Page 1

™

Power-Vee

Operating Instructions

For 1-1/4‖ through 3‖ lines

(30mm—100mm)

Your Power-Vee is designed to give

you years of trouble-free, profitable

service. However, no machine is better

than its operator.

Read, understand and follow all safety

warnings and instructions provided with

the product. Failure to follow the warnings

and instructions may result in electric

shock and/or serious injury. Save all warnings and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Pour français voir la page 7

Para ver el español vea la paginá 15

Page 2

Power-Vee™

GENERAL SAFETY RULES

WARNING! Read and understand all

instructions. Failure to follow all instruc-

tions listed below may result in electric shock,

fire and/or serious personal injury. Replacement manuals are available upon request at no

charge, or may be downloaded from our website, www.drainbrain.com. Instructional videos

are available for download on our website, and

may be ordered. If you have any questions or

problems, please call General’s customer

service department at 412-771-6300.

Electric shock resulting in

death can occur if you plug

this machine into an improperly wired outlet. If the ground

wire is electrified, you can be

electrocuted by just touching

the machine, even when the

power switch is off. A ground

fault circuit interrupter will not protect you in this situation. Use a

UL approved tester to determine

if the outlet is safe.

Do not operate power tools in

explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which

may ignite the dust or fumes.

SAVE THESE INSTRUCTIONS!

These instructions are intended to

familiarize all personnel with the safe

operation and maintenance

procedures for the Power-Vee.

This is the safety alert symbol. It is

used to alert you to potential personal

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARINING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Only wear leather gloves.

Never use any other type of

glove, such as cloth, rubber, or

coated gloves. Never grasp a

rotating cable with a rag.

These items could become

wrapped around the cable and

cause serious injury.

Always wear safety glasses

and rubber soled, non-slip

shoes. Use of this safety equip-

ment may prevent serious injury.

Do not overstress cables.

Overstressing cables may cause

twisting, kinking, or breaking of

the cable and may result in serious injury.

CAUTION indicates a hazard with a low level of risk which,

if not avoided, will result in minor or moderate injury.

2

Page 3

Power-Vee™

GENERAL SAFETY RULES

Work Area

1. Keep work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

1. Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tool should

electrically malfunction or break down, grounding

provides a low resistance path to carry electricity

away from the user.

2. Double insulated tools are equipped with a polar-

ized plug (one blade is wider than the other).

This plug will fit a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation

eliminates the need for the three wire grounded

power cord and grounded power supply system.

3. Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your

body is grounded.

4. Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electric shock.

5. Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

6. When operating a power tool outside use an out-

door extension cord marked ―W-A‖ or ―W‖. These

cords are rated for outdoor use and reduce the risk of

electric shock.

7. Keep all electric connections dry and off the

ground. Reduces the risk of electric shock.

8. Do not touch plugs or tools with wet hands. Re-

duces the risk of electric shock.

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving

parts.

3. Avoid accidental starting. Be sure switch is off

before plugging in. Plugging in tools that have the

switch on invites accidents.

4. Remove adjusting keys or switches before turn-

ing the tool on. A wrench or key that is left attached

to a rotating part of the tool may result in personal

injury.

5. Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

6. Always wear safety glasses and rubber soled,

non-slip shoes. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

1. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable

and may lead to loss of control.

2. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

3. Do not use tool if switch does not turn it on or off.

Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

4. Disconnect the plug from the power source be-

fore making any adjustments, changing accessories, or storing the tool. Such preventative safety

measures reduce the risk of starting the tool accidentally.

5. Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the

hands of untrained users.

6. Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to

control.

7. Inspect for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

8. Only use accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous

when used on another tool.

3

Page 4

Power-Vee™

Service

1. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified repair personnel could result in

injury.

2. When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions

may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

1. Only wear leather gloves. Never use any other type

of glove, such as cloth, rubber, or coated gloves.

Never grasp a rotating cable with a rag. These items

could become wrapped around the cable and cause

serious injury.

2. Be sure that the unit is plugged into a properly

grounded receptacle. If in doubt, check receptacle

before plugging in machine. Check the power cord to

see that there are no cuts or frays, and that the

grounding prong on the plug is still in place.

3. The drive unit used in the Power-Vee is double

insulated, and therefore has no grounding wire.

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider

than the other). The plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the outlet, reverse the plug. If the plug still does not fit, contact a qualified electrician to install the proper outlet.

Do not change the plug in any way.

4. If the power cord supplied with the machine is

not long enough, be sure to use a 16 gauge

heavy duty extension cord no more than 50 feet

long and in good condition. Using lighter cords can

result in severe power loss and motor overheating.

5. Place the machine at a distance not greater than

six inches from drain opening. Greater distances

can result in cable twisting or kinking.

6. Machine is designed for ONE-PERSON operation.

Operator must control trigger switch and cable.

7. Never take hold of a rotating cable. Pull the cable

out, or push it back into the container by hand

only when the motor is stopped. When the motor

is turning, always have one hand controlling the

trigger switch and the other hand around the grip

shield. Operator’s hand may be caught in the moving

parts resulting in serious injury.

8. Be careful when cleaning drains where cleaning

chemicals have been used. Avoid direct contact

with corrosive drain cleaners. Drain cleaning chemicals can cause serious burns, as well as damage the

cable. Neutralize or remove corrosive drain cleaners

in the drain before starting the job.

9. Do not operate machine if operator or machine is

standing in water. Will increase risk of electrical

shock.

10. Wear safety glasses and rubber soled, non-slip

shoes. Use of this safety equipment may prevent

serious injury.

11. Before starting each job, check that the cable in

the drum is not broken or kinked, by pulling the

cable out and checking for wear or breakage. Al-

ways replace worn out (kinked or broken) cables with

genuine GENERAL replacement cables.

12. Only use this tool in the application for which it

was designed. Follow the instructions on the

proper use of the machine. Other uses or modifying

the drain cleaner for other applications may increase

risk of injury.

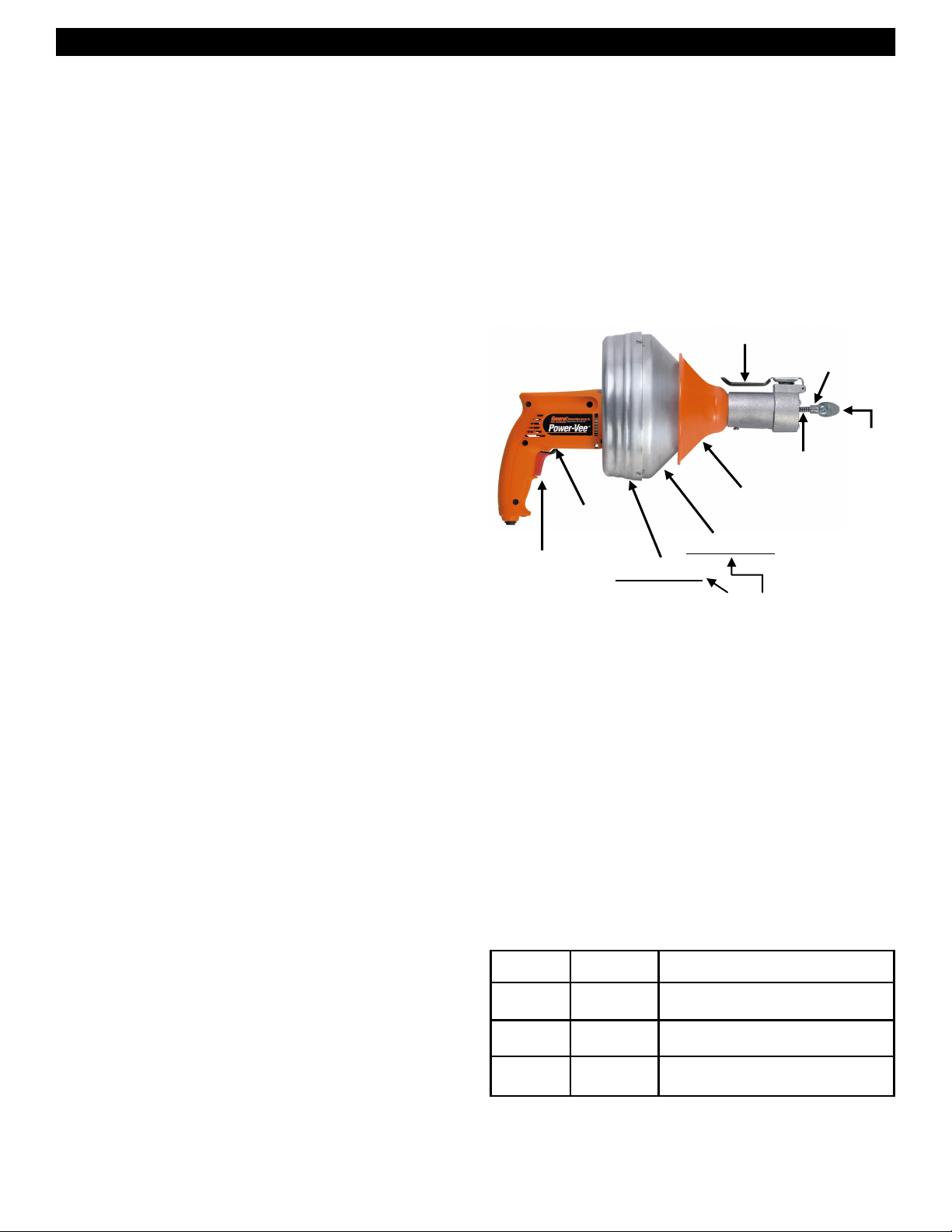

FEATURES

Power Cable Feed Lever

Female Connector

Cable

Grip Shield

Forward/Off/

Reverse Switch

Variable Speed

Trigger Switch

Container Back

VARIABLE SPEED SWITCH

A variable speed control is built into the trigger mechanism. You can control and increase the machine's speed

by applying more trigger pressure until you get the speed

that you want.

