9-IN-1 THERMO-HYGROMETER/

MOISTURE METER

USER’S MANUAL

RHMG650

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Please read this manual carefully and thoroughly before using this product.

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 –4

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

What’s in the Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 –6

Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 – 12

Powering On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Selecting a Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 –8

General Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 –9

Recalling Stored Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setting Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 – 11

Measuring Moisture Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 – 12

Checking Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating & Maintenance Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return for Repair Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION

Thank you for purchasing General Tools & Instruments’ (General’s) RHMG650 9-in-1 ThermoHygrometer/Moisture Meter. Please read this user’s manual carefully and thoroughly before using

the instrument.

The RHMG650 is a handheld instrument that will prove useful to four groups of users: water

damage restoration contractors, HVAC/R system installers and technicians, facility maintenance

professionals and electronics manufacturers.

The first three groups will exploit the meter’s ability to measure, display and store/recall six

condensation-related parameters: temperature, relative humidity (RH), absolute humidity, dew

point, atmospheric pressure and vapor pressure. The meter’s large, primary readouts of each of

the last five parameters are accompanied by a smaller, secondary readout of the first parameter:

ambient temperature. The six parameters measured, monitored and displayed by the RHMG650

are most valuable in water damage remediation and the following two applications:

•

Environmental monitoring

facilities, wineries, freezers, shipping containers, HVAC/R installations, computer rooms, labs,

libraries, museums and saunas.

2

of office buildings, greenhouses, food and equipment storage

•

Electronics manufacturing

. Alerts provided by the low RH alarm of the RHMG650 can

mitigate the risk of damaging high-voltage static discharges.

Water damage remediators will also make use of the RHMG650’s ability to calculate an

environment’s mixing ratio (often represented by the unit GPP, or grains per pound). GPP is a

more useful moisture metric than RH to water damage remediators. Using RH alone, a remediator

might unknowingly introduce moist air—with a low RH but a high GPP—during a job’s drying

phase. The RHMG650’s atmospheric pressure sensor makes its calculations of GPP—as well as

dew point and vapor pressure—more accurate than those of competitive units which use

standard atmospheric pressure at sea level.

Another parameter of interest to water damage remediators is the moisture level of a substance

(typically, wood or building materials). The RHMG650 can measure this parameter using either a

pinless (non-marring) or pin-type (penetrating) probe; the meter includes both kinds of probe.

Operating in internal moisture mode, the meter uses a non-invasive (pinless) sensor on the back

of the unit to detect moisture up to 3/4 in. (20mm) below the surface of wallboard, masonry,

hardwood and softwood. It infers the level of moisture from the material’s capacitance, which the

meter measures by gauging its effect on an electric field that the meter generates each time it is

operated in internal moisture mode.

In internal moisture mode

, the meter exploits two physical phenomena to make its

measurements:

1. The linear relationship between a solid material’s moisture level and its dielectric

constant—and therefore its capacitance.

2. The so-called fringing-field effect—the slight spreading of the electric field produced by

current flowing between two electrodes when both electrodes are on the same side of a

material.

Behind the back cover of the RHMG650 are two metal plates. When the meter is powered on, the

plates are given small and opposite charges. The potential difference causes current to flow,

creating a three-dimensional electric field.

When the back of the meter is placed against one side of a material with moisture on or slightly

below its surface, the increased capacitance of the material distorts the electric field to an extent

that can be sensed (as a change in flux over the sensing area) and measured. Displayed readings

reflect the average moisture level of the material between its surface and the electric field’s

maximum penetration of 3/4 in. Moisture closer to the surface has a greater effect on readings

than moisture at the maximum penetration depth.

In external moisture mode

, the meter bases its measurements on the relationship between the

moisture content of a material and its electrical conductivity. The wetter a material, the higher its

conductivity. The two replaceable steel pins of the included external probe serve as the

electrodes of a conductance meter optimized for measuring moisture content. The meter displays

measurements in the unit %WME (Wood Moisture Equivalent).

