Genesis BIG BOY4-8-8-4, BIG BOY 4005, BIG BOY 4006, BIG BOY 4019, BIG BOY 4024 User Manual

...Page 1

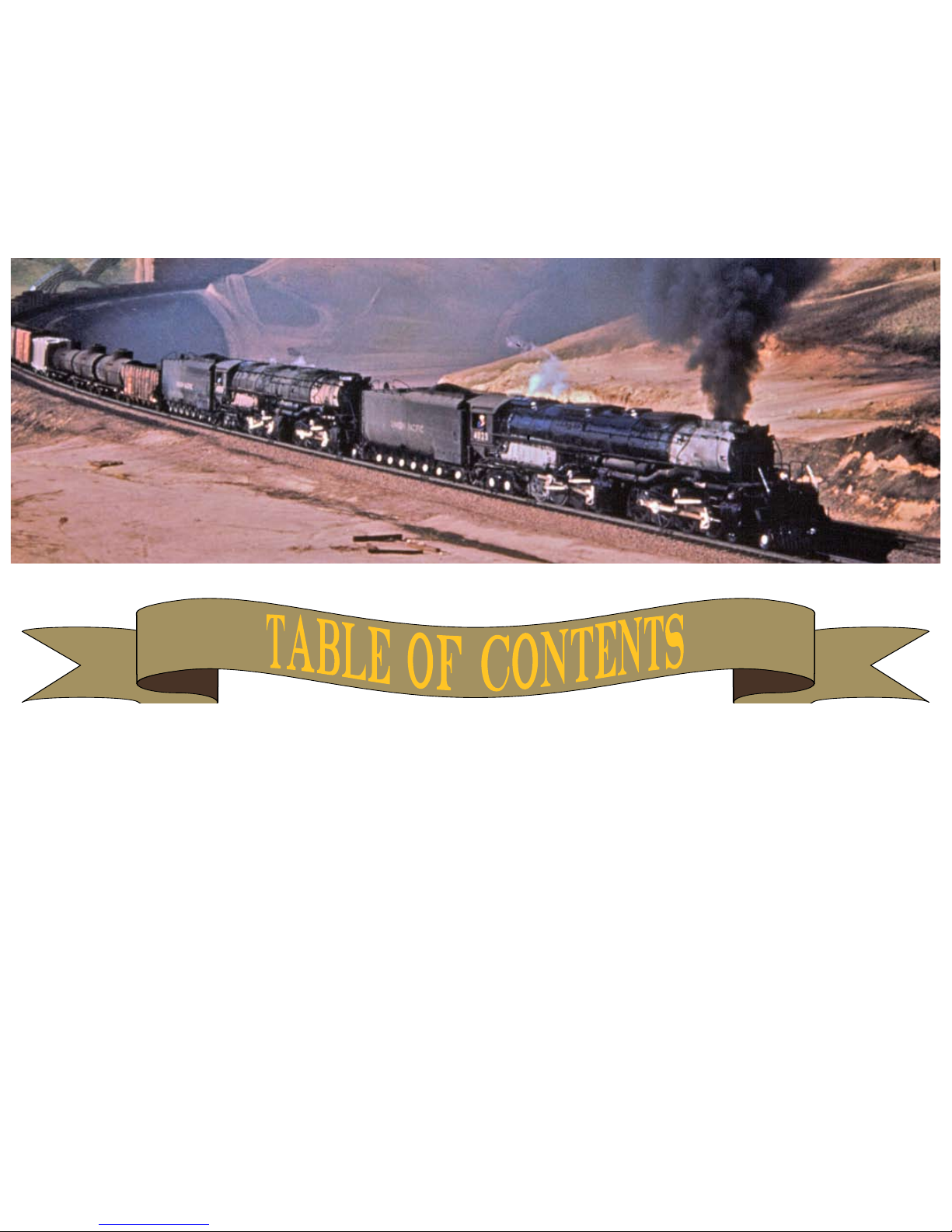

BIG BOY

4-8-8-4

Page 2

• Big Boy History Page…2

• Big Boy…The Model Page…3

• Model Features Page…4

• Sound and DCC Features Page…5

• Operating the Big Boy Page…6

• Lubrication and Maintenance Page…9

• CV Charts Page…11

• Big Boy Tender Diagrams Page…12

• Big Boy Locomotive Diagrams Page…14

Jack Pfeifer photo

Page 3

The Union Pacific was built as the eastern portion of the

Transcontinental Railroad. The original line was built west

from Omaha across Nebraska and Wyoming, into Utah to

a meeting with the Central Pacific at Promontory. Within a

few years the junction was moved east to Ogden. In the early

1900s, the mainline of the Los Angeles and Salt Lake, an UP

subsidiary, joined the original Overland Route at Ogden. The

majority of UP’s traffic went through Ogden.

The line across the Nebraska prairies from Omaha to

Cheyenne, Wyoming had no serious grades as it followed

the Platte River most of the way. West from Cheyenne, it

was a much different story. First, the railroad had to cross the

Continental Divide on Sherman Hill. West of Sherman Hill,

the railroad encountered several grades near one percent as it

traversed the Basin and Range country. Eastbound trains faced

their toughest challenge immediately after leaving Ogden. The

Echo Canyon line through the Wahsatch Mountains was the

steepest grade on Union Pacific’s part of the Overland Route.

It meant that most of UP’s eastbound traffic had to contend

with the grade.

From 1918 through 1924, UP acquired a group of 65

compound 2-8-8-0 locomotives to replace double-headed 28-0s on the grades of Wyoming and Utah. The 2-8-8-0s could

handle the tonnage, but being compounds with 57-inch driv

ers, they were not very fast. 2-10-2s, three-cylinder 4-10-2s,

and the three-cylinder “Union Pacific” type 4-12-2s were also

used. They could not handle as much tonnage, and the 2-8-80s remained the primary locomotive between Cheyenne and

Ogden. By the 1930s, speed was becoming a much bigger

factor, but with the grades, pulling power was still the most

important part. UP finally found a solution by splitting the 412-2 design into a simple articulated locomotive. This resulted

in the Challenger 4-6-6-4 locomotives. Fifteen Challengers

were delivered in 1936 and twenty-five more in 1937.

The Challengers were much faster than the 2-8-8-0s and

only marginally less powerful. They were equipped with 69inch drivers and designed for 80 miles per hour. The Challeng

ers were rated at over 5,000 tons across Nebraska and 4,290

tons across Wyoming. But on the grade over the Wahsatch

Mountains, they were limited to 3,100 tons eastbound. UP

wanted something that could make the same speeds as the

Challengers and could handle the same 4,290-ton trains

over the Wahsatch without a helper. In 1940, Union Pacific

President William Jeffers gave orders to the Department of

Research and Mechanical Standards.

Formed in 1936, the Department was under the leadership

of Vice President Otto Jabelmann. The easiest solution was to

scale up the successful Challenger design by adding another

pair of drivers to each half of the locomotive making a 4-8-84 design. The task before Jabelmann’s department was to fit

such a large machine into the real world. To be of any use,

the new locomotive had to negotiate the existing curves and

fit within the weight limits of the railroad’s bridges.

They had an advantage in that the new locomotive was

intended for a limited operating area, where the mainline was

engineered for high-speed and heavy traffic. The basic Chal

lenger design was lengthened, given a larger firebox, and

larger cylinders, while the driver diameter was reduced one

inch to 68 inches. Other changes were the result of improved

technology such as the cast frame with integral cylinders

instead of the built up frames of the Challengers. Like the

Challengers, they were designed to burn the semi-bituminous

coal from Wyoming mines. The tender used the successful

“centipede” design from the 1939 built 4-8-4s. The coal and

water capacity was based on calculations of usage on a run

through Echo Canyon with yard delays and meets factored in.

