Page 1

™

Drain-Rooter PH

Operating Instructions

For 1-1/4” through 3” lines

(30mm—75mm)

Your Drain-Rooter PH is designed to

give you years of trouble-free, profitable

service. However, no machine is better

than its operator.

Read, understand and follow all safety

warnings and instructions provided with

the product. Failure to follow the warnings

and instructions may result in electric

shock and/or serious injury. Save all warnings and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Pour français voir la page 9

Para ver el español vea la paginá 17

Page 2

Drain-Rooter PH™

To reduce the risk of injury,

user must read instruction

manual. Failure to follow operating instructions could result

in death or serious injury.

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/or serious injury. Save all warnings

and instructions for future reference.

Replacement manuals are available upon request at no charge, or may be downloaded

from our website, www.drainbrain.com. In-

structional videos are available for download

on our website, and may be ordered. If you

have any questions or problems, please call

General’s customer service department at

412-771-6300.

Save all warnings and instructions

Electric shock resulting in

death can occur if you plug

this machine into an improperly wired outlet. If the ground

wire is electrified, you can be

electrocuted by just touching

the machine, even when the

power switch is off. A ground

fault circuit interrupter will not protect you in this situation. Use a

UL listed tester to determine if the

outlet is safe.

Do not operate power tools in

explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which

may ignite the dust or fumes.

for future reference.

These instructions are intended to

familiarize all personnel with the safe

operation and maintenance

procedures for the Drain-Rooter PH.

SAFETY SYMBOLS

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Only wear leather gloves.

Never use any other type of

glove, such as cloth, rubber, or

coated gloves. Never grasp a

rotating cable with a rag.

These items could become

wrapped around the cable and

cause serious injury.

Always wear safety glasses

and rubber soled, non-slip

shoes. Use of this safety equip-

ment may prevent serious injury.

Do not overstress cables.

Overstressing cables may cause

twisting, kinking, or breaking of

the cable and may result in serious injury.

CAUTION indicates a hazard with a low level of risk which,

if not avoided, will result in minor or moderate injury.

2

Page 3

Drain-Rooter PH™

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure to follow all

instructions listed below may result in electric shock, fire, and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE USE!

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

Work Area Safety

1. Keep work area clean and well lit. Cluttered or dark areas in-

vite accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching out-

lets will reduce risk of electric shock.

2. Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or

grounded.

3. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged cords increase the risk

of electric shock.

5. When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

6. If operating a power tool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of electric shock.

7. Double insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit a polarized outlet only one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

Personal Safety

1. Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools

may result in serious personal injury.

2. Use personal protective equipment. Always wear eye protec-

tion. Protective equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

3. Prevent unintentional starting. Ensure the switch is in the off

-position before connecting to power source and/or battery

pack, picking up or carrying the tool. Carrying power tools

with your finger on the switch or energizing power tools that have

the switch on invites accidents.

4. Remove any adjusting key or wrench before turning the

power tool on. A wrench or key that is left attached to a rotating

part of the power tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jewelry. Keep

your hair, clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught in moving

parts.

7. If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust-related

hazards.

Power Tool Use and Care

1. Do not force the power tool. Use the correct power tool for

your application. The correct tool will do the job better and safer

at the rate for which it is designed.

2. Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the switch

is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preven-

tive safety measures reduce the risk of starting the power tool

accidentally.

4. Store idle power tools out of reach of children and do not

allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are danger-

ous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly maintained cut-

ting tools with sharp cutting edges are less likely to bind and are

easier to control.

7. Use the power tool, accessories and tool bits, etc. in accor-

dance with these instructions, taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could

result in a hazardous situation.

3

Page 4

Drain-Rooter PH™

Service

1. Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that

the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

Electric shock resulting in death can occur if you

plug this machine into an improperly wired outlet. If

the ground wire is electrified, you can be electrocuted

by just touching the machine, even when the power

switch is off. A ground fault circuit interrupter will not

protect you in this situation. Use a UL listed tester to

determine if the outlet is safe.

Do not overstress cables. Overstressing cables may

cause twisting, kinking, or breaking of the cable and may

result in serious injury.

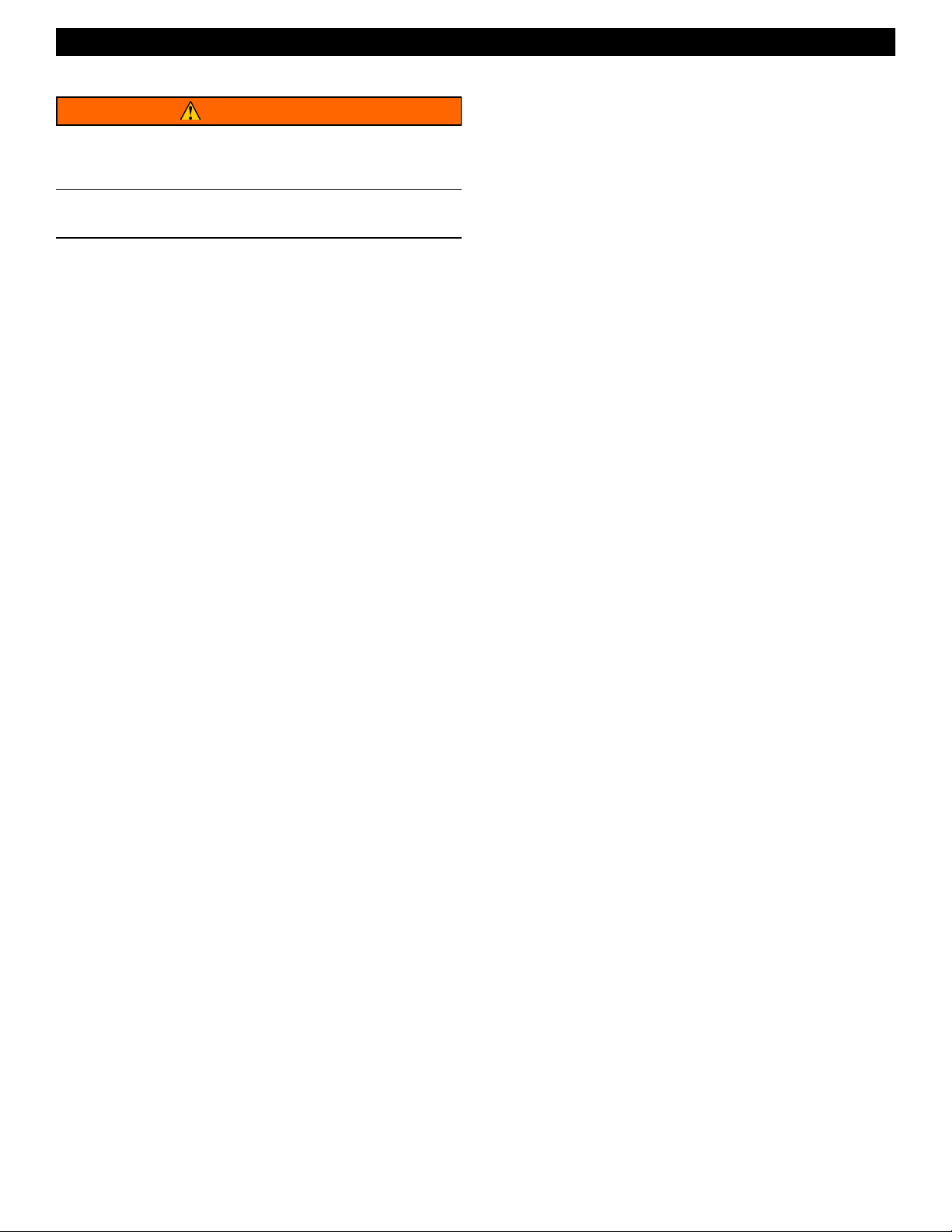

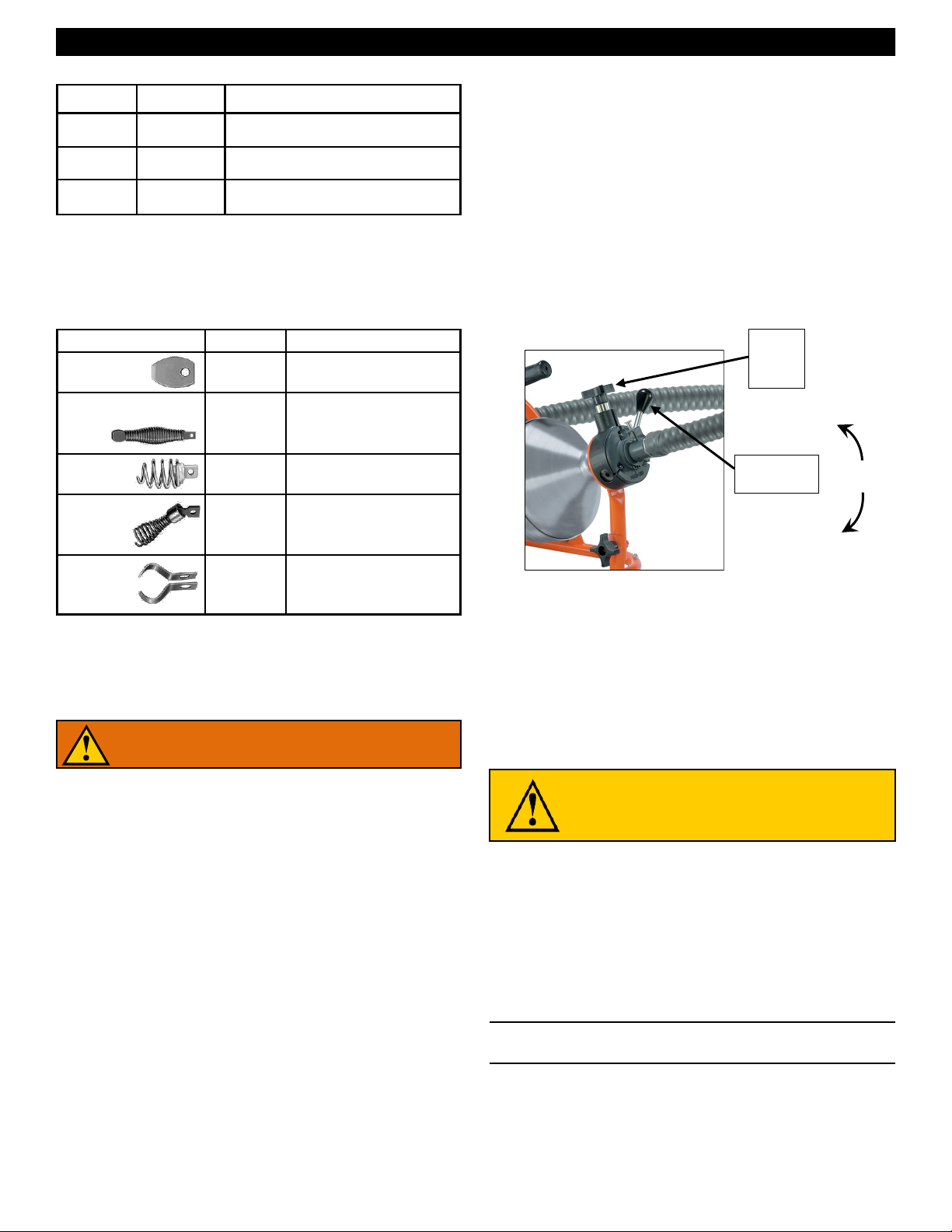

FEATURES - Closed Drum Drain-Rooter PH

Handle Feed Pressure

Knob

Cutter

Motor

NOTE: Do not operate machine if warning labels on the container

front and power cord are missing or illegible.