For hard materials like wood or concrete, the meter’s readings largely reflect surface moisture

content because: 1) Moisture close to a surface has a greater effect on a reading than moisture

deep below it; and 2) The pins of the external probe are only 3/8 in. (10mm) long and cannot be

3

driven deep into a hard material. For softer materials like soil, paper or powders, readings are

more likely to reflect the average moisture level of the material between its surface and the

penetration depth of the pins (normally far less than 3/8 in.).

The RHMG650 can store and recall 20 pairs of measurements in its nonvolatile memory. The

instrument also can be set up to sound an alarm if a measured RH or moisture level is above or

below a user-defined setpoint. Finally, the unit can track the maximum or minimum reading of

any parameter over the duration of a measurement session. The unit is powered by an included

“9V” battery.

KEY FEATURES

• Measures 1) ambient temperature, 2) relative humidity (RH), 3) absolute humidity (in

mg/L or g/m

level using pinless sensor, 6) absolute moisture level using included pin-type probe,

7) dew point, 8) atmospheric pressure and 9) vapor pressure

• Stores/recalls 20 pairs of readings

• Settable high and low alarms for RH, relative moisture level and absolute moisture

level

• Backlit LCD with 3-digit primary readout + 4-digit secondary readout

• Zero reset in pinless moisture level mode

• Min/Max, Data Hold, and 30-minute Auto Power Off functions

• 1 year limited warranty

3

), 4) GPP (mixing ratio—in grains per pound or g/kg), 5) relative moisture

SAFETY INSTRUCTIONS

Do not operate the RHMG650 in the presence of flammable or explosive gases.

The steel pins of the external moisture probe are very sharp. When using the probe, be careful

not to stab yourself or anyone else. Remember to replace the protective cap over the pins when

finished using the probe.

WHAT’S IN THE BOX

The RHMG650 comes in a soft pouch inside an illustrated box. Also inside the pouch are a

pin-type moisture probe, a sensor protection cap, a “9V” battery and this user’s manual.

PRODUCT OVERVIEW

Fig. 1 shows the names and locations of all of the controls, connectors and physical structures of

the RHMG650. Fig. 2 shows all possible indications on the unit’s LCD. Familiarize yourself with

the labels, positions and functions of all buttons and connectors before moving on to the Setup

Instructions and Operating Instructions.

4

Fig. 1. The controls and physical structures

of the RHMG650

A. Humidity/temperature sensor

B

B. Removable hanger tab

C. LCD

ON/OFF HOLD

D.

button powers it on.

button.

With meter off

With meter on

, pressing

, briefly pressing

button freezes primary and secondary readouts;

pressing and holding button powers meter off.

AX/MIN

E. M

level,

since entering that measurement mode.

button twice displays lowest reading

button. For all parameters except moisture

pressing button once displays highest reading

Pressing

since entering

E

H

that measurement mode. Pressing button a third

time resumes measurement and display of same

parameter.

ZERO

F.

Also used to enter alarm set mode

button.

With meter off

, used to disable Auto

.

K

Power Off (APO) function. In measurement mode, used to reset baseline of pinless moisture

MOIST INT

(

UNIT

G.

) measurements.

button.

In measurement mode, each press toggles between Imperial and metric

In memory mode

, used to clear stored readings.

measurement units for the following parameters: Ambient Temperature & Dew Point (°F or

3

°C); Absolute Humidity (mg/L or g/m

Vapor Pressure (mBAR or KPa).

to enter alarm set mode

H.

<DN

button.

In measurement mode, each press shifts mode selector one position to the

.

left. In memory mode, each press decrements record counter

mode, each press decreases alarm setpoint

I.

UP>

button.

In measurement mode, each press shifts mode selector one position to the

right. In memory mode, each press increments record counter

mode, each press increases alarm setpoint

J.

STORE/ENTER

button.

In measurement mode, stores both displayed readings

when pressed and held for >2 seconds.

setpoint

and advances to Lo alarm setting, or saves displayed Lo alarm setpoint and

resumes measurement mode.

); Mixing Ratio (GPP or g/kg); Barometric Pressure and

In memory mode, used to clear

stored readings.

by one digit.

In alarm set

by 0.1%.

by one digit.

by 0.1%.

In alarm set mode, saves displayed Hi alarm

In memory mode, exits memory

mode and resumes

In alarm set

in memory

measurement and display of last selected parameter.

