Page 1

No. 870

USER’S MANUAL

(U.S. PATENTS APPLIED FOR)

PLEASE READ THESE INSTRUCTIONS FULLY BEFORE USING THIS JIG

For more information and video instructions visit

www.generaltools.com/mortise-tenon

Page 2

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Anatomy of the Jig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Anatomy of the “Quick Change” Router Base Bushing Assembly . . . . . . 4

Preparing the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 6

Mounting the Jig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 – 12

Capacity and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 3

What’s in the Jig Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the “Quick Change” Guide Sleeve . . . . . . . . . . . . 5

Centering the Base Plate and the

“Quick Change Guide System” . . . . . . . . . . . . . . . . . . . . . . . 5

Setting the Cutting Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. Marking Joint Centers and Location . . . . . . . . . . . . . . . . 7

2. Centering the Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Positioning the Stock using the Positioning Bars . . . . . . 8

4. Setting the Joint Length . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Length of Mortise & Tenon Chart . . . . . . . . . . . . . . . . . . . 9

5. Setting the Depth of the Router Bit . . . . . . . . . . . . . . . . . 10

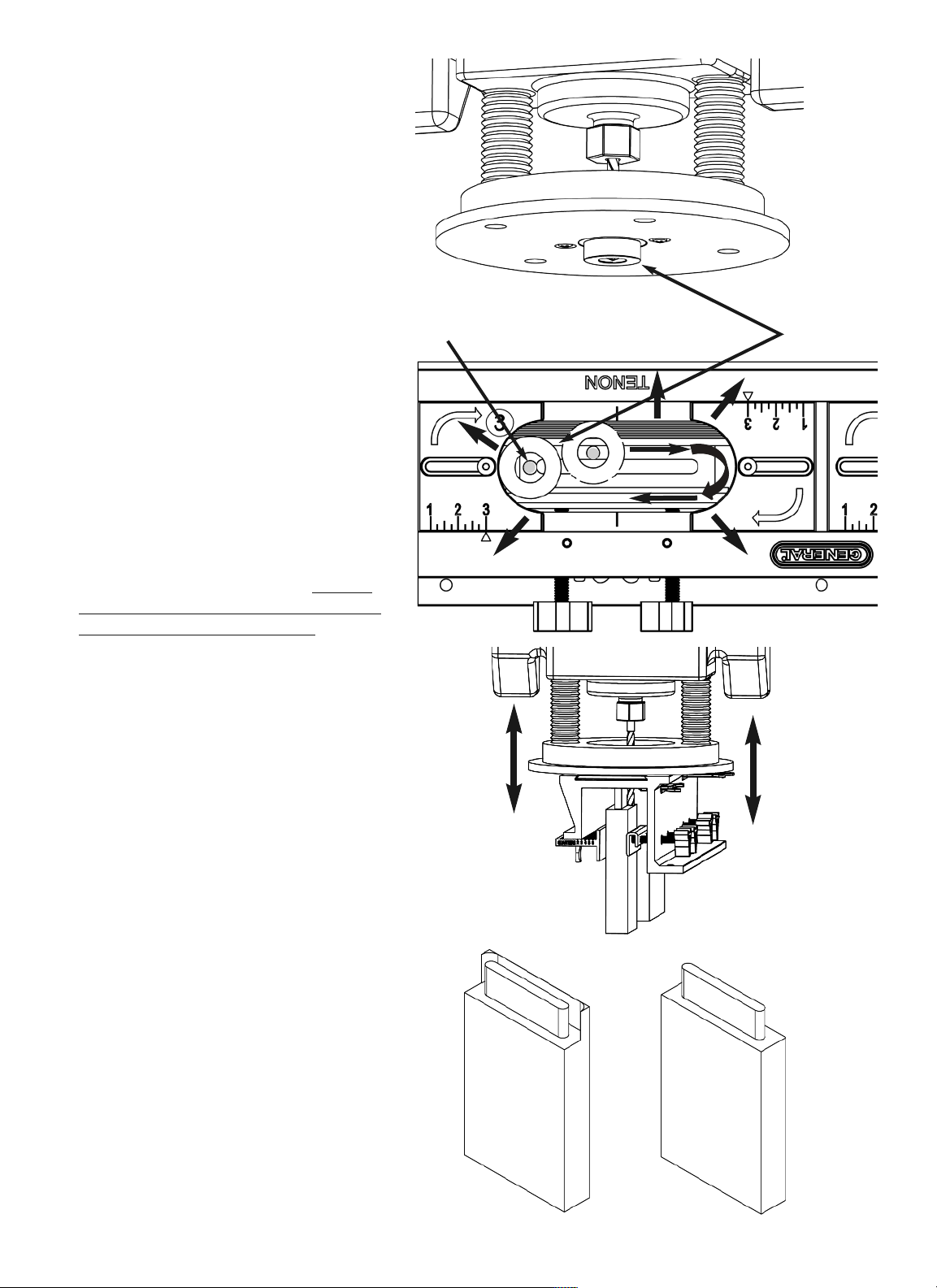

6. Routing the Tenon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7. Routing the Mortise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Routing Other Size Mortise and Tenons . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spanish Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 – 28

French Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 – 42

Sample Mortise &

Tenon Joints

2

Page 3

INTRODUCTION

Thank you for purchasing General Tools & Instruments’ E-Z™Pro Combination Mortise & Tenon

Jig (M&T Jig)— the woodworking industry’s first integrated jig capable of making matching mortise

and tenon joints of professional quality “right out of the box.” The jig makes creating Mortise &

Tenon joints—the sturdiest of all wood joints—for furniture, cabinets and frames – an easy, simple

and fast process.

The Mortise & Tenon Kit comes with a fully assembled jig and includes a 1/4" straight upcut router

bit and 1/4" tenon Guide Bushing. Also included are the guide bushings for cutting 3/8" and 1/2"

joints. You will need to supply your own 3/8" and 1/2" upcut router bits.

The M&T Jig has a one-piece heat treated, high grade aluminum body with adjusting bolts, upcut

fasteners and bit made of steel to SAE specifications. The unit’s adjustable Positioning Bars and

Router Bushing assembly are also made of solid steel.

Capacity and Specifications:

Accommodates stock from 1/2" to 1½" thick and any length

Mortise and Tenon thickness: 1/4", 3/8" and 1/2"

Minimum length M&T Joint: 1" +/- 1/8" (depending on bit used)

Maximum Length M&T Joint: 3" +/- 1/8" (depending on bit used)

What’s in the M&T Jig Kit

1. The fully assembled jig

2. “Quick Change” Router Base Bushing assembly consists of:

• One “Quick Change” 1-3/16" Guide Sleeve

and Locking Nut

• One 1/4" Guide Bushing (1-1/4" OD)

• One 1/4" shank Centering Pin

• One flat Spanner Wrench for guide sleeve

Locking Nut adjustment

• One 3/8" Guide Bushing

• One 1/2" Guide Bushing

3. One 1/4" straight Upcut Spiral Carbide

Router Bit

4. Alignment Tool

It is highly recommended that you familiarize yourself with the nomenclature in Fig. 1 and

Fig. 2 on p. 4 before proceeding.

1

2

3

4

3

Page 4

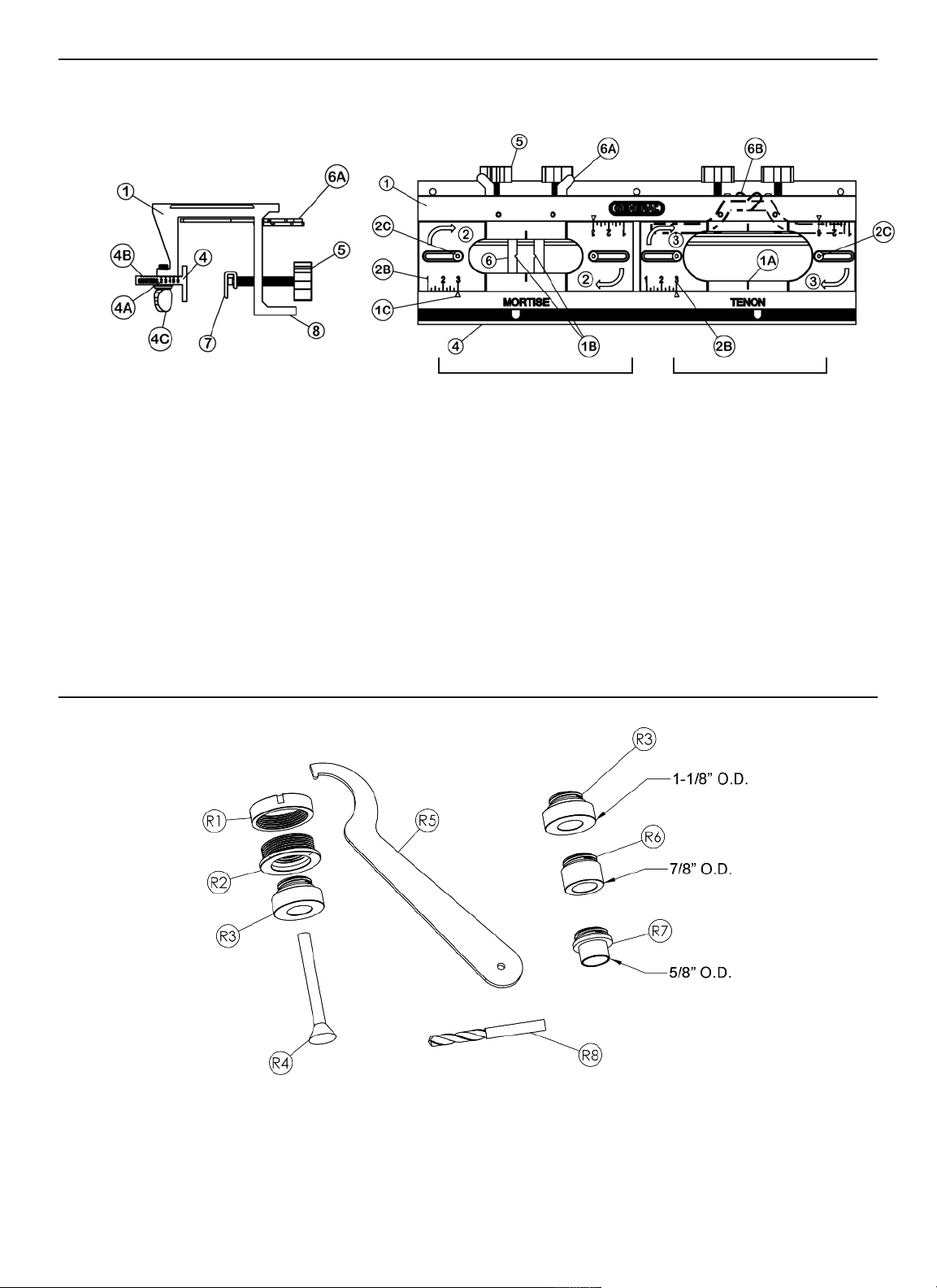

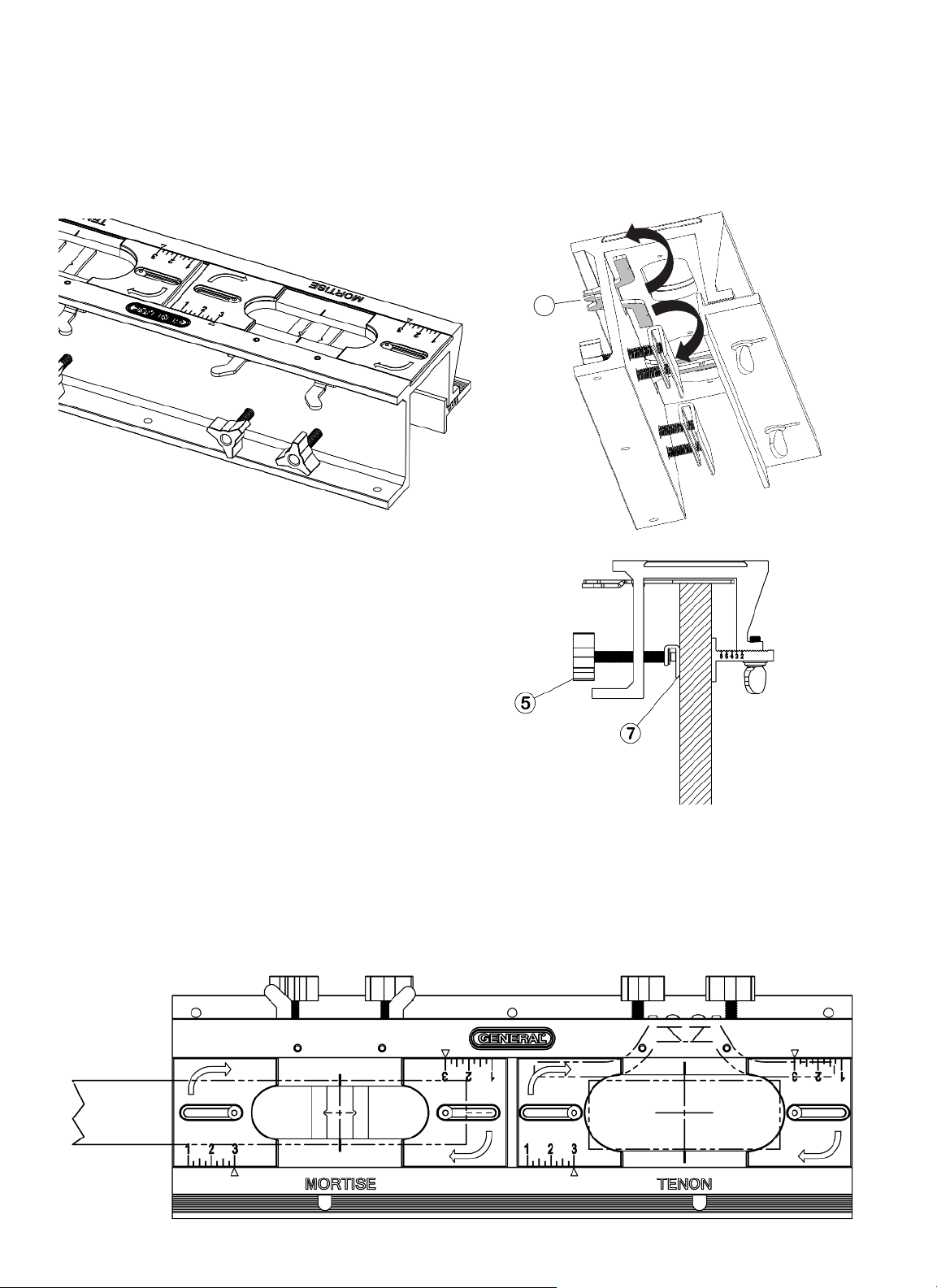

ANATOMY OF THE E-Z PRO MORTISE & TENON JIG

Fig. 1

IG ASSEMBLY IN PROFILE

J

JIG ASSEMBLY

MORTISE SECTION

1 - Jig Assembly

1A - Centering Marks

1B - Centering Notches

1C - Template Positioning Indicators

2 - Mortise Section Templates

2B - Template Position Rule

2C - Template Lock Screws

3 - Tenon Section Templates

4 - Centering Wall, [4A] Markings,

[4B] Serrations, [4C] Thumb Screws

5 - Face Clamp Thumb Screws

6 - Positioning Bars

6A - Positioning Bars deployed

6B - Positioning Bars retracted for storage

and cutting

7 - Face Clamps

8 - Mounting Flange

ANATOMY OF THE “QUICK CHANGE” ROUTER BASE

BUSHING ASSEMBLY:

