Genicom 170, 220 TM, 140 TM, 90 TM User Manual

ZEBRA PERFORMANCE-LINE

TM

TM

XiII

-Series

User's Guide

For the Zebra

Xi Xi

90 ™, 140 ™,

Xi Xi

170 ™, and 220 ™

II II

II II

Printers

Zebra XiII-Series Printer

User’s Guide

Customer order # 48460L

Manufacturer part # 48460LB Rev. 1

Proprietary Statement

This manual conta in s proprietary informa tio n of Zebr a Tech no logies C orp ora tio n. It is intended solely for the informatio n and u se of parties operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to

any other parties for any other purpose without the expressed written permission of Zebra Technologies Corporation.

Product Improvements

Continu ou s imp rovement of prod ucts is a policy of Zebra Tech no lo gi es Cor po ratio n . All sp ecificatio ns and sign s are s ubject to change

without notice.

FCC Compliance Statement

Note: This equipment has been tested and found to comply with the limits for a Class A digital Device, pur sua nt to Part 15 of the FCC

Rules. These limits are designed to prov id e reasona ble pro tect ion against harmful inter fer ence w hen the equip men t is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

In order to insure compliance, this printer must be used with a Shielded Power Cord and Shielded Communication Cables.

“The user is cautioned that any changes or modifications not expressly approved by Zebra Technologies Corporation could void the user’s

authority to operate the equipment.”

Canadian DOC Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in the radio interference

regulations of the Canadian Department of Communications.

CE Compliance

If the accompanying printer displays the CE mark, it also meets EMC directive 89/336/EEC, with ammendments effective at the time of

manufacture.

Liability Disclaimer

Zebra Technolo gi es Corpo ra tion tak es steps to assu r e that its published Engine erin g sp ecific ations and Manuals are corr ec t; how ever,

errors do occur. Zebr a Technolo gies Corpo rati on has been advised of the possibility of such damages. Bec ause some sta tes do not allow

the exclusio n or limita tio n of liability for consequ ential or inciden tal da mag es, the abo ve limita tion may not apply to you.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra Technologies Corporation. All rights are reserved.

Unauthorized r ep rodu ctio n of this ma nua l or the softwar e in the label prin ter may resul t in impriso nment of up to one y ea r and fines of up

to $10,000 (17 U.S.C .5 06). Cop yr ig ht vio lator s may be subjec t to civil lia bility.

All trademarks are the property of their respective owners. Centronics is a registered trademark of Genicom Corporation. Compugraphic is

a registered tradema rk and CG Triumv irat e, CG Trium vira te Conden sed , CG Palacio , and CG Times are all Tradema rks of AGFA Corporation. Futura is a trademark of Fundicion Tipografica Neufville, S.A. TrueType is a registered trademark of Apple Computer, Inc. Univers

is a registered tr adem a rk of Lino typ e AG and/ or its subsidiaries. IBM is a registered trademar k and Windows is a trademark of IBM Corporation. BAR-ONE, SCAN-ONE, Stripe, TRACK-ONE, WEDGE-ONE, Zebra, ZPL, and ZPL II are registered trademarks and TotalCare is a tradem ark of Zebr a Techn olo gi es C orpo r ation.

Copyright Zebra Technologies Corporation. All rights reserved.

Zebra XiII Printer User’s Guide

Warranty Info rmation

1. Printer Warranty

ZEBRA prin ters, excludin g thermal printheads which are wa rra n ted sepa r a tely below, are war r a nted ag ai nst defects in mater ia l o r workmanship for six (6) months from the date of original shipment by ZEBRA Technologies Corporation. This warranty does not cover normal

wear and tear and shall be null and void if the equipment is modified, imp roper ly installed or used, damaged by accident or neglect, or in

the event any parts are improperly installed or replac ed by the user.

Since printh ea d wear is part of norma l oper ations, the original printhead and replac em ent pr in thea d s are cover ed by a limited warranty of

six (6) months from the date of original shipment by ZEBRA Technologies. To qualify for this warranty, the printer must be returned to the

factory or other authorized service center. Although the user is not required to purchase ZEBRA brand supplies (media and/or ribbons), to

the extent it is determined that the use of other supplies (media and/or ribb o ns ) shal l hav e ca us ed any defec t in the th erm a l printhead for

which a warran ty cla im is made, the user sh al l be respons ible fo r ZEBRA Tech nologies’ custom ary charg es fo r labor and materia ls to

repair such defect. To the extent that it is determined that failure to follow the preventive maintenance schedule and procedures listed in the

User’s Guide shall have caused any defect in the thermal printhead for which a warranty claim is made, this limited warranty shall be void.

ZEBRA TECHNOLOGIES’ SOLE OBLIGATION UNDER THIS WARRANTY SHALL BE TO FURNISH PARTS AND LABOR FOR

THE REPAIR OR REPLACEMENT OF PRODUCTS FOUND TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP DURING

THE WARRANTY PERIOD.

As a condition of this warranty, the user must: (a) obtain a ZEBRA Return Authorization for the printer, or subassembly(s); (b) ship the

printer or subass emb ly (s), transpo rta tio n prepa id to the author ized serv ic e location; and (c) include with the Pro duc t or subassembly(s) a

written descri ptio n of the claim ed def ect. Unless ZEBR A Techn olo gies authorizes return of the entire Product, the user shall ret urn only

the subassembly(s). Products returned shall be packaged in the original packing and shipping container or comparable container. In the

event equipment is not so packaged or if shipping damage is evident, it will not be accepted for service under warranty. Surface t ransportation charges for the return of the printer to the customer shall be paid by ZEBRA Technologies within the 48 contiguous states and the District of Columbia. Customer shall pay shipping costs, customs clearance, and other related charges outside the designated area. If ZEBRA

Technolog ies determines that the Produ ct retur n ed to it for warran ty service or replac em ent is no t defective as herein defined, BUYER

shall pay all costs of hand lin g and transpo rtatio n .

2. Supplies Warranty

ZEBRA supplies are warranted to be free from defects in materials or workmanship for a period of either the stated material shelf life or 6

months from date of shipm ent, whichever occurs first, prov ided that the BUYER has comp lied w ith ZEB RA Techn o logies’ guidelines on

storage, handling , and usage of the labeling su pplies in ZEBR A printers. ZEBRA Techno logies do es not wa rran t the perf orm ance of

ZEBRA labeling supplies on non-ZEBRA printers.

Any supplies product shown to the satisfaction of ZEBRA Technologies, within the time provided, to be so defective shall be replaced

without charge, or ZEBRA Technologies may issue a credit in such an amount as it deems reasonable.

3. Warranty Exclusions and Conditions

The above warranties are in lieu of all other warranties, expressed or implied, oral or written, statutory or otherwise, including any implied

warranty of merchant-ability or fitness for a particular purpose.

ZEBRA Techn olog ies sha ll not be respo ns ible for the speci fic app lic ation to whic h any Produ ct s are applied , inc lu ding bu t not limited to

compatibility with other equipment.

Zebra XiII Printer User’s Guide

All statements, technical information and recommendations relating to ZEBRA Products are based upon tests believed to be reliable but do

not constitute a guarantee or warranty.

ZEBRA TECHNOLOGIES SHALL NOT, UNDER ANY CIRCUMSTA NCES WHATSO EVER, BE LIABLE TO BUYER OR ANY

OTHER PARTY FOR LOST PROFITS, DIMINUTION OF GOOD WILL OR ANY OTHER SPECIAL OR CONSEQUENTIAL DAMAGES WHATSOEVER WITH RESPECT TO ANY CLAIM HEREUNDER. IN ADDITION, ZEBRA TECHNOLOGIES’ LIABILITY

FOR WARRANTY CLAIMS SHALL NOT, IN ANY EVENT, EXCEED THE INVOICE PRICE OF THE PRODUCT CLAIMED

DEFECTIVE, NOR SHALL ZEBRA TECHNOLOGIES BE LIAB LE FOR DELAYS IN REPL A CEMENT OR REPAIR OF PRODUCTS.