You can also control the machine's direction of rotation

by switching the forward and reverse lever, which is located just above the trigger switch. Move the lever toward the Forward arrow for forward rotation and toward

the Back arrow for reverse rotation. Switch to OFF position when the tool is not in use.

Cable Application Chart (Table 1)

Cable Size Pipe Size Typical Applications

1/4” 1-1/4" to 2" Small lines, tubs, and shower drains.

5/16" 1-1/2" to 2" Sinks, basins, and small drains.

3/8" 2" to 3" Stacks, toilets, small drains (No Roots).

The 1/4" and 5/16" diameter cables with EL Basin plug heads

can be spun through most strainer crossbars and work well in

lines blocked by soft stoppages such as hair, soap, fats, etc.

4

Container Front

Cable Cartridge - inside container

Cutter

Page 5

Power-Vee™

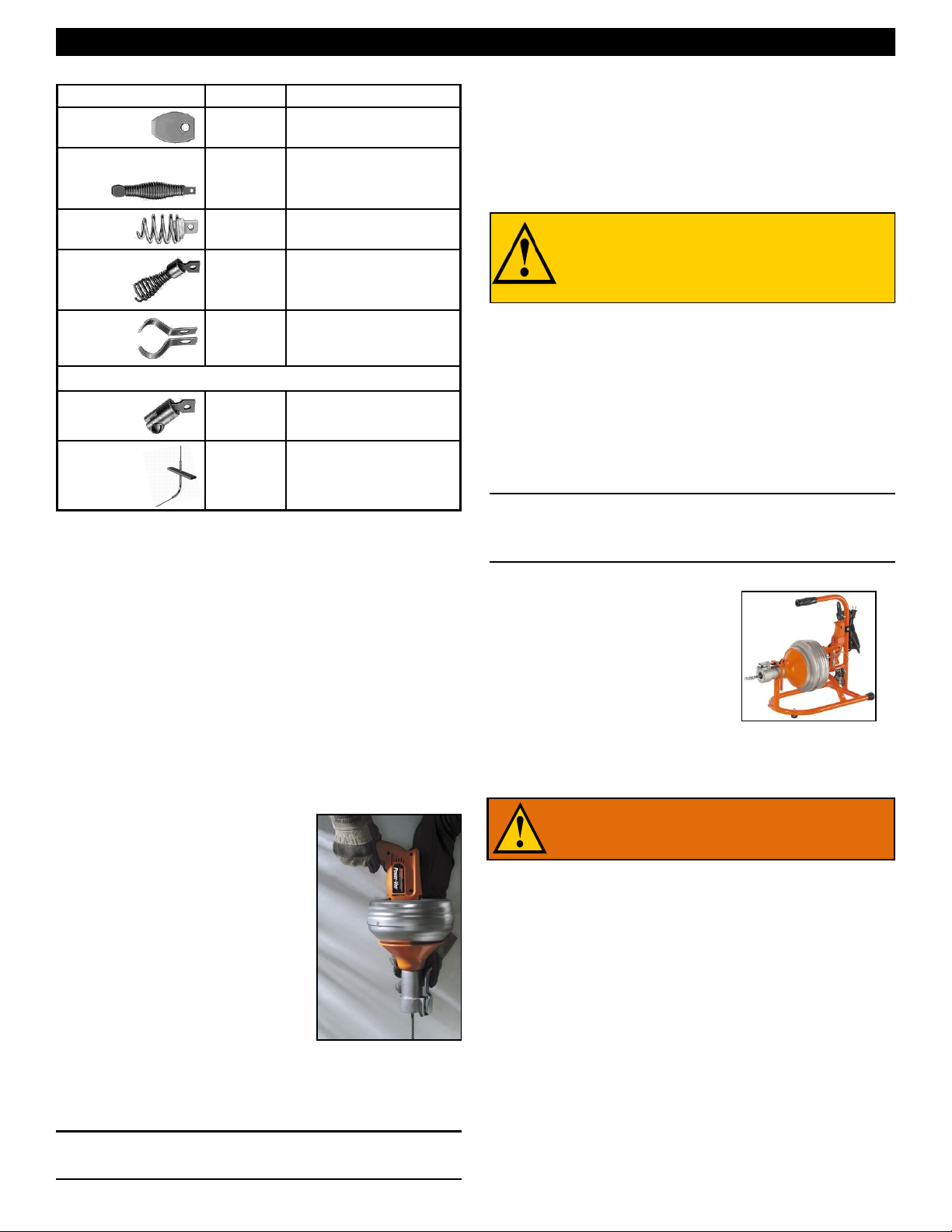

Cutter Application Chart (Table 2)

Cutter Catalog # Typical Applications

Arrow

Head

Flexible Arrow

Head

Boring

Gimlet

Down Head

Boring

Gimlet

1-1/4"

Side

Cutter

Other Available Accessories:

Down Head

Fitting

Toilet

Attachment

DHBG

1-1/4SCB

AH

FAH

BG

DHF

CAA

Ideal for heavy cutting and

scraping.

More flexibility than Arrow

Head; can take sharp turns in

small lines.

To remove or retrieve loose

objects.

Leads cable down drain line

rather than up vent or across

tee.

Works well in grease stoppages, scrapes walls of pipe.

Converts various cutters to

the down-head style

For cleaning stoppages in

toilet bowl

8. Use the variable speed trigger to adjust the feed rate

to the resistance met. Do not force the cable or feed

faster than the cable can go into the drain.

9. Do not leave too much slack in the cable since this

will cause whipping. If the cable starts to bend or

build up too much twist, release the trigger. Push any

excess cable back into the drum and then continue.

DO NOT ALLOW TOO MUCH SLACK IN

THE CABLE BETWEEN MACHINE AND

DRAIN OPENING SINCE THIS CAN

CAUSE CABLE WHIPPING.

10. When the cable reaches the stoppage, put feed in

neutral by releasing feed lever. Move the machine

back and forth as the cable is rotating until the stoppage has been cleared. Slight feed lever pressure

may be applied as required to maintain contact with

the stoppage.

11. To retract the cable, put Forward/Off/Reverse switch

in the Reverse position and press the feed lever and

motor trigger.

Hint: It's often helpful to have a small stream of

water running in the line to wash the cuttings away

while the machine is in operation and after.

OPERATING INSTRUCTIONS

1. The cable may have a drop-head spring on the end

to help the cable around tight bends, or it may have a

connector for attaching cutters to the end.

2. To attach a cutter, first unplug the machine. Then,

remove the screw and lock washer from the connector at the end of the cable. Slide the cutter into the

slot, then replace the lock washer and connecting

screw. Tighten the screw firmly.

3. The Boring Gimlet and Arrow Head are good cutters

to start with. Then change to the larger cutters after

you've gotten the water flowing.

4. Place machine at a distance

not greater than six inches

from the drain opening. If you

can’t place the machine this

close to the drain opening, run

the cable through a hose or

pipe to prevent cable whipping.

5. Insert the cable into the drain

opening as far as it will go.

6. Be sure the Forward/Off/

Reverse switch is in the FOR-

WARD position.

7. Gently squeeze the motor trigger. Then, squeeze the

power cable feed lever to feed cable into the line.

DO NOT FORCE THE CABLE. The job won’t go

any faster and you could kink the cable.

DO NOT USE TOO MUCH FORCE –

LET THE CUTTER DO THE WORK.

Note: An optional Handy

Stand™ (shown at right)

holds the Power-Vee for

greater control of the machine

and cable.

TO CHANGE CABLE CARTRIDGES

DISCONNECT MACHINE FROM POWER

SOURCE BEFORE INSTALLING CABLES OR

DRUMS!

1. Remove the cutter and connecting screw from the

cable, if one is attached.

2. Squeeze the feed lever and pull back on the retaining

latch. Swing the feed lever open. Remove the top

roller assembly.

3. Loosen three screws that hold front and back of container together. Pull the container front off of the machine, revealing the cable cartridge within.

4. Remove the cable cartridge.

5. Press replacement cartridge firmly into back of container. Make sure to line up the grooves in the cartridge with the slots in the container back.

6. Slide the cable through the container front.

7. Position the container front so that the three screws

aligned with the slots in the container back. Press

the container front into the container back.

5

Page 6

Power-Vee™

8. Tighten screws firmly, making sure the screw heads

are centered in the slots and flush with the container

surface.

9. Insert top roller assembly into the feed housing.

Make sure that the guide pin in the carrier is aligned

with the slot in the housing.

10. Swing the feed lever

closed. Squeeze the

lever and push the

retaining latch forward to

secure the feed lever in

place.

MAINTENANCE

DISCONNECT MACHINE FROM POWER

SOURCE BEFORE PERFORMING

MAINTENANCE ON MACHINE!

To keep your machine operating smoothly, it is essential

that all bearings and bushings be lubricated. Oiling moving parts is particularly important where machine comes

in contact with sand, grit and other abrasive material.

CABLE MAINTENENCE

To get maximum service from

your cables, be sure that they are

clean and well oiled. This not

only provides running lubrication

but greatly extends the life of the

cables as well. Some users periodically pour oil directly into the

drum. Then, as the drum turns,

the cables get complete lubrication. Our SNAKE OIL is ideally

suited for this purpose, since it

not only lubricates the cables, it

deodorizes them as well.

