Page 1

JM-1450™ Electric Jet

Operating Instructions

For 2” to 4” lines up to 150 ft. long

Your JM-1450 Jet-Set electric water jet

is designed to give you years of troublefree, profitable service. However, no machine is better than its operator.

Read, understand and follow all safety

warnings and instructions provided with

the product. Failure to follow the warnings

and instructions may result in electric

shock and/or serious injury. Save all warnings and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Pour français voir la page 11

Para ver el español vea la paginá 21

Page 2

Jet-Set JM-1450™

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious personal injury.

Replacement manuals are available upon request at no

charge, or may be downloaded from our website,

www.drainbrain.com. Instructional videos are available

for download on our website, and may be ordered. If you

have any questions or problems, please call General’s

customer service department at 412-771-6300.

SAVE THESE INSTRUCTIONS!

These instructions are intended to

familiarize all personnel with the safe operation

and maintenance procedures for the JM-1450.

Electric shock resulting in death can

occur if you plug this machine into an

improperly wired outlet. If the ground

wire is electrified, you can be electrocuted by just touching the machine,

even when the power switch is off. A

ground fault circuit interrupter will not

protect you in this situation. Use a UL

approved tester to determine if the outlet

is safe.

Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases,

or dust. Power tools create sparks which

may ignite the dust of fumes.

Do not spray flammable liquids. Risk

of explosion. Flammable liquids can create fumes which can ignite causing property damage or severe injury.

SAFETY SYMBOLS

This is the safety alert symbol. It is used

to alert you to potential personal injury

DANGER indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

Do not direct discharge stream at people. This equipment can produce a high

pressure stream of fluid that can pierce

skin and its underlying tissues, leading to

serious injury and possible amputation or

death.

Always wear safety glasses and rubber soled, non-slip shoes. High pres-

sure spray can cause paint chips or

other particles to become airborne

and fly at high speeds. Use of this

safety equipment may prevent serious

injury.

WARNING

This product can expose you to chemicals including lead,

which is known to the State of California to cause cancer and

birth defects or other reproductive harm. For more information

go to www.P65Warnings.ca.gov.

CAUTION indicates a hazard with a low level of risk which, if not

avoided, will result in minor or moderate injury.

2

Page 3

Jet-Set JM-1450™

GENERAL SAFETY RULES

WARNING

Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire, and/or

serious injury.

SAVE THESE INSTRUCTIONS!

WORK AREA SAFETY

1. All installations must comply with local codes. Contact your

electrician, plumber, utility company or the selling distributor for

specific details. To comply with the National Electrical code (NFPA

70) and provide additional protection from risk of electric shock,

the machines are equipped with a UL approved ground fault circuit

interrupter (GFCI) power cord.

2. Risk of explosion. Do not spray flammable liquids or operate

in an area where flammable or explosive materials are used

or stored. Power tools create sparks which may ignite dust and

fumes.

3. Keep bystanders, children, and visitors away while operating

machine. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Grounded tools must be plugged into an outlet, properly installed and grounded in accordance with all codes and ordinances. Never remove the grounding prong or modify the

plug in any way. Do not use any adapter plugs. Check with a

qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tool should electrically malfunc-

tion or break down, grounding provides a low resistance path to

carry electricity away from the user.

2. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

3. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

4. When operating a power tool outside use an outdoor exten-

sion cord marked “W-A” or “W”. These cords are rated for outdoor use and reduce the risk of electric shock.

5. Test the Ground Fault Circuit Interrupter (GFCI) provided with

the power cord to insure it is operating correctly before operating machine. Machine must have a properly functioning ground

fault circuit interrupter on the power cord. GFCI reduces the risk of

electric shock.

6. Extension cords are not recommended unless they are

plugged into a Ground Fault Circuit Interrupter (GFCI) found

in circuit boxes or outlet receptacles. The GFCI on the ma-

chine power cord will not prevent electric shock from the extension

cords.

7. Only use proper three-wire extension cords in good condition

of no more than 50 ft. in length which have three-prong

grounding plugs and three-pole receptacles which accept the

tools plug. Use of damaged, inferior, or other extension cords will

not ground the tool, increases the risk of damage to the machine,

electric shock, bodily injury or death.

8. Keep all electric connections dry and off the ground. Reduces

the risk of electric shock.

9. DO NOT touch plugs or tools with wet hands. Reduces the risk

of electric shock.

GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

Your machine is equipped with a ground fault circuit interrupter, which

protects you against shock if a short circuit should occur. Check that

receptacle is properly grounded. Test the GFCI before each use.

1. Plug into 120-volt receptacle.

2. Push test button. Indicator light will go out and power to machine

should cut off.

3. If light does not go out when test button is pushed, DO NOT USE

THE MACHINE until proper repairs can be made.

4. To restore power after test, push reset button. With the reset button depressed, if the machine doesn't start, stops while running, or

if the operator experiences a mild shock, DO NOT USE THE MA-

CHINE! Tag the machine out of service and take it to a motor

repair center or return it to the factory for repairs.

PERSONAL SAFETY

1. High pressure developed by jet machines will cause personal

injury. Water spray should not be pointed at any person. High

pressure spray can result in serious injury. If fluid seems to have

penetrated the skin, seek emergency medical attention at once.

2. Grip jet hose or spray wand securely with both hands before

starting the machine. Failure to do so could result in injury from a

whipping hose or wand.

3. Always wear eye protection and rubber gloves. Safety equipment, eye safety devices, non-skid safety shoes and protective

clothing must be worn when using this equipment.

4. Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A mo-

ment of inattention while operating power tools may result in serious personal injury.

