THE SEEKER

THE SEEKER

™

200 SERIES &

™

300 SERIES

VIDEO INSPECTION SYSTEMS

DCS200

(shown)

DCS300

(shown)

DCS200/DCS200-09/DCS200-05

DCS300/DCS300-09/DCS355

USER’S MANUAL

Please read this manual carefully and thoroughly before using this product.

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Probe Tip Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disconnecting and Reconnecting the Probe . . . . . . . 6

Installing the Accessories . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Image Rotation and Zoom Operation . . . . . . . . . . . . . . 7

Camera Tipped Probes . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . 9

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Return For Repair Policy . . . . . . . . . . . . . . . . . . . . . . . 11

INTRODUCTION

The Seeker™200 and Seeker 300 Series Inspection Systems have

been designed as a user friendly and economical way of viewing

hidden problems and increasing productivity. Each system has a

high clarity color LCD for clear imaging. The differences between the

3 systems are the size of the screen and the diameter of the probes.

The Seeker

Seeker

head is housed inside the tip of each probe with adjustable white

LED lights, which helps you to see in those dark gaps and holes.

These video inspection systems have the advantage of clear images,

easy operation and portability. They are widely used in applications

such as HVAC/R building, aviation and vehicles maintenance.

™

200 Series has a 2.4" (60.9mm) diagonal screen and the

™

300 Series has a 3.5" (88.9mm) diagonal screen. The camera

FEATURES

• DCS200 Series: 2.4" (60.9mm) Color LCD Screen

for a crystal clear image

• DCS300 Series: 3.5" (88.9mm) Color LCD Screen

for superb clarity and viewing effect

• Camera-tipped probes are flexible and strong with built-in

adjustable LED lighting, and are slim enough to perform

automotive engine check-up

• Flexible probes retain configured shape to suit

different inspection needs

• View findings instantaneously

• 2X digital zoom and 180º image rotation

• Optional probes of different diameters and lengths

• All probes are interchangeable between DCS100, DCS200,

DCS300 and DCS400 series

3

PRODUCT OVERVIEW

A. LCD Screen

B. Image Rotation

C. Image Zoom

D. Battery Compartment

E. ON/OFF Switch /

LED Lighting Intensity

F. Probe Connector

G. Probe

H. Camera Head

12mm Probe accessories

I. Magnetic Tip

J. Hook Tip

K. 45º Mirror Tip

B

H

A

5mm Probe accessories

L. Mirror

M. Thread Protector

N. Ball Guide

9.0mm Probe accessories

O. Mirror

P. Thread Protector

Q. Magnet

R. Hook

F

Fig. 1

C

E

12mmProbeaccessories

D

LNM

Fig. 2

4

5.5mmProbeaccessories

ORQP

9.0mmProbeaccessories

G

I

J

K

BATTERY INSTALLATION

1. Use the included Phillips screwdriver to open the screw on

the battery compartment cover (See Fig. 3).

2. Insert one “9V” alkaline battery into the battery

compartment (See Fig. 4). Close the battery cover and fasten

the screw.

Battery

Battery

Compartment

Cover

Screw

Compartment

Fig. 3

Fig. 4

PRECAUTIONS!

• Remove the battery before storing the unit for a long

period of time.

• Be sure to install the battery with the correct polarity as

indicated in the battery compartment.

• Properly dispose of the batteries. Exposure to high

temperatures can cause the batteries to explode.

Do not dispose in fire. Place tape over the terminals

to prevent direct contact with other objects. Some

countries have regulations concerning battery disposal.

Please follow all applicable regulations.

5

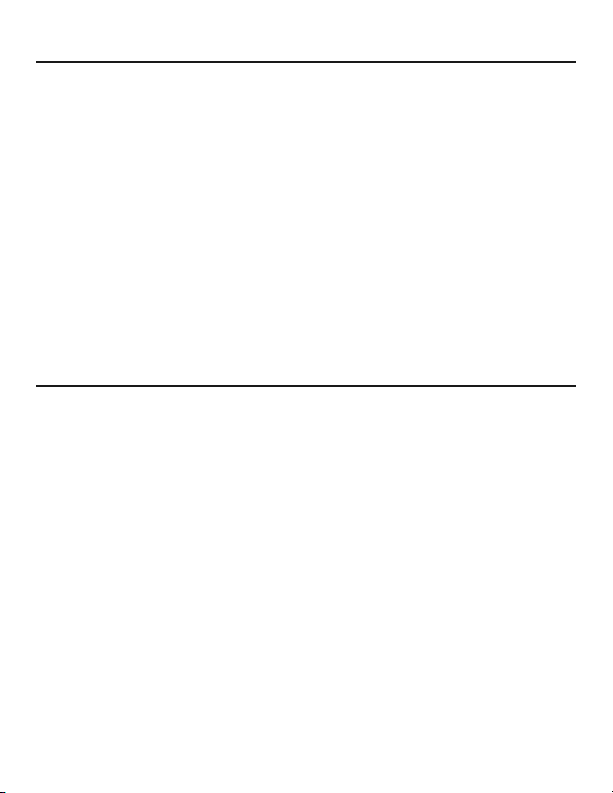

DISCONNECTING AND

RECONNECTING THE PROBE:

All of the probes from these

3 systems are interchangeable and in the case of the

12mm dia. probe, you can

add extensions to extend the

camera tip up to 16 ft. (5m).

To disconnect the probe

from the display unit, twist

the retaining collar counter clockwise several turns and pull

away from the unit. Then pull the probe straight away from the

unit. To reconnect the probe or probe extensions to the

display unit, make sure the keyed ends are properly aligned

(See Fig. 5). Once they are aligned, tighten the retaining collar

by twisting it clockwise.

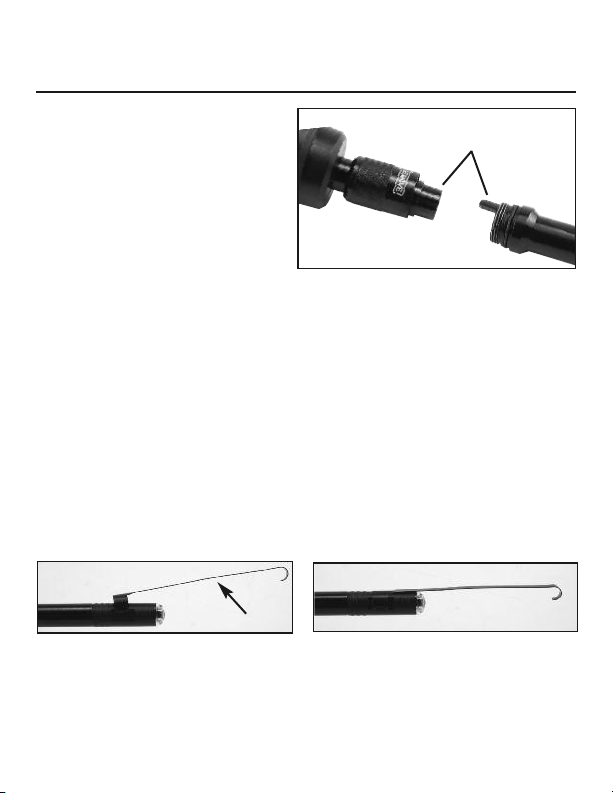

INSTALLING ACCESSORIES: (From Fig. 2)

12mm dia. tip:

tip and magnetic tip. All are attached to the camera head

the same way. As shown in Fig. 6, slip the semicircle end of

the accessory over the flats of the camera head and then

press down to fix as shown in Fig. 7.

Fig. 6

5.5mm dia. tip and and 9.0mm dia. tip: Each of the three

accessories screw directly onto the top of the probe.

The thread protector is used when the mirror or the ball guide

are not attached.

The three accessories include mirror tip, hook

Fig. 7

Accessory

KeyedEnds

Fig. 5

6

OPERATING INSTRUCTIONS

LCDScreen

RotationButton

ZoomButton

ON/OFF

BRIGHTNESS

Fig. 8

BASIC OPERATION:

To turn the unit on, hold the LCD display unit facing you

(See Fig. 8). Roll the on/off/brightness switch away from you

to turn the power on. The switch then acts as a dimmer for the

LED’s in the tips of the probes. Activating the switch also

illuminates the LCD screen. Note: There is no auto off. Make

sure to roll the switch back towards you until it clicks to turn

off the unit after use.

IMAGE ROTATION AND ZOOM OPERATION

The left button on the back of the monitor housing is the

“Image Rotation” button. Press once to flip image (seen in the

LCD monitor) by 180º. The right side button is the “Zoom”

button. Press this multiple times to achieve a full 2X enlargement of the image (seen in the monitor).

7

CAMERA TIPPED PROBES

LED

Camera

12mmprobetip

LED

Camera

LED

LED

5.5mmprobetip

LED

Camera

LED

LED

LED

9mmprobetip

LED

LED

OPERATING PRECAUTIONS!

• Maximum bending radius is 2"; exceeding this may damage

the probe.