Drum Container

Back

Drum Container

Feed Control

Lever

Guide Hose

(Cable Inside)

Front Post

Knob

Front

1. Only wear leather gloves. Never use any other type of glove,

such as cloth, rubber, or coated gloves. Never grasp a rotating

cable with a rag. These items could become wrapped around the

cable and cause serious injury.

2. Do not overstress cables. Overstressing cables because of an

obstruction may cause twisting, kinking, or breaking of the cable

and may result in serious injury.

3. Place the machine at a distance not greater than six inches

(15cm) from drain opening. Greater distances can result in

cable twisting or kinking.

4. Machine is designed for ONE-PERSON operation. Operator

must control trigger switch and cable.

5. Never take hold of a rotating cable. Pull the cable out, or

push it back into the container by hand only when the motor

is stopped. When the motor is turning, always have one

hand controlling the trigger switch and the other hand

around the grip shield. Operator’s hand may be caught in the

moving parts resulting in serious injury.

6. Be careful when cleaning drains where cleaning chemicals

have been used. Avoid direct contact with corrosive drain cleaners. Drain cleaning chemicals can cause serious burns, as well

as damage the cable.

7. Do not operate machine if operator or machine is standing

in water. Will increase risk of electrical shock.

8. Wear safety glasses and rubber soled, non-slip shoes. Use

of this safety equipment may prevent serious injury.

FEATURES - Open Drum Drain-Rooter PH

Handle

Cutter

Motor

NOTE: Do not operate machine if warning labels are missing or illegible.

VARIABLE SPEED SWITCH

A variable speed control is built into the trigger mechanism. You can

control and increase the machine's speed by applying more trigger

pressure until you get the speed that you want.

You can also control the machine's direction of rotation by switching

the forward and reverse lever, which is located just above the trigger

switch. Move the lever toward the Forward arrow for forward rotation

and toward the Back arrow for reverse rotation. Switch to OFF position when the tool is not in use.

Feed Pressure

Open Drum

Knob

Feed Control

Lever

Guide Hose

(Cable Inside)

Front Post

Knob

4

Page 5

Drain-Rooter PH™

Cable Application Chart (Table 1)

Cable Size Pipe Size Typical Applications

1/4” 1-1/4" to 2" Small lines, tubs, and shower drains.

5/16" 1-1/2" to 2" Sinks, basins, and small drains.

3/8" 2" to 3" Stacks, toilets, small drains (No Roots).

The 1/4" and 5/16" diameter cables with EL Basin plug heads can be spun

through most strainer crossbars and work well in lines blocked by soft stoppages such as hair, soap, fats, etc.

Maximum Capacity: 50 ft. of 1/4” or 5/16” cable, or 35 ft. of 3/8” cable.

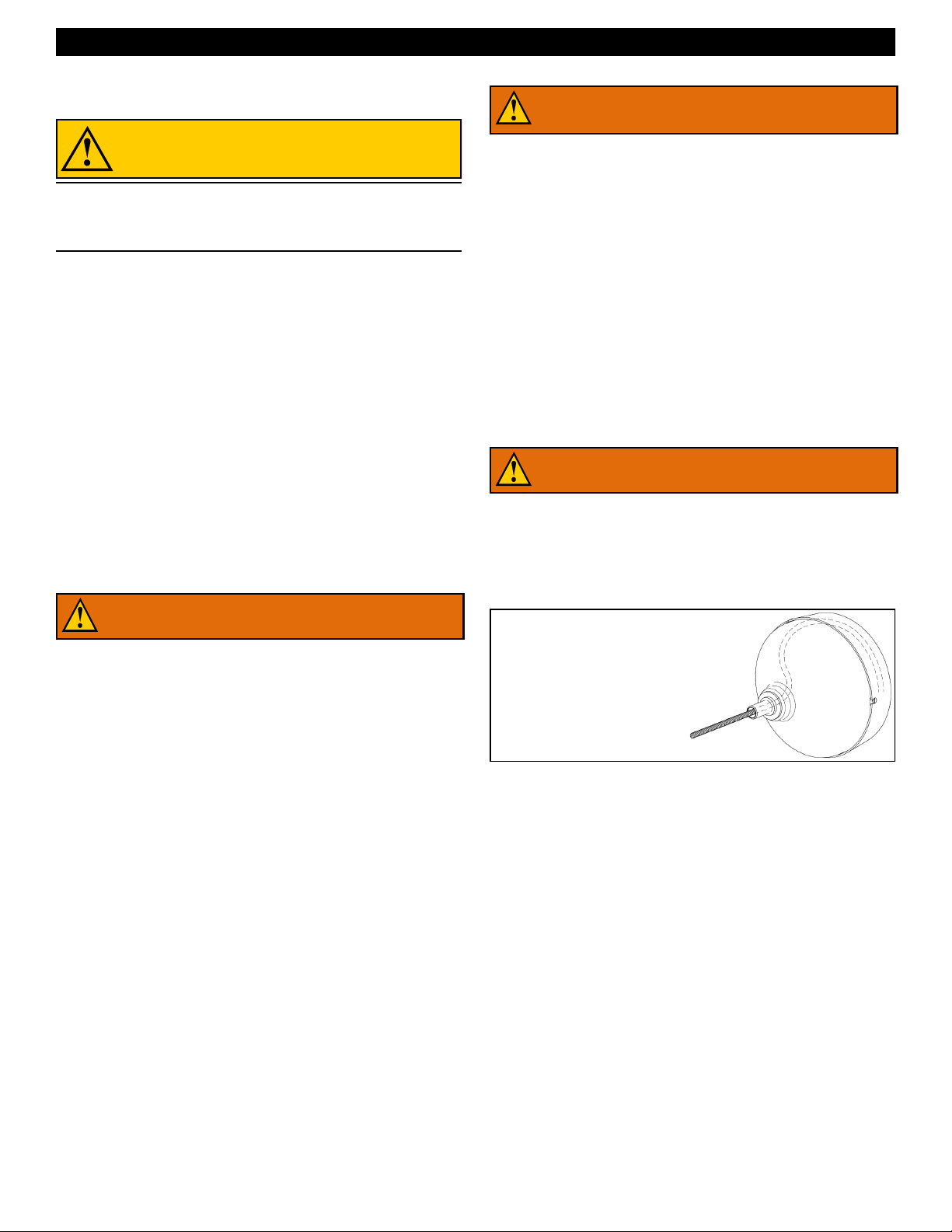

Cutter Application Chart (Table 2)

Cutter Catalog # Typical Applications

Arrow

Head

Flexible Arrow

Head

Boring

Gimlet

Down Head

Boring

Gimlet

1-1/4"

Side

Cutter

AH

FAH

BG

DHBG

1-1/4SCB

Ideal for heavy cutting and

scraping.

More flexibility than Arrow

Head; can take sharp turns in

small lines.

To remove or retrieve loose

objects.

Leads cable down drain line

rather than up vent or across

tee.

Works well in grease stoppages, scrapes walls of pipe.

OPERATION

SET-UP

DISCONNECT MACHING FROM POWER SOURCE

BEFORE ATTACHING CUTTER!

OPERATION

1. Plug machine into a properly grounded outlet.

2. Make sure the Forward/Off/Reverse switch is in the FORWARD

position.

3. Tighten the knob on top of the variable speed power cable feed

so that the feed roller presses against the cable. Be sure not to

over tighten since this could cause excessive cable wear.

4. The feed lever controls the feeding rate and direction of the cable. Move the feed lever down to feed the cable out of the drum.

The farther the lever is moved downward, the faster the cable will

feed out. Move the lever up to retract the cable into the drum.

When the lever is in the middle (neutral) position, the cable will

spin in place.

Feed

Pressure

Knob

Reverse

Feed Control

Lever

Forward

5. Place the cable end and cutter into the drain opening.

6. With a hand on the guide hose, start the machine by stepping

slowly but firmly on the foot pedal. The harder you press on the

pedal, the faster the motor will rotate and the faster the cable will

feed.

7. Feed the cable slowly. Use both the foot pedal and power cable

feed to adjust feeding speed as resistance is met. Don’t feed

faster than the cable can go into the drain. Too much cable between the guide hose and drain will cause whipping and kinking.

Neutral

1. Slide the connector over the spout until the spring pops into

place.

2. The cable may have an EL-Basin plug head on the end to help

the cable around tight bends, or it may have a connector for attaching cutters to the end.

3. To attach a cutter, first unplug the machine. Then, remove the

screw and lock washer from the connector at the end of the cable. Slide the cutter into the slot, then replace the lock washer

and connecting screw. Tighten the screw firmly.

4. The Boring Gimlet and Arrow Head are good cutters to start with.

Change to the larger cutters after you've gotten the water flowing.

5. Position the machine so that the guide hose can be placed within

6 in. (15 cm) of the drain opening without excessive bending of

the guide hose.

Note: Avoid sharp bends or kinking of the guide hose by repositioning

the machine. The Drain-Rooter PH is designed to be positioned either horizontally or vertically to facilitate this.

DO NOT ALLOW TOO MUCH SLACK IN THE CABLE BETWEEN MACHINE AND DRAIN OPENING

SINCE THIS CAN CAUSE CABLE WHIPPING.

8. If the cable starts to bend or build up too much twist, take your

foot off the pedal and rotate the drum in the opposite direction to

relieve the twist on the cable. Push any excess cable back into

the drum and then continue.

9. When the cable reaches the stoppage, put the feed in neutral.

Then allow the cable to progress slowly, chewing into the stoppage as it goes. This slow forward movement will reduce stress

on the cable while doing a more thorough cleaning job. A back

and forth action usually works best.

DO NOT USE TOO MUCH FORCE –

LET THE CUTTER DO THE WORK.

5

Page 6

Drain-Rooter PH™

10. When the obstruction is cleared, retract the cable by moving the

feed lever into the reverse position. Keep the motor in the for-

ward position.

DO NOT USE REVERSE TO PULL THE CABLE OUT OF

THE DRAIN. RUNNING MACHINE IN REVERSE CAN

CAUSE THE CABLE TO TANGLE IN THE DRUM.