5. Dress properly. Do not wear loose clothing or jewelry. Con-

tain long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long hair can be caught

in moving parts.

SERVICE

1. Tool service must only be performed by qualified service

personnel. Service or maintenance performed by untrained per-

sonnel could result in injury and damage to the equipment.

2. When servicing tool, use only identical replacement parts.

Follow instructions in maintenance section of this manual.

Use of unauthorized parts or failure to follow maintenance instructions may cause injury or damage to equipment.

JET SAFETY

1. Do not operate jet above rate pressure or above 140 degrees

(rated water temperature). Operating jet above rate specifica-

tions risks damage to the pump and related components, and will

void the warranty.

2. Do not operate jet with the output valve in the off position for

extensive periods of time. This will cause the water to overheat

and damage the pump.

3. Never run pump without water in it. Operating the machine

without water will cause the pump to fail and void the warranty.

3

Page 4

Jet-Set JM-1450™

4. Check for worn hose and components before each use.

Check that all fittings are secured before using jet. Worn or

lose fittings can cause damage to the machine and injure the operator.

5. Protect machine and pump from freezing. Storing or operating

the jet in temperatures below freezing can damage pump, hose

and other jet components. Store unit indoors or protect with antifreeze when not in use.

6. General Wire Spring Co. will not be liable for any changes

made to our standard machines or any components not purchased from General Wire Spring Co.

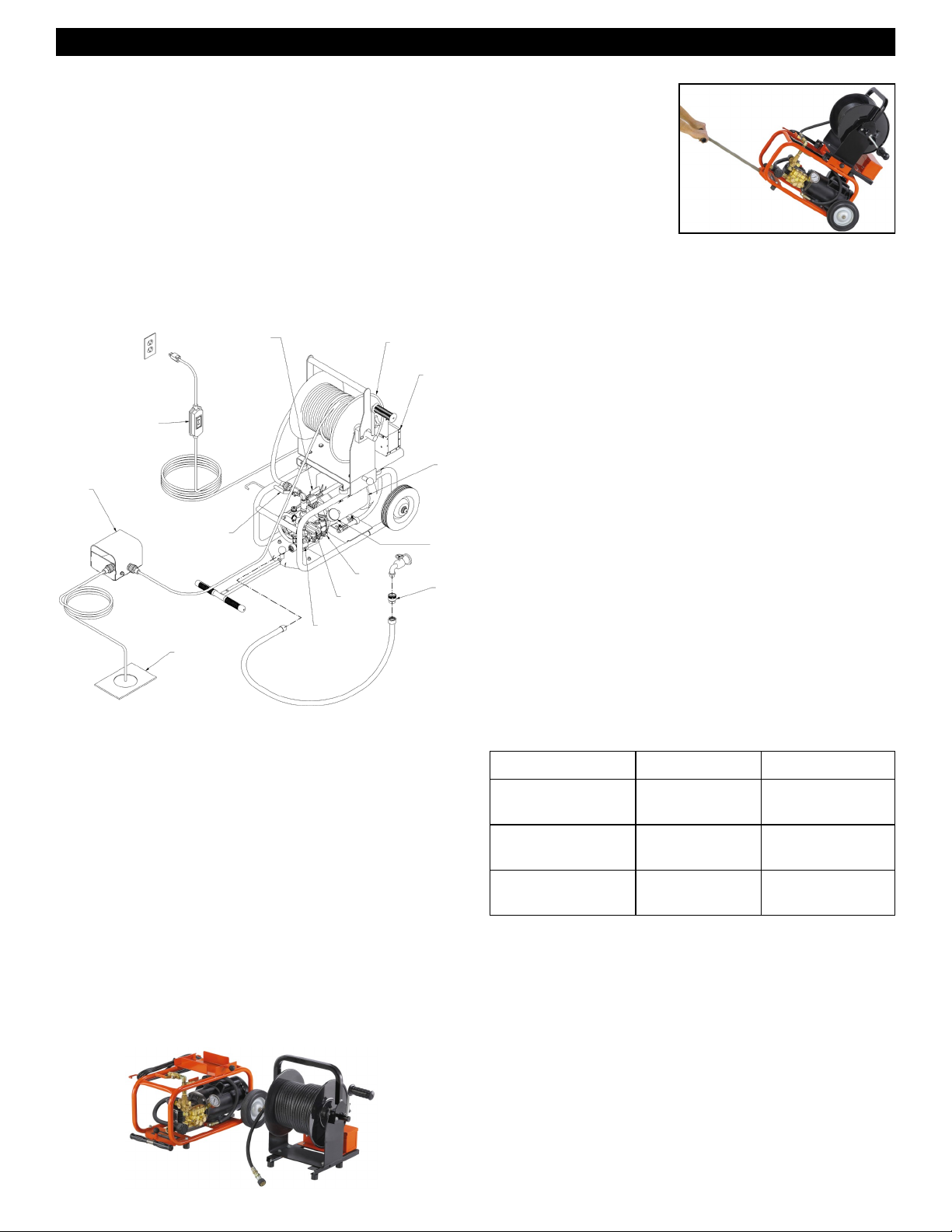

JM-1450 SPECIFICATIONS

3

2

1

12

10

11

13

1. Foot Pedal (optional)

2. GFCI

3. Vibra-Pulse Control Valve

4. Hose Reel

5. Tool Box

6. Motor

7. Pressure Gauge

8. Anti-Siphon Valve

9. Pump

10. Unloader

11. Inlet Filter

12. Pressure Control Valve

13. Drain

REMOVABLE HOSE REEL

The JM-1450 features a removable hose reel. It easily detaches in

seconds to make the machine more compact to fit in small spaces in

your truck, or crawl spaces under a building, or to more easily carry

the machine up to a roof to clear lines via the roof vents. To remove

reel, unscrew twist connect at the output valve, then simply pull the

knob at the base of the hose reel, then lift the reel. To reattach reel,

align the slot in the base of the reel with the tab on the support

bracket. Then seat reel into bracket and allow the knob to snap back

into place.

