Page 1

USERS MANUAL

No. 861

PLEASE READ THESE INSTRUCTIONS FULLY BEFORE USING THIS JIG

FOR MORE INFORMATION AND VIDEO INSTRUCTIONS VISIT

WWW.GENERALTOOLS.COM/DOVETAILER2

THE

DOVETAIL JIG

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 1

Page 2

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Capacity and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

What’s in the Jig Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Anatomy of the DOVETAILER

II Jig . . . . . . . . . . . . . . . . . . . . 5 –6

Dovetail Router Bit and Bearings . . . . . . . . . . . . . . . . . . . . . . 5

Using the Built-In Depth Gauge . . . . . . . . . . . . . . . . . . . . . . . 6

Preparing the Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 –7

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Router Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 –7

Cutting Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 – 13

Cutting a Half Blind Dovetail Joint . . . . . . . . . . . . . . . . . 7 –9

Cutting Joints Longer Than the Jig Opening . . . . . . . . . . . 10

Cutting a Full Through Dovetail Joint . . . . . . . . . . . . . . . . . 10

Edge to Edge Jointing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cutting a Box Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 – 13

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return for Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 2

Page 3

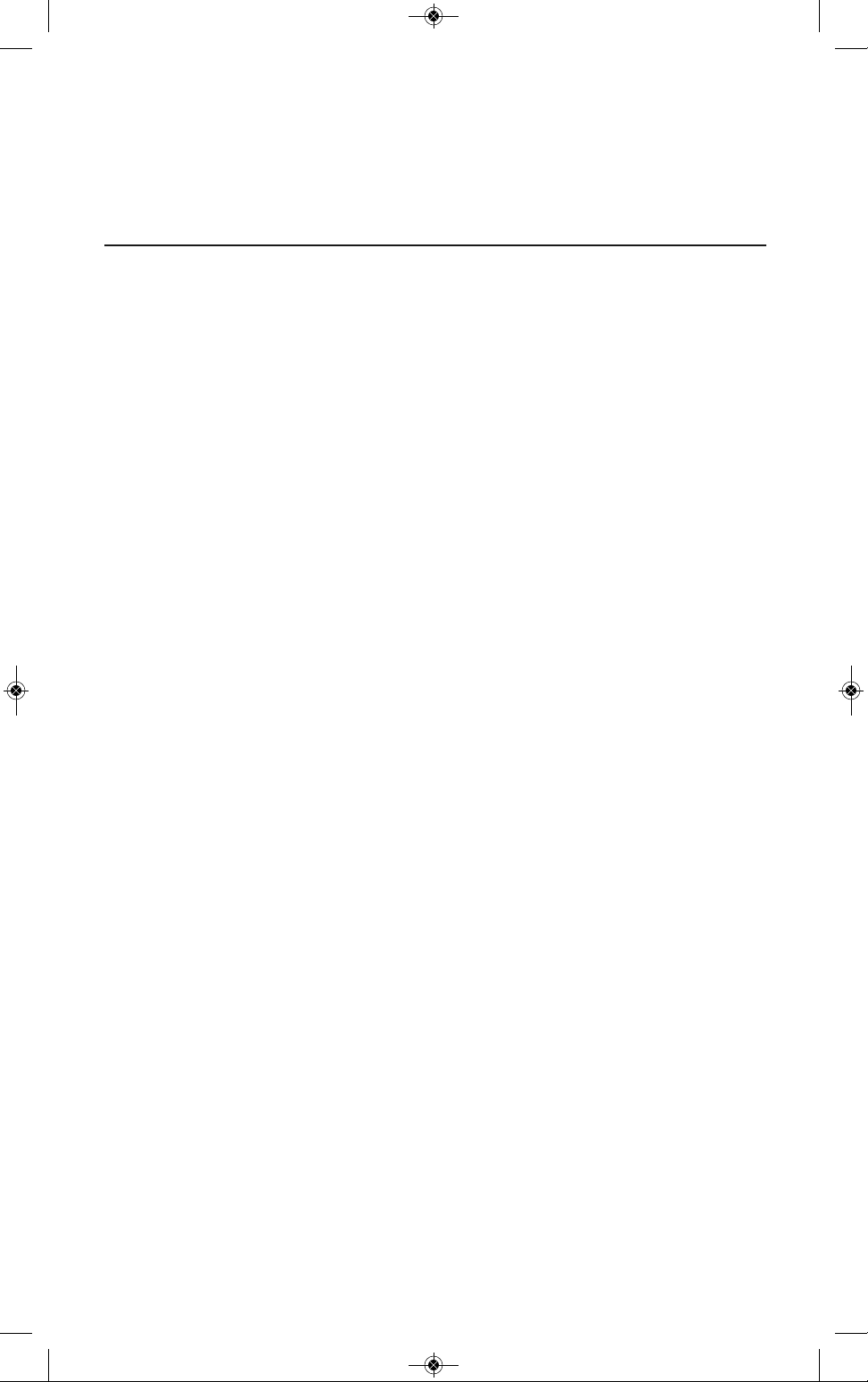

INTRODUCTION

Thank you for purchasing General Tools & Instruments’ DOVETAILERII Dovetail Jig. A simple and

easy way to make professional dovetail joints, the DOVETAILERII enables you to cut half blind,

full through and box joints as well as edge to edge joining. The DOVETAILERII can be used on a

router table (Fig. 1 or free hand with a handheld router (Fig. 2).

3

FULL THROUGH

HALF BLIND

BOX JOINT

EDGE JOINT

FIG. 2

FIG. 1

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 3

Page 4

CAPACITY AND SPECIFICATIONS:

Accommodates stock from 1/2 in. to 1 in. thick.

WHAT’S IN THE JIG KIT