No salesperson , repres entative or agent of ZEBRA Technologies is authori zed to make any guar antee, wa rrant y, or represen tation in addition to the foregoing warranty.

NO WAIVER, ALTERATION, ADDITION, OR MOD IFICATION OF THE FOREGOING WARRANTIES SHALL BE VALID

UNLESS MADE IN WRITING AND SIGNED BY AN EXECUTIVE OFFICER OF ZEBRA TECHNOLOGIES .

Zebra Software License Agreement

The enclosed software and documentation are protected by the United States copyright law and international treaty, and therefore you must

treat them like a book, with the exceptio n that yo u may make copies to protect yourself against loss of the original.

Your right to use the enclosed software and documentation as described below is non-exclusive and non-transferable. Zebra retains o wn ership in the software and documentation and all other right, title and interest. The enclosed software and documentation may be used by any

number of people and may be freely moved from one computer to another as long as there is no possibility of their being used by more than

one person on more than one compu ter at the same time.

Machine readable files representing graphics or fonts which you have created independently may be converted to ZPL format files using

the enclosed softwar e and such files may be used, copied onto diskettes or font cards, giv en awa y, or sold without payi ng licen se fees to

Zebra.

Pictorial or graph ic images and machine reada bl e files represen ting them may be protected by United States copyr ig ht law and international trea ty pro vis ions which pro hib it s you from tran sc r ib ing or sca nn in g such ima ges or using copyin g , or con ver ting such file s witho ut

permission of the copyright owner. You may not use this software in violation of U.S. copyright law or international treaty. By using this

software, you agree to be bound by these terms.

Zebra Technologies Corporation (“Zebra”) warrants the enclosed diskette to be free of defects in material and workmanship for a period of

60 days from the date of purchase. In the event of notific atio n with in the war ra nty period of defects in materia l a nd workm anship, Zebra

will replace the defective dis kette or documen tation. Zebra specifically disclaims all other warranties, expressed or implied, including but

not limited to implied warranties of merchantability and fitness for a particular purpose. IN NO EVENT WILL ZEBRA TECHNOLOGIES

BE LIABLE FOR LOST PROFITS, LOST DATA, OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED

BY ABUSE OR MISAPPLICATION OF THE SOFTWARE OR BY ITS USE IN VIOLATION OF THE U.S. COPYRIGHT LAW OR

INTERNATIONAL TREATY.

Zebra XiII Printer User’s Guide

Contents

Warrant y Information .. ..... .. ..... .. ..... ... ..... .. ..... .. ..... ..... ... .... ... .. ..... ..... .. ..... ... ..... .. ...iii

1. Printer Warra nty................... ..... ..... ..... .... ..... ..... ..... ..... ..... ..... .... .iii

2. Sup pl i es W a rra n ty .... ....... .. ........ ....... ... ....... ....... ... ....... ....... ... .....iii

3. Warranty Exclusions and Conditions .........................................iii

Zebra Software Licens e Agreem ent..... ............ ............... ............ ............ ............ . iv

List of Figures...................................................................................................... xi

List of Tables ......................................................................................................xii

Chapter 1 Getting Started 1

Introduction...........................................................................................................1

Prin t M ec ha n ism Capa bilitie s ............ ....... .. ........ ....... .. ........ ....... .. .. 2

Media Transport Mechanism Capabilities ...................................... 2

Fron t Panel Displa y. ....... ....... ........ ....... ... ....... ....... ....... ........ ....... .... 2

System Requirements ...........................................................................................3

Med ia and Ri bbon Requ irement s ............... ... ....... ... ....... .. ........ .. ....... ... ....... ... ...... 3

Unpacking .......... ....... ........ ....... ....... ............ ........ ....... ....... ........ ............ ....... ....... .. 4

Reporting Damage...........................................................................4

Storage and Reshipping................... ............ ............... ............ ......... 5

Site Requirements.................................................................................................5

Printer Power-Up............................................................................. 6

Voltage Selection....................................................... 6

Power Cord................................................................ 6

Communications................................................................................................... 7

Loading Media......................................................................................................7

Intro d u ction to Media Loading .. ........ ....... ....... ........ ....... ....... ....... .. 7

Non-Continuous Medi a.... ................ ............. .. .. ........8

Con ti n uou s Media...... ... ....... ....... ... ....... ....... ... ....... .... 8

Blac k-Mark Med ia ........ ....... .. ........ ....... .. ........ ....... .. .. 8

Tear-Off M od e Media Lo a ding.. ........ ....... ....... ........ ....... ....... ....... .. 9

Roll Media Loading................................................. 10

Fanfold Media Loading ........................................... 10

Con ti n uo u s M ed i a L o ad i n g ...... ....... ... ....... ....... ....... 11

Cutt er M o de Me d ia Loa d in g .... .. ........ .. ....... ........ .. ....... ... ....... ....... 12

Rew in d Mod e M ed i a Lo ad i n g .. ....... ... ....... ....... ... ....... .. ........ ....... .. 12

Rewind Mode C onfi gura ti on fo r Print ers Wi thou t the

Cutter Optio n....................... ........ .... ........ ....... .. 12

Zebra XiII Printer User’s Guide v

Rewind Mode for Prin ters W ith the Cutter Opti o n..13

Peel-Off Mode Medi a Lo ading.............. ....... ....... ........ ....... ....... ....1 4

Remov i ng th e Label Backing Material ....... .. ............... .. ....... ............... .. ........ .. ....1 4

Adjusting th e Tr a nsmissi ve Me d ia Se n so r As sembl y Po si ti o n............. ... ....... ....1 5

Adjusting th e U p pe r Me d ia Senso r Po si ti o n . ....... ........ .. ....... ........ . 16

Lowe r Media Sen so r Ad j u stment ............ ... ....... ....... ... ....... ....... ... .17

Ribbon Loadi n g ..... ....... ... ....... ....... ... ....... ....... ... ....... ........ .. ....... ........ .. ....... ........ . 1 9

Ribbon Remov al.... ....... ........ .. ....... ........ .. ....... ........ .. ........ ....... .. ........ ....... .. ........ . 21

Chapter 2 Operation 23

Operating Your Ze bra XiII-Series Printer............... ..... ..... .... ..... ..... ..... .. ..... ..... .... 2 3

Printer O perating Modes ............................................... ......................................24

Tear-Off Mode...............................................................................24

Peel-Off Mode ....... ............ ....... ........ ....... ....... ........ ....... ....... ........ .24

Rewi nd M ode ....... ....... ....... ....... ........ ....... ............ ........ ....... ....... ....2 4

Cutter Mode...................................................................................25

Operator Controls................................................................................................25

Power Sw it ch ....... ....... .. ........ ....... .. ........ ....... .. ........ ....... .. ........ ...... 2 5

Front Panel Display .......................................................................26

Front Panel Keys ......................................................27

Front Panel Lights....................................................28

Printer Sta tus Sen so r s.... ... .. ... .... ... .. ... ..... .. .. ... ..... .. ... . 2 9

Initial Printer P ower-Up ......................................................................................30

Confi gu r a ti o n an d Ca li b ra t io n....... ........ .. ....... ........ .. ........ ....... .. ........ ....... .. ........ . 31

Ente ring the P r ogram Mode......... ....... ............ ........ ....... ............ ....3 1

Changing Password-Protected Parameters ....................................32

Leaving the Program Mode ................ ........ ....... ....... ....... ........ ...... 32

Confi gu r a ti o n an d Ca li b ra t io n Seq ue n ce .... .. .. ........ ....... .. ........ ...... 3 4

Samp le ZPL II Label Formats ..... ....... ........ ....... ....... ........ ....... ....... ....... ........ ...... 51