Hint: It's often helpful to have a small stream of water running in the

line to wash the cuttings away while the machine is in operation and

after.

SPECIAL OPERATION

IF CABLE GETS CAUGHT IN LINE

The motor can be reversed to free the cable if it gets caught in the

line. Use the following procedure:

1. Move the motor switch to the Reverse position.

2. Tighten the chuck against the cable.

3. Pull on the cable while the drum is turning in reverse.

4. When the cable has been freed, move the motor switch to the

FORWARD position.

TO CHANGE CABLE CARTRIDGES

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE CHANGING CARTRIDGES !

1. Remove the cutter and connecting screw from the cable if one is

attached.

2. Loosen the knob at the base of the front post and swing the front

post and power cable feed forward.

3. Loosen the three screws around the outside of the drum that hold

the front and back of the drum together.

4. Pull the drum front off the machine, revealing the cable cartridge

within.

5. Pull the cable out of the feed and guide tube and slide it into the

cable cartridge by hand.

6. Remove the cable cartridge.

7. Press replacement cartridge firmly into the back of the drum.

Make sure to line up the grooves in the cartridge with the slots in

the drum back.

8. Slide the cable through the drum front, power cable feed, and

guide tube.

9. Position the drum front so that the three screws align with the

slots in the drum back. Press the drum front into the drum back

and tighten the screws firmly, making sure the screws are centered in the slots and the heads are flush with the drum.

10. Swing the front post and feed back into position and tighten

knob.

IF CABLE TANGLES IN DRUM

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE INSTALLING CABLES !

This is caused by using too much pressure when feeding the cable or

by feeding the cable while running in reverse.

1. To untangle, rotate the drum in the opposite direction to relieve

the twist.

2. If the cable has become badly tangled, disassemble the drum by

loosening the screws around the rim of the drum and pull the

drum front off the drum. (Note: Open drum units cannot be disassembled.)

3. Pull the cable completely out of the drum shell. Then, reassemble the drum.

4. Straighten the cable out and push it back in the drum. (See “To

Install Cable into Drum” below.)

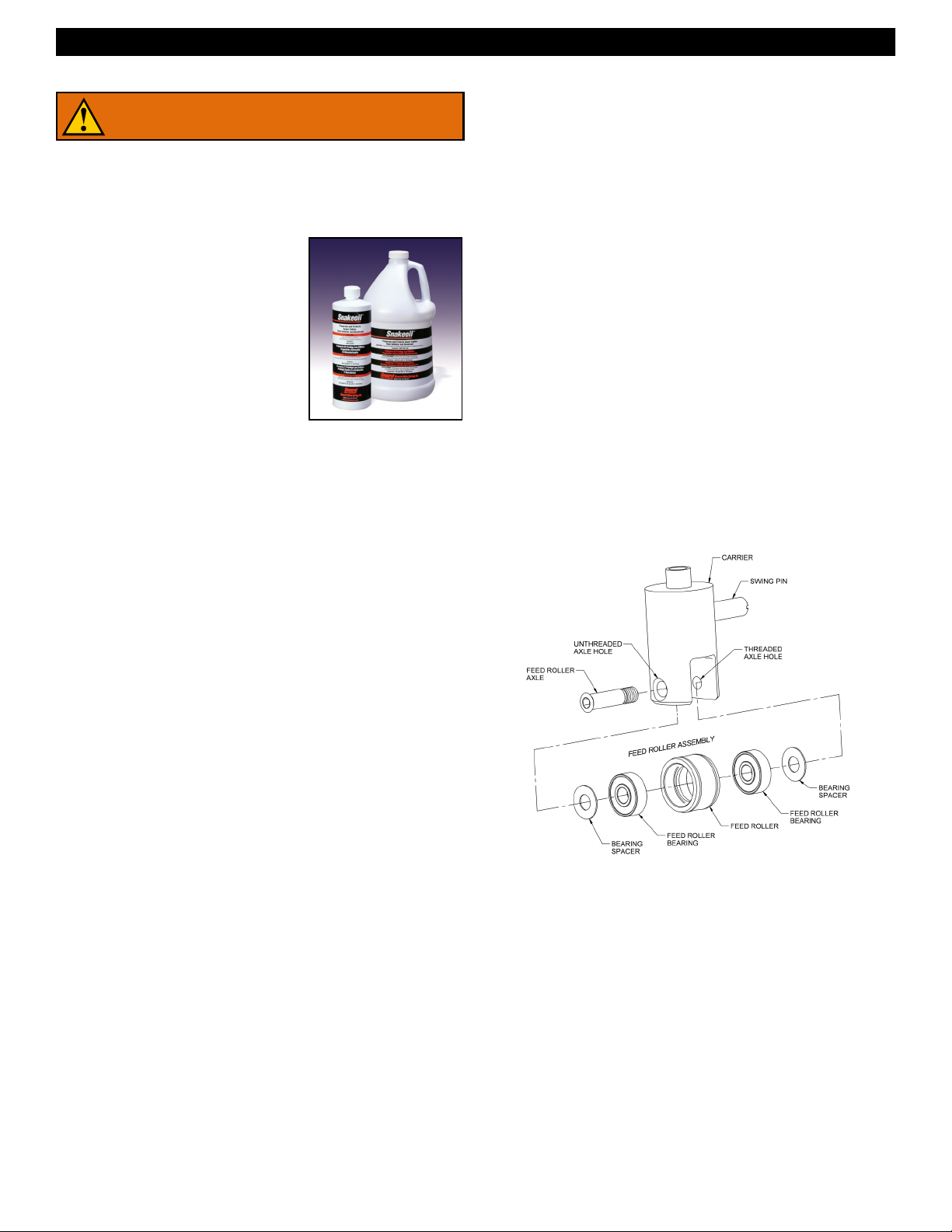

TO INSTALL CABLE IN DRUM

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE INSTALLING CABLES !

1. Loosen feed control knob so that the cable can pass through

easily.

2. Push the back of the cable through the spout into the drum.

3. It will be easier to load the cable if you put a slight bend in the

cable about one inch from the end.

Note: The cable should lay in the

drum in a clockwise direction.

6

Page 7

Drain-Rooter PH™

MAINTENANCE

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE PERFORMING MAINTENANCE!

To keep your machine operating smoothly, it is essential that all bearings and distributor tube bushings be lubricated. Oiling moving parts is

particularly important where machine comes in contact with sand, grit

and other abrasive material.

CABLE MAINTENENCE

To get maximum service from your cables,

be sure that they are clean and well oiled.

This not only provides running lubrication

but greatly extends the life of the cables as

well. Some users periodically pour oil directly into the drum. Then, as the drum

turns, the cables get complete lubrication.

Our SNAKE OIL is ideally suited for this

purpose, since it not only lubricates the

cables, it deodorizes them as well.

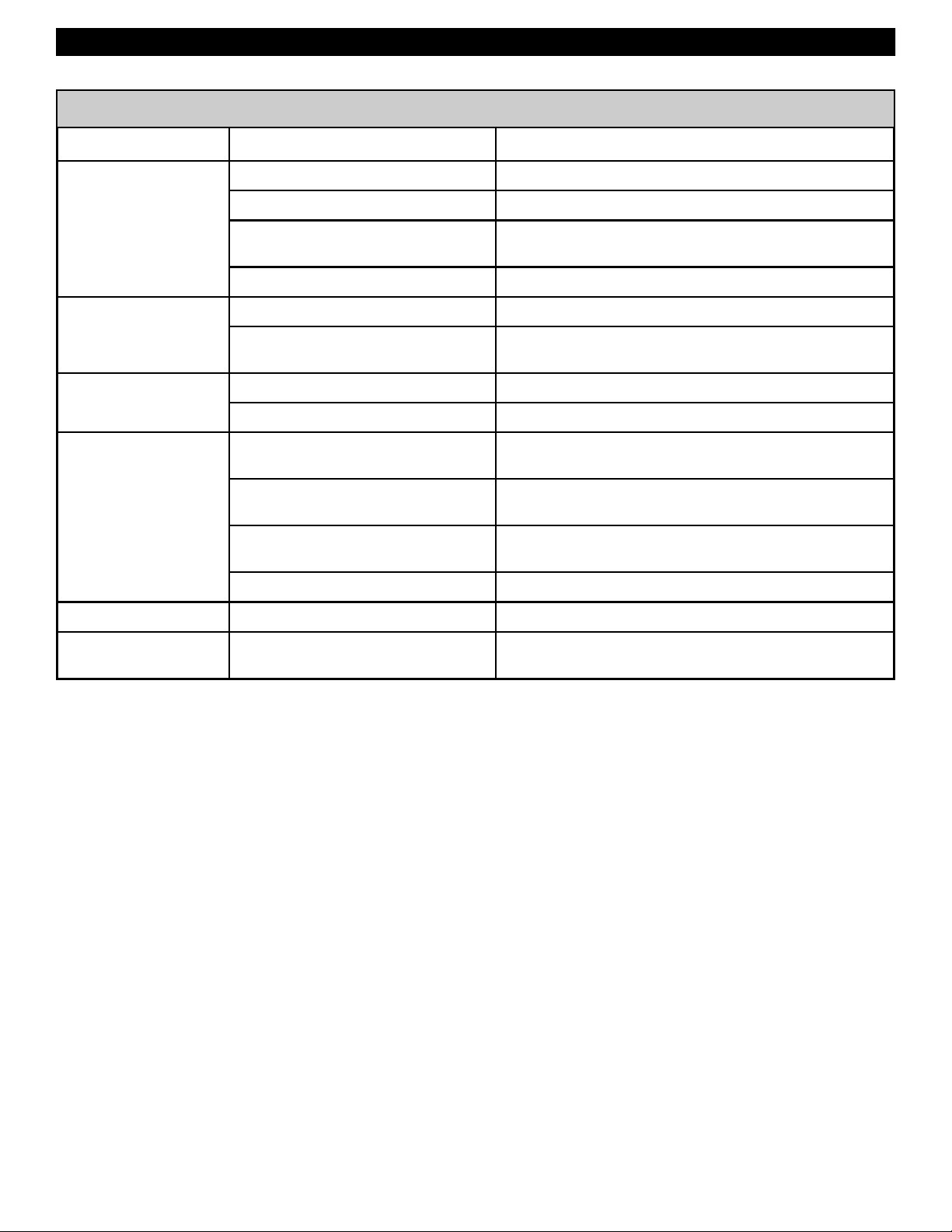

POWER FEED MAINTENANCE

Keep feed free of excessive soil and grit. It is recommended that the

feed be flushed with fresh water followed by a light oiling of the moving parts. No disassembly is normally required. Failure to feed can

usually be traced to the following possibilities:

DIRT ACCUMULATION

Over time, dirt can harden enough to stop roller rotation. Flushing with

water followed by liberal oiling can usually restore function. If disassembly is required, proceed as follows:

1. Remove the feed pressure knob, springs and spring plunger. Note

the positioning of these parts to ease re-assembly. The top roller

can now be removed.