Fig. 2

TENON SECTION

R1 - Lock Nut

R2 - 1-3/16" Router Base Guide Sleeve

R3 - 1-1/8" O.D. Router Guide Bushing for

the 1/4" Tenon (as well as for all

mortises)

R4 - Centering Pin

4

R5 - Flat Spanner Wrench

R6 - 7/8" O.D. Router Guide Bushing

for the 3/8" Tenon

R7 - 5/8" O.D. Router Guide Bushing

for the 1/2" Tenon

R8 - 1/4" Upcut Routing Bit

Page 5

PREPARING THE ROUTER

SAFETY OVERVIEW

1. KNOW YOUR ROUTER. Read the owner’s manual that came with your router before you use it.

Understand the machine’s applications and limitations, as well as the specific potential hazards

inherent in its use. Before using the router, check that none of its moving parts is broken, loose

or misaligned.

NOTE: General Tools & Instruments is not responsible for router misuse or the disregard of

standard safety precautions associated with using a router.

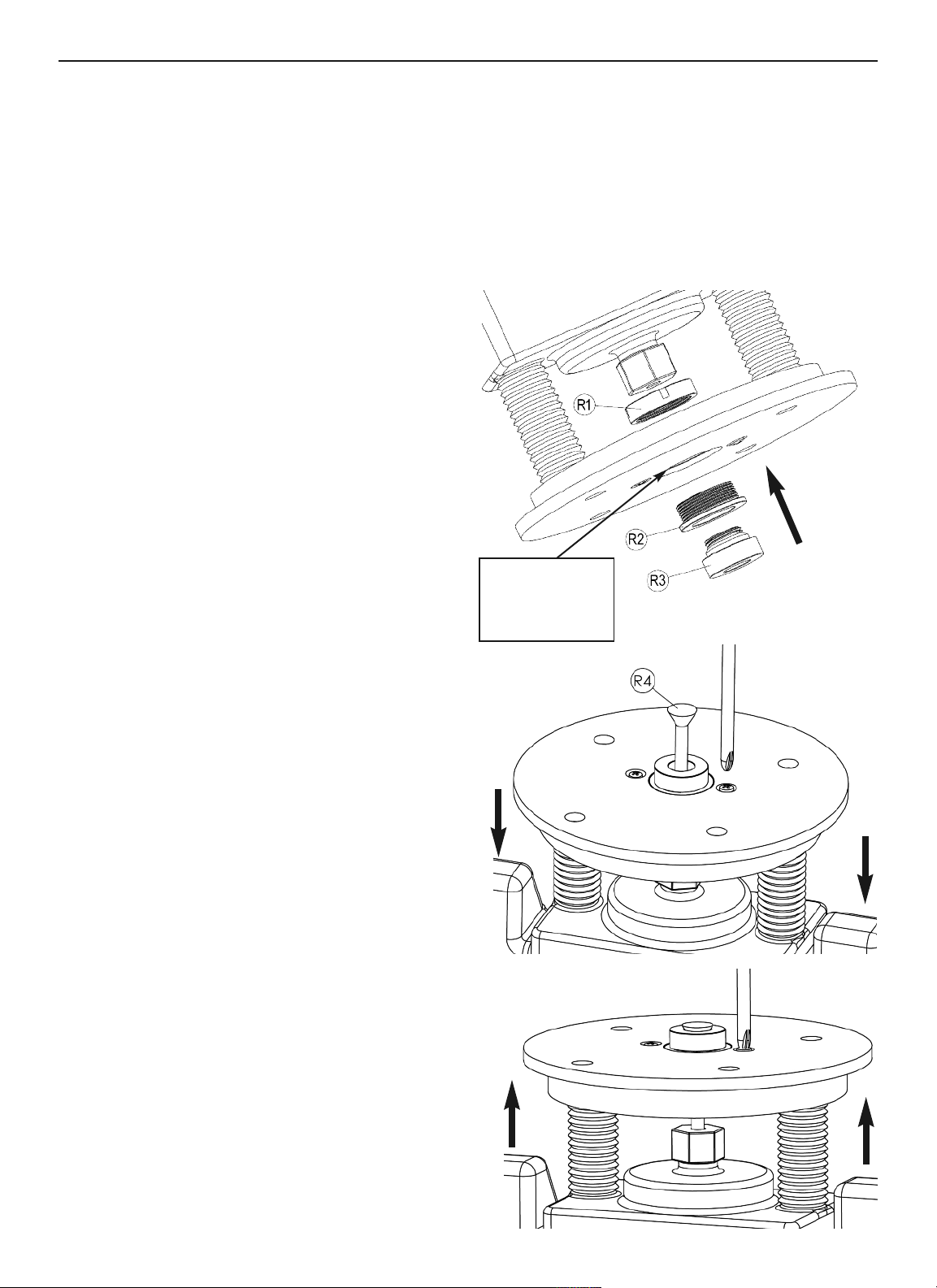

Installing the “Quick Change”

Guide Sleeve

The E•Z Pro M&T Jig is designed to be used with

plunge routers with base plates with a 1-3/16"

center hole and a 1-3/8" counter-bore. This is to

accommodate the included “Quick Change”

guide sleeve and bushing. If your router base

cannot mate with the guide sleeve, you can

purchase a “Universal Router Plate” with the

appropriate center hole dimensions to attach

to or replace your current router base.

Fig. 3

With the proper base plate installed:

1. Insert the Guide Sleeve [R-2] into the base

plate.

2. Secure the Lock Nut [R-1] firmly with

the flat Spanner Wrench Provided.

3. Screw the 1-1/8" Router Guide Bushing [R-3]

into the center of the Guide Sleeve and hand

tighten. (Fig. 3)

Centering the Base Plate and

the “Quick Change Guide System”

1. With your router upside down, plunge the base

plate and lock it.

2. Insert the 1/4" Centering Pin [R-4] in the router

chuck and tighten it securely.

3. Loosen the mounting screws of the base plate

just enough to allow a little movement.

(Fig. 4)

4. Carefully release the plunge lock and gently

guide the plunge base to extension on the cone

section of the Centering Pin; (Fig. 5) this allows

the loosened base plate to move on its screw

holes to a perfect centering position.

BASE PLATE WITH

1-3/16" CENTER

HOLE AND A

1-3/8" COUNTER

Fig. 4

Fig. 5

5. Tighten the base plate screws securely.

5

Page 6

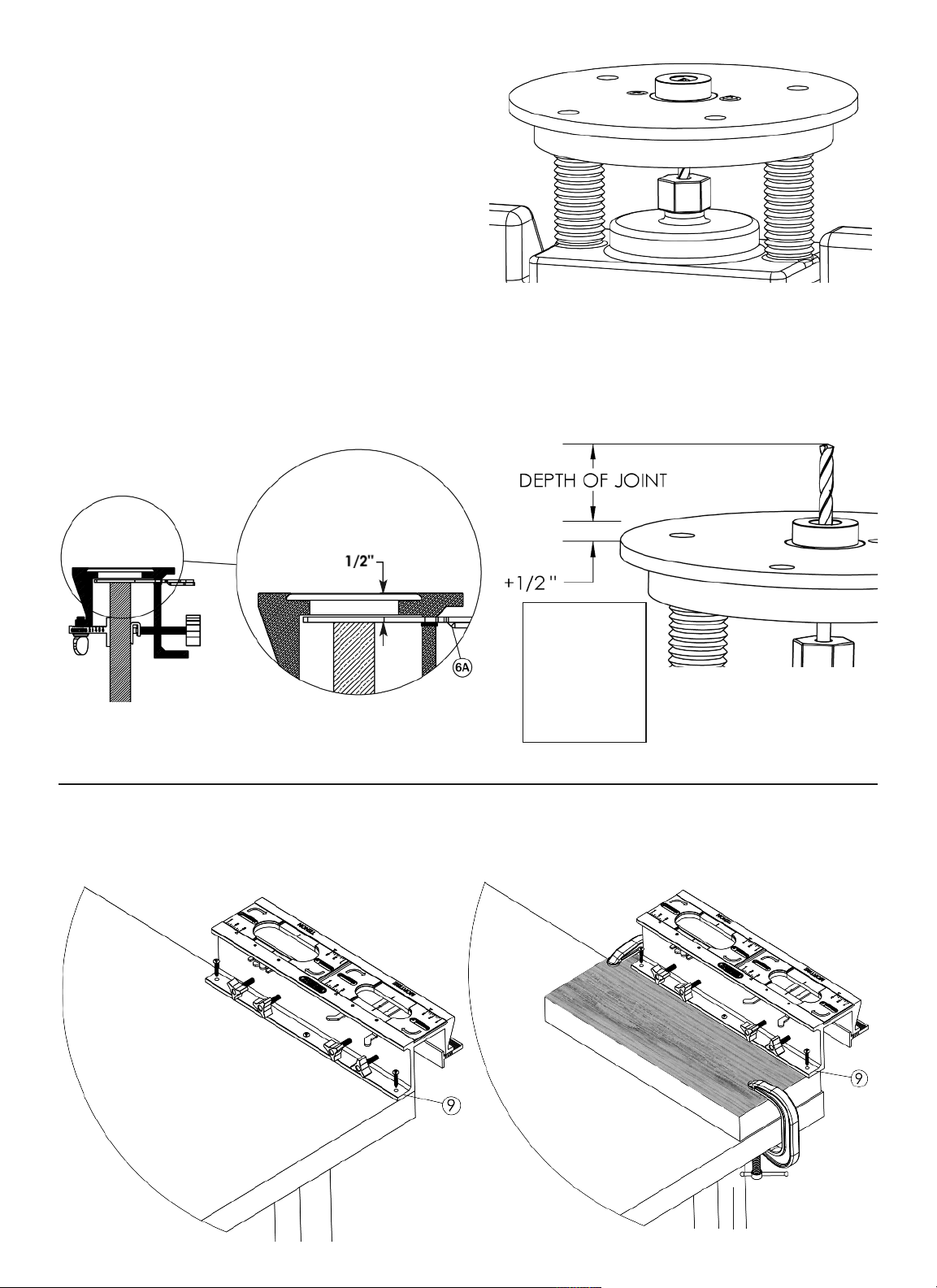

Fig. 6

• Once you have completed this centering

operation, remove the Centering Pin from the

router and replace it with the router bit (Fig. 6).

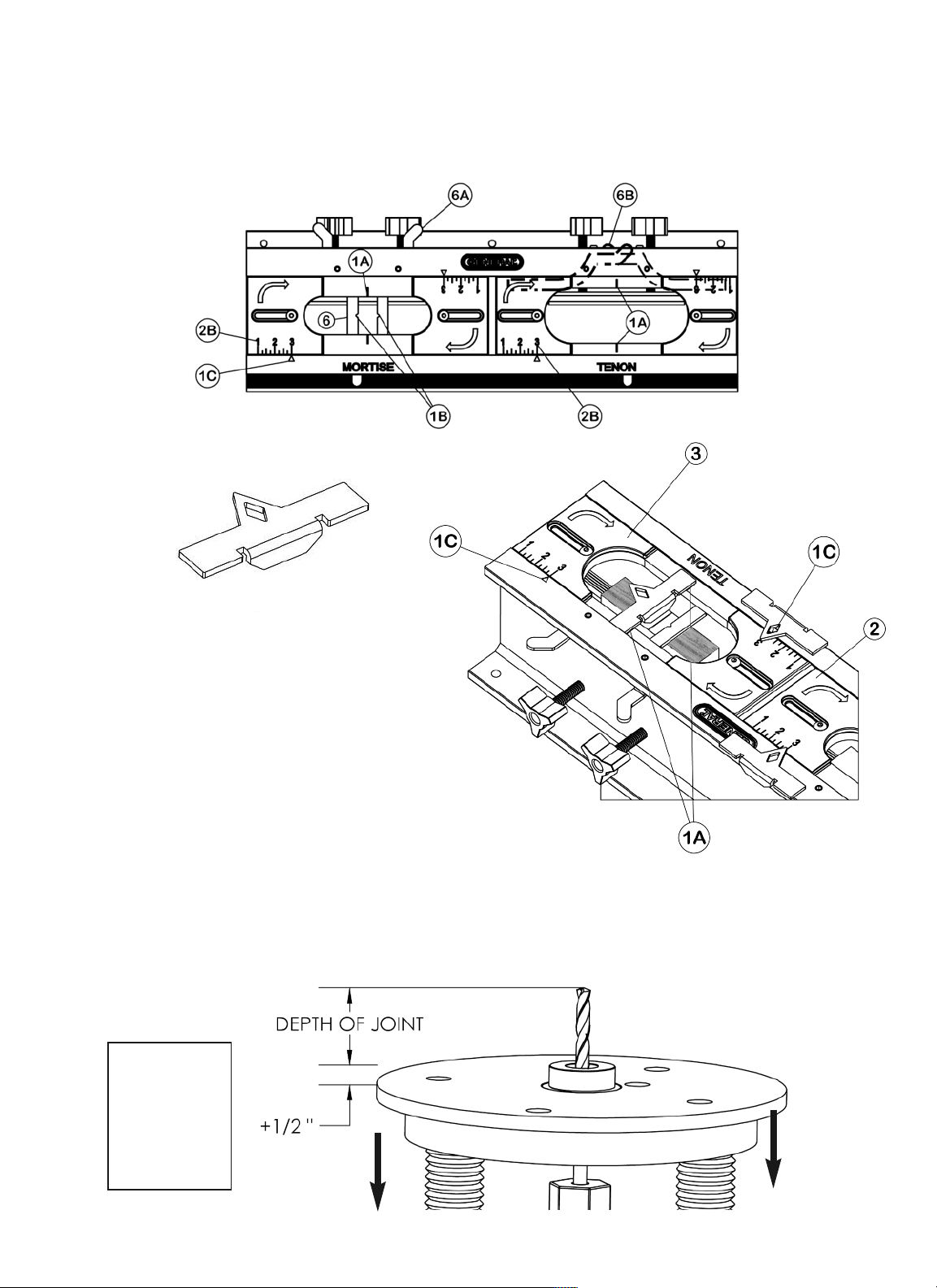

Setting the Cutting Depth

• Set the depth of your plunge router for the desired depth of your mortise and tenon.