Format 1: Simple Text and a Barcode ...........................................52

Format 2: Saving a Label Format As a Graphic Imag e ........ ........ .5 2

Format 3: Using a Serialized Data Field........................................53

Chapter 3 R outine Care and Adjustm ent 55

Cleaning.................................. ............ ......................... ............ ........................ ....55

Clean in g th e Ex t er i or ......... ... ....... ....... ... ....... ....... ... ....... ....... ... ...... 5 6

Clean in g th e In te ri o r ........ .. ....... ........ .. ........ ....... .. ........ ....... .. ........ . 56

Cleaning the Print h ea d and Pla te n Roll er ....... ..... ... ..... .. ..... .. ..... ... . 5 6

vi Zebra XiII Printer User’s Guide

Cleaning the Sensors ............................................... 57

Cleaning the Cutter Mod ul e ....... ........ ............ ....... .. 58

Lubricatio n.... ........ ....... ....... ....... ........ ....... ....... .......... ....... ........ ....... ....... ........ .... 58

Fuse Replacement ............................................................................................... 59

Adjustments ........................................................................................................ 61

Togg l e Po sitioni n g ............ ....... .. ........ ....... .. ........ ....... .. ........ ....... .. 61

Printhead Pressure Adjustment ..................................................... 62

Med ia Se nsor Posi ti o n Ad ju st m e n t...... ....... ........ .. ....... ........ .. ....... 62

Chapter 4 Troubleshooting and Diagnostics 63

Printer Diagnostics.............................................................................................. 69

Power-On Self Test....................................................................... 69

Additi ona l Prin t er Sel f Test s ......... .. ... .. ..... .. ... .. ..... ... .. .. ..... ... .. ..... .. 69

Cancel Key Self Test ............................................... 70

Pause Key Self Test................................................. 71

Feed K ey Self Test ......... ....... ........ ....... ............ ....... 72

Feed Key and Pause Key Self Test.......................... 72

Communications Diagnostics Test .......................... 72

Additio nal Prin t er Dia gno sti cs ........ ..... ..... .. ..... ..... .. 72

Chapter 5 Options 75

Rewind Option....................................................................... ............................. 75

Cutter .................................. ...................................................... .......................... 76

Internal Fanfold Media Supply Bin .................................................................... 76

Memory SIMMs ................................................................................................. 76

Zebra On-Li ne Verifi er...................... ....... ..... ....... ..... ....... ..... ........ .... ........ ....... .. 77

Appl icator Int e rf a ce ....... ........ .. ....... ........ .. ....... ........ .. ....... ........ .. ....... ........ .. ....... 77

Media Supply Spindle......................................................................................... 77

Optional Media Supply Fins............................................................................... 78

Fonts.................................................................................................................... 78

PCMCIA Type I Memory Cards ....................................................................... 78

KMT Printhead ................................................................................................... 79

Communication Interfaces.................................................................................. 79

IBM® Twinax Interface................................................................ 79

IBM® Coax Interface.................................................................... 79

ZebraNet™ (Et hern et) Interface ............... ....... ............ .......... ....... 79

RS-485 Interface ...........................................................................80

Zebra XiII Printer User’s Guide vii

Chapter 6 Specifications 81

Medi a H an d li n g ..... ... ....... .. ........ ....... .. ........ ....... .. ........ ....... .. ........ ....... .. ........ ...... 8 1

Options ....................... ............ ............ ............ ............... .......... ............ ............ ....8 2

Zebra Programming Language (ZPL II®) ...........................................................82

Bar Codes ............................................................................................................83

General Specifications.........................................................................................84

Printing Specifications.........................................................................................85

Ribbon Specifications. .........................................................................................85

Media Specifi cati ons .. .. ..... ..... ....... ..... ..... ..... .. ........ ..... ..... .... ..... ..... ..... ..... ..... ..... .86

Power Line Cord Speci ficat ion s.. .. ..... ..... ..... ....... ..... ..... ..... .. ........ ..... .... ..... ..... .... 8 7

Printer Fonts ........................................................................................................88

Standard Printer Fonts ...................................................................88

Standard Printer Font Examples...............................90

Optional Print er Fo nts........ ..... ..... ..... ..... ....... .. ..... ..... ..... ....... ..... .... 9 0

Optional Printer Font Exam ple s... .......... ....... ....... ....9 2

Chapter 7 Support Services 93

How to R ea ch Us. .. ....... ........ .. ....... ........ .. ....... ........ .. ........ ....... .. ........ ....... .. ........ . 93

Technical Support................................................................................................94

Zebra Technical Support Bulletin Board Service..........................94

Technical Support Service via Telephone.....................................94

Technical Support via Mail or Fax ................................................95

Product Servi ce and Su pport Pro g rams.................. ..... ..... .... ..... ..... ..... ..... ..... ..... .9 7

Selec t the Pro g ram that Fi ts Your Bus in e s s .. ....... ........ .. ....... ........ . 97

Extended Factory Service Agreement ...........................................98

Third Party Support and Main tenan ce ........................... ............ .... 9 8

Zebra Solution Center and

Nationa l Sal es and Serv ic e Cen te r Supp o rt ...... 9 8

Wang Custom e r Service s D iv i sion ..... ....... ........ ...... 98

Zebra Factory Services . ........ ....... ....... ........ ....... ....... ....... ........ ...... 99

User Self-Maintenance ...... ............ ............... ............ ............ .......1 0 0

Intern a ti o na l Se rvi ce and Support ....... ........ .. ....... ........ .. ....... ....... 1 0 0

Zebra Training Programs...................................................................................101

Operation and Maintena nce C ourse s .............. ............... ....... ....... 1 02

Bar Codes at Work.......................................................................103

Labeling .......................................................................................103

Printer Interface Technical Information............................................................105

Syste m Considerati o ns....... ....... ........ ....... ............ ........ ....... ....... ..105

viii Zebra XiII Printer User’s Guide

Communications Code..........................................105

Interfaces...............................................................105

Data Specifications................................................106

RS-232/RS-422/RS-485 Serial Data Port...................................106

RS-232 Interconnections.......................................107

RS-422/RS-485 Interconnections..........................108

Parallel Data Port........................................................................109

Parallel Port Interconnections................................110

Cabling Requirements.................................................................111

ASCII Code Chart.............................................................................................112

Adjusting Darkness for “In-Spec” Bar Codes..................................................113

Too Dark.....................................................................................113

Slightly Dark...............................................................................114

Slightly L ight...............................................................................114

Too Light.....................................................................................114

“In-Spec”.....................................................................................114

