Page 1

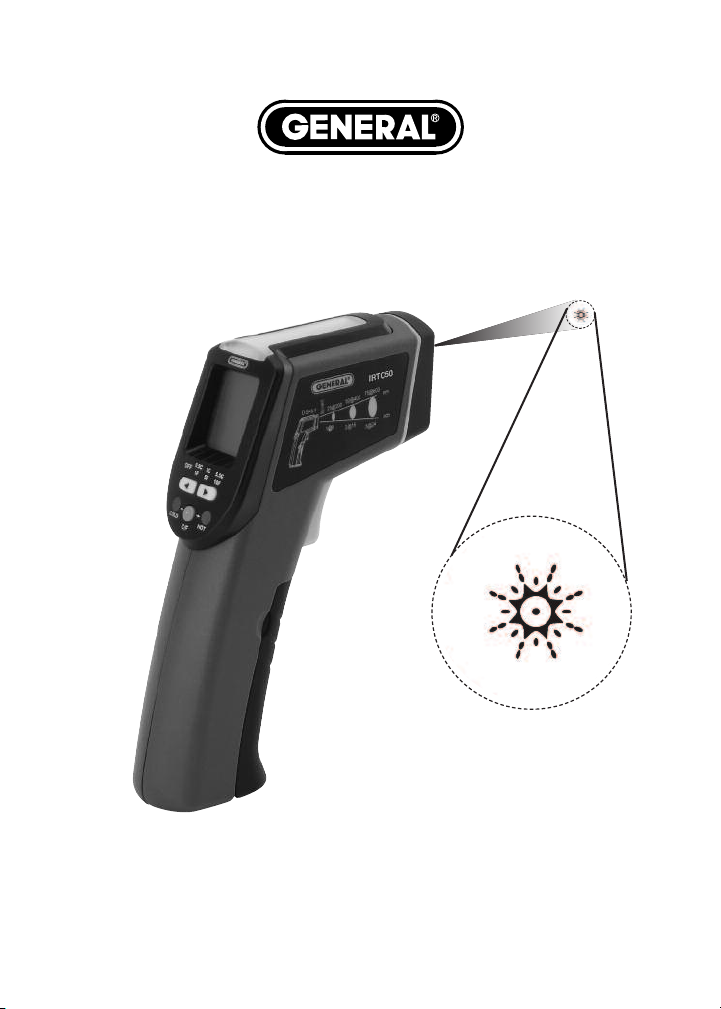

INFRARED THERMAL SCANNER

WITH

LASER STAR BURST

TARGETING SYSTEM

Laser Star Burst

Targeting

IRTC50

USER’S MANUAL

Please read this manual carefully and thoroughly before using this product.

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . 5 –8

Front Panel Controls and Indicators . . . . . . . . . . . . . 5

Making Basic Temperature Measurements . . . . . 5 –6

Using Reference Temperatures and Setpoints

A Few Final Pointers On Operating the

IR Thermal Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operational Warnings and Notes . . . . . . . . . . . . . . . . 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . 6 –7

General’s Return For Repair Policy . . . . . . . . . . . . . . . 11

2

Page 3

INTRODUCTION

Thank you for purchasing the IRTC50 InfraRed Thermal Scanner with Laser Star

Burst Targeting System from General Tools & Instruments’. Please read this

manual carefully and thoroughly before using the instrument.

It’s a handheld non-contact Infrared thermometer with 8:1 distance to spot ratio,

above and below tri-color visual and audible set-point alarms, plus a UNIQUE

LASER STAR BURST targeting system. It is used to measure and display surface

temperatures within the range of -40° to 428°F and has an accuracy of 2%.

It incorporates a user selectable 3-temperature band of 1°, 5° and 10°F

(0.5°, 3° and 5.5°C), set-point with tri-color light and sound indication when

the temperature reading goes above or drops below the set-point.

APPLICATIONS

1.

It is ideal for quickly locating hot spots on electrical equipment such as:

a.

Motors

b.

Fans

c.

Breakers

d.

Junction boxes

e.

Wiring

2.

HVAC technicians and home inspectors can quickly locate:

a.

Thermal leaks in forced air heating and AC systems

b.

Poor or missing insulation

c.

Defective hot water radiator grills

3.

In manufacturing, it can be used at assembly lines and burn-in rooms to

quickly identify:

a.

Product failure during production and testing

b.

Incoming QA of temperature sensitive or heat related products

4.

For food processing, to spot check

a.

Assembly line baking process

b.

Verify refrigeration systems by spot checking food samples

In summary the IRTC50, with its fast response time

(0.5 sec) wide temperature range -40° to 428°F a 8:1 DS ratio and tri-color/Audible set-point alarm, Starburst Laser Targeting System is superior to comparable products in its price range. It is powered with a 9V battery and complies

with Class II UK/EU laser safety standard EN60285.

3

Page 4

KEY FEATURES

• Point and shoot non-contact surface temperature measurement

• User selectable 3-temperature band, 1°, 5° and 10°F (0.5°, 3° and 5.5°C)

alarm set-point

• Tri-Color light and fast-slow buzzer sound indication when the target temperature reading goes above or below the set-point

• Fast response time of 0.5 seconds

• Unique STAR BURST laser targeting system helps in approximating the target

spot size

• Large backlit LCD

• Automatic temperature hold when the trigger is released

• Auto-display/back light shut off after 15 seconds of inactivity

• Auto-power off after 60 seconds of inactivity

SAFETY INSTRUCTIONS

WARNING!

• Keep this instrument out of the hands of children.

• This laser may cause discomfort or damage if pointed into eyes.

• Do not stare at the laser beam through binoculars or a magnifying glass!

• Do not operate this instrument in the presence of

flammable/explosive gases!

• Do not operate in environments full of dust or static electricity.

• Do not operate near sources of strong electromagnetic fields, such as arc

welders or induction heaters.

Finally, be aware that it is a federal offence (punishable by a fine of up to

$10,000 and imprisonment) to point a laser beam at aircraft.

4

Page 5

OPERATING INSTRUCTIONS

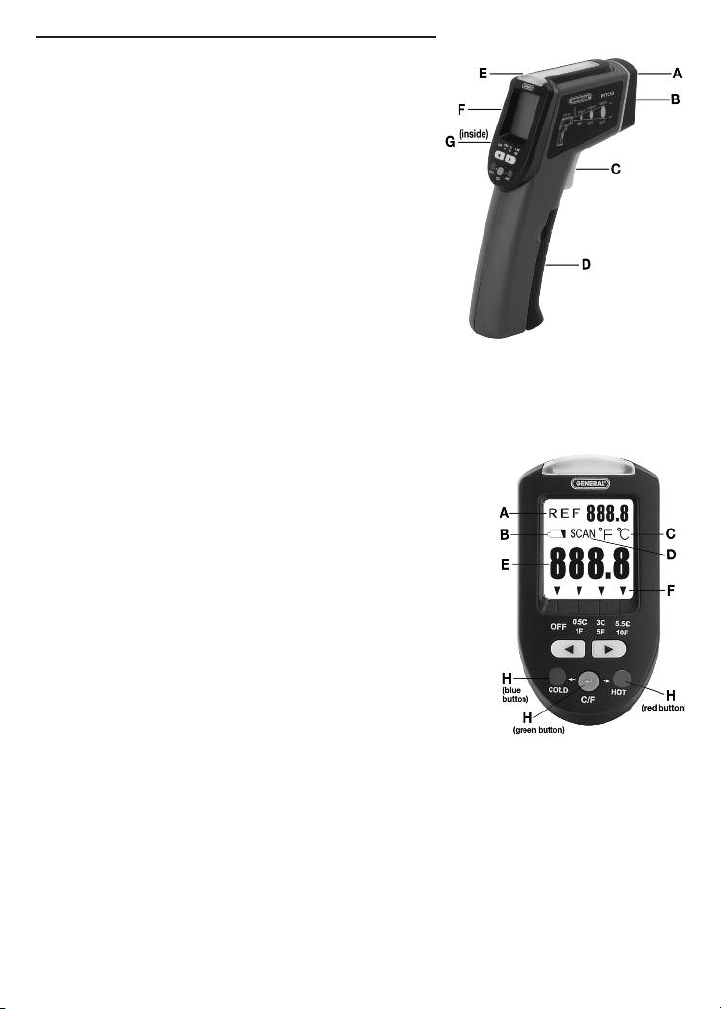

Familiarize yourself with the nomenclature in the

two images provided before using the IRTC50 IR

Scanner with Laser Star Burst Targeting System.