K. Jack for included pin-type moisture probe

L. Pinless moisture sensor (on back)

M. Battery compartment (on back)

A

L

C

D

F

G

I

J

M

Also used

5

Fig. 2. All possible display indications

▼: Mode selector

: Relative humidity mode indicator

: Absolute humidity mode indicator

[Upper] : Dew point mode indicator

: Vapor pressure mode indicator

: GPP mode indicator

: Ambient pressure mode indicator

: Pin-type moisture measurement mode

indicator

: Pinless moisture measurement mode

indicator

: Maximum & minimum value

indicators

: Data hold indicator

: Primary readout

: Secondary readout

: Recall mode indicator

: Record number indicator

: Low battery icon

[Lower] : Dew point temperature indicator

: Auto power off enabled indicator

: Mixing ratio units

: Alarm limit indicators

: Zero reset indicator

: Pin/pinless moisture level indicator

6

: Relative humidity unit

: Temperature units

: Absolute humidity units

: Pressure units

SETUP INSTRUCTIONS

°F

INSTALL BATTERY

To open the battery compartment:

1. Turn the meter over and loosen the single screw securing the battery compartment cover.

Remove the screw and set it aside.

2. Lift the tab at the bottom of the cover in order to remove it and set it aside.

3. Plug the included “9V” battery into the wired socket inside the compartment. The terminals

of the battery and the socket mate in only one way, with the smaller male terminal plugging

into the larger female terminal.

4. Replace the battery compartment cover and reinstall the screw to secure it.

OPERATING INSTRUCTIONS

POWERING ON & OFF

To power on the meter

immediately begin making and displaying RH (relative humidity) measurements.

Before using the meter to make measurements, remove the dust cap protecting the

humidity/temperature sensor.

To power off the meter

shutdown will be announced by two short beeps.

After powering off the meter, replace the sensor protection cap if you do not expect to use the

instrument within the next few hours.

By default, the meter will automatically power itself off if no front-panel button is pressed within

any 30-minute period. The upcoming shutdown will be announced by three beeps of the beeper.

When this Auto Power Off function is active, the term

LCD (see Fig. 2).

To disable the APO functio

holding the

ZERO

been disabled, the term

SELECTING A PARAMETER

, press the

ON/OFF HOLD

, press and hold the

n, you must power on the meter in a special way, by pressing and

button while pressing the

APO

will not appear on the LCD.

The RHMG650 can measure and display the value of eight different

moisture-related parameters. When the meter is in measurement

mode, you select a parameter by pressing either the

buttons to move the ▼ pointer on the top line of the LCD directly

above it. For example, the following is the display for RH

measurement mode—the operating mode that the meter enters by

default when it is powered on.

button. By default, the instrument will

ON/OFF HOLD

ON/OFF HOLD

button for at least 2 seconds. The

APO

will appear at the bottom left of the

button. When the

APO

function has

UP>

and

<DN

7

As the figure on the left shows, moving the ▼ pointer four

UP>

positions to the right (by pressing the

button four times)

switches the meter to operate in Ambient pressure mode.

In Dew point measurement mode, will appear at the left of

the secondary readout to remind you that the value shown reflects

the dew point temperature, rather than the ambient temperature.

GENERAL CONTROLS

Changing measurement units

readouts.

To switch to metric units

will then be displayed as °C rather than °F; absolute humidity values will be stated in g/m

. By default, the RHMG650 uses Imperial units for all parametric

, press the

UNIT

button. Ambient temperatures and dew points

3

rather

than in mg/L; mixing ratios will be displayed in units of g/kg rather than GPP; and barometric

pressures and vapor pressures will be stated in KPa rather than mBAR.

Backlight

. The RHMG650 has a green backlight that automatically illuminates whenever any

button is pressed. It will remain on for 30 seconds and then extinguish to extend battery life.

Holding readings. Briefly

pressing the

ON/OFF HOLD

button freezes

both the primary and secondary readouts. will appear on

the display to remind you that the readouts are frozen.

To release the hold, briefly press the

ON/OFF HOLD

button again.