FEED MAINTENANCE

Keep feed free of excessive soil and grit. It is recommended that the feed be flushed with fresh water followed by a light oiling of the moving parts. No disassembly is normally required. Failure to feed can usually be

traced to dirt accumulation.

Over time, dirt can harden enough to stop roller rotation.

Flushing with water followed by liberal oiling can usually

restore function. If disassembly is required, proceed as

follows,

TO CLEAN OR REPLACE FEED ROLLERS

1. Squeeze the feed lever and pull back on the lever

retaining latch.

2. Swing the feed lever open. Remove the top roller

assembly.

3. Remove the three Cover Plate retaining screws to

expose the two lower rollers.

4. Loosen and remove the screws holding the lower two

rollers in place.

5. Re-assembly is done in reverse order.

TO REMOVE MOTOR

1. Loosen the three screws that hold the container front

and back together.

2. Pull the container front off of the machine.

3. Loosen the two set screws in the beveled collar and

remove both the collar and the felt washer.

4. Slide a flat head screw driver into the Hub Spindle

and unscrew the Left Hand locking screw from the

drive shaft by turning it clockwise.

5. Unscrew the Hub Spindle from the Right Hand Drive

Shaft by rotating the container back counterclockwise. Note: The Hub Spindle, Hub, and Con-

tainer Back remain as one unit. The thrust bearing

will spin freely.

6. Reverse these instructions to re-assemble.

TROUBLE SHOOTING GUIDE (TABLE 3)

Problem Probable Cause Solution

Cable kinks or breaks. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Too much slack between machine and drain. Do not allow more than six inches between machine and drain.

Cable used in wrong size drain line. A cable that is too large or too small in diameter for a line is more

likely to kink. (Consult Table 1—Cable Applications.)

Cable exposed to acid Clean and oil cables regularly.

Cable tangles in container. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Failure to feed. Feed Rollers frozen. Clean and lubricate feed rollers regularly. Replace worn rollers.

Cable tangled in drum. Use proper cable size. (Consult Cable Application Chart—Table 1).

Motor does not run. Trigger in neutral (off) position. Switch Trigger to either Forward or Reverse.

Motor turns in one direction

but not other.

Reverse switch failure. Replace reverse switch.

See pages 22 and 23 for Parts List and Schematic Diagram.

6

Page 7

™

Power-Vee

Manuel d'instructions

Pour canalisations de 1-1/4 à 3 pouces

(30–100 mm)

Votre débouchoir Power-Vee est conçu

pour vous procurer de nombreuses années

de service fiable et rentable. Toutefois aucun

appareil ne peut donner son plein rendement

si l'opérateur ne le connaît pas à fond.

Lisez, comprenez et respectez toutes

les consignes de sécurité et instructions four-

nies avec ce produit. Le fait de ne pas suivre

ces consignes et instructions risquerait de

provoquer une électrocution et/ou des blessu-

res graves. Conservez ces documents pour

future référence.

CONSERVEZ CES INSTRUCTIONS !

Page 8

Power-Vee™

CONSIGNES DE SÉCURITÉ

GÉNÉRALES

AVERTISSEMENT! Lisez attentivement toutes les instructions. Le fait de ne pas suivre

toutes les instructions risque de provoquer une

électrocution, un incendie et/ou des blessures

graves. Des manuels de rechange peuvent

être obtenus gratuitement sur demande, ou

téléchargées à partir de notre site Internet,

www.drainbrain.com. Des films d'instruction

peuvent également être téléchargés de notre

site Internet ou nous être commandés. En cas

de question ou de problème, veuillez contacter

le service clientèle de General au 412-771-

6300.

CONSERVEZ CES INSTRUCTIONS !

L'appareil doit être branché

dans une prise correctement

mise à la terre. À défaut de sui-

vre ces instructions, il peut

s'ensuivre un choc électrique

et la mort. Si le fil de mise à la

terre est électrifié, vous pouvez

être électrocuté par un simple

contact avec l'appareil et ce,

même si l’interrupteur est à Arrêt (Off). Dans ce cas, le disjonc-

teur de fuite à la terre ne peut pas

vous protéger. Utilisez un testeur

certifié UL pour vérifier si la prise

de courant est sécuritaire.

N'utilisez jamais des outils mo-

torisés dans une atmosphère

explosive générée par des li-

quides inflammables, des gaz

ou de la poussière. Les outils

électriques provoquent des étincelles qui risquent d’enflammer la

poussière ou les vapeurs.

Ces instructions ont pour objet de fa-

miliariser tous les employés avec l’u-

tilisation et l’entretien sans danger

du Power-Vee.

Ce symbole de sécurité vous avertit

de l’existence d'un danger pour votre

DANGER signale un danger de haut risque qui, s’il n’est

pas évité, entraînera des blessures graves ou mortelles.

AVERTISSEMENT signale un danger de risque moyen qui,

s’il n’est pas évité, peut entraîner des blessures graves ou

mortelles.

MISE EN GARDE signale un danger de faible risque qui,

s’il n’est pas évité, peut entraîner des blessures de faible

ou moyenne gravité.

sécurité personnelle. Respectez toutes les consignes de sécurité suivant

ce symbole afin d’éviter des blessu-

res graves ou mortelles.

Ne portez que des gants en

cuir. N’utilisez aucun autre ty-

pe de gants, en tissu, caoutchouc ou enduit. Ne saisissez

jamais un câble en mouvement

avec des gants en tissu ou un

chiffon; ces matériaux peuvent

s’enrouler autour du câble et cau-

ser des blessures graves.

Portez toujours des lunettes de

sécurité et des chaussures à

semelles de caoutchouc anti-

dérapantes. L'emploi de ces

équipements de sécurité peut

empêcher des blessures graves.

Ne forcez jamais les câbles

exagérément. Une tension ex-

cessive peut causer la torsion, le

vrillage ou la rupture du câble et

pourrait provoquer des blessures

graves.

8

Page 9

Power-Vee™

CONSIGNES DE SÉCURITÉ GÉNÉRALES

Sécurité du site

1. Conservez l’espace de travail propre et bien éclairé. Des établis encombrés et des zones mal éclairées

sont causes d'accident.

2. N'utilisez jamais des outils motorisés dans une

atmosphère explosive générée par des liquides

inflammables, des gaz ou de la poussière. Ces ou-

tils produisent des étincelles qui peuvent allumer les

vapeurs inflammables ou les poussières.

3. Ne laissez pas les curieux, les enfants et les visiteurs s'approcher quand vous faites fonctionner

un outil motorisé. Des distractions pourraient vous

faire perdre le contrôle.

Électricité et sécurité

1. Les outils mis à la terre doivent être branchés

dans une prise de secteur correctement installée

et mise à la terre conformément à tous les codes

et décrets. Ne retirez jamais le plot de mise à la

terre et ne modifiez la prise en aucune faēon. N’utilisez pas de prise-adaptateur. Consultez un électricien qualifié en cas de doute sur la bonne mise

à la terre de la prise de secteur. Si l’outil subit un

mauvais fonctionnement ou une panne électrique, la

mise à la terre offre un chemin de faible résistance

éloignant le courant de l’utilisateur.

2. Les outils à double isolation sont équipés d'une

fiche polarisée (une broche plus large que l'autre).

Ce type de fiche ne peut être inséré dans une prise

de courant polarisée que d'une seule façon. Si la

fiche ne peut pas entrer complètement dans la pri-

se, faites-la pivoter d'un demi-tour. S'il est tou-

jours impossible de la faire entrer complètement,

demandez à un électricien qualifié d'installer une

prise de courant polarisée. Ne changez la fiche

pour aucune raison. La double isolation élimine le

besoin d’une fiche à trois broches et d’un câblage

électrique mis à la terre.

3. Votre corps ne doit pas toucher à des objets mis à

la terre, tels les tuyaux, radiateurs, cuisinière ou

réfrigérateur. Si votre corps se trouve mis à la terre,

vous augmentez les risques de choc électrique.

4. N'utilisez pas d'outils électriques mouillés ou sous

la pluie. L'eau qui s'infiltre dans un outil électrique

augmente les risques de choc électrique.

5. Attention au cordon électrique. Ne transportez ja-

mais un outil par le cordon et ne débranchez ja-

mais un outil en tirant sur le cordon. Maintenez

toujours le cordon éloigné de la chaleur, de l'huile,

d'objets coupants ou de pièces en mouvement.

Remplacez immédiatement un cordon endommagé, car cela augmente les risques de choc électrique.

6. Servez-vous uniquement d’une rallonge électrique

extérieure marquée « W-A » ou « W » lorsque vous

utilisez un outil électrique dehors. Ces rallonges

sont homologuées pour un usage extérieur et réduisent le risque d'électrocution.

7. Maintenez tous les branchements électriques au

sec et au-dessus du sol. Réduit le risque d’électro-

cution.

8. Ne touchez pas les prises ou les outils avec des

mains mouillées. Réduit le risque d’électrocution.

Sécurité personnelle

1. Ne vous laissez pas distraire, prêtez attention à

ce que vous faites et usez de bon sens lorsque

vous utilisez un outil électrique. N'utilisez pas cet

outil si vous êtes fatigué ou sous l’influence

d'une drogue, de l'alcool ou de médicaments. Des

blessures graves peuvent résulter d'un moment

d'inattention.

2. Habillez-vous correctement. Ne portez pas de bi-

joux ou de vêtements risquant de se prendre

dans l’appareil. Éloignez les cheveux, vêtements

et gants des pièces en mouvement. Les vêtements

lâches, les bijoux ou les cheveux longs peuvent facilement se prendre dans des pièces en mouvement.

