Page 1

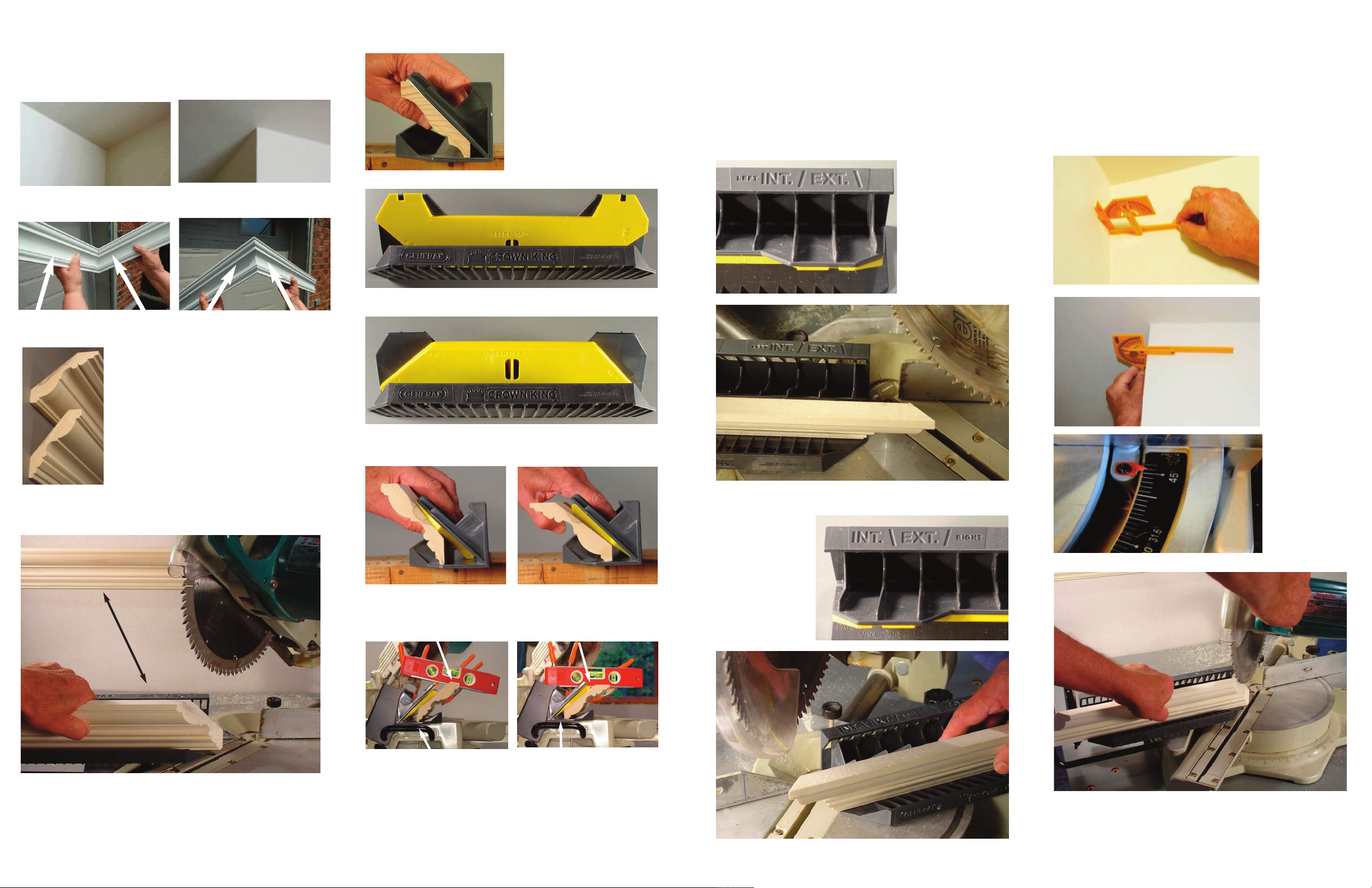

2. BASICS OF CROWN MOLDING

TERMINOLOGY

Interior wall corner

Interior (INT) joint

Exterior wall corner

Exterior (EXT) joint

4. INSERT POSITIONING

For a 45◦spring angle

Insert is not needed.