4

5

6

7

9

8

SLIDE OUT HANDLE

A convenient slide-out handle

makes the JM-1450 really portable. Lift the knob and extend

the handle, then roll the machine to and from the job on the

8” wheels. Lift the knob to slide

the handle back into place.

JET HOSE

1. When selecting hose size, consider that pressure is lost as the

water travels down the length of the hose. As the length increases,

the pressure decreases. In addition, the smaller the diameter of

the hose, the greater the loss of pressure per foot will be. As an

example, a 2 GPM a 1/4” hose will lose 180 lbs. of pressure over

100 ft. of hose, yet a 3/8” hose will only lose 25 lbs. of pressure

over the same length and at the same flow rate. At 4 GPM, a 3/8”

hose will lose 90 lbs. of pressure over a 100 ft. length. The gauge

reflects pressure from the pump only, not pressure at the end of

the hose. It is important to select the largest possible hose size in

order to have as much pressure as possible at the end of the

hose.

2. Hoses of the same diameter may be coupled together using the

CC-1 coupling, but it is not recommended for use in lines smaller

than 8” in diameter. The long length of the hose connectors and

coupling together can get caught in bends in the line. It is not advisable to have two different hose sizes coupled in a drain line.

There is a tremendous loss of pressure when combined, aside

from the difficulty of getting around bends.

3. The 3/8” and 1/4” hoses may be attached to the fitting in the core

of the hose reel using the swivel at one end of the hose. The 1/8”

accessory hose may also be attached directly to the output valve

by using the twist connect supplied on the hose.

HOSE SELECTION GUIDE

Hose Size (ID*) Pipe Size Typical Applications

1/8”

(3.175mm)

1/4”

(6.350mm)

3/8”

(9.925mm)

* Inside Diameter

1-1/2” - 2”

(38mm - 51mm)

2” - 4”

(51mm - 102mm)

4” - 8”

(102mm - 230mm)