Glossary 117

Index 121

Zebra XiII Printer User’s Guide ix

x Zebra XiII Printer User’s Guide

List of Figures

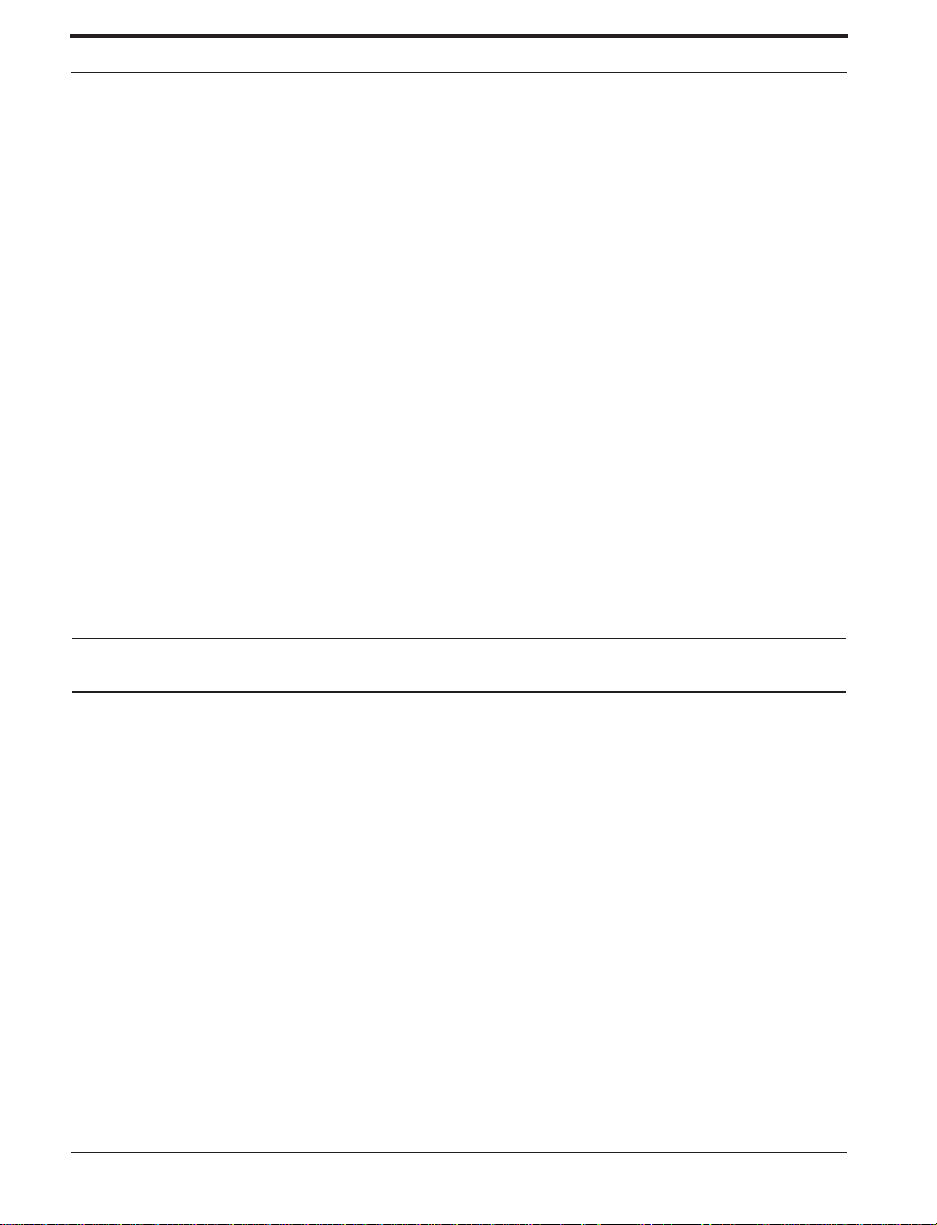

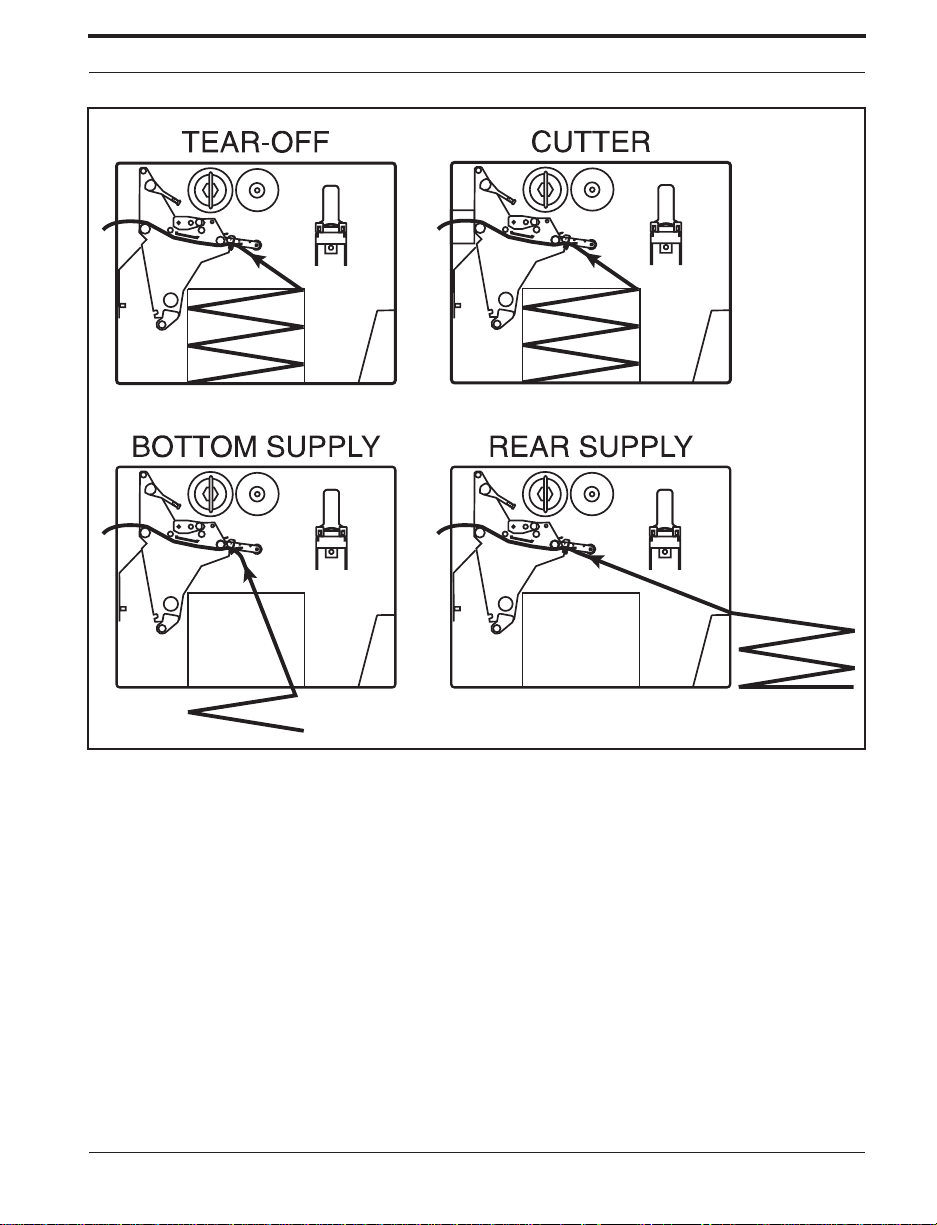

1. Media Loadin g 9

2. Roll Media Loading 10

3. Fanfold Media Loadin g 11

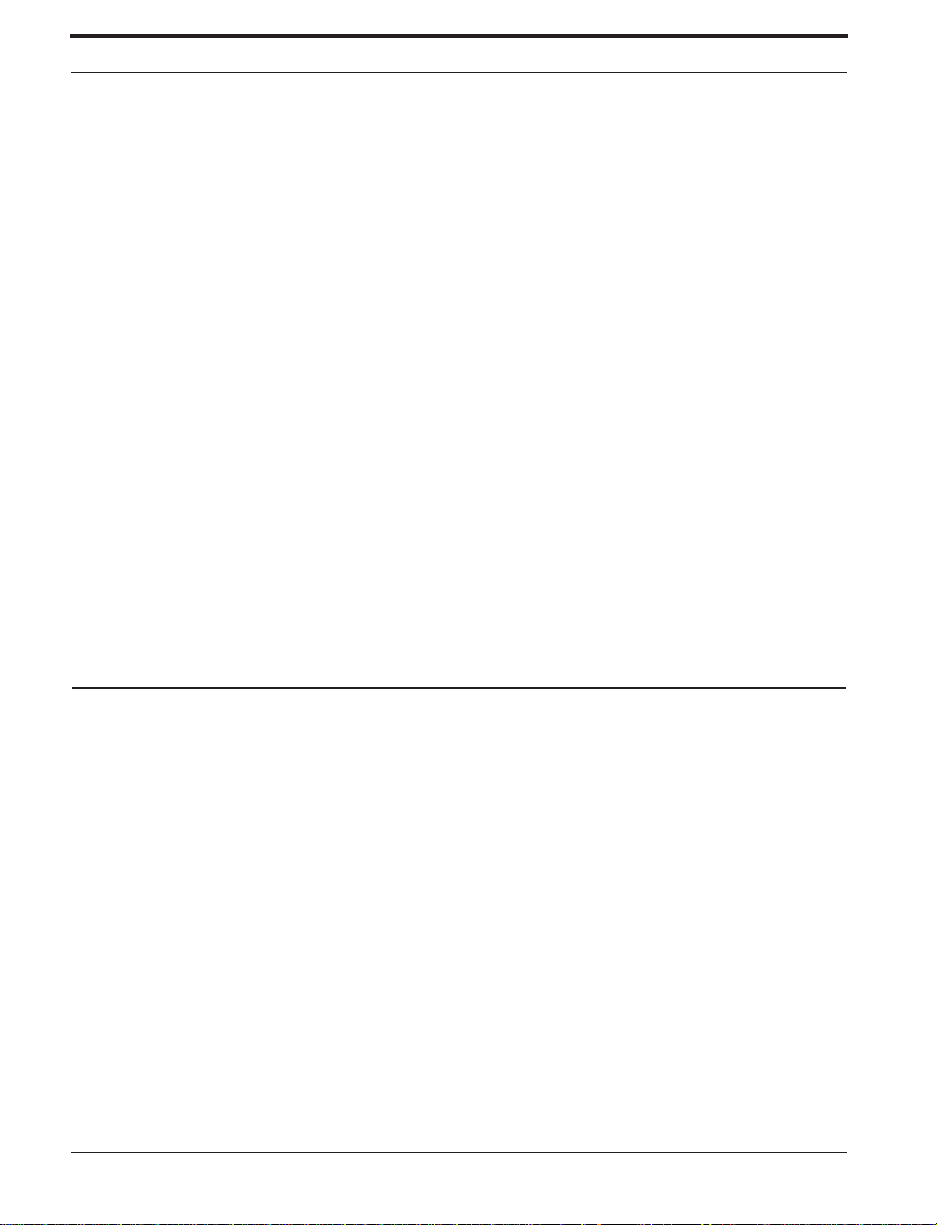

4. Upper Media Sensor Adjustmen t 16

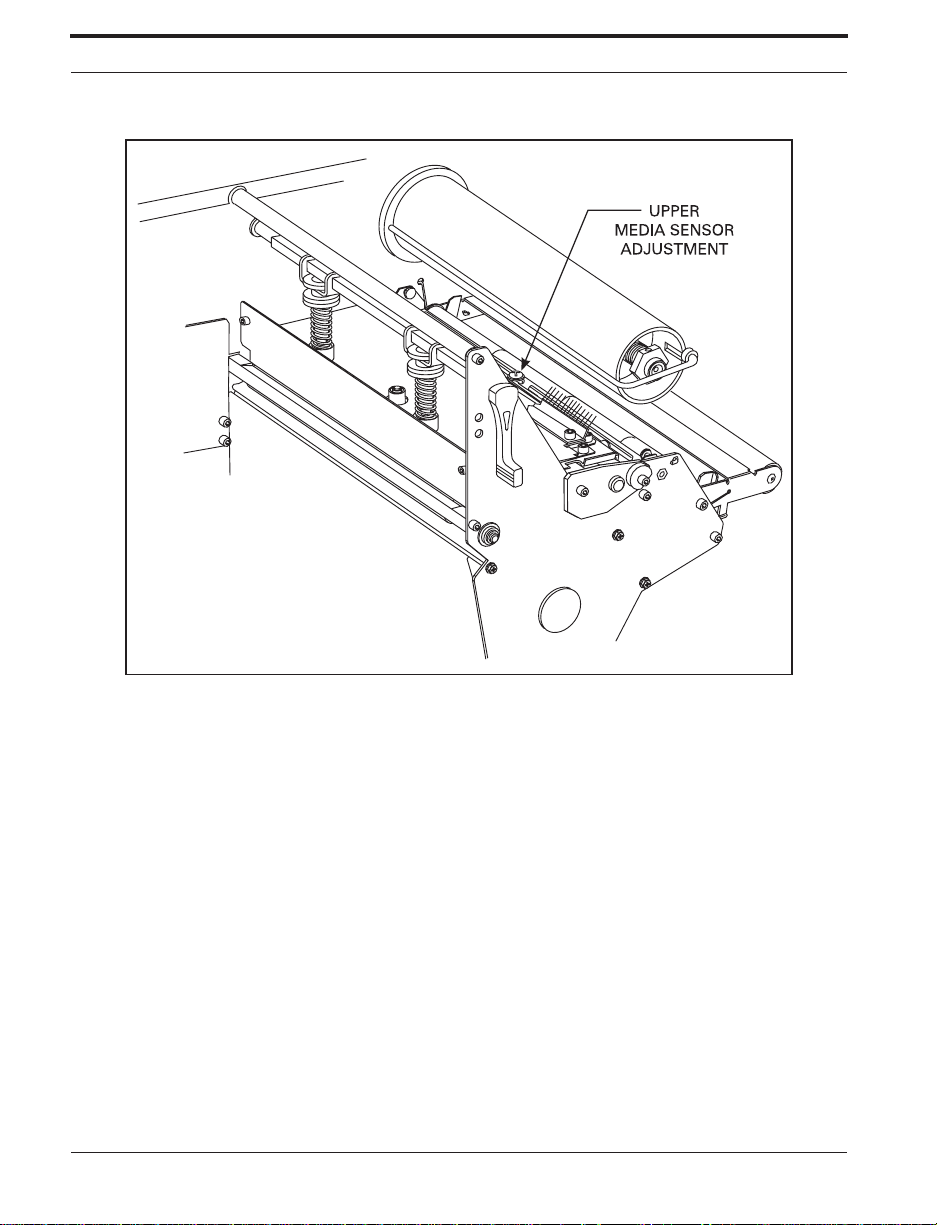

5. Lower Media Sensor Adjustment 17

6. Ribbon Loading Diagram for the 90XiII and 140XiII Printers 18

7. Ribbon Loading Diagram for the 170XiII and 220XiII Printers 19

8. Removing Used Ribbo n 21

9. Front Panel 26

10. Media and Ribbon Sensor Prof ile Sample Printo ut 50

11. Cleaning Diagram 57

12. Fuse Replacemen t—St ep 1 60

13. Fuse Replacemen t—St ep 2 60

14. Toggle Adjustment 61

15. Cancel Key Self Test Sampl e Prin tout 70

16. Pause Key Self Test Sample Printo ut 71

17. Feed Key Test Sample Printout 73

18. Communication s Diag nos tics Test Sample Prin tout 73

19. Power Line Cord 87

20. International Safety Organ izati ons 87

21. Standard Printer Font Exam ple s 90

22. Bitmap Smooth Fonts: Point Size Example s 91