Markings on the insert

quickly help you to position the insert for the

correct spring angle of

38 or 52 degrees.

Positioning of insert for 38◦cuts.

5. JIG ALIGNMENT

Cutting sequences are simplified by guide marks

embossed on the jig top. All interior (INT) and

exterior (EXT) corner miters for left-side moldings are made on the left side of the blade; cuts

to the right-side moldings are made on the right

side of the saw blade.

TOP markings

for LEFT side

cutting.

B. FABRICATING YOUR

CROWN MOLDING

1. MEASURI

Measure interior (INT) or exterior (EXT) corners.

Divide the angle in half and set the saw blade to

this number.

NG AND LAYOUT

Measuring

the interior

joint angle

Left Inside Right Inside

Crown moldings may be installed

either-side up, however, the

spring angles will be different.

Left outside Right outside

3. CROWN KING PRODUCT OVERVIEW

Positioning of insert for 52◦cuts.

38◦spring angle

Incorrect ceiling angle Correct ceiling angle

52◦spring angle

Detail of left side jig positioning.

TOP markings

for RIGHT side

cutting.

Measuring

the exterior

joint angle.

Set the saw

at ½ of the

measured

angle

The Crown King jig lets you cut perfectly mitered

interior (INT) and exterior (EXT) corner joints—

right out of the box—on 38, 45, or 52 degree

(spring angle) crown moldings. Moldings are cut

the way they look on the wall.

Incorrect wall angle

To check molding angle before cutting, place molding

in jig; the wall face angle should be vertical and the

top (ceiling) angle horizontall. ). If the ceiling angle is

not horizontal, rotate or remove/insert yellow plastic

adapter until angle is correct.

Correct wall angle

Detail of right side jig positioning.

Position the jig and the molding on the miter saw

table with the jig against the saw fence as far

back from the saw blade as needed. Moldings

are hand-held for cutting.