2. Remove the snap rings and thrust washers from the bottom housing cylinders. The bottom rollers can now be removed.

3. Re-assembly is done in reverse order.

DAMAGED ROLLER

Excessive use may wear a roller to the point of failure. It is recommended that all three rollers be replaced at the same time (Cat # POMR-703). The replacement roller is an assembly consisting of one

Feed Roller, two Feed Roller Bearings, and two Bearing Spacers.

Note: The Bearing Spacers must be installed between the Carrier

and each Feed Roller Bearing (as illustrated below) in order to

ensure proper operation and to obtain maximum Feed Roller life.

To Replace the Feed Roller Assembly:

1. Remove the Feed Roller Assembly by unscrewing and removing

the Feed Roller Axle.

2. For convenience, the components are assembled and wired together at the factory. Before attempting to install the assembly,

hold the assembly together and remove the wire.

3. While still holding the Feed Roller Assembly together, insert it into

the slot opening of the Carrier.

4. In order to help align the Spacers and Bearings, insert a pencil

point or similar object through the un-threaded end of the Axle

hole in the Carrier. After removing the pencil point, continue to

maintain the alignment of the components.

5. The Feed Roller Axle should then be inserted through the same un

-threaded Axle hole and should continue to be guided through the

Spacers and Bearings to the threaded Axle hole on the other side

of the Carrier.

6. Securely tighten the Axle to the Carrier with a 3/16” allen wrench.

TANGLED CABLE

If a cable loops over itself in the drum/cage, it will not feed properly.

Remove and reload the cable to restore function. If the cable kinks, it

is evidence of abuse and results from the use of too much pressure or

use of the wrong size cable for the line. Do not force the cable — let

the cutter do the work.

7

Page 8

Drain-Rooter PH™

TROUBLE SHOOTING GUIDE (TABLE 3)

Problem Probable Cause Solution

Cable kinks or breaks. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Too much slack between machine and drain. Do not allow more than six inches between guide hose and drain.

Cable used in wrong size drain line. A cable that is too large or too small in diameter for a line is more

likely to kink (See Table 1—Cable Application Chart).

Cable exposed to acid. Clean and oil cables regularly.

Cable tangles in drum. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Machine run in reverse. Do not run machine in reverse to retract cable from drain. Use re-

verse only if cable is caught in line.

Hole in pedal or hose. Replace as required. Drum stops while foot pedal

depressed.

Failure to feed. Frozen or worn rollers. Clean debris from around rollers. If rollers do not turn, cable will not

Hole in diaphragm switch. If no hole found in pedal or hose, replace diaphragm switch.

feed. Badly worn rollers must be replaced.

Cable tangled in drum. Make sure to use proper size cable for the job (see Table 1 – Cable

Application Chart).

Feed misadjusted. If feed tension knob is too loose, the cable will slip. If it is too tight,

the feed rollers will wear prematurely.

Worn cable. When cable coils wear flat, cable should be replaced.

Motor does not run. Trigger in neutral (off) position. Switch Trigger to either Forward or Reverse.

Motor turns in one direction

Reverse switch failure. Replace reverse switch.

but not other.

8

Page 9

Drain-Rooter PH™

Mode d’emploi

Pour canalisations de 1-1/4 à 3 pouces

(30mm—75mm)

Votre déboucheur Drain-Rooter PH est conçu

pour vous procurer de nombreuses années

de service fiable et rentable. Toutefois aucune

machine ne peut donner son plein rendement

si l'opérateur ne la connaît pas à fond.

Lisez, comprenez et respectez toutes les consignes de sécurité et instructions fournies

avec ce produit. Le fait de ne pas suivre ces

consignes et instructions risquerait de provoquer une électrocution et/ou des blessures

graves. Conservez ces documents pour future

référence.

CONSERVEZ CES INSTRUCTIONS !

Page 10

Drain-Rooter PH™

CONSIGNES DE SÉCURITÉ GÉNÉRALES

Afin de minimiser les risques de

blessures, l'utilisateur doit lire le

mode d'emploi. Manquer de respecter les consignes d'utilisation

peut entrainer des blessures graves ou la mort.

ATTENTION Lisez toutes les consignes et

avertissements de sécurité. Manquer de sui-

vre les avertissements et consignes peut entraîner des risques de chocs électriques, d'incendie et/ou des blessures graves. Conservez

tous les avertissements et consignes d'utilisation pour référence. Des manuels de re-

change peuvent être obtenus gratuitement sur

demande, ou téléchargées à partir de notre

site Internet, www.drainbrain.com. Des films

d'instruction peuvent également être téléchargés de notre site Internet ou nous être commandés. En cas de question ou de problème,

veuillez contacter le service clientèle de General au 412-771-6300.

Conservez tous les avertissements et

consignes d'utilisation pour référence!

Ces instructions ont pour objet de familiari-

ser tous les employés avec l’utilisation et

l’entretien sans danger du Drain-Rooter PH.

L'appareil doit être branché

dans une prise correctement

mise à la terre. Si le fil de mise à

la terre est électrifié, vous

pouvez être électrocuté par un

simple contact avec l'appareil et

ce, même si l’interrupteur est à

Arrêt (Off). Dans ce cas, le

disjoncteur de fuite à la terre ne

peut pas vous protéger. Utilisez un

testeur muni d'un label UL pour

vérifier que la prise est sûre.

N'utilisez jamais des outils motorisés dans une atmosphère

explosive générée par des liquides inflammables, des gaz

ou de la poussière. Les outils

électriques provoquent des étin-

celles qui risquent d’enflammer la

poussière ou les vapeurs.

Ne portez que des gants en

cuir. N’utilisez aucun autre ty-pe

de gants, en tissu, caout-chouc

ou enduit. Ne saisissez jamais

un câble en mouvement avec des

gants en tissu ou un chiffon;

ces matériaux peuvent s’enrouler

autour du câble et cau-ser des

blessures graves.

Ce symbole de sécurité vous avertit de

l’existence d'un danger pour votre sécu-

rité personnelle. Respectez toutes les

consignes de sécurité suivant ce symbo-

le afin d’éviter des blessures graves ou

mortelles.

DANGER signale un danger de haut risque qui, s’il n’est

pas évité, entraînera des blessures graves ou mortelles.

AVERTISSEMENT signale un danger de risque moyen qui,

s’il n’est pas évité, peut entraîner des blessures graves ou

mortelles

MISE EN GARDE signale un danger de faible risque qui,

s’il n’est pas évité, peut entraîner des blessures de faible

ou moyenne gravité.

Portez toujours des lunettes de

sécurité et des chaussures à

semelles de caoutchouc antidérapantes. L'emploi de ces

équipements de sécurité peut

empêcher des blessures graves.

Ne forcez jamais les câbles

exagérément. Une tension ex-

cessive peut causer la torsion, le

vrillage ou la rupture du câble et

pourrait provoquer des blessures

graves.

10

Page 11

Drain-Rooter PH™

AVERTISSEMENTS GÉNÉRAUX DE SÉCURITÉ

CONCERNANT LES OUTILS ÉLECTRIQUES

AVERTISSEMENT !

Lisez toutes les consignes et avertissements de sécurité. Le fait

de ne pas suivre toutes les instructions risque de provoquer une électrocution, un incendie et/ou des blessures graves.

Conservez tous les avertissements et consignes d'utilisation

pour référence !

Le terme « outil électrique » dans les avertissements se réfère à votre

outil électrique fonctionnant sur secteur (à fil) ou sur pile (sans fil).

SÉCURITÉ DE L'ESPACE DE TRAVAIL

1. Conservez l’espace de travail propre et bien éclairé. Des éta-

blis encombrés et des zones mal éclairées sont causes d'accident.

2. N'utilisez jamais des outils motorisés dans une atmosphère

explosive générée par des liquides inflammables, des gaz ou

de la poussière. Ces outils produisent des étincelles qui peuvent

allumer les vapeurs inflammables ou les poussières.

3. Ne laissez pas les curieux, les enfants et les visiteurs s'ap-

procher quand vous faites fonctionner un outil motorisé. Des

distractions pourraient vous faire perdre le contrôle.

ÉLECTRICITÉ ET SÉCURITÉ

1. Les fiches des outils électriques doivent correspondre aux

prises. Ne modifiez jamais la fiche de quelque manière que ce

soit. N'utilisez jamais de fiche d'adaptation avec des outils

électriques mis à la masse. Les fiches non modifiées et leurs

prises correspondantes réduiront les risques de chocs électriques.

2. Évitez tout contact du corps avec des surfaces mises à la

masse telles que tuyaux, radiateurs, cuisinières et réfrigérateurs. Les risques de chocs électriques augmentent lorsque le

corps est mis à la masse ou à la terre.

3. N'utilisez pas d'outils électriques mouillés ou sous la pluie.

L'eau qui s'infiltre dans un outil électrique augmente les risques de

choc électrique.

4. Attention au cordon électrique. Ne transportez jamais un outil

par le cordon et ne débranchez jamais un outil en tirant sur le

cordon. Maintenez toujours le cordon éloigné de la chaleur,

de l'huile, d'objets coupants ou de pièces en mouvement.

Remplacez immédiatement un cordon endommagé, car cela

augmente les risques de choc électrique.

5. Lorsque l'outil électrique doit être utilisé à l'extérieur, utilisez

une rallonge qui convient aux activités en plein air. L'utilisation

d'une rallonge convenant aux activités en plein air diminue le risque de chocs électriques.

6. Si l'outil électrique doit être utilisé dans un lieu humide, utili-

sez une alimentation protégée par disjoncteur de fuite à la

terre (GFCI). L'utilisation d'un disjoncteur de fuite à la terre réduit

le risque de chocs électriques.

7. Les outils à double isolation sont équipés d'une fiche polari-

sée (une broche plus large que l'autre). Ce type de fiche ne

peut être inséré dans une prise de courant polarisée que

d'une seule façon. Si la fiche ne peut pas entrer complètement dans la prise, faites-la pivoter d'un demi-tour. S'il est

toujours impossible de la faire entrer complètement, demandez à un électricien qualifié d'installer une prise de courant

polarisée. Ne changez la fiche pour aucune raison. La double

isolation élimine le besoin d’une fiche à trois broches et d’un câ-

blage électrique mis à la terre.

SÉCURITÉ PERSONNELLE

1. Ne vous laissez pas distraire, prêtez attention à ce que vous

faites et usez de bon sens lorsque vous utilisez un outil électrique. N'utilisez pas cet outil si vous êtes fatigué ou sous

l’influence d'une drogue, de l'alcool ou de médicaments. Des

blessures graves peuvent résulter d'un moment d'inattention.