Small lines, bathroom

sinks, tight bends

Kitchen sinks, laundry

drains, clean outs

Floor drains, septic

lines, long runs

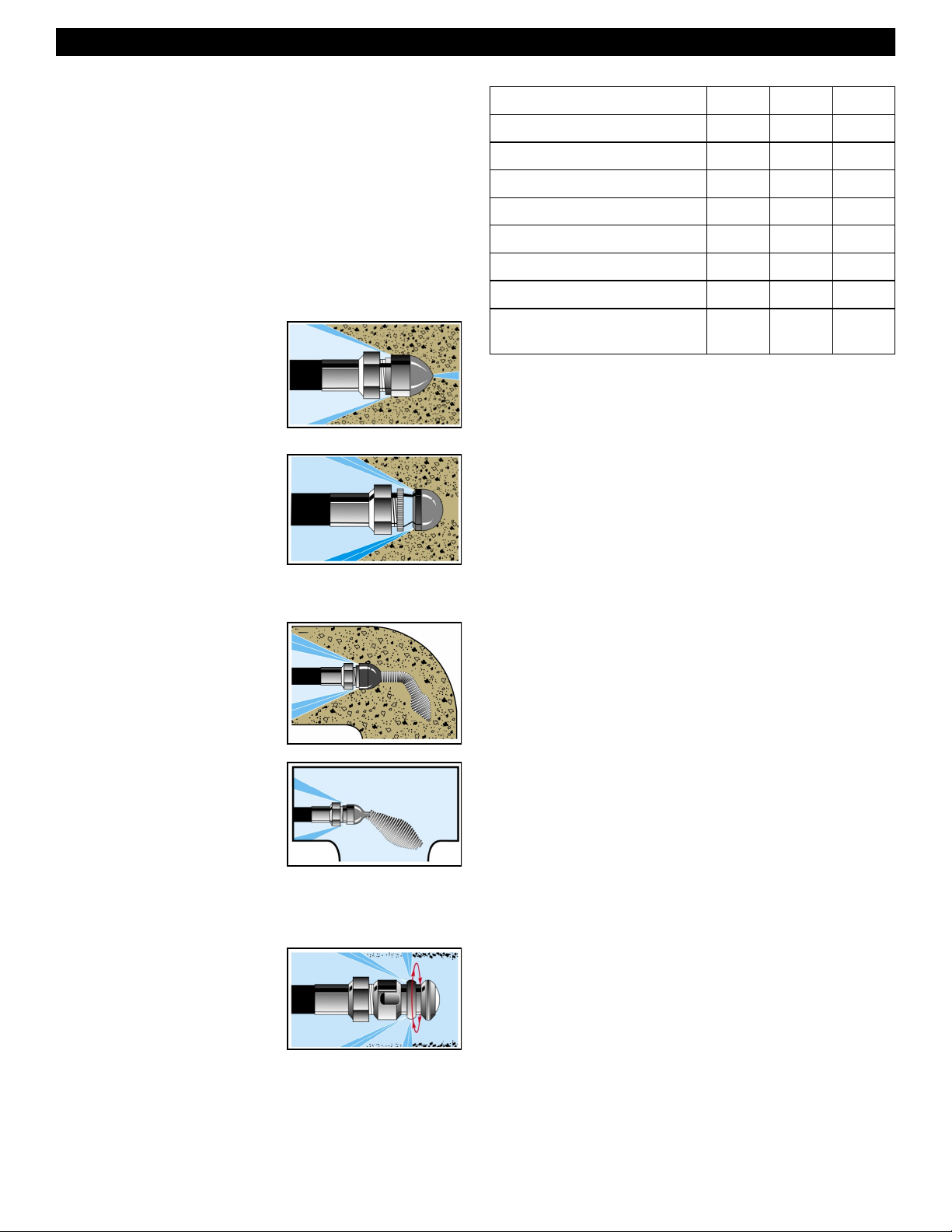

JET NOZZLES

1. A variety of jet nozzles are available for drain cleaning. Each has a

different spray pattern and purpose. Some nozzles may have an

orifice in the front to cut through the stoppage. All will have holes

in the back to drive the hose down the line and clean the walls of

the pipe. A tight spray pattern (15°) has more driving power for

long runs, a wide spray pattern (40°) does a better job of cutting

the grease off of the walls of the pipe. A combination of nozzles

may be required to clear a line. Always turn off the machine and

turn off output valve before changing nozzles.

4

Page 5

Jet-Set JM-1450™

2. Make sure the nozzle you are using matches the pump size. A

3000 psi pump requires a different nozzle orifice than a 1500 psi

pump. Mismatching nozzles with pump size will either cause too

little pressure, which may not clear the drain, or too much pressure, which may damage the machine.

3. Check nozzles before and after each use for clogged holes which

can cause pressure to increase to dangerously high levels and

damage the pump. A clogged hole can be cleared by simply using

the NCT Nozzle Cleaning Tool.

4. Use the nozzle selection guide to determine what nozzle you will

need for various applications. Examples: If a nozzle is stamped

#12, it is a JN-12, drilled for 1.7 GPM @ 1500 PSI with several

15° rear jets and one forward cutting jet.

Powerful penetrating nozzle cuts

through grease and ice.

Wide spray flushing nozzle cleans

inside of pipe thoroughly.

SPECIALTY NOZZLES

Spring leader nozzles and down head

nozzles are special nozzles to help

hose travel through the pipe when

there are a lot of Tee’s, curves, and

bends.

NOZZLE SELECTION GUIDE

HOSE SIZE 1/8” 1/4” 3/8”

CAT # CAT # CAT #

15° Rear Jets w/No Forward Jet JN-1 JN-11 JN-21

15° Rear Jets w/One Forward Jet JN-2 JN-12 JN-22

30° Rear Jets w/No Forward Jet JN-3 - -

40° Rear Jets w/No Forward Jet - JN-14 JN-24

Spring Leader JNSL-1 JNSL-2 JNSL-3

Down Head Nozzle JNDH-1 - -

Rotary Nozzle* (Optional) - JNRA-2

* Rotary Nozzles can be adapted to 1/8” and 3/8” hose using AD-3 or

AD-4 adapters.

-

JNRB-2

JET ASSEMBLY

Upon arrival, inspect the shipping crate for damages. Uncrate and

examine all parts. Note any damage to machine or components

for claims against freight carrier.

Jet must be stored and operated in horizontal position. Never

store in upright position or oil may leak from pump. If low, fill with

SAE 30 weight non-detergent oil.

Jet machines are meant to be used at or near the working area

and under operator supervision. If machine must be located out of

sight of operator, special controls may be required for proper machine operation and operator safety

ROTARY NOZZLES

Rotary nozzles are useful as a finishing

tool. After the line has been cleared,

you may switch to the rotary nozzle to

more thoroughly clean the walls of the

pipe. Use these nozzles only in a predominantly straight run since they are

longer than regular nozzles and may

get caught in tight bends.

OPERATION

SET-UP

1. Locate the jet near the drain line on a level surface with drainage.

Tip: Ideally, the drain line should be cleared from the downstream

side, that is, from the street back toward the house. If you must

clear the line from the drain toward the street, you may need to

use a siphon pump to clear away excess water.

2. Check the oil level in the pump. If low, fill with SAE 30 weight nondetergent oil.

3. Check the inlet filter to make sure it’s clean before each use. To

clean, unscrew filter cap, remove the screen and rinse thoroughly

with water. Then, replace screen.

4. Check that incoming water supply is clean and free of debris.

Turn the water source on for at least 15 seconds to remove any

possible debris in the water before connecting hose to water inlet.

5. Connect one end of a water supply hose (not included) to the water supply and the other end to the water inlet of the jet machine.Water supply must be a minimum of 20 psi and not to exceed 100

psi. Caution: Water temperature must not exceed 140 degrees or

damage to the pump can occur. Use only heavy duty 3/4” hose of

5

Page 6

Jet-Set JM-1450™

no more than 50 ft. in length. If run without an adequate water

supply, the pump will cavitate. Cavitation causes the pump to vibrate, causing damage to the pump. Note: Lack of water supply

can lead to seal damage, causing a loss of pressure and will void

the warranty to the pump.

6. Maximum temperature from the water source should not exceed

140°F (60°C). Using water hotter than 140°F (60°C) can cause

damage to the pump and void the warranty. If jet is being used to

clear ice blockages, see instructions on Ice Blockages.

7. Select the proper hose diameter for the line to be cleaned. When

using new hose, run water through it to clean it out before attaching the nozzle.

OPERATION

NEVER POINT THE END OF THE JET HOSE AT A

PERSON WHILE OPERATING.

1. Select the correct jet hose size to match the line size you are

clearing. (See Hose Section Guide) Check all hoses for wear and

damage. Tighten all connections securely.