23. Select Examples of Optional Fonts 92

24. RS-232 Connections 107

25. 9 Pin to 25 Pin Interconnecting Cable 108

26. 25 Pin to 25 Pin Interconnecting Ca ble 108

27. RS-422/RS-485 Interconnecting Cable 109

28. RS-422/RS-485 Connections 109

29 . Bar Code Ex amples 115

Zebra XiII Printer User’s Guide xi

List of Tables

1. Front Panel Keys 27

2. Front Panel Lights 28

3. Printer Status Sensors 29

4. Power-On Self Test Sequence 30

5. Cleaning Schedule 55

6. Troubleshooting 63

7. Eight Dots/mm Printhead 88

8. Twelve Dots/mm Printhead 89

9. Optional Printer Fonts Currently Available 91

10. Zebra® Printer Operation and Maintenance Courses 103

11. RS-232/RS-422/RS-485 Pinouts 106

12. Paralle l C onn e ctor Pinouts 110

13. ASCII Code Chart 112

xii Zebra XiII Printer User’s Guide

Chapter 1 Getting Started

Congratulations! You have just purchased a high-quality ther mal demand

printer manufactured by the industry leader in quality, service, and value—

Zebra Technologies Corporation. For over 25 years, Zebra has provided

customers with the highest caliber of products and support.