3. Prenez garde à tout démarrage accidentel. Vérifiez que l'interrupteur soit en position ARRÊT

avant de brancher l'appareil. Brancher un appareil

dont l'interrupteur est en position MARCHE est une

cause d'accidents.

4. Retirez toute clé ou outil d'ajustement avant la

mise en marche. Une clé ou tout autre outil laissés

sur une pièce rotative peuvent causer des blessures.

5. N'étendez pas trop les bras. Conservez votre

équilibre en tout temps ainsi qu'un appui solide.

Un bon appui ainsi qu'un bon équilibre permettent de

conserver un meilleur contrôle de l'outil en cas d’imprévu.

6. Portez toujours des lunettes de sécurité et des

chaussures à semelle en caoutchouc antidéra-

pante. Un masque à poussières, des chaussures de

sécurité antidérapantes, un casque ou une protection

auditive peuvent être nécessaires selon l’application.

Utilisation et soin de l'appareil

1. Servez-vous de pinces ou d’une autre méthode

pour fixer et soutenir la piêce travaillée sur un

support stable. Tenir la pièce à la main ou contre

votre corps ne fournit pas la stabilité nécessaire et

risque de conduire à une perte de contrōle

2. Ne forcez pas cet outil. Utiliser le bon appareil

pour telle application. L’outil approprié effectue un

meilleur travail, dans des conditions plus sécuritaires

et à la vitesse pour laquelle il a été conçu.

3. N'utilisez pas cet outil si l'interrupteur ne contrôle pas la mise en marche ou l'arrêt. Un outil qui ne

peut pas être contrôlé par l'interrupteur est dangereux et doit être réparé avant toute utilisation.

4. Débranchez la prise de la source de courant

avant de faire des réglages, de changer d’acces-

soire ou de ranger votre outil. Cette mesure de

prévention réduit les risques de démarrage acciden-

tel de l'outil.

5. Rangez les outils en attente hors de portée des

enfants et des autres personnes inexpérimentées. Les outils sont dangereux dans les mains d'uti-

lisateurs inexpérimentés.

9

Page 10

Power-Vee™

6. Entretenez soigneusement vos outils. Affûtez et

nettoyez la lame des outils de coupe. Des outils correctement entretenus et dont la lame est tranchante

ont moins de risque de se coincer et sont plus faciles

à contrôler.

7. Surveillez le désalignement ou le grippage des

pièces mobiles, les bris de pièce ou toute autre

condition qui peut nuire au bon fonctionnement

de l’appareil. Si un outil est endommagé, faites-le

réparer avant toute utilisation. Plusieurs accidents

sont causés par des outils mal entretenus.

8. N'utilisez que les accessoires recommandés par

le manufacturier pour votre modèle. L’accessoire

qui convient à un outil peut devenir dangereux sur un

autre.

Entretien et réparations

1. Toute réparation de l'appareil ne doit être effectuée que par du personnel qualifié. Des blessures

peuvent résulter d'un travail effectué par du personnel non qualifié.

2. Si un appareil doit être réparé, seules des pièces

identiques d'origine doivent être utilisées. Suivez

les instructions dans la section Entretien de ce

manuel. L'utilisation de pièces non autorisées ou le

défaut de suivre les instructions d'entretien peuvent

causer un choc électrique ou des blessures.

CONSIGNES DE SÉCURITÉ

PARTICULIÈRES

1. Portez uniquement des gants en cuir. N’utilisez

jamais d’autres types de gants, tels que gants en

toile, en caoutchouc ou en tissu enduit. Ne saisissez

jamais un câble en rotation avec un chiffon. Ces objets peuvent se prendre dans le câble et provoquer

un accident grave.

2. Assurez-vous que l'outil soit branché dans une

prise de courant correctement mise à la terre. En

cas de doute, vérifiez la prise avant d'y brancher l'outil. Vérifiez que le cordon électrique n'est pas coupé

ou effiloché, et que la broche de mise à la terre est

encore bien en place.

3. Le moteur du Power-Vee est à double isolation et

n'a donc pas de mise à la terre. Pour réduire les

risques de choc électrique, cet outil est pourvu

d'une fiche polarisée (une broche plus large que

l’autre). Ce type de fiche ne peut être inséré dans

une prise de courant polarisée que d'une seule façon. Si la fiche ne peut pas entrer complètement

dans la prise, faites-la pivoter d'un demi-tour. S'il est

toujours impossible de la faire entrer complètement,

demandez à un électricien qualifié d'installer une prise de courant polarisée. Ne changez la fiche pour

aucune raison.

4. Si le cordon d'alimentation de l'outil n'est pas

suffisamment long, vous pouvez utiliser une ral-

longe pour usage intensif en bon état de calibre

16 et ne dépassant pas 15 m (50 pi). Un cordon de

calibre plus petit peut entraîner une importante chute

de puissance et la surchauffe du moteur.

5. Placez l’appareil le plus près possible du drain, à

une distance de 15,24 cm maximum. Une distance

plus grande risque de conduire à une torsion ou un

vrillage du câble.

6. Cet appareil est prévu pour être utilisé PAR UNE

PERSONNE seulement à la fois. L’utilisateur doit

contrôler la gâchette et le câble.

7. Ne saisissez jamais un câble en mouvement. Ne

saisissez le câble pour le sortir de son logement

ou l'y rentrer que lorsque le moteur est arrêté.

Lorsque le moteur tourne, ayez toujours une

main sur la gâchette et l'autre main autour de la

poignée bouclier conique. La main de l’utilisateur

risque de se prendre dans des pièces en mouvement, ce qui peut entraîner des blessures graves.

8. Faites attention lorsque vous nettoyez un drain

dans lequel des produits chimiques ont été utilisés. Évitez tout contact direct avec les produits de

débouchage de drain corrosifs. Ces produits chimi-

ques peuvent causer des blessures à l'opérateur et

endommager le câble. Neutralisez ou évacuez les

produits de nettoyage corrosifs des tuyaux avant

d'utiliser l'outil.

9. Ne faites pas fonctionner la machine si elle ou

l'utilisateur se trouve sur un sol inondé. Ceci augmenterait le risque d’électrocution.

10. Portez toujours des lunettes de sécurité et des

chaussures à semelle en caoutchouc antidéra-

pant. L'emploi de ces équipements de sécurité peut

empêcher des blessures graves.

11. Avant chaque utilisation, vérifiez que le câble

n'est ni cassé ni emmêlé à l'intérieur du tambour,

en extrayant le câble et en vérifiant qu'il n'est pas

usé ni cassé. Remplacez toujours les câbles usés

(entortillés ou cassés) par des câbles de remplace-

ment GENERAL authentiques.

12. N’utiliser cet outil que pour la tâche à laquelle il

est destiné. Suivez le mode d’emploi. Toute autre

utilisation ou la modification du débouchoir pour d’autres applications risquent d’augmenter le risque de se

blesser.

CARACTÉRISTIQUES

Levier d’avance du cāble électrique

Raccord femelle

Câble

Protège-poignée

Devant du récipient

Gāchette à

vitesse variable

10

Commutateur

Avance/Arrêt/

Recul

Dos du récipient

Cartouche du cāble - à l’intérieur du récipient

Couteau

Page 11

Power-Vee™

COMMANDE À VITESSE VARIABLE

Une commande à vitesse variable est intégrée dans le

mécanisme de la gâchette. Vous pouvez contrôler et

augmenter la vitesse du moteur selon la pression appli-

quée sur la gâchette jusqu'à l'obtention de la vitesse désirée.

Vous pouvez aussi contrôler le sens de rotation de l'outil

au moyen du levier situé juste au-dessus de la gâchette.

Déplacez le levier vers la flèche Avance pour la marche

avant et vers la flèche Recul pour la marche arrière. Laissez le levier en position d'arrêt (OFF) quand l'outil n'est

pas utilisé.

Sélection du câble (Tableau 1)

Diamètre

du câble

1/4”

6.3 mm

5/16"

7.9 mm

3/8"

9.5 mm

Les câbles de 1/4" et 5/16" (6.3 mm et 7.9 mm) équipés d'une tête EL

pour les bouchons des cuves peuvent être insérés dans la plupart des

crépines en croix pour libérer les blocages mous, telles les accumulations de cheveux, de savon, de graisse, etc.

Diamètre de

conduite

1-1/4" à 2"

30-50 mm

1-1/2" à 2"

38-50 mm

2" à 3"

50-75 mm

Applications typiques

Petites conduites, drains de baignoire

et de douche

Éviers, cuves, petits drains

Colonnes, toilettes, petits drains (pas

de racines)

DIRECTIVES D'UTILISATION

1. Le câble peut être muni d’une tête à ressort (afin de

l’aider à passer dans les courbes) ou d’un connecteur

de couteau.

2. Pour fixer un couteau, débranchez d’abord la machi-

ne. Dévissez ensuite la vis et la rondelle d’arrêt du

connecteur situé en bout de câble. Glissez le couteau

dans la fente, puis remettez en place la rondelle d’arrêt et la vis de fixation. Serrez fermement la vis.

3. La queue de cochon et la tête de flèche sont de bons

couteaux de départ. Passez ensuite à des couteaux

plus grands une fois que l’eau recommence à circuler.

4. Placez la machine à une distan-

ce de 15,24 cm maximum de

l’ouverture du drain. Si ceci

n’est pas possible, faites passer

le câble à travers un tuyau ou

une conduite pour éviter que le

câble ne fouette.

5. Enfoncez le câble le plus loin

possible dans l’ouverture.

6. Vérifiez que le commutateur

Avance/Arrêt/Recul est sur la

position AVANCE.

