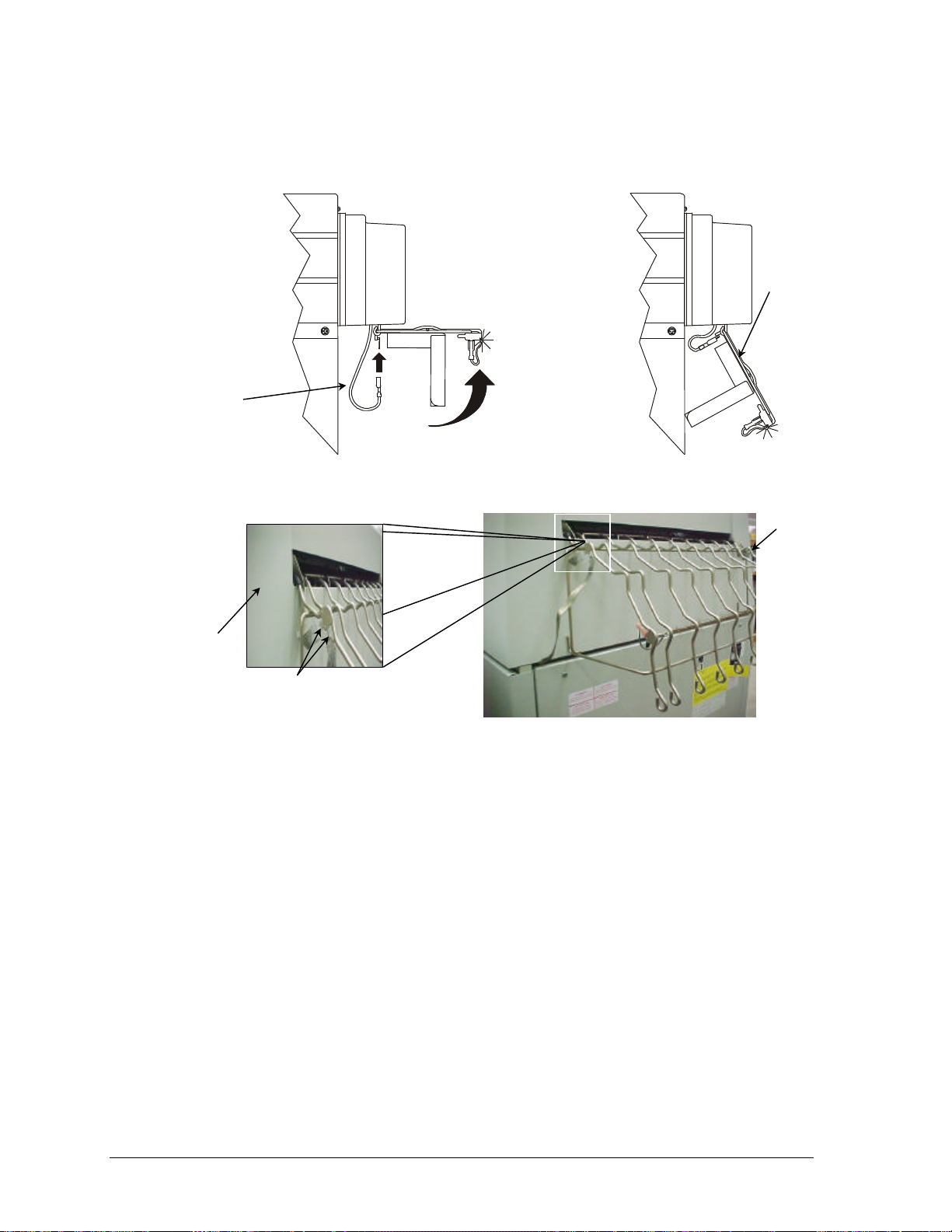

Wire Paper Guide..................................................................................................................................... 2-12

L

OADING PAPER

............................................................................................................................................ 2-14

Manual Paper Loading............................................................................................................................. 2-14

Semiautomatic Paper Loading ................................................................................................................. 2-18

H

ORIZONTAL POSITIONING OF THE PAPER

T

HE RIBBON DECK

5050/5100 (55

T

HE RIBBON DECK

5180 (52 OR 55

THE RIBBON CARTRIDGE

5050/5100 (50,55

RIBBON REMOVAL AND INSTALLATION

5050/5100 (50,55

........................................................................................................................................ 2-20

60 DBA)

OR

CABINET MODEL

........................................................................................................................................ 2-21

) C

DBA

ABINET MODEL

............................................................................................................................... 2-22

60 DBA) C

OR

60 DBA)

OR

ABINET MODEL

CABINET M

..................................................................................................... 2-19

................................................................................................ 2-20

....................................................................................................... 2-21

........................................................................................... 2-22

.......................................................................................................... 2-22

ODEL ......................................................................................... 2-22

Removing a Ribbon (50,55, or 60 dBa) Cabinet Model ........................................................................... 2-25

RIBBON REMOVAL AND INSTALLATION

5180 (52

S

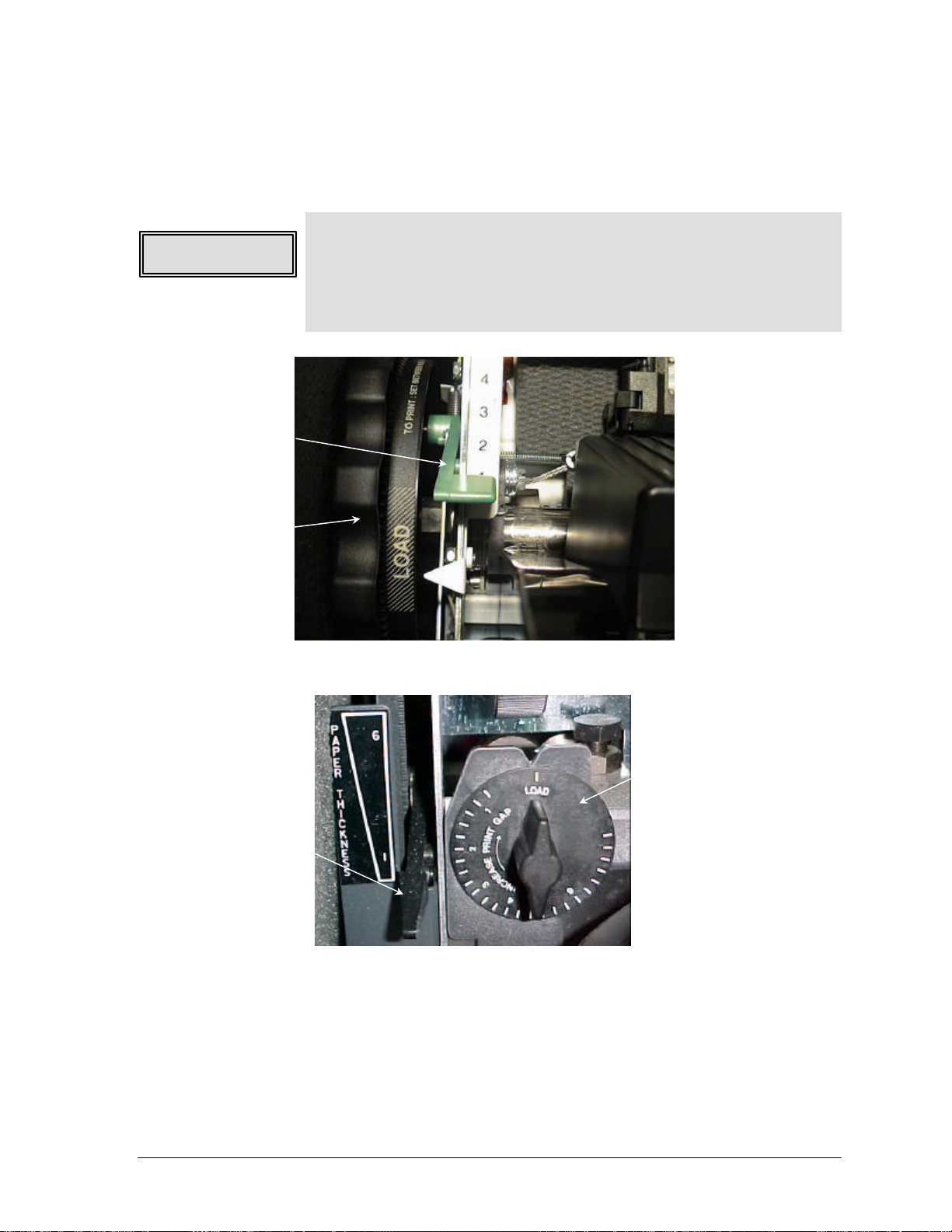

ETTING THE PRINT GAP

55 DBA)

OR

CABINET M

............................................................................................................................... 2-27

