Page 1

VERSION ACT.11.17

BATTERY HYDRAULIC USER GUIDE

C165 EFORCE 2.0, C185 NXTGEN EFORCE 2.0,

C195 NXTGEN EFORCE 2.0, C236 NXTGEN EFORCE 2.0, All-9

S20, S45-SL EFORCE 2.0, S53 EFORCE 2.0

21/36 EFORCE 2.0, 22/54 EFORCE 2.0

2780 CULVER AVE | KETTERING, OHIO 45429 | TEL: 1.937.293.6240 | WWW.GENESISRESCUE.COM

THIS GUIDE COVERS

11c EFORCE 2.0, 14c EFORCE 2.0,

15c EFORCE 2.0, 17c EFORCE 2.0

CONCRETE CRUSHER EFORCE 2.0,

DOOR OPENER EFORCE 2.0

Page 2

CONTENTS

GENERAL INFO

ABOUT THE USER GUIDE 4

EXPLANATION OF SYMBOLS 5

LIMITATIONS OF LIABILITY 6

COPYRIGHT 6

WARRANTY CONDITIONS 7

CUSTOMER SERVICE 7

SAFETY

INTENDED USE 8-9

RESPONSIBILITY OF USER 10

OPERATING PERSONNEL 11

PERSONAL PROTECTIVE EQUIPMENT 12

SPECIFIC HAZARDS 13-14

HOW TO RESPOND 15

SIGNAGE 16

TECHNICAL DATA

COMBI TOOLS 17

CUTTERS 18

SPREADERS 19

RAM 19

OPERATING CONDITIONS 20

TYPE PLATE 20

17

4

8

DESIGN AND FUNCTION

OVERVIEW OF DEVICES 21-24

HYDRAULIC SUPPLY 25

ELECTRICAL SUPPLY 26-27

REPLACING BLADE INSERTS 28-29

CHANGING SPREADER TIPS 30

POSSIBLE APPLICATIONS

SAFETY INFORMATION 31

CUTTING 31-32

LIFTING / PRESSING 32

SPREADING 33

PULLING 34

2

WWW.GENESISRESCUE.COM

21

31

Page 3

CRUSHING 35

LIFTING 36

PEELING 36

BATTERY AND CHARGER

CHARGER TECHNICAL DATA 37

SPECIAL SAFETY INSTRUCTIONS 37

INTENDED USE 39

POWER LINE CONNECTION 39

LI-ION BATTERY 39

CHARGING 40

MAINTENANCE 41

CHARGING CYCLES 41

TRANSPORT AND STORAGE

SAFETY INFORMATION 42

TRANSPORT INSPECTION 42

DISPOSAL OF PACKAGING 43

STORAGE 43

INSTALLATION AND USE

SAFETY INFORMATION 44

CHECKING 44

SHUT-DOWN 45

37

42

44

SERVICE

SAFETY INFORMATION 46

CARE AND MAINTENANCE 46

MAINTENANCE SCHEDULE 47

TROUBLESHOOTING

DISPOSAL

NOTES

46

48-49

50

51

3

Page 4

GENERAL INFORMATION

About the operating manual

This operating manual provides important information on using E-FORCE devices. Proper

compliance with all specied safety instructions and guidelines is a prerequisite for safe work.

Furthermore, adhere to the local accident prevention guidelines and general safety

regulations for the region in which the devices are used.

These operating instructions must be carefully read prior to starting any work! They are an

inherent part of the product and must be kept in a place that is known and accessible to

personnel

at all times.

This documentation contains information for operating your equipment. However,

you may also nd information which may not directly apply to your specic equipment.

All information, technical data, graphics and diagrams contained in these operating

instructions are based on the latest data available at the time of the document’s creation.

We recommend that, in addition to carefully reading through the operating manual, you be

trained on handling the rescue equipment (possible applications, application tactics,

etc.) by our qualied trainers.

4

WWW.GENESISRESCUE.COM

Page 5

EXPLANATION OF SYMBOLS

Warnings

Warnings are marked by symbols in this operating manual. The individual instructions are

introduced by signal words that express the severity of the hazard.

It is essential to comply with the instructions in order to prevent accidents, injuries and

damage to property.

DANGER!

… indicates an imminently dangerous situation that can result in death

or serious injury if not avoided.

WARNING!

… indicates a potentially dangerous situation that can result in death or

serious injury if not avoided.

CAUTION!

… indicates a potentially dangerous situation that can result in minor or

light injuries if not avoided.

ATTENTION!

… indicates a potentially dangerous situation that can result in

material damage if not avoided.

5

Page 6

NOTE!

... highlights useful tips and recommendations, as well as information for

efcient, trouble-free operation.

LIMITATIONS OF LIABILITY

All information and instructions in this operating manual have been compiled in keeping with

applicable standards and guidelines, the current state of technology, and our many years of

knowledge and experience.

The manufacturer assumes no liability for damage due to:

• Failure to comply with the operating manual

• Unintended use

• Assignment of untrained personnel

• Unauthorized modications

• Technical changes

• Use of non-approved replacement parts

• Use of non-original replacement parts

The actual scope of delivery can vary from the explanations and graphic representations

provided in this manual in the case of special versions, or due to technical changes.

COPYRIGHT

All texts, diagrams, drawings and images in this operating manual may be used without

restriction and without any prior approval.

6

WWW.GENESISRESCUE.COM

Page 7

NOTE!

Further information, images and drawings can be found on our website

www.genesisrescue.com

WARRANTY CONDITIONS

The warranty conditions can be found as a separate document in the sales documentation.

CUSTOMER SERVICE

Contact your local Genesis sales representative. If you are unsure you can contact Genesis

Rescue Systems direct at:

American Rescue Technology

2780 Culver Ave.

Kettering, Ohio

45429

Tel: 1.937.293.6240

Fax: 1.937.293.7049

www.genesisrescue.com

NOTE!

When contacting customer service please state your equipment’s designation, type and production year. These details can be found on the

equipment type plate.

7

Page 8

SAFETY

This section of the operating manual provides a comprehensive overview of all important

safety aspects for optimal protecting operating personnel and for safe, trouble-free

operation.

Signicant hazards may occur if the handling and safety instructions in this manual are not

complied with.

INTENDED USE

The hydraulic battery-powered devices are designed and tested exclusively for the intended

applications described here. All other activities are strictly forbidden.

BATTERY-POWERED DEVICES 11c EFORCE 2.0, 14c EFORCE 2.0, 15c EFORCE 2.0, 17c EFORCE

2.0, C165 EFORCE 2.0, C185 NXTGEN EFORCE 2.0, C195 NXTGEN EFORCE 2.0, C236 NXTGEN

EFORCE 2.0, S20, S45-SL EFORCE 2.0, S53 EFORCE 2.0, 21/36 EFORCE 2.0, 22/54 EFORCE 2.0

CONCRETE CRUSHER EFORCE 2.0, DOOR OPENER EFORCE 2.0

• All battery-powered devices are designed as one-man devices and

are therefore to be operated by only one person.