7. Appuyez doucement sur la gâ-

chette. Puis appuyez sur le levier d’avance du câble

pour faire avancer le câble dans la canalisation. NE

FORCEZ PAS LE CÂBLE. Ceci ne fera pas aller le

travail plus vite et vous risqueriez de tordre le câble.

Applications des couteaux (Tableau 2)

Couteau N° de pièce Applications typiques

Tête de

flèche

Tête de flèche

flexible

Queue de

cochon

Queue de

cochon vers

le bas

Lame à

tranchant

latéral 1-1/4 po

Autres accessoires disponibles:

Support de

tête vers le bas

Guide coudé

pour toilette

AH

FAH

BG

DHBG

1-1/4SCB

DHF

CAA

Idéal pour couper et gratter

Tête de flèche flexible

Plus de flexibilité que la tête

de flèche; capable de virage

serré dans une petite conduite

Pour retirer des objets perdus

Dirige le câble vers le bas à

travers l'évacuation plutôt

que vers le haut par l'évent

ou à travers un té

Pour les bouchons de graisse, pour gratter les parois de

la conduite

Convertit divers couteaux en

têtes vers le bas

Pour enlever des bouchons

dans les cuvettes de toilette

N'UTILISEZ PAS UNE FORCE TROP GRANDE -

LAISSEZ LE COUTEAU TRAVAILLER POUR VOUS

8. Ajustez la rapidité d'avancement avec la gâchette de

vitesse variable en fonction de la résistance rencontrée. Ne forcez pas le câble et ne l’avancez pas

plus vite qu’il ne peut pénétrer.

9. Le câble ne doit pas être lâche car il risquerait alors

de fouetter. Si le câble commence à se courber ou à

trop se tordre, relâcher la gâchette. Repoussez l’excès de câble dans le tambour, puis continuez.

NE LAISSEZ PAS TROP DE CÂBLE EN-

TRE L'APPAREIL ET L'OUVERTURE DU

DRAIN CAR LE CÂBLE RISQUERAIT DE

FOUETTER.

10. Quand le câble atteint le bouchon, mettez l'avance

au point mort en relâchant le levier d'avance. Imprimez à l'appareil un mouvement de va-et-vient tout en

laissant tourner le câble jusqu'à ce que le bouchon

soit percé. Vous pouvez appliquer une légère pression au levier d'avance lorsque c'est nécessaire pour

maintenir le contact avec le bouchon.

11. Pour faire revenir le câble, mettez le levier d'Avance/

Arrêt/Recul sur la position de Recul et appuyez sur

le levier d'avance et sur la gâchette du moteur.

Truc: Il peut être avantageux de faire couler un filet

d'eau dans la canalisation pendant et après l'utilisation

de l'appareil, pour dégager les débris coupés par le cou-

teau.

11

Page 12

Power-Vee™

Note: Un support pratique

optionnel Handy Stand™

(illustré à droite) maintient le

Power-Vee pour un meilleur

contrôle de l'appareil et du

câble.

POUR CHANGER LA CARTOUCHE DE CÂBLE

DÉBRANCHEZ L’APPAREIL AVANT DE

CHANGER UNE CARTOUCHE !

1. Si un couteau est attaché au câble, détachez-le, ainsi

que la vis de fixation.

2. Appuyez sur le levier d'avance et tirez sur le verrou

de retenue du levier. Tournez le levier d'avance pour

l'ouvrir. Retirez l'ensemble de roulement supérieur.

3. Desserrez les trois vis qui tiennent ensemble les par-

ties avant et arrière du logement. Séparez la partie

avant du logement de l'appareil, et vous voyez alors

la cartouche de câble à l'intérieur.

4. Retirez la cartouche de câble.

5. Enfoncez fermement la cartouche de remplacement

dans la partie arrière du logement. Veillez à bien ali-

gner les rainures de la cartouche avec les encoches

de la partie arrière du logement.

6. Glissez le câble à travers la partie avant du loge-

ment.

7. Positionnez la partie avant du logement de manière à

ce que les trois vis soient alignées avec les encoches

de la partie arrière du logement. Enfoncez la partie

avant du logement dans la partie arrière.

8. Serrez les vis fermement, en veillant à ce que les

têtes des vis soient centrées dans les encoches et ne

dépassent pas la surface du logement.

9. Insérez l'ensemble de roulement supérieur dans le

boîtier d'avance. Veillez à ce que la broche guide du

porteur soit alignée avec l'encoche dans le boîtier.

10. Tournez le levier d'avance pour le fermer. Poussez sur le levier et repoussez le verrou de

retenue pour maintenir

le levier d'avance en

place.

ENTRETIEN

DÉCONNECTEZ L'APPAREIL DE SA

SOURCE D'ALIMENTATION ÉLEC-

TRIQUE AVANT TOUT ENTRETIEN !

Pour maintenir votre appareil en état de marche optimal,

il est essentiel que tous les roulements et coussinets soit

lubrifiés. La lubrification de toutes les pièces mobiles est

particulièrement importante si l’appareil est exposé au

sable, au gravier ou à d'autres matières abrasives.

ENTRETIEN DES CÂBLES

Pour obtenir un rendement maximal des câbles, assurez-vous

qu'ils soient propres et bien lubri-

fiés. Cela est nécessaire à leur

utilisation et prolonge grande-

ment leur durée. Certains utilisateurs versant périodiquement de

l'huile directement dans le tambour. Alors, quand le tambour

tourne, le câble est complètement lubrifié. Notre huile SNAKE

OIL est idéale à cette fin puisqu'elle désinfecte et déso-

dorise tout en lubrifiant.

ENTRETIEN DE L'AVANCE

Veillez à maintenir le mécanisme d'avance propre, sans

trop de débris ou de poussière. Il est recommandé de le

nettoyer avec un jet d'eau fraîche puis de huiler légèrement les parties mobiles. Normalement il n'est pas nécessaire de démonter. L’impossibilité d’avancer est habituellement due à une accumulation de saletés.

À la longue, la crasse peut durcir assez pour empêcher la

rotation des roulements. On peut d'habitude y remédier

en soumettant les roulements à un jet d'eau sous pression suivi d'une bonne lubrification. Si un démontage est

nécessaire, procédez comme suit:

POUR NETTOYER OU REMPLACER LES

ROULEMENTS D'AVANCE

1. Poussez sur le levier d'avance et retirez vers l'arrière

le verrou de retenue du levier.

2. Tourner le levier d'avance pour l'ouvrir. Retirez l'en-

semble de roulement supérieur.

3. Retirez les trois vis retenant le couvercle pour expo-

ser les deux roulements inférieurs.

4. Dévissez et retirez les vis maintenant en place les

deux roulements inférieurs.

5. Le remontage s’effectue dans l’ordre inverse du dé-

montage.

POUR RETIRER LE MOTEUR

1. Desserrez les trois vis qui tiennent ensemble les parties avant et arrière du logement.

2. Séparez la partie avant du logement de l'appareil.

3. Desserrez les deux vis de réglage dans le collier

chanfreiné et retirez le collier et la rondelle en feutre.

4. Glissez un tournevis à tête plate dans l'axe de moyeu

et dévissez la vis de fixation de gauche de l'axe d'en-

traînement en tournant dans le sens horlogique.

5. Dévissez l'axe de moyeu de l'axe d'entraînement à

droite en tournant la partie arrière du logement dans

le sens antihorlogique. Note: l'axe de moyeu, le

moyeu et la partie arrière du logement restent com-

me un ensemble. Le palier de guidage est libéré.

6. Suivez ces étapes en sens inverse pour remonter le

moteur.

12

Page 13

GUIDE DE DÉPANNAGE (Tableau 3)

Power-Vee™

Problème

Le câble vrille ou

casse.

Le câble s’emmêle

dans le dévidoir.

Le câble n'avance

pas.

Le moteur ne fonctionne pas.

Le moteur tourne

dans une direction et

pas dans l'autre.

Cause probable Solution

L’opérateur force le câble. Ne forcez pas le câble. Laisser le couteau faire le tra-

vail.

Trop de mou entre l’appareil et le

tuyau d'évacuation.

Mauvais diamètre de câble pour cette

canalisation.

Câble attaqué par l’acide. Nettoyer et lubrifier les câbles régulièrement.

L’opérateur force le câble. Ne forcez pas le câble. Laisser le couteau faire le tra-

Roulement(s) d'avance bloqué(s). Nettoyez et lubrifiez régulièrement les roulements

Câble emmêlé dans le tambour. Utilisez un câble de dimension appropriée. (Consultez

Gâchette en position d'arrêt (off). Placez la gâchette en marche avant (Avance) ou arrière

Panne du levier de marche arrière. Remplacez le levier de marche arrière.

Ne laissez pas plus de 15 cm (6 po) entre l’outil et le

drain.

Un câble dont le diamètre est trop petit ou trop grand

pour une canalisation est plus sujet au vrillage. (Voir

tableau 1 - Sélection du câble)

vail.

d'avance. Remplacez les roulements usés.

le guide de sélection du câble - tableau 1)

(Recul).

Voyez aux pages 22 et 23 la liste de pièces et le schéma éclaté.

Symbole Nom Symbole Nom

V

A

Hz

n

o

…/min

Volts

Ampères

Hertz

Vitesse sans charge

Tours/minute

Certification Canadian Standards Association

Sens du mouvement ou flèche

Courant alternatif

Double isolation

Certification Underwriters Laboratories

13

Page 14

Power-Vee™

14

Page 15

™

Power-Vee

Instrucciones de operación

Para líneas de 1-1/4 a 3 pulgadas

(30 a 100 mm)

Su Power-Vee está diseñado para dar-

le años de servicio rentables y sin problemas.