• When the stock is correctly mounted in the jig, its top edge will be 1/2" below the top (working)

surface of the jig (Fig.7a).

• Accordingly, add 1/2" to the desired depth of the mortise and tenon when setting the “plunge”

depth of the router (Fig.7b).

FROM THE FACE

OF THE BASE

PLATE TO THE

Fig. 7A

POSITIONING ARM

SHOWN DEPLOYED

TIP OF THE

CUTTING BIT

EQUALS THE

DEPTH OF THE

JOINT PLUS 1/2"

Fig. 7B

ROUTER IN THE FULLY

PLUNGED POSITION

MOUNTING THE JIG

The M&T Jig can be mounted directly on the edge of a bench using the integral mounting flange [9]

(Fig. 8A), or secured to a mounting board which can then be clamped to a bench (Fig. 8B).

Fig. 8A

6

WORK BENCH

WORK BENCH

Fig. 8B

Page 7

OPERATING INSTRUCTIONS:

1. Marking Joint Centers and Location

Mark the stock with center marks at the positions for the length of the tenon and the mortise.

These marks will be needed to center the tenon and the longitudinal position of the mortise on the

stock. If you have correctly set the Centering Wall for the thickness of the stock, the stock will

automatically be centered** for stock thickness when clamped in the jig.

**Tip: if there is a variation in the thickness of the stock used, you may adjust for this by use of

appropriate shims or by readjusting the Centering Bar.

CENTER POSITION OF THE MORTISE

Fig. 9

MORTISE SECTION

2. Centering the Stock

• Centering the stock in the jig is

accomplished by adjusting the

Centering Wall [4] (Fig.10) for

the thickness of the stock.

• The jig will handle stock with

a thickness between 1/2" and

1-1/2".

• Using the lumber industry’s

nomenclature, these two

thicknesses, designated as,

“2 quarter” (1/2") and

“6 quarter” (1-1/2"), indicating

the number of 1/4" increments of thickness.

CENTER POSITION OF THE TENON

TENON SECTION

INNER WALL

Fig. 10

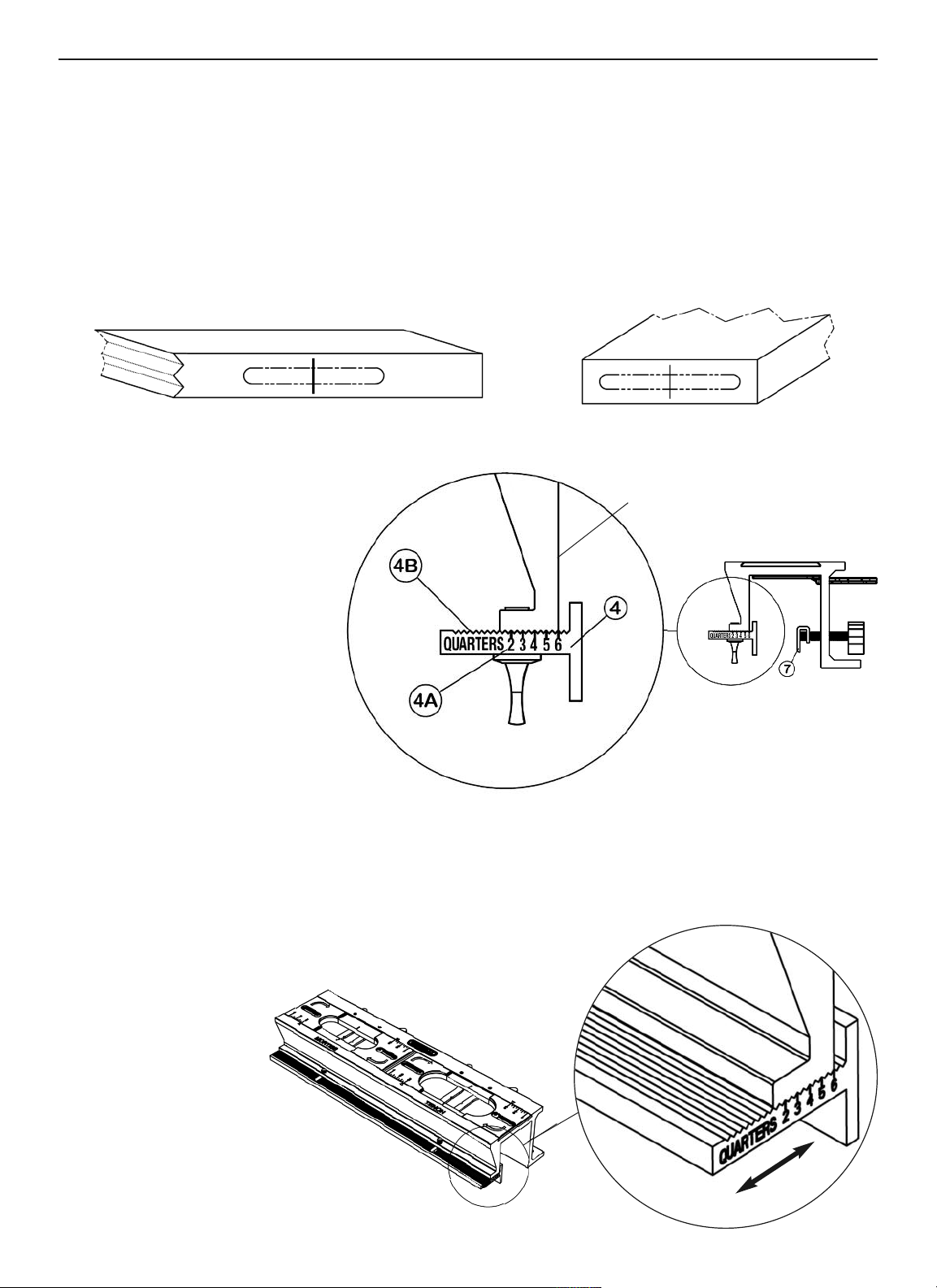

• The markings are on the tenon end of the Centering Wall [4A]. Use these “quarter” units to adjust

for the thickness of your stock in “quarters”. For example: if you are using 3/4" (three quarter)

stock, align the number “3” with the inner wall of the jig (Fig. 11), and the stock will be at its

nominal center in the templates.

• When adjusting the Centering Wall, and to maintain parallel

alignment, always make sure the bar is correctly seated

on the jig body with its serrated matching surface

[4B] (Fig.11) in the jig.

Tips: to assure an accurate joint

alignment, particularly if you are making

a Face Frame or similar matching

surface type joint, always keep the

Fig. 11

matching faces to the same side of the jig.

7

Page 8

3. Positioning the Stock Using the Positioning Bars

When in the deployed position (Fig 12), the Positioning Bars serve two basic purposes:

1. Then position the stock at the correct depth below the underside of the template for routing

2. Then align the stock so it is squared, at 90 degrees, to the jig longitudinally

A

6

Fig. 12

Fig. 13

The Positioning Bars [Fig 12 and 13] are stored along

the inside edge of the underside of the jig’s top when

routing.

1. To extend the bars, use the Positioning Bar handles

[6A], located under the outside top edge.

2. After you fully deploy the Positioning Bars, you’re

Fig. 14

ready to place the stock in the jig. Insert the stock

gently up against the deployed Positioning Bars

(Fig. 14) and tighten the Thumb Screws [5] just

enough so the stock is held loosely by the

Face Clamps [7].

3. Center the stock longitudinally using the jig’s Centering Marks [1A] on the jig (Fig. 15). Before

tightening the Face Clamps, be sure the stock is flat and square against the Positioning Bars

(but not too tight), and correctly centered.

4. Tighten the Face Clamps, enough to secure the stock from moving.

5. Using their handles, return the Positioning Bars to their storage position (Fig15).

Fig. 15

8

IN USE POSITION

STORED FOR ROUTING

Page 9

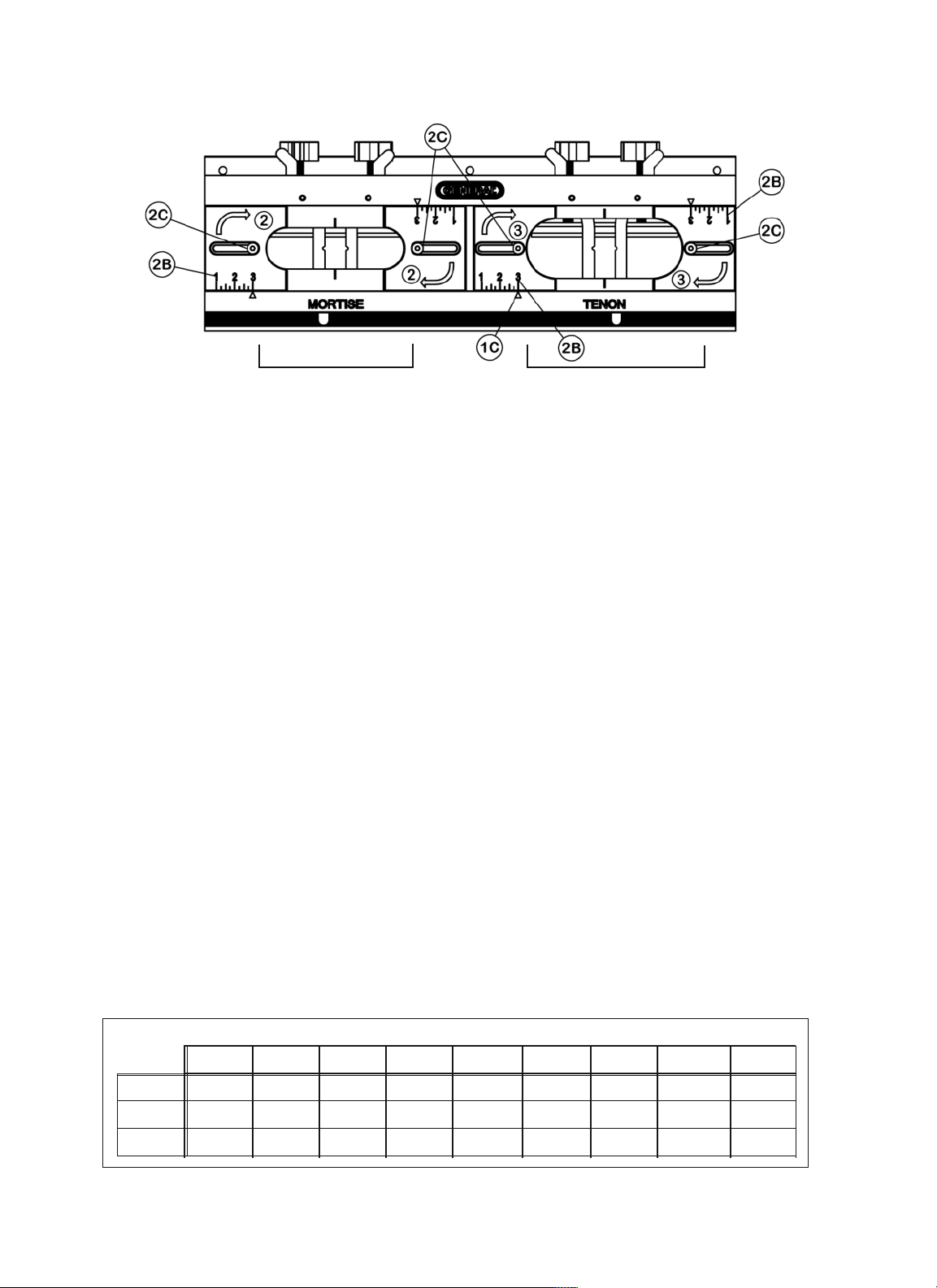

4. Setting the Joint Length

The M&T jig has two working sections, the mortise section and the tenon section (Fig. 16).

Fig. 16

MORTISE SECTION

TENON SECTION

Both the mortise section and the tenon section of the jig are equipped with left and right

Adjustable Sliding Templates [#2 & #3] (Fig.16) that are used to set the length of the joint. Visible

are the numbers 1, 2 and 3 along with associated ruled markings on each template’s edge [2B].

To adjust the templates for the desired joint length, loosen the Lock Screws [2C] on the right

and left templates on both sides of each joint and slide them to the desired opening indication (as

referred to in the chart based on your bit diameter). All four (4) sliding templates should be at the

same setting. Re-tighten the screws.

The numbers 1, 2 and 3 on the adjustable sliding templates directly correlate to the 3/8" bit

reference in the chart that follows. For example, if you set the template positions to #2 you will

create a 2" long joint. Set the templates to #1 and you’ll create a 1" long joint.

If you’re using a 1/4" or 1/2" diameter bit, refer to the settings in the chart for the actual size of the

joint at these same markings. The chart compensates for the difference in bushing size and bit

diameter from a 3/8" bit. For example, using a 1/4" bit with the templates positioned at #2 would

produce a joint that is 1-7/8" long. Similarly, using a 1/2" bit with the templates at the #2 position

would produce a 2-1/8" long joint.

Notes:

1. The chart below indicates the exact length of each joint for each marking on the

template and for each bit size.