• The battery-powered cutting devices are used exclusively for cutting

doors and roof beams, pillars and door sills, the ring and the spokes of

the steering wheel.

• If possible, for cutting solid material, always position the material at

the base of the cutter blades closest to the pivot point, as it is equipped

with special edges for cutting round material.

• In industrial application, the devices can also be used to cut pipes,

structural steels, proles, sheets and cables.

• The battery-powered spreading devices can be used for opening

doors, lifting vehicles or other moveable loads, pushing away and

moving vehicle parts and loads, and crushing pipes and tie bars.

• If possible, always use the tips of the spreader for crushing.

8

WWW.GENESISRESCUE.COM

Page 9

• The tips of the spreader can also be used as a peeling tool.

• The chain set is solely to be used for pulling.

• The combi devices 11C E-Force 2.0, 14C E-FORCE 2.0, 15C E-Force

2.0, 17C E-FORCE 2.0 and 15C E-FORCE 2.0 can be used for both The

applications indicated for the C236 E-FORCE 2.0, C185 E-FORCE 2.0 and

C165 E-FORCE 2.0 and those for S45 E-FORCE 2.0. The tips of the spreader can also be used as a peeling tool.

21/36 RAM 22/54 RAM & Power Wedge

• The Ram and Power Wedge are designed as one-man devices and

are therefore to be operated by only one person.

• the Ram is exclusively for pushing up steering columns, vehicle roofs

and other obstacles and for pushing away vehicle body parts.

• They can also be used for supporting and bracing loads.

• The Power Wedge is used for opening doors.

WARNING!

Improper use can be dangerous!

Any improper or unintended use of the devices can be hazardous!

Therefore, make absolutely sure that:

» The devices are used only for the applications stated above.

9

Page 10

RESPONSIBILITY OF THE CUSTOMER

In addition to the health and safety instructions in this operating manual, one must adhere

to the safety, accident prevention, and environmental protection guidelines for the region in

which the equipment is used. Particularly applicable in this regard:

• The customer must be familiar with the applicable health and

safety provisions and in a hazard analysis identify other hazards that

may exist at the equipment’s installation site due to the special working

conditions.

• The customer must clearly regulate and specify responsibilities for

installation, operation, maintenance and cleaning.

• The customer must ensure that all personnel who handle the

equipment have fully read and understood the operating manual.

• In addition, at regular intervals, the operator must train personnel

and inform them of the hazards of working with the equipment.

Moreover, the customer is responsible for ensuring that the equipment is always in

technically faultless condition. Consequently, the following applies:

• After each use, and at least once a year, a visual inspection of the

equipment must be carried out by a trained individual (according to

GUV-G 9102 or country-specic guidelines).

• Every three years, or if you have doubts about the safety or reliability

of the equipment, functional testing and stress testing must be carried

out (according to GUV-G 9102 or country-specic guidelines).

10

WWW.GENESISRESCUE.COM

Page 11

OPERATING PERSONNEL

The following qualications are cited in the operating instructions for the various activity

areas:

• Trained individual

is informed through training offered by the customer about the tasks

assigned to him and the

possible dangers of improper conduct.

• Specialist

is someone who, due to specialized training, skills and experience, as

well as knowledge of the applicable stipulations by the manufacturer,

is capable of executing the tasks assigned to him or her and of

independently recognizing possible hazards.

WARNING!

Inadequate training can result in injuries!

Improper handling of the equipment can lead to serious injury or

material damage.

Therefore, make absolutely sure to:

» allow particular tasks to be carried out only by the persons stated in

the relevant chapter of this manual.

» When in doubt, call in specialists immediately.

NOTE!

The equipment may not be used by personnel who have consumed

alcohol, medication or drugs!

11

Page 12

PERSONAL PROTECTIVE EQUIPMENT

Wearing personal protective equipment (PPE) is essential to minimize the risks

to operating personnel when working with the hydraulic rescue devices.

It is essential to wear the following protective clothing for all work:

Protective work clothing

Tight-tting work clothing with tight sleeves and no protruding parts

must be worn when working. It mostly serves to protect against

entanglement by moving equipment parts.

Safety shoes

Steel-toed safety shoes must always be worn as protection against

heavy falling parts and from slipping on slick surfaces.

Work gloves

Work gloves must be worn when working with the equipment

to provide protection from sharp edges and shards of glass.

Helmet with face shield

A helmet with face shield must be worn for protection against ying

or falling parts and shards of glass.

Protective goggles

Protective goggles must also be worn in addition to the face

shield in order to protect the eyes from ying objects.

The following must also be worn for certain work:

Ear protectors

In addition to the basic protective equipment, ear protectors

must also be worn to protect your hearing.

12

WWW.GENESISRESCUE.COM

Page 13

SPECIFIC HAZARDS

The hazards arising from the risk analysis are listed in the following section.

Follow the safety instructions listed here and the warnings in the other sections of this manual

to minimize potential health hazards and avoid dangerous situations.

ELECTRICITY

DANGER!

Danger of fatal electric shock!

There is an imminent life-threatening danger if live parts are touched.

Damage to insulation or to specic components can pose a fatal

hazard.

Therefore:

» If the insulation is damaged, immediately disconnect the power

supply and arrange for repairs.

» Allow only qualied electricians to work on the electrical

equipment.

» For all work on the electrical equipment, it must be disconnected

from the power source, and it must be checked that the device is

powered off.

» Prior to maintenance, cleaning and repair work, the power supply

must be switched off and secured to prevent it from being switched

back on again.

» Do not bypass or disable fuses. When changing the fuses, ensure

that they have the correct amperage.

» Keep moisture away from live parts. This can lead to a short-circuit.

13

Page 14

NOISE

WARNING!

Noise can damage hearing!

The noise occurring in the work area can cause severe hearing

damage.

Therefore:

»» You should also wear ear protectors when carrying out

certain noise-producing tasks.

»» Do not stay in the hazardous area longer than necessary.

HYDRAULIC POWER

WARNING!

Hydraulic power hazard!

Serious injury can result due to the released hydraulic forces

and escaping hydraulic oil.

Therefore:

»» Constantly monitor the device during the work procedure and set

down if necessary.

»» Inspect the hose lines and devices for damage after every use.

»» Avoid skin contact with the hydraulic oil (wear protective gloves).

»» Immediately remove the hydraulic oil from wounds and consult

a doctor.