Not every limitation could be overcome. One was the

length of the locomotive. The boiler overhang would have

resulted in sideswipe collisions on some double track curves.

These curves were widened a few feet to eliminate that prob

lem. The length also meant the new locomotive was too

long for existing turntables, so new 135 foot turntables were

installed at Ogden and Green River, the western and eastern

terminals for the planned operation of the new locomotive.

In 1941, UP placed an order for twenty 4-8-8-4’s, num

bers 4000 – 4019, with the American Locomotive Company,

or ALCO as it is better known. Each engine cost $265,174.

According to legend, an unidentified machinist at the ALCO

plant is responsible for the name “Big Boy”, having written it

in chalk on a partially complete locomotive. Although there is

some evidence that UP intended to call it’s newest and largest

locomotives “Wahsatch” in honor of the grade they were built

to overcome, the Big Boy name stuck.

The first Big Boy, number 4000, was formally accepted

by the UP at Omaha at 6 P.M. on September 5, 1941. Traffic

during World War Two resulted in 5 more Big Boys, numbers

4020 – 4024, being built in 1944. These were slightly heavier

due to wartime restrictions of various metals and had a differ

ent arraignment of boiler tubes and flues.

In service, the Big Boys started out on the Ogden to Green

River segment. A typical freight train powered by a Big Boy

took four hours to go the 75 miles from Ogden to Evanston,

Wyoming, consuming 20 tons of coal and 12 to 13 thousand

gallons of water. Big Boys were also cleared to run from

Big Boy Locomotive Weights and Dimensions

4000 - 4019 4020 - 4024

Tractive Effort 137,375 Lbs. 137,375 Lbs.

Cylinders, diameter and stroke (4) 23.75 in. x 32 in. 23.75 in. x 32 in.

Driver diameter 68 in. 68 in.

Grate area 150 sq. ft. 150 sq. ft.

Steam Pressure 300 Psi. 300 Psi.

Total Evaporating Heating Surface 5,889 sq. ft. 5,755 sq. ft.

Superheater Type Type E Type A

Superheating Surface 2,466 sq. ft. 2,043 sq. ft.

Total Engine Weight 762,000 Lbs. 772,250 Lbs.

Weight on Drivers 540,000 Lbs. 545,200 Lbs.

Boiler Diameter 95 in. 95 in.

Driving Wheel base (each) 18 ft. 3 in. 18 ft. 3 in.

Driving Wheel base (total) 47 ft. 3 in. 47 ft. 3 in.

Total Engine Wheel base

72 ft. 5 in.

72 ft. 5 in.

Engine Length 85 ft. 9 in. 85 ft. 9 in.

Tender Weight (full load) 427,500 Lbs. 436,500 Lbs.

Tender Coal Capacity (level) 28 tons 28 tons

Tender Water Capacity 24,000 gal. 25,000 gal.

Tender Length 47 ft. 47 ft.

Overall Wheel base 117 ft. 7 in. 117 ft. 7 in.

Overall Length 132 ft. 10in. 132 ft. 10 in.

Total Weight (full load) 1,189,500 Lbs. 1,208,750 Lbs.

Page 4

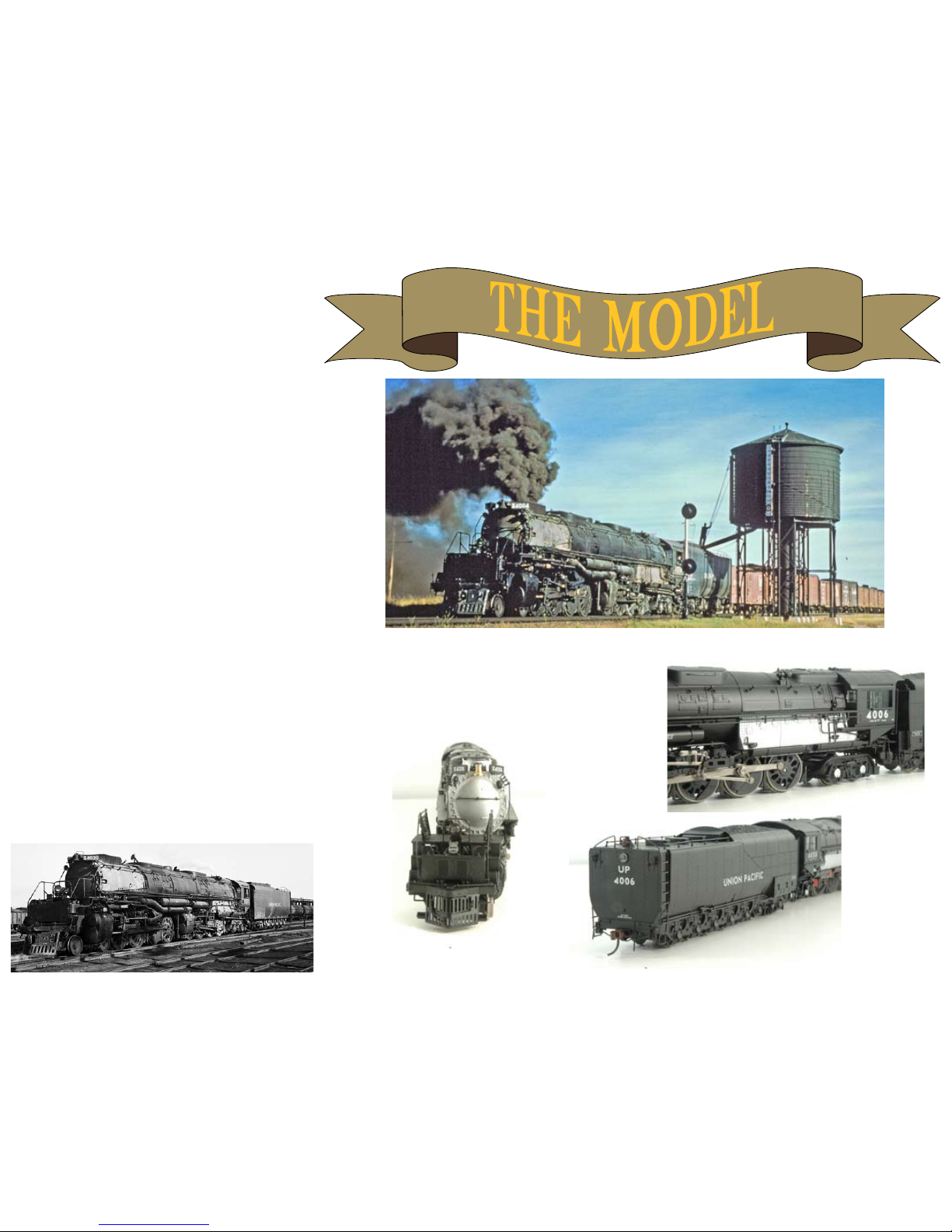

G9150 BIG BOY UNDECORATED W/O DEFLECTORS

G9151 BIG BOY UNDECORATED W/ DEFLECTORS

G9152 BIG BOY #4005

G9153 BIG BOY #4006

G9154 BIG BOY #4019 WITH DEFLECTORS

G9155 BIG BOY #4024

Ogden to Pocatello, Idaho and from Granger, Wyoming to

McCammon, Idaho, but they were not used on those lines.