• Do not use the probe (camera head) to clear pathways or

clogged areas.

• The hand-held display unit is NOT waterproof and may

become damaged when exposed to water. The camera head

of the probe and its cover are waterproof, but NOT acid-proof

or fireproof. Exposure to these materials will damage the

camera heads protective plastic. Avoid submerging the

camera head into corrosive solvents. Do not expose to high

temperatures.

• Do not place the camera head or probe into areas that may

contain exposed live electrical wires.

For construction: When inspecting inside walls, make sure

there are no exposed live wires, if you are not sure, shut off

the circuit breaker to the whole area before probing with

the scope.

For automobile engine inspections: Be sure the automobile is

not running during inspection. Metal and liquid under the

hood may be hot. Don’t submerge the camera head in oil

or gasoline.

8

MAINTENANCE INSTRUCTIONS

• Service must be performed by qualified repair personnel.

• When servicing this product, only use identical replacement

parts. Use of unauthorized parts or failure to follow

maintenance instructions will void the warranty.

• Disassembling this unit will void the warranty.

• Do not use acetones to clean this product. Use mild soap

and a soft cloth to clean. Gently clean the LCD with a dry

cloth.

TROUBLE SHOOTING

Symptoms Reasons Solutions

Display is on,

but no image

• LED’s on the camera

head are dim at

max bright

• Color display

changes to

black and white

• Color display turns

itself off after a

period of time

The product

won’t turn on

The probes

connection to the

main grip is loose

Cameras head

covered by

debris or safety

cap is on

Low battery

Dead battery

Tighten connection

and try again

Clean camera head

Replace battery

Replace battery

9

SPECIFICATIONS

CAMERA TIPPED PROBES

12mm 9mm 5.5mm

Resolution (pixels NTSC) 320 x 240 320 x 240 320 x 240

Resolution (pixels PAL) 704 x 576 704 x 576 704 x 576

Minimmum Focus Distance 100mm (4") 10mm (0.5 in.)

Field of View 60º 60º 60º

DCS200 2.4" (60.9mm) TFT/LCD

Image Display

Resolution 320 x 240 pixels

Probe Length (supplied) 39" (1m)

Light Source Adjustable LED

Power Source One “9V” alkaline battery

Estimated Battery Life About 2.5 hours

Operating Temperature 32° to 113°F (0° to 45°C)

Operating Humidity 5% to 95%RH non-condensing

Storage Temperature -4° to 140°F (-20° to 60°C)

Body Dimensions

Weight Approx. 16 oz. (454g)

Series

DCS300

Series

DCS200 8.5 x 4.6 x 3.2 in.

Series (215 x 156 x 80mm)

DCS300

Series (215 x 156 x 96mm)

3.5"(88.9mm) TFT/LCD

2x digital zoom

180º image rotation

≤85% (w/o battery)

8.5 x 4.6 x 3.8 in.

10

WARRANTY INFORMATION

THREE YEAR LIMITED WARRANTY

The General Tools & Instruments (General®) DCS200 Series and DCS300 Series

digital video Inspection Systems are warranted to the original purchaser to be free

from defects in material and workmanship for a period of three (3) years. Subject

to certain restrictions, General will repair or replace this instrument, if after examination, it is determined by General to be defective in material or work manship.

This warranty does not apply to damages that General determines to be from

an attempted repair by non-authorized personnel or misuse, alterations, normal

wear and tear or accidental damage. The defective unit must be returned to

General Tools & Instruments or a General authorized service center, freight

prepaid and insured.

Acceptance of the exclusive repair and replacement remedies described

herein is a condition of the contract for purchase of this product. In no event shall

General be liable for any incidental, special, consequential or punitive damages,

or any cost, attorneys fees, expenses, losses alleged to be as a consequence of

any damage due to failure of, or defect in any product including, but not limited

to, any claims for loss of profits.

TIP! Most parts of this products can be recycled.

Please refer to your local regulations for proper disposal.

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable, product of superior quality. However, in the event your instrument requires repair, please contact our Customer Service to obtain a RGA# (Return Goods Authorization) before forwarding the

unit via prepaid freight to the attention of our Service Center at this address:

Remember to include a copy of your proof of purchase, your return address, and

your phone number and/or e-mail address.

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

11

GENERAL TOOLS & INSTRUMENTS

80 White Street

New York, NY 10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

DCS200/DCS300 Series User’s Manual

Specifications subject to change

without notice

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

©2010 GENERAL TOOLS & INSTRUMENTS

MAN#DCS200/DCS300 Series

11/23/10

Loading...

Loading...