14

WWW.GENESISRESCUE.COM

Page 15

HOW TO RESPOND IN THE EVENT OF DANGER

OR ACCIDENTS

Preventive measures

• Always be prepared for accidents

• Keep rst aid equipment (rst aid kit, blankets, etc.) at hand

• Familiarize personnel with accident alarms, rst aid gear, and emergency equipment

• Keep entryways clear for emergency vehicles

In the event of an accident

• Shut down equipment immediately

• Initiate rst aid measures

• Get people out of the danger zone

• Inform the responsible parties at the site of the incident

• Notify a doctor and/or the re brigade

• Clear entryways for emergency vehicles

15

Page 16

SIGNAGE

The equipment bears the following WARNING label.

Comply with the operating manual

Do not use the marked equipment until you have read this operating manual.

WARNING!

Danger of injury due to illegible symbols!

Over time, stickers and symbols on the equipment can become soiled

or otherwise illegible.

Therefore, make absolutely sure to:

» Keep all safety, warning and operating information on the device

easily legible.

» Replace damaged signs and stickers immediately.

16

WWW.GENESISRESCUE.COM

Page 17

TECHNICAL DATA

ART.107.525.0

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

EFORCE 11C VARIO

VERSION.PCT.3.2015

ACCESSORIES

• LED TOOL LIGHT - ART.813.595.0

• MECHANICAL RAM - ART.105.647.8

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.378.5

• 3 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

LENGTH(IN/MM) - 31.4/798

WIDTH(IN/MM) - 7.5/192

DEPTH(IN/MM) - 9.4/240

WEIGHT(LBS/KGS) - 31.3/14.2

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 10.6/270

MAX CUTTING FORCE(LBF/KN) - 72,838/324

MAX SPREADING FORCE(LBF/KN) - 132,975/591

The eForce 11c vario is a ideal tool for

rst responders, usar teams, and tactical teams. This tool offers a lightweight

ergonomic design and non-proprietary

battery power.

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A6 | B5 | C6 | D6 | E7

LOWEST SPREADING FORCE(LBF/KN) - 7,200/32

HIGHEST SPREADING FORCE(LBF/KN) - 9,100/40.5

LOWEST PULLING FORCE(LBF/KN) - 5,850/26

HIGHEST PULLING FORCE(LBF/KN) - 8,325/37

17

Page 18

TECHNICAL DATA

ART.107.525.0

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

11C EFORCE 2.0

VERSION.ACT.11.17

ACCESSORIES

• MECHANICAL RAM - ART.105.647.8

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

LENGTH(IN/MM) - 31.4/798

WIDTH(IN/MM) - 7.5/195

DEPTH(IN/MM) - 9.4/241

WEIGHT(LBS/KGS) - 31.3/14.2

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 10.6/270

PULLING DISTANCE(IN/MM) - 13.6/345

OPENING(IN/MM) - 7.6/193

The eForce 11c vario is a ideal tool for

rst responders, usar teams, and tactical teams. This tool offers a lightweight

ergonomic design and non-proprietary

battery power.

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A6 | B5 | C6 | D7 | E7

LOWEST SPREADING FORCE(LBF/KN) - 7,200/32

HIGHEST SPREADING FORCE(LBF/KN) - 9,100/40.5

LOWEST PULLING FORCE(LBF/KN) - 5,850/26

HIGHEST PULLING FORCE(LBF/KN) - 8,325/37

18

WWW.GENESISRESCUE.COM

Page 19

TECHNICAL DATA

ART.107.445.8

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

14C EFORCE 2.0

ACCESSORIES

• MECHANICAL RAM - ART.105.647.8

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

VERSION PCT.3.2016

LENGTH(IN/MM) - 35.9/914

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 9.5/241

WEIGHT(LBS/KGS) - 41/18.6

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/720

SPREADING DISTANCE(IN/MM) - 14.2/360

PULLING DISTANCE(IN/MM) - 15.6/396

OPENING(IN/MM) - 10.1/257

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A6 | B8 | C6 | D8 | E7

LOWEST SPREADING FORCE(LBF/KN) - 8,663/38.5

HIGHEST SPREADING FORCE(LBF/KN) - 9,563/42.5

LOWEST PULLING FORCE(LBF/KN) - 8,768/39

HIGHEST PULLING FORCE(LBF/KN) - 10,913/48.5

19

Page 20

TECHNICAL DATA

ART.107.767.6

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

15C EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

VERSION PCT.11.17

The eForce 15c vario is a ideal tool for

rst responders. Unlike the 14c the 15c

has removable tips. This tool offers

a lightweight ergonomic design and

non-proprietary battery power.