Because Cheyenne was their home shop for heavy work, the

Big Boys regularly ran from Ogden to Cheyenne for shopping. When released from the shop, it was customary to

use the Big Boy as a helper for Sherman Hill for a few runs

before releasing it back to the freight pool. Before long, the

run from Ogden to Cheyenne was the normal Big Boy operat

ing area. Each Big Boy ran about 7,000 miles each month

throughout their careers. Producing about 6,000 horsepower,

the Big Boys were very well suited to hustling hot Pacific Fruit

Express trains over the grades of Wyoming.

Big Boys had been cleared to run the LA&SL to Los

Angeles from the beginning with some speed restrictions

on the tighter curves found in several areas. .None ran into

Nevada or California, but during World War Two, traffic on

the LA&SL route to Southern California was near the line’s

peak capacity. Several Big Boys operated for a while from

Salt Lake City to Milford, Utah to see if their power could ease

the traffic crunch. Since the LA&SL used oil instead of coal,

a clamshell coal loader was used at Lynndyl, Utah to supply

coal to the Big Boys. The biggest problem encountered was

the lack of water and very poor quality of the water found in

the desert.

Another experiment was the conversion of number 4005

to an oil burner just after the end of World War Two. The

experiment was not a success as only one burner was installed

and it heated just one spot of the crown sheet so much that the

crown sheet leaked considerable amounts of water into the

firebox. After a short period of testing, the 4005 was convert

ed back to coal. Without dieselization, it is probable that more

Big Boys would have been acquired including oil burners for

the LA&SL.

Despite the influx of diesels following World War Two,

the Big Boys and Challengers remained the prime power on

the Overland Route from Ogden to Cheyenne. Helpers were

used on Sherman Hill including double-headed Big Boys.

They also saw service as helpers, leading gas turbines and

diesels over Sherman Hill. They remained active on through

the 1950s, not being retired until the early 1960s.

Jack Pfeifer Collection

Dave Martindell photo,

Clayton Tinkham collection

UNION PACIFIC

Page 5

The Genesis™ 4-8-8-4 Big Boy is the culmination of

the art of design and tooling integrating the latest inno

vations in electronic technology. The Big Boy model

has been developed from its inception as the finest three

dimensional operating miniature representation of the

prototype available.

Enclosed in the premium quality box are the following

items:

1. History and Instruction Book that includes a warranty

and instruction card

2. HO scale 4-8-8-4 Big Boy Locomotive

3. HO scale tender with full electronics package

installed

4. Hand Held Wireless DC Controller

Upon inspecting the locomotive and tender note the

many details that have been incorporated in its con

-

struction.

Locomotive and tender features

• Boiler backhead with full details and printed manual

controls.

• Individually applied detail parts such as piping,

valves, generators, etc.

• Blackened metal RP25 wheels.

• Eccentric cranks operating on both sides in correct

direction.

• Front and rear engines (cylinders and coupled drive

wheel sets) both pivot in order to manage 18” radius

curves.

• Pilot has open/closed positions. Coupler pocket can be

inserted to mount coupler.

• Adjustable cab windows.

• Headlights and tender lights have directional light

change, while the number boards are permanently

illuminated.

• Five-pole, skewed armature motor with two flywheels with very smooth-running features.

• Cab hatches can be either closed or open.

• See-through running boards.

• Each undecorated version includes all parts for that

specific ver

sion.

• Locomotive is smoke-unit-ready. No soldering

needed.

• 6-pin connector plug between loco and tender.

• Current pick-up on all 16 driver wheels and 8 tender

wheels.

• Consumer-friendly disassembly features for spare part

replacement.

• Detailed instruction sheets with exploded view drawings and history booklet.

• Cabin is closed with opening door feature.

Prototype Specific Features

• Coal load.

• Coal rack for additional coal storage.

• Wood tender deck.

• Smoke deflectors.

• Ashpans applied to coal fueled versions only.

• Closed cab with opening door feature.

M o d e l F e a t u r e s

Page 6

DCC Features:

The decoder provided with the GenesisTM Big Boy Locomotive will operate with any NMRA compatible DCC system.

The default setting is address 3. The decoder is rated at 2 amps

and will support either 2 or 4 digit addresses. The decoder

functions are fully programmable by the adjustment of CVs.

A CV table is included in the operating instructions. Either 14

speed steps or 28/128 speed steps are supported by this system.

Available accessory and sound functions are as follows:

• Directional Lighting • Bell (4 types)

• Whistle (12 types) • Air Release

• Coupling • Brake Squeal

• Sound On/Off • Fire Box Door

• Water Injector • Sand Release

• Cylinder Cock/Flange squeal • Blower Hiss

• Conductor’s Voice or rail clack

In addition to Function Ø (Directional lighting) there are nineteen additional sound functions to allow the operator to capture

the full range of unique sounds found on an operating steam

locomotive. You can now fully immerse yourself in the com

plexities of prototype operation and add a new level of realism

to your railroading experience.

Dual-Function decoder is made by Model Rectifier Corpora

tion for Athearn, Inc.

The installation of sound in a locomotive adds a new dimension to operation. Sound makes a technically perfect static

model come alive and enhances the experience of operation.

You will find that you will no longer "run" the engine but,

rather, operate it in the context of your layout. Whether you

are using conventional DC control or a DCC system, the incor

poration of advanced electronic technology will provide the

ultimate railroading experience.

The Genesis

TM

Big Boy Locomotive includes a factory

installed Dual Function DCC Decoder with speakers. The

board is mounted in the tender. The DCC decoder automati

cally senses the power supply type (either DC or NMRA compliant DCC system) that is being used and will operate without

intervention from the user.

Hand-Held Wireless Controller

Included with the Big Boy locomotive is a hand-held wireless

controller. When operating with conventional DC, this control

unit is designed specifically to allow control of the speed and

direction of the locomotive as well as these six individual

sound functions:

• Bell • Whistle

• Water Injector • Air Release

• Blower Hiss • Fire Box Door

These are more sound features than have been previously

available to the conventional DC user in any format. The GenesisTM Big Boy Locomotive will operate on DC without the use

of this hand held, however, only the steam chuff sounds will be

available in this operational mode.

S o u n d a n d D C C F e a t u r e s

LED Indicator

Whistle

Bell

Stop

AccelerateDecelerate

Direction

The 12-volt transmitter battery, # A23-12, is available at any

electronics or office supply store.

Page 7

Your new GenesisTM Big Boy Locomotive comes factory

equipped with a state-of-the-art Dual Function decoder. This

means your locomotive will run on any NMRA compatible

DCC system or on any regular DC Train Control (HO power

pack).

Caution: Do not run your new GenesisTM Big Boy Locomotive with power

packs intended for “G” scale [do not exceed 18 V DC] as you may damage the locomotive circuitry. Also, never operate your locomotive with a

transformer designed for use with AC powered model trains, O-27 trains

or some European HO models. Some DCC systems also come equipped

with a switch for extra voltage for larger scales [“O” or “G”] but if you

use your locomotive on this setting damage will occur to the on-board

electronics due to the higher constant track voltage [22 volts].

When running on a DC power pack, this locomotive features a

wireless radio control. This makes accessing the sound functions

and running the locomotive more convenient when following

your train around the layout. The transmitter (battery included)

that comes with your locomotive has the following functions:

1. Button 1 [Bell Button] will start or stop the bell sounds.

2. Button 2 [Whistle Button] will operate the steam whistle.

3. Button 3 [Speed down Button] will decelerate the locomo

-

tive. Press Button 3 when the locomotive is stopped and you

will hear an air release sound.