2. Utilisez des équipements de protection personnels. Portez

toujours une protection pour les yeux. Les équipements de

protection tels que masques de poussière, chaussures de sécurité

antidérapantes, casque ou protections de l'ouïe, utilisés dans les

conditions appropriées, auront pour effet de diminuer les risques

de blessures corporelles.

3. Évitez les démarrages accidentels. Assurez-vous que l'inter-

rupteur est en position arrêt avant de brancher l'outil à une

source d'alimentation et/ou à la pile, ou avant de soulever ou

de porter l'outil. La probabilité d'un accident augmente lorsque

vous portez des outils électriques avec le doigt sur l'interrupteur

ou si l'interrupteur des outils électriques est en position de marche

au moment de les brancher.

4. Retirez toute clé de réglage avant de mettre l'outil électrique

en marche. Une clé qui reste attachée à une partie tournante de

l'outil électrique peut entraîner des blessures corporelles.

5. N'étendez pas trop les bras. Conservez votre équilibre en tout

temps ainsi qu'un appui solide. Un bon appui ainsi qu'un bon

équilibre permettent de conserver un meilleur contrôle de l'outil en

cas d’imprévu.

6. Habillez-vous correctement. Ne portez pas de bijoux ou de

vêtements risquant de se prendre dans l’appareil. Éloignez

les cheveux, vêtements et gants des pièces en mouvement.

Les vêtements lâches, les bijoux ou les cheveux longs peuvent

facilement se prendre dans des pièces en mouvement.

7. S'il est possible de raccorder des dispositifs de dépoussiéra-

ge, assurez-vous que ceux-ci sont bien raccordés et correctement utilisés. L'utilisation de dispositifs pour le dépoussiérage

peut diminuer les risques liés à la poussière.

UTILISATION ET SOINS DES OUTILS ÉLECTRIQUES

1. Ne forcez jamais l'outil électrique. Utilisez le bon outil élec-

trique pour votre application. Le bon outil fera mieux le travail

et dans des conditions plus sécuritaires s'il fonctionne à la puissance à laquelle il a été conçu.

2. N'utilisez pas l'outil électrique si l'interrupteur pour la mise

en marche/arrêt ne fonctionne pas. Tout outil électrique ne

pouvant pas être contrôlé avec l'interrupteur présente un danger

et doit être réparé.

3. Débranchez la fiche d'alimentation électrique et/ou la pile de

l'outil électrique avant d'effectuer tout réglage, modification

d'accessoire ou pour stocker l'outil électrique. De telles me-

sures de prévention réduisent les risques de mettre l'outil électrique en marche accidentellement.

4. Conservez les outils non utilisés hors de la portée des en-

fants et n'autorisez pas les personnes n'ayant pas d'expérience avec l'outil électrique ou avec ces consignes de manipuler l'outil électrique. Les outils électriques présentent un

danger lorsqu'ils sont aux mains d'utilisateurs non expérimentés.

11

Page 12

Drain-Rooter PH™

5. Entretien des outils électriques : Vérifiez que les pièces mobiles ne sont ni mal alignées ni grippées, cassées ni présentent toute autre condition pouvant affecter le fonctionnement de l'outil électrique. Si endommagé, faites réparer l'outil électrique avant de vous en servir. De nombreux accidents

sont dus à des outils électriques mal entretenus.

6. Maintenez les outils tranchants aiguisés et propres. Les ou-

tils tranchants dont les bords tranchants sont aiguisés ont moins

de chance de se gripper et sont plus faciles à contrôler.

7. Utilisez l'outil électrique, ses accessoires et forets, etc. en

respectant ces consignes et en tenant compte des conditions de travail et du travail à effectuer. L'utilisation de l'outil

électrique pour des opérations autres que celles pour lesquelles

il est prévu peut entraîner des situations dangereuses.

ENTRETIEN ET RÉPARATIONS

1. Faites réparer votre outil électroportatif que par un réparateur

qualifié utilisant uniquement des pièces de rechange identiques.

Cela permettra d'assurer que la sécurité de l'outil est maintenue.

CONSIGNES DE SÉCURITÉ PARTICULIÈRES

Ce symbole de sécurité vous avertit de l’existence

d'un danger pour votre sécurité personnelle. Respectez toutes les consignes de sécurité suivant ce

symbole afin d’éviter des blessures graves ou mor-

telles.

5. Ne saisissez jamais un câble en mouvement. Ne saisissez le

câble pour le sortir de son logement ou l'y rentrer que lorsque le moteur est arrêté. Lorsque le moteur tourne, ayez toujours une main sur la gâchette et l'autre main autour de la

poignée bouclier. La main de l’utilisateur risque de se prendre

dans des pièces en mouvement, ce qui peut entraîner des blessures graves.

6. Faites attention lorsque vous nettoyez un drain dans lequel

des produits chimiques ont été utilisés. Évitez tout contact

direct avec la peau et les yeux. Ces produits chimiques peuvent

causer des brûlures graves à l'opérateur et endommager le câble.

7. Ne faites pas fonctionner la machine si elle ou l'utilisateur se

trouve sur un sol inondé. Ceci augmenterait le risque d’électro-

cution.

8. Portez toujours des lunettes de sécurité et des chaussures à

semelle en caoutchouc antidérapant. L'emploi de ces équipe-

ments de sécurité peut empêcher des blessures graves.

9. Avant chaque utilisation, vérifiez que le câble n'est ni cassé

ni emmêlé à l'intérieur du tambour, en extrayant le câble et en

vérifiant qu'il n'est pas usé ni cassé. Remplacez toujours les

câbles usés (entortillés ou cassés) par des câbles de remplacement GENERAL authentiques.

10. N’utiliser cet outil que pour la tâche à laquelle il est destiné.

Suivez le mode d’emploi. Toute autre utilisation ou la modifica-

tion du débouchoir pour d’autres applications risquent d’augmen-

ter le risque de se blesser.

L'appareil doit être branché dans une prise correctement mise à la terre. Si le fil de mise à la terre est

électrifié, vous pouvez être électrocuté par un simple

contact avec l'appareil et ce, même si l’interrupteur

est à Arrêt (Off). Dans ce cas, le disjoncteur de fuite à la

terre ne peut pas vous protéger. Utilisez un testeur muni

d'un label UL pour vérifier que la prise est sûre.

Ne forcez jamais les câbles exagérément. Une tension

excessive peut causer la torsion, le vrillage ou la rupture

du câble et pourrait provoquer des blessures graves.

1. Portez uniquement des gants en cuir. N’utilisez jamais d’autres

types de gants, tels que gants en toile, en caoutchouc ou en tissu

enduit. Ne saisissez jamais un câble en rotation avec un chiffon.

Ces objets peuvent se prendre dans le câble et provoquer un

accident grave.

2. Ne forcez jamais les câbles exagérément. Quand l'appareil

fonctionne, maintenez une main gantée sur le câble pour le

contrôler. Une tension excessive du câble à cause d'un obstacle

peut causer une torsion, un vrillage ou la rupture et pourrait provoquer des blessures graves.

3. Placez l’appareil le plus près possible du drain, à une distan-

ce de 15 cm (6 po) maximum. Une distance plus grande risque

de conduire à une torsion ou un vrillage du câble.

4. Cet appareil est prévu pour être utilisé PAR UNE PERSONNE

seulement à la fois. L’utilisateur doit contrôler la gâchette et le

câble.

CARACTÉRISTIQUES

Drain-Rooter PH à dévidoir fermé

Poignée

Couteau

Moteur

REMARQUE : ne faites pas fonctionner la machine si les étiquettes

d’avertissement de l’avant du dévidoir et du cordon électrique sont

absentes ou illisibles.

Molette de

tension

d’alimentation

Arrière du

dévidoir

Avant du

dévidoir

Levier de

contrôle

d’alimentation

Tuyau-guide

(câble à l’intérieur)

Molette de

tige avant

12

Page 13

CARACTÉRISTIQUES

Drain-Rooter PH à dévidoir ouvert

Poignée

Molette de

tension

d’alimentation

Levier de

contrôle

d’alimentation

Applications des couteaux (Tableau 2)

Couteau

Tête de

flèche

Tête de

flèche

flexible

N° de pièce Applications typiques

AH

FAH

Idéal pour couper et gratter

Plus de flexibilité que la tête

de flèche; capable de virage

serré dans une petite conduite

Drain-Rooter PH™

Tuyau-guide

Couteau

Moteur

REMARQUE : ne faites pas fonctionner la machine si les étiquettes

d’avertissement de l’avant du dévidoir et du cordon électrique sont

absentes ou illisibles.

Dévidoir ouvert

(câble à l’intérieur)

Molette de

tige avant

VARIATEUR DE VITESSE

Un variateur de vitesse est intégré au mécanisme de déclenchement.

Vous pouvez contrôler la vitesse de la machine et l'accélérer en appliquant une tension supérieure sur le déclencheur, jusqu'à ce que vous

obteniez la vitesse désirée.

Vous pouvez aussi contrôler la direction de rotation de la machine en

déplaçant la manette de marche avant et de marche arrière, située

juste au-dessus du déclencheur. Avancez la manette vers la flèche de

marche avant pour une rotation vers l'avant et vers la flèche de marche arrière pour une rotation vers l'arrière. Mettez sur OFF (arrêt) en

dehors des périodes d’utilisation.

Sélection du câble (Tableau 1)

Diamètre

du câble

1/4 po

6.3 mm

5/16 po

7.9 mm

3/8 po

9.5 mm

Les câbles de 1/4 et 5/16 po (6.3 et 7.9 mm) équipés d'une tête EL

pour les bouchons des cuves peuvent être insérés dans la plupart des

crépines en croix pour libérer les blocages mous, telles les accumulations de cheveux, de savon, de graisse, etc.

Capacité maximale : 50 pi de câble de ¼ ou 5/16 po ; 35 pi de câble

de 3/8 po.

Diamètre de

conduite

1-1/4 à 2 po

30–50 mm

1-1/2 à 2 po

38–50 mm

2 à 3 po

50–75 mm

Applications typiques

Petites conduites, drains de baignoire

et de douche

Éviers, cuves, petits drains

Colonnes, toilettes, petits drains (pas

de racines)

Queue

de cochon

Queue de

cochon

vers le bas

Lame à

tranchant

latéral 1-1/4 po

BG

DHBG

1-1/4SCB

Pour retirer des objets perdus

Dirige le câble vers le bas à

travers l'évacuation plutôt

que vers le haut par l'évent

ou à travers un té

Pour les bouchons de graisse, pour gratter les parois de

la conduite

UTILISATION

Préparation

DÉBRANCHEZ LA MACHINE DU COURANT ÉLEC-

TRIQUE AVANT D’INSTALLER LE COUTEAU !

1. Glissez le raccord sur le bec, jusqu’à ce que le ressort se mette en

place.

2. Le câble peut être muni d’une tête à lavabo EL (afin de l’aider à

passer dans les courbes) ou d’un connecteur de couteau.