LENGTH(IN/MM) - 36.2/920

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 9.5/241

WEIGHT(LBS/KGS) - 43.9/19.9

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 14.6/370

PULLING DISTANCE(IN/MM) - 13.6/346

OPENING(IN/MM) - 11.6/295

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A6 | B8 | C6 | D8 | E7

LOWEST SPREADING FORCE(LBF/KN) - 8,100/36

HIGHEST SPREADING FORCE(LBF/KN) - 9,900/44

LOWEST PULLING FORCE(LBF/KN) - 9113/40.5

HIGHEST PULLING FORCE(LBF/KN) - 13,275/59

20

WWW.GENESISRESCUE.COM

Page 21

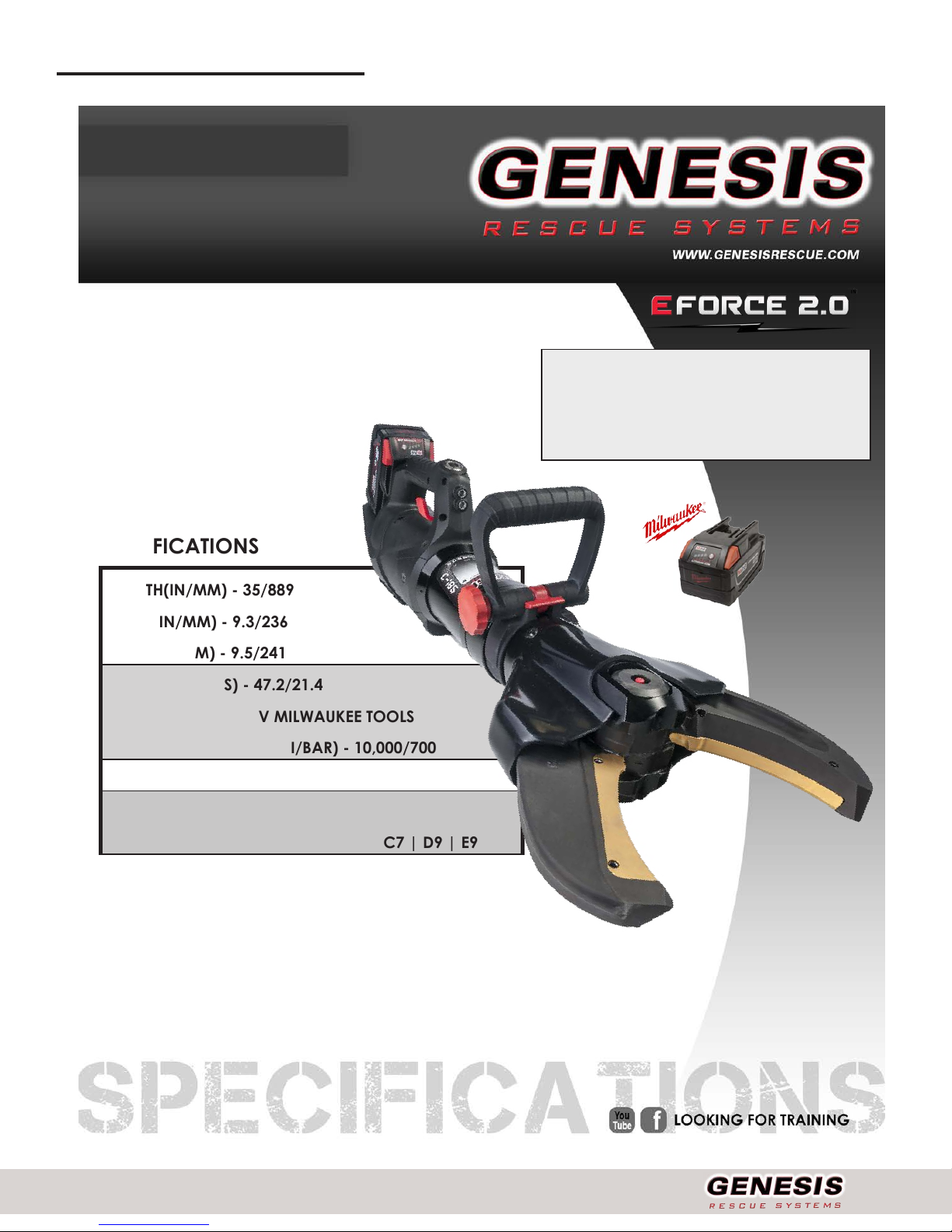

TECHNICAL DATA

ART.107.918.1

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

17C BRUTE EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION PCT.3.2016

The “Brute” boasts some impressive

NFPA ratings, a Max cutting force of

115k and a spreading distance of 16

inches !

SPECIFICATIONS

LENGTH(IN/MM) - 37.6/956

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 9.5/241

WEIGHT(LBS/KGS) - 48.5/22

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 16.5/420

PULLING DISTANCE(IN/MM) - 15.9/405

CUTTING OPENING(IN/MM) - 13.2/335

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A7 | B9 | C7 | D9 | E9

LOWEST SPREADING FORCE(LBF/KN) - 8,100/36

HIGHEST SPREADING FORCE(LBF/KN) - 10,125/45

LOWEST PULLING FORCE(LBF/KN) - 11,250/50

HIGHEST PULLING FORCE(LBF/KN) - 13,275/59

21

Page 22

TECHNICAL DATA

ART.107.527.2

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

21/36 EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION PCT.3.2016

With a high pushing force, light weight

and non-proprietary battery the 2136

eForce is a must have addition to any

departments extrication toolbox.

SPECIFICATIONS

LENGTH CLOSED(IN/MM) - 21.3/542

WIDTH(IN/MM) - 5.3/134

DEPTH(IN/MM) - 12.8/325

WEIGHT(LBS/KGS) - 34.6/15.7

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

LENGTH EXTENDED(IN/MM) - 35.8/910

STROKE(IN/MM) - 14.6/370

HIGHEST SPREADING FORCE(LBF/KN) - 25,021/111.3

NFPA 1936 COMPLIANT - YES

22

WWW.GENESISRESCUE.COM

Page 23

TECHNICAL DATA

ART.107.834.2

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

22/54 EFORCE 2.0

MILWAUKEE TOOLS

28V 5AH BATTERY

Can provide up to 30

minutes of continuous

operation.

VERSION ACT.11.17

ON/OFF SWITCH

Pushing switch puts the

tool into idle mode and

will run in idle mode

for 30 seconds unless

variable control is used.

LED LIGHTS

Will illuminate for the

entire duration of the

operation of the tool.

VARIABLE CONTROL

SWITCH

To the left - Closes

To the right - Opens

SPECIFICATIONS

LENGTH CLOSED(IN/MM) - 22/560

WIDTH(IN/MM) - 5.3/134

DEPTH(IN/MM) - 13.7/347

WEIGHT(LBS/KGS) - 43/19.5

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 7,980/550

LENGTH EXTENDED(IN/MM) - 53.5/1360

STROKE(IN/MM) - 31.5/800

HIGHEST PUSHING FORCE STAGE 1(LBF/KN) - 24,279/108

HIGHEST PUSHING FORCE STAGE 2(LBF/KN) - 13,950/62

NFPA 1936 COMPLIANT - YES

23

Page 24

TECHNICAL DATA

ART.107.202.6

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

C165 EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION PCT.11.17

The C165 is light weight and packed full

of power. With a max cutting for of 144k

it will make short work of a extrication

scene.

SPECIFICATIONS

LENGTH(IN/MM) - 33.3/845

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 8.5/217

WEIGHT(LBS/KGS) - 43/19.5

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

OPENING(IN/MM) - 5.9/150

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A8 | B5 | C6 | D7 | E9

24

WWW.GENESISRESCUE.COM

Page 25

TECHNICAL DATA

ART.107.525.5

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

C185 NXTGEN EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION ACT.11.17

NXTgen replaceable blade inserts allow

for this cutter to cut UHSS and Boron

more effectively.

SPECIFICATIONS

LENGTH(IN/MM) - 35/889

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 9.5/241

WEIGHT(LBS/KGS) - 47.2/21.4

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

OPENING(IN/MM) - 7.1/180

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A7 | B9 | C7 | D9 | E9

25

Page 26

TECHNICAL DATA

ART.107.526.2

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

C236 NXTGEN EFORCE 2.0

ACCESSORIES

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.409.7

• TOOL BACKPACK - ART.EXTBP

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION ACT.11.17

NXTgen replaceable blade inserts allow

for this cutter to cut UHSS and Boron

more effectively.

SPECIFICATIONS

LENGTH(IN/MM) - 38.7/982

WIDTH(IN/MM) - 10.2/260

DEPTH(IN/MM) - 9.4/241

WEIGHT(LBS/KGS) - 51.8/23.5

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

OPENING(IN/MM) - 7.9/200

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A8 | B9 | C8 | D9 | E9

26

WWW.GENESISRESCUE.COM

Page 27

TECHNICAL DATA

ART.108.234.3

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

C195 NXTGEN EFORCE 2.0

VERSION PCT.10.2017

ACCESSORIES

• 3 BAY CHARGER - ART.105.409.7

NXTgen replaceable blade inserts allow

for this cutter to cut UHSS and Boron

more effectively.