.......................................................................................................... 2-25

ODEL ....................................................................................................... 2-25

Reading the Scale ..................................................................................................................................... 2-27

Using the White Scale ............................................................................................................................................2-27

Using the Black Scale............................................................................................................................................. 2-28

P

APER TENSION ADJUSTMENT

....................................................................................................................... 2-28

GEK-99044 Table of Contents

v

P

OWER-ON SEQUENCE

I

NTERLOCK CIRCUIT

.................................................................................................................................. 2-29

...................................................................................................................................... 2-29

5050/5100 (55 or 60 dBa) Cabinet Model................................................................................................ 2-30

5180 (55 dBa) Model................................................................................................................................ 2-31

Top Access Door Interlock Switch......................................................................................................................... 2-31

Print Module Access Panel AC Interlock Switch ...................................................................................................2-31

I

NITIALIZING THE PRINTER

............................................................................................................................ 2-32

When to Initialize...................................................................................................................................... 2-32

U

SING THE KEYPAD TO INITIALIZE

................................................................................................................ 2-32

Control Panel Initialization...................................................................................................................... 2-32

TEST PATTERN PRINTING

................................................................................................................................2-33

CHAPTER 3.OPERATING THE PRINTER ................................................................................................ 3-1

P

RINTER OPERATIONAL MODES

....................................................................................................................... 3-1

Online ......................................................................................................................................................... 3-1

Offline ......................................................................................................................................................... 3-1

Fault ........................................................................................................................................................... 3-1

Menu........................................................................................................................................................... 3-1

Status Display........................................................................................................................................................... 3-1

M

AIN MENU

.................................................................................................................................................... 3-2

Operator Menu ........................................................................................................................................... 3-2

Setup Menu ................................................................................................................................................. 3-2

Maintenance Menu ..................................................................................................................................... 3-2

Menu Control.............................................................................................................................................. 3-3

S

ETTING UP A FORMAT

.................................................................................................................................... 3-3

Active Format ............................................................................................................................................. 3-3

Setting up an Active Format ....................................................................................................................... 3-4

Form Length ............................................................................................................................................... 3-4

Top Margin................................................................................................................................................. 3-4

Bottom Margin............................................................................................................................................ 3-4

Top Print Ref ..............................................................................................................................................3-4

Explanation of the Top Print Ref..............................................................................................................................3-5

Example.................................................................................................................................................................... 3-5

L

OW PAPER PRINTING

..................................................................................................................................... 3-7

Low Paper .................................................................................................................................................. 3-7

Replenishing Paper Supply......................................................................................................................... 3-7

S

ETTING TOP OF FORM

P

APER TEAR-OFF FEATURE

..................................................................................................................................... 3-8

............................................................................................................................. 3-9

Paper Path (5050/5100 (55 or 60 dBa) Cabinet Model Only) ................................................................... 3-9

Number of Forms Ejected........................................................................................................................... 3-9

Special Forms........................................................................................................................................... 3-10

L

OCAL AUTO VIEW FEATURE

........................................................................................................................ 3-12

Viewing ..................................................................................................................................................... 3-12

Retracting ................................................................................................................................................. 3-12

U

SING THE MENU CONTROL MENU

................................................................................................................ 3-12

CHAPTER 4.USING THE OPERATOR MENU.......................................................................................... 4-1

EW RIBBON

N

S

ELECT FORMAT

F

ONT STYLE

C

HAR SET/COUNTRY

................................................................................................................................................... 4-1

............................................................................................................................................. 4-1

.................................................................................................................................................... 4-2

....................................................................................................................................... 4-3

Character Set.............................................................................................................................................. 4-3

Country....................................................................................................................................................... 4-4

S

CPI..................................................................................................................................................... 4-4

ELECT

Select CPI (User Set).................................................................................................................................. 4-4

S

5000 Series User’s Manual GEK-99044

LPI ..................................................................................................................................................... 4-5

ELECT

vi

Select LPI (User Set) .................................................................................................................................. 4-5

I

NTERFACE

E

MULATION

F

ILTER

...................................................................................................................................................... 4-6

..................................................................................................................................................... 4-6

............................................................................................................................................................. 4-7

Serial .......................................................................................................................................................... 4-7

Parallel(1284) ............................................................................................................................................ 4-8

Expansion1/Expansion2 ............................................................................................................................. 4-9

S

.............................................................................................................................................................. 4-9

HOW

Software IDs............................................................................................................................................. 4-10

Sample Status Page .................................................................................................................................. 4-11

Sample Format Page ................................................................................................................................ 4-14

Sample Character Set............................................................................................................................... 4-15

Sample Font Page .................................................................................................................................... 4-15

A

TOF ................................................................................................................................................. 4-17

DJUST

Print At TOF............................................................................................................................................. 4-17

Set TOF..................................................................................................................................................... 4-18

Rolling ASCII ........................................................................................................................................... 4-18

D

ISCARD JOB

................................................................................................................................................. 4-18

CHAPTER 5.USING THE SET UP MENU .................................................................................................. 5-1

ORMAT

.......................................................................................................................................................... 5-1

F

Modify Format............................................................................................................................................ 5-2

Format Name............................................................................................................................................................5-2

Font Style..................................................................................................................................................................5-2

CharSet/Country....................................................................................................................................................... 5-3

Character Set ........................................................................................................................................................ 5-3

Country.................................................................................................................................................................5-3

CPI............................................................................................................................................................................ 5-4

LPI............................................................................................................................................................................5-4

Form Length ............................................................................................................................................................. 5-5

Top Margin............................................................................................................................................................... 5-5

Bottom Margin .........................................................................................................................................................5-6

Left Margin...............................................................................................................................................................5-6

Right Margin ............................................................................................................................................................5-7

Top Print Ref ............................................................................................................................................................5-8

Left Print Ref............................................................................................................................................................ 5-9

Horiz Expansion ....................................................................................................................................................... 5-9

Vert Expansion ....................................................................................................................................................... 5-10

VertExp Options.....................................................................................................................................................5-10

Print Modifiers........................................................................................................................................................5-11

Print Options...........................................................................................................................................................5-11

Slew Rate................................................................................................................................................................ 5-12

Save Format ............................................................................................................................................. 5-12

H

ORIZ TAB

V

ERTICAL FORMAT

.................................................................................................................................................... 5-13

....................................................................................................................................... 5-13

Vertical Tabs ............................................................................................................................................ 5-14

Emulation VFU......................................................................................................................................... 5-14

I

NTERFACE SETTINGS

.................................................................................................................................... 5-15

MultiSource .............................................................................................................................................. 5-15

Parallel Setup ........................................................................................................................................... 5-16

Serial ........................................................................................................................................................ 5-16

Serial Type..............................................................................................................................................................5-16

Serial Setup.............................................................................................................................................................5-17

Protocol .............................................................................................................................................................. 5-17

XON/XOFF........................................................................................................................................................ 5-17

CD(DTR)............................................................................................................................................................5-18

CA(RTS) ............................................................................................................................................................5-19

SCA(SRTS)........................................................................................................................................................ 5-19

ETX/ACK ..........................................................................................................................................................5-20

GEK-99044 Table of Contents

vii

Inhibit Xmit........................................................................................................................................................ 5-20

Lead Polarity...................................................................................................................................................... 5-21

CD(DTR)....................................................................................................................................................... 5-21

CA(RTS)........................................................................................................................................................ 5-21