This manual provides all of the information you will need to operate your

printer on a daily basis. To create la bel formats, ref er to the ZPL II Pro-

gramming Guide (part # 46469L—if you did not order one with your

printer, it is avai l able by send ing in the card at the front of this manual).

There is also a maintenance manual for this printer: The maintenance manual (part # 48452L) contains the information you may need in order to

maintain you r pri nte r.

Introduction

The XiII printer, when connected to a host computer, functions as a complete sys te m fo r pr intin g lab els, ti c k ets, and tag s. Th e prin te r re c e ives

instructions from the host computer. Microprocessors continuously monitor

Zebra XiII Printer User’s Guide 1

Getting Started

these signals along with the inputs received from the control panel and various sensors. The microprocessors interpret this information and control the

XiII printer’s m echanics, pr inthead, communicatio n s, co m ma nd inte r pre t ation, label formatting, media control, and mechanical drive.

Print Mechanism Capabilities

The XiII print m echanism has been designed to print information on labels,

tickets, and tags. It use s a square o r rectan gular dot thermal printhead that

heats a ribbon as it passes beneath the print elem ents, melting its ink onto

the media (direct thermal print mode involves using heat-sensitive m edia

instead of an ink ed ribbo n). Print speeds m ay be sel ecte d v ia softw are control.

Media Transport Mechanism Capabilities

The media transpor t me chan ism of the XiII printer has been designed to

accommodate var ious typ es of media including die-cut labels, ticket an d tag

stock, continuous roll media, fanfold media, and black-mark media.

Media may be rew o und inte r na lly onto stand ard three-inc h core s if the

Rewind Option is installed. The Re wind Option also allows backing material to be re woun d in terna ll y , s o that th e printer can operate in Peel - O ff

mode.

Front Panel Display

The XiII printer featu res a two-line by 16-character-per-line liquid crystal

display screen. Operational status, programming modes and parameters,

and other mes sag es are displ ay ed here. Thi s displ ay featu re s adj ustable

backlighting f or added visib ility.

2 Zebra XiII Printer User’s Guide

Getting Started

System Requirements

In addition to the XiII printer, you will need the following items to form a

compl ete la be l prep a rati on sy stem :

• Label-, tic ket-, o r tagsto ck .

• A device, such as a compu ter, for data e n try and output of labe l formats.

• A data communication cable to connect the controlling device to the XiII

printer. (Remote installation s may requ i re additio nal cables and communication devices such as modems and/or protocol converters.)

• Thermal transfer ribbon (if printing in Thermal Transfer mode).

Media and Ribbon Requirements

Print quality not only depends on the Zebra XiII-Seri es printe r but also on

the printe r ’s m ed i a an d ribb o n . Fac tor s such as reflectiv i ty an d co ntr a s t are

impor ta nt fo r ba r cod e sca n n ing appli ca tions. Fac tor s such as paper abra -

sion and temperature requirements are important to maintaining the life of

the printh ea d .

We STRONGLY RECOMMEND the use of Zebra Te chnologies Corpora-

tion-brand supplies for continuous high-quali ty printing. A wide range of

paper, po lypro py l en e, poly es ter, an d vinyl stock has been specifically engi-

neered to enhance the printing capabilities of the Zebra XiII-Series printer

and to ensure agai n s t prem ature printhe ad wear.

Continuous roll form paper, fan f ol d med i a, or card sto ck with opti o n al per-

foration s an d registration holes may be used . Th e life of the pri n thea d may

be reduced by the abrasion of exposed paper fibers when using perforated

media.

Zebra XiII Printer User’s Guide 3

Ribbons used in the Z ebra XiII printer MUST be as wide as or wider than

the media used. Zebra-brand ribbons provide an extremely smooth backing

surface which protects the printhead from abrasion by the media. If the ribbon is narrower than the media, areas of the printhead will be unprotected

and w ill be subject to premature wear.

Since print qu ality is affe cted by medi a and ribbo n, pri nting speeds, and

printer oper atin g mod es, it is very important to run tests for your applications. This is especially true if you’re operating in Peel-Off mode, where

these varia bles comb ine with label size, backing content, die-cut depth, and

even humid ity to affe ct prin te r ope rati o n.

Unpacking

Save the carto n an d all pac k ing materials i n case shi ppi ng is eve r requ i red .

Inspect the printer for possible damage incurred during shipment.

• Check all exterior surfaces.

• Raise the media ac cess do or an d ins pect the media compartment.

Getting Started

Reporting Damage

If you discover shipping damage upon inspection:

• Immediate ly no tify the shipping com pan y of the da ma g e.

• Retain all packaging material for shipping company inspection.

• File a damage report w ith the shipping compan y an d notif y you r loca l

distributor and Zebra Technologies Corporati on o f the d am ag e.

Zebra Technologies Corporation is not responsible for any damage incurred

during shipment of the equipme nt and will not repair this damage under

warranty. Immediate noti fi cati on of dama ge to the sh ipping company or its

insuring agency will generally result in ensuring any damage claim val idity

and ultimate monetary compensation.

4 Zebra XiII Printer User’s Guide

Getting Started

Storage and Reshipping

If you are not placing the XiII printer into operation immediately, repackage

it using the original packing materials. The XiII printer may be stored under

the following conditions:

• Temperature: -4° to +140° F (-20° to +60° C)

• Relative humidity: 5 to 85% non-condensing

To ship the Zebra XiII-Series print er, car efully pack it in a suitab le contai ner

to avoid damage during transit. Whenever possible, use the original con-

tainer from the factory. A shipping container can be purchased from Zebra

Technologies Corporation if the original one is lost or destroyed. If you use

a different container, package the printer carefully to avoid dam age. Zebra

will not be responsible for shipping damage incurred due to improper pack-

aging!

CAUTION: When packaging the printer in a rigid container, us e shock mounts or shock-

absorbing packing material. A rigid container will allow shock on the out-

side to be transmitted un damped to the prin te r wh ic h may cau se da ma ge .

Also, before packing, remove all ribbon and medi a from the supp ly an d

take-up/re wind spi nd les to prevent dam age to the printer.

Site Requirements

CAUTION: To insure that the printe r h as proper ventilatio n an d cooling, do not place

any padding or cushioning material under the unit because this restricts air

flow.

The Zebra XiII-Series printer may be installed on any solid, level surface of

sufficient size and strength to accommodate the physical dimensions and

weight of the unit. The a r ea enclosur e in which the pr inter will o p erate must

meet the environmental conditions specified. Electrical power must be

available and in close proximity to the printer.

Zebra XiII Printer User’s Guide 5

Since the Zebr a XiII-Seri es prin te r was desig ned and is fabricate d as an

industrial-type unit, it will functio n satisfacto rily in areas such as warehouses, factory floors, and office environme nts that conform to specified

environmental and electrical conditions.

Printer Power-Up

Follow the instructions in this section to connect this printer to a sour ce of

electrical power and a data source.

Voltage Selection

The XiII printer auto-adjusts for 90-264 VAC electrica l pow er. No further

adjustment is requir ed.

Power Cord

Getting Started

WARNING! For personnel and equ ipm en t safety, always use a three-prong plu g with a

ground (earth) connection.

Make sure that the Power On/Off Switch (located at the back of the printer)

is in the off positi on befor e co nne ctin g the pow er ca ble to an electrical outlet.