SPECIFICATIONS

LENGTH(IN/MM) - 34.8/885

WIDTH(IN/MM) - 9.3/236

DEPTH(IN/MM) - 9.5/241

WEIGHT(LBS/KGS) - 45/20.4

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

OPENING(IN/MM) - 7.1/180

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - A8 | B9 | C7 | D9 | E9

27

Page 28

TECHNICAL DATA

ART.107.772.1

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

EFORCE CONCRETE CRUSHER

VERSION PCT.3.2016

ACCESSORIES

• LED TOOL LIGHT - ART.813.595.0

• BATTERY - ART.105.378.5

• 3 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

LENGTH(IN/MM) - 34.5/878

WIDTH(IN/MM) - 10.3/262

The Concrete Crusher is a ideal tool for

USAR teams, and tactical teams. This

tool offers ergonomic design and function.

DEPTH(IN/MM) - 11.9/303

WEIGHT(LBS/KGS) - 47.4/21.5

OPERATING PRESSURE(PSI/BAR) - 10,500/720

MAX CRUSHING FORCE(LBF/KN) - 24,504/109

MIN CRUSHING FORCE(LBF/KN) - 15,736/70

MAX OPENING(IN/MM) - 9.8/250

28

WWW.GENESISRESCUE.COM

Page 29

TECHNICAL DATA

29

Page 30

TECHNICAL DATA

ART.107.779.1

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

S53 EFORCE 2.0

ACCESSORIES

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.375.5

• 3 BAY CHARGER - ART.105.410.8

• 1 BAY CHARGER - ART.105.409.7

VERSION.ACT.11.17

SPECIFICATIONS

LENGTH(IN/MM) - 39.1/993

WIDTH(IN/MM) - 11.7/298

DEPTH(IN/MM) - 9.4/241

WEIGHT(LBS/KGS) - 52.9/24

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 31.5/800

NFPA 1936 COMPLIANT - YES

NFPA 1936 LEVEL RATING - N/A

LOWEST SPREADING FORCE(LBF/KN) - 11,870/52.8

HIGHEST SPREADING FORCE(LBF/KN) - 18,277/81.3

LOWEST PULLING FORCE(LBF/KN) - 8,678/38.6

HIGHEST PULLING FORCE(LBF/KN) - 14,837/66

30

WWW.GENESISRESCUE.COM

Page 31

TECHNICAL DATA

ART.107.781.2

CERTIFICATIONS

• NFPA 1936:2015 COMPLIANT

• ISO 9001:2008

EFORCE S250 SPREADER

ACCESSORIES

• LED TOOL LIGHT - ART.813.595.0

• BATTERY - ART.105.378.5

• 3 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

VERSION ACT.3.2016

LENGTH(IN/MM) - 34.4/875

WIDTH(IN/MM) - 5.9/150

DEPTH(IN/MM) - 9.4/240

WEIGHT(LBS/KGS) - 27.8/12.6

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

SPREADING DISTANCE(IN/MM) - 2.4/61

MAX SPREADING FORCE(LBF/KN) - 55,800/248

31

Page 32

TECHNICAL DATA

ART.106.360.4

EFORCE DOOR OPENER

VERSION PCT.6.2013

ACCESSORIES

• LED TOOL LIGHT - ART.813.595.0

• TOOL BACKPACK - ART.EXTBP

• BATTERY - ART.105.378.5

• 3 BAY CHARGER - ART.105.409.7

SPECIFICATIONS

LENGTH(IN/MM) - 22.6/574

WIDTH(IN/MM) - 7.6/194

DEPTH(IN/MM) - 9/230

WEIGHT(LBS/KGS) - 31.5/14.3

POWER SOURCE - 28V MILWAUKEE TOOLS

OPERATING PRESSURE(PSI/BAR) - 10,000/700

The eForce Power Wedge is a ideal tool

for rst responders, usar teams, and

tactical teams. This tool offers a lightweight ergonomic design and non-proprietary battery power.

DISTANCE OPEN(IN/MM) - 10.4/140

PUSHING FORCE(LBF/KN) - 23649.9/105.2

32

WWW.GENESISRESCUE.COM

Page 33

OPERATING CONDITIONS

The permissible temperature range of the E-FORCE devices is between -4°F and +176°F.

Reliable operation cannot be guaranteed outside of this range.

TYPE PLATE

On all E-FORCE devices, the type plate is located on the body. It shows the serial

number, production date, nominal pressure and device designation.

33

Page 34

DESIGN AND FUNCTION

Overview of E-FORCE devices

VARIO | COMBINATION TOOLS

9

8

7

6

3

1 Blades (arms)

2 Protective cover

3 Hand grip

4 Cylinder body

5 Pumps / oil reservoirs

6 Control lever

7 Control handle

8 ON/OFF button

9 Battery

2

5

4

1

Brief description of combi devices

Battery-powered combi devices are specially designed rescue equipment for cutting and

spreading vehicle body parts. They are used to rescue trapped or enclosed accident vic-

tims. The combi device’s uses include cutting door and roof beams, columns and sills, as well

as opening doors, lifting vehicle parts and loads, and crushing pipes and beams.

Because the devices are equipped with internal electro-hydraulic drive, they are not linked

to a power unit and can therefore be used in hard-to-reach locations.

The movement speed of the cutter blades (arms) is affected by moving the rocker lever on

the control handle with greater or lesser force. The maximum force is achieved

only when the rocker lever is on full activation.

34

WWW.GENESISRESCUE.COM

Page 35

DESIGN AND FUNCTION

Cutters

7

8

6

3

4

2

1

9

5

1 Blades (arms)

2 Protective cover

3 Hand grip

4 Cylinder body

5 Pumps / oil reservoirs

6 Control lever

7 Control handle

8 ON/OFF button

9 Battery

Brief description of cutter

Battery-powered cutters are specially designed rescue equipment for cutting vehicle body

parts.

They are used to rescue trapped or enclosed accident victims. The cutter’s uses include cutting door and roof beams, columns and sills.

Because the devices are equipped with internal electro-hydraulic drive, they are not linked

to a power unit and can therefore be used in hard-to-reach locations.

The movement speed of the cutter blades is affected by moving the rocker lever on the

control handle with greater or lesser force. The maximum cutting force is achieved only

when the rocker lever is on full activation.

35

Page 36

DESIGN AND FUNCTION

RAM | Power Wedge

8

4

6

7

1

3

5

2

1

1 Battery

2 Pumps / oil reservoirs

3 ON/OFF button

4 Control handle

5 Control lever

6 Guide piece

7 Piston

8 Pushing head

3

4

5

7

2

6

Brief description of Rams / Power Wedge

Battery-powered rams are specially designed rescue devices for pushing away parts of a

vehicle body. They are used to rescue trapped or enclosed accident victims. The rescue cylinder is suitable for tasks such as pushing up steering columns, vehicle roofs and other obstacles. The Power Wedge is designed for forcible entry.