A.

Laser Star Burst pointer

B.

Infrared sensor

C.

Trigger

D.

Battery compartment

E.

Light panel (glows green/red/blue to indicate

normal/hot/cold readings relative to reference

temperature)

F.

Front panel, including backlit liquid crystal display (LCD) screen

(see accompanying image for details)

G.

Built-in buzzer

Front Panel Controls and Indicators

A.

Reference temperature (for use with setpoints)

B.

Low battery indicator

C.

Selected temperature scale

D.

Scanning mode indicator

E.

Scanned/held temperature

F.

Selected setpoint band indicators

G.

Differential temperature setpoint band

(1°F/0.5°C, 5°F/3°C, 10°F/5.5°C) selectors

H.

Green button has three functions: toggles between

°F and °C, sets reference temperature, turns unit off

Making Basic Temperature Measurements

Point the IRTC50 thermometer at various objects within view, including those

not at ambient temperature (for example, a light bulb or an air-conditioner or

heating register) while pressing and holding the trigger. For the most accurate

reading make sure your target fills the target spot diameter see illustration on

page 8 Fig. 1.

5

Page 6

Note that in this mode, called SCAN mode, the temperature shown on the front

panel display tracks the surface temperatures (in °F) of the objects scanned,

with fast response time of 0.5 seconds. Also note that when you release the

trigger, the display holds the last scanned temperature.

Note:

To conserve battery life:

• 15 seconds after you release the trigger, the display’s backlight goes off.

• 60 seconds after you release the trigger, the instrument automatically powers off.

Repeat this procedure while looking closely at the display. Note that when you

press and hold the trigger:

• You hear two beeps.

• The display backlight comes on.

• The SCAN and “REF——” icons illuminate.

• A temperature reading is displayed in °F. (To convert the reading to °C,

momentarily press the green “C/F” button below the display).

• To power off, hold the green button for more than two seconds, the instrument

will sound two beeps and power off.

• There is a pointer at the bottom left of the display above the word “OFF”

stenciled on the front panel. This indicates that the set-point is not activated.

Using Reference Temperatures and Setpoints

Once you learn how to make basic temperature measurements, it’s easy to

move on to using the IR Thermal Scanner the way the pros do. In many applications—such as detecting thermal leaks in a house or a batch of undercooked

food—tracking the absolute temperature of a surface is less important (and

more time-consuming) than sensing how hot or cold that surface is, relative to

the surfaces around it.

The IRTC50 supports operation in this advanced “temperature differential”

mode. First, you define the expected, “normal” temperature of a surface as the

reference temperature. Then, you define the maximum deviation from the reference temperature that can be tolerated under specific environmental conditions. This maximum deviation is called the setpoint band. Typically, a narrow

setpoint band (1°F/0.5°C) would be used to monitor temperature in processes

requiring precise quality control (food preparation, for example). A wider band

(10°F/5.5°C) would be used to detect deviations from normal that are more

tolerable (a tiny heat leak through a crack that would be too expensive to

repair, for example).

6

Page 7

To use the IR Thermal Scanner in this mode, you must first set the reference

temperature to the expected, normal temperature.

1.

Squeeze and hold the trigger and point IRT the Infrared Thermometer at an

object which has a temperature you want to use as reference, that temperature is displayed.

2.

Then, without releasing the trigger, press the green “C/F” button below the

display and note that that temperature is now displayed to the right of the

REF icon at the top of the display.

3.

Now release the trigger and note that if you squeeze it again to enter scan

mode, the reference temperature remains constant while the main temperature display changes.

4.

Now that you have set a reference temperature, you must quickly (within

60 seconds) determine a setpoint band for it (or the reference temperature

will default to OFF).

5.

To choose a setpoint band, use the yellow arrow buttons below the display

to move the pointer from the OFF position at left to one of the three possible

positions, labeled 1°F/0.5°C, 5°F/3°C and 10°F/5.5°C.

Consider these the narrow, normal and wide setpoint band settings.) For

your first use of the IRTC50 in this mode, don’t be concerned about which

position to choose. From experience you will learn whether a narrow, normal or wide setpoint band is best for your particular application and needs.

6.

If you have correctly set up the reference temperature and accompanying

setpoint band, there should be a reference temperature reading at the top

right of the display and a pointer above one of the setpoint band readings

(other than OFF) below the display. Now, keep in mind that both settings are

stored for only 60 seconds, squeeze and hold the trigger and scan various

surfaces within view.

7.

As you scan across a surface whose temperature is same as the REF

Temperature, the light panel at the top of the instrument glows green and

no beeping alarm is heard.

8.

When the surface temperature exceeds the REF Temperature by the selected

(setpoint band) temperature differential, the light panel at the top of the IRT

changes from green to red and a fast beep (twice per second) is heard.

9.

When the surface is cooler than the reference (setpoint temperature) differential, minus the setpoint, the color of the light panel switches to blue and

you hear a slow (once per second) beep.

7

Page 8

A Few Final Pointers on Operating the IR Thermal Scanner:

• Experiment with setpoint bands, for example, note that if you narrow the

band, a temperature reading that had produced a green light now produces

a red or blue light.