The fully assembled jig

Two router table guide knobs

One 14° x 1/2 in. dovetail router bit with guide bearings

(1/4 in. shank)

One alignment tool

One allen wrench

It is highly recommended that you familiarize yourself with the nomenclature in Fig. 3 before

proceeding.

4

FIG. 3

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 4

Page 5

ANATOMY OF THE DOVETAILER II JIG

DOVETAIL JIG ASSEMBLY

NOTE: Your jig comes fully assembled for use. The addition of the router control knobs aids in the

use of this jig on router tables.

1. For use on a router table, securely screw in the two Router Table Guide Knobs [6] into the holes

provided on the ends of the jig. Always use the Router Table Guide Knobs when using the jig on

a router table.(FIG. 4)

DOVETAIL ROUTER BIT AND BEARINGS

Included bearings are 1/2 in. outside diameter (OD) and 1/4 in. inner diameter (ID). Router sleeves

or bushings can be used in place of the guide bearings as long as they are also 1/2 in. OD.

Included router bit is 14˚ x 1/2 in. Other bits can be substituted provided they have a 1/4 in.

diameter shank have no greater diameter than 17/32 in.

Caution: Keep fingers on control knobs only when using the jig on a router table.

5

FIG.4

– Jig Assembly

– Depth Plate

– Template Position Rule

–

Depth Adjuster Plate

– Depth Measuring Working Surface

– Edge Alignment Teeth

– Template Lock Screws

– Two Router Table Guide Knobs

– Face Clamp

– Face Clamp Thumb Screws

2A

3A

3B

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 5

Page 6

U

SING THE BUILT-IN DEPTH GAUGE

The built-in Depth Gauge is used to set both the depth of the Dovetail Cutter during router setup

as well as to control the length of the pins during cutting. (FIG. 5).

1. Loosen the Template Lock Screws

on the face of the Depth Plate .

2. Align the Depth Measuring Working Surface with the desired measurement on the

Template Position Rule Make sure both sides are at the same measurement.

3. Tighten the Template Lock Screws

to lock the Depth Adjuster Plate in position .