Depending on how your printer was ordered, a power cord may or may not

be included. If one is not included, or if the one included is not suitable for

your require me nts, refer to “Po wer L ine Cord Specifi cati on s” on page 87.

The power cord connector must be plugged into the m ating conn ector o n th e

rear of the printer.

6 Zebra XiII Printer User’s Guide

Getting Started

Communications

The XiII printer has been designed with flexible communication capabilities

that allow the pri n ter to be interfaced to a variety of con tro lli ng devi ces. A

single DB25 connecto r i nc lud e s al l signals necessa r y for interfac ing the

printer to RS-232, RS-422, or RS-485 serial data communication devices at

data rates from 110 to 57,6 00 baud. Baud rate , parity, data len gth, numbe r

of stop bits, and handsha king prot ocol ar e programmabl e via the front panel

display and keypad.

A parallel data communication port is also provided. This port allows data

to be sent to the printer at a higher speed than seria l communications and

still permits printer status information to be sent back to the host via the RS-

232 serial port.

CAUTION: Zebra printers comply with international regulations governing radiated

emissions when using fully shielded data cables. Data cables must be fully

shielded and fitte d with metal or metalize d connector shells. Shielded data

cables and connectors are requ i red to pre v en t rad i atio n an d re ception of

electrical noise. Use of unshielded data cables may increase radiated emis-

sions above the regulated limits.

Loading Media

Introduction to Media Loading

Note: A Calibration must be perform ed whe n medi a and ribbon (if used) are first

installed i n the prin te r and whe n a dif ferent type of medi a or ribbon is

installed. See “Media and Ribbon Sensor Calibration” on page 38.

Note: Media widths and thicknesses vary between applications. To maintain print

quality from one applic atio n to an o the r, refer to “Adjustments” on page 61.

Zebra XiII Printer User’s Guide 7

Getting Started

Non-Continuous Media

This type of media has some type of physical characteristic (gap, notch, perforation, etc.) which indicates the start/end of each label. The Media Sensor

must be properly positioned to sense these indicators. See “Adjusting the

Transmissi ve Med ia Senso r As sembl y Po sitio n” on pag e 15.

Continuous Media

Since continuous media does not contain label start/end indicators, y ou

must tell the printer via software how long each label is. If you are using

ZPL or ZPL II, include a Label Length (^LL) instruction in each label format you send to the printer (refer to your ZPL II Programming Guide). If

you are using other software to communicate with your printer, refer to the

instructions pro vide d with that so ftw are .

Black-Mark Media

This type of media has black marks printed on the back that indicate the

start/end of each label. The Reflective Media Sensor detects these marks,

which allows the printer to differentiat e bet ween labels. It is generally used

with a cutter to separate the labels b ecaus e t here is no gap bet ween the

labels to allow them to b e peeled off.

To load media, refer to Figures 1 through 3 and follow the loading procedure for your application. This section details the media loading instru ctions

for the printe r. For d esc ripti ons of the ope rati n g mod e s, refer to Ch apte r 2

starting on pag e 23.

8 Zebra XiII Printer User’s Guide

Getting Started

Tear-Off Mode Media Lo ading

Figure 1. Media Loading

Figure 1 illustrates the method of loading media. First, move the Printhead

Open Lever counterclockwise to the open positio n an d rai se th e prin th ea d.

Second, slide the Media Guide and the Media Supply Guide as far out from

the printe r frame as possibl e an d flip d own the Media Supply Guide.

Zebra XiII Printer User’s Guide 9

Getting Started

Roll Media Loading

Place the media roll on the Media Supply Hanger and thread the media

through the prin the ad assembly as shown in the “Tear- Off” l oad ing part of

Figu re 2. F l ip u p the Medi a Suppl y G u i de and ad j u st th e Medi a S u pply

Guide and the Media Guide against t he outer edge of the media. These

guides must not cause pressure or excessive drag on the media. Close the

Printhead Open Lever and see “Adjusting the Transmissive Media Sensor

Assembly Position” on page 15.

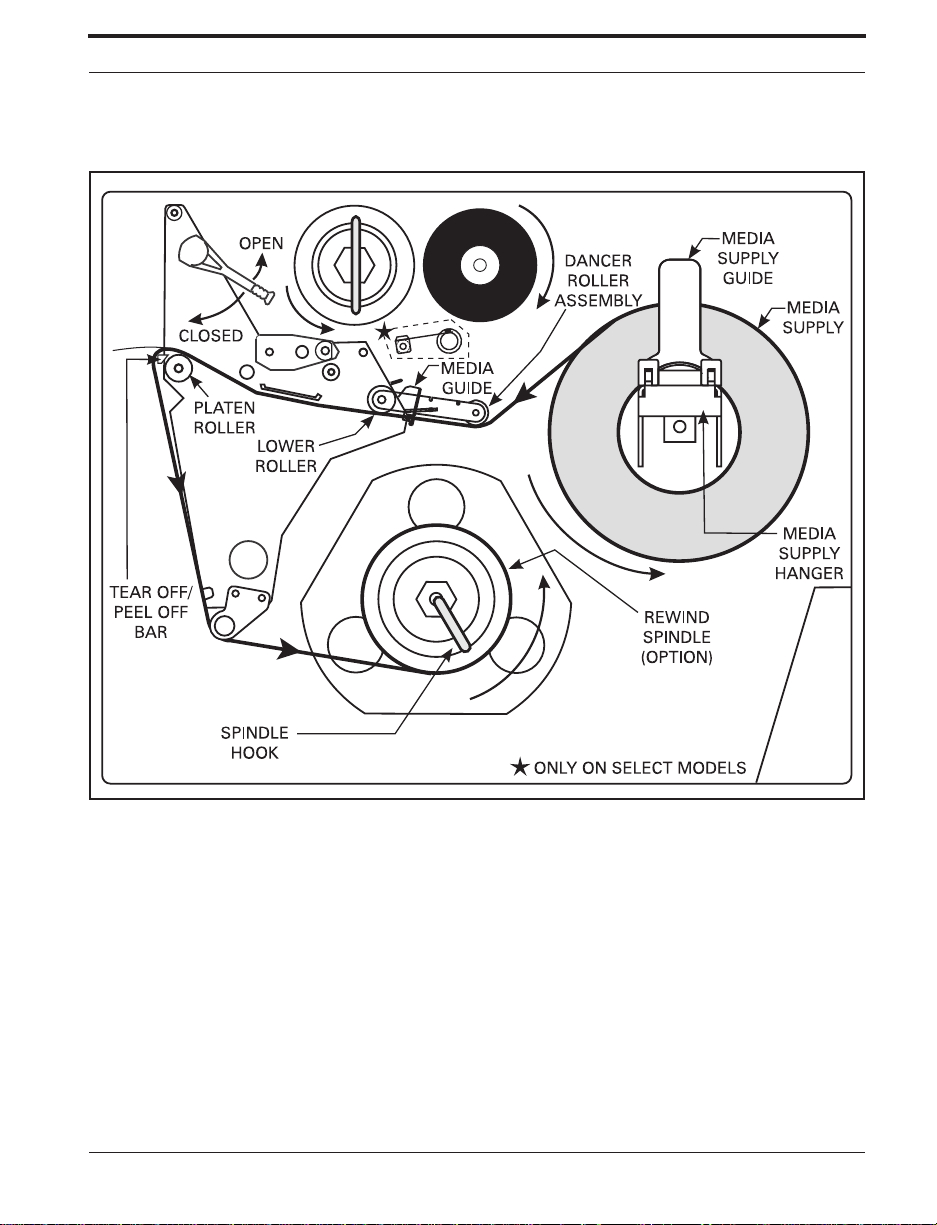

Figure 2. Ro ll Medi a Loadi ng

Fanfold Media Loading

Fanfold me dia, from outsid e the printer, feed s thr oug h ei ther the bottom or

rear a ccess slo t. You m ay also use the Fanfold Supply Bi n to hold media

inside the prin ter hou si n g.