4. Button 4 [Speed up Button] will accelerate the locomo

-

tive. When the locomotive has reached its maximum speed,

pressing Button 4 will activate the sound of the fire box door

opening and closing.

5. Button 5 [Direction Button] should be used after bringing

the locomotive to a stop. If pressed while the locomotive is

moving, the locomotive will slow down to a gradual stop,

change its direction and then gradually speed up. This is also

a built in safety feature. Press Button 5 when the locomotive

is in idle (25%—35% throttle setting) to activate the blower

hiss sound.

6. Button STP [Stop Button] will bring the locomotive to a

gradual stop. This is a built in safety feature. Press Button

STP while the locomotive is stopped and you will hear the

water injector sound.

NOTE: If you turn the "Load Control" feature on (CV #123 from 0 to 1)

while using this locomotive on a DCC layout, this changes the operation

of this locomotive in the analog DC mode. To operate this locomotive

on analog DC, you must use the transmitter as your main control, your

powerpack just supplies the constant track voltage. Adjust your throttle

control to your desired top speed setting, [do not exceed 18 vdc]. The locomotive will start to idle, now use your transmitter to control the speed and

direction of your locomotive. If you want to use your powerpack’s throttle

control to run this locomotive, please have someone with a DCC system

disable the “Load Control” feature by changing CV #123 to a value “0”..

DC Operation-(Analog Mode)

To set up your Hand Held Controller and operate your locomo

-

tive with a DC power pack, follow these easy directions:

1. Install the battery in the transmitter.

2. Connect the wires from your DC power pack's "variable

track terminals" to your track.

3. Place the locomotive on the track making sure all wheels are

aligned correctly to avoid short circuits, which can possibly

damage your locomotive circuitry and power pack.

4. Turn the switch on the power pack to ON.

5. Slowly adjust the throttle until you hear the locomotive begin

to idle. Only during idle can you use the direction switch on

the power pack to change the locomotive’s direction. Either

the headlight or back-up light will illuminate to indicate the

locomotive’s direction. Once the locomotive begins moving,

you cannot use the direction switch on the power pack to

change direction. You can only use the transmitter to change

the locomotive direction while it is moving. This feature

allows you to control another analog locomotive on the same

track.

NOTE: Your new GenesisTM Big Boy Locomotive will always

remember its last direction of operation regardless of the position of

the direction switch on the power pack.

6. When you use the power pack's throttle to control the

locomotive’s speed, the top speed will be limited by the

transmitter’s speed setting. When you use the transmitter to

control the locomotive’s speed, the top speed will be limited

by the power pack's throttle setting.

7. If the locomotive's top speed is too low, do not set the

power pack's throttle to maximum. We recommend you set

the throttle to 60%-70% and use the transmitter to control

the locomotive speed. This will give you the best operating

range.

8. Never exceed 18 volts DC to the track in analog operation.

Excessive track voltage may damage the locomotive’s circuitry.

Never try to operate the locomotive on AC power.

9. If the transmitter’s range begins to decrease, the battery

needs to be replaced. On larger layouts, or if your layout is

in a room that has a lot of radio interference, (metal pipes,

screen wire scenery, etc.) we recommend that you hold the

transmitters antenna wire close to, or touching, the running

rails of the layout if the locomotive is traveling far from your

position.

10. We recommend you always use the power pack's throttle

to control the locomotive’s speed. Not only will you

get a smoother speed control, but the battery life will be

extended.

11. Whenever you feel that the locomotive is not operating

properly you should move the throttle to zero or 25%-35%

throttle setting (depending on your power pack) and slowly

move the throttle up again to control the locomotive.

12. If you hear the locomotive say “Program” while running

in the analog DC mode, do not press any buttons on the

transmitter. Power down with the power pack’s throttle to

zero, bringing your train to a gradual stop. Then turn the

power pack’s on/off switch to "off" to reset your locomotive.

(Entering program mode might occur if you are attempting

to use the stop button [STP] while the locomotive is travers

ing a long dirty section of track. The locomotive will read

this as a power down/ power up sequence.) If you press any

buttons on the transmitter at this time you can change some

of your settings inadvertently.

Programming in DC Operation-(Analog Mode)

While in analog mode, you can program the chuff rate [up or

down], chuff starting point, and you can also select different

bells or whistles.

NOTE: Please wait at least 2 seconds between button presses when in

the Program Mode. Multiple, rapid pressing of buttons will confuse the

system.

Page 8

1. Place the locomotive on track

2. Turn the power switch on the power pack to ON

3. Slowly turn the throttle until the idle sounds come on. Once

the idle sounds steady out, leave the throttle as is, and turn

the power pack’s power switch to off.

4. Enter the program mode by pressing and holding the Stop

Button [STP] while you turn the power switch back on.

When the locomotive says “Program,” quickly release the

stop button. The locomotive will say “Program” a second

time, this will confirm that you are now in the Program

Mode.

5. Press Button 4 [Speed up Button] or Button 3 [Speed down

Button] to increase or decrease the chuff rate. Each press of

the button adjusts the chuff rate by one unit. You will hear

a steam release after each press of the button as an audible

confirmation.

6. Press Button 2 [Whistle Button] to toggle between the different types of whistles. Once you hear a type of whistle you

like, stop pressing the button.

7. Press Button 1 [Bell Button] to toggle between the different

bell types. Once you hear a bell you like, stop pressing the

button.

8. Press Button 5 [Direction Button] to change the master

volume of the locomotive. There is no "off", but there are 3

levels of volume control—low, middle, and maximum.

TIPS for Analog Operation

1. Turn up the throttle until sounds start and locomotive idles.

2. Select the locomotive’s direction either with the direction

switch on the power pack or by the transmitter.

3. Slowly start your locomotive moving by using the power

pack’s throttle to set desired top voltage setting.

4. Once underway, press and hold Button 4 [Speed up Button]

or Button 3 [Speed down Button] until you reach the desired

speed.

Remove this hatch to adjust sound

9. To reset the locomotive back to it’s factory defaults; Press

the Stop Button [STP] 5 times. Wait at least 2 seconds

between presses. After each press the locomotive will say

“program,” After the 5th press, you will hear “program” fol

lowed by a steam hiss. This confirms that the reset process

is completed.

10. Once finished programming, turn the power switch on

the power pack to OFF. This will reset the locomo

tive and lock in your programming. To resume operation, follow the steps under “DC Operation.”

NOTE-When programming the chuff rate, it is recommended that after

each press of the buttons, leave the program mode and run the locomotive.

If the chuff rate is still not to your liking, re-enter the Program Mode and

try the next setting. It takes some experimentation on the part of the user

to get these rates as close as possible.

Manual Volume Control

Located on the top of the tender, towards the rear, there are 3

oval hatches. Remove the middle hatch and use a small flatbladed jeweler’s screwdriver to adjust the volume. Adjustment

this volume control lowers or raises the overall volume of the

locomotive, not individual sound volumes.

Page 9

test the bell and whistle. Turn the light on and off. If everything works correctly, then you can program the parameters

that you want.

To acquire your locomotive, select it’s current address on your

DCC system (address #3 if it is just out of the box). Press any

function button (other than F1 or F2) or bring the throttle up

one click. These steps, after turning on your DCC system,

acquire the locomotive’s address, and now you can run it.