Note: When the RHMG650 is in Hold mode, it takes two separate

presses of the

ON/OFF HOLD

button to power off the meter. The first

(brief) press (which is accompanied by a short beep) releases the

hold. The second press (and hold) initiates shutdown (which is announced by two short beeps).

Storing readings

. Pressing and holding the

STORE/ENTER

button for at least 2 seconds saves the

values shown on the primary and secondary readouts as a pair in the meter’s nonvolatile

memory. Each “save” automatically increases by one the Record number indicator—the number

above

MEM

at the lower left of the LCD. The readings remain in memory, available for recall, after

the meter powers off.

The next section of this manual contains instructions for recalling saved readings.

8

MIN/MAX tracking

• Pressing the MAX/MIN button once displays the highest reading

. For all parameters except moisture level:

since entering that

measurement mode. will appear at the left of the primary readout.

Pressing the button twice displays the lowest reading

•

since entering that measurement

mode. will appear at the left of the primary readout.

Pressing the button a third time resumes real-time measurement

•

and display of the same

parameter.

RECALLING STORED READINGS

To enter Recall mode

, press the

<DN

and

UP>

buttons at the same time. will appear

above the Record number indicator at the lower left of the LCD. The Record number indicator will

correspond to the last pair of readings stored.

<DN

and

UP>

You can now use the

buttons to navigate to and display a specific pair of readings.

For example, the screen shot below shows that a pair of readings of 63.8% for RH and 28.8°C for

temperature were stored in Record location 08.

UP>

Alternatively, you can repeatedly press the

readings in the order in which they were stored, or the

recall them in reverse order. Pressing the

button to recall all

<DN

UP>

button when the last

button to

stored pair of readings is displayed returns the Record number

indicator to 01, corresponding to the first pair of readings stored.

<DN

Pressing the

button when the first stored pair of readings is

displayed returns the indicator to the record number of the last pair

of readings stored.

To exit Recall mode

and resume making real-time measurements, press the

STORE/ENTER

button.

To erase all stored readings

, press and hold the

ZERO

and

UNIT

buttons at the same time for at least 2 seconds. The meter will

respond by sounding three short beeps and resetting the Record

number to 01. You can clear all stored readings while operating in

Recall mode or Measurement mode. Clearing the memory in Recall

mode produces the display at left.

SETTING ALARMS

The RHMG650 allows you to set alarms that will repeatedly sound the beeper if the measured

RH level or the moisture level of a material (measured by either the pinless or pin-type sensor)

is above or below a certain value. The upper and lower limits are called alarm setpoints. For

example, the screen shot at the top of the next page shows that the upper limit for RH—the

HIGH

setpoint of the RH alarm—has been set to 63.8%.

9

T

o enter Alarm set mode

the same time while in

, press the

RH, MOIST INT

MAX/MIN

or

MOIST EXT

and

UNIT

mode. Doing so

buttons at

will display the current value of the selected parameter’s high

HIGH

setpoint and cause the word

to appear near the upper left of

the display, as shown on the left.

All three parameters require you to use the same three-step

sequence of button presses for changing their setpoint(s). After

HIGH

entering Alarm set mode (with

setpoint by using the

LOW

setpoint). Each press of the

<DN

button decreases the setpoint by 0.1%. To change the value of the setpoint by a large

UP>

or

amount, you can press and hold the

Whether or not you change the

proceed to the next step in the sequence: changing the

Pressing the

STORE/ENTER

button with

readout as the selected parameter’s new

switches the primary readout to show the current value of the parameter’s

LOW

Once

parameter’s

you can leave the

must be to press the

appears on-screen, you can use the

LOW

setpoint, as explained earlier in the paragraph on

LOW

setpoint unchanged. Whether or not you make a change, your next step

STORE/ENTER

readout as the selected parameter’s new

appearing on screen), you can either raise or lower the

<DN

button, or leave it unchanged (if you wish to change only the

UP>

button increases the setpoint by 0.1%. Each press of the

UP>

or

<DN

button for at least 3 seconds.

HIGH

setpoint, you must press the

LOW

HIGH

on-screen saves the value shown on the primary

HIGH

setpoint. It also changes

STORE/ENTER

setpoint or leaving it unchanged.