2. Select the correct nozzle and attach to the end of the hose. (See

Nozzle Selection Guide) Note: If you are using a new jet hose, run

water through it to flush out debris before connecting a nozzle.

3. Insert the jet hose 2 to 3 feet into the drain line before turning on

machine.

4. Turn on the water supply valve fully to allow for maximum flow.

5. Turn on the jet output valve and allow water to run through the

supply hose, jet, and jet hose to purge air from system before

turning on the machine.

6. Make sure that the output valve is turned on and the water is flowing.

7. Plug in GFCI power cord to proper receptacle and voltage.

8. While holding onto hose firmly to prevent hose from whipping

around, turn the jet motor switch on.

9. Guide the jet hose into the drain line. Do not feed the hose continuously, but rather, move the hose forward and back to allow the

pressure to break up the stoppage and the water flow to flush it

away. If you are clearing the line from the upstream side, this may

take more time. Clearing the line from the downstream side allows

debris to flow away easily.

10. It is often helpful to turn on the Vibra-pulse valve. The vibration

generated helps to hose overcome the friction in the line and glide

farther down the line. See Vibra-pulse section.

11. When the jet hose encounters a bend, it’s advance will usually

slow or stop. The hose has a slight bend in it from the hose reel. It

may be necessary to manually feed or rotate the jet hose to work it

around the bends. If the hose won’t advance, put the hose in a

loop and rotate it a quarter to half turn so the curve of the hose

matches the pipe. It may also be necessary to pull the hose back

six inches and snap it forward to hop across a gap in the pipe

fitting.

12. Once you reach the stoppage, pass the hose back and forth

through the section several times to ensure the line is thoroughly

cleared. You may also switch nozzles to a wide spray or rotary

(optional) nozzle for wall to wall cleaning action.

VIBRA-PULSE®

Pulsation makes the hose vibrate, helping the jet go longer distances

and around tight bends easier. The pulse control valve is located on

the front of the pump. Simply turn the valve on to engage the

pulse. Vibra-pulse is most effective in a 1/8” hose. You’ll notice less

vibration with a 1/4” hose, and almost none with a 3/8” hose. How-

ever, the pulse is still effective, causing the water to burst from the

nozzle hundreds of times per second. If you are still having difficulty

getting hose around a tight bend, switch to a smaller diameter hose.

SHUT DOWN INSTRUCTIONS

After drain cleaning or spray washing is completed, run clear water

through the system. Always leave the output valve in the on position

when turning off motor. Turn off water supply and drain as much water

from the pump as possible. Remove water supply hose from inlet. If

you are in a cold climate, see Freeze Protection section.

SPECIAL APPLICATIONS

ICE BLOCKAGES

High pressure water can be used to clear an ice blockage. A 3000 psi

gas jet can clear a 4” line at an approximate rate of one foot per min-

ute. The smaller, electric jet will take twice as long. Ambient air temperature will effect these times. Use a 15° nozzle with a forward jet.

DO NOT allow the incoming water supply to exceed 140°F (60°C) or

it could cause damage to the pump. Remember to follow the cold

weather precautions found in the Freeze Protection section.

FREEZE PROTECTION

To protect your machine from severe damage caused by water freezing inside the components, it is important to winterize it whenever it is

subjected to freezing temperatures.

The best way to protect the system is to keep it out of the cold. Barring that, the next best way is to flush the system with anti-freeze. To

do so, simply attach a short garden hose (not to exceed four feet) to

inlet on the pump and put other end into the anti-freeze container. Be

sure to remove the nozzle from the hose. Turn the machine on to

draw anti-freeze into the system. When anti-freeze flows out of the

end of the hose, turn the machine off. Connect high pressure hose

and trigger, and follow above procedure. Cycle trigger on/off so that

the anti-freeze will flow into unloader and injector section of machine.

When preparing to operate equipment for the next job, remove the

anti-freeze. To do so, reconnect water source, turn pump on and

direct flow of anti-freeze back into container. Be careful not to dilute

anti-freeze with incoming water supply. Anti-freeze, if kept relatively

undiluted, can be used again and again.

Hoses can also be protected from freezing by using compressed air to

clear them of residual water. Remember to remove nozzle from jet

hose and hold trigger of spray wand in open position.

ADJUSTING PRESSURE UNLOADER

The machine is equipped with a regulating pressure unloader to prevent pressure overload in the event that the nozzle is clogged or the

output valve or spray wand trigger is off. When the machine is in the

bypass mode, the pump will continue to run. However, running in

bypass mode for extended periods will cause damage to the pump no more than 5 minutes with the J-1450 pump. Excessive temperatures will damage the pump and void the warranty.

6

Page 7

Jet-Set JM-1450™

If you are operating the electric jet with limited amperage available,

you can reduce the amp draw of the machine by turning down the

unloader. By turning the pressure down to 1000 psi, you can reduce

the amp draw to less than 10 amps. To adjust the unloader, loosen

the lock nut and turn the knob counter-clockwise to decrease pressure

and clockwise to increase pressure. Caution: Do not over-tighten

unloader. Tighten lock nut after adjustments are made.

ACCESSORIES

HANDY-REEL WITH FOOT PEDAL - Cat # HM-200-W

(OPTIONAL)

The Handy-Reel allows for remote application of the jet. The jet can

be positioned at ground level, while the Handy-Reel can be carried up

on a roof to clear vents and stacks. With the help of the Handy-Reel,

gas jets can be used for indoor applications while the machine operates safely outside. The Foot Pedal interrupts the flow of water between the pump and the nozzle while leaving both hands free to guide

the hose. Position the Handy-Reel at the drain site. Connect the jet

machine to the inlet on the Foot Pedal. Select and attach nozzle to the

hose on the reel. Put the hose 2 to 3 ft. into the drain line. Follow the

start-up procedures.