Sin embargo, no hay máquina que sea mejor

que el operario.

Lea, entienda y cumpla con todas las

advertencias de seguridad e instrucciones

que vienen con el producto. Si no se siguen

todas estas advertencias e instrucciones se

pueden producir descargas eléctricas y/o gra-

ves lesiones. Guarde todas las advertencias

e instrucciones como referencias futuras.

¡GUARDE ESTAS INSTRUCCIONES!

Page 16

Power-Vee™

REGLAS GENERALES

DE SEGURIDAD

ADVERTENCIA: Lea y entienda todas las

instrucciones. Si no se siguen todas las instruc-

ciones que se indican a continuación pueden pro-

ducirse descargas eléctricas, incendios y/o graves

lesiones corporales. El usuario puede solicitar manuales de repuesto de forma gratis o puede descar ga rl os en nues tr o sit io we b en

www.drainbrain.com. También hay videos de ins-

trucciones que pueden descargarse de nuestro

sitio web, o que pueden pedirse. Si tiene preguntas

o problemas, comuníquese con el Departamento

de Servicio al Cliente de General, llamando al 412771-6300.

¡GUARDE ESTAS INSTRUCCIONES!

Estas instrucciones están concebidas pa-

ra que todo el personal quede familiariza-

do con los procedimientos de operación

y mantenimiento seguros de Power-Vee.

Este es un símbolo de alerta de segu-

ridad. Se utiliza para alertar al usuario

ante aquellos posibles peligros que

pueden causar una lesión personal.

Obedezca todos los mensajes de se-

guridad asociados a este símbolo

para evitar posibles lesiones o la

muerte.

Si enchufa la máquina en un

tomacorriente alambrado incorrectamente se puede producir

una descarga eléctrica, que

puede resultar en la muerte. Si

el alambre de conexión a tierra

está vivo, usted puede ser

electrocutado con sólo tocar la

máquina, incluso cuando el

interruptor de potencia esté

apagado. En esta situación, un

interruptor de circuito de falla de

la conexión a tierra no lo protegerá. Use un probador aprobado

por UL para determinar si el to-

macorriente está bien protegido.

No opere herramientas mecánicas en atmósferas explosivas,

como por ejemplo en presencia

de líquidos, gases o polvos in-

flamables. Las herramientas

eléctricas generan chispas que

pueden encender el polvo o los

vapores.

Use sólo guantes de cuero.

Nunca use ningún otro tipo de

guante, como por ejemplo los

de tela, caucho o recubiertos.

Nunca agarre con un trapo un

cable que esté girando. Estos

artículos podrían enredarse en el

cable y causar graves lesiones.

PELIGRO indica un peligro con un alto nivel de riesgo que

si no se evita resultará en la muerte o en una lesión grave.

ADVERTENCIA indica un peligro con un nivel medio de

riesgo que si no se evita podría resultar en la muerte o en

una lesión grave.

PRECAUCIÓN indica un peligro con un bajo nivel de riesgo que si no se evita resultará en una lesión de grado me-

nor o moderado.

Use siempre gafas de seguridad y calzado antideslizante

con suela de goma. El uso de

este equipo de seguridad puede

evitar graves lesiones.

No tense en exceso los cables.

La tensión excesiva de los cables

puede causar la torcedura, for-

mación de dobleces o rotura del

cable y puede producir graves

lesiones.

16

Page 17

Power-Vee™

REGLAS GENERALES DE SEGURIDAD

El área de trabajo

1. Mantenga su área de trabajo limpia y bien ilumi-

nada. Los bancos desordenados y las áreas oscuras

se prestan a accidentes.

2. No opere herramientas mecánicas en atmósferas

explosivas, como por ejemplo en presencia de

líquidos, gases o polvos inflamables. Las herra-

mientas eléctricas generan chispas que pueden en-

cender el polvo o los vapores.

3. Mantenga alejados a los espectadores, niños y

visitantes mientras opera una herramienta eléctri-

ca. Las distracciones pueden hacerle perder el control.

Seguridad eléctrica

1. Las herramientas conectadas a tierra deben en-

chufarse en una toma de corriente correctamente

instalada y conectada a tierra de acuerdo con

todos los códigos y ordenanzas. Nunca saque la

espiga de conexión a tierra ni modifique el en-

chufe de forma alguna. No utilice enchufes adaptadores. Si tiene dudas acerca de si la toma de

corriente está correctamente conectada a tierra,

pídale a un electricista calificado que la revise. Si

la herramienta tiene fallas eléctricas o se descompone, la conexión a tierra proporciona una trayectoria

de baja resistencia para desviar la electricidad en

dirección opuesta al usuario..

2. Las herramientas con doble aislamiento están

provistas de un enchufe polarizado (una hoja es

más ancha que la otra). Este enchufe encaja en

una toma de corriente polarizada de una sola manera. Si el enchufe no encaja completamente en

la toma de corriente, déle vuelta. Si todavía no

encaja, póngase en contacto con un electricista

califica para instalar una toma de corriente polarizada. No altere el enchufe de forma alguna. El

doble aislamiento elimina la necesidad de un cordón

eléctrico conectado con tierra de tres hilos y de un

sistema de fuente de poder conectado con tierra.

3. Evite el contacto del cuerpo con superficies co-

nectadas a tierra como tuberías, radiadores, coci-

nas y refrigeradores. El riesgo de que se produzca

una descarga eléctrica es mayor si su cuerpo está

conectado a tierra.

4. No exponga las herramientas eléctricas a la lluvia

o al agua. Si entra agua en una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

5. No maltrate el cordón. Nunca utilice el cordón

para trasladar las herramientas ni para sacar el

enchufe de una toma de corriente. Mantenga el

cordón alejado del calor, aceite, bordes afilados

o piezas móviles. Reemplace inmediatamente los

cordones dañados. Los cordones dañados aumen-

tan el riesgo de descarga eléctrica.

6. Al operar una herramienta eléctrica en exteriores,

utilice un cordón de extensión para uso en exteriores designado como “W-A” o “W”. Estos cordo-

nes están calificados para uso en exteriores y reducen el riesgo de descargas eléctricas.

7. Mantenga todas las conexiones eléctricas secas

y alejadas del suelo. Así reducirá el riesgo de des-

carga eléctrica.

8. No toque los enchufes ni las herramientas con

las manos mojadas. Así reducirá el riesgo de des-

carga eléctrica.

Seguridad personal

1. Manténgase alerta, ponga atención a lo que está

haciendo y use sentido común al operar una

herramienta mecánica. No use la herramienta si

está cansado o está bajo el efecto de drogas, al-

cohol o medicamentos. Un momento de descuido

al operar herramientas eléctricas puede producir gra-

ves lesiones corporales.

2. Vístase adecuadamente. No use ropa suelta o

joyas. Mantenga sujeto el pelo largo. Mantenga

su pelo, ropa y guantes alejados de las piezas

móviles. La ropa suelta, las joyas o el pelo largo

pueden quedar atrapados en las piezas móviles.

3. Evite los arranques accidentales. Antes de en-

chufar la máquina, asegúrese de que el interruptor esté en la posición apagado. Enchufar herra-

mientas que tienen el interruptor en la posición en-

cendido se presta a accidentes.

4. Antes de encender la herramienta, retire las lla-

ves o interruptores de ajuste. Una llave que se

haya dejado instalada en una pieza giratoria de la

herramienta puede causar lesiones corporales.

5. No se estire en exceso. Mantenga en todo mo-

mento su apoyo y equilibrio correctos. Un apoyo

y equilibrio correctos permiten controlar mejor la

herramienta en situaciones inesperadas.

6. Use siempre gafas de seguridad y calzado anti-

deslizante con suela de goma. Según las condiciones se deben utilizar máscaras contra el polvo, cal-

zado de seguridad antideslizante, casco duro o protección auditiva.

Uso y cuidado de la herramienta

1. Use abrazaderas u otra manera práctica de suje-

tar y apoyar la pieza en una plataforma estable.

Sostener la pieza con la mano o contra su cuerpo es

inestable y puede llevar a una pérdida del control.

2. No fuerce la herramienta. Utilice la herramienta

correcta para su aplicación. La herramienta correc-

ta hará mejor el trabajo y de una manera más segura

a la velocidad para la que está diseñada.

3. No use la herramienta si el interruptor no la enciende o apaga. Cualquier herramienta que no se

pueda controlar con el interruptor es peligrosa y debe

repararse.

4. Desconecte el enchufe de la fuente de alimenta-

ción antes de hacer cualquier ajuste, cambiar ac-

cesorios o guardar la herramienta. Estas medidas

de seguridad preventiva reducen el riesgo de un

arranque accidental de la herramienta.

5. Guarde las herramientas fuera del alcance de los

niños y otras personas no capacitadas. Las herramientas son peligrosas en manos de usuarios no

capacitados.

17

Page 18

Power-Vee™

6. Mantenga las herramientas con cuidado. Mantenga las herramientas cortantes afiladas y limpias. Las

herramientas mantenidas correctamente, con bordes

cortantes afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar.

7. Revise si hay piezas móviles desalineadas o

atascadas, piezas rotas y cualquier otra condi-

ción que pueda afectar la operación de la herra-

mienta. Si hay daños, haga reparar la herramienta

antes de utilizarla. Muchos accidentes se deben a un

mantenimiento deficiente de las herramientas.

8. Use únicamente accesorios recomendados por el

fabricante para su modelo. Los accesorios que

pueden ser adecuados para una herramienta pueden

ser riesgosos si se utilizan en otra herramienta.