2. When you set the size of the opening, make sure that ALL of the templates indicate

the same measurement; this assures that both the mortise and the tenon will be the

same size. (Fig. 16)

Length of Mortise and Tenon Chart

Joint

Thickness

1/4" 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8 7/8

3/8" 3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

1/2" 3-1/8 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8

3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

Template Position Markings

9

Page 10

Both the tenon and mortise sections have has two Centering Marks [1A] (Fig. 17) which indicate

the longitudinal center of the templates. There are also Centering Notches [1B] on the deployed

Positioning Bars [6]; they indicate the center of the template’s width.

TIP: It may be advisable to size the mortise slightly longer than the tenon (or the tenon slightly

shorter than the mortise) for ease of insertion, adjustment and gluing.

Fig. 17

Fig. 18

The Alignment Tool (Fig. 18) is used to help center

the uncut wood in the jig. Before securing the

wood in the jig, place the Alignment Tool as

shown and align it with the Centering Marks [1A]

on the jig (Fig19).

The Alignment Tool can also be used to more

accurately align the Adjustable Sliding Templates

Fig. 19

[#2 & #3] to the Template Positioning Indicators

[1C].

5. Set the Depth of the Router Bit

(See also “Setting the Cutting Depth” on page 6)

To set the “plunge” depth of the router (Fig. 20) and subsequently the cutting depth of the bit,

remember to add 1/2" to the desired depth of the joint. Therefore, if you’re setting the joint depth

to be 1" then your measurement would be a total of 1-1/2" from the face of the base plate to the

tip of the bit.

FROM THE FACE

OF THE BASE

PLATE TO THE

TIP OF THE

CUTTING BIT

EQUALS THE

DEPTH OF THE

JOINT PLUS 1/2"

10

Fig. 20

Page 11

6. Routing the Tenon

When routing the tenon, make sure the

Guide Bushing [R-3] only rides against

the outer edges of the tenon template [3]

(Fig. 21) at all times.

1. Start the cut by putting the guide

bushing into the end of the template.

2. With the Guide Bushing in the end of

the template and the router base

squarely on the jig surface, turn the

router on.

3. Plunge the router to a workable depth

and guide the router bit clockwise

through the cutting process making

sure to keep the Guide Bushing tight

to the outer edge at all times.

1/4" UP

CUT BIT

SHOWN

Fig. 21

R-3 GUIDE

BUSHING

NOTE: You can make successive

plunges to any depth while moving the

Guide Bushing clockwise around the

tenon template always riding against

the edge to make the cleanest joint

possible. We recommend making

successive shallow plunges and cutting

sweeps to avoid over stressing the

cutting bit. (Fig. 21 & 22)

Caution: before retracting the router bit

from the cut, be sure to turn the router

off.

Tip: depending on the actual thickness

of your stock, you may at times get a

“fence” or “flash” around the edge of

your tenon (Fig 23). Be sure to cut, file or

sand it off cleanly to ensure a tight fit.

Fig. 22

Fig. 23

11

Page 12

Fig. 24

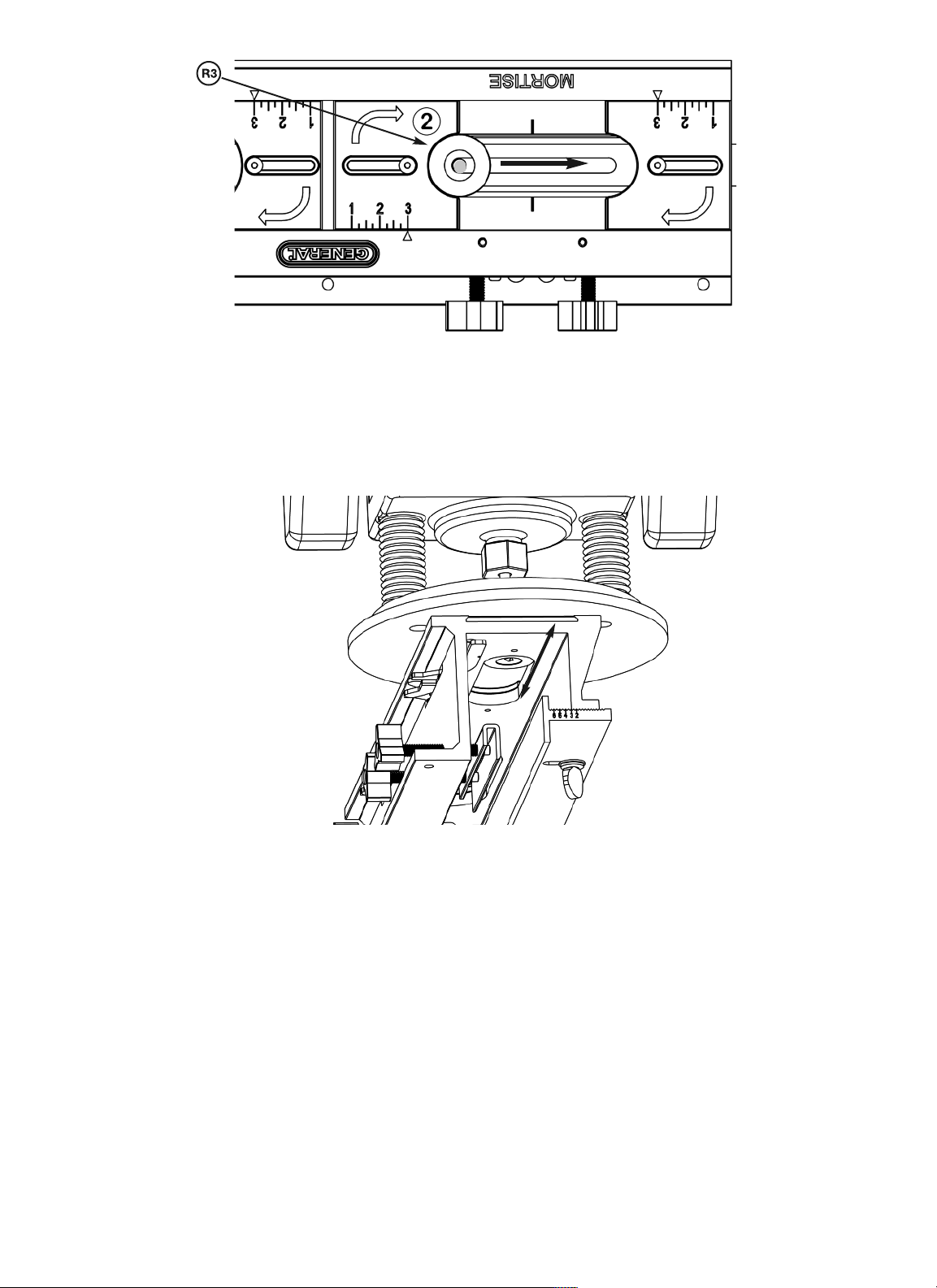

7. Routing the Mortise

Tip: when routing the mortise, it is advisable to increase the depth of cut slightly more than that of

the tenon to allow space for glue to be put on the tenon before inserting it into the mortise.

The Guide Bushing [R-3] fits the Mortise Template [2] (Fig. 24) exactly to prevent it from wandering

out of line. It will be used for all mortises regardless of size.

Fig. 25

1. Before turning on the router, place the Guide Bushing in the end of the mortise template and

slide it through the template to be sure it moves freely. (Fig. 25)

2. With the Guide Bushing in the end of the template and the router base squarely on the jig

surface, turn the router on.

3. Plunge the router and guide the router bit through the cutting process.

NOTE: We recommend cutting the mortise in successive overlapping plunges to depth and

then repeatedly move the bit back and forth to clean up the mortise slot.

12

Page 13

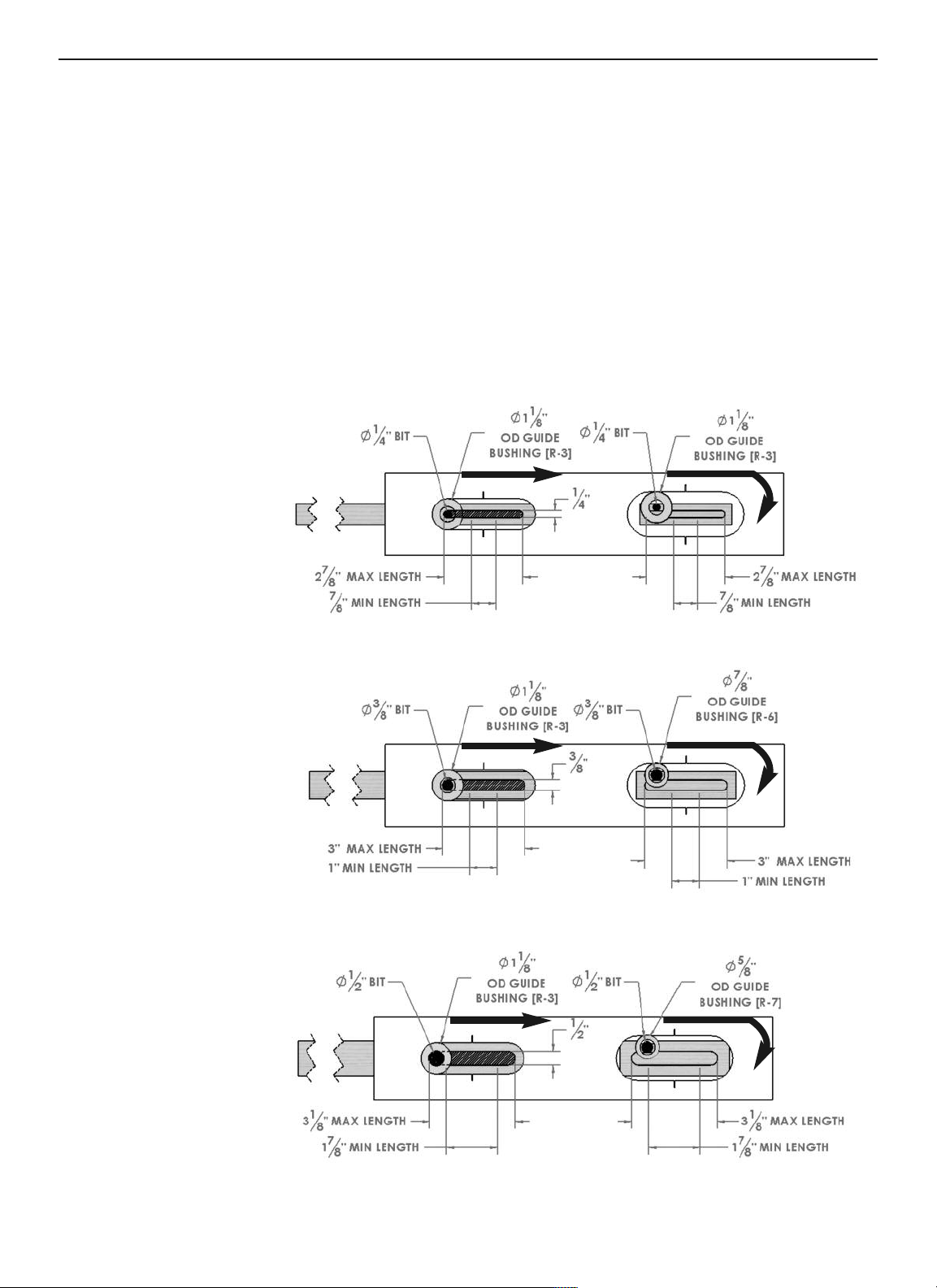

ROUTING OTHER SIZE MORTISE AND TENONS

The E•Z Pro Mortise and Router Guide Bushing Tenon Jig Kit includes the guide sleeve with

Locking Nut [R2, R1], a 1-1/8" Router Guide Bushing for 1/4" joints [R3], a 1/4" Upcut Spiral

Router Bit and a Centering Pin [R4]. These parts will permit you to make 1/4" mortises and tenons

suitable for 3/4" thick board (Fig 26). The kit also includes the Guide Bushing you will need to make

mortises and tenons of 1/2" [R7] or 3/8" [R6] (Page 4), however, you will need to make a separate

purchase of the corresponding Upcut Spiral Bits. Please see sizing chart on Page 10.

• To make a 3/8" tenon, you’ll need a 3/8" Upcut Spiral Bit and the 7/8" Guide Bushing [R6].

• To make the matching 3/8" mortise, change to the 1-1/8" Guide Sleeve [R-3]. (Fig. 27)

• To make a 1/2" tenon, you’ll need a 1/2" Upcut Spiral Bit and the 5/8" Guide Bushing [R7].

• To make the matching 1/2" mortise, change to the 1-1/8" Guide Sleeve [R-3]. (Fig. 28)

NOTE: Guide Bushings can be changed without removing router bit.

Fig. 26

1/4" JOINT

(shown on

1" stock)

Fig. 27

Fig. 28

3/8" JOINT

(shown on

1-1/4" stock)

1/2" JOINT

(shown on

2" stock)

MORTISE

MORTISE

TENON

TENON

MORTISE

TENON

13

Page 14

CUSTOMER SUPPORT

Please visit our website at www.generaltools.com/woodworking to obtain additional woodworking

information, instructional videos and product manual.

http://www.generaltools.com/mortise-tenon

WARRANTY INFORMATION

The No. 870 Mortise & Tenon Jig Kit from General Tools & Instruments is warranted to the

original purchaser to be free from defects in material and workmanship for a period of one year.

Subject to certain restrictions, General will repair or replace this product, if, after examination,

it is determined by General to be defective in material or workmanship.