HIGH

to

LOW

UP>

or

<DN

button to change the value of the

HIGH

setpoints. Alternatively,

button. Doing so saves the value shown on the primary

LOW

setpoint. It also causes

LOW

to disappear and

button to

LOW

setpoint.

HIGH

and

returns the RHMG650 to operation in real-time RH measurement mode.

To disarm any of the six alarms(HIGH

reset its setpoint to 100.0% or 0.0% by pressing the

alarm, it is faster to use the

UP>

and

LOW

for

RH, MOIST INT

UP>

or

and

MOIST EXT

<DN

button. When disarming a

), you must

button to increase its setpoint to 100% than to use the

HIGH

<DN

button to decrease its setpoint to 0.0%. In practice, what you would do is: 1) press and hold the

UP>

button until the display shows a value greater than 99%, 2) release the button, and 3) use

brief presses to reach 99.9%. When the primary readout shows 99.9%, the next press of the

button will change the readout to

HIGH

the

alarm for that parameter.

Similarly, you would disarm a

OFF

. Pressing the

LOW

alarm by 1) pressing and holding the

STORE/ENTER

button at this point will disarm

<DN

button until the

UP>

display shows a value less than 1%, 2) releasing the button, and 3) using brief presses to reach

0.1%. When the primary readout shows 0.1%, the next press of the

<DN

button will change the readout to

STORE/ENTER

button at this point will disarm the

OFF

. Pressing the

LOW

alarm for that

parameter. The screen at left shows the next-to-last step (prior to

pressing the

MOIST INT

.

STORE/ENTER

button) of disarming the

LOW

alarm for

10

Two notes related to alarms:

HIGH

•

alarm setpoints must be higher than

LOW

in Alarm set mode, pressing the

LOW

alarm setpoints. When the display is showing

STORE/ENTER

button to save a change that violates

this rule will not succeed in returning the RHMG650 to real-time measurement. Instead, the

beeper will sound four times and the Alarm set sequence will return to the first step.

Consider this a prompt to reset the

alarm setpoint to a value greater than the

LOW

HIGH

alarm setpoint.

HIGH

and

LOW

• The original factory settings of the

alarm setpoints are 85% and 25%,

respectively. So if your first use of the meter is in a exceptionally humid or dry environment,

an alarm may sound immediately. To disarm the alarm, follow the instructions in the

preceding two paragraphs.

MEASURING MOISTURE LEVELS

In addition to the modes for measuring five condensation-related parameters, the RHMG650 has

two separate moisture level measurement modes:

MOIST INT

and

MOIST EXT

. In

MOIST INT

mode, the meter uses a non-invasive (pinless) sensor on the back of the unit to detect moisture

on or within 0.75 in. (19mm) of the surface of a material. In

MOIST EXT

mode, the meter uses the

included pin-type probe to measure the conductivity of a material as a proxy for its moisture

content.