3. Pour fixer un couteau, débranchez d’abord la machine. Dévissez

ensuite la vis et la rondelle d’arrêt du connecteur situé en bout de

câble. Glissez le couteau dans la fente, puis remettez en place la

rondelle d’arrêt et la vis de fixation. Serrez fermement la vis.

4. La queue de cochon pivotante et la tête de flèche sont de bons

couteaux de départ. Passez ensuite à des couteaux plus grands

une fois que l’eau recommence à circuler.

5. Placez la machine de façon à ce que le tuyau-guide puisse être

mis à une distance de 15 cm (6 po) maximum de l’ouverture du

drain, sans recourbement excessif.

Remarque : évitez de tordre ou courber excessivement le tuyau-guide

en repositionnant la machine. Pour faciliter ceci, le Drain-Rooter PH

est conçu pour être placé soit horizontalement, soit verticalement.

UTILISATION

1. Branchez la machine dans une prise correctement mise à la terre.

2. Vérifiez que le commutateur Marche avant/Arrêt/Marche arrière

est sur la position de marche AVANT.

3. Serrez la molette en haut du dispositif d’alimentation électrique du

câble à vitesse variable de façon à ce que le rouleau d’alimenta-

tion se presse contre le câble. Ne serrez pas trop, afin de ne pas

user le câble excessivement.

13

Page 14

Drain-Rooter PH™

4. Le levier d’alimentation contrôle la vitesse d’alimentation et la

direction du câble. Déplacez le levier vers le bas pour sortir le

câble du dévidoir. Plus le levier est abaissé, plus le câble sort

vite. Remontez le levier pour rentrer le câble dans le dévidoir.

Lorsque le levier est à sa position centrale (point mort), le câble

tourne en place.

Molette de tension

d’alimentation

Marche arrière

Levier de

contrôle

d’alimentation

Marche avant

5. Introduisez l’extrémité du câble et le couteau dans l’ouverture du

drain.

6. En mettant une main sur le tuyau-guide, démarrez la machine en

appuyant lentement, mais fermement sur la pédale. Plus vous

appuyez sur la pédale, plus le moteur tourne vite et plus le câble

avance rapidement.

7. Faites avancer le câble avec précaution. Servez-vous de la pé-

dale et du dispositif d’alimentation du câble pour ajuster la vites-

se quand vous rencontrez une résistance. Ne faites pas avancer

le câble plus vite qu’il n’est possible. Trop de câble entre le mécanisme d’alimentation électrique et le drain risque de provoquer

un fouettement et une torsion du câble.

Point mort

NE LAISSEZ PAS TROP DE CÂBLE ENTRE LA

MACHINE ET L'OUVERTURE DU DRAIN CAR

LE CÂBLE RISQUERAIT DE FOUETTER.

8. Si le câble commence à se plie ou se tord trop, relâchez la pression sur la pédale et faites tourner le dévidoir dans le sens oppo-

sé pour détordre le câble. Repoussez l’excès de câble dans le

tambour, puis continuez.

9. Une fois que le câble a atteint l’obstruction, mettez le dispositif

d’alimentation du câble au point mort. Laissez ensuite le câble

avancer lentement, en grignotant l’obstruction au fur et à mesure.

Ce mouvement lent vers l’avant réduit la fatigue du câble et donne un meilleur résultat. Il est utile d’alterner un mouvement vers

l’avant et un mouvement vers l’arrière.

N’APPLIQUEZ PAS UNE FORCE EXCESSIVE –

LAISSEZ LE COUTEAU FAIRE SON TRAVAIL.

10. Lorsque la conduite a été dégagée, rentrez le câble dans le dévidoir en mettant le levier en marche arrière. Laissez le moteur

en marche avant.

NE METTEZ PAS LE MOTEUR EN MARCHE ARRIÈRE

POUR SORTIR LE CÂBLE DU DRAIN. CECI RISQUE

D’EMMÊLER LE CÂBLE DANS LE DÉVIDOIR.

Conseil : il peut être utile de faire couler un filet d'eau dans la cana-

lisation pour dégager les débris coupés par le couteau, pendant

et après que la machine fonctionne.

SITUATIONS SPÉCIALES

CÂBLE COINCÉ DANS UNE CANALISATION

Le moteur peut être mis en marche arrière pour dégager le câble

lorsqu'il est coincé dans une canalisation. Suivez les instructions ciaprès.

1. Déplacez l'interrupteur du moteur en position de marche arrière.

2. Serrez le mandrin contre le câble.

3. Tirez sur le câble pendant que le tambour/dévidoir tourne en

arrière.

4. Une fois le câble dégagé, remettez l'interrupteur en position de

marche avant.

REMPLACEMENT DES CARTOUCHES DE CÂBLE

DÉBRANCHEZ LA MACHINE DU COURANT ÉLECTRI-

QUE AVANT DE CHANGER LES CARTOUCHES !

1. Le cas échéant, enlevez le couteau et la vis de fixation en bout

de câble.

2. Desserrez la molette située à la base de la tige avant et basculez

celle-ci et le dispositif d’alimentation électrique vers l’avant.

3. Desserrez les trois vis autour du dévidoir assemblant l’avant et

l’arrière de celui-ci.

4. Sortez le dévidoir de la machine, en révélant la cartouche de

câble à l’intérieur.

5. Sortez le câble du dispositif d’alimentation et du tube-guide et

glissez-le à la main dans la cartouche.

6. Enlevez la cartouche de câble.

7. Enfoncez fermement la cartouche de rechange au dos du dévi-

doir. Alignez les rainures de la cartouche et les fentes de l’arrière

du dévidoir.

8. Glissez le câble à travers l’avant du dévidoir, le dispositif d’ali-

mentation électrique et le tube-guide.

9. Placez l’avant du dévidoir de façon à ce que les trois vis se trou-

vent en face des fentes de l’arrière du dévidoir. Enfoncez l’avant

du dévidoir sur l’arrière du dévidoir. Serrez les vis solidement, en

les centrant dans les fentes et en vous assurant que les têtes ne

dépassent pas du dévidoir.

10. Basculez la tige avant et le dispositif d’alimentation de nouveau

en position et serrez la molette.

CÂBLE EMMÊLÉ DANS LE DÉVIDOIR

DÉBRANCHEZ LA MACHINE AVANT

D’INSTALLER LES CÂBLES !

Cette situation peut survenir en appliquant une tension trop grande à

l'avance du câble ou en faisant avancer le câble dans la canalisation

alors que la machine tourne en marche arrière.

1. Pour démêler, faites tourner le dévidoir dans la direction opposée

à la torsion.

2. Si le câble est excessivement emmêlé, désassemblez le dévidoir

en desserrant les vis tout autour et en sortant l’avant du dévidoir

(remarque : les dévidoirs ouverts ne peuvent pas être désassem-

blés).

14

Page 15

Drain-Rooter PH™

3. Sortez complètement le câble du fond du dévidoir. Puis réassemblez le dévidoir.

4. Redressez le câble et enfoncez-le dans le dévidoir (voir

« Comment installer un câble dans le dévidoir », ci-dessous).

COMMENT INSTALLER UN CÂBLE DANS

LE DÉVIDOIR

DÉBRANCHEZ LA MACHINE AVANT

D’INSTALLER LES CÂBLES !

1. Desserrez la molette de contrôle d’alimentation afin que le câble

puisse circuler facilement.

2. Enfoncez l’arrière du câble à travers le mandrin jusque dans le

dévidoir.

3. Il est plus facile de charger le câble si vous le recourbez légère-

ment à 2,5 cm de l’extrémité.

Remarque : le câble devrait

se trouver enroulé dans le

sens horaire à l'intérieur du

dévidoir.

ENTRETIEN

DÉBRANCHEZ L’APPAREIL AVANT TOUT ENTRETIEN !

Pour maintenir votre appareil en état de marche optimal, il est essentiel que tous les roulements et coussinets du tube distributeur soit

lubrifiés. La lubrification de toutes les pièces mobiles est particulière-

ment importante si l’appareil est exposé au sable, au gravier et à d'au-

tres matières abrasives.

ENTRETIEN DU CÂBLE

Pour obtenir un rendement maximal des câbles,

assurez-vous qu'ils soient propres et bien lubrifiés.

Cela est nécessaire à leur utilisation et prolonge

grandement leur durée. Certains utilisateurs versent

périodiquement de l'huile directement dans le dévidoir ; le mouvement du dévidoir assure alors la lubrification complète du câble. Notre huile SNAKE OIL est idéale à cette

fin puisqu'elle désodorise tout en lubrifiant.

pour faciliter le remontage. Le rouleau du dessus peut maintenant

être enlevé.

2. Enlevez les anneaux élastiques et les rondelles de butée des

cylindres de logement inférieurs. Les rouleaux inférieurs peuvent

être retirés.

3. Le remontage s'effectue dans l'ordre inverse.

ROULEAU ENDOMMAGÉ

L'utilisation de l'appareil entraîne l'usure normale des rouleaux après

un certain temps. Il est recommandé de changer les 3 rouleaux en

même temps (N° de pièce PO-MR-703). L’ensemble de rouleau de

rechange consiste en un rouleau d’alimentation, deux roulements à

billes et deux intercalaires.

Remarque : les intercalaires doivent être installés entre le support et chaque roulement à billes (voir illustration ci-dessous),

afin d’assurer un fonctionnement correct et de prolonger la du-

rée de vie du rouleau d’alimentation.

Pour remplacer l’ensemble rouleau d’alimentation :

1. Enlevez l'ensemble rouleau d’alimentation en dévissant et en reti-

rant son axe.

2. Les pièces de rechange sont préassemblées et fixées par un fil

métallique à l’usine. Commencez par retirer le fil métallique en

maintenant les pièces ensemble.

3. En continuant de ce faire, insérez l’ensemble dans la fente de la

pièce porteuse.

4. Afin d’aligner les intercalaires et les roulements, introduisez la

pointe d’un crayon ou un objet similaire dans l'extrémité non filetée du trou de l'axe sur la pièce porteuse. Après avoir retiré le

crayon, continuez de maintenir l'alignement des pièces.

5. L'axe du rouleau d’alimentation doit alors être introduit à travers le

même trou d’axe non fileté, et doit être guidé à travers les intercalaires et les roulements jusqu’au trou d’axe fileté, de l'autre côté

de la pièce porteuse.