• Try scanning at a slow rate, and move closer or farther from the target so it

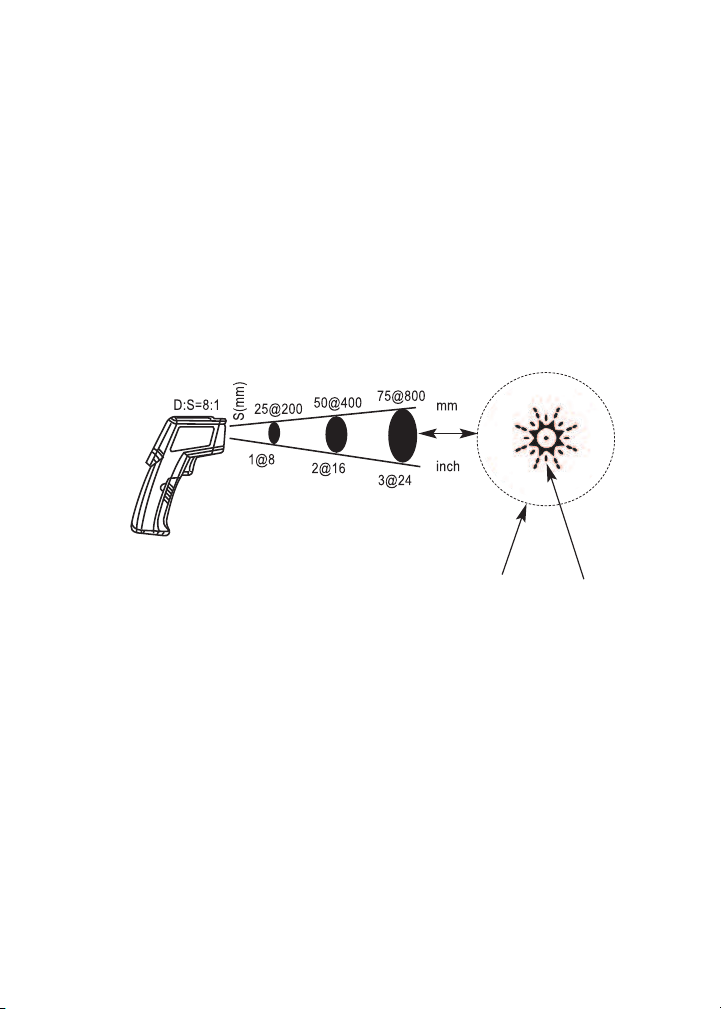

fills the laser spot. The laser has a distance/spot size ratio of 8:1. Accord ingly, 8 in. is the optimum distance at which to detect a 1 in. dia. target.

• The diameter of the laser spot’s starburst is about half that of the overall spot

diameter. For best results, the target should be about twice the size of the

laser starburst. See illustration below:

Starburst to Target Relationship

Fig.1

Target Size = 2x Starburst

Operational Warnings and Notes

Diameter

When the ambient temperature exceeds the IRTC50’s maximum operating

temperature (104°F/40°C), the instrument will sound a fast (2-Hz) alarm and

the display will show an error message of “ErAH”. When the ambient temperature falls below the unit’s minimum operating temperature (32°F/0°C) the

instrument will sound a slow (1-Hz) alarm and the display will show an error

message of “ErAL”.

When the temperature of the target exceeds the specified maximum

(428°F/220°C), the instrument will sound a fast alarm and the display will show

an error message of ErOH. When the temperature of the target temperature

falls below the specified minimum (-40°F/-40°C), the instrument will sound a

slow alarm and the display will show an error message of “ErOL”.

8

Page 9

SPECIFICATIONS

Temperature measurement range: -40° to 428°F (-40° to 220°C)

Operating temperature range: 32° to 104°F (0° to 40°C)

Operating humidity range (relative): 10 to 90% (non-condensing)

Storage temperature: -40° to 122°F (-20° to 50°C)

(not including battery)

Measurement accuracy: ±2°C or ±2% of reading

(for readings >0°C)

±3°C or ±3% of reading, whichever is greater

(for readings ≤0°C)

Repeatability +/- 1.5°F (1°C)

Response time 0.5 second

Distance/spot size ratio 8:1

Emissivity 0.95 (factory set)

Display resolution 0.1°F (±0.1°C)

Laser pointer wavelength 630-660nm

Power of laser <3mW

Response wavelength 8앑14애m

Laser class Class II

Laser on switch Trigger

Backlight on switch Trigger

Data hold Yes (60 seconds)

Fahrenheit/Celsius unit toggling Yes

High/Low setpoint warning buzzer High 2/sec, Low 1/sec pulses

Low battery indication Yes

Visual Indication Maximum <30mA

current consumption

High/Low Visual Indication High-RED, Low-Blue,

Backlight auto shutoff Inactive for 15 seconds

Auto power off Inactive for 60 seconds

Dimensions 5.31 x 1.65 x 6.81 in.

Weight 6.24 oz. (177g) (w/o battery)

Power Source 1 “9V” battery (included)

Normal-Green

(135 x 42 x 173mm)

9

Page 10

MAINTENANCE TIPS

Clean the lens often—but never use a solvent. Abrupt

temperature changes will cause condensation and possible vapor penetration.

Clean after the vapor evaporates. Blow off loose particles with clean, compressed air. Gently brush remaining debris away with a lens hair brush.

Carefully wipe the surface with a moist cotton swab.

Avoid water, moisture and corrosive gas or liquids. The housing can be cleaned

with a wet sponge.

Remove the battery when storing this product for an extended period of time.

Do not drop or disassemble the instrument or immerse it in water.

WARRANTY INFORMATION

The IRTC50 IRT InfraRed Thermal Scanner with Laser Star Burst Targeting

System from General Tools & Instruments (General

purchaser to be free from defects in material and workmanship for a period of

1 year. Subject to certain restrictions, General will repair or replace this instrument, if after examination, it is determined by General to be defective in material or workmanship.

This warranty does not apply to damages that General determines to be from

an attempted repair by non-authorized personnel or misuse, alterations, normal

wear and tear or accidental damage. The defective unit must be returned

to General Tools & Instruments or a General authorized service center, freight

prepaid and insured.

Acceptance of the exclusive repair and replacement remedies described herein

is a condition of the contract for purchase of this product. In no event shall

General be liable for any incidental, special, consequential or punitive damages,

or any cost, attorneys fees, expenses, losses alleged to be as a consequence of

any damage due to failure of, or defect in any product including, but not limited

to, any claims for loss of profits.

®

) is warranted to the original

10

Page 11

GENERAL’S RETURN

FOR REPAIR POLICY

Every effort has been made to provide you with a reliable, product of superior

quality. However, in the event your instrument requires repair, please contact

our Customer Service to obtain a RGA# (Return Goods Authorization) before

forwarding the unit via prepaid freight to the attention of our Service Center at

this address:

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Remember to include a copy of your proof of purchase, your return address,

and your phone number and/or e-mail address.

11

Page 12

ESCÁNER TÉRMICO

INFRARROJO CON SISTEMA

DE FIJACIÓN DE OBJETIVOS

ESTRELLA LÁSER

láser estallido

IRTC50

MANUAL DEL USUARIO

12

Por favor, lea este manual detenidamente antes de usar este producto.

Page 13

ÍNDICE

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Aplicaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 – 15

Características principales . . . . . . . . . . . . . . . . . . . . . . 15

Instrucciones de seguridad . . . . . . . . . . . . . . . . . 15 – 16

Instrucciones de funcionamiento . . . . . . . . . . . . 16 – 20

Controles e indicadores del panel frontal . . . . . . . . 16

Realizar mediciones básicas de temperatura . . . . . 17

Utilización de las temperaturas de referencia

y los puntos de referencia . . . . . . . . . . . . . . . . . 17 – 19

Algunas sugerencias finales para operar

el escáner térmico infrarrojo . . . . . . . . . . . . . . . 19 – 20

Advertencias y notas de operación . . . . . . . . . . . . . 20

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . 20 – 21

Consejos para el mantenimiento . . . . . . . . . . . . . . . . . 22

Información de garantía . . . . . . . . . . . . . . . . . . . . . . . . 22

Política de General sobre las devoluciones

para reparaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13

Page 14

INTRODUCCIÓN

Gracias por comprar el escáner térmico infrarrojo IRTC50 con sistema de

fijación de objetivos estrella láser de General Tools & Instruments. Lea este

manual en detalle y por completo antes de utilizar el instrumento.

Es un termómetro infrarrojo de mano, sin contacto, con relación 8:1 entre

distancia y punto de enfoque, alarmas sonoras y visuales tricolores de punto de

referencia (superiores e inferiores), más un exclusivo sistema de fijación de

objetivos ESTRELLA LÁSER. Se lo utiliza para medir temperaturas de superficie y

mostrarlas en pantalla, en un rango de -40 a 428 ºF, y tiene una exactitud de 2%.