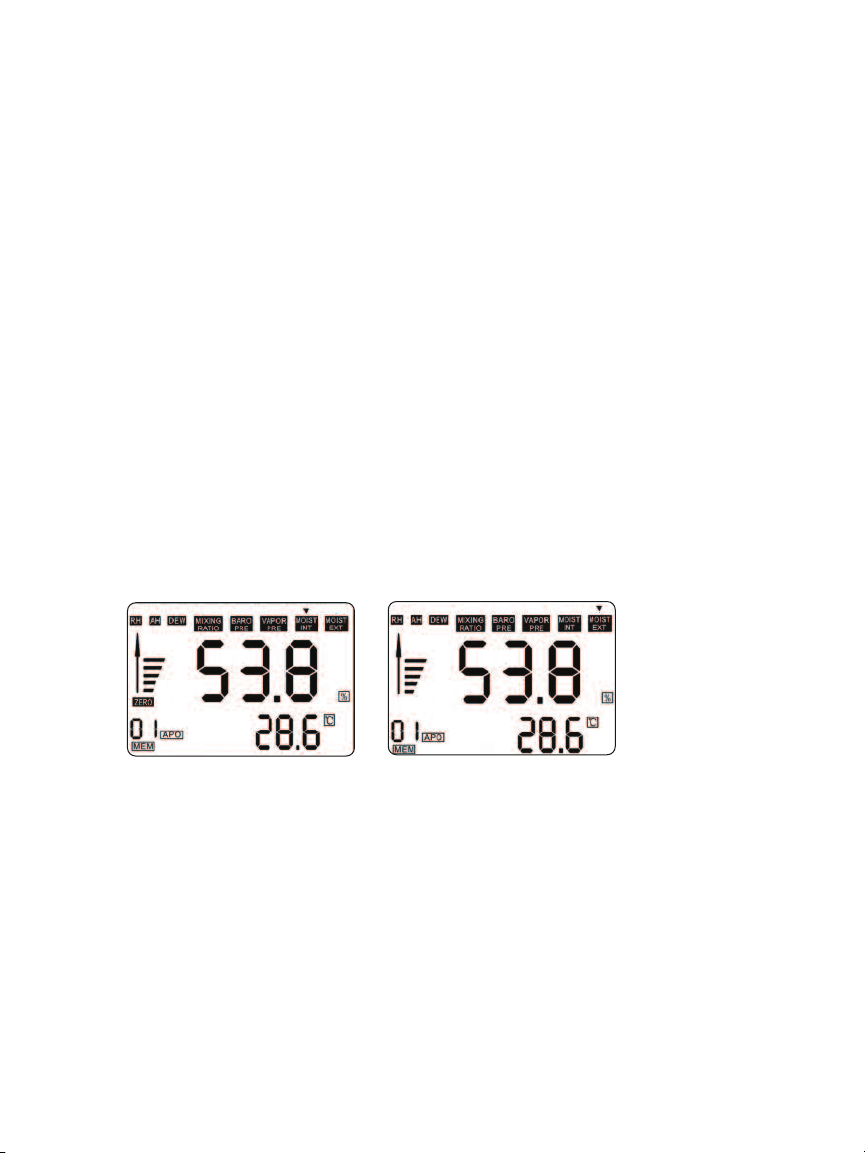

In both moisture level measurement modes, the RHMG650’s display adds a vertical bar graph to

the digital readout of a material’s moisture level. The bar graphs (see below) have no scale; they

exist only to provide an analog way to quickly track changes in relative moisture levels.

To use the included pin-type probe to measure the moisture level of a material:

1. Use the

UP>

or

<DN

button to move the ▼ pointer above

MOIST EXT

.

2. Insert the plug of the probe into the jack on the bottom of the RHMG650.

3. Remove the protective cap from the business end of the probe and set it aside.

4. Insert the pins of the probe into the material whose moisture level you wish to measure.

The measured moisture level will appear on the primary readout as a percentage, with the

ambient temperature below it on the secondary readout.

To use the pinless sensor to measure the moisture level of a material

button to move the ▼ pointer above

MOIST INT

. Hold the meter in either hand by wrapping your

, use the

UP>

or

<DN

fingers around the rubber grip at the bottom of the unit. Make sure that no part of your hand or

fingers is touching—or even near—the pinless sensor on the back of the meter.

11

If the primary readout shows

0.0%

with the meter in your hand (and not touching anything), the

meter is ready to make measurements. To measure the moisture level of a material, press the

pinless sensor on the back of the meter (Fig. 1, Callout L) against it. The moisture level, as

percentage, will appear on the primary readout.

If the primary readout shows a value other than 0.0%, you should reset the baseline of

measurements in

MOIST INT

nothing) and press the

bar graph at the left of the display, the primary readout will show

will again be accurate in

mode. To do so, continue to hold the meter in your hand (touching

ZERO

button. Immediately after the term

MOIST INT

mode.

ZERO

appears briefly below the

0.0%

and the measurements

To obtain accurate readings in

MOIST INT

mode, you should reset

the readout to 0.0% each time you re-enter that mode from

another mode.

CHECKING CALIBRATION

check

Although you cannot calibrate the RHMG650 yourself, you can

the meter’s calibration

periodically to assure yourself of the accuracy of humidity-related readings (RH, absolute

humidity, dew point and mixing ratio). Factory calibration should minimize the humidity sensor’s

drift for several years—well beyond the warranty period.