Because the devices are equipped with internal electro-hydraulic drive, they are not linked

to a power unit and can therefore be used in hard-to-reach locations.

The ram is a supplement to the spreader and can be used, for example, if the

spreading arm’s spreading distance is no longer adequate.

The movement speed of the piston is affected by moving the rocker lever on the control

handle with greater or lesser force. The maximum compressive force is achieved only when

the rocker lever is on full activation.

8

36

WWW.GENESISRESCUE.COM

Page 37

DESIGN AND FUNCTION

Spreader

8

9

7

6

3

4

5

1 Spreader tips

2 Spreader arms

3 Hand grips

4 Cylinder body

5 Pumps / oil reservoirs

6 Control lever

2

7 Control handle

8 ON/OFF button

9 Battery

1

Brief description of spreader

Battery-powered spreaders are specially designed rescue devices for spreading, pressing

and pulling. They are used to rescue trapped or enclosed accident victims. The spreaders

are mainly suitable for opening doors, and for lifting vehicles and other movable loads.

Because the devices are equipped with internal electro-hydraulic drive, they are not linked

to a power unit and can therefore be used in hard-to-reach locations. The movement speed

of the spreading arms is affected by moving the rocker lever on the control handle with

greater or lesser force. The maximum spreading force is achieved only when the rocker lever

is on full activation.

37

Page 38

HYDRAULIC SUPPLY

Drive

The battery devices are driven by a 28V DC motor with nominal power of approx.

700 watts. The drive motor runs only as long as the rocker lever is actuated.

Pump

The hydraulic pressure is generated by a high-pressure hydraulic pump (in the pumping

unit). The pump is an swash plate axial piston pump with four pistons. The pressure

operates directly on the working cylinder, making connection lines unnecessary.

Oil tank

The volume of oil for operation is taken from a piston accumulator. This means

the entire hydraulic system is completely closed and void of air. The system pressure (accumulator pressure) is 7.25 PSI. Any possible volume expansion

due to heat is balanced by the accumulator.

Hydraulic oil

All battery-powered devices should use a special hydraulic oil for rescue equipment

in accordance with WN 4841751. Normally the oil does not have to be changed, but,

if this becomes necessary, it can be changed only by service engineers at

GENESIS RESCUE SYSTEMS.

38

WWW.GENESISRESCUE.COM

Page 39

ELECTRICAL SUPPLY

Inserting the battery

Connect battery (1) to the rescue equipment (2). Slide the battery along the rails (3) provided for this purpose, until the battery clicks in. To release, press the push buttons

on both sides of the battery (4). Then pull the battery up and out.

39

Page 40

OPERATING E-FORCE 2.0 DEVICES

To start the battery-powered device, activate the ON/OFF switch (1). The switch glows

green. The battery-powered device is operated by the rocker lever on the control handle.

The movement speed can be precisely controlled by pressing with greater or lesser force.

The maximum cutting, spreading or compressive force is reached only if the rocker lever is

pushed completely through.

Close cutter / Close spreader / Retract ram

The device’s direction of movement is triggered by moving the rocker lever to the left.

Open cutter / Open spreader / Extend ram

The device’s direction of movement is triggered by moving the rocker lever to the right.

Dead man’s switch

If the rocker lever is released, it automatically goes back to the zero position. The device

remains in the same place in every position (even under load).

EFORCE Control Unit Left to close | Right to open

40

WWW.GENESISRESCUE.COM

Page 41

REPLACING BLADE INSERTS (C185, C195, C236 NXTGEN EFORCE 2.0)

During blade replacement, the cutter is xed in place. Any slipping should be avoided. Replacing the blade requires a soft-face hammer, the roll pins supplied, a punch and the blade

inserts themselves. It makes sense to replace both blade inserts so that the cutting behavior

is not impaired.

NOTE!

The blade inserts should not be reground, simply cleaning off any soil is

recommended.

Procedure:

The cutter is positioned with the type plate pointing

upward and is xed in place. A clamping

device, as shown in the illustrations, is not obliga-

tory. When the blade insert is being changed, the

battery must be removed from the cutter and not

under load.

This means that the shear is not completely open

or closed. The blade insert for the cutter blade with

the smooth surface can now be replaced. The

roll pins are knocked out and downward from the

punch (see gure 1).

Fig. 1

Fig. 2

After the roll pins have been knocked out of their

position, the blade insert can be pulled out. The

use of a forked screwdriver is recommended. If

the blade insert cannot be loosened immediately,

it can be gently levered out using a punch in the

holes (see gure 2).

41

Page 42

Fig. 3

Next, the cutter is rotated and the blade insert is

placed in the cutter blade with no insert. When

inserting, make sure that the blade insert does not

twist.

If the blade inserts cannot be inserted by hand, use

the soft-face hammer (see gure 3).

The roll pins are located using a punch and light

blows of a hammer from above into the position

holes provided for this purpose. Roll pins should be

pushed into position until They are ush with the top

surface of the blade (see gure 4).

Fig. 4

42

WWW.GENESISRESCUE.COM

Page 43

Changing the spreader tips (S45)

The spreader tips are secured in the spreader arms with collar studs. The studs are secured

by a spring-loaded ball and must be pressed out for replacement. After the tips have been

replaced, the collar studs can be pushed back through. Check that the studs are seated

correctly (pressed completely in).

The holder for the chain set must be mounted in identical fashion. The chain lock must be

installed with the latch facing upward.

NOTE!

The chain lock is mounted in exactly the same way on the 11c

E-FORCE,14c EFORCE, and 17c E-FORCE. However, for this the spreader

tips must rst be removed. To do this, pulling device 2096617 must be

attached to 11c E-FORCE, pulling device 2835746 for 14c E-FORCE and

pulling device 2836033 for 17c E-FORCE.

43

Page 44

POSSIBLE APPLICATIONS

Safety information

WARNING!

Never reach between the blade arms!

WARNING!

During any work with battery-powered devices, voltage-carrying

parts can break or y off, thereby endangering people.

Uninvolved parties must therefore remain a safe distance away or

stay in the danger zone only as long as necessary.

Cutting (Cutters, Combination devices)

The devices’ cutting capabilities can only be used optimally if they are placed as near

as possible to the blades’ pivot point (Figure 1).

This means it may be necessary to readjust the device.

The device only achieves full cutting performance when the rocker lever is pressed

all the way through. In addition, it can take several seconds for the unit to reach full

operating pressure.

Fig. 1

44

WWW.GENESISRESCUE.COM

Page 45

CUTTING (CUTTERS, COMBINATION DEVICES)

To prevent the blades from being damaged, they must always be placed at right angles

to the material to be cut.

Also, the tips of the blades must not be more than 5 mm apart during the cutting

process. If this value is exceeded, the cutting process must be stopped and then

started again.

CAUTION!

Do not sever any parts with loose ends, because

this can result in personal injury due to parts ying

off.

ATTENTION!