Once these steps have been performed, follow the included CV

chart to program any new programming features you want into

the locomotive. For best results, you should initially program

your new Big Boy locomotive on a program track. You must

know how to properly use your DCC system’s programming

mode to program any decoder. If you are unsure of program

ming a decoder with your system, please consult your DCC

system’s instruction book regarding programming or contact

the manufacturer of your DCC system for proper guidance.

Programming for DCC Operation - Digital Mode

This decoder supports all program methods including register

mode, paged mode, CV programming, direct mode and pro

gramming on the main (OPS mode programming). Program

the locomotive the same way you would program any other

NMRA compatible decoder with your DCC system.

NOTE- Some DCC systems do not have enough power on the Program

Track for programming sound decoders. If your system is one of these, there

are Program track Boosters available from aftermarket DCC supplier.

NOTE- Because this locomotive has a dual function sound decoder onboard, it does not support CV read back features.

Additional Information

The dual-function decoder installed in this locomotive should

perform well when used with any NMRA compatible DCC

system. You should be familiar with your DCC system’s pro

gramming and operating functions to get the most enjoyment

out of any decoder equipped locomotive. For more information about Register/CVs and their functions, please refer to the

NMRA DCC standards and recommended practices, RP-9.2.2.

This is available directly from NMRA or on their website at

www.nmra.org.

FCC Compliance

This device complies with Part 15 of FCC rules. Operation is

subject to the following two conditions:

1) This device may not cause harmful interference

5. If the top voltage setting at maximum speed is too low, use

the power pack's throttle to adjust the top voltage setting.

6. To conserve battery life, use the throttle to control locomotive speed and use the transmitter to activate sounds.

7. When finished running your locomotive, turn your powerpack throttle to OFF and turn off the power pack’s power

switch. Any programming changes made in DC analog

mode will affect any prior DCC mode settings.

NOTE- Whenever you use the transmitter to control speed, direction,

or stop, [button numbers 3,4,5, and STP], this will over ride your power

pack's throttle control. If you want to regain use of the power pack's

throttle, use the transmitter to bring the loco to a stop. Then bring your

power pack's throttle knob to approx. the idle setting, then flip your

power packs direction switch. You will hear an audible air release, that

lets you know that the power packs throttle is now in control.

DCC Operation- Digital Mode

Your new Genesis

TM

Big Boy Locomotive will operate on any

NMRA compatible Digital Command Control [DCC] system.

The dual-function decoder has the following features:

• Synchronized steam chuff with random sounds

• 2 amp capacity

• Programmable for either 2 digit, (1-127) or 4 digit,

(1-9,999) addresses

• Programmable start voltage

• Programmable acceleration rate

• Programmable deceleration rate

• Programmable top voltage

• Programmable chuff rate

• Programmable volume

• Programmable 14-28/128 speed steps

• Directional lighting (FØ)

• 19 accessory sound functions, (F1-F19)

• Advanced consisting (CV19)

• OPS mode programming

• Compatible with NMRA DCC standard

• Complies with Part 15 of FCC Rules

NOTE- If you know someone with a DCC System, you can have them

program the individual sound volume configuration variables [CV] to

your liking.

The GenesisTM Big Boy Locomotive can be operated with the

steam sounds on or off, by double clicking your headlight button (FØ). When the steam sounds are turned off, all associated

sounds are also turned off.

Before attempting any programming, you should test run your

locomotive first on address #3 (factory default), to make sure it

works correctly out of the box. Run it forward and backwards,

2) This device must accept any interference received, including

interference that may cause undesirable operation.

Troubleshooting

Always check the three steps below first if you encounter any

trouble with your Big Boy Locomotive.

1. Make sure the plug between the locomotive and tender are

securely connected.

2. When placing the locomotive on the tracks make sure all

wheels are properly aligned as not to cause a short circuit.

3. Make sure battery is correctly installed in the transmitter,

[DC analog use only].

Analog use:

1. Locomotive does not make sounds or respond when power

is applied to track. Check that power pack is plugged in, and

that wires to track are connected properly. Turn throttle to

zero position, turn the power packs power switch to off, wait

a few seconds, then try again as in the analog operation section of the instructions.

2.

Sounds do not activate with transmitter all the time. Check

battery power and change if needed. Different atmospheric

conditions and/or metal pipes, conduits, and screen wire

scenery can cause range problems. Try holding the trans

mitter antenna close to or on one of the running rails if the

locomotive is far away from you.

3. Locomotive does not idle, [starts moving at a low voltage],

or locomotive makes idling sounds but does not move. The

decoder has a memory, and may not have been shut down

correctly after it’s last use, in the DC analog mode only. Turn

the throttle up slowly to place locomotive in “True Idle”. You

can confirm the “True Idle” setting by changing the direction

switch on your power pack. You will hear an audible steam

noise and the headlight will change direction. If the headlight

does not change direction, you are not in “True Idle”. Turn

the throttle voltage down slightly and try again. Once you are

sure you are in “True Idle”, flip the direction switch again to

reset the decoder. This can occur in the DC analog mode with

the "Load Control" feature in it's "off" setting.

DCC use:

1. Locomotive runs on address #3, but will not take a 4 digit

address. Some DCC systems do not have enough power on

the program Track to program sound decoders.

2. Locomotive responds to Bell/Whistle functions but does

not move. CV #29 is not programmed correctly for either a

2 digit address or a 4 digit address. Input a value of “2” in

Page 10

CV29 for a 2 digit address, or a value of “34” in CV29 for

a 4 digit address.

3.

Locomotive idles but does not move or respond to func-

tions. Make sure you did not program the locomotive into

an advanced consist, [CV #19]. In your DCC system’s “Pro

-

gram CV Mode”, input a value of “0” into CV #19.

4. Any misguided programming of values in the DCC mode

can cause a decoder to malfunction. Always try to first set

the decoder back to it’s factory defaults by using CV #125.

If this does not work, try programming the following CV’s

with the following values; CV1=3, CV17=0, CV18=0,

CV19=0, CV29=2. If this does not work, try running the

locomotive in the Analog D.C. Mode. If the locomotive runs

in analog, chances are it will run in the DCC Mode, but the

programming of the decoder is way off.

5. Reset the decoder in the Analog DC Mode. Perform the

following steps using a DC power pack:

1. Turn power packs on/off switch to on.

2. Slowly bring up throttle until you hear hissing/idling

sounds.

3. Leaving throttle in it’s position, turn power switch off.

4. Hold down program button, [#6/STP], on transmitter

while turning power switch back on. You will hear decod

er say “Program”. Release transmitter button, decoder will

say “Program” again. This confirms you are in the analog

DC program mode.

5. Wait 2 seconds, press the program button, [#6/STP], again

and listen for “Program”.

6. Perform step #5 four more times, [total of 5 times].

7. After you hear the decoder say “Program” after the 5th

time, you will hear a steam release. This will confirm that

the decoder has been reset to it’s factory defaults, [for both

DC and DCC modes].

8. Try running the locomotive again on DCC.

9. Sometimes you may simply turn your power supply off

and on again, and the locomotive will run again,

10. If you are still having trouble with your Big Boy contact

Athearn Trains for further assistance.

Lubrication and Maintenance of the GenesisTM

4-8-8-4 Big Boy

The GenesisTM Big Boy Locomotive has been carefully engineered to provide years of trouble free operation. However, as

with all things mechanical, a small amount of care and main

tenance is required to insure the flawless operation of this fine

model. These simple procedures will provide the necessary

information to give you years of trouble-free enjoyment.