14

Page 15

PLANTILLA PARA

MORTAJA Y ESPIGA

No. 870

MANUAL DEL USUARIO

(PATENTE PENDIENTE EN USA)

LEA COMPLETAMENTE LAS INSTRUCCIONES ANTES DE UTILIZAR ESTA PLANTILLA

PARA MÁS INFORMACION E INSTRUCCIONES DE VIDEO VISITE NUESTRA

PÁGINA WEB www.generaltools.com/mortise-tenon

15

Page 16

CONTENIDOS:

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Capacidad y Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contenido del Paquete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Anatomía de la Plantilla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Anatomía del Ensamblaje del cojinete de la

base de la Fresadora “Cambio Rápido” . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Preparando la Fresadora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 – 20

Información General de Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . 19

Instalando el Manguito de Guía “Cambio Rápido” . . . . . . . . . . . . . 19

Centrado de la placa de base y el “Sistema de Guía de

Fijando la profundidad del corte . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Montando la Plantilla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Instrucciones de Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 – 26

1. Marcando la ubicación y los centros de las Juntas . . . . . . . . . . 21

2. Centrado de la pieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cambio Rápido” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. Fijando la pieza utilizando las barras posicionadoras . . . . . . . . 22

4. Fijando el largo de la junta . . . . . . . . . . . . . . . . . . . . . . . . . . 23 – 24

Cuadro del largo de la Mortaja y la Espiga . . . . . . . . . . . . . . . . . 23

5. Fijando la profundidad de la broca buriladora . . . . . . . . . . . . . . 24

6. Enrutamiento de la Espiga . . . . . . . . . . . . . . . . . . . . . . . . . . 25 – 26

7. Enrutamiento de la Mortaja . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Enrutamiento de otros tamaños de Mortajas y Espigas . . . . . . . . . . . . . . . 27

Soporte al Cliente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Información de Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

16

Ejemplo de

ensambladura de

Mortaja y Espiga

Page 17

INTRODUCCIÓN

Gracias por adquirir la E Z Pro Plantilla Combinación Mortaja y Espiga (M&T Jig) de General

Tools & Instruments. La primer plantilla integrada en la industria de trabajos de madera con la

capacidad de hacer combinaciones de ensambladura de Mortaja y Espiga de manera profesional

“Lista para instalar”. La plantilla hace que la ensambladura de Mortaja y Espiga sean de las juntas

más resistentes en madera para muebles, gabinetes y marcos — un proceso fácil, rápido y simple.

El paquete de Mortaja y Espiga viene con una plantilla completamente ensamblada, incluye una

broca buriladora de espiral de 1/4" para cortes rectos y una guía de cojinete para espiga de 1/4".

También incluye la guía de cojinetes para corte de juntas de 3/8" y 1/2". Tome en cuenta que

tendrá que adquirir sus propias brocas buriladoras de 3/8" y 1/2".

La plantilla para Mortaja y Espiga posee una pieza tratada a calor con cuerpo de aluminio de alto

grado, pernos ajustables, sujetadores y una broca que cumple con las especificaciones de la

Sociedad Norteamericana de Ingenieros Automotores (SAE). El ensamblaje de las unidades

ajustables, Barras Posicionadoras y Cojinete, están también fabricados de acero sólido.

Capacidad y Especificaciones:

Acomoda piezas de 1/2" a 1 1/2" de grueso y de cualquier medida de largo

Grosor de la Mortaja y Espiga: 1/4", 3/8" y 1/2"

Largo mínimo de la junta de la Mortaja y Espiga: 1" +/- 1/8" (dependiendo de la broca que utilice)

Largo máximo de la junta de la Mortaja y Espiga: 3" +/- 1/8" (dependiendo de la broca que utilice)

Contenido del Paquete

1. Plantilla completamente ensamblada

2. “Cambio Rápido” el ensamblaje del cojinete de la base de la fresadora consiste en:

• Un manguito de guía y tuerca de retención

de 1-3/16” “Cambio Rápido”

• Una guía de cojinete de 1/4"

(1-1/4" de diámetro exterior)

• Un perno de centrado de 1/4"

• Una llave plana de tuerca para ajustar el

manguito de guía y tuerca de retención

• Una guía de cojinete de 3/8"

• Una guía de cojinete de 1/2"

3. Una broca buriladora espiral de carburo de

corte recto de 1/4"

4. Herramienta de alineación

1

2

3

4

Se recomienda que se familiarice con la nomenclatura de la figura 1 y figura 2 de la

página 18 antes de proceder.

17

Page 18

ANATOMÍA DE LA E Z PRO PLANTILLA PARA MORTAJA Y ESPIGA

Figura 1.

ENSAMBLAJE DE LA

PLANTILLA EN PERFIL

ENSAMBLAJE DE LA PLANTILLA

SECCIÓN DE LA ESPIGA

1 - Ensamblaje de la Plantilla

1A - Marcas de Centrado

1B - Muescas de Centrado

1C - Plantilla de Indicadores de

Posicionamiento

2 - Plantillas de la Sección de la Mortaja

2B - Plantillas de la Regla de posición

2C - Plantilla de los Tornillos de cierre

3 - Plantillas de la Sección de la Espiga

SECCIÓN DE LA MORTAJA

4 - Pared de Centrado, [4A] Marcadores,

[4B] Bordes Dentados, [4C] Tornillos de

mano

5 - Tornillos de mano para las tenazas

6 - Barras posicionadoras

6A - Barras posicionadoras desplegadas

6B - Barras posicionadoras guardadas para

almacenamiento y corte

7 - Tenazas

8 - Pestaña de montaje

ANATOMÍA DEL ENSAMBLAJE DEL COJINETE DE LA BASE

DE LA FRESADORA “CAMBIO RÁPIDO”.

Figura 2.

1-1/8" diámetro exterior

R1 - Tuerca de Retención

R2 - Manguito de guía de la base de la

fresadora de 1-3/16"

R3 -

Guía de cojinete de la fresadora de 1-1/8"

diámetro exterior para la espiga de 1/4"

(así como para todas las mortajas)

R4 - Perno de Centrado

18

7/8" diámetro exterior

5/8" diámetro exterior

R5 - Llave plana de tuerca

R6 - Guía de cojinete de la fresadora de 7/8"

diámetro exterior para la espiga de 3/8"

R7 - Guía de cojinete de la fresadora de 5/8"

diámetro exterior para la espiga de 1/2"

R8 - Broca buriladora de 1/4"

Page 19

PREPARANDO LA FRESADORA

INFORMACION GENERAL DE SEGURIDAD

1. CONOZCA SU FRESADORA. Previo a utilizarla, lea el manual incluido con su fresadora.

Antes de utilizar, entienda las aplicaciones y limitaciones de la máquina, así como los riesgos

específicos potenciales inherentes en su uso. Verifique que ninguna pieza esté quebrada, floja o

desalineada.

NOTA: General Tools & Instruments no se hace responsable por el mal uso o por hacer caso omiso

de las normas de precaución de seguridad asociadas con el uso de la fresadora.

INSTALANDO EL MANGUITO DE GUÍA

“CAMBIO RÁPIDO”

La E Z Pro Plantilla de Mortaja y Espiga está

diseñada para utilizarse con fresadoras de

superficie con placas de base con agujero central

de 1-3/16" y un contra-taladro de 1-3/8". Esto es

para acomodar el “Cambio Rápido” manguito de

guía y broca incluidos. Si su base para fresadora

no se ajusta con el manguito de guía, usted deberá

comprar una “Placa Universal de Fresadora” con

las dimensiones apropiadas del agujero central

para adjuntar o reemplazar a la base de su

fresadora.

Con la placa de base apropiada instalada, realice

lo siguiente:

1. Inserte el Manguito de Guía [R-2] dentro de la

placa de base.

2. Asegure firmemente la tuerca de retención [R-1]

con la llave plana de tuerca proporcionada.

PLACA DE BASE CON

AGUJERO CENTRAL

DE 1-3/16" Y UN

CONTRA-TALADRO

DE 1-3/8".

Figura 3

Figura 4

3. Atornille la guía de cojinete de la fresadora de

1-1/8" [R-3] dentro del centro del Manguito de

Guía y apriételo manualmente. (Figura 3)

CENTRANDO LA PLACA DE BASE Y

EL “SISTEMA DE GUÍA DE CAMBIO

RÁPIDO”

1. Coloque su fresadora cabeza abajo, descienda

la placa de base y ciérrela.

2. Inserte el perno de centrado de 1/4" [R-4] en el

cabezal giratorio y apriete firmemente.

3. Afloje sólo lo necesario los tornillos de montaje

en la placa de base, para permitir pequeños

movimientos (Figura 4).

4. Suelte cuidadosamente el tornillo de cierre y

guíe cuidadosamente la base para que se

extienda en la sección cónica del perno de

centrado; (Figura 5); esto permite que la placa

de base floja, se mueva en los agujeros de sus

tornillos para una perfecta posición de centrado.

5. Apriete firmemente los tornillos de la placa de

base.

Figura 5

19

Page 20

Una vez completada la operación de centrado,

remueva el perno de centrado de la fresadora

y reemplace con la broca buriladora

(Figura 6).

Figura 6

Fijando la profundidad del Corte

• Fije la profundidad de su fresadora de superficie para obtener la profundidad deseada de su

mortaja y espiga.

• Cuando la pieza esté correctamente montada en la plantilla, su orilla superior estará 1/2" debajo

la superficie superior (de trabajo) de la plantilla (Figura 7A)

• Por consiguiente, aumente 1/2" a la profundidad deseada de la mortaja y espiga cuando fije la

profundidad “descendiente” de la fresadora (Figura 7B)

PROFUNDIDAD DE LA JUNTA

DE LA CARA DE LA

BASE DE LA PLACA,

A LA PUNTA DE

LA BROCA

Figura 7A

BRAZO DE POSICIONAMIENTO

EN POSICIÓN DESPLEGADA

CORTADORA,

ES IGUAL A LA

PROFUNDIDAD

DE LA JUNTA,

MÁS 1/2”

Figura 7B

FRESADORA EN LA POSICIÓN

DE MÁXIMO HUNDIMIENTO

MONTANDO LA PLANTILLA

La Plantilla de Mortaja y Espiga puede montarse directamente al borde de un banco de trabajo

utilizando la pestaña de montaje integral [9] (Figura 8A) o asegurarla a un tablero de montaje, y

fijarse a un banco de trabajo (Figura 8B).

Figura 8A

20

BANCO DE TRABAJO

BANCO DE TRABAJO

Figura 8B

Page 21

INSTRUCCIONES DE OPERACIÓN:

1. MARCANDO LA UBICACIÓN Y CENTROS DE LAS JUNTAS

Marque la pieza con las marcas de centros en las posiciones para el largo de la espiga y la mortaja.

Éstas marcas serán necesarias para centrar la espiga y la posición longitudinal de la mortaja de la

pieza. Si usted fijó correctamente la pared de centrado para el grosor de la pieza, la pieza se

centrará automáticamente** para el grosor de la pieza al momento de sujetarla a la plantilla.

**Consejo: Si existe variación en el grosor de la pieza utilizada, puede ajustarlo utilizando las

zapatas apropiadas o reajustando la barra de centrado.

POSICIÓN CENTRAL DE LA MORTAJA

Figura 9

SECCIÓN DE LA MORTAJA

2. CENTRADO DE LA PIEZA

• Para centrar la pieza en la plantilla se

debe ajustar la pared de centrado

[4] (Figura 10) para el grosor

de la pieza.

• La plantilla manejará la pieza

con un grosor entre 1/2" y

1-1/2".

• Al utilizar la nomenclatura de la

industria de madera, estos dos

grosores, designados como,

“2 cuartos” (1/2") y “6 cuartos”

(1-1/2"), indicando un

incremento en el grosor de 1/4".

POSICIÓN CENTRAL DE LA ESPIGA

SECCIÓN DE LA ESPIGA

PARED INTERIOR

Figura 10

• Las marcas están en el extremo

de la espiga de la pared de centrado [4A]. Utilice las unidades de “cuarto” para ajustar el grosor

de su pieza en “cuartos”. Por ejemplo: Si usted utiliza una pieza de 3/4" (tres cuartos) alineélo en

el número “3” con la pared interior de la plantilla (Figura 11), y la pieza estará en el centro

nominal de las plantillas.

• Cuando ajuste la pared de centrado, y para mantener una alineación

paralela, asegúrese siempre que la barra esté correctamente

sentada en el cuerpo de la plantilla con la superficie dentada

que haga juego [4B] (Figura 11) en la plantilla.

Consejos: Para asegurar

un alineamiento

exacto de juntas, y

especialmente si está

haciendo un marco de

frente o una superficie similar

tipo junta que haga juego,

mantenga siempre las caras que

hagan juego del mismo lado de la plantilla.

Figura 11

21

Page 22

3. POSICIONANDO LA PIEZA, UTILIZANDO LAS BARRAS

POSICIONADORAS

Cuando las barras posicionadoras están en la posición de despliegue (Figura 12), éstas sirven para

2 propósitos básicos:

1. Posicionar la pieza en la profundidad correcta debajo de la parte inferior de la plantilla para

enrutamiento.

2. Alinear la pieza para que cuadre a 90 grados

longitudinalmente a la plantilla.

A

6

Figura 13

Figura 12

Al momento del enrutamiento, las barras posicionadoras (Figuras 12 y 13)

se almacenan en la orilla interior de la parte inferior de la plantilla.

1. Para extender las barras, utilice las manecillas de las Barras

Posicionadoras [6A] ubicadas debajo de la orilla exterior

superior.

2. Después de haber desplegado completamente las barras

posicionadoras, estará listo para reemplazar la pieza en la

plantilla. Inserte la pieza cuidadosamente contra las barras

posicionadoras desplegadas (Figura 14) y apriete los tornillos de

mano sólo lo necesario [5] para que la pieza quede sostenida

Figura 14

por las tenazas holgadamente[7].

3. Centre la pieza longitudinalmente utilizando las marcas de centrado de la plantilla [1A] en la

plantilla (Figura 15). Antes de apretar las tenazas, asegúrese que la pieza quede plana y

cuadrada contra las barras posicionadoras (pero no muy apretadas) y correctamente centrada.

4. Apriete las tenazas sólo lo necesario para que la pieza no se mueva.

5. Utilizando sus manecillas, regrese las barras posicionadoras a su posición de almacenamiento

(Figura 15).

EN POSICIÓN DE USO

ALMACENADO PARA ENRUTAMIENTO

Figura 15

22

Page 23

4. FIJANDO EL LARGO DE LA JUNTA

La Plantilla de Mortaja y Espiga consta de 2 secciones de trabajo, la sección de la mortaja y la

sección de la espiga (Figura 16)

Figura 16

SECCIÓN DE LA MORTAJA

SECCIÓN DE LA ESPIGA

Tanto la sección de la mortaja como la sección de la espiga están equipadas con plantillas

deslizantes ajustables, derecho e izquierdo [#2 y #3] (Figura 16) las cuales se utilizan para fijar el

largo de la junta.