SCA(SRTS) ................................................................................................................................................... 5-22

CB(CTS)........................................................................................................................................................ 5-22

CC(DSR) .......................................................................................................................................................5-22

Data Bits ........................................................................................................................................................ 5-23

Parity.............................................................................................................................................................. 5-23

Stop Bits ........................................................................................................................................................5-24

Baud Rate ......................................................................................................................................................5-24

High Trip Pt%................................................................................................................................................ 5-25

Expansion1/Expansion2 ........................................................................................................................... 5-25

Legacy Parallel....................................................................................................................................................... 5-26

Centronics .......................................................................................................................................................... 5-26

DP(Short) ........................................................................................................................................................... 5-26

DP(Long) ...........................................................................................................................................................5-27

I/F Straps............................................................................................................................................................ 5-28

Token Ring............................................................................................................................................................. 5-28

Coax .......................................................................................................................................................................5-29

Twinax.................................................................................................................................................................... 5-29

TCP/IP.................................................................................................................................................................... 5-30

Netware ..................................................................................................................................................................5-30

E

NGINE OPTIONS

........................................................................................................................................... 5-31

Direction................................................................................................................................................... 5-31

EngineOff Delay ....................................................................................................................................... 5-31

Print Intensity ........................................................................................................................................... 5-32

P

RINT CONTROL

............................................................................................................................................ 5-32

Define LF.................................................................................................................................................. 5-33

Define CR ................................................................................................................................................. 5-33

Define FF.................................................................................................................................................. 5-33

Define HT ................................................................................................................................................. 5-34

VertMove ..................................................................................................................................................5-34

AutoWrap.................................................................................................................................................. 5-34

FF @ TOF ................................................................................................................................................ 5-35

GenPtrOpts ................................................................................................................................................... 5-35

T

EAROFF

....................................................................................................................................................... 5-35

Path .......................................................................................................................................................... 5-36

Retract ......................................................................................................................................................5-36

Auto .......................................................................................................................................................... 5-36

E

MULATION

................................................................................................................................................... 5-37

ANSI (4800).............................................................................................................................................. 5-38

ANSI (4410).............................................................................................................................................. 5-38

FX286E..................................................................................................................................................... 5-39

ProPrinter................................................................................................................................................. 5-39

P 300/600.................................................................................................................................................. 5-40

DEC LG .................................................................................................................................................... 5-40

Pseries ......................................................................................................................................................5-41

DEC PPL3 ................................................................................................................................................ 5-41

ESC/P2 ..................................................................................................................................................... 5-42

D

ISPLAY LAN

FILTER

................................................................................................................................................ 5-42

........................................................................................................................................................... 5-42

QMS.......................................................................................................................................................... 5-43

BC Density ............................................................................................................................................................. 5-43

Control Chars..........................................................................................................................................................5-44

Language ................................................................................................................................................................ 5-44

Code V.................................................................................................................................................................... 5-45

Free Format ............................................................................................................................................................5-45

Ignore Mode ...........................................................................................................................................................5-46

5000 Series User’s Manual GEK-99044

viii

Slashed Zero ........................................................................................................................................................... 5-46

PY Terminator........................................................................................................................................................ 5-46

PN Terminator........................................................................................................................................................ 5-47

Vertical DPI............................................................................................................................................................ 5-47

LPI Grid.................................................................................................................................................................. 5-47

Version ...................................................................................................................................................................5-48

Magnum Spaces...................................................................................................................................................... 5-48

Ignore Chr Mode ....................................................................................................................................................5-48

Ignore Char............................................................................................................................................................. 5-49

IGP ........................................................................................................................................................... 5-49

BC Density .............................................................................................................................................................5-49

Control Chars..........................................................................................................................................................5-50

Language ................................................................................................................................................................5-51

IGP Terminator....................................................................................................................................................... 5-51

Quiet Mode............................................................................................................................................................. 5-51

Delete Logos...........................................................................................................................................................5-52

Default OCR-B.......................................................................................................................................................5-52

Vertical DPI............................................................................................................................................................ 5-52

Slashed Zero ........................................................................................................................................................... 5-53

Clip Text................................................................................................................................................................. 5-53

Ignore Chr Mode ....................................................................................................................................................5-53

Ignore Char............................................................................................................................................................. 5-54

IPDS ......................................................................................................................................................... 5-54

IPDS BC Stagger.................................................................................................................................................... 5-54

IPDS BC Density.................................................................................................................................................... 5-55

IPDS GR Density....................................................................................................................................................5-55

IPDS Image Density ............................................................................................................................................... 5-55

IPDS Dens Ovr....................................................................................................................................................... 5-56

IBM Format.............................................................................................................................................. 5-56

Code Page...............................................................................................................................................................5-56

Code Pg Override ...................................................................................................................................................5-57

LPI Override...........................................................................................................................................................5-57

CPI Override........................................................................................................................................................... 5-57

MPP Override.........................................................................................................................................................5-58

MPL Override......................................................................................................................................................... 5-58

Override Text..........................................................................................................................................................5-59

Override All............................................................................................................................................................ 5-59

Hex Print.................................................................................................................................................................5-60

Hex 1 ......................................................................................................................................................................5-60

Hex 2 ......................................................................................................................................................................5-61

Hex Term................................................................................................................................................................ 5-61

DCF1 ......................................................................................................................................................................5-61

DCF2 ......................................................................................................................................................................5-62

DCF Term...............................................................................................................................................................5-63

Coax Compat.......................................................................................................................................................... 5-63

Case....................................................................................................................................................................5-64

LOC Copy FF.....................................................................................................................................................5-64

FF Before LC .....................................................................................................................................................5-64

Interv Req........................................................................................................................................................... 5-65

Irq Err TO...........................................................................................................................................................5-65

Irq Bsy TO..........................................................................................................................................................5-66

CR at MPP+1 ..................................................................................................................................................... 5-66

NL at MPP+1 .....................................................................................................................................................5-67

FF Data............................................................................................................................................................... 5-67

FF EndBuff.........................................................................................................................................................5-68

Null Sup .............................................................................................................................................................5-68

FF Pos ................................................................................................................................................................5-69

Auto Funct..........................................................................................................................................................5-69

LAST LF/FF.......................................................................................................................................................5-69

Supp CCode .......................................................................................................................................................5-70

VCS....................................................................................................................................................................5-70

Comm................................................................................................................................................................. 5-71

GEK-99044 Table of Contents

ix

CHAPTER 6.USING THE MAINTENANCE MENU.................................................................................. 6-1

R

ESET TO DEFLTS

A

LIGNMENT

............................................................................................................................................ 6-1

..................................................................................................................................................... 6-2

Patterns....................................................................................................................................................... 6-2

AdjustAmplitude.......................................................................................................................................... 6-3

H

EADSERVICE

................................................................................................................................................. 6-4

Dot Counts.................................................................................................................................................. 6-4

Print Chart.................................................................................................................................................. 6-5

Actuator Status ...........................................................................................................................................6-6

P

OWER ON TIME

P

RINT TIME

U

PGRADE FLASH

R

IBBONMONITOR

.............................................................................................................................................. 6-6

..................................................................................................................................................... 6-6

............................................................................................................................................. 6-7

............................................................................................................................................ 6-7

CHAPTER 7.OPERATOR CARE AND MAINTENANCE ........................................................................ 7-1

I

NTRODUCTION

O

PERATOR CLEANING PROCEDURES

5050/5100 (50, 55

O

PERATOR CLEANING PROCEDURES

5180 (52

O

PERATOR TROUBLESHOOTING

................................................................................................................................................ 7-1

............................................................................................................... 7-1

60 DBA) C

OR

ABINET MODEL

............................................................................................ 7-1

............................................................................................................... 7-2

55 DBA) C

OR

ABINET MODEL

........................................................................................................... 7-2

....................................................................................................................... 7-3

Soft Faults................................................................................................................................................... 7-4

Miscellaneous Non-Fault Messages ........................................................................................................... 7-7

Hard Faults ................................................................................................................................................ 7-8

Electrical Problems .................................................................................................................................. 7-10