Care and Cleaning

Dust and debris are among the leading contributors to poor

operation of any miniature mechanism. To maintain the qual

ity performance of your locomotive, inspection and cleaning

should be performed on a regular basis. A soft bristle brush

should be used to remove dust from the superstructure. The use

of soaps, solvents or detergents is not recommended for this

purpose as they will have a tendency to mar the finish.

When not in use it is recommended that the locomotive and

tender be stored in the protective sleeve in which it was

packed. Also, store the wireless controller in the locomotive

box with the battery removed.

When inspecting the underframe, make sure that all lint and

dust are removed from the back of all wheel sets. Dirt build up

in this area will foul the pick-up wipers and not allow proper

electrical contact, negatively impacting performance.

Wheel Cleaning

The Genesis

TM

Big Boy Locomotive receives electric power

from all drivers as well as eight of the tender wheels from both

rails. This, coupled with the long overall wheelbase, provides

for excellent electrical contact. There should be few cases of

erratic performance due to poor contact. However, over time,

dirt from the rails will accumulate on the wheel surfaces and

will need to be removed to assure peak operation. The use

of a cotton swab to apply either alcohol or a good quality

track cleaning solution is recommended. Carefully apply the

solvents, taking care not to spill any on the painted surfaces.

Alternatively, either an ink eraser or ‘Bright Boy’ abrasive

block can be used to remove dirt deposits by carefully burnish

ing the wheel surfaces. When cleaning the wheels, also remove

any dirt build up from the metal surfaces on the back rims of the

wheels. This will assure that the wiper contacts will maintain good

contact with the wheels.

Lubrication

This locomotive will arrive pre-lubricated from the factory

and will not need additional lubrication until it has been run

for quite some time. When it comes time to lubricate the

locomotive, use only light weight oil and gear grease that is

plastic compatible. Use a minimum amount. The plastics used

for many of the components, such as the gears and drive lines,

make them inherently self lubricating. Remember that too

much lubrication can be more detrimental to the locomotive

than too little.

The main points of lubrication, and type of lubricant are as

follows:

• Axle bearings on the drivers – light oil

• Armature bearings on the motors – light oil

• Oil light bearings on the worm gear shafts – light oil

• Bearings on the centipede tender wheels – light oil

• Side rods at the crank pins – light oil

• Gear towers – light gear grease

By following the exploded drawings, access to each of these

areas should be easily accomplished. If you are not comfort

able with disassembling this locomotive for lubrication take

it to one of the many Model Railroad hobby shops that can

provide this service.

Smoke Unit Installation

The Genesis

TM

Big Boy Locomotive is designed to accept

Seuthe #9 or #10 smoke generator units. These are not provided with the locomotive and may be added by the pur-

Page 11

0

chaser at their discretion. If it is decided that smoke units will

be installed, carefully follow the installation and operating

instructions provided by the smoke unit manufacturer. Genesis

does not warranty any defects in these smoke units or damage

that may occur to the locomotive through their use.

Installation is very easily accomplished: Slide the smoke unit

down the smoke stack until it engages the electric contacts

inside the boiler. Add a minimal amount of smoke fluid to the

unit and operate the locomotive normally. It may take a short

amount of time when running to heat up the smoke unit before

smoke is produced. This is normal.

Coupler Installation

The Athearn GenesisTM Big Boy model comes with the swivel

coupler installed on the pilot. As on the prototype engines, you

can have the coupler exposed on the pilot, or swing it around

so that the pilot has no coupler in use. The "coupler" on this

part is a dummy (non-operating) coupler.

An operating coupler can be installed on the pilot. Simply

unscrew and remove this dummy coupler. Once removed,

you will note that there are two threaded nuts. An operating

coupler should fit in the rear most hole with no clearance

problems, and the coupler and it’s box can be attached using

screw #212 (supplied, see drawing). If, however, your choice

of coupler does have clearance problems when mounted in the

rear threaded nut, simply mount it to the threaded nut further

forward.

Replacing the Traction Tire or

Replacing the Traction Tire Equipped Driver

To provide tractive effort that rivals the prototype, two trac

tion tires are factory installed on last set of drivers of the rear

engine. Replacement traction tires #210 are available from

your local hobby retailer.

To replace a worn or loose traction tire:

• Remove the crank pin nuts from the traction tire equipped

driver.

• Loosen the remaining crank pin screws from the other

drivers.

• Remove the eccentric crank, main rods, bushing and drive

rod from the crank pin on the traction tire equipped driver.

• Slide off the traction tire and replace with a new tire.

• Reverse the procedure of disassembly.

To replace a driver:

• Remove the crank pin screw and nuts from the side rods.

• Remove the side rods and eccentric cranks.

• Remove the retaining plate from the bottom of the engine

by removing the three retaining plate screws.

• Remove the wiper assembly.

• Remove the driver assembly.

• Replace with new driver assembly making sure that the

quartering matches the other drivers on the engine.

• Assemble in the reverse order that was used in the disas

-

sembly.

Use of the exploded drawings in this booklet will greatly assist

in the above listed procedures.

Replacement parts are available from Athearn Trains to the

original purchaser for warranty repairs only. A warranty reg

istration form must be on file at Athearn Trains to honor any

parts requests.

Jack Pfeifer photo

Page 12

Function Idle/Moving

Double click F0 Sound on/off

F1 Bell on/off

F2 Whistle

F3 Air release (2 types)

F4 Coupling/Uncoupling sounds (2 types)

F5 Brake squeal (repeat press will increase length)

F6 Conductor while idle /toggle chuff or 2 different

types of rail clack while moving

F7 Fire box door open and close

F8 Whistle type select

F9 Metallic cylinder sound on/off while moving,

steam associated sound while idle

F10 Water

F11 Blower hiss

F12 Master Volume Control

F13 Coal auger

F14 Air hose ring

F15 Associated Locomotive Sounds

F16 Shoveling

F17 Crash sound

F18 Injector

F19 Bell type select

F20 Bell ring rate

F21 Bell volume

F22 Whistle volume control

F23 Chuff volume control

F24 Chuff type

F25 Air brake release

F26 Associated Locomotive Sounds

F27 Associated Locomotive Sounds

F28 Scraping coal shovel

NOTE: Presently there are only a few DCC systems on the market

that can access function numbers higher than F12

CV Register Description Range Default

CV1 R1 Short address 1-127 3

CV2 R2 Start voltage 0-32 0

CV3 R3 Acceleration 0-32 8

CV4 R4 Deceleration 0-32 8

CV5 --- Top voltage 0-32 32

--- R6 Page number --- ---

CV29 R5 Basic conguration --- 2

CV7 R7 Manufacturer version

number

--- 32

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper

byte

192-231 192

CV18 --- Long address lower

byte

0-255 3

CV19 --- Advanced consist

address

0-127 0

CV21 --- When CV21=0, all

accessory functions

will follow their own

address. When CV21=1,

all functions will follow

the consist address

0-1 0

CV49 Master Volume Control

(0=off,1=low,2=mid,

3=max)

0-3 2

CV50 --- Whistle type 0-18 5

CV51 --- Whistle volume 0-3 3

CV52 --- Bell type 0-3 0

CV53 --- Bell volume 0-3 3

CV54 --- Bell ring rate 0-50 10

CV55 --- Chuff type 0-3 0

CV56 --- Chuff volume 0-3 3

CV57 --- Brake squeal volume 0-3 1

CV58 --- Air release volume 0-3 3

CV Register Description Range Default

CV59 --- Blower hiss volume 0-3 3

CV60 --- Fire box door volume 0-3 3

CV61 --- Injector volume 0-3 3

CV62 --- Coupling volume 0-3 3

CV63 --- Air pump volume 0-3 0

CV64 --- Rail clack volume 0-3 3

CV105 --- User identication

number

0-255 0

CV106 --- User identication

number

0-255 0

CV112 --- Conductor volume 0-3 3

CV113 --- Directional light enable 0-1 1

(enable)