PREPARING THE ROUTER

SAFETY OVERVIEW

1. KNOW YOUR ROUTER. Read the owner’s manual that came with your router before

you use it. Understand the machine’s applications and limitations, as well as the

specific potential hazards inherent in its use. Before using the router, check that none

of its moving parts are broken, loose or misaligned.

NOTE: General Tools & Instruments is not responsible for router misuse or the disregard of

standard safety precautions associated with using a router.

ROUTER SETUP

1. Insert the dovetail cutter with

its guide bearings fully into the

router.

2. Set the height of the Dovetail

Cutter Bit using the Depth

Measureing Working Surface

. (FIG.6)

For instructions on setting the

depth gauge see USING THE

DEPTH GAUGE above.

3A

2A

3A

6

FIG. 5

FIG. 6

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 6

Page 7

7

3

. FIG.7 shows the dimension of the

dovetail joint affected by the cutter

height.

NOTE: Setting this height affects the

length of the Tails and the depth of

the Pins.

4. Now that the router is setup,

you need to reset the Depth

Adjuster Plate

for the length

of the pins. (FIG. 8) Set the

depth gauge for the length of

the “PINS”. This should be

equal to the thickness of the

wood used for the “TAILS”

board. (FIG. 9)

CUTTING JOINTS

Note: Always cut the “TAILS” side of the joint first.

CUTTING A HALF BLIND DOVETAIL JOINT

1. When cutting a half-blind dovetail joint, using the included dovetail cutter, start with a bit

height setting equal to the depth of the joint you desire. (FIG. 7)

2. Cut a test joint with scrap wood to confirm the fit of the

joint. If the boards do not fit together easily, the joint

may be too tight. The joint can be made looser or

tighter by setting the cutter depth shallower or deeper

as shown in FIG. 8.

3. Mark the center of your board, then center the mark

on any one of the guide teeth in the “TAILS” portion

of the jig.

4. Make sure the outside face of the board faces inwards

towards the clamp.