FOOT PEDAL ONLY - Cat # FM-1 (OPTIONAL)

The Foot Pedal can be used with any jet manufactured by General. It

interrupts the flow of water between the pump and the nozzle while

leaving both hands free to guide the hose. The pump will continue to

run in by-pass mode. Do not leave pump in by-pass for more than a

few minutes or the pump can be damaged. (See Pressure Unloader)

The Foot Pedal may be connected either at the machine or remotely

at the drain site. To use the foot pedal at the machine, remove the

hose going to the swivel on the hose reel and attach it to the inlet side

of the Foot Pedal. Then, connect the accessory hose (available in 6

ft., 25 ft., or 50 ft. lengths) between the outlet of the pedal and the

swivel on the hose reel. Some jet models may need the added length

of the accessory hose on the inlet side of the pedal.

For remote operation, pull the hose from the hose reel to the drain

site. Attach the hose to the inlet of the pedal. The pedal is designed

for 3/8” hose fittings. If using a 1/4” hose, use the AD-1 adapter, as

well. Then, attach the smaller hose (1/8” or 1/4”) to the outlet side of

the pedal. Use the smaller hose to clear the drain line.

SPRAY WAND - Cat # SWA-1500 (OPTIONAL)

USE CAUTION WHEN PRESSURE WASHING. WEAR

GOGGLES AND RUBBER GLOVES AND BOOTS.

ANALYZE ANGLE OF SPRAY AND ANTICIPATE

ANGLE OF BACK SPLASH. DO NOT POINT SPRAY

AT ANYONE, INCLUDING YOURSELF. DO NOT PUT

YOUR HAND IN FRONT OF WATER SPRAY. IT CAN

PENETRATE THE SKIN AND CAUSE A NEED FOR

AMPUTATION. IT IS BEST TO START AT A 45°

ANGLE AT A 7 TO 10 FT. (2 TO 3M) DISTANCE FROM

OBJECT TO BE CLEANED. DIRECT SPRAY AT

CLOSE RANGE CAN BE POWERFUL ENOUGH TO

CAUSE DAMAGE.

The Spray Wand can be used to clean your truck or other applications. Caution: Never clean the machine with its own spray. Follow

the same procedures listed previously for safety, set-up, operation,

and maintenance. To operate the spray wand with your water jet,

disconnect the twist connect at the output valve. Then, connect the

spray wand hose, trigger and wand at the output valve. Turn on the

water supply, then squeeze the trigger to purge air from the system.

Continue to squeeze trigger as you turn on the machine.

Hold the high pressure spray nozzle approximately 6 – 8 ft. from the

surface to be cleaned. When cleaning with a detergent, apply from

bottom up with an even left to right movement. Rinse from top down

with a similar motion. This will help reduce potential streaking. Always

apply soap to a dry surface. This will enhance penetration and detergent cling and reduce dilution of detergent with an already wet surface.

You may draw soap through the spray wand in conjunction with the

optional chemical injector. First set up the Chemical injector system

(see Chemical Injector). Then, simply turn the nozzle barrel on the

end of the wand counter-clockwise. As the spray pattern widens, more

of the detergent will be drawn through the wand. Turn the nozzle

clockwise to reduce the detergent flow and narrow the water spray

pattern to return to high pressure.

CHEMICAL INJECTOR – Cat # CMA-1 (Optional)

To use the chemical injector, disconnect the Twist Connect at the

output valve on the jet. Then thread the Chemical Injector on to it. The

Spray Wand then threads onto the free end of the Chemical Injector.

Do not attach Chemical Injector to the inlet side of the pump. Detergents can damage pump.

To use the detergent injector, attach one end of the siphon hose to

the barbed fitting on the injector and put the filter end into the detergent solution. Be sure the end of the hose is at the bottom of the container or bucket. Some models have adjustable valves to control the

amount of detergent drawn through the hose.

MAINTENANCE

DISCONNECT JETTER FROM POWER SOURCE

BEFORE PERFORMING MAINTENANCE OR MAKING

ANY ADJUSTMENTS.

Regular inspection is the key to preventing breakdowns and prolonging the life of the equipment. Follow this simple procedure religiously.

DAILY

Check INLET FILTER for debris before each use.

Check that the PUMP OIL LEVEL is within operating range on

dipstick or sight glass.

Check that the jet nozzles are not clogged or worn out.

WEEKLY

Check the pressure hose for wear and damage. . Damaged hose

can be repaired at a local service dealer of by your equipment

dealer.

Pump Crankcase Oil Change: Service after the 1st month, or after

20 hours. Then service every year or 500 hours. Use SAE 30W NonDetergent Motor Oil to full mark on dipstick or to dot on sight glass.

7

Page 8

Jet-Set JM-1450™

TROUBLE SHOOTING GUIDE

Problem Probable Cause Solution

Low pressure. Worn, clogged, or oversized nozzle. Clean or replace worn nozzle. Check nozzle size.

Clogged water inlet strainer. Clean or replace strainers.

Rough operation with loss of

pressure.

Water leakage at intake

manifold or crankcase.

Inadequate water supply.

Make certain water supply valve is on fully. Make certain water

supply hose is at least 3/4” in diameter, in good condition, with

no kinks or damage, and is not longer than 50 ft.

Worn or damaged piston cups. Replace piston cups.

Worn or damaged inlet or discharge valve. Replace worn valve poppets or valve springs.

Dirt or foreign particles in valve assembly. Remove any dirt particles.