Incorpora una banda de tres temperaturas de 0,5; 3 y 5,5 ºC (1, 5 y 10 ºF) que

puede elegir el usuario, permite establecer un punto de referencia y emite una

indicación sonora y de luz tricolor si la lectura de la temperatura supera o cae

por debajo de ese punto de referencia.

APLICACIONES

1.

Es ideal para localizar con rapidez puntos calientes en equipos eléctricos,

como:

a.

motores; b.ventiladores;

c.

disyuntores; d.cajas de conexiones; y

e.

cableados.

2.

Los inspectores de vivienda y los técnicos de equipos de calefacción,

ventilación y aire acondicionado pueden ubicar rápidamente:

a.

fugas térmicas en sistemas de aire acondicionado y de calefacción por

aire forzado;

b.

falta de aislamiento o aislamiento insuficiente;

c.

rejillas defectuosas de radiadores de agua caliente.

3.

En los procesos de fabricación, se lo puede usar en las líneas de producción

y los probadores de envejecimiento para identificar de manera rápida:

a.

fallas en los productos durante la producción y las pruebas;

b.

la garantía de calidad que ingresará de los productos sensibles a la

temperatura o al calor.

4.

Para controles al azar en el procesamiento de alimentos:

a.

para el proceso de horneado en las líneas de producción;

b.

para verificar los sistemas de refrigeración por medio de controles al azar

sobre muestras de alimentos.

14

Page 15

En resumen, el IRTC50, con su veloz tiempo de respuesta (0,5 seg.), el amplio

rango de temperaturas de -40 a 428 ºF, la relación 8:1 entre distancia y punto

de referencia, alarma tricolor y sonora para el punto de referencia y con el

sistema de fijación de objetivos estrella láser, es superior a otros productos en

la misma escala de precios. La fuente de alimentación es una batería de 9 V y

cumple con la clasificación II de la norma EN60285 sobre seguridad láser de

Reino Unido/Unión Europea.

CARACTERÍSTICAS PRINCIPALES

• Medición de la temperatura de superficie, sin necesidad de contacto, con

sólo “apuntar y disparar”.

• Banda de tres temperaturas que puede elegir el usuario, con un punto de

referencia de 0,5; 3 y 5,5 ºC (1, 5 y 10 ºF) con alarma.

• Indicación sonora y de luz tricolor si la lectura de la temperatura supera o cae

por debajo de ese punto de referencia.

• Veloz tiempo de respuesta de 0,5 segundos.

• El exclusivo sistema de fijación de objetivos ESTRELLA láser ayuda a

aproximar el tamaño del punto de enfoque del objetivo.

• Pantalla LCD grande con luz de fondo.

• La temperatura queda fija en forma automática cuando se suelta el gatillo.

• Apagado automático de la pantalla de visualización y luz de fondo después

de 15 segundos de inactividad.

• Apagado automático del instrumento después de 60 segundos de inactividad.

INSTRUCCIONES DE SEGURIDAD

¡ADVERTENCIA!

• Mantenga este instrumento fuera del alcance de niños.

• Este láser puede producir molestias o lesiones si se lo apunta a los ojos.

• ¡No mire hacia el rayo láser ni con binoculares, ni con lupas!

• ¡No opera el instrumento alrededor de gases inflamables o explosivos!

• No opere este instrumento en ambientes con polvo o electricidad estática.

• No opere este instrumento cerca de fuentes de campos electromagnéticos de

gran intensidad, como soldadoras por arco o calentadores por corrientes de

inducción.

15

Page 16

Por último, tenga en cuenta que apuntar un rayo láser a una aeronave es un

delito federal (que se castiga con multas de hasta USD 10.000 y

encarcelamiento).

INSTRUCCIONES DE

FUNCIONAMIENTO

Familiarícese con la nomenclatura de las dos imágenes suministradas antes de

usar el escáner infrarrojo IRTC50 con sistema de fijación de objetivos estrella

láser.

A.

Puntero de estrella láser.

B.

Sensor infrarrojo.

C.

Gatillo.

D.

Compartimiento para la batería

E.

Panel de luces (resplandece en color

verde, rojo o azul para indicar lecturas

normales, calientes o frías respecto de

la temperatura de referencia).

F.

Panel frontal, incluye la pantalla de

visualización de cristal líquido (LCD) con

luz de fondo (vea la imagen que

acompaña esta sección para conocer

más detalles).

G.

Timbre incorporado.

Controles e indicadores del panel frontal

A. Temperatura de referencia (para usar con puntos

de referencia).

B. Indicador de batería baja.

C. Escala de temperatura seleccionada.

D. Indicador de modo de escaneo.

E. Temperatura escaneada o fija.

F. Indicadores de banda de punto

de referencia seleccionado.

G. Selectores de banda de puntos de

referencia de temperatura diferencial

(1 ºF/0,5 ºC; 5 ºF/3 ºC; 10 ºF/5,5 ºC).

H. El botón verde tiene tres funciones: alterna entre ºF y ºC, establece la

temperatura de referencia y apaga la unidad.

16

Interior

(botón

azul)

(botón

verde)

(botón

rojo)

Page 17

Realizar mediciones básicas de temperatura

Apunte el termómetro IRTC50 a diferentes objetos que estén a la vista, incluso

aquellos que no estén a temperatura ambiente (por ejemplo, una bombilla

eléctrica, un acondicionador de aire o una rejilla de calefacción) y presione el

gatillo sin soltarlo. Para lograr mediciones más exactas, compruebe que su

objetivo ocupe el diámetro del punto de enfoque del objetivo (ver la figura 1

de la página 20).

Tenga en cuenta que en este modo, que se llama modo SCAN (ESCANEO),

la temperatura que se muestra en la pantalla del panel frontal rastrea las

temperaturas de superficie (en ºF) de los objetos escaneados, con un tiempo

de respuesta veloz de 0,5 segundos. Tenga en cuenta también que, al soltar el

gatillo, la última temperatura escaneada queda fija en la pantalla.

Nota:

para preservar la vida útil de la batería:

• 15 segundos después de soltar el gatillo, la luz de fondo de la pantalla

se apaga;

• 60 segundos después de soltar el gatillo, el instrumento se apaga

automáticamente.

Repita este procedimiento mientras mira la pantalla con atención. Observe que

cuando mantiene presionado el gatillo:

• Se escuchan dos “bips”.

• Se enciende la luz de fondo de la pantalla.

• Se iluminan los íconos SCAN y “REF------”.

• Se muestra en pantalla la lectura de temperatura en ºF (para convertirla a °C,

presione unos instantes el botón verde “C/F” que se encuentra debajo de la

pantalla).

• Para apagar el dispositivo, mantenga apretado el botón verde por más de dos

segundos; el instrumento emitirá dos “bips” y se apagará.

• Hay un puntero en la parte inferior izquierda de la pantalla, arriba de la

palabra “OFF” (Apagado), impresa en el panel frontal, que indica que el punto

de referencia no está activado.

Utilización de las temperaturas de referencia y los puntos de referencia

Una vez que aprende cómo hacer las mediciones básicas de temperatura,

es fácil comenzar a utilizar el Escáner térmico infrarrojo como lo hacen los

profesionales. En muchas aplicaciones –como la detección de fugas térmicas

17

Page 18

en una casa o un lote de alimentos poco cocidos– hacer un seguimiento de la

temperatura absoluta de una superficie es menos importante (y lleva más

tiempo) que determinar qué tan caliente o fría está la superficie con relación a

las superficies que la rodean.