6. Vissez l’axe sur la pièce porteuse avec une clé de 3/16 po.

ENTRETIEN DE L'ALIMENTEUR

Maintenez l'alimenteur libre de saletés. Il est recommandé de le nettoyer à l'eau propre puis de lubrifier légèrement toutes les pièces

mobiles après chaque utilisation. Normalement, il ne devrait pas être

nécessaire de le démonter. Le mauvais fonctionnement de l'alimenteur est habituellement dû aux causes suivantes :

ACCUMULATION DE SALETÉS

Avec le temps, la saleté peut durcir suffisamment pour empêcher la

rotation des rouleaux. Le lavage à l'eau et une lubrification abondante

peuvent habituellement y remédier. Si le démontage est nécessaire,

faites comme suit :

1. Enlevez le bouton de réglage de la pression de l'alimenteur, les

ressorts et le piston à ressort. Notez bien la position des pièces

15

Page 16

Drain-Rooter PH™

CÂBLE EMMÊLÉ

Si un câble s'emmêle dans le dévidoir, il ne peut pas avancer correctement. Retirez puis replacez correctement le câble à la main pour

corriger la situation. Si le câble a vrillé, c'est une preuve qu’il a été

forcé ou le résultat d'une pression excessive ou de l'usage du mauvais diamètre de câble dans une canalisation. Ne forcez pas un câble,

laissez le couteau faire le travail.

GUIDE DE DÉPANNAGE (tableau 3)

Problème Cause probable Solution

Le câble vrille ou casse.

Le câble s’emmêle dans le

dévidoir.

l’on appuie sur la pédale.

Le câble n’avance pas. Rouleaux coincés ou usés. Nettoyez autour des rouleaux. Si les rouleaux ne tournent pas, le

L’opérateur force le câble Ne forcez pas le câble. Laissez le couteau faire le travail.

Trop de mou entre la machine et le drain Le tuyau-guide de la machine doit être placé à moins de 15 cm du

drain.

Mauvais diamètre de câble pour cette canalisation

Câble exposé à l’acide Nettoyez et lubrifiez les câbles régulièrement.

L’opérateur force le câble Ne forcez pas le câble. Laissez le couteau faire son travail.

La machine tourne en marche arrière. Ne faites pas tourner l’appareil en marche arrière pour sortir le câble

Trou dans la pédale ou dans le tuyau. Remplacez si nécessaire. Le dévidoir s’arrête lorsque

Trou dans l’interrupteur à diaphragme. Si la pédale ou le tuyau ne sont pas percés, remplacez l’interrupteur

Câble emmêlé dans le dévidoir. Vérifiez que le câble choisi est du bon diamètre pour le travail à

Un câble dont le diamètre est trop petit ou trop grand pour une canalisation est plus sujet au vrillage. (Voir tableau 1 ‑ Sélection du

câble)

du drain. Utilisez uniquement la marche arrière que si le câble est

coincé dans la conduite.

à diaphragme.

câble n’avance pas. Les rouleaux excessivement usés doivent être

remplacés.

effectuer (voir le Tableau 1 – Sélection du câble).

Dispositif d’alimentation mal réglé. Si la molette de tension est trop lâche, le câble glissera. Si elle est

trop serrée, les rouleaux s’useront prématurément.

Câble usé. Lorsque les enroulements du câble deviennent plats, le câble doit

être remplacé.

Le moteur ne tourne pas. Déclencheur au point mort (arrêt). Faites passer le déclencheur en position Marche avant ou Marche

arrière.

Le dévidoir tourne dans un

sens, mais pas dans l’autre.

Interrupteur de marche arrière défectueux Remplacez l’interrupteur de marche arrière.

16

Page 17

™

Drain-Rooter PH

Instrucciones de operación

Para líneas de 1-1/4 a 3 pulgadas

(30 a 75 mm)

Su Drain-Rooter PH está diseñado para darle años de servicio rentable y sin problemas.

Sin embargo, no hay máquina que sea mejor

que el operario.

Lea, entienda y cumpla con todas las advertencias de seguridad e instrucciones que vienen con el producto. Si no se siguen todas

estas advertencias e instrucciones se pueden producir descargas eléctricas y/o graves

lesiones. Guarde todas las advertencias e

instrucciones como referencias futuras.

¡GUARDE ESTAS INSTRUCCIONES!

Page 18

Drain-Rooter PH™

Para reducir el riesgo de lesiones, el usuario debe leer el manual de instrucciones. De no seguir las instrucciones de operación se pueden producir lesiones

graves o mortales.

ADVERTENCIA Lea todas las advertencias de

seguridad y todas las instrucciones. De no se-

guir las advertencias e instrucciones se pueden

producir descargas eléctricas, incendios y lesiones

graves. Guarde todas las advertencias e ins-

trucciones para futura referencia. El usuario

puede solicitar manuales de repuesto de forma

gratis o puede descargarlos en nuestro sitio web

en www.drainbrain.com. También hay videos de

instrucciones que pueden descargarse de nuestro

sitio web, o que pueden pedirse. Si tiene preguntas

o problemas, comuníquese con el Departamento

de Servicio al Cliente de General, llamando al 412-

771-6300.

¡Guarde todas las advertencias e instruc-

ciones para futura referencia!

Estas instrucciones están concebidas para

que todo el personal quede familiarizado

con los procedimientos de operación y man-

tenimiento seguros del Drain-Rooter PH.

Si enchufa la máquina en un tomacorriente alambrado incorrectamente se

puede producir una descarga eléctri-ca,

que puede resultar en la muerte. Si el

alambre de conexión a tierra está vivo,

usted puede ser electrocutado con

sólo tocar la máquina, incluso cuando

el interruptor de potencia esté apagado.

En esta situación, un interrup-tor de circuito

de falla de la conexión a tierra no lo

protegerá. Use un probador homologado

por UL para determinar si la toma de

corriente es segura.

No opere herramientas mecánicas en

atmósferas explosivas, como por

ejemplo en presencia de líquidos, ga-ses

o polvos inflamables. Las herra-mientas

eléctricas generan chispas que pueden

encender el polvo o los vapores.

Use sólo guantes de cuero. Nunca

use ningún otro tipo de guante, como por

ejemplo los de tela, caucho o recubiertos. Nunca agarre con un trapo un

cable que esté girando. Estos artí-culos

podrían enredarse en el cable y causar

graves lesiones.

SÍMBOLOS DE SEGURIDAD

Este es un símbolo de alerta de seguridad. Se utiliza para alertar al usuario

ante aquellos posibles peligros que pueden causar una lesión personal. Obedezca todos los mensajes de seguridad

asociados a este símbolo para evitar

posibles lesiones o la muerte.

PELIGRO indica un peligro con un alto nivel de riesgo que si no

se evita resultará en la muerte o en una lesión grave.

ADVERTENCIA indica un peligro con un nivel medio de riesgo que

si no se evita podría resultar en la muerte o en una lesión grave.

PRECAUCIÓN indica un peligro con un bajo nivel de riesgo que si

no se evita resultará en una lesión de grado menor o moderado.

Use siempre gafas de seguridad y

calzado antideslizante con suela de

goma. El uso de este equipo de seguri-dad

puede evitar graves lesiones.

Nunca opere la máquina sin el protec-tor

de la correa. Los dedos pueden que-dar

atrapados entre la correa y la polea.

No tense en exceso los cables. La

tensión excesiva de los cables puede

causar la torcedura, formación de doble-ces

o rotura del cable y puede producir graves

lesiones.

18

Page 19

Drain-Rooter PH™

ADVERTENCIAS DE SEGURIDAD GENERALES DE HERRAMIENTAS ELÉCTRICAS

ADVERTENCIA

ADVERTENCIA Lea todas las advertencias de seguridad y todas

las instrucciones. Si no se siguen todas las instrucciones que se

indican a continuación pueden producirse descargas eléctricas, incendios y/o graves lesiones corporales.

¡Guarde todas las advertencias e instrucciones para

futura referencia!

El término “herramienta eléctrica” en las advertencias se refiere a una

herramienta operada por corriente de la red (con cordón) o por baterías (sin cordón).

SEGURIDAD DEL ÁREA DE TRABAJO

1. Mantenga su área de trabajo limpia y bien iluminada. Los ban-

cos desordenados y las áreas oscuras se prestan a accidentes.

2. No opere herramientas mecánicas en atmósferas explosivas,

como por ejemplo en presencia de líquidos, gases o polvos

inflamables. Las herramientas eléctricas generan chispas que

pueden encender el polvo o los vapores.

3. Mantenga alejados a los espectadores, niños y visitantes

mientras opera una herramienta eléctrica. Las distracciones

pueden hacerle perder el control.

SEGURIDAD ELÉCTRICA

1. Los enchufes de las herramientas eléctricas deben corres-

ponder a la toma de corriente. No modifique nunca el enchufe

de ninguna manera. No use ningún enchufe de adaptador con

herramientas eléctricas conectadas a tierra. Los enchufes sin

modificar y las tomas de corriente correspondientes reducirán el

riesgo de descarga eléctrica.

2. Evite el contacto del cuerpo con superficies conectadas a

tierra como tuberías, radiadores, hornillos y refrigeradores.

Hay un mayor riesgo de descarga eléctrica si su cuerpo está conectado a tierra.

3. No exponga las herramientas eléctricas a la lluvia o al agua.

Si entra agua en una herramienta eléctrica, aumentará el riesgo

de descarga eléctrica.

4. No maltrate el cordón. Nunca utilice el cordón para trasladar

las herramientas ni para sacar el enchufe de una toma de

corriente. Mantenga el cordón alejado del calor, aceite, bordes afilados o piezas móviles. Reemplace inmediatamente los

cordones dañados. Los cordones dañados aumentan el riesgo

de descarga eléctrica.

5. Al operar una herramienta eléctrica al aire libre, use un

cordón de alargamiento para exteriores. El uso de un cordón

adecuado para el exterior reduce el riesgo de descarga eléctrica.

6. Si no se puede evitar operar una herramienta eléctrica en un

lugar húmedo, use un suministro protegido por un interruptor

de circuito por falla a tierra (GFCI). El uso de un tal interruptor

reduce el riesgo de descarga eléctrica.

7. Las herramientas con doble aislamiento están provistas de

un enchufe polarizado (una hoja es más ancha que la otra).

Este enchufe encaja en una toma de corriente polarizada de

una sola manera. Si el enchufe no encaja completamente en

la toma de corriente, déle vuelta. Si todavía no encaja,

póngase en contacto con un electricista califica para instalar

una toma de corriente polarizada. No altere el enchufe de

forma alguna. El doble aislamiento elimina la necesidad de un

cordón eléctrico conectado con tierra de tres hilos y de un sistema

de fuente de poder conectado con tierra.

SEGURIDAD PERSONAL

1. Manténgase alerta, ponga atención a lo que está haciendo y

use sentido común al operar una herramienta mecánica. No

use la herramienta si está cansado o está bajo el efecto de

drogas, alcohol o medicamentos. Un momento de descuido al

operar herramientas eléctricas puede producir graves lesiones

corporales.

2. Use equipos de protección personal. Lleve siempre protecto-

res de ojos. Los equipos protectores como máscara contra el

polvo, zapatos de seguridad antideslizantes, casco o protectores

de oídos usados para las condiciones apropiadas reducirán las

lesiones personales.