Air leak in inlet plumbing. Locate air leak. Re-seal connection or replace damaged port.

Restricted inlet plumbing or air leak in inlet

plumbing.

Damaged piston, cup or pump valve.

Repair clogged inlet fittings. Check supply hose and ensure

adequate water supply.

Replace any damaged pump parts and clean out any foreign

particles.

Clogged nozzle. Clean or replace nozzle.

Worn manifold seals, piston or o-rings, or

condensation inside crankcase.

Inadequate water supply to pump, creating a

Replace seals, sleeves or o-rings. Change oil at regular intervals.

Ensure adequate tap water supply. Clear inlet filter.

vacuum lock.

Oil leaks.

Worn pistons and/or leaking crank seals,

Replace seals, sleeves or o-rings.

crankcase cover seal, or drain plugs.

Excessive wear. Worn or loose bearings.

Replace bearings. Check bearing seals, spacers and retainers.

Replace any worn parts.

Short pump life.

Scored cylinders from pumping acids.

Replace cylinders. Do no pump acid solutions. For acid application, ask your dealer for a pump saver injector.

Abrasive particles in fluid being pumped.

Replace water and detergent strainers if damaged or missing.

Install additional filter if fine abrasives are still evident.

Operator(s) running pump without water

Do not allow jet to be run without proper water supply.

supply.

Hot water in pump.

Do not run in bypass for more than 5 minutes. Do not let water

supply exceed 140°F (60°C).

Irregular spray pattern. Worn or partially clogged nozzle. Clean or replace nozzle.

8

Page 9

TROUBLE SHOOTING GUIDE continued

Problem Probable Cause Solution

Jet-Set JM-1450™

Washer fails to draw detergent.

Detergent solution too weak. Clogged detergent strainer. Clean or replace strainer.

Detergent solution too concentrated.

Detergent in rinse cycle.

Detergent metering valve closed, or

valve clogged or defective.

Back pressure in hose (when using

additional lengths of pressure hose).

Back pressure in pressure hose (when

using dual lance wand).

Suction tube not below liquid surface.

Clogged or damaged suction strainer. Clean or replace strainer.

Air leak in detergent suction tube or

inlet plumbing.

Original detergent too concentrated. Dilute product as necessary to achieve proper concentration.

Dual lance wand or adjustable nozzle

holder in open position or chemical

metering valve open.

Open detergent metering valve, following procedure in operating

instructions.

Contact dealer for proper injector size when adding lengths of

hose.

Use proper size flood nozzle in dual lance wand (refer to parts

breakdown).

Completely submerge suction tube and strainer in detergent

solution.

Find air leak and clean or replace parts as necessary.

Close dual lance wand adjustable lance holder to achieve high

pressure. Close detergent metering valve.

Worn or defective internal check valve. Repair or replace check valve or injector parts as necessary.

Dilution of detergent concentrate

during cycle.

Unloader cycles. Fitting leaking downstream. Tighten/replace fitting.

Fluid leaking from body. O-ring worn or cut. Replace part as necessary.

Unloader will not come to pressure.

Defective check valve in detergent

tank.

Piston or valve spring broken or worn. Replace parts as necessary.

Clogged nozzle. Clean or replace nozzle.

Foreign particle in valve. Clean or replace valve.

Nozzle worn or wrong size. Replace part as necessary.

Piston or valve worn. Replace part as necessary.

Adjusting nut turned completely into

unloader.

Clogged nozzle. Clean or replace nozzle.

Replace parts as necessary.

Back off adjusting nut. Extreme pressure spikes.

See pages 30 - 31 for Parts List and Schematic Diagram.

9

Page 10

Jet-Set JM-1450™

10

Page 11

DELETE

Jet-Set JM-1450™

Page 12

Jet-Set JM-1450™

JM-1450 PARTS LIST

ITEM DESCRIPTION PART # QTY ITEM DESCRIPTION PART # QTY

1 HOSE REEL HANDLE JM7-0225A01 1 38 UNLOADER JM8-0629 1

2 DECAL - WARNING/OPERATION

SEWER JET ELEC (SEE JM71-0001)