Se puede operar en El IRTC50 en este modo avanzado de “temperatura

diferencial”. Primero, debe definirse la temperatura “normal” que se espera de

una superficie como la temperatura de referencia. Luego, debe definirse la

desviación máxima que se puede tolerar en las condiciones ambientales

específicas. A esta desviación máxima se la llama banda de puntos de

referencia. Lo habitual es que utilizar una banda angosta de puntos de

referencia (1 ºF/0.5 ºC) para comprobar la temperatura en procesos que

requieran un control de calidad preciso (por ejemplo, preparación de

alimentos). Se usa una banda más ancha (10 ºF/5.5 ºC) para detectar

desviaciones con respecto a la temperatura normal que sean más tolerables

(una fuga de calor diminuta que sería muy caro reparar, por ejemplo).

Para usar el escáner térmico infrarrojo en este modo, primero se debe

configurar la temperatura de referencia al valor de temperatura normal

esperado.

1.

Mantenga presionado el gatillo y apunte el termómetro infrarrojo a un objeto

con la temperatura que quiera usar como referencia. Esa temperatura se

muestra en pantalla.

2.

Luego, sin soltar el gatillo, presione el botón verde “C/F” que se encuentra

debajo de la pantalla y observe que esa temperatura ahora se muestra a la

derecha del ícono REF, en la parte superior de la pantalla.

3.

Ahora suelte el gatillo y observe que si lo presiona otra vez para ingresar al

modo de escaneo, la temperatura de referencia permanece constante

mientras que la temperatura principal de la pantalla cambia.

4.

Ahora que ha establecido una temperatura de referencia, debe determinar

rápidamente (antes de que transcurran 60 segundos) una banda de puntos

de referencia para esa temperatura (o se posicionará por defecto en OFF).

5.

Para elegir una banda de punto de ajuste, use los botones con flechas

amarillas que se encuentran debajo de la pantalla para mover el puntero de

la posición OFF, a la izquierda, hacia una de las tres posiciones posibles, con

el nombre 1 ºF/0,5 ºC; 5 ºF/3 ºC y 10 ºF/5,5 ºC. (Considérelas como las

configuraciones de banda de puntos de referencia angosta, normal y ancha.)

Para el primer uso del IRTC50 en este modo, no se preocupe por cuál

18

Page 19

posición elegir. Aprenderá por experiencia si es mejor una banda de punto de

ajuste angosta, normal o ancha para la aplicación o las necesidades

específicas.

6.

Si ha establecido correctamente la temperatura de referencia y la banda de

punto de ajuste correspondiente, debe aparecer una lectura de temperatura

de referencia en la parte superior derecha de la pantalla y un puntero por

encima de una de las lecturas de banda de puntos de referencia (que no sea

OFF) debajo de la pantalla. Tenga en cuenta que ambas configuraciones se

almacenan sólo por 60 segundos y mantenga presionado el gatillo y escanee

diferentes superficies que estén a la vista.

7.

Cuando escanea una superficie cuya temperatura es igual a la temperatura

de referencia (REF), el panel de luces que se encuentra en la parte superior

del instrumento brilla en color verde y no se escucha ninguna alarma sonora.

8.

Cuando la temperatura de la superficie excede la temperatura REF por la

temperatura diferencial (de la banda de puntos de referencia) seleccionada,

el panel de luces de la parte superior del termómetro infrarrojo cambia de

verde a rojo y se oye un “bip” rápido (dos veces por segundo).

9.

Cuando la superficie es más fría que el diferencial de (la temperatura de

punto de ajuste) referencia, menos el punto de referencia, el color del panel

de luces cambia a azul y se oye un "bip" lento (una vez por segundo).

Algunas sugerencias finales para operar el escáner término infrarrojo:

• Experimente con las bandas de punto de ajuste. Por ejemplo, observe que,

si usa una banda más angosta, las lecturas de temperatura que habían

generado una luz verde ahora causan una luz roja o azul.

• Intente escanear con lentitud y acérquese o aléjese del objetivo para que

ocupe el punto de enfoque del láser. El láser tiene una relación 8:1 entre

distancia y punto de enfoque. Por lo tanto, la distancia 8 pulgadas es la

distancia óptima para detectar un objetivo de una pulgada de diámetro.

• El diámetro de la estrella del punto de enfoque del láser es

aproximadamente la mitad del diámetro total del punto de enfoque. Para

obtener mejores resultados, el objetivo debería ser de aproximadamente dos

veces el tamaño de la estrella del láser. Vea la imagen a continuación:

19

Page 20

Relación entre la estrella y el objetivo

Fig.1

Advertencias y notas de operación

Tamaño del objetivo = Dos veces el

diámetro de la estrella

Cuando la temperatura ambiente sobrepasa la temperatura máxima de

funcionamiento (104 ºF/40 ºC) del IRTC50, el instrumento hará sonar una

alarma rápida (2-Hz) y la pantalla mostrará el mensaje de error “ErAH”. Cuando

la temperatura ambiente caiga por debajo de la temperatura mínima de

funcionamiento (32 ºF/0 ºC), el instrumento hará sonar una alarma lenta (1-Hz)

y la pantalla mostrará el mensaje de error “ErAL”.

Cuando la temperatura del objetivo supera la temperatura máxima especificada

(428°F/220°C), el instrumento hará sonar una alarma rápida y la pantalla

mostrará el mensaje de error “ErOH”. Cuando la temperatura del objetivo cae

por debajo de la temperatura mínima especificada (40 ºF/-40 ºC), el

instrumento hará sonar una alarma lenta y la pantalla mostrará el mensaje de

error “ErOL”.

ESPECIFICACIONES

Rango de medición de temperatura: -40 a 428 ºF (-40 a 220 ºC)

Rango de temperatura operativa: 32 a 104 ºF (0 a 40 ºC)

Rango de humedad

de funcionamiento (relativa):

Temperatura de almacenamiento: -4 a 122 ºF (-20 a 50 ºC)

(sin incluir la batería)

Exactitud de la medición: ±2 ºC o ±2% de la lectura

(para lecturas mayores a 0 ºC)

±3 ºC o ±3% de la lectura, la que sea mayor

(para lecturas mayores a 20 ºC)

Repetibilidad: +/- 1.5 ºF (1 ºC)

20

10 a 90% (sin condensación)

Page 21

Tiempo de respuesta: 0,5 segundo

Relación entre distancia y punto

8:1

de enfoque:

Emisividad: 0,95 (configuración de fábrica)

Precisión de la pantalla: 0.1 ºF (±0.1 ºC)

Longitud de onda del puntero láser: 630-660 nm.

Potencia del láser: < 3 mW.

Longitud de onda de respuesta: 8앑14애m

Clase de láser: Clasificación II

Interruptor para encender el láser: gatillo

Interruptor para encender la luz

gatillo

de fondo:

Retención de datos: sí (60 segundos)

Conversión de unidades

sí

Fahrenheit/Celsius:

Timbre de advertencia de punto de

referencia alto o bajo:

2 pulsos por segundo para punto alto, 1 pulso por segundo para punto bajo

Indicación de batería baja: sí

Máximo de indicación visual: < 30 mA de consumo de corriente

Indicación visual de lectura alta

rojo para alta, azul para baja y verde para normal

o baja:

Apagado automático de la luz

inactivo por 15 segundos

de fondo:

Apagado automático del instrumento: inactivo por 60 segundos

Dimensiones: 5,31 x 1,65 x 6,81 pulgadas

(135 x 42 x 173 mm.)