Mechanical Problems............................................................................................................................... 7-11

Self-test Error Messages........................................................................................................................... 7-12

S

ERIAL INTERFACE ERRORS

P

RINT HEAD REPLACEMENT

5050/5100 (50, 55

OR

........................................................................................................................... 7-13

.......................................................................................................................... 7-13

60 DBA)

CABINET MODEL

.......................................................................................... 7-13

Replacement Procedure............................................................................................................................ 7-14

P

RINT HEAD REPLACEMENT

5180 (52

55 DBA)

OR

.......................................................................................................................... 7-18

CABINET MODEL

......................................................................................................... 7-18

Resetting Print Head Counters................................................................................................................. 7-21

APPENDIX A UNPACKING INSTRUCTIONS.......................................................................................... A-1

U

NPACKING

(5180 52

DBA MODEL

)............................................................................................................... A-1

Unpacking (5050/5100 55 DbA Model)......................................................................................................A-4

Repacking ...................................................................................................................................................A-6

U

NPACKING

(5180 M

) ........................................................................................................................... A-6

ODEL

Removing the Shipping Blocks and Hardware ...........................................................................................A-7

APPENDIX B PAPER SPECIFICATIONS.................................................................................................. B-1

R

ECOMMENDED PAPER WEIGHTS

....................................................................................................................B-1

APPENDIX C CONSIDERATIONS FOR OPERATION ........................................................................... C-1

APPENDIX D................................................................................................................................................... D-1

PARTS, ACCESSORIES, CONSUMABLES AND OPTIONS................................................................... D-1

APPENDIX E. FONT PRINT SAMPLES......................................................................................................E-1

H

IGH SPEED FONT

GOTHIC DRAFT

GOTHIC NEAR LETTER QUALITY

5000 Series User’s Manual GEK-99044

............................................................................................................................................E-1

– D

ATA PROCESSING FONT

......................................................................................................E-1

.......................................................................................................................E-1

x

CHARACTER GRAPHICS FONT

CORRESPONDENCE FONT

OCR-A FONT

OCR-B

COURIER NLQ FONT

ITALIC NLQ FONT

H

IGH SPEED

CANADIAN PST

.....................................................................................................................................................E-2

..................................................................................................................................................E-2

FONT

..........................................................................................................................................E-2

.............................................................................................................................................E-2

2.................................................................................................................................................. E-3

.................................................................................................................................................E-3

...........................................................................................................................E-1

..................................................................................................................................E-2

APPENDIX F. FLASH UPGRADE INSTRUCTIONS.................................................................................F-1

APPENDIX G DESCRIPTION OF STRAPPING OPTIONS .................................................................... G-1

L

EGACY PARALLEL HARDWARE STRAP DEFINITIONS

L

EGACY PARALLEL SOFTWARE STRAP DEFINIT IONS

G

ENERAL PRINTER OPTIONS DEFINIT IONS

E

MULATION OPTION DESCRIPTIONS

..................................................................................................... G-4

............................................................................................................... G-6

...................................................................................... G-2

...................................................................................... G-3

APPENDIX H. ................................................................................................................................................. H-1

INTERFACE EMULATION COMPATIBILITY........................................................................................ G-1

APPENDIX I. LCD MENU MAPS ..................................................................................................................I-1

GEK-99044 Table of Contents

xi

CHAPTER 1. INTRODUCTION

This printer is a high duty cycle, line matrix printer. Among the

advanced features of this printer are:

! High speed at 500/1000/1800 lpm

! Industry’s only lifetime warranty on shuttle mechanism and

striker bar

! IBM-compatible models

! Ideal for manufacturing pick lists and shipping documents

! Remote network printing

! Auto interface switching

! Top demand exit or rear exit standard (5050/5100 (55 or 60 dBa)

Cabinet Model)

! Industrial graphics, bar codes, and labels

Other characteristics include:

! Input voltage:

5050/5100 Models auto range selecting 115V or 230V

5180 Models switchable 115V or 230V

! Hardware interfaces: menu selectable or auto switching between

CENTRONICS parallel and RS-232 serial

! Standard emulation’s: menu- or host-selectable ANSI 4800, ANSI

4410, Epson FX286e, IBM Proprinter III XL, P 300/600, DEC LG

and PPL3, Pseries, and ESC/P2.

! Standard fonts: menu- or host-selectable Data Processing,

Correspondence, Gothic NLQ, Graphics, Courier NLQ, Italic NLQ,

High Speed, OCR-A, OCR-B and Oversize.

GEK-99044 Chapter 1. Introduction

1-1

REFERENCE USAGE:

Warning is used to alert a user of a hazard that could cause

personal injury or severe damage to the equipment.

Caution is used where there is a risk of damaging the equipment,

parts or supplies.

Indicates additional information.

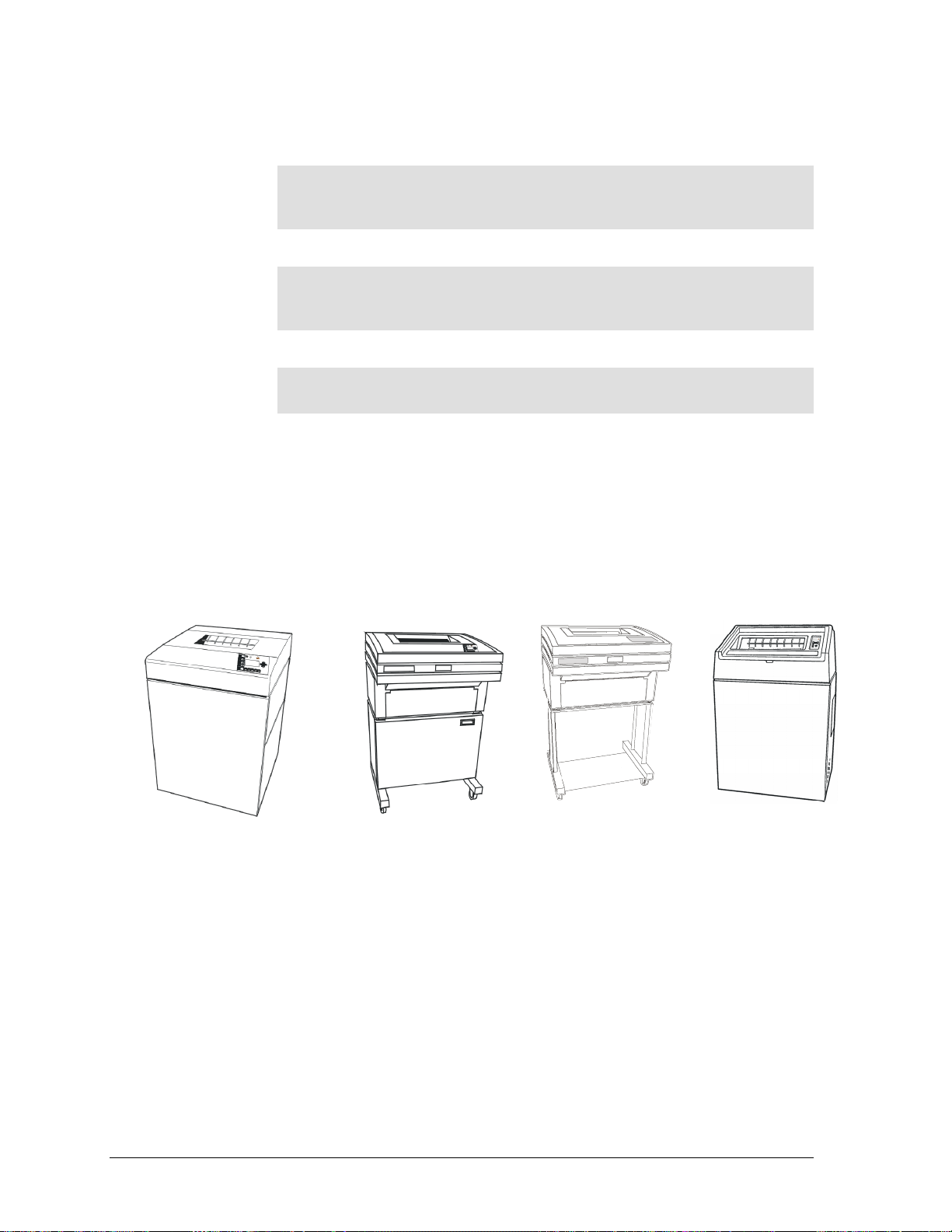

ORGANIZATION OF THIS MANUAL

This User’s Manual covers the 5000 series printers. Some procedures

discussed in this manual are model number and/or cabinet specific.