When cutting high-strength vehicle body parts, such as shock

absorbers, hinges or steering columns, the shear blades (arms) may

cause severe damage.

Lifting / pressing (Rams)

In its closed state, the rescue cylinder is positioned for lifting or pushing away vehicle

body parts. Therefore, make sure that the cylinder is placed as centrally as possible

and at a right angle to the load.

For better positioning, the pushing head can be turned on the piston rod.

Suspended parts must immediately be suitably braced and supported. It is forbidden

to stay under suspended loads.

NOTE!

Before the rescue cylinder is used, the attachment point must be

supported so that force develops in the desired direction.

45

Page 46

SPREADING (SPREADERS, COMBI DEVICES)

The spreading function’s uses include opening doors, lifting vehicles and other

movable loads, pushing vehicle parts away, and squashing tubes and beams. For this,

the vehicle must be stably stabilized and supported.

To prevent any sliding during spreading, the arms and tips are uted inside and out.

Whenever possible, the tips should be used only to enlarge a gap, because

repositioning the spreader prevents slipping.

46

WWW.GENESISRESCUE.COM

Page 47

PULLING (SPREADERS, COMBI DEVICES)

After the chain set has been mounted on the spreader tips, the combi device can also be

used for pulling.

For this, the chains must be tightly tensioned and must be tensed only in the pulling direction. To tension the chain, only one lock can be pressed in, so that the chain can be pulled

through the holder.

If the range of movement is not sufcient, tension chains or other means must be used so

that the spreader can be reopened and the chain re-tensioned.

ATTENTION!

Store the pulling chains with locks mounted about 4-8 in from the end.

Check the chains prior to every use. Check that the weight does not

stress the tip of the hook, but lies in the middle of the hook instead.

» Do not make any repairs on your own.

» Do not stress the chains beyond the permitted load carrying

capacity.

» Do not load with a jerking movement.

» Do not galvanize or paint the chains.

» Do not shorten the chain by knotting it.

» Do not subject the chains to heat stress.

» Use the chains and accessories only between –40°F and +392°F.

» During all maintenance work, observe the applicable safety

regulations

» Chains must only be used for lashing. Lifting loads is not permitted.

ATTENTION!

Chains must not be used if:

» Deformations, cracks, signs of corrosion are present.

» The wire diameter of the chain link has decreased by 10% of the

nominal thickness.

» An individual chain link has been permanently stretched.

» An individual link has been enlarged by more than 2%.

» The internal chain pitch over a measuring distance of 11 chain links

has increased by more than 2%.

47

Page 48

CRUSHING (SPREADERS, COMBI DEVICES)

Pipes and other hollow proles are crushed by closing the spreader arms. With combi devices, however, crushing is only to be performed in the tip area.

ATTENTION!

Material to be crushed can suddenly jump away.

Do not remain in the work area of the spreading and combi devices!

48

WWW.GENESISRESCUE.COM

Page 49

LIFTING (SPREADERS, COMBI DEVICES)

The combi device can also be used for lifting vehicles or other movable loads. Care must be

taken to secure the load against slipping away and to position the spreader tips far enough

apart under the load to prevent slipping.

The load being lifted must be constantly monitored (tipping, rolling away or changing position). Also, the lifted load must immediately be propped up and supported in a suitable way.

PEELING

To create entry openings after bus and train accidents, in silos, etc., both the spreader

tips and the peeling tool can be used.

49

Page 50

BATTERY AND CHARGER

Charger Technical Data

TECHNICAL DATA CHARGER MCU

VOLTAGE RANGE

CHARGING CURRENT,QUICK CHARGING

CHARGING TIME

WEIGHT (LBS/G)

INPUT VOLTAGE PART NUMBER

220/240V AC 50/60 HZ EUROPE

240V AC AUSTRALIA

120V AC USA

28V

3.5A

ca. 1h

1.5/700

ART.105.409.7

ART.105.409.8

ART.105.409.9

SPECIAL SAFETY INSTRUCTIONS

WARNING!

Do not throw used rechargeable batteries into a re or into

household waste. Your dealer can dispose of batteries

in an environmentally sound manner.

The following batteries can be charged with the charger:

VOLTAGE BATTERY TYPE NOMINAL CAPACITY NUMBER OF CELLS

28V

28V

28V

50

WWW.GENESISRESCUE.COM

M28XC

M28BX

LI 28 V

≥ 5.0 Ah

≥ 3.0 Ah

≥ 3.0 Ah

2X7

2X7

2X7

Page 51

BATTERY AND CHARGER

WARNING!

Important safety information concerning the battery and charger.

» Do not use the charger to charge non-rechargeable batteries.

» Do not store batteries together with metal objects (danger of short

circuit).

» Do not allow metal parts to enter the charger’s battery insertion slot

(danger of short circuit).

» Do not open batteries and chargers, and store only in dry rooms.

Protect from moisture.

» The charger carries voltage from the power grid. Do not reach into

the device with conductive objects.

» Do not load a damaged battery — replace it immediately instead.

» Before every use, check the device, connection cable, battery

pack, extension cable and plug for damage and aging. Allow only

qualied personnel to repair damaged parts.

» This device is not designed for use by persons (including children)

with limited physical, sensory or mental abilities, or lacking experience,

and/or lacking expertise, unless they are supervised by a person responsible for their safety or have received instructions from this person

on how to use the device. Children should be supervised to ensure that

they do not play with the device.

51

Page 52

BATTERY AND CHARGER

Intended use

This charger charges the 28V Li-ion battery of the M 28/V28 system delivered with the

battery-powered device. This device must be used only as specied and intended.

Power line connection

Only connect to single-phase AC current and only to the line voltage specied on the type

plate. Connection to power sockets without an earthing contact is possible, because this is a

protection class II design.

Li-ion battery

For safety reasons (air transport regulations), the batteries are delivered uncharged. Before

rst use, the battery must be completely charged.

LED charge status display

Figure 1

If the battery is not used for a prolonged period of time, the battery switches to standby

mode. To use again, the battery must be reactivated (recharged).

The charge status can be called up by pressing the button on the battery(see Fig 1). To do

this, the battery can remain in the battery-powered device, but it must be switched off at

least 1 minute beforehand (otherwise the display will not be accurate). The number of glowing LEDs indicates the charge status.

The basic principle is: If the battery-powered device does not function after the battery is

inserted, put the battery onto the charger for testing. The displays on the battery and charger give information about the battery charge status.

At low temperatures, the work can be still be carried out with lower performance.

For best operational readiness, the batteries must be fully charged after use.

52

WWW.GENESISRESCUE.COM

Page 53

CHARGING PROCESS

After inserting the battery into the charger’s insertion slot, the battery is charged automatically (red LED glows continuously).