Peso: 6,24 onzas (177 g) (sin la batería)

Fuente de alimentación: una batería de “9 V” (incluida)

21

Page 22

CONSEJOS PRÁCTICOS DE MANTENIMIENTO

Limpie el lente con frecuencia, pero nunca use solventes. Los cambios

abruptos de temperatura producen condensación y es posible que el vapor

penetre. Limpie el instrumento después de que se evapore el vapor. Quite las

partículas sueltas con aire comprimido limpio. Elimine con delicadeza los

residuos restantes con un cepillo para lentes. Limpie con cuidado la superficie

con un hisopo de algodón húmedo.

Evite que el instrumento esté en contacto con agua, humedad y gases o

líquidos corrosivos.

La carcasa se puede limpiar con una esponja húmeda.

Cuando almacene el producto por un tiempo prolongado, quítele la batería.

No deje caer, ni desarme, ni sumerja en agua el instrumento.

INFORMACIÓN DE GARANTÍA

Se garantiza al comprador original que el escáner térmico infrarrojo IRTC50 con

sistema de fijación de objetivos estrella láser de General Tools & Instruments

(General®) estará libre de defectos de materiales y mano de obra por un

período de un año. Con ciertas restricciones, General reparará o reemplazará el

instrumento si, después de un examinarlo, General determina que presenta

defectos de material o mano de obra.

Esta garantía no se aplica a daños que, según lo determine General, sean

consecuencia de intentos de reparación por parte de personal no autorizado o

de la mala utilización, alteraciones, desgaste natural o daño accidental. La

unidad defectuosa se debe devolver a General Tools & Instruments o a un

centro de servicios autorizado por General, asegurada y con flete pagado en

forma anticipada.

La aceptación de las reparaciones y los reemplazos exclusivos descritos en

este documento es una condición del contrato de compra de este producto. En

ningún caso General será responsable de cualquier daño imprevisto, especial,

emergente o punitivo, ni de cualquier costo, honorario de abogado, gasto,

pérdida supuesta como consecuencia de cualquier daño debido a una falla, ni

de ningún defecto en producto alguno, incluso, entre otros, todo reclamo por

lucro cesante.

22

Page 23

POLÍTICA DE DEVOLUCIONES PARA

REPARACIONES DE GENERAL

Se han llevado a cabo todas las medidas posibles para proporcionarle un

producto confiable de calidad superior. Sin embargo, en caso de que necesite

reparar su instrumento, comuníquese con nuestro Servicio de Atención al

Cliente para obtener un número de Autorización de devolución de mercancía

(RGA, por su sigla en inglés) antes de enviar la unidad por flete pago con

anticipación a nombre de nuestro Servicio de Atención al Cliente, a esta

dirección:

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Recuerde incluir una copia del comprobante de compra, su dirección de

devolución y su número de teléfono o dirección de correo electrónico.

23

Page 24

SCANNER THERMIQUE

INFRAROUGE AVEC SYSTÈME

DE CIBLAGE À ÉTOILE LASER

Star burst avec objectif de laser

IRTC50

MANUEL D’INSTRUCTIONS

24

S’il vous plaît lisez attentivement ce manuel et avant d’utiliser ce produit.

Page 25

TABLE DES MATIÈRES

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 – 27

Caractéristiques principales . . . . . . . . . . . . . . . . . . . . 27

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . 27 – 28

Instructions d'utilisation . . . . . . . . . . . . . . . . . . . . 28 – 32

Contrôles et indicateurs du panneau avant . . . . . . 29

Prendre des mesures de températures

basiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 – 30

Utiliser les températures de référence et les

points de réglage . . . . . . . . . . . . . . . . . . . . . . . . 30 – 31

Quelques indicateurs finaux sur l’utilisation du

scanner thermique infrarouge . . . . . . . . . . . . . . . . . 32

Remarques et avertissements relatifs

au fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Conseils d’entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Informations concernant la garantie . . . . . . . . . . . . . . 34

Retour de General pour la politique de réparation . . 35

25

Page 26

INTRODUCTION

Merci d’avoir acheté le scanner thermique avec système de ciblage à étoile

laser de General Tools & Instruments. Veuillez lire ce manuel attentivement et

entièrement avant d'utiliser l'instrument.

C’est un thermomètre infrarouge portable sans contact avec un ratio de

distance/point de 8:1, des alarmes supérieures et inférieures au point de

réglage tricolores visuelles et sonores, ainsi qu’un système de ciblage À ÉTOILE

LASER UNIQUE. Il est utilisé pour mesurer et afficher les températures de

surface dans une plage comprise entre -40 et 428 ºF et a une précision de 2%.

Il intègre une plage de 3 températures sélectionnables par l’utilisateur de 1º, 5º

et 10 ºF (0,5º, 3º et 5,5 ºC), un point de réglage avec une lumière tricolore et

une indication sonore quand la température lue passe dépasse ou tombe en

dessous du point de réglage.

APPLICATIONS

1.

`Il est idéal pour localiser rapidement les points chauds sur un équipement

électrique tel que :

a.

Des moteurs

b.

Des ventilateurs

c.

Des disjoncteurs

d.

Des boîtes de jonction

e.

Un câblage

2.

Les techniciens CVC et les inspecteurs de domiciles peuvent rapidement

localiser :

a.

Les fuites thermiques dans les systèmes à air conditionné et de

chauffage à air pulsé

b.

L’isolation faible ou absente

c.

Les grilles de radiateur d’eau chaude défectueuses

3.

Dans l’industrie, il peut être utilisé sur des lignes d’assemblage et dans des

salles de déverminage pour identifier rapidement :

a.

La défaillance du produit pendant la production et lors des tests

b.

L’assurance qualité à venir des produits sensibles à la température ou liés

à la chaleur

26

Page 27

4.

Pour la transformation des aliments, afin d'effectuer des vérifications

ponctuelles

a.

Le processus de cuisson en ligne d’assemblage

b.

Le contrôle des systèmes réfrigérants grâce à des vérifications

ponctuelles d’échantillons d’alimentaires

En résumé, l’IRTC50, avec son temps de réponse rapide (0,5 s), sa plage de

température étendue de -40 ºF à 428 ºF, un ratio DS de 8:1 et son alarme

tricolore/sonore de point de réglage, le système de ciblage laser à étoile est

supérieur aux produits comparables dans sa gamme de prix. Il est alimenté par

une pile de 9V et répond à la norme EN60285 de sécurité laser de Classe II

RU/UE.

CARACTÉRISTIQUES PRINCIPALES

• Cible et relève la température de surface sans contact

• Point de réglage avec plage de 3 températures sélectionnables par

l’utilisateur de 1°, 5° et 10 °F (0,5°, 3° et 5,5 °C)

• Indication lumineuse tricolore et sonore lente-rapide quand la lecture de la

température cible passe au-dessus ou en-dessous du point de réglage

• Temps de réponse rapide de 0,5 secondes

• Système unique de ciblage laser À ÉTOILE qui aide à se approximer la taille

du point cible

• Grand écran LCD rétroéclairé

• Maintien automatique de la température quand la gâchette est relâchée

• Extinction automatique de l’affichage/rétro éclairage après 15 secondes

d’inactivité

• Extinction automatique de l’appareil après 60 secondes d’inactivité

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT !

• Gardez cet instrument hors de portée des enfants.

• Ce laser peut provoquer une gêne ou des blessures s’il est dirigé vers les

yeux.

• Ne regardez pas fixement le rayon du laser à travers des lunettes ou une

loupe !

27

Page 28

• N’utilisez pas cet instrument en présence de gaz inflammables/explosifs !

• Ne faites pas fonctionner dans des environnements remplis de poussière ou

d'électricité statique.

• Ne faites pas fonctionner près de sources de champs électromagnétiques

puissants, telles que des postes de soudures à l’arc ou des chauffages à

induction.

Enfin, soyez conscient qu’il s’agit d’une infraction fédérale (passible d’une

amende pouvant aller jusqu’à 10 000 dollars et d’une peine d’emprisonnement)

de diriger un rayon laser en direction d’un avion.

INSTRUCTIONS D’UTILISATION

Familiarisez-vous avec la nomenclature

des deux images fournies avant d'utiliser

le scanner IRTC50 IR avec système de

ciblage à étoile laser.

A.

Pointeur à étoile laser

B.

Capteur infrarouge

C.

Gâchette

D.

Compartiment de la pile

E.

Panneau lumineux (lumières

vertes/rouges/bleues pour indiquer des

lectures normales/chaudes/froides en

fonction de la température de

référence)

F.

Panneau frontal, y compris l’écran rétroéclairé d’affichage à cristaux

liquides (LCD) (voir l’image ci-jointe pour plus de détails)

G.

Avertisseur sonore intégré

à l’intérieur

28

Page 29

Contrôles et indicateurs du panneau avant

A.

Température de référence (pour utiliser avec les

points de réglage)

B.

Indicateur de pile faible

C.

Échelle de température sélectionnée

D.

Indicateur du mode de balayage

E.

Température scannée/enregistrée

F.

Indicateurs de plage de points de réglage

sélectionnés

G.

Sélecteurs de plage différentielle du point de

réglage de la température

(bouton

bleu)

(bouton

vert)

(botón

rojo)

(1º/0,5 ºC, 5º/3 ºC, 10º/5,5 ºC)

H.

Le bouton vert a trois fonctions : bascule entre les températures en ºF et ºC,

règle la température de référence, éteint l’unité

Prendre des mesures de températures basiques

Pointez le thermomètre IRTC50 sur différents objets dans le viseur, y compris

ceux qui ne sont pas à température ambiante (par exemple, une ampoule, un

climatiseur ou un registre de chauffage) tout en maintenant la gâchette

enfoncée. Pour une lecture plus précise, assurez-vous que votre cible remplisse

le diamètre du point cible ; consulter l’illustration de la Fig. 1 à la page 32.

Notez que dans ce mode, appelé mode SCAN, la température indiquée sur

l’affichage du panneau frontal suit la température de surface (en ºF) des objets

scannés, avec un temps de réponse rapide de 0,5 secondes. Notez aussi que

quand vous relâchez la gâchette, l’affichage conserve la dernière température

scannée.

Remarque :

Pour préserver la durée de vie de la pile :

• 15 secondes après que vous relâchez la gâchette,

le rétroéclairage de l’affichage s’éteint.

• 60 secondes après que vous relâchez la gâchette, l’instrument

s’éteint automatiquement.

Répétez cette procédure tout en observant attentivement l’affichage.

Remarquez que quand vous pressez et maintenez enfoncée la gâchette :

• Vous écoutez deux bips.

• Le rétroéclairage de l’affichage s’allume.

29

Page 30

• Les icônes SCAN et « REF------ » s’illuminent.

• Une lecture de température est affichée en ºF. (Pour convertir la lecture en °C,

appuyez momentanément sur le bouton vert « C/F » sous l'affichage).

• Pour éteindre, maintenez enfoncé le bouton vert pendant plus de deux

secondes, l’instrument émettra deux bips et s’éteindra.

• Il y a un pointeur en bas à gauche de l'affichage

au-dessus du mot « OFF » en surimpression sur le panneau frontal. Cela

indique que le point de réglage n’est pas activé.

Utiliser les températures de référence et les points de réglage

Une fois que vous avez appris comment effectuer des mesures basiques de

température, il est facile de passer à l’utilisation du scanner thermique

infrarouge comme le font les professionnels. Dans de nombreuses applications

— telles que la détection de fuites thermiques dans une maison ou un lot de

nourriture pas assez cuite —, suivre la température absolue à la surface est

moins important (et nécessite plus de temps) que détecter combien une

surface est chaude ou froide, par rapport aux surfaces adjacentes qui l’entoure.

L'IRTC50 permet un fonctionnement dans ce mode avancé « température

différentielle ». Tout d’abord, vous définissez la température « normale » d’une

surface comme température de référence. Ensuite, vous définissez l’écart

maximum par rapport à la température de référence qui peut être toléré dans

des conditions environnementales particulières. Cet écart maximum est appelé

la plage du point de réglage. Généralement, une plage du point de réglage

limitée (1 ºF/0,5 ºC) sera utilisée pour surveiller la température dans des

processus qui nécessitent un contrôle de qualité précis (préparation

alimentaire, par exemple). Une plage plus large (10 ºF/ 5,5 ºC) sera utilisée pour

détecter des écarts avec la température normale qui sont plus tolérables (une

petite fuite de chaleur à travers une fissure qui serait trop chère à réparer,

par exemple).

Pour utiliser le scanner thermique infrarouge dans ce mode, vous devez

d'abord régler la température de référence à la température normale souhaitée.

1.

Pressez et maintenez enfoncée la gâchette puis pointez le thermomètre

infrarouge IRT vers un objet qui a une température que vous souhaitez

utiliser comme référence, cette température est affichée.

2.

Ensuite, sans relâcher la gâchette, appuyez sur le bouton vert « C/F » sous

l’affichage et remarquez que cette température est maintenant affichée à

droite de l’icône REF en haut de l’affichage.

30

Page 31

3.

Relâchez maintenant la gâchette et remarquez que si vous la pressez de

nouveau pour entrer en mode scan, la température de référence reste

constante tandis que l’affichage principal de la température change.

4.

Maintenant que vous avez réglé une température de référence, vous devez

rapidement (dans les 60 secondes) déterminer une plage de point de réglage

pour celle-ci (ou la température de référence sera mise par défaut sur OFF).

5.

Pour choisir une plage du point de réglage, utilisez

les flèches jaunes sous l’affichage pour déplacer le pointeur de la position

OFF à gauche vers une des

trois positions possibles, marquées 1 ºF/0,5 ºC, 5 ºF/3 ºC et 10 ºF/5,5 ºC.

(Considérez ces valeurs comme les configurations des plages du point de

réglage limitées, normale et large).

Lors de votre première utilisation de l’IRTC50 dans ce mode, ne vous

préoccupez pas de la position à choisir. Avec l’expérience, vous apprendrez

quand une plage de point de réglage limitée, normale ou large est la plus

adaptée pour vos applications et besoins particuliers.

6.

Si vous avez réglé correctement la température de référence et la plage du

point de réglage qui l’accompagne, il devrait y avoir une lecture de

température de référence dans le coin supérieur droit de l’affichage et un

pointeur au-dessus d'une des lectures de la plage du point de réglage (autre

que OFF) en dessous de l'affichage. Maintenant, gardez à l’esprit que les

deux réglages sont enregistrés pendant seulement 60 secondes, pressez et

maintenez enfoncée la gâchette puis scannez différentes surfaces dans le

viseur.