CV114 Air pump type 0-3 1

CV118 --- Shoveling volume 0-3 3

CV119 --- Coupling re volume 0-3 3

CV120 --- Chuff rate 0-30 12

CV121 --- Chuff start point

adjustment

0-7 3

CV122 Double chuff enable 0-1 1

(enable)

CV123 Load Control on/off

(1=on)

0-1 0

(disable)

CV124 Speed curve select

(0=linear, 1=slow

increase at slow speed,

2=fast increase at slow

speed

0-2 0

CV125 --- Factory default setting:

Program it to 1 will

restore all the CV to

default setting

--- 0

Page 13

348

301

349

339

338

337

342

341

340

361

344

345

346

343

347

358

357

354

353

352

351

350

355

356

334

335

333

331

309

375

374

376

332

308

305

313

318

360

360

330

329

328

327

326

325

324

322

323

321

320

312

311

310

319

307

317

316

315

314

306

304

303

302

459

460

377

348

301

349

339

338

337

336

342

341

340

361

344

345

346

343

347

359

358

357

354

353

352

351

350

355

356

334

333

331

332

305

313

318

360

360

330

329

328

327

326

325

324

322

323

321

320

312

311

310

319

307

317

316

315

314

306

304

303

302

335

309

375

374

376

308

377

COAL TENDER with WOOD DECKCOAL TENDER

Page 14

348

349

339

337

342

341

340

361

344

345

346

343

347

355

356

358

567

568

569

570

571

566

565

564

561

563

562

560

559

357

354

353

352

351

350

301

334

333

331

332

305

313

318

360

360

330

329

328

327

326

325

324

322

323

321

320

312

311

310

319

307

317

316

315

314

306

304

303

302

336

338

335

309

375

374

376

308

377

Item # Description QTY

301 Tender lead truck wheel and axle assy. 2

302 Centipede side frame mounting screw 3

303 Centipede side frame 1

304 Tender coupler screw 1

305 Tender coupler box cover 1

306 Rear coupler 1

307 Screw 2

308 Front Tender Weight 1

309 Rear Tender Weight 1

310 Tender lead truck side frame 1

311 Tender lead truck spring 1

312 Tender lead truck washer 1

313 Tender coupler box 1

314 Tender air hose 1

315 Coupler cut lever assy. 1

316 Coupler cut lever wire 1

317 Centipede wheel with bearings assy. 2

318 Centipede wheel assy. 3

319 Equalizing spring 3

320 Tender end chassis detail 1

321 Tender plug socket 1

322 Tender plug-in PCB 1

323 Tender plug-in PCB mounting screws 2

324 Tender draw bar attachment post 1

325 Centipede pick-up bottom insulator 1

326 Centipede pick-up wipers-right 1

327 Centipede pick-up mounting screw-short 1

328 Centipede pick-up top insulator 1

329 Centipede pick-up wipers-left 1

330 Tender bottom 1

331 DCC circuit board 1

332 DCC board mounting screw 2

333 Left tool box-short 1

334 Left tool box-long 1

335 Speaker Housing 1

336 Left tool box-medium 1

337 Rear tender ladder 2

338 Side pipe-left 1

339 Tender body for Engine #3985 1

340 Tender apron 1

341 Tender front grab irons-type 2 1

Item # Description QTY

342 Tender front grab irons-type 1 4

343 Tender front detail 2

344 Side pipe-right 1

345 Right tool box-short 1

346 Right tool box-long 1

347 Tender hold down screw 2

348 Tender marker lamps 2

349 Tender rear light lens (clear) 1

350 Tender deck rear handrail 2

351 Tender light bar (clear) 1

352 Back-up light lens (clear) 1

353 Back-up light base 1

354 Back-up light conduit 1

355 Tender deck handrail wire 2

356 Tender deck handrail 2

357 Water fill hatches 3

358 Tender deck tool box 1

359 Coal bunker (full) 1

360 Brass sleeve 2

361 Tender side handrail 2

362 Tender Body 1

374 Front Tender Weight Screws 2

375 Centipede pick-up mounting screw-Long 2

376 Speaker 2

377 Speaker Housing Mounting Screw 1

459 Coal bunker (partially full) 1

460 Wood tender deck 1

Parts specific to Tender with Oil Bunker

559 Oil bunker 1

560 Oil filler hatches 2

561 Oil filler vents 1

562 Oil bunker walk way 1

563 Oil dip stick 1

564 Oil pipe #1 1

565 Oil bunker detail #1 1

566 Oil bunker detail #2 1

567 Sand box 1

568 Oil bunker detail #3 1

569 Oil pipe #2 1

570 Oil bunker hand rail wire 2

571 Oil bunker hand rail assy. 2

OIL TENDER

Page 15

6

5

4

3

1

2

9

18

10 11

12

13

208

15

14

16

7 8

19

20

21

22

23

24

25

26

27

28

29

33

34

200

38

35

36

39

40

45

46

47

49

48

50

51

44

4342

41

54

55

53

69

68

66

115

67

78

76

64

63

62

65

61

52

58

59

60

56

57

32

37

225

226

30

31

17

LOCOMOTIVE

114

85

83

84

113

112

186

163

162

183

178

70

71

72

74

77

79

80

75

82

81

87

86

88

93

94

96

97

91

98

102

109

110

107

105

100

119

73

90

89

92

111

123

101

104

106

132

108

138

157

99

95

187

Page 16

Item # Description QTY

41 Numberboard Lens (Clear) 2

42 Numberboard Front Housing 2

43 Numberboard PCB 2

44 Numberboard Mounting Bracket

(R)

1

45 Long Wire - Boiler Handrail (L) 1

46 Body Handrail (L) 1

47 Numberboard Mounting Bracket

(L)