The differences are noted within sections where possible and

separated into section where necessary. The following is a visual

representation of the cabinet models available:

Warning

Caution

Note

5000 SERIES CABINET STYLES AND MODEL NUMBERS

5050/5100 (50 dBa)

5180 (52 dBa)

This User’s Manual is divided into the following main sections:

Chapter 1: Introduction

This chapter contains a brief introduction to the key features of the

printer and the organization of this manual.

Chapter 2: Getting Started

This chapter contains the instructions necessary to get the printer up

and running.

5050/5100 (55 dBa) 5050/5100 (60 dBa) 5180 (55 dBa)

Chapter 3: Operating the Printer

5000 Series User’s Manual GEK-99044

1-2

This chapter contains descriptions of the control panel, the

pushbuttons and navigation through the menu options.

Chapter 4: Using the Operator Menu

This chapter details the procedures for accessing the options under

the Operator Menu.

Chapter 5: Using the Setup Menu

This chapter details the procedures for accessing the options under

the Set Up Menu.

Chapter 6: Using the Maintenance Menu

This chapter details the procedures for accessing the options under

the Maintenance Menu

Chapter 7: Operator Care and Maintenance

This chapter contains information for the user to care and maintain

the printer.

The following appendices are provided for reference information:

Appendix A: Unpacking & Repacking

This appendix contains information necessary to unpack the printer

or repack the printer for shipment.

Appendix B: Paper Considerations

This appendix contains information as a guide to paper supplies.

Appendix C: Considerations for Operation

This appendix contains specifications on the printer.

Appendix D: Parts, Accessories, Consumables, Options

This appendix contains a list of available parts, accessories,

consumables and options available for the printer.

Appendix E: Font Print Samples

This appendix contains print samples of the font styles available on

this printer.

Appendix F: Flash Software Procedures

This appendix contains upgrade software procedures.

Appendix G: Description of Strapping Options

This appendix contains reference tables listing hardware and

software strapping options.

Appendix H: Emulation Interface Compatibility

This appendix contains reference tables for Emulation to Interface

compatibility issues.

GEK-99044 Chapter 1. Introduction

1-3

CHAPTER 2. GETTING STARTED

PREPARING THE PRINTER FOR OPERATION

Printer unpacking is complete when all accessories have been

removed from the packaging and printer cabinet or pedestal. See

“Appendix A Unpacking Procedures” for more information.

Move the printer to a suitable operating location. See Appendix C for

considerations on the space and conditions required for normal

operation.

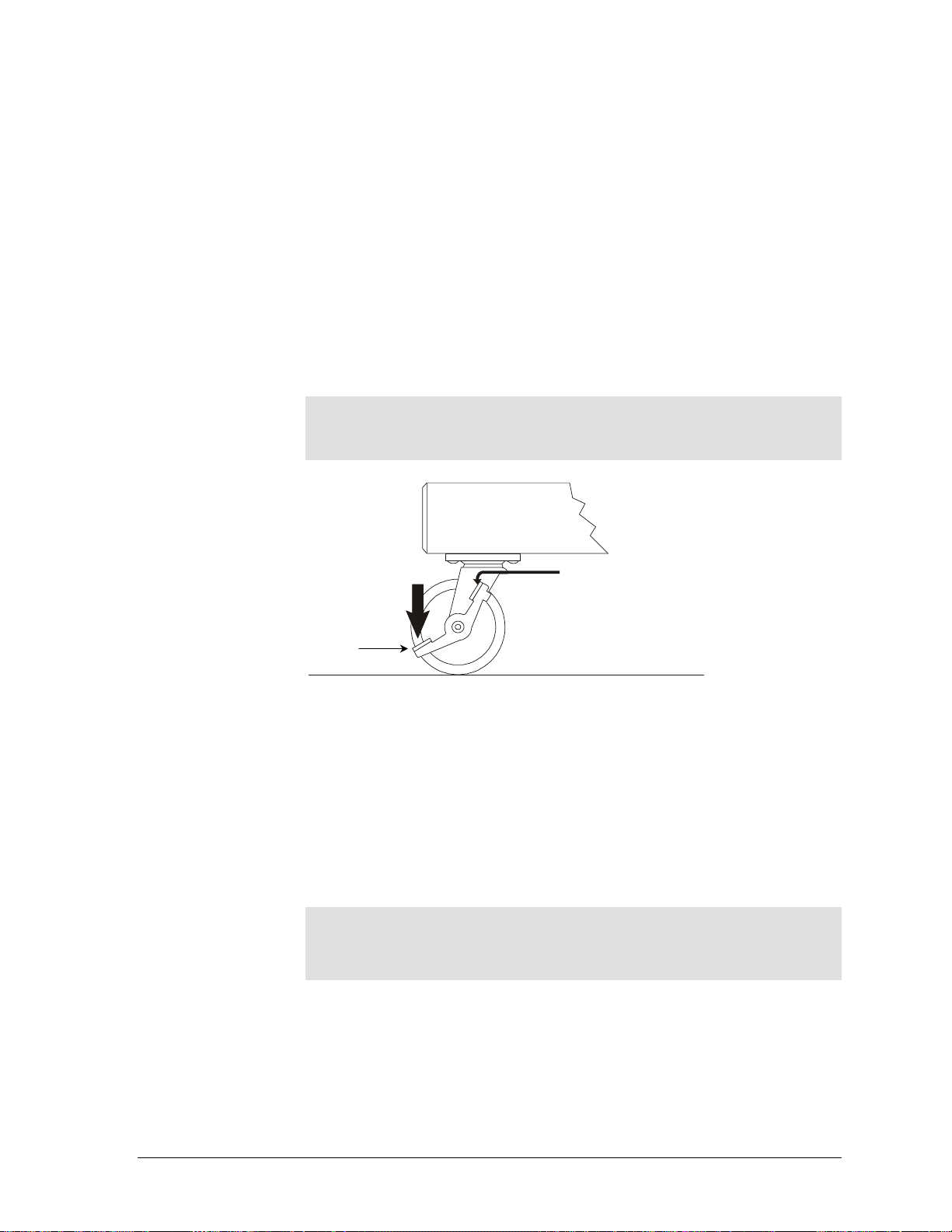

The two front casters have locks to stabilize the printer once it has

been moved to its location. Press one brake tab to lock the wheel of

the caster and press the other tab to unlock. See Figure 2-1.

Note

The printer should be initially setup following the instructions

given in this chapter, in the order presented.

BRAKE TAB

Figure 2-1 Brake Tab on Front Caster

CONNECTING THE POWER CORD

The 5050/5100 (50, 55 or 60 dBa) Cabinet Model printer is equipped

with an auto-switching power supply and can be connected to either

a 115V or 230V source without damage or manually changing a

switch setting.

The 5180 (52 or 55 dBa) Cabinet Model has a voltage selection switch

located on the back panel. The switch has two positions, 115V and

230V. The factory default is set to 230V.

(5180 (52 or 55 dBa) Cabinet Model)

Set the voltage selection switch to the proper line voltage before

plugging in the power cable.

The allowable voltage variation is ±15% and the allowable frequency

is 48 to 65 Hz.