5. Tighten the clamps securely.

FIG. 9

OUTSIDE FACE

PINS

TAILS

FIG. 8

FIG. 7

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 7

Page 8

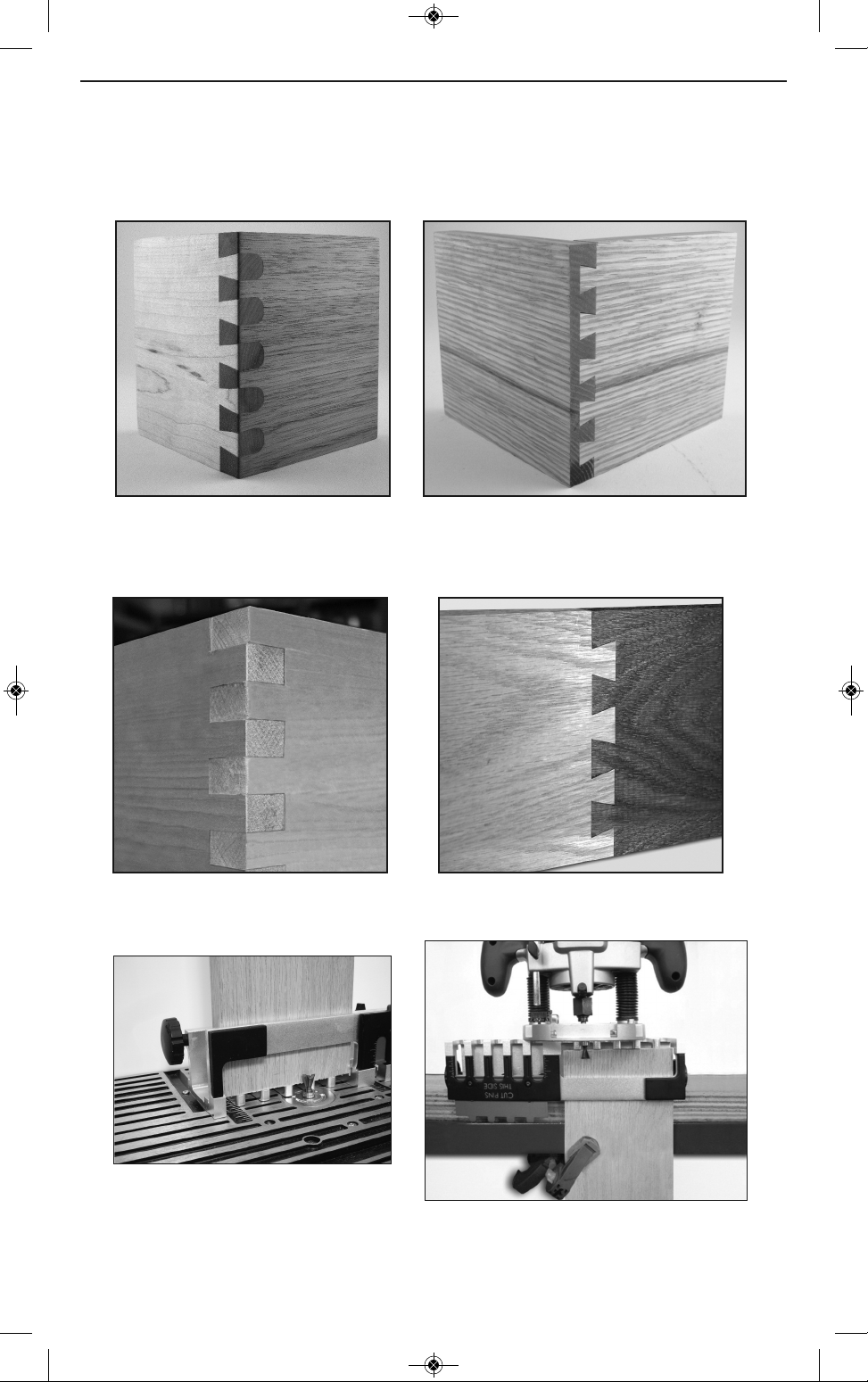

6. Clamp the board to a workbench or

secure it in a vice as shown (FIG. 10)

or if using a router table, make sure

the face saying “cut tails this side” is

faced to the router table (FIG. 11).

7. Cut the “TAILS” portion of the joint

always keeping the guide bearings

against the template edges. When

finished, remove “TAILS” board from

the jig.

8. Then to cut the “PINS”. Loosely

clamp the “PINS” board into

the jig with the outside face

pointing inward.

9. To align the edges, insert the

tails of the “TAILS” board

into the Edge Alignment

Teeth teeth on the top of

the Adjuster plate

with

the rounded side in (inside

face), and slide the loosely

clamped “PINS” board to

align its edges with the

edges of the “TAILS” board.

Now securely tighten the

clamps and remove the

“TAILS” board

(FIG. 12).

8

FIG. 10

FIG. 11

FIG. 12

3

B

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 8

Page 9

1

0. Make all cuts to the pins board. For those cuts, the router should ride on the surface

marked “cut pins this side” shown in FIG. 13 & 14. Be sure to follow the jig profile.

11. Dry fit the two sections together. If problems arise, file or trim the joint as needed.

9

FIG. 13

FIG. 14

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 9

Page 10

CUTTING JOINTS LONGER THAN THE JIG OPENING

Joints longer than the opening must be cut in multiple continuous segments. To align the jig with

the previous cut, the aligning tool provided must be used.

1. Move the previously cut wood in the jig and position the last slot from the previous cut in

the last channel of the jig either going to the right or to the left.

2. Loosely clamp the wood in the jig.

3. Insert the aligning tool into the slot to properly align the wood with the jig. (FIG. 15)

4. Tighten the clamps securely, and continue cutting.

5. Repeat as necessary.

CUTTING A FULL THROUGH DOVETAIL JOINT

* This requires a dovetail cutter bit with a depth equal to or

greater than the wood thickness you are cutting.