At a minimum, a calibration check should entail immersing the slotted structure protecting the

humidity sensor in two bottles containing saturated salts. One reference salt should produce a

reading of a 33%; the other should produce a reading of 75%.

Two salts of this type are available from General: the HR33 (33%) MgCl Calibration Salt and the

HR75 (75%) NaCl Calibration Salt.

Depending on the size and shape of the calibration salt bottle that you use, you may have to

remove the hanger tab (Fig. 1, Callout B) from the meter to provide sufficient clearance for the

bottle to fit snugly over the slotted structure protecting the humidity/temperature sensor (after

removing the dust cap). The hanger tab is removable for that reason.

12

SPECIFICATIONS

Ambient Temperature Measurement Range -20° to 167°F (-29° to 75°C)/±3.6°F (2°C)

Ambient Temperature Measurement Accuracy ±3.6°F (2°C)

RH Measurement Range 0 to 100%

RH Measurement Accuracy ±2.5% from 11 to 90%RH; ±3%RH elsewhere

Absolute Humidity Range 0.5 to 240mg/m3(mg/L)

GPP Range 0 to 999 GPP (0 to 160g/kg)

Relative/Absolute Moisture Level Range 0 to 99.9%

Pinless Moisture Measurement Depth 0.75 in. (19mm)

Dew Point Range -76° to 140°F (-60° to 60°C)

Atmospheric Pressure Range 30 to 120 kPA

Vapor Pressure Range 0 to 20.0 kPA

Sampling Rate 2X/sec

Memory Capacity 20 pairs of readings

Auto Power Off Trigger 30 minutes of inactivity

Backlight Duration 30 seconds

Battery Life 6 to 8 weeks (4 hrs/day use)

Operating Temperature 32° to 110°F (0° to 43°C)

Storage Temperature -22° to 140°F (-30° to 60°C)

Dimensions 7.3 x 2.8 x 1.4 in. (185 × 72 × 36mm)

Weight 6.2 oz. (175g), without battery

Power Source (1) “9V” battery (included)

13

OPERATING & MAINTENANCE TIPS

• When the icon appears on the bottom row of the LCD, it’s time to install a fresh “9V”

battery using the procedure on p.7.

• Do not immerse the RHMG650 in water or get water on it.

• Do not disassemble the unit. Opening the case voids the warranty.

• To avoid fouling the humidity/temperature sensor, do not operate the unit in very dusty

environments. Replace the dust cap protecting the sensor after each measurement session.

• Remove the battery if you do not expect to use the unit for several months or longer. This will

avoid potential leaks of battery acid that might damage or destroy the unit.

WARRANTY INFORMATION

General Tools & Instruments’ (General’s) RHMG650 9-in-1 Thermo-Hygrometer/Moisture Meter is

warranted to the original purchaser to be free from defects in material and workmanship for a

period of one year. Subject to certain restrictions, General will repair or replace this instrument if,

after examination, the company determines it to be defective in material or workmanship.

This warranty does not apply to damages that General determines to be from an attempted repair

by non-authorized personnel or misuse, alterations, normal wear and tear, or accidental damage.

The defective unit must be returned to General Tools & Instruments or to a General-authorized

service center, freight prepaid and insured.

Acceptance of the exclusive repair and replacement remedies described herein is a condition of

the contract for purchase of this product. In no event shall General be liable for any incidental,

special, consequential or punitive damages, or for any cost, attorneys’ fees, expenses, or losses

alleged to be a consequence of damage due to failure of, or defect in any product including, but

not limited to, any claims for loss of profits.

14

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable product of superior quality. However, in

the event your instrument requires repair, please contact our Customer Service to obtain an RGA

(Return Goods Authorization) number before forwarding the unit via prepaid freight to the

attention of our Service Center at this address:

Remember to include a copy of your proof of purchase, your return address, and your phone

number and/or e-mail address.

15

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Specifications subject to change without notice

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

©2013 GENERAL TOOLS & INSTRUMENTS

MAN# RHMG650

6/12/13

Loading...

Loading...