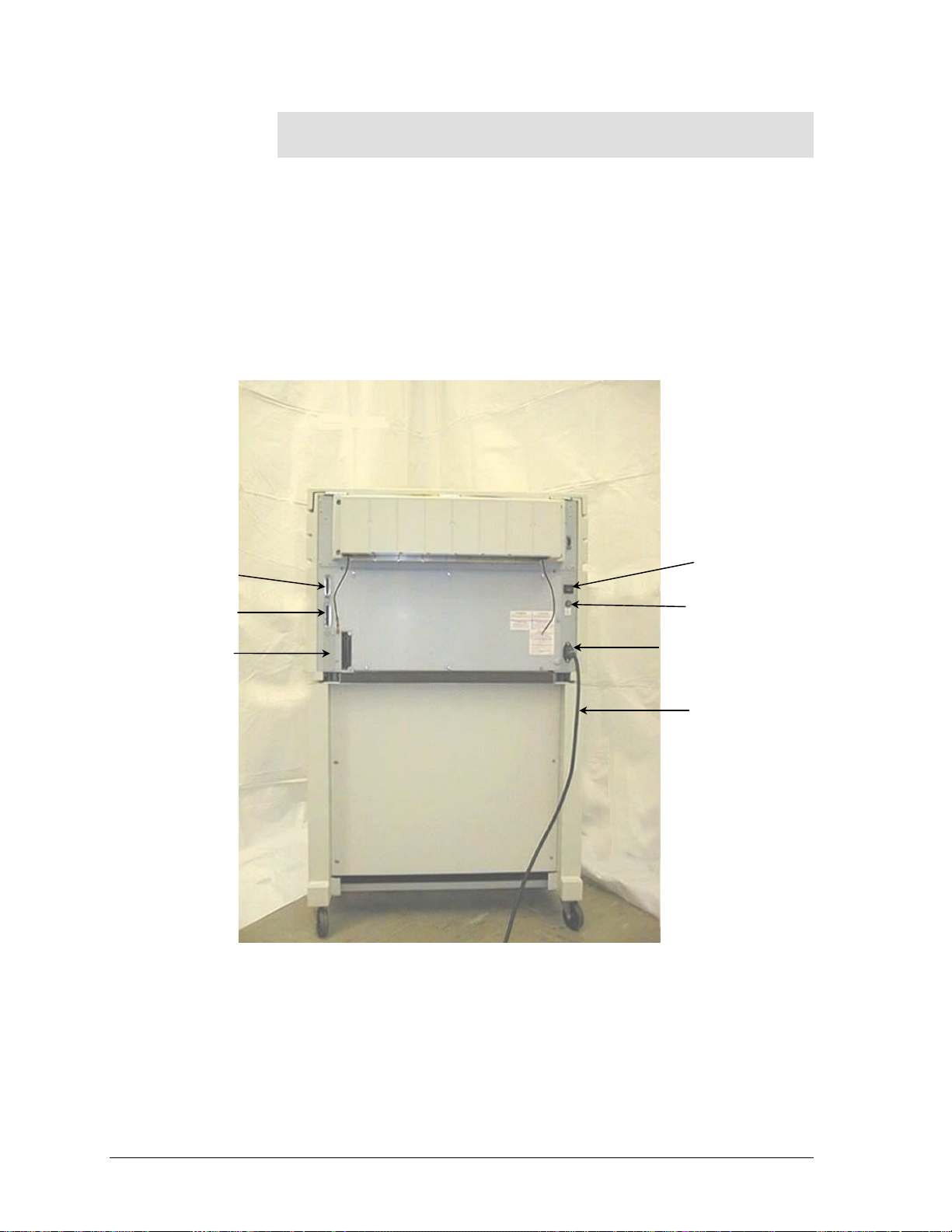

A power cord is packed with the printer. Plug the female end of the

cord into the recessed connector at the rear of the printer. See Figure

2-2. Plug the other end into a compatible, properly grounded AC

outlet.

Caution

GEK-99044 Chapter 2. Getting Started

2-1

Note

The AC outlet must be rated for at least 10-ampere service.

Avoid using AC circuits serving other equipment which may cause

chronic low voltage, noise interference, or power fluctuations. Data

loss may result.

CONNECTING THE INTERFACE CABLE

Both a 25-pin RS-232C serial interface connector and a 36-pin

CENTRONICS parallel interface connector are standard on this

printer. Both connectors are located on the data connector plate on

the rear of the printer. See Figure 2-2.

25-PIN SERIAL

CONNECTOR

36-PIN PARALLEL

CONNECTOR

I/O CARD

INTERFACE SLOTS

POWER ON/OFF

(I/O) SWITCH

FUSE HOLDER

RECESSED CONNECTOR

POWER CORD

FIGURE 2-2 REAR VIEW OF PRINTER

5050/5100 (55 dBa) MODEL

5000 Series User’s Manual GEK-99044

2-2

I/O Interface Card Options available

5180 (55 dBa) MODEL

There are two expansion slots located in the rear of the printer. The

interface options available are:

§ Legacy parallel

§ DPSL (Dataproducts short line)

§ DPLL (Dataproducts long line)

§ IBM/TX/CX

§ Ethernet (10/100, 10baseT, and Token Ring)

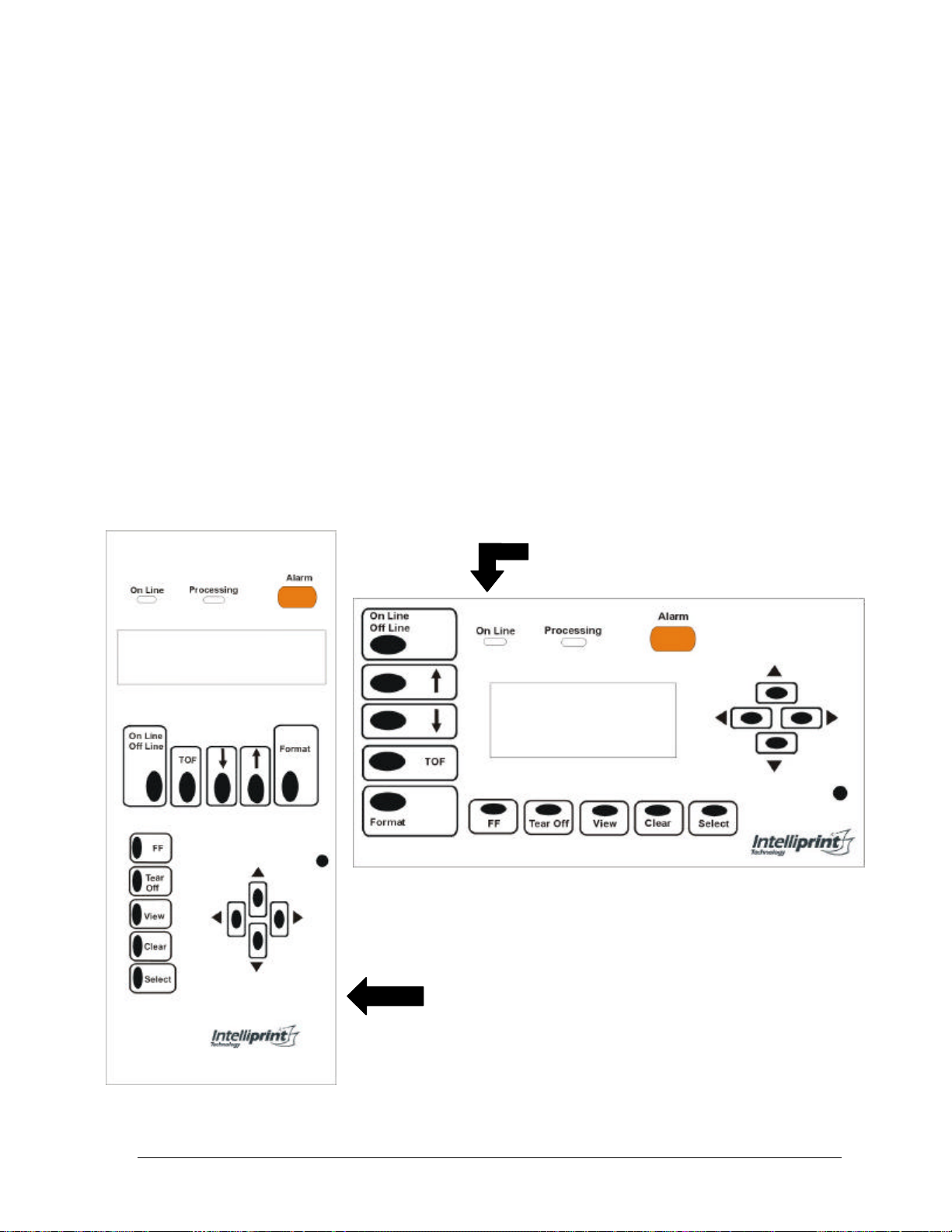

DESCRIPTION OF THE CONTROL PANEL

The control panel is mounted in the top of the printer and is

accessible with the top cover either open or closed. The Control Panel

utilizes a display panel composed of two rows of sixteen characters

each. With the top cover open, the control panel will move around

slightly to the touch. This is normal. The floating mount allows the

panel to align itself when the top cover is closed.