Los números 1, 2 y 3 al igual que las marcas asociadas del reglado en cada orilla de las plantilla

[2B] están a la vista.

Para ajustar las plantillas para el largo de junta deseado, afloje los tornillos de cierre [2C] en

las plantillas ubicados del lado derecho e izquierdo en ambos lados de cada junta y deslícelos

de acuerdo a la apertura deseada. (Tal como lo muestra el cuadro, basado en el diámetro de su

broca). Todas las (4) plantillas deslizantes deben estar en la misma posición. Vuelva a apretar los

tornillos.

Los números 1, 2 y 3 en las plantillas deslizantes ajustables se correlacionan directamente

a la broca de 3/8" como lo muestra el cuadro de abajo. Por ejemplo, si usted fija las posiciones

de la plantilla en #2, creará una junta de 2" de largo. Al fijar las plantillas en #1, creará una junta

de 1" de largo.

Si utiliza una broca de diámetro de 1/4" o 1/2" refiérase a la tabla para el tamaño actual de la junta

en estas mismas marcas. La tabla compensa por la diferencia en el tamaño del cojinete y el

diámetro de una broca de 3/8". Por ejemplo, al utilizar una broca de 1/4" con las plantillas

posicionadas en #2, se produciría una junta de 1-7/8" de largo. De igual manera, al utilizar una

broca de 1/2" con las plantillas en la posición #2 se producirá una junta de 2-1/8" de largo.

Notas:

1. La tabla de abajo muestra el largo exacto de cada junta para cada marca en la plantilla y

para cada tamaño de broca.

2. Cuando fije el tamaño de la apertura, asegúrese que TODAS las plantillas tengan las

mismas medidas; esto asegura que ambas, la mortaja y la espiga sean del mismo tamaño.

(Figura 16)

Tabla Del Largo de Mortaja Y Espiga

Grosor de

la Junta

1/4" 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8 7/8

3/8" 3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

1/2" 3-1/8 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8

3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

Marcas Posición de la Plantilla

23

Page 24

Ambas Secciones, la mortaja y la espiga tienen dos marcas de centrado [1A] (Figura 17) las cuales

indican el centro longitudinal de las plantillas. Cuenta también con ranuras de centrado [1B] en la

las barras de posicionamiento desplegadas [6] ; éstas indican el centro del ancho de la plantilla.

CONSEJO: Es recomendable darle a la mortaja un tamaño ligeramente más largo que la espiga

(o la espiga un poco más corta que la mortaja) para fácil inserción, ajuste y pegado.

Figura 17

Figura 18

La herramienta de alineamiento (Figura 18)

se utiliza para ayudar a centrar la madera no

cortada en la plantilla. Antes de asegurar la

madera en la plantilla, coloque la herramienta

de alineación como se muestra, y colóquela

en línea con las marcas de centrado [1A] en

la plantilla (Figura 19).

La herramienta de alineamiento también

puede usarse para alinear las plantillas

[#2 & #3] más exactamente a las plantillas

Figura 19

de indicadores de posicionamiento [1C].

5. Establezca la profundidad de la broca buriladora

(Consulte la página 20: “Fijando la profundidad del Corte”)

Para fijar la profundidad del “hundimiento” de la plantilla (Figura 20) y subsecuentemente la

profundidad del corte de la broca, recuerde aumentar 1/2" a la profundidad deseada de la junta.

Por lo tanto, si fijó la profundidad de la junta para que sea de 1", su medida será de un total de

1-1/2" de la cara de la base de la placa a la punta de la broca.

DE LA CARA DE LA

BASE DE LA PLACA,

A LA PUNTA DE LA

BROCA CORTADORA,

ES IGUAL A LA

PROFUNDIDAD DE

LA JUNTA, + 1/2".

24

PROFUNDIDAD DE LA JUNTA

Fig. 20

Page 25

6. Enrutamiento de la Espiga

Al momento del enrutamiento de la

espiga, asegúrese que la manguita de

guía [R3] se conduzca todo el tiempo

únicamente en el sentido contrario de

las orillas exteriores de la plantilla de la

espiga [3] (Figura 21).

1. Inicie el corte colocando la guía del

cojinete en el extremo de la plantilla.

Figura 21

2. Con la guía de cojinete en el extremo

de la plantilla, y la base de la

fresadora en ángulo recto en la

superficie de la plantilla, encienda la

fresadora.

3. Hunda la fresadora a una profundidad

que se pueda trabajar, y guíe la broca

buriladora en el sentido de las agujas

del reloj a través del proceso de

corte, asegúrese de mantener en todo

momento la guía de cojinete ajustada

a la orilla exterior.

NOTA: Usted puede realizar

hundimientos consecutivos a cualquier

profundidad mientras la guía de cojinete

gire en el sentido de las agujas del reloj

alrededor de la plantilla de la espiga,

conduciéndose siempre en el sentido

contrario de la orilla, para obtener

una junta lo más limpia posible.

Recomendamos hacer hundimientos

consecutivos no muy profundos y

remover los residuos del corte para

evitar tensión en la broca cortadora.

(Figura 21 y 22).

MUESTRA

UNA BROCA

DE 1/4"

R-3 GUÍA DE

COJINETE

Figura 22

Precaución: Antes de retirar la broca

buriladora del corte, asegúrese de

apagar la fresadora.

Consejo: Dependiendo del grosor de su

pieza, pueda que a veces obtenga una

“valla” o “pestaña” alrededor de la orilla

de la espiga (Figura 23). Asegúrese de

cortar, limar o pulir para obtener un

ajuste perfecto.

Figura 23

25

Page 26

Figura 24

7. Enrutamiento de la Mortaja

Consejo: Al momento del enrutamiento de la mortaja, es recomendable aumentar ligeramente la

profundidad del corte de la mortaja que el de la espiga, esto permite dejar espacio para la goma

que aplicará en la espiga antes de insertarla dentro de la mortaja.

La guía de cojinete [R3] encaja exactamente en la plantilla de la Mortaja [2] (Figura 24) lo cual

evitará que la misma se desplace fuera de su lugar. Se usará para todas las mortajas sin importar

su tamaño.

Figura 25

1. Antes de encender la Fresadora, coloque la broca buriladora en el extremo de la plantilla de la

mortaja y deslícela a través de la plantilla para asegurar un movimiento libre. (Figura 25).

2. Con la broca buriladora en el extremo de la plantilla y la base de la Fresadora en ángulo recto en

la superficie de la plantilla, encienda la fresadora.

3. Hunda la fresadora y guíe la broca buriladora a través del proceso de corte.

NOTA: Recomendamos cortar la mortaja en hundimientos traslapados consecutivos a

profundidad y desplazar la broca continuamente de atrás para adelante para limpiar la

ranura de la mortaja.

26

Page 27

ENRUTAMIENTO DE OTROS TAMAÑOS DE MORTAJAS Y ESPIGAS

La E Z Pro Plantilla de Mortaja y Espiga y la guía de cojinete de la fresadora incluyen el

manguito de guía con una tuerca de retención [R2, R1] y una guía de cojinete de 1-1/8" para

juntas de 1/4" [R3], una broca buriladora y un perno de centrado [R4]. Estas piezas le permitirán

hacer mortajas y espigas de 1/4" ajustables para una tabla de un grueso de 3/4" (Figura 26). El

paquete también incluye la guía de cojinete que necesitará para hacer mortajas y espigas de 1/2"

[R7] ó 3/8" [R6] (Página 18), sin embargo, tome nota que necesitará comprar por separado las

brocas buriladoras correspondientes. Vea la tabla de tamaños en la página 24.

•

Para hacer una espiga de 3/8", necesitará una broca buriladora y la manguita de guía de 7/8" [R6].

• Para hacer la mortaja de 3/8" que haga juego, cambie la manguita de guía de 1-1/8" [R3]

(Figura 27)

• Para hacer una espiga de 1/2", necesitará una broca buriladora de 1/2" y la manguita de guía de

5/8" [R7].

• Para hacer la mortaja de 1/2" que haga juego, cambie la manguita de guía de 1-1/8" [R3]

(Figura 28)

NOTA: Las Manguitas de Guía se pueden cambiar sin necesidad de remover la broca buriladora.

Figura 26

BROCA DE 1/4"

GUÍA DE COJINETE

DE 1-1/8" DE

DIÁMETRO

EXTERIOR [R-3]

BROCA

DE 1/4"

UÍA DE COJINETE

G

E 1-1/8" DE

D

IÁMETRO

D

XTERIOR [R-3]

E

JUNTA de 1/4"

(mostrada en

una pieza de 1")

Figura 27

JUNTA de 3/8"

(mostrada en

una pieza de

1-1/4")

Figura 28

LARGO MÁXIMO 2-7/8"

LARGO MÍNIMO 7/8"

BROCA DE 3/8"

LARGO MÁXIMO 3"

LARGO MÍNIMO 1"

BROCA DE 1/2"

MORTAJA

GUÍA DE COJINETE

DE 1-1/8" DE

EXTERIOR [R-3]

MORTAJA

GUÍA DE COJINETE

DE 1-1/8" DE

EXTERIOR [R-3]

DIÁMETRO

DIÁMETRO

BROCA

DE 3/8"

BROCA

DE 1/2"

ESPIGA

ESPIGA

LARGO MÁXIMO 2-7/8"

LARGO MÍNIMO 7/8"

GUÍA DE COJINETE

DE 7/8" DE

DIÁMETRO

EXTERIOR [R-3]

LARGO MÁXIMO 3"

LARGO MÍNIMO 1"

GUÍA DE COJINETE

DE 5/8" DE

DIÁMETRO

EXTERIOR [R-3]

JUNTA de 3/8"

(mostrada en

una pieza de 2")

LARGO MÁXIMO 3-1/8"

LARGO MÍNIMO 1-7/8"

MORTAJA

LARGO MÁXIMO 3-1/8"

LARGO MÍNIMO 1-7/8"

ESPIGA

27

Page 28

SERVICIO AL CLIENTE

Visite nuestro sitio de Internet www.generaltools.com/woodworking para obtener información

adicional para trabajos en madera, videos instructivos y manual del producto.

http://www.generaltools.com/mortise-tenon

INFORMACION DE GARANTÍA

General Tools & Instruments garantiza al comprador original que el material y la fabricación del

paquete de la Plantilla de Mortaja y Espiga No. 870 está libre de defectos durante un período de

un año. Sujeto a ciertas restricciones, General Tools reparará o reemplazará este producto,

únicamente si después de examinarlo determina que el material y fabricación está defectuoso.

28

Page 29

GABARIT À MORTAISE

ET TENON

N° 870

MANUEL DE L’UTILISATEUR

BREVETS AMÉRICAINS DEMANDÉS

VEUILLEZ LIRE ATTENTIVEMENT TOUT LE MANUEL AVANT D’UTILISER CE PRODUIT.

Pour plus de détails et des instructions vidéo, visitez le site

www.generaltools.com/mortise-tenon

29

Page 30

TABLE DES MATIÈRES

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Capacité et caractéristiques techniques . . . . . . . . . . . . . . . 31

Contenu de l’ensemble pour mortaise et tenon . . . . . . . . . . 32

Anatomie du gabarit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Anatomie de l’assemblage de la douille de la

toupie à changement rapide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Préparation de la toupie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 – 34

Aperçu des mesures de sécurité . . . . . . . . . . . . . . . . . . . . . . 33

Installation du manchon de guidage à

changement rapide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Centrage de la plaque de base et du système

de guide à changement rapide . . . . . . . . . . . . . . . . . . 33 – 34

Réglage de la profondeur de la coupe . . . . . . . . . . . . . . . . . . 34

Assemblage du gabarit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Instructions de fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 – 41

1. Emplacement et marquage des centres

de la mortaise et du tenon . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2. Centrage du bois . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3. Positionnement du bois avec les barres

de positionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4. Réglage de la longueur des mortaises et tenons

Tableau des longueurs des mortaises et tenons . . . . 37 – 38

5. Réglage de la profondeur de la fraise . . . . . . . . . . . . . . . . 38

6. Taille du tenon avec la toupie . . . . . . . . . . . . . . . . . . . 39 – 40

7. Taille de la mortaise avec la toupie . . . . . . . . . . . . . . . . . . . 40

Taille de mortaises et tenons à la toupie - Autres formats . . . . . . . . . . . . . 41

Service à la clientèle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Information sur la garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

30

Exemples

d’assemblages à

mortaise et tenon

Page 31

INTRODUCTION

Merci d’avoir acheté un gabarit à mortaise et tenon E-Z Pro de General Tools & Instruments –

le premier gabarit intégré de l’industrie du travail du bois en mesure de faire des assemblages à

mortaise et tenon de qualité professionnelle dès son déballage. Ce gabarit facilite et simplifie la

fabrication de mortaises et tenons – l’assemblage le plus solide qui soit pour les meubles, les

cabinets et les cadres.

L’ensemble pour mortaise et tenon contient un gabarit entièrement assemblé, une fraise de 1/4 po

et une douille de guidage pour tenon de ¼ po. De plus, des douilles de guidage de 3/8 po et de

1/2 po sont aussi incluses. Vous devrez vous procurer vos propres fraises de 3/8 po et de 1/2 po.

Ce gabarit a un boîtier fait d’une seule pièce en aluminium riche et traité à la chaleur et doté de

boulons d’ajustement, d’attaches de fraise et de fraises d’acier respectant les normes SAE. Les

barres de positionnement ajustables et l’assemblage de la douille de la toupie sont aussi faits en

acier massif.

Capacité et caractéristiques techniques :

Convient au bois de 1/2 po à 1 1/2 po d’épaisseur, peu importe la longueur

Épaisseur des mortaises et tenons : 1/4 po, 3/8 po et 1/2 po

Longueur minimale de l’assemblage à mortaise et tenon : ± 1/8 po (selon la fraise utilisée)

Longueur maximale de l’assemblage à mortaise et tenon : ± 1/8 po (selon la fraise utilisée)

Contenu de l’ensemble pour mortaise et tenon

1. Le gabarit entièrement assemblé

2. L’assemblage du système de guide à

changement rapide, qui se compose de :

• un manchon de guidage de 1 3/16 po à

changement rapide et d’un contre-écrou

• une douille de guidage de 1/4 po (1 1/4 po)

dia. ext.