Note: Do not use router bit with a maximum diameter

greater than 17/32 in.

The steps required to cut a full through joint (FIG. 16) are the

same as to those described in the previous section CUTTING A

HALF BLIND DOVETAIL JOINT. With the following exceptions:

When cutting the “PINS” portion of the joint, set the depth

gauge equal to the thickness of the “TAILS” board.

10

TAILS

PINS

FIG. 15

FIG. 16

FIG. 15

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 10

Page 11

E

DGE TO EDGE JOINTING

1

. When cutting an edge joint, the round-over

created by the dovetail jig must be eliminated in

order to join the two pieces of wood using a

Dovetail-Joint. (FIG.17)

2. Insert the first board into the “TAILS” section of

the Dovetail Jig along with 1/4 in. thick shim to

offset the board away from the rounded postion

of the template in the jig. (FIG. 18)

3. Align one edge of the board to be cut with the

outside edge of the jig. (FIG. 18)

4. Tighten the clamps securely, and make all cuts.

5. Insert the second board into the jig along with the same shim and offset one edge of the

board 1/2 in. in from the outside edge of the jig. FIG. 19. This spacing will offset the

“TAILS” of the second board so that they align with the slots cut into the first board.

11

FIG. 17

FIG. 18

FIG. 19

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 11

Page 12

CUTTING A BOX JOINT

• When cutting a box joint, only use the “TAILS” portion of the jig for all cuts.

• For box jointing, use a 1/2 in. diameter straight bit with a 1/4 in. shank with either a 1/2 in.

O.D. guide bearing or a 1/2 in. O.D. guide sleeve insert in your router. Set the depth of the

cutter to equal, or slightly greater than the thickness of the wood you are joining.

Tip: Always make sure that the guide bearing or the guide sleeve tracks in the guide slot.

• To avoid the “round-over” part of the jig’s guide finger, use a 1/4 in. thick shim between

the wood and the inner surface of the jig to offset the board from the “round-over”.

Tip: If you’re doing more than one joint, you can use a piece of double-face tape to hold

the shim in place.

12

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 12

Page 13

•

Cut the slots in the first board with the board edge set flush with the right hand edge of the

jig. (FIG. 20). Make the entry and exit cuts using the left side of the guide slot only

(FIG. 20)

• For the joining board, clamp it in the jig with its edge offset 3/8 in. in from the right hand

edge of the jig. Make entry and exit cuts using the right side of the guide slot only

(FIG. 21).

• Dry fit the joint before gluing to be sure it is tight. If necessary, use a wood mallet to bring

the two parts together.

13

FIG. 20

FIG. 21

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 13

Page 14

CUSTOMER SUPPORT

Please visit our website at www.generaltools.com/dovetailer2 to obtain additional woodworking

information, instructional videos and product manual.

WARRANTY INFORMATION

The No. 861 DovetailerII Dovetail Jig Kit from General Tools & Instruments is warranted to the

original purchaser to be free from defects in material and workmanship for a period of one year.

Subject to certain restrictions, General will repair or replace this product, if, after examination,

it is determined by General to be defective in material or workmanship.

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable product of superior quality. However, in

the event your instrument requires repair, please contact our Customer Service to obtain an RGA

(Return Goods Authorization) number before forwarding the unit via prepaid freight to the

attention of our Service Center at this address:

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Remember to include a copy of your proof of purchase, your return address, and your phone

number and/or e-mail address.

14

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 14

Page 15

NOTES

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

________________________________________________________

15

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 15

Page 16

GENERAL TOOLS & INSTRUMENTS

80 White Street, New York,NY10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

861 User’s Manual

Specifications subject to change without notice

©2011 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

MAN#861 8/17/11

861 Dovetailer II Manual 11P-081711_Layout 1 8/17/11 5:12 PM Page 16

Loading...

Loading...