Servicio

1. El servicio de la herramienta sólo debe realizarlo

personal de reparaciones calificado. Un servicio o

mantenimiento realizado por personal de reparaciones no calificado puede causar lesiones.

2. Al dar servicio a una herramienta, utilice sólo pie-

zas de repuesto idénticas. Siga las instrucciones

descritas en la sección Mantenimiento de este

manual. El uso de piezas no autorizadas o la inobservancia de las instrucciones de mantenimiento

pueden crear un riesgo de descarga eléctrica o lesio-

nes.

REGLAS ESPECÍFICAS DE SEGURIDAD

1. Use sólo guantes de cuero. Nunca use ningún otro

tipo de guante, como por ejemplo los de tela, caucho

o recubiertos. Nunca agarre con un trapo un cable

que esté girando. Estos artículos podrían enredarse

en el cable y causar graves lesiones.

2. Asegúrese de que la unidad esté enchufada en

un receptáculo correctamente conectado con tie-

rra. Si tiene dudas, revise el receptáculo antes de

enchufar la máquina. Revise el cordón eléctrico para

ver que no haya cortes o desgaste y que el diente de

conexión con tierra del enchufe todavía esté en su

lugar.

3. El motor utilizado en el Power-Vee tiene doble

aislamiento y por consiguiente no tiene un hilo

de conexión con tierra. Para reducir el riesgo de

choque eléctrico, este equipo tiene un enchufe

polarizado (una hoja es más ancha que la otra). El

enchufe encaja en una toma de corriente polarizada

de una sola manera. Si el enchufe no encaja comple-

tamente en la toma de corriente, déle vuelta. Si todavía no encaja, póngase en contacto con un electri-

cista calificado para instalar la toma de corriente adecuada. No altere el enchufe de forma alguna.

4. Si el cordón eléctrico que viene con la máquina

no es lo suficientemente largo, asegúrese de utilizar una extensión de trabajo pesado de calibre

16 que no tenga más de 50 pies y esté en buen

estado. El uso de cordones más livianos puede producir una grave pérdida de energía y recalentamien-

to del motor.

5. Coloque la máquina a una distancia de no más de

seis pulgadas del orificio del desagüe. Distancias

mayores pueden hacer que el cable se tuerza o doble.

6. La máquina está diseñada para ser operada por

UNA SOLA PERSONA. El operario está obligado a

controlar el interruptor del disparador y el cable.

7. Nunca agarre un cable que está girando. Saque o

meta el cable en el envase con la mano solamen-

te cuando el motor esté detenido. Cuando el motor esté girando, tenga siempre una mano contro-

lando el disparador y la otra agarrando el protector de la agarradera. Las piezas móviles pueden

atrapar las manos del operario y causarle así una

lesión grave.

8. Tenga cuidado al limpiar desagües donde se han

utilizado productos químicos de limpieza. Evite el

contacto directo con limpiadores de desagües que

sean corrosivos. La exposición a esos productos quí-

micos puede causar lesiones al operario y dañar el

cable. Neutralice o quite los limpiadores de desagüe

corrosivos que estén en el desagüe antes de comen-

zar.

9. No opere la máquina si el operario o la máquina

están parados sobre el agua. Ello aumentará el

riesgo de descarga eléctrica.

10. Use gafas de seguridad y calzado antideslizante

con suela de goma. El uso de este equipo de segu-

ridad puede evitar graves lesiones.

11. Antes de comenzar cada trabajo, compruebe que

el cable en el tambor no esté roto ni doblado,

sacándolo y revisando si presenta desgaste o

roturas. Reemplace siempre los cables gastados

(que tienen dobleces o están rotos) por cables de

repuesto GENERAL auténticos.

12. Utilice esta herramienta sólo en la aplicación para la que fue diseñada. Siga las instrucciones so-

bre uso adecuado de la herramienta. Otros usos o

la modificación del limpiador de desagües para otras

aplicaciones pueden aumentar el riesgo de lesiones.

CARACTERÍSTICAS

9

8

6 7

18

3 4 5

2

1

1. Interruptor de disparador de velocidad variable

2. Interruptor de marcha hacia adelante/apagado/

marcha atrás

3. Parte trasera del envase. Cartucho de cable - dentro

del envase

4. Parte delantera del envase

5. Protector de agarre

6. Cable

7. Cortador

8. Conector hembra

9. Palanca de avance automático de cable

Page 19

Power-Vee™

INTERRUPTOR DE VELOCIDAD VARIABLE

En el mecanismo accionador existe un control de velocidad variable. Usted puede controlar y aumentar la veloci-

dad de la máquina aplicando más presión al disparador

hasta obtener la velocidad que desea.

También puede controlar la dirección de rotación de la

máquina moviendo la palanca de avance y retroceso que

se encuentra justo encima del interruptor accionador.

Mueva la palanca hacia la flecha Forward para una rota-

ción hacia adelante y hacia la flecha Back para una rotación en reversa. Póngala en la posición apagada (OFF)

cuando no esté usando la herramienta.

Cuadro de aplicaciones de cables (Tabla 1)

Calibre

del cable

1/4 pulg

6.3 mm

5/16 pulg

7.9 mm

3/8 pulg

9.5 mm

Los cables de 1/4 y 5/16 pulgada (6.3 mm y 7.9 mm) de diámetro con

cabezas EL para obstrucciones en lavamanos se pueden pasar por

las crucetas de la mayoría de los filtros y funcionan bien en líneas

bloqueadas por obstrucciones blandas como pelo, jabón, grasas, etc.

Cuadro de aplicaciones de cortadores (Tabla 2)

Cortador

Cabeza

de flecha

Cabeza

de flecha

flexible

Gusanilo

Gusanillo

de taladro

Cortador

lateral de

1-1/4 pulg

Otros accesorios disponibles:

Tamaño de la tubería

1-1/4 a 2 pulg

30 a 50 mm

1-1/2 a 2 pulgadas

38 a 50 mm

2 a 3 pulgadas

50 a 75 mm

Nº de

Catálogo Aplicaciones típicas

DHBG

1-1/4SCB

Aplicaciones típicas

Desagües de duchas, tinas y

líneas pequeñas.

Fregaderos, lavamanos y desagües pequeños.

Bajantes, retretes, desagües pequeños (sin raíces).

AH

FAH

BG

Ideal para corte y raspado

pesado.

Más flexible que el de punta

de flecha; puede usarse en

curvas pronunciadas en líneas pequeñas.

Para sacar o recuperar objetos sueltos.

Baja el cable por la línea de

desagüe en lugar de subirlo

por el respiradero o a través

de la T.

Trabaja bien en obstrucciones con grasa; raspa las

paredes de la tubería.

INSTRUCCIONES DE OPERACIÓN

1. El cable puede tener un cabezal tipo tapón de lava-

manos en la punta para ayudar al paso por dobleces

pronunciados o puede tener un conector para acoplar cortadores a la punta.

2. Para acoplar un cortador, primero desconecte la

máquina. Luego, quite el tornillo y la arandela de seguridad del conector que está en la punta del cable.

Meta el cortador en la ranura, luego ponga la arande-

la de seguridad y el tornillo de conexión. Apriete el

tornillo firmemente.

3. Los cortadores tipo barrena perforadora y cabeza de

flecha son buenos para comenzar. Luego puede

cambiar para cortadores más grandes después que

haya logrado que el agua fluya.

4. Coloque la máquina a una dis-

tancia de no más de seis pulgadas del orificio del desagüe.

Si no puede acercar la máquina tanto al orificio de desagüe,

pase el cable a través de una

manguera o tubería para evitar

que se golpee.

5. Inserte el cable en el orificio de

desagüe lo más profundo que

pueda.

6. Asegúrese de que el interrup-

tor Forward/Off/Reverse esté

en la posición FORWARD.

7. Apriete con cuidado el disparador del motor. Luego,

apriete la palanca de avance del cable de alimenta-

ción para avanzarlo hacia la línea. NO FUERCE EL

CABLE. El trabajo no avanzará más rápidamente y

podría doblar el cable.

NO USE DEMASIADA FUERZA:

DEJE QUE EL CORTADOR HAGA EL TRABAJO.

8. Utilice el gatillo de velocidad variable para ajustar la

velocidad de avance a la resistencia que se esté

ejerciendo. No fuerce al cable ni lo haga avanzar

más rápido de lo que el cable puede entrar en el desagüe.

9. No deje demasiado cable suelto ya que ello causará

que se agite. Si el cable comienza a doblarse o torcerse demasiado, libere el gatillo. Empuje el cable

sobrante de vuelta al tambor y luego continúe.

NO PERMITA DEMASIADO HOLGURA EN

EL CABLE ENTRE LA MÁQUINA Y EL

ORIFICIO DEL DESAGÜE YA QUE ESTO

PUEDE CAUSAR AZOTES DEL CABLE.

Aditamento

con cabezal

de taladro

Accesorio

Para

inodoros

DHF

CAA

Convierte a varios cortadores

al estilo de cabezal hacia

abajo.

Para limpiar atascamientos

en las tazas de los inodoros.

10. Cuando el cable llegue al atasco, ponga el avance

en neutro liberando la palanca de avance. Mueva la

máquina de un lado al otro a medida que el cable

gira hasta que se despeje el atasco. Se puede apli-

car una presión ligera a la palanca de avance según

se requiere para mantener contacto con el atasco.

19

Page 20

Power-Vee™

11. Para retraer el cable, ponga el interruptor de marcha

hacia delante/apagado/reversa en la posición Reversa y presione la palanca de avance y el disparador

del motor.