• une tige de centrage de 1/4 po

• une clé de serrage plate pour ajuster le

contre-écrou du manchon de guidage

• une douille de guidage de 3/8 po

• une douille de guidage de 1/2 po

3. Une fraise à denture droite pour toupie de 1/4 po en carbure métallique

4. Outil pour l’alignement

1

2

3

4

Il est fortement recommandé de vous familiariser avec la nomenclature des figures 1 et 2 de

la page 32 avant de commencer.

31

Page 32

ANATOMIE DU GABARIT À MORTAISE ET TENON E-Z PRO

Fig. 1

PROFIL DE L’ASSEMBLAGE

DU GABARIT

ASSEMBLAGE DU GABARIT

SECTION MORTAISE

SECTION TENON

1 - Assemblage du gabarit

1A - Marques de centrage

1B - Embrèvements de centrage

1C - Indicateurs de positionnement du

gabarit

2 - Guides de la section mortaise

2B - Règle de positionnement du guide

2C - Vis de blocage du guide

3 - Guides de la section tenon

4 - Barre de centrage, [4A] marques, [4B]

dentelure, [4C] vis de serrage

5 - Vis de serrage du serre-joints

6 - Barres de positionnement

6A - Barres de positionnement déployées

6B - Barres de positionnement rétractées

pour le rangement et la coupe

7 - Serre-joints

8 - Rebord de montage

ANATOMIE DE L’ASSEMBLAGE DE LA DOUILLE DE LA TOUPIE À CHANGEMENT RAPIDE :

Fig. 2

1 1/8 po dia. ext.

7/8 po dia. ext.

R1 - Contre-écrou

R2 - Manchon de guidage de 1 3/16 po

R3 - Douille de guidage de 1 1/8 po dia. ext.

pour les tenons de 1/4 po (et pour les

mortaises)

R4 - Tige de centrage

32

5/8 po dia. ext.

R5 - Clé de serrage plate

R6 - Douille de guidage de 7/8 po dia. ext.

pour les tenons de 3/8 po

R7 - Douille de guidage de 5/8 po dia. ext.

pour les tenons de 1/2 po

R8 - Fraise de 1/4 po

Page 33

PRÉPARATION DE LA TOUPIE

APERÇU DES MESURES DE SÉCURITÉ

1. BIEN CONNAÎTRE SA TOUPIE. Lisez le manuel de l’utilisateur qui accompagne la toupie avant

de l’utiliser. Vous devez comprendre les applications et les limitations de l’outil, de même que les

risques potentiels propres à son utilisation. Avant d’utiliser la toupie, vérifiez qu’aucune de ses

parties mobiles n’est brisée, lâche ou désalignée.

REMARQUE : General Tools & Instruments n’est pas responsable du mauvais usage de la toupie

ni de la non-observation des mesures de sécurité normales associées à l’utilisation d’une toupie.

Installation du manchon de

guidage à changement rapide

Le gabarit E-Z Pro est conçu pour une utilisation

avec des toupies plongeantes dont la plaque de

base présente un trou central de 1 3/16 po et un

trou contre-percé de 1 3/8 po, ce qui sert à

installer rapidement le manchon et la douille de

guidage. Si la base de votre toupie ne peut

recevoir le manchon de guidage, vous pouvez

acheter une plaque de toupie universelle ayant un

trou central aux dimensions appropriées et qui se

fixe à votre toupie. Vous pouvez aussi remplacer

votre base actuelle.

Avec la base appropriée mise en place :

1. Insérer le manchon de guidage [R-2] dans la

plaque de la base.

PLAQUE DE BASE

AVEC TROU CENTRAL

DE 1 3/16 PO ET TROU

CONTRE-PERCÉ DE

1 3/8 PO

Fig. 3

2. Serrez fermement le contre-écrou [R-1] avec

la clé de serrage fournie.

3. Vissez la douille de guidage de la toupie de

1 1/8 po [R-3] dans le centre du manchon de

guidage et serrez-la à la main (fig. 3).

Centrage de la plaque de base et

du système de guide à changement

rapide

1. Placez la toupie à l’envers et y déposer la

plaque de base et la serrer.

2. Insérer la tige de centrage de 1/4 po [R-4] dans

le mandrin de la toupie et la serrer solidement.

3. Dévissez suffisamment les vis de montage de la

plaque de la base de façon à permettre un

léger mouvement (fig. 4).

4. Dévisser soigneusement le verrou de plongée

et amener doucement la base de plongée vers

la partie conique de la tige de centrage (fig. 5),

ce qui permet à la plaque de la base

maintenant légèrement mobile de bouger dans

les trous de vis et d’atteindre une position

centrale parfaite.

Fig. 4

Fig. 5

5. Serrez bien les vis de la plaque de la base.

33

Page 34

Fig. 6

Une fois que l’étape du centrage est terminée,

retirez la tige de centrage de la toupie et

remplacez-la par la fraise de la toupie (fig. 6).

RÉGLAGE DE LA PROFONDEUR DE LA COUPE

• Réglez la profondeur de votre toupie plongeante à la profondeur désirée pour la mortaise et le

tenon.

• Lorsque le bois est correctement installé sur le gabarit, son bord supérieur sera 1/2 po sous la

surface de travail (le dessus) du gabarit (fig. 7a).

• Ajouter 1/2 po à la profondeur désirée de la mortaise et du tenon lorsque vous réglerez la

profondeur de « plongée » de la toupie (fig. 7b).

PROFONDEUR DE LA MORTAISE

+ 1/2 po

LA MESURE ENTRE

LA SURFACE DE LA

PLAQUE ET L’EX-

Fig. 7A

TIGE DE POSITIONNEMENT DÉPLOYÉE

TRÉMITÉ DE LA

FRAISE EST ÉGALE

À LA PROFONDEUR

DE LA MORTAISE

PLUS 1/2 PO

Fig. 7B

TOUPIE EN POSITION DE

PLEINE PLONGÉE

ASSEMBLAGE DU GABARIT

Le gabarit à mortaise et tenon peut être directement monté sur le bord d’un établi à l’aide du

rebord de montage [9] (fig. 8A) ou fixé sur un panneau de montage qui peut ensuite être retenu à

un établi par des serres (fig. 8B).

Fig. 8A

34

ÉTABLI

ÉTABLI

Fig. 8B

Page 35

INSTRUCTIONS D’UTILISATION :

1. Emplacement et marquage des centres de la mortaise et du tenon

Faites des marques centrales aux positions correspondant à la longueur du tenon et de la

mortaise. Ces marques seront nécessaires pour centrer le tenon et la position longitudinale de la

mortaise sur le bois. Si vous avez correctement réglé la barre de centrage pour l’épaisseur du bois,

ce dernier sera automatiquement centré** en conséquence pour l’épaisseur du bois lorsque la

pièce de bois sera fixée dans le gabarit.

** Truc : S’il y a une variation dans l’épaisseur du bois utilisé, vous pouvez régler ce problème en

utilisant des cales appropriées ou en réajustant la barre de centrage.

POSITION CENTRALE DE LA MORTAISE

POSITION CENTRALE DE LA MORTAISE

POSITION CENTRALE DU TENON

Fig. 9

SECTION MORTAISE

SECTION TENON

2. Centrage du bois

• Pour centrer le bois dans le gabarit, il

faut ajuster la barre de centrage [4]

(fig. 10) selon l’épaisseur du bois.

• Le gabarit peut accepter du

bois dont l’épaisseur varie entre

1/2 po et 1 1/2 po.

• En utilisant la nomenclature de

l’industrie du sciage, ces deux

épaisseurs sont désignées

comme « 2 quarts » (1/2 po) et

« 6 quarts » (1 1/2 po), indiquant le

nombre de tranches de 1/4 po

d’épaisseur.

• Les marques se trouvent sur l’extrémité du tenon de la barre de centrage [4A]. Utilisez ces unités

« quarts » pour ajuster l’épaisseur de votre bois en « quarts ». Par exemple, si vous utilisez du

bois de 3/4 po (3 quarts), alignez le chiffre « 3 » avec la paroi interne du gabarit (fig. 11) et le bois

sera à son centre nominal dans les guides.

PAROI INTERNE

Fig. 10

• Lorsque vous ajustez la barre de centrage, ainsi que pour maintenir l’alignement parallèle,

assurez-vous chaque fois que la tige est correctement appuyée sur

le corps du gabarit avec la surface en dents de scie

correspondante [4B] (fig. 11) dans le gabarit.

Truc : Pour s’assurer

que l’assemblage est

bien aligné, particulièrement

si vous faites un cadrage en

façade ou un autre type

d’assemblage de surfaces,

gardez toujours les façades à

agencer du même côté que le gabarit.

Fig. 11

35

Page 36

3. Positionnement du bois avec les barres de positionnement

Lorsqu’elles sont déployées (fig. 12), les barres de positionnement ont deux fonctions de base :

1. Positionner le bois à la profondeur adéquate sous le dessous du guide pour le passer à la

toupie;

2. Aligner le bois pour qu’il soit à angle droit (90 degrés) par rapport à la longitudinale du gabarit.

A

6

Fig. 12

Fig. 13

Les barres de positionnement (fig. 12 et 13) sont rangées le long

du côté interne du dessous de la surface du gabarit lorsque la

toupie est utilisée.

1. Pour étendre les barres, utilisez les poignées des barres de

positionnement [6A], situées sous le côté supérieur extérieur.

2. Après avoir déployé complètement les barres de

positionnement, vous êtes prêt à placer le bois dans le gabarit.

Insérez le bois délicatement contre les barres de

positionnement déployées (fig. 14) et serrez la vis de serrage

suffisamment pour que le bois soit retenu lâchement par les

Fig. 14

serre-joints [7].

3. Centrez le bois dans le sens longitudinal avec les marques de centrage [1A] sur le gabarit

(fig. 15). Avant de serrer les serre-joints [7], veillez à ce que le bois soit bien à plat et à angle de

90 degrés par rapport aux barres de positionnement (mais pas trop serré) et bien centré.

4. Serrez les serre-joints suffisamment pour empêcher le bois de bouger.

5. À l’aide des poignées, rangez les barres de positionnement à l’endroit désigné (fig. 15).

Fig. 15

36

POSITION D’UTILISATION

RANGEMENT PENDANT

L’UTILISATION DE LA TOUPIE

Page 37

4. Réglage de la longueur des mortaises

Le gabarit comporte deux sections de travail : la section mortaise et la section tenon (fig. 16).

SECTION MORTAISE

SECTION TENON

Les sections mortaise et tenon du gabarit sont toutes deux dotées de guides coulissants

ajustables [# 2 et # 3] (fig. 16) qui servent à régler la longueur de la mortaise et du tenon. Les

chiffres 1, 2 et 3 sont visibles, ainsi que les marques graduées sur le côté de chaque guide [2B].

Pour ajuster les guides à la longueur désirée, dévissez les vis de blocage [2C] des guides droit

et gauche sur les deux côtés de la mortaise et du tenon, puis glissez-les jusqu’à l’indication de

l’ouverture désirée (selon le tableau établi à partir du diamètre de la fraise). Les quatre guides

coulissants devraient être réglés de la même façon. Resserrez les vis.

Les numéros 1, 2 et 3 indiqués sur les guides coulissants ajustables font directement

référence à la fraise de 3/8 po dans le tableau qui suit. Par exemple, si vous réglez les guides à

2, vous créerez un joint d’une longueur de . Si vous réglez les guides à 1, vous obtiendrez des

joints d’une longueur de 1 po.

Si vous utilisez une fraise dont le diamètre est de 1/4 po ou 1/2 po, référez-vous aux réglages du

tableau pour la taille réelle du joint pour ces mêmes marques. Le tableau compense pour la

différence de taille de douille et du diamètre de la fraise de 3/8 po. Par exemple, si vous utilisez

une fraise de 1/4 po et que les guides sont réglés à 2, vous obtiendrez un joint d’une longueur de

1 7/8 po. De la même façon, avec une fraise de 1/2 po et les guides réglés en position 2, le joint

obtenu mesurera 2 1/8 po.

Remarques :

1. Le tableau ci-dessous indique la longueur exacte de chaque joint pour chaque marque sur

le guide et selon la taille de la fraise.

2. Au moment de régler la taille de l’ouverture, assurez-vous que TOUS les guides indiquent

la même mesure; de cette façon, la mortaise et le tenon seront de la même taille (fig. 16).

Tableau des longueurs des mortaises et tenons

Épaisseur

des

mortaises

et tenons

1/4 po 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8 7/8

3/8 po 3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

1/2 po 3-1/8 2-7/8 2-5/8 2-3/8 2-1/8 1-7/8 1-5/8 1-3/8 1-1/8

3 2-3/4 2-1/2 2-1/4 2 1-3/4 1-1/2 1-1/4 1

Marques de position des guides

37

Page 38

Les sections tenon et mortaise comportent toutes deux des marques de centrage [1A] (fig. 17) qui

indiquent le centre longitudinal des guides. On trouve aussi des embrèvements de centrage [1B]

sur les barres de positionnement [6]; ils indiquent le centre de la largeur du guide.

TRUC : Il est conseillé de tailler la mortaise pour qu’elle soit un peu plus longue que le tenon

(ou bien le tenon un peu plus court que la mortaise) pour faciliter l’insertion et le collage.

Fig. 17

Fig. 18

L’outil pour l’alignement (fig. 18) sert à

centrer le bois non coupé dans le gabarit.

Avant de fixer le bois dans le gabarit,

placez l’outil pour l’alignement comme

le montre l’image et alignez-le par rapport

aux marques de centrage [1A] sur le

gabarit (fig. 19).

L’outil pour l’alignement peut aussi servir

Fig. 19

à aligner avec plus de précision les guides

coulissants ajustables [# 2 et # 3] par rapport

aux indicateurs de positionnement du guide [1C].

5. Réglage de la profondeur de la fraise

(voir aussi « Réglage de la profondeur de la coupe, à la page 34)

Pour régler la profondeur de la « plongée » de la toupie (fig. 20), et par la suite la profondeur de la

coupe faite par la fraise, vous devez vous rappeler d’ajouter 1/2 po à la profondeur désirée pour la

mortaise. Par conséquent, si vous réglez la profondeur de la taille à , votre mesure aura un total de

1 1/2 po de la surface de la plaque de base jusqu’à l’extrémité de la fraise.