3. Impida un arranque no intencionado. Asegúrese de que el

interruptor esté en la posición de apagado antes de conectar

la fuente de alimentación o el grupo de baterías, recoger o

transportar la herramienta. El transporte de herramientas eléctri-

cas con el dedo en el interruptor o el suministro de energía a

herramientas eléctricas que tengan el interruptor en la posición de

encendido invitan a accidentes.

4. Quite cualquier llave de ajuste antes de encender la herra-

mienta. Una llave que se deje sujeta a una parte giratoria de la

herramienta eléctrica puede producir lesiones personales.

5. No se estire en exceso. Mantenga en todo momento su apoyo

y equilibrio correctos. Un apoyo y equilibrio correctos permiten

controlar mejor la herramienta en situaciones inesperadas.

6. Vístase adecuadamente. No use ropa suelta ni joyas. Manten-

ga sujeto el pelo largo. Mantenga su pelo, ropa y guantes

alejados de las piezas móviles. La ropa suelta, las joyas o el

pelo largo pueden quedar atrapados en las piezas móviles.

7. Si se suministran dispositivos para la conexión de instalacio-

nes de extracción y recogida de polvo, asegúrese de que se

conecten y se usen debidamente. El uso de la recogida de pol-

vo puede reducir los peligros relacionados con el polvo.

USO Y CUIDADO DE HERRAMIENTAS ELÉCTRICAS

1. No fuerce la herramienta eléctrica. Use la herramienta eléctri-

ca correcta para su aplicación. La herramienta correcta hará el

trabajo mejor y de forma más segura a la velocidad para la que se

ha diseñado.

2. No use la herramienta eléctrica si el interruptor no se puede

poner en encendido y apagado. Cualquier herramienta eléctrica

que no pueda controlarse con el interruptor es peligrosa y debe

repararse.

3. Desconecte el enchufe de la fuente de alimentación o el gru-

po de baterías de la herramienta eléctrica antes de efectuar

cualquier ajuste, cambiar accesorios o guardar herramientas

eléctricas. Dichas medidas preventivas reducen el riesgo de

arrancar la herramienta eléctrica por accidente.

4. Guarde las herramientas eléctricas inactivas fuera del alcan-

ce de los niños y no permita a personas no familiarizadas con

la herramienta eléctrica o estas instrucciones operar la herramienta eléctrica. Las herramientas eléctricas son peligrosas en

manos de usuarios sin adiestrar.

5. Efectúe el mantenimiento de las herramientas eléctricas.

19

Page 20

Drain-Rooter PH™

Compruebe si hay piezas móviles desalineadas o que se

atasquen, piezas que se rompan y cualquier otra condición

que pueda afectar la operación de la herramienta eléctrica. Si

está dañada, repárela antes de usar. Muchos accidentes son

causados por herramientas eléctricas mal mantenidas.

6. Mantenga afiladas y limpias las herramientas de corte. Es

menos probable que se atasquen las herramientas de corte debidamente mantenidas con cuchillas afiladas y son más fáciles de

controlar.

7. Use la herramienta eléctrica, los accesorios y las brocas, etc.

según estas instrucciones, teniendo en cuanta las condiciones de trabajo y el trabajo que se vaya a realizar. El uso de la

herramienta eléctrica para operaciones diferentes de las previstas

podría producir una situación peligrosa.

SERVICIO

1. Haga que su herramienta eléctrica por un experto cualificado

que utilice sólo piezas de repuesto idénticas. Esto asegurará

que la seguridad de la herramienta eléctrica.

REGLAS ESPECÍFICAS DE SEGURIDAD

Este es un símbolo de alerta de seguridad. Se utiliza para alertar al usuario ante aquellos posibles

peligros que pueden causar una lesión personal.

Obedezca todos los mensajes de seguridad asociados a este símbolo para evitar posibles lesiones o

la muerte.

4. La máquina está diseñada para ser operada por UNA SOLA

PERSONA. El operario está obligado a controlar el interruptor del

disparador y el cable.

5. Nunca agarre un cable que está girando. Saque o meta el

cable en el envase con la mano solamente cuando el motor

esté detenido. Cuando el motor esté girando, tenga siempre

una mano controlando el disparador y la otra agarrando el

escudo de tracción. Las piezas móviles pueden atrapar las ma-

nos del operario y causarle así una lesión grave.

6. Tenga cuidado al limpiar desagües donde se han utilizado

productos químicos de limpieza. Evite el contacto directo con

limpiadores de desagües que sean corrosivos. La exposición a

esos productos químicos puede causar lesiones al operario y

dañar el cable. Neutralice o quite los limpiadores de desagüe

corrosivos que estén en el desagüe antes de comenzar.

7. No opere la máquina si el operario o la máquina están para-

dos sobre el agua. Ello aumentará el riesgo de descarga eléctri-

ca.

8. Use gafas de seguridad y calzado antideslizante con suela de

goma. El uso de este equipo de seguridad puede evitar graves

lesiones.

9. Antes de comenzar cada trabajo, compruebe que el cable en

el tambor no esté roto ni doblado, sacándolo y revisando si

presenta desgaste o roturas. Reemplace siempre los cables

gastados (que tienen dobleces o están rotos) por cables de repuesto GENERAL auténticos.

10. Utilice esta herramienta sólo en la aplicación para la que fue

diseñada. Siga las instrucciones sobre uso adecuado de la

herramienta. Otros usos o la modificación del limpiador de desa-

gües para otras aplicaciones pueden aumentar el riesgo de lesiones.

Si enchufa la máquina en un tomacorriente alambrado incorrectamente se puede producir una descarga

eléctrica, que puede resultar en la muerte. Si el alambre de conexión a tierra está vivo, usted puede ser

electrocutado con sólo tocar la máquina, incluso

cuando el interruptor de potencia esté apagado. En

esta situación, un interruptor de circuito de falla de la

conexión a tierra no lo protegerá. Use un probador homologado por UL para determinar si la toma de corriente es

segura.

No tense en exceso los cables. La tensión excesiva de

los cables puede causar la torcedura, formación de dobleces o rotura del cable y puede producir graves lesiones.

1. Use sólo guantes de cuero. Nunca use ningún otro tipo de guan-

te, como por ejemplo los de tela, caucho o recubiertos. Nunca

agarre con un trapo un cable que esté girando. Estos artículos

podrían enredarse en el cable y causar graves lesiones.

2. No tense en exceso los cables. Mantenga la mano enguantada

en el cable para tener el control mientras la máquina está en funcionamiento. La tensión excesiva de los cables debido a una obstrucción puede causar la torcedura, formación de dobleces o rotura del cable y puede producir graves lesiones.

3. Coloque la máquina a una distancia de no más de dos pies

del orificio del desagüe. Distancias mayores pueden hacer que

el cable se tuerza o doble.

CARACTERÍSTICAS – Drain-Rooter PH

de tambor cerrado

Asa Perilla de presión

de avance

Cortador

Motor

AVISO: No opere la máquina si faltan las etiquetas de advertencia en

la caja de interruptores y el cordón de fuerza, o si están ilegibles.

Parte trasera

del recipiente

del tambor

Parte delantera

del recipiente

del tambor

Palanca de control

de avance

Manguera guía

(cable en el interior)

Perilla de

poste

frontal

20

Page 21

Drain-Rooter PH™

CARACTERÍSTICAS – Drain-Rooter PH

de tambor abierto

Asa

Cortador

Motor

AVISO: No opere la máquina si faltan las etiquetas de advertencia en

la caja de interruptores y el cordón de fuerza, o si están ilegibles.

Perilla de presión

de avance

Tambor abierto

Palanca de control

de avance

Manguera guía

(cable en el interior)

Perilla de

poste

frontal

Cuadro de aplicaciones de cortadores (Tabla 2)

Nº de

Cortador

Cabeza

de flecha

Cabeza

de flecha

flexible

Gusanilo

Gusanillo

de taladro

Cortador

lateral de

1-1/4 pulg

Catálogo Aplicaciones típicas

AH

FAH

BG

DHBG

1-1/4SCB

Ideal para corte y raspado

pesado.

Más flexible que el de punta

de flecha; puede usarse en

curvas pronunciadas en

líneas pequeñas.

Para sacar o recuperar

objetos sueltos.

Baja el cable por la línea de

desagüe en lugar de subirlo

por el respiradero o a través

de la T.

Trabaja bien en obstrucciones con grasa; raspa las

paredes de la tubería.

INSTRUCCIONES DE OPERACIÓN

CONFIGURACIÓN

INTERRUPTOR DE VELOCIDAD VARIABLE

El mecanismo del gatillo dispone de un control de velocidad variable

integrado. Se puede controlar y aumentar la velocidad de la máquina

aplicando mayor presión al gatillo hasta alcanzar la velocidad deseada.

También se puede controlar el sentido de rotación de la máquina

intercambiando la palanca de avance y reversa, que está ubicada

justo por encima del gatillo. Mueva la palanca hacia la flecha de avance para girar en sentido de avance y hacia la flecha atrás para el

sentido inverso. Ponga en la posición OFF (Apagado) cuando no se

use la herramienta.

Cuadro de aplicaciones de cables (Tabla 1)

Calibre

del cable

1/4 pulg

6.3 mm

5/16 pulg

7.9 mm

3/8 pulg

9.5 mm

Los cables de 1/4 y 5/16 pulgada (6.3 mm y 7.9 mm) de diámetro

con cabezas EL para obstrucciones en lavamanos se pueden

pasar por las crucetas de la mayoría de los filtros y funcionan

bien en líneas bloqueadas por obstrucciones blandas como pelo,

jabón, grasas, etc.

Capacidad máxima: 50 pies de cable de 1/4 ó 5/16 pulg., o 35 pies

de cable de 3/8 pulg.

Tamaño de la tubería

1-1/4 a 2 pulg

30 a 50 mm

1-1/2 a 2 pulgadas

38 a 50 mm

2 a 3 pulgadas

50 a 75 mm

Aplicaciones típicas

Desagües de duchas, tinas y

líneas pequeñas.

Fregaderos, lavamanos y

desagües pequeños.

Bajantes, retretes, desagües

pequeños (sin raíces).

¡DESCONECTE LA MÁQUINA DE LA FUENTE DE ALIMENTACIÓN ANTES DE CONECTAR EL CORTADOR!

1. Deslice el conector por la boca hasta que el resorte se coloque

en posición.

2. El cable puede tener una cabeza de tapón de sumidero EL en el

extremo para ayudar a que el cable pase por curvas cerradas, o

puede tener un conector para conectar cortadores al extremo.

3. Para conectar un cortador, desenchufe primero la máquina. Después, quite el tornillo y la arandela de traba del conector en el

extremo del cable. Deslice el cortador en la ranura y después

vuelva a colocar la arandela de traba y el tornillo de conexión.

Apriete firmemente el tornillo.

4. La barrena de perforación y el cabezal de flecha son buenos