If too warm or cold a battery is inserted into the charger (red LED ashes), the charging process starts automatically as soon as the battery has reached the correct

charging temperature (0°C to 65°C). The maximum charging current ows if the temperature

of the Li-ion battery is between 0°C and 65°C.

The charging time is between 1 min. and 60 min., depending on how much the battery has

drained (at 3.0 Ah).

If the battery is fully charged, the LED on the charger switches from red to green.

The battery does not need to be removed from the charger after charging. The battery can

continue to stay in the charger. This cannot overload the battery, and it keeps the battery

ready to use.

If both LEDs ash alternately, the battery is either not correctly placed or a malfunction of

either the battery or charger has occurred. For safety reasons, remove the charger and

battery from service immediately and have it checked by an authorized customer service

center.

ashing alternately

If the power adapter is overloaded, all LEDs ash 4 times. To be able to continue charging,

unplug the power adapter and plug it back in.

ashing simultaneously

53

Page 54

MAINTENANCE

If the power cable is damaged, it must be replaced by a customer service center.

Use only approved accessories and replacement parts. Parts whose replacement has not

been described must be replaced by an authorized customer service center.

CHARGING CYCLES

TECHNICAL DATA EXPLANATION

CHARGING CYCLES

PARTIAL DISCHARGE

PARTIAL DISCHARGE AND SUBSEQUENT RECHARGE

DEEP CHARGE PROTECTION

~ 1000

NO EFFECT

EACH RECHARGE COUNTS AS A FULL CHARGE

IS PROVIDED

54

WWW.GENESISRESCUE.COM

Page 55

TRANSPORT, PACKAGING AND STORAGE

Safety information

CAUTION!

Incorrect transport can cause damage!

Improper transport can cause signicant material damage.

Therefore:

» Proceed with caution when unloading the packages, and observe

the symbols on the packaging.

» Do not fully open and remove the package until it has reached its

actual storage location.

Transport inspection

Upon receipt, the delivery should be checked immediately for completeness

and damage during transport so that a quick remedy can be performed, if necessary.

If there is visible external damage, please proceed as follows:

• Do not accept the delivery, or only accept it with reservation.

• Note the extent of the transport damage on the transport documents or on the transport

company’s delivery note.

• File a complaint.

NOTE!

Report any defect as soon as it is detected.

Claims for damages can be directed to our customer service

department.

55

Page 56

DISPOSAL OF PACKAGING

All packaging materials and disassembled parts (transport protection)

must be disposed of properly, in accordance with local regulations.

STORAGE

The equipment must be stored in a dry and dust-free environment, where possible.

Avoid direct UV radiation to the hoses.

CAUTION!

The equipment must be stowed securely in the mountings provided

in order to avoid damage during transit, etc.

56

WWW.GENESISRESCUE.COM

Page 57

INSTALLATION AND COMMISSIONING

Safety information

WARNING!

Danger of injury due to improper operation!

Improper operation can cause serious injury or material damage.

Therefore, make absolutely sure to:

» All operating steps are executed in keeping with the information in

this operating manual.

» All covers and protective devices are installed and in proper working order prior to starting work.

Personal protective equipment

Wear the protective equipment for all work!

NOTE!

Special reference is made where it is necessary to wear additional protective equipment for certain work with or on the device.

CHECKING

Inspect the E-FORCE device for damage. If the cutting device is not in pristine

condition, it must not be used! In this case, immediately contact your supplier.

57

Page 58

E-FORCE combi devices, cutters and spreaders:

• Check the blades (for damage)

• Inspect the spreader tips (for damage)

• Check the control handle including the rocker lever (function)

• Check the handle (secure attachment)

• Check the protective cover (for damage)

E-FORCE rescue cylinder:

• Check the piston rod (for damage)

• Check the control handle including the rocker lever (function)

• Check the plungers (for damage)

• Check the guide piece (for damage)

SHUT-DOWN (END OF WORK)

Cutters:

After work is over, the blade tips must be placed one above the other to prevent injury. The

blades of the cutting device must not be completely closed, as otherwise tension will build

up in the device.

Rescue cylinder:

After work is over, the cylinder’s piston rod must be completely retracted, so as to relieve the

hydraulic load on the device.

Combi devices and spreaders:

After work is over, the spreading arms must remain slightly open, so as to relieve

the hydraulic load on the device.

58

WWW.GENESISRESCUE.COM

Page 59

SERVICE

Safety information

WARNING!

Risk of injury due to improperly performed maintenance work!

Improper maintenance of the equipment can cause serious injury or

material damage.

Therefore, make absolutely sure to:

» Only let qualied personnel carry out maintenance work.

» Make sure the installation site is organized and clean! Loose components and tools lying around are sources of danger.

» Wear protective gloves for all work!

CARE AND MAINTENANCE

PREVENTATIVE MAINTENANCE

Genesis recommends that all hydraulic rescue tools be serviced by a certied factory

technician at a frequency of once every 12 months. Just like a vehicle this crucial

maintenace ensures the tool functions at top performance and safety. Your sales

representative can answer any question you may have.

We recommend only quailied personnel carry out maintenance.

GENESIS PREVENTATIVE MAINTENANCE PROGRAM

The following are recommended service intervals for Genesis tools.

Each Use

-Equipment should be wiped down to remove debris

-Clean cutter blades

-check cutter blades for damage

-Check Spreader Tips and arms for damage

-Check Vario Tips and arms for damage

-Lubricate blades, pins and toggles with WD40 or equivilent

Weekly Inspections and Maintenance

-Run each tool and build pressure

-Check handles and guards, tighten if necessary

-Torque centerbolt on cutters

59

Page 60

ATTENTION!

Prior to all maintenance work, the equipment must be cleaned of any

dirt so that it does not get into the hydraulic system.

The cleaning can be carried out using a conventional citrus cleaner or

using WD 40.

MAINTENANCE SCHEDULE

A precise maintenance plan with testing intervals, regulations and results can be requested

from your sales representative.

NOTE!

If there are any problems with the maintenance of the devices, contact

your local sales representative.

60

WWW.GENESISRESCUE.COM

Page 61

TROUBLE SHOOTING

61

Page 62

RAM

SPREADER

62

WWW.GENESISRESCUE.COM

Page 63

DECOMMISSIONING/RECYCLING

After the end of the normal service life, the equipment must be professionally disposed

of. Individual parts can, however, certainly be used again.

The hydraulic oil must be completely drained and collected. Make sure that

the hydraulic oil is disposed of separately!

For disposal of all device components and packaging materials, the disposal conditions

of the specic location apply.

Do not discard electric tools with household waste!

NOTE!

Please ask your supplier about disposing of the device.

63

Page 64

NOTES

64

WWW.GENESISRESCUE.COM

Page 65

GENESIS RESCUE SYSTEMS

2780 CULVER AVE.

KETTERING, OHIO 45329

TEL: 1.937.293.6240

WWW.GENESISRESCUE.COM

65

Loading...

Loading...