Page 2

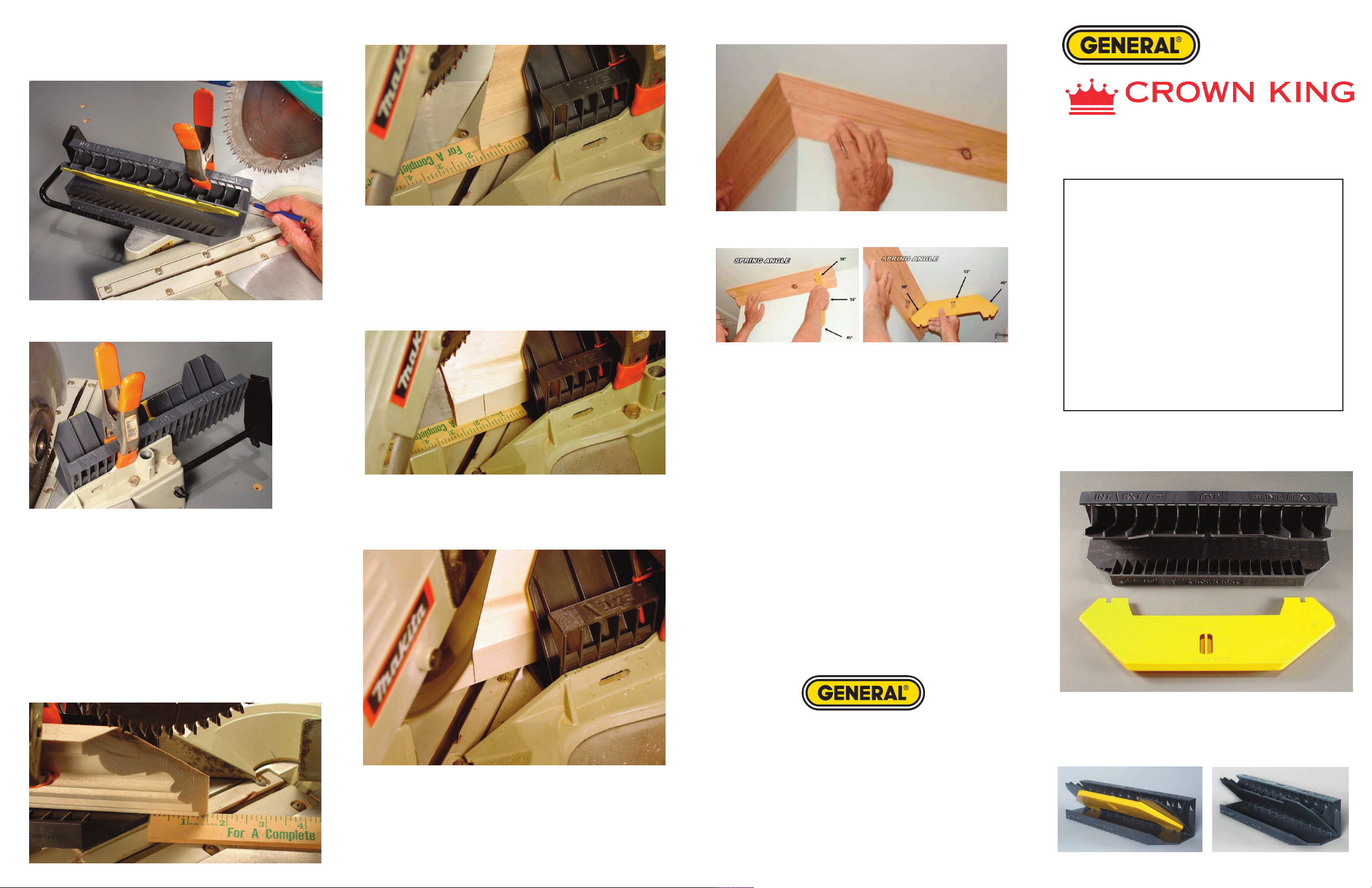

Mark the location of the jig on the fence for future

reference.Then either clamp the jig, set the rail

end stop or hand hold the workpiece fo

r cutting.

Measuring the test cut – (Front view)

Measuring the test cut – (Rear view)

3. MOLDING INSTALLATION

After cutting, test-fit moldings in place.

A CUTTING GUIDE FOR CROWN MOLDINGS

Professionally Cut Crown Molding...

Easily and Precisely

TABLE OF CONTENTS

A. UNDERSTANDING THE PRODUCT

1. BASIC DESCRIPTION

Clamping is optional but not required.

2. BASIC MITRE CUTTING

To easily obtain an accurate miter cut length, first

set your saw at the proper angle for your cut

(right or left) and set the Crown King jig on the

saw table, at the mark you previously made.

Place a piece of scrap molding into the jig and

make a test cut. With the piece still in the jig,

measure from the bottom of the jig to the cut

edge. This is the measurement you will need

to offset your fi

nal cuts.

When making final cuts, extend your molding

(wall length) mark beyond the jig by this same

distance and cut the molding as shown. Repeat

the procedure when making cuts on the opposite

angle.

Set work piece at same measured distance –

(Rear view)

Then make the cut – (Rear view)

It’s as easy as that!

The yellow angle insert can also be used as an

installation guide; hold the insert against the wall

to check 38◦and 45◦angles, or against the ceiling to check 52◦angles.

GENERAL TOOLS & INSTRUMENTS

80 White Street New York, NY 10013-3567

PHONE (212) 431-6100 FAX (212) 431-6499

TOLL FREE (800) 697-8665

www.generaltools.com

880 User’s Manual 03/01/2013

2. BASICS OF CROWN MOLDING

3. CROWN KING PRODUCT OVERVIEW

4. INSERT POSITIONING

5. JIG ALIGNMENT

B. FABRICATING YOUR CROWN MOLDING

1. MEASURING AND LAYOUT

2. BASIC MITER CUTTING

3. MOLDING INSTALLATION

A. UNDERSTANDING THE PRODUCT

1. BASIC DESCRIPTION

A

B

The jig consists of two pieces:

A. the gray jig molded at a 45◦spring angle

B. a versatile and reconfigurable yellow insert

for 38◦and 52◦spring angles.

©2013 GENERAL TOOLS & INSTRUMENTS

Loading...

Loading...