7.

Quand vous scannez vers une surface dont la température est identique à la

température REF, le panneau lumineux en haut de l’instrument s’allume en

vert et aucune alarme sonore n’est entendue.

8.

Quand une température de surface dépasse la température REF du

différentiel de température sélectionné (plage du point de réglage), le

panneau lumineux en haut de l’IRT passe du vert au rouge et des bips

rapides (deux par seconde) sont entendus.

9.

Quand la surface est plus froide que le différentiel de référence (température

du point de réglage), moins le point de réglage, la couleur du panneau

lumineux passe au bleu et vous entendez des bips lents (un par seconde).

31

Page 32

Quelques indicateurs finaux sur l’utilisation du scanner thermique

infrarouge :

• Testez les plages du point de réglage, par exemple, remarquez que si vous

limitez la plage, une lecture de température qui a produit une lumière verte,

produit maintenant une lumière rouge ou bleue.

• Essayez de scanner à une vitesse lente et approchez ou éloignez-vous de la

cible afin qu'elle remplisse le point laser. Le laser a un ratio de taille

distance/point de 8:1. Par conséquent, 8 pouces est la distance optimale

pour détecter une cible d’1 pouce de diamètre.

• Le diamètre d’un point laser à étoile est à peu près de la moitié du diamètre

du point dans son ensemble. Pour de meilleurs résultats, la cible devra être à

peu près de deux fois la taille de l’étoile du laser. Voir illustration ci-dessous :

Relation de l’étoile à la cible

Fig.1

Taille de la cible = 2 x diamètre de l’étoile

Remarques et avertissements relatifs au fonctionnement

Quand la température ambiante dépasse la température d’utilisation maximum

de l’IRTC50 (104 ºF/40 ºC), l’instrument émettra une alarme sonore rapide

(2-Hz) et l’affichage indiquera un message d’erreur « ErAH ». Quand la

température ambiante tombe sous la température d’utilisation minimum

(32 ºF/ 0ºC), l’instrument émettra une alarme sonore lente (1-Hz) et l’affichage

indiquera un message d’erreur « ErAL ».

Quand la température de la cible dépasse la température maximum spécifiée

(428°F/220°C), l’instrument émettra une alarme sonore rapide et l’affichage

indiquera un message d’erreur « ErOH ». Quand la température de la cible

tombe sous la température minimum spécifiée (40 ºF/-40 ºC), l’instrument

émettra une alarme sonore lente et l’affichage indiquera un message d’erreur «

ErOL ».

32

Page 33

SPÉCIFICATIONS

Plage de mesure de températures : -40º à 428 ºF (-40º à 220 ºC)

Plage de températures d’utilisation : 32º à 104 ºF (0 à 40 ºC)

Plage d’humidité (relative)

d’utilisation :

Température de stockage : -4º à 122 ºF (-20 à 50 ºC) (sans inclure la pile)

Précision de mesure : ±2 ºC ou ±2% de la lecture (pour des lectures > 0 ºC

Fidélité : +/- 1,5 ºF (1 ºC)

Temps de réponse : 0,5 seconde

Ratio de la taille distance/point : 8:1

Émissivité : 0,95 (réglage d’usine)

Résolution de l’affichage 0,1 ºF (±0,1 ºC)

Longueur d’onde du pointeur laser : 630-660 nm

Puissance du laser : < 3mW

Longueur d’onde de la réponse : 8앑14애m

Classe du laser : Classe II

Commutateur du laser : Gâchette

Commutateur du rétroéclairage : Gâchette

Mémoire des données : Oui (60 secondes)

Basculement entre les unités

Fahrenheit/Celsius :

Signal sonore d’avertissement du

point de réglage supérieur/inférieur:

Indication de pile faible : Oui

Maximum d’indication visuelle : < 30 mA consommation électrique

Indication visuelle élevée/faible : Élevée-ROUGE, faible-bleue, normale-verte

Extinction automatique du

rétroéclairage :

Extinction automatique : Inactif pendant 60 secondes

Dimensions : 5,31 x 1,65 x 6,81 pouces (135 x 42 x 173 mm)

Poids : 6,24 oz. (177 g) (sans pile)

Alimentation : 1 pile de 9V (comprise)

10 à 90% (sans condensation)

±3 ºC ou ±3% de la lecture, suivant ce qui est le plus

élevé (pour des lectures de 20 ºC

Oui

Supérieur 2 impulsions/s, inférieur 1 impulsion/s

Inactif pendant 15 secondes

33

Page 34

CONSEILS D’ENTRETIEN

Nettoyez l’objectif souvent--mais n’utilisez jamais de solvant. Des

changements brusques de température provoqueront de la condensation et une

possible infiltration de vapeur. Nettoyez après que la vapeur se soit évaporée.

Évacuez les particules libres avec de l’air comprimé propre. Brossez

délicatement les débris restants avec une brosse à poils pour objectifs.

Essuyez soigneusement la surface avec un tampon en coton humide.

Évitez l’eau, l’humidité et les gaz ou liquides corrosifs. Le boîtier peut être lavé

avec une éponge mouillée.

Retirez la pile quand vous stockez ce produit pour une longue période.

Ne pas faire tomber ni démonter l’instrument, ni l’immerger dans l’eau.

INFORMATIONS CONCERNANT

LA GARANTIE

Le scanner thermique infrarouge avec système de ciblage à étoile laser IRTC50

IRT de General Tools & Instruments (General®) est garanti pour l'acheteur

originel sans défauts matériels et de fabrication pour une période d’1 an. Sujet

à certaines restrictions, General réparera ou remplacera cet instrument si,

après examen, il est déterminé par General comme ayant des défauts matières

ou de fabrication.

Cette garantie ne s’applique pas aux dégâts que General détermine comme

provenant d’une tentative de réparation par du personnel non autorisé ou une

mauvaise utilisation, des modifications, une usure normale ou des dommages

accidentels. L'unité défectueuse doit être retournée à General Tools &

Instruments ou à un centre de service General agréé, port payé et assuré.

L’acceptation des réparations exclusives et des solutions de remplacement

décrites ci-dessus est une condition du contrat d’achat de ce produit. En aucun

cas, General ne saurait être tenu responsable de dommages accessoires,

spéciaux, indirects ou punitifs, ni de coûts, d’honoraires d’avocat, de dépenses,

de pertes prétendues faisant suite à des dégâts dus à une panne ou un défaut

du produit, y compris, mais sans s’y limiter, toutes réclamations pour perte de

profits.

34

Page 35

RETOUR DE GENERAL POUR LA POLITIQUE

DE RÉPARATION

Tous les efforts ont été faits pour vous fournir un produit fiable de qualité

supérieure. Cependant, dans le cas où votre instrument nécessite une

réparation, veuillez contacter notre service client pour obtenir un RGA#

(autorisation de retour de marchandise, en anglais) avant de transmettre l’unité

via un envoi prépayé à l’attention de notre service client à cette adresse :

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Rappelez-vous de joindre une copie de votre preuve d’achat, votre adresse de

retour et votre numéro de téléphone et/ou votre adresse électronique.

35

Page 36

GENERAL TOOLS & INSTRUMENTS

80 White Street

New York, NY 10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

IRTC50 User’s Manual

Specifications subject to change without notice

©2010 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE FOR

TYPOGRAPHICAL ERRORS.

MAN#IRTC50 11/10

Loading...

Loading...