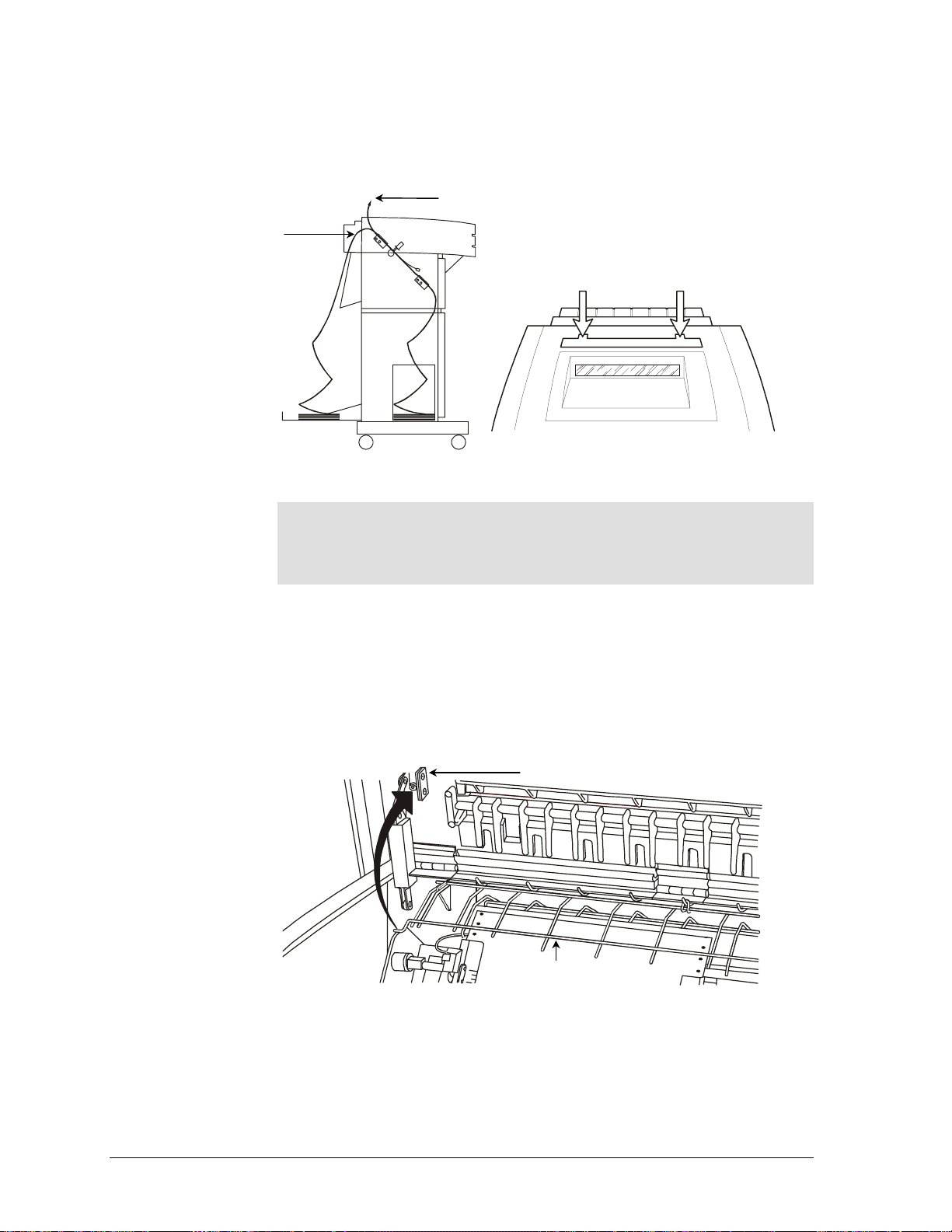

5050/5100 MODELS

5180 (52 dBa) MODEL

GEK-99044 Chapter 2. Getting Started

2-3

The basic look and layout of the 5050/5100 (55 dBa) Cabinet Model

control panel is represented by the following:

The four pushbuttons to the right of the display are to navigate the

menu tree structure and are referred as menu browse pushbuttons.

The On Line/Off Line pushbutton is located at the top of the left row of

pushbuttons. The three pushbuttons below the On Line/Off Line

pushbutton,↑ (up arrow), ↓ (down arrow), and TOF, are used to set

top of form. See “Setting Top of Form” in Chapter 3 for additional

information. The bottom left pushbutton, Format (in conjunction with

the Select pushbutton), is used to select one of ten stored form

formats. The FF, Tear Off, and View pushbuttons under the display

are additional paper positioning functions. The Clear and Select

pushbuttons are used in data entry.

Note

The locations of the pushbuttons and display on the 5180 (55

dBa) Cabinet Model are different, however the functionality of

each is the same.

When in the online state, only the FF, On Line/Off Line, Tear Off, &

View pushbuttons and limited functionality of the Clear and Select

pushbuttons are active. Pressing any other pushbutton causes a

“beep.” The “Processing” LED indicator is lit whenever data is being

received and or being processed/printed. In multi-source I/O mode,

the “Processing” LED indicator will blink for the duration of the

timeout period when processing is complete.

Beeper

Note

The control panel mount on the 5050/5100 (55 or 60 dBa) and

5180 (52 dBa) Cabinet Model is hinged so that it can be tilted

forward to remove the ribbon deck for service.

The control panel beeper sounds momentarily when:

! A pushbutton is pressed.

! A BEL control code is received. (The host can send a “bell” code to

sound the printer’s beeper. For more information, see the

Programmer’s Manual.)

! A PAPER LOW condition exists.

! An EVFU loading error occurs. (For more information on the

EVFU, see the Programmer’s Manual.)

! A hard fault occurs. (See Chapter 7 for an explanation of hard

faults.)

5000 Series User’s Manual GEK-99044

2-4

Display

The two row by sixteen-character LCD provide the following

information:

! The printer’s status - Online, Local, Self-test, etc.

! Which menu or menu option is presently on display to assist in

making selections.

! When a fault condition exists.

Pushbuttons

The pushbuttons are sealed and raised rubber-type switches used to

make menu selections, clear faults, and position the paper. An

explanation of the pushbuttons’ functions is given in the following

section on “Operation of the Control Panel.”