LA MESURE

ENTRE LA

SURFACE DE LA

PLAQUE ET

L’EXTRÉMITÉ DE

LA FRAISE EST

ÉGALE À LA

PROFONDEUR DE

LA MORTAISE

PLUS 1/2 PO

PROFONDEUR DE LA MORTAISE

+ 1/2 po

38

Fig. 20

Page 39

6. Taille du tenon avec la toupie

Lorsque vous taillez le tenon, veillez à ce

que la douille de guidage [R-3] se

déplace seulement contre les parois

extérieures du guide du tenon [3] (fig. 21)

en tout temps.

1. Commencez la taille en plaçant la

douille de guidage dans l’extrémité

du guide.

Fig. 21

2. Une fois que la douille de guidage est

placée à l’extrémité du guide et que la

base de la toupie est bien ajustée à la

surface du gabarit, mettez la toupie

en marche.

3. Plongez la toupie à une profondeur

facile à travailler et guidez la fraise de

la toupie dans le sens des aiguilles

d’une montre tout au long du

processus de taille. Assurez-vous de

garder la douille de guidage bien

appuyée contre le côté extérieur en

tout temps.

REMARQUE : Vous pouvez faire des

plongeons successifs à toute profondeur

pendant que vous déplacez la douille de

guidage dans le sens des aiguilles d’une

montre autour du guide du tenon,

toujours en déplaçant la toupie contre les

parois afin que le tenon soit le plus

proprement taillé possible. Nous

recommandons de faire une succession

de plongeons peu profonds et de couper

par grands mouvements afin d’éviter de

mettre trop de pression sur la fraise

(fig. 21 et 22).

FRAISE DE

1/4 PO

MONTRÉ

R-3 DOUILLE

DE GUIDAGE

Fig. 22

Avertissement : Fermez la toupie avant

de retirer la fraise de l’entaille.

Truc : Selon l’épaisseur réelle du bois,

il se peut qu’une mince paroi persiste

en bordure du tenon (fig. 23). Dans ce

cas, coupez-la, limez-la ou poncez-la

bien pour que l’ajustement soit parfait.

Fig. 23

39

Page 40

Fig. 24

7. Taille de la mortaise avec la toupie

Truc : Lorsque vous taillez la mortaise à la toupie, il est conseillé d’augmenter légèrement la

profondeur de la taille par rapport à la longueur du tenon pour laisser de l’espace à la colle qui sera

mise sur le tenon avant de l’insérer dans la mortaise.

La douille de guidage [R-3] s’ajuste précisément au guide de la mortaise [2] (fig. 24) pour

l’empêcher de se déplacer en dehors de la ligne. Elle sera utilisée pour toutes les mortaises,

peu importe les dimensions.

Fig. 25

1. Avant de mettre la toupie en marche, placez la douille de guidage dans l’extrémité du guide de

la mortaise et glissez-la au travers du guide pour s’assurer qu’elle bouge librement.

2. Une fois que la douille de guidage est placée à l’extrémité du guide et que la base de la toupie

est bien ajustée à la surface du gabarit, mettez la toupie en marche.

3. Plongez la toupie et guidez la fraise de la toupie tout au long du processus de taille.

REMARQUE : Nous recommandons de tailler la mortaise en faisant des plongeons

successifs qui se chevauchent et en relevant et abaissant de façon répétitive

la fraise afin de bien nettoyer l’entaille de la mortaise.

40

Page 41

TAILLE DE MORTAISES ET TENONS À LA TOUPIE - AUTRES FORMATS

L’ensemble de gabarit à mortaise et tenon E-Z Pro avec douille de guidage pour la toupie

inclut un manchon de guidage avec contre-écrou [R2, R1], une douille de guidage pour la toupie

de 1 1/8 po pour les assemblages de 1/4 po [R3], une fraise de 1/4 po et une tige de centrage [R4].

Ces éléments vous permettront de faire des mortaises et tenons de 1/4 po convenant à des

panneaux d’une épaisseur de 3/4 po (fig. 26). L’ensemble comprend aussi une douille de guidage

dont vous aurez besoin pour fabriquer des mortaises et tenons de 1/2 po [R7] ou de 3/8 po [R6]

(page 32). Cependant, vous devrez achetez séparément les fraises correspondantes. Veuillez

consulter le tableau des dimensions à la page 38.

• Pour fabriquer un tenon de 3/8 po, il vous faudra une fraise de 3/8 po et une douille de guidage

de 7/8 po [R6].

• Pour fabriquer la mortaise de 3/8 po correspondante, changez le manchon de guidage de

1 1/8 po [R-3] (fig. 27).

• Pour fabriquer un tenon de 1/2 po, il vous faudra une fraise de 1/2 po et une douille de guidage

de 5/8 po [R7].

• Pour fabriquer la mortaise de 1/2 po correspondante, changez le manchon de guidage de

1 1/8 po [R-3] (fig. 28).

REMARQUE : Les douilles de guidage peuvent être changées sans que la fraise soit enlevée de la

toupie.

FRAISE DE 1/4 PO

Fig. 26

OUILLE DE

D

UIDAGE DE

G

1/8 PO DIA. EXT.

1

R-3]

[

RAISE

F

E 1/4

D

O

P

OUILLE DE

D

UIDAGE DE

G

1/8 PO DIA. EXT.

1

R-3]

[

MORTAISE/TENON

de 1/4 po (pour du

bois de 1 po)

Fig. 27

MORTAISE/TENON

de 3/8 po (pour du

bois de 1 1/4 po)

Fig. 28

LONGUEUR MAX. 2 7/8 PO

LONGUEUR MIN. 7/8 PO

FRAISE

DE 3/8

PO

LONGUEUR MAX. 3 PO

LONGUEUR MIN. 1 PO

FRAISE

DE 1/2

PO

MORTAISE

DOUILLE DE

GUIDAGE DE

1 1/8 PO DIA. EXT.

MORTAISE

DOUILLE DE

GUIDAGE DE

1 1/8 PO DIA. EXT.

[R-3]

[R-3]

1/4 PO

FRAISE

DE 3/8

PO

FRAISE

DE 1/2

PO

TENON

TENON

LONGUEUR MAX. 2 7/8 PO

LONGUEUR MIN. 7/8 PO

DOUILLE DE

GUIDAGE DE

7/8 PO DIA. EXT.

[R-3]

LONGUEUR MAX. 3 PO

LONGUEUR MIN. 1 PO

DOUILLE DE

GUIDAGE DE

5/8 PO DIA. EXT.

[R-3]

MORTAISE/TENON

de 1/2 po (pour du

bois de 2 po)

LONGUEUR MAX. 3 1/8 PO

LONGUEUR MIN. 1 7/8 PO

MORTAISE

LONGUEUR MAX. 3 1/8 PO

LONGUEUR MIN. 1 7/8 PO

TENON

41

Page 42

SERVICE À LA CLIENTÈLE

Veuillez visiter notre site Web au www.generaltools.com/woodworking pour obtenir des

renseignements additionnels sur le travail du bois, des vidéos d’instructions et le manuel de

l’utilisateur.

http://www.generaltools.com/mortise-tenon

INFORMATION SUR LA GARANTIE

Le gabarit à mortaise et tenon n° 870 de General Tools & Instruments est garanti pour l’acheteur

original contre tout défaut de matériau et de main-d’œuvre pour une période de un an. General

réparera ou remplacera, sous certaines restrictions, cet instrument si, après examen, l’entreprise

détermine qu’il y a un défaut de matériau ou de main-d’œuvre.

42

Page 43

NOTES

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

43

Page 44

GENERAL TOOLS & INSTRUMENTS

80 White Street, New York,NY10013

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

870 User’s Manual

Specifications subject to change without notice

©2011 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

MAN#870 8/11 /11

-

3567

Page 45

No. 870

ADDITIONAL TIPS & TRICKS

TWO WAYS TO MORTISE A WORK PIECE THAT IS LESS THAN 2" WIDE

Method #1

The center of the clamp which holds the work piece is 2" below the positioning bars so if you wish to clamp stock in the

jig for mortising that is less than 2" wide you’ll need to position the stock using a ‘shim’ as well as re-setting the bit in the

router to accommodate the width of the shim.

Assuming you were going to mortise a work piece that was 1-1/2" wide. You would use a 1/2" shim and place it on top of

the work piece when bringing it up to the positioning (swing) arms. You would then tighten the clamp screws and retract

the positioning arms and remove the shim before cutting. Adjust the router bit depth by increasing it by the thickness of

the shim (in this case 1/2") over the desired mortise setting.

Method #2

The second method would be to have a work piece that was twice the width of your finished work piece (plus the

kerf of your saw blade). Then you would cut your mortises on both sides of this piece. Follow the regular mounting

instructions and after completion of the mortise cutting you would simply rip the work piece lengthwise (in half)

yielding two finished pieces.

Page 46

TWO WAYS TO ELIMINATE OR REMOVE THE “FENCE” WHEN CUTTING TENONS

Method #1

On a 3/4" thick piece of wood if you cut a 3/8" tenon with the 3/8" bit. This will create joints with no fence. Simply use

the corresponding bushings as directed on Fig. 27 on page 13 of the instruction manual for mortise and tenon sections.

Method #2

Using the same example as Method #1, if you wanted to cut a 1/4" tenon on a nominal 3/4" thick piece of wood you

would use the 1/4" bit and bushing to center the tenon and make the appropriate cut, but then, replace the 1/4" bit and

bushing with the 3/8" bit and bushing to rout off the fence. This will clean-up the joint leaving no remnants of a fence.

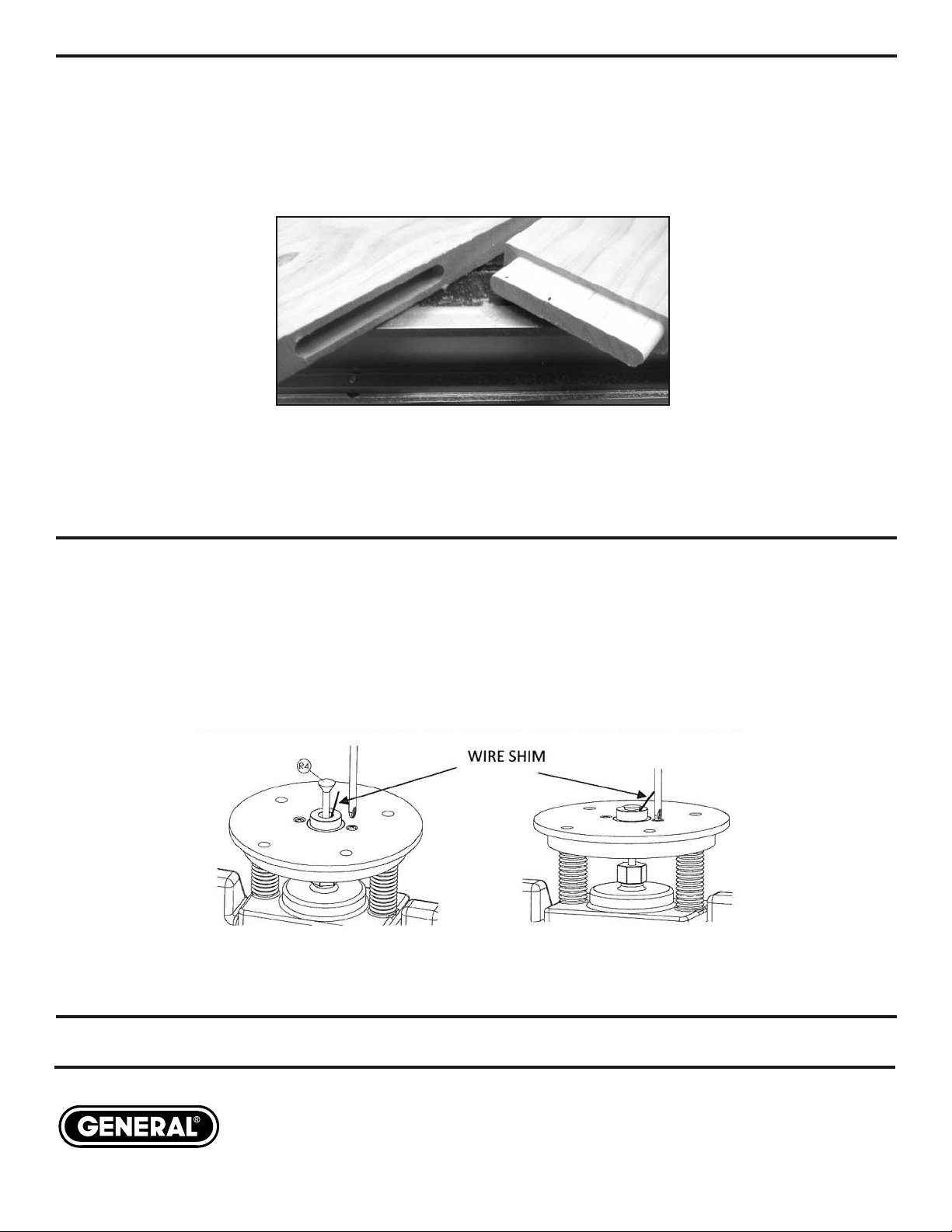

How to Adjust the Fit of the Mortise and Tenon

The E•Z Pro Mortise & Tenon Jig is designed to make a “line-to-line” fit of the tenon onto the mortise which insures a

tight close fit. If a looser fit is desired, this can be accomplished when centering the guide system (see “Centering the

Base Plate and the Quick Change Guide System” on page 5 of the instructions). Insert a fine wire shim of about a 1/32"

between the cone of the centering pin (R4) Fig. 4 on page 5, and the base plate before retracting the base plate onto the

centering pin and then tighten the base plate screws. Thus, the router base plate will be offset to create a gap equal to

the diameter of the shim between the mortise and tenon when cutting.

A practice cut with different size shims may be made to establish the preferred tightness or looseness of the fit.

Of course, as an alternative, the tenon may be sanded down to establish the desired fit as well.

If, at any time, you need additional help, feel free to call a wood joining expert at General!

GENERAL TOOLS & INSTRUMENTS

80 White Street, New York,NY10013-3567

PHONE (212) 431-6100 FAX (212) 431-6499 TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com www.generaltools.com

Loading...

Loading...