1

48 Smoke Box Door 1

49 Marker Lights 2

50 Stanchions - Smoke Box Handrail 1

51 Wire for Smoke Box Handrail 1

52 Smoke Unit PCB 1

53 Main Frame (Upper) 1

54 Smoke Unit (Not Supplied) 2

55 Locomotive PCB 1

56 Long Wire - Boiler Handrail (R) 1

57 Body Handrail (R) 1

58 Lever 1

59 Wire #1 for Lever 1

60 Wire #2 for Lever 1

61 Draw Bar 1

62 Link Rod 2

63 Hex Coupling Shaft 2

64 Motor/Flywheel Assembly 1

65 Draw Bar Centering Spring 1

66 Washer 2

67 Main Frame (Lower) 1

68 Smoke Unit Contact Strip 1

69 Insulator Plate for Smoke Unit 1

70 Rear Walkway (L) 1

71 Rear Walkway (R) 1

72 Piping Under Cabin (C-3) 1

73 Detail Part (L) 1

74 Piping #5 1

75 Piping Under Cab 1

76 Smoke Unit Plug 1

77 Piping Under Cabin (C-4) 1

78 Insulate Plate 1

LOCOMOTIVE PARTS LIST

Item # Description QTY

1 Cab Sliding Window Glazing (R) 1

2 Cab Fixed Window Glazing (R) 1

3 Cab Door Spring 1

4 Cab Door Hinge Pin 1

5 Cab Door Support 1

6 Cab Rear Handrail 1

7 Cab Door 1

8 Cab Door Glazing (L) 1

9 Cab Door Glazing (R) 1

10 Cab 1

11 Roof Hatch 1

12 Roof Hatch Hinge 1

13 Roof Hatch Hinge Pins 2

14 Cab Fixed Window Glazing (L) 1

15 Cab Sliding Window Glazing (L) 1

16 Cab Front Window Glazing 2

17 Screw 8

18 Cab Grabiron (R) 1

19 Boiler Half (Top) 1

20 Generators 1

21 Boiler Top #1 1

22 Safety Valves 2

23 Safety Valve Base (3 Valve) 1

24 Safety Valve 1

25 Safety Valve Base (2 Valve) 1

26 Steam Dome Cover 1

27 Boiler Screw 6

28 Piping (B-R) 1

29 Piping (E) 1

30 Steel Support (L) 1

31 Smoke Deflector (L) 1

32 Small Handrail 4

33 Whistle 1

34 Piping (B-L) 1

35 Smoke Stack 2

36 Bell Bracket 1

37 Bell 1

38 Sand Dome Handrail 4

39 Piping (D) 1

40 Piping #10 1

Item # Description QTY

79 Piping #4 1

80 Wire for Piping #4 1

81 Piping #9 1

82 Piping Under Cabin (C-5) 1

83 Cab Jump Seats 2

84 Car Seat 2

85 Johnson Bar 1

86 Airtank 1

87 Piping #3 1

88 Piping #12 1

89 Front Walkway (L) 1

90 Front Walkway (R) 1

91 Ball Head Shaft 2

92 Piping #6 1

93 Piping for Rear Cylinder (L-1) 1

94 Link Bar for Front Cylinder 2

95 Screw for Piping 2

96 Piping for Front Cylinder 2

97 Column 2

98 Boiler Side Part 1

99 Piping for Rear Cylinder (R-1) 1

100 Power Reverse Cylinder 1

101 Screw 1

102 Boiler Bottom Piping 1

103 Screw 1

104 Trailing Truck Spring 2

105 Piping #1 1

106 Screw 1

107 Ash Pans #1 (L) 1

108 Frame Cover 1

109 Ash Pans #1 (R) 1

110 Hand Wheel (under body) 2

111 Piping 1

112 Drop Plate 1

113 Backhead 1

114 Firebox Door 1

115 Screw 2

116 Trailing Truck Wheel & Axel Assy 2

117 Trailing Truck Hand Wheel 1

Item # Description QTY

118 Trailing Truck Frame 1

119 Detail Part (R) 1

120 Rear Engine Pick-up Wiper As-

sembly

1

121 Pick-up Wiper 8

122 Pick-up Insulators 4

123 Pin 1

124 Crank Pin Screw 12

125 Main Rod 4

126 Screw 2

127 Eccentric Rod 4

128 Eccentric Rod Rivet 4

129 Eccentric Crank Rivet 4

130 Crank Pin Nut 4

131 Eccentric Crank (R) 2

132 Piping #7 1

133 Rear Engine Wheel Assembly #1

(Geared) with Traction Tires

1

134 Rear Engine Wheel Assembly #2 1

135 Rear Engine Wheel Assembly #3 1

136 Front Engine Wheel Assy #1 1

137 Front Engine Wheel Assy #2-

Geared

1

138 Frame 1

139 Rear Engine Frame & Gear Tower 1

140 Idler Gear #3 2

141 Idler Gear #2 2

142 Rear Engine Valve Gear Assy (R) 1

143 Rear Engine Gear Tower Cover 1

144 Idler Gear #1 2

145 Compound Gear 2

146 Worm Gear Assembly 2

147 Worm Gear Assembly Retainer 2

148 Rear Engine Valve Gear Hanger 1

149 Rear Engine Valve Gear Assy (L) 1

150 Rear Engine Piston Valve Guides

(R)

1

151 Rear Engine Cylinder Part (R) 1

152 Rear Cylinder Casting 1

153 Front & Rear Engine Cylinder

Part #2

2

Page 17

RUNNING GEAR and PILOT

WHEEL ASSY WITHOUT TIRES

227

116

117

118

216

215

134

135

214

121

120

122

153

154

152

155

156

151

150

172

171

169

212

170

173

199

104

168

167

160

159

136

147

137

135

143

145

148

149

158

139

140

141

144

142

133

190

164

165

174

161

166

146

188

128

129

127

130

131

219

125

218

217

124

213

209

126

210

211

193

192

203

193

204

223

182

185

164

221

220

191

201

202 189

180

179

181

222

224

221

205

206

165

207

175

103

177

176

195

197

198

196

194

Item # Description QTY

190 Gearbox Top Part #1 1

191 Headlight Numberboard Lens 2

192 Pilot Handrail Right #2 1

193 Wire #1 for Pilot Handrail 1

194 Coupler 1

195 Coupler Support 1

196 Front Coupler Box 1

197 Front Coupler Box Cover 1

198 Pilot Coupler Box Screw 1

199 Pilot Truck Washer & Spring 1

200 Plug 1

201 Headlight #1 1

202 Handrail on deck 1

203 Pilot Handrail Left #2 1

204 Cooling Pipe (B) 1

205 Pilot Shield 1

206 Headlight Bar 1

207 Pilot 1

208 Cab Grabiron (L) 1

209 Screw 2

210 Traction Tires 2

211 Wheel Assembly without Traction

Tires

1

212 Gear Box Cover (Front) 1

213 Screw 11

214 Gear Box Cover (Rear) 1

215 Brake Cylinder with Lever (L) 1

216 Brake Cylinder with Lever (R) 1

217 Side Rod #1 4

218 Side Rod #2 4

219 Washer 1

220 Pilot Handrail Right #1 1

221 Wire #2 for Pilot Handrail 2

222 Small Detail (R) 1

223 Pilot Handrail Left #1 1

224 Small Detail (L) 1

225 Smoke Deflector (R) 1

226 Steel Support (R) 1

227 Trailing Truck Weight 1

Item # Description QTY

154 Front & Rear Engine Cylinder

Part #1

2

155 Rear Engine Cylinder Part (L) 1

156 Rear Engine Piston Valve Guides

(L)

1

157 Piping Under Cabin (C-1) 1

158 Front Engine Pick-up Assembly 1

159 Front Engine Valve Gear Assy (R) 1

160 Front Engine Gear Tower Cover 1

161 Front Engine Frame & Gear

Tower

1

162 Wire for Piping #2 1

163 Piping #2 1

164 Piston Valve Shaft 2

165 Front Engine Valve Gear Assy (L) 1

166 Eccentric Crank (L) 2

167 Cylinder Part 1

168 Front Cylinder Casting 1

169 Pilot Truck Axle Retainers 2

170 Pilot Truck Frame 1

171 Pilot Truck Wheels & Axles 2

172 Screw for Pilot Truck 1

173 Cylinder Weight 4

174 Cylinder Part 1

175 Coupler Support #2 1

176 Pilot Air Hose 1

177 Dummy Swivel Coupler 1

178 Boiler Bottom Part (R) 1

179 Coupler Lift Bar Assembly 1

180 Coupler Lift Bar Wire 1

181 Flag Holder 2

182 Air Compressor 2

183 Piping Under Cabin (C-2) 1

184 LED Access Plug 1

185 LED Headlight 1

186 Boiler Bottom 1

187 Boiler Side 1

188 Gearbox Top Part #2 1

189 Headlight Lens-Clear 1

Page 18

Athearn

1550 Glenn Curtiss Street

Carson, CA 90746

www.athearn.com

Loading...

Loading...