10 Zebra XiII Printer User’s Guide

Getting Started

Figure 3. Fanf o ld Medi a Loadi ng

To load fanfold media, thread the media thr ough the Printhea d Assembly as

shown in Figure 3. Adjust the Media Guide against the outer edge of the

media. Thi s gu ide mu st not c ause pr essu re or exc essive drag on the med ia.

Close the Printhead Open Lever, and turn to “Adjusting the Transmissive

Media Sensor Assembly Position” on page 15.

Continuous Media Loading

Continuous media mounts inside the printer in the same manner as roll

media. For proper printer operation, a label length instruction must be

included in the label format sent to the printer.

Zebra XiII Printer User’s Guide 11

Getting Started

Cutter Mode Media Lo ad ing

(Cutter Option Required)

Figures 2 and 3 illustr ate a prin ter equ ipped with the Cu tter Option . To

ensure proper media loading, follow the directions for the Tear -Off Mode

with the exception that the media must also be routed through the Cutter

Module as shown in Figures 2 and 3.

Close the Printhead Open Lever. The printer will automatically feed out and

cut one label when the printer is powered on. Turn to “Adjusting the Transmissive Media Sensor Assembly Position” on page 15

Rewi nd Mode Media Loading

(Rewind Option Required)

Rewind Mode Configuration for Printers Without the

Cutter Option

1. Remove the Media Rewind Plate from its storage location in front of the

print mechanism inside the media c ompartment.

2. Invert the Rewind Plate so that the lip on the attached Hook Plate points

down.

3. Insert the Hook Plate lip a short distance (½") into the lower opening in

the Side Plate.

4. Align the upper end of the Rewind Plat e with the corresponding opening

in the Side Plate and slide the Rewind Plate in so that it stop s against the

printer’s ma in frame.

5. Load the media as described in the instructions for Roll Media Loading

on page 10.

6. R emove the Spindle Hook from the Rewind Spindle.

7. R oute the media as shown in Figures 1 and 2 and wind it once or twice

around either (1) the Rewind Spindle and reinstal l the H ook, or (2) a 3”

core.

12 Zebra XiII Printer User’s Guide

Getting Started

8. Media loadi ng is now complete. See “Adjusting the Transmissive Media

Sensor Assembly Position” on page 15.

Rewind Mode for Printers With the Cutter Option

1. Remove the Media Rewind Plate from its storage loc ation in front of the

print mechanism inside the media compartment.

2. Invert the Rewind Plate so that the lip on the attached Hook Plate points

down.

3. Insert the Hook Pl ate lip a short d istance (½") into the l owe r ope ni ng in

the Side Plate and sli de the Rewind Plate in so that it stops aga inst the

printer’s main frame.

4. Insert the two small tabs on the Rewind Plate into the cor responding

slots in the Cutter Support Bracket. (The Rewind Plate should spring into

the proper posi ti on. )

5. Load the media as described in the instructions for Roll Media Loading

on p a ge 10.

6. Remove the Hook from the Rewind Spindle.

7. Route the media as shown in Figures 1 and 2 and wind it once or twice

around either (1) the Rewind Spindle and reins tall the Hook, or (2) a 3”

core.

8. Media loadi ng is now complete. See “Adjusting the Transmissive Media

Sensor Assembly Position” on page 15.

Zebra XiII Printer User’s Guide 13

Getting Started

Peel-Off Mode Media Loading

(Rewind Option Required)

Figure 2 illustrate s a printer with the Rewind Option. To insure proper

media loading, see Figure 2 and follow the procedure below.

1. Remove the Rewind Plate if one is present and store it on the two mounting screws on the inside of the f ront panel. Align the not ch in the bracket

so the Label Ava ilable Sensor (shown in Figure 14 on page 61) can

detect a peeled label.

2. Load media as shown in Figure 1 or 2.

3. Remove the Hook from the Rewind Spindle.

4. Remove the labels from about one ya rd ( one meter) of t he media ba cking

and then wind the backing around the Rewind Spindle and reinstall the

hook. Make sure that the m edia backing is against the Backing Guide

Plate.

5. See “Adjustin g the Tran smi ssiv e M ed ia Sen so r Assembly Position ” on

page 15.

Removing the Label Backing Material

(Rewind Option Required)

Since the Backing Rewind Spindle holds the backing from a standard-size

media roll, we recommend that you perform this procedure wheneve r you

chan g e the med i a .

To remove the backing material from the Backing Re wind Spindle, follow

these steps (you don’t need to turn the printer power off for this procedure):

1. Unwind about one yard (one meter) of backing from the Backing

Rewind Spindle and cut it off at the spindle.

2. Pull out the Spindle Hook and slide the backing material off of the spindle and discard.

3. Wind the media around the Rewind Spindle once or twice and reinstall

the Spindle Hook. Continue winding to remove any slac k in the media.

14 Zebra XiII Printer User’s Guide

Getting Started

Adjusting the Transmissive Media Sensor Assembly

Position

When the XiII printer is powered on, it performs a self test and configures its

operatin g ch ara cte ri stics. Some of the se characteristi cs a re d etermined by

the position of the Tran sm i ssiv e Media Senso r. See Fig u re 4 on page 16 .

The factory-set position is sufficient for most types of media. However, if

media sensor adjustments are needed, follow the procedures below.

Note: The Reflective (Black-Mark) Media Sensor position is not adjustable; it is

positioned to accommodate all black-mark media that meets the specifications listed in “Media Specifications” on page 86.

Note: If you are using continuous media (no gap, notch, or hole between labels) or

black- ma rk med ia, position the transm i ssi ve se n sor over the med ia so tha t

the printer can detect an out-o f-paper condition. The factory-set position

should be sufficient for this purpose.

The Transm issi v e Medi a Se n sor Asse m bly con sis ts of two se ctio ns. The

media passes between a light source and a light sensor. The light source is

positioned below the media, while the light sensor is positioned above the

media.

This adjus tmen t a lign s the position of the light sen so r with the notch or

edge of the label.

Zebra XiII Printer User’s Guide 15

Getting Started

Figure 4. Upper Media Sensor Adjustment

Adjusting the Upper Media Sensor Position

Note: If you own a 140XiII or 170XiII printer and n eed to mo v e th e senso r to the

outside half of the maximum media width, or from the outside half to the

inside half, cont a ct a service technic ian to p erfor m this procedur e because it

will require additional steps which are beyong the scope of this user’s

guide.

To adjust the upper media sensor, follow these st eps.

1. Remove ribbon if it is installed.

2. Locate the Upper Media Sensor. Refer to Figure 4. The Upper Media

Sensor is directly b elow the adjust ment screw head.

3. Loosen the Upper Media S ensor Adjustment screw (Phillips head).

16 Zebra XiII Printer User’s Guide

Getting Started

4. Sli de the upper sensor along the slot to the desired position. When using

label stock that has a gap between labels (die-cut labelstock), position

the media sensor anywhere along the gap EXCEPT whe re the rounded

corners of the label are detected. When using tagstock, position the

upper sensor directly over the hole or notch.

5. Tighten the screw.

Figure 5. Lowe r Media Sens or Adju stmen t

Lower Media Sensor A djustm en t

Refer to Figure 5 throughout this procedure.

1. Lo cate the Lower Media Sensor assembly (a spring clip holding a circuit

board) near the bottom rear of the printhead assembly.

2. Position the sensor by sliding it in its slot so that the two brass-colored

infrared emi tters are centered u nder the u pper sensor.

3. If you are moving the sensor away from the printer’s main frame:

Gently pull wires out of the printer fram e as required. (Wires should

have a little slack.) Call a service technician if there is not enough slack

Zebra XiII Printer User’s Guide 17

Loading...

Loading...