3 COMPONENT TOOL BOX JM20-1213A64 1 40 NIPPLE JM24-0010 1

4 BOLT JM27-0015 2 41 BALL VALVE JM22-0494 2

5 WASHER JM28-0002 10 42 SCREW NIPPLE JM23-0493 1

6 13" HOSE REEL ASSEMBLY JM50-0191 1 43 HANDLE GRIP JM7-0226 1

7 NUT N/A 1 44 HANDLE GRIP JM7-0230 1

8 BOLT N/A 1 45 REDUCER JM23-0017 2

9 HOSE REEL N/A 1 46 PRESSURE GAUGE JM22-0466 1

10 EDGING *(ONE FOOT REQUIRED) JM33-0020 1 47 TEE JM23-0127 1

11 HOSE REEL SWIVEL JM24-0335 1 48 DECAL - WARNING RISK OF INJECTION/

12 LOCKNUT JM30-0155 8 49 CLIP JM33-0291 1

13 HOSE REEL MOUNTING PLATE JM20-1218A01 1 50 HOSE - 24" LONG JM15-0308 1

14 WASHER JM28-0003 8 51 TAG - WARNING RISK OF

15 LOCKNUT JM30-0157 9 52 CABLE TIE JM33-0022 1

16 ISOLATOR JM14-0069 4 53 MOTOR ASSEMBLY JM851-0388 1

17 BOLT JM27-0016 4 54 DECAL-ON/OFF

18 SCREW COUPLER JM23-0490 1 55 DECAL - WARNING BACKFLOW

19 HOSE - 18" LONG JM15-0313 1 56 DECAL - WARNING RISK OF

20 HUB CAP JM33-0055 2 57 HANDLE GRIP JM7-0167 1

21 WHEEL JM14-0124 2 58 DECAL - ON/OFF JM-1450

22 FRAME JM5-0305A64 1 59 DECAL - CAUTION/IMPORTANT - (E/S)

23 WASHER JM28-0022 10 60 DECAL- SILVER STICKER N/A 1

24 BOLT JM27-0067 8 61 LOCKWASHER JM29-0008 4

25 SPRING PIN JM43-0138 1 62 KEY JM43-0072 1

26 BOLT JM27-0850 2 63 POP-OFF VALVE JM22-0046 1

27 ISOLATOR JM14-0119 2 64 HEAT DUMP VALVE JM22-0408 1

28 SHOULDER SCREW JM27-0895 2 65 DECAL - JM-1450 BASEPLATE

29 SPRING JM49-0165 2 66 DECAL - JM-1450 1500PSI MAX

30 HANDLE JM7-0224 1 67 BOLT JM27-0117 4

31 HANDLE GRIP JM7-0143 2 68 DECAL - PUMP INSTRUCTIONS

32 BALL KNOB JM7-0223 2 69 PUMP JM3-0367 1

33 BYPASS HOSE JM15-0020 1 70 TAG - IMPORTANT OIL PLUG JM34-1067 1

34 HOSE CLAMP JM42-0011 2 71 HOSE BARB JM23-0073 1

35 ELBOW JM23-0123 1 - DECAL SET/JM-1450 JM71-0001 1

36 FILTER JM19-0207 1

37 ELBOW JM24-0105 2

N/A 1 39 TEE JM24-0184 1

N/A 1

EXPLOSION (SEE JM71-0001)

JM34-1035 1

ELECTROCUTION

N/A 1

(SEE JM71-0001)

N/A 1

PROTECTION (SEE JM71-0001)

N/A 1

ELECTROCUTION (SEE JM71-0001)

N/A 1

(SEE JM71-0001)

N/A 1

(SEE JM71-0001)

N/A 1

(SEE JM71-0001)

N/A 1

(SEE JM71-0001)

N/A 1

(SEE JM71-0001)

*MUST ORDER IN ONE FOOT LENGTHS

30

Page 13

Jet-Set JM-1450™

31

Page 14

Jet-Set JM-1450™

JM-1450 PUMP ASSEMBLY PARTS LIST

ITEM DESCRIPTION PART # QTY ITEM DESCRIPTION PART # QTY

1 VALVE PLUG JM39-0241 6 27 OIL CAP JM39-0090 1

2 O-RING - 15.6mm X 1.78mm

(SEE 70-0565)

3 COMPLETE VALVE (SEE 70-0456) N/A 6 29 WASHER JM26-0187 3

4 SCREW N/A 8 30 PISTON JM46-1459 3

5 WASHER N/A 8 31 SPACER JM28-1027 3

6 HEAD N/A 1 32 SEAL (SEE 70-0566) JM26-0193 3

7 O-RING (SEE 70-0565) JM25-0372 1 33 O-RING (SEE 70-0565) JM25-0371 3

8 PLUG JM39-0202 1 34 PISTON GUIDE N/A 3

9 O-RING (SEE 70-0565) JM25-0510 1 35 CONNECTING ROD N/A 3

10 PLUG JM39-0206 1 36 CONNECTING ROD PIN JM46-0721 3

11 RING (SEE 70-0563) N/A 3 37 O-RING (SEE 70-0565) N/A 1

12 GASKET (SEE 70-0581) N/A 3 38 REAR COVER JM46-1455 1

13 PACKING RETAINER JM46-1457 3 39 O-RING (SEE 70-0565) JM25-0387 1

14 GASKET (SEE 70-0581) N/A 3 40 PLUG JM9-0096 1

15 RING (SEE 70-0581) N/A 3 41 SCREW N/A 4

16 O-RING (SEE 70-0581) JM25-0149 3 42 CRANKSHAFT N/A 1

17 RETAINER JM46-1458 3 43 BEARING N/A 1

18 PUMP BODY N/A 1 44 SEAL (SEE 70-0566) JM26-0192 1

19 BEARING JM48-0063 1 45 FLANGE JM46-1460 1

20 SNAP RING JM46-0676 2 46 SCREW N/A 4

21 SNAP RING JM46-0732 1 - KIT - VALVES (INCLUDES ITEM #3) JM70-0456

22 O-RING (SEE 70-0565) N/A 1 - KIT - SUPPORT RING

JM25-0644 6 28 NUT JM30-6016 3

JM70-0563

(INCLUDES ITEM #11)

23 OIL DISC JM46-1451 1 - KIT - O-RINGS

(INCLUDES ITEMS 2,7,9,16,22,33,37,39)

24 OIL INDICATOR JM46-1452 1 - KIT - OIL SEALS (INCLUDES ITEMS 32,44) JM70-0566

25 COVER JM46-1453 1 - KIT - WATER SEALS

(INCLUDES ITEMS 12,14,15,16)

26 SCREW JM27-8888 8

JM70-0565

JM70-0581

32

Page 15

Jet-Set JM-1450™

33

Page 16

Jet-Set JM-1450™

DATE SERIAL # BREAK REASON FOR CHANGE

05/01/12 29001393 Unloader change

General Wire Spring Co,

1101 Thompson Avenue

McKees Rocks, PA 15136

412-771-6300 www.drainbrain.com

© General Wire Spring Co. 2018 C-JM-1450OI-073118

Loading...

Loading...