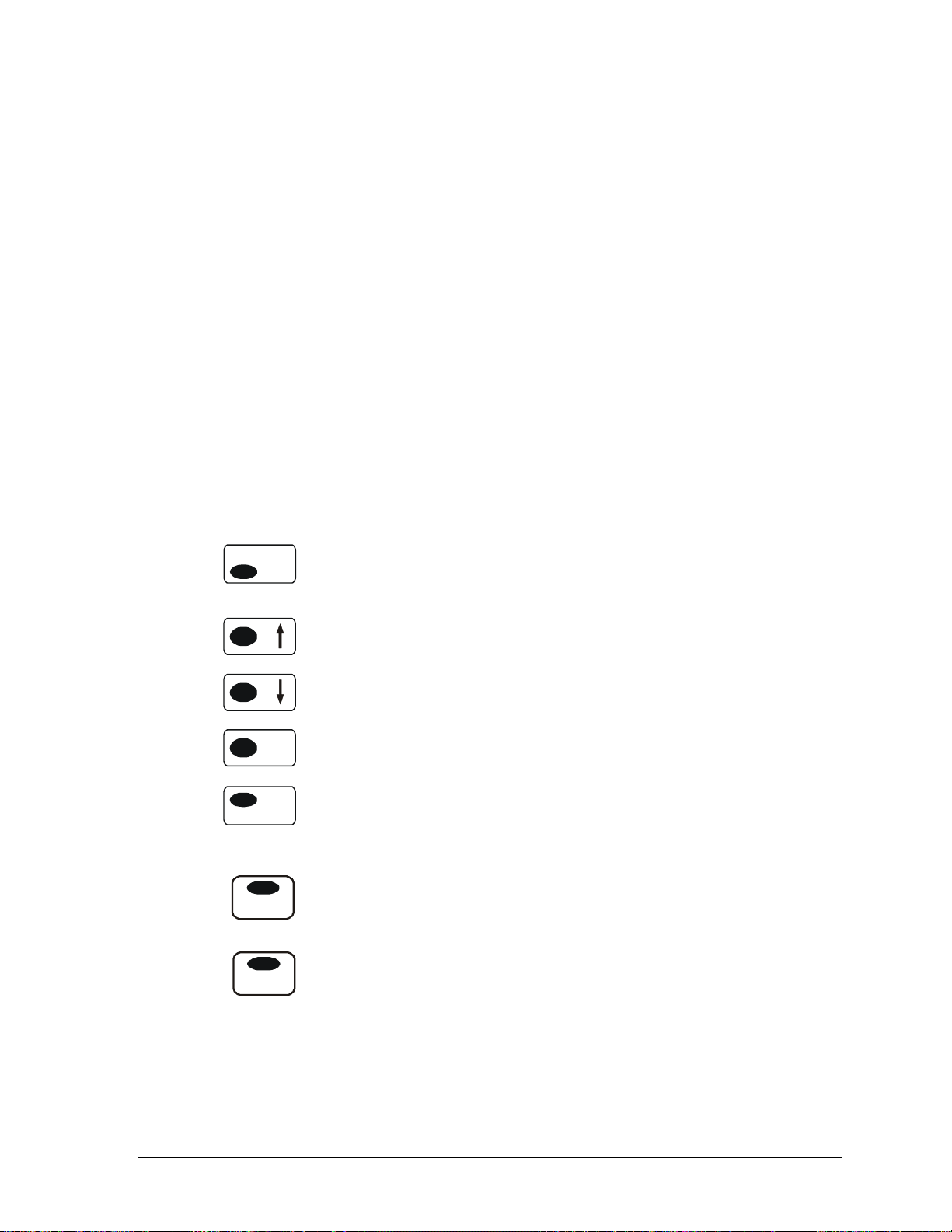

OPERATION OF THE CONTROL PANEL

The primary use of each pushbutton is printed beside the button

itself.

On Line

Off Line

Pressing the On Line/Off Line pushbutton causes the printer to toggle

between online and offline operation. Offline operation allows access

to the menu functions.

FORMAT

Tear Off

FF

Pressing the ↑↑↑↑ pushbutton moves paper up incrementally.

Pressing the ↓↓↓↓ pushbutton moves paper down incrementally.

Pressing the TOF (Top of Form) pushbutton sets the top of form

TOF

position on the printer.

Pressing the Format pushbutton allows the operator to select from up

to ten stored formats. The pushbutton is repeatedly pressed until the

desired set up format is being displayed, press the Select pushbutton

to activate the selected format.

Pressing the FF pushbutton moves paper to next top of form

according to the top of form set for the printer.

Pressing the Tear Off pushbutton advances the paper to the selected

tear position and will auto retract to the selected retract position after

15 seconds. Pressing the tear off pushbutton any time within that 15

second wait period will retract the paper to the selected retract

position. The printer will emit three beeps prior to retracting the

paper.

GEK-99044 Chapter 2. Getting Started

2-5

Data Entry

View

Clear

Select

Pressing the View pushbutton advances the paper such that the last

printed line is visible in the top cover window. Pressing the View

pushbutton a second time will return the paper to the last print

position. Receipt of any data will also retract the paper to the print

position.

Press the Clear pushbutton to exit or backup data entry and selection

levels.

Press the Select pushbutton to enter or select data entry.

Pressing the menu browse pushbuttons allows navigation of menu

selections. Press the ◄ (left) or ► (right) menu browse pushbuttons

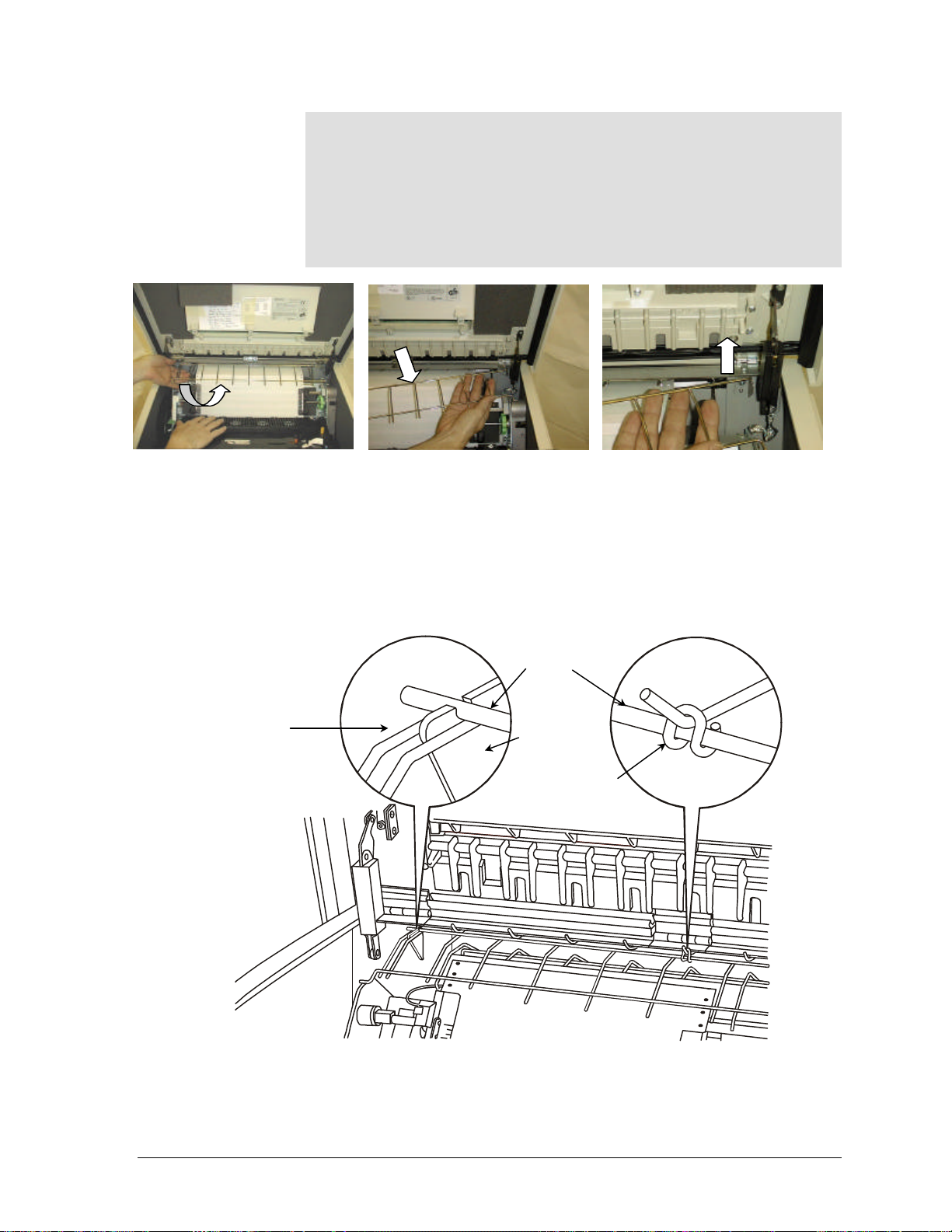

allows navigation of menu selections laterally within the same level.