Consejo: Suele ser útil tener un pequeño flujo de agua

en la línea para eliminar los residuos de cortaduras

mientras la máquina está en operación y después de

ello.

Nota: Hay a disposición un

Handy Stand™ (mostrado a

la derecha) opcional. Este

pedestal sujeta la Power-Vee,

con lo que se aumenta el control de la máquina y el cable.

PARA CAMBIAR LOS CARTUCHOS

DE CABLE

¡DESCONECTE LA MÁQUINA DE LA FUEN-

TE DE ELECTRICIDAD ANTES DE CAMBIAR

LOS CARTUCHOS!

1. Quite el cortador y el tornillo de conexión del cable, si

es que tiene uno conectado.

2. Apriete la palanca de avance y tire del seguro de

retención de la palanca. Gire la palanca de avance

para abrirla. Quite el ensamble del rodillo superior.

3. Afloje los tres tornillos que sujetan las partes frontal y

posterior del envase. Saque el frente del envase de

la máquina, para que se vea el cartucho del cable.

4. Quite el cartucho del cable.

5. Presione el cartucho de repuesto firmemente en la

parte posterior del envase. Asegúrese de alinear las

muescas en el cartucho con las ranuras en la parte

de atrás del envase.

6. Pase el cable a través del frente del envase.

7. Posicione el frente del envase de forma que los tres

tornillos estén alineados con las ranuras en la parte

de atrás del envase. Presione el frente del envase en

la parte de atrás del envase.

8. Apriete los tornillos firmemente, asegurándose de

que las cabezas de los tornillos estén centradas en

las ranuras y a ras con la superficie del envase.

9. Inserte el conjunto del

rodillo superior en el

alojamiento de avance.

Asegúrese de que el

pasador guía del portador esté alineado con la

ranura en el alojamiento.

10. Gire la palanca de avance para cerrarla. Apriete la

palanca y empuje el cerrojo retenedor hacia adelante

para asegurar la palanca de avance en su posición.

MANTENIMIENTO

¡DESCONECTE LA MÁQUINA DE LA FUENTE

DE ALIMENTACIÓN ANTES DE DARLE

CUALQUIER MANTENIMIENTO!

Para mantener su máquina operando sin problemas, es

esencial que todos los rodamientos y bujes estén lubricados. La lubricación de las piezas móviles es particularmente importante si la máquina debe entrar en contacto

con arena, arenisca y otros materiales abrasivos.

MANTENIMIENTO DEL CABLE

Para obtener el máximo de servicio de los cables, asegúrese de

que estén limpios y bien lubricados. Esto no sólo proporciona

lubricación continua, sino que

también prolonga en gran medida la vida útil de los cables. Algunos usuarios periódicamente

echan aceite directamente en el

tambor. Así, al girar el tambor,

los cables se lubrican completamente. Nuestro ACEITE SNAKE

es ideal para esto, dado que no sólo lubrica los cables

sino también los desodoriza.

MANTENIMIENTO DEL ALIMENTADOR

Mantenga el alimentador sin acumulación excesiva de

tierra y arenisca. Se recomienda que el alimentador se

enjuague con agua limpia seguido de una ligera aplica-

ción de aceite a las partes móviles. Normalmente no se

requiere desmontar el equipo. La razón habitual por la

que el cable no avanza es la acumulación de mugre.

En el tiempo, la suciedad puede endurecerse lo suficien-

te para detener la rotación del rodillo. Una limpieza con

agua seguido de abundante aplicación de aceite habi-

tualmente puede restaurar el funcionamiento. Si necesita

desarmar el equipo, hágalo de la manera siguiente:

PARA LIMPIAR O CAMBIAR LOS RODILLOS

1. Apriete la palanca de avance y tire del seguro de

retención de la palanca.

2. Gire la palanca de avance para abrirla. Quite el ensamble del rodillo superior.

3. Quite los tres tornillos retenedores de la placa de

cubierta para exponer los dos rodillos inferiores.

4. Afloje y quite los tornillos que sujetan los dos rodillos

inferiores en su posición.

5. Para ensamblar de nuevo, siga el orden inverso.

PARA SACAR EL MOTOR

1. Afloje los tres tornillos que sujetan el frente y la parte

de atrás del envase.

2. Saque el frente del envase de la máquina.

3. Afloje los dos tornillos de fijación en el collarín bisela-

do y quite tanto el collarín como la arandela de fiel-

tro.

20

Page 21

4. Meta un destornillador plano en el huso de núcleo y

saque el tornillo de bloqueo izquierdo del eje de

mando girándolo en el sentido de las manecillas del

reloj.

5. Desentornille el huso de núcleo del eje de mando

derecho girando la parte de atrás del envase en el

sentido contrario a las manecillas del reloj. Nota: El

huso del núcleo, el núcleo y la parte posterior del

envase se quedan como una unidad única. El cojine-

te de empuje quedará libre.

6. Invierta las instrucciones para volverlo a ensamblar.

GUÍA DE SOLUCIÓN DE PROBLEMAS (Tabla 3)

Power-Vee™

Problema

Cocas o roturas en el cable. El operario forzó el cable. No fuerce el cable. Deje que el cortador haga el trabajo.

Cable enredado en el tambor.

No alimenta. Rodillo(s) de avance congelado(s). Limpie y lubrique los rodillos de alimentación de manera regular.

El motor no funciona. El activador está en posición neutra (Off). Lleve el activador a Forward o a Reverse.

El motor gira en una dirección pero no en la otra.

Causa Probable Solución

Demasiado cable suelto entre la máquina y

el desagüe.

Se usó el cable en una línea de desagüe del

tamaño incorrecto.

Cable expuesto al ácido. Limpie y lubrique regularmente los cables.

El operario forzó el cable. No fuerce el cable. Deje que el cortador haga el trabajo.

El cable está enredado en el tambor. Utilice el tamaño adecuado de cable. (Consulte el Cuadro de aplica-

Falla del interruptor de reversa. Reemplace el interruptor de reversa.

No deje más de seis pulgadas entre la máquina y el desagüe.

Un cable de diámetro demasiado grande o demasiado pequeño

para una línea tiene más probabilidades de formar cocas. (Consulte

la Tabla 1: Aplicaciones de Cables).

Sustituya los rodillos desgastados.

ciones de cables - Tabla 1).

Vea las páginas 22 y 23 para la Lista de Piezas y una Vista Despiezada.

Símbolo Nombre Símbolo Nombre

V

A

Hz

n

o

…/min

Voltios

Amperios

Hertzios

Velocidad sin carga

Revoluciones por minuto

Indica que esta herramienta está registrada por Underwriters Laboratories

Indica que esta herramienta está registrada por la Asociación Canadiense de

Dirección de la acción o flecha

Corriente alterna

Indica doble aislamiento

Estándares

21

Page 22

Power-Vee™

POWER-VEE PARTS LIST

CAT. NO. DESCRIPTION CAT. NO. DESCRIPTION

PV-M-S Skil Variable Speed Motor (Model #81596) PV-36-4 Brush, Spring & Connector (2) (#81596)

PV-M-S3 Skil Variable Speed Motor (Model #6355-GWS) PV-37 Handle Covers (#81596)

PV-M-S/220 Skil Variable Speed Motor (for 220 volt/50Hz) PV-37-1 Handle Covers (#6355-GWS)

PV-N-2 Complete Power-Vee Front Assembly PV-38 Motor Housing (#81596)

PV-51 Container Front (w/PV-51-A/B) PV-39-3 Holder for Brush & Spring (2) (#81596)

*PV-51-1 Container Front—Gripperless PV-39-5 Holder for Brush & Spring (2) (#6355-GWS)

PV-51-A/B “U” Nuts & Flat Head Screws (3) *PV-50 Bushing

PV-02 Container Back PV-61 Feed Housing

*PV-03 Grip Shield PV-61-1 Feed Housing (Gripperless)

PV-04 Gear Case Body *PV-61-2 Feed Housing

PV-05 Gear Case Cap PV-62-2 Feed Lever w/Sleeve

PV-05-1 Container Hub for Direct Drive PV-62-A Sleeve for PV-62-2

PV-06 Internal Ring Gear PV-63 Adjusting Knob

PV-07 Pinion & Spindle Gear Assembly PV-64 Tension Spring

PV-08 Reverse-Thread Screw for Direct Drive Unit PV-64-2 Tension Spring

PV-09 Beveled Collar w/2 Set Screws PV-65 Adjusting Nut

PV-10 Spindle Sleeve (Inc. PV-10-A) PV-66 Adjusting Screw

*PV-10-1 Spindle Sleeve—Gripperless PV-67 Set Screws & Washers (2)

PV-10-A Spindle Sleeve Retaining Ring *PV-68 Philips Head Screw

PV-10-C Snap Ring *PV-69 Feed Lever Pin

PV-10-D Spacer PV-70 Inner Feed Body

PV-12 Thrust Washer PV-71 Feed Roller Assy. (Incl. PV-72-2, 73, 74, 75)

PV-16 Thrust Bearing for Motor (#6355-GWS) *PV-71-2 Feed Roller Assy. (Incl. PV-64-2, 72-2, 73-2, 74-2)

PV-22 Machine Screws with Lock Washers (5) PV-72 Carrier

PV-23 Fillister Head Screws (4) PV-72-2 Carrier

PV-25 Cable Grippers (2) PV-73 Feed Roller

PV-26 Screws with Locktite (2) PV-74 Feed Roller

*PV-28 Collar with Set Screw PV-74-2 Shaft Pin

*PV-29 Lock Screw PV-75 Shaft Pin

PV-30-S Cord Set (Model #81596) *PV-77 Guide Pin (Included with PV-71 Only)