Page 1

DOVETAIL JIG No. 860

USER’S MANUAL

INTRODUCTION

Thank you for purchasing General’s DOVETAILER™Dovetail Jig. A simple and easy way to make professional furniture joints.

SAFETY RULES FOR A HANDHELD ROUTER AND ROUTERS USED WITH A ROUTER TABLE

1. KNOW YOUR ROUTER. Read the owner’s manual carefully before use. Learn the router's applications and limitations, as well as the

specific potential hazards involved in its use.

2. KEEP GUARDS IN PLACE and in working order.

3. GROUND ALL TOOLS. Most routers are equipped with a three-prong plug, and it should be plugged into a three-hole electrical outlet. If an

adapter is used to accommodate a two-prong outlet, the adapter lug must be attached to a known ground, such as the outlet holding

screw. Never remove the third prong.

4. REMOVE ANY ADJUSTING KEYS AND WRENCHES. Make it a habit to check that keys and adjusting wrenches are removed from the router

before operating.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. AVOID POTENTIAL DANGERS. Don’t use your router in damp or wet locations, or expose them to rain. Keep work area well lighted.

7. KEEP CHILDREN AND VISITORS AWAY. Distractions can easily lead to accidents — your own or others’.

8. MAKE YOUR WORKSHOP CHILDPROOF. Use pad-locks, master switches, or remove start keys.

9. DON’T FORCE THE ROUTER. It will do the job better and safer at the rate for which it was designed.

10. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, or jewelry to get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

11. USE SAFETY GLASSES.

12. USE A FACE OR DUST MASK.

13. DON’T OVERREACH. Keep your proper footing and balance at all times.

14. MAINTAIN YOUR ROUTER IN TOP CONDITION. Keep router bits sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

15. DISCONNECT YOUR ROUTER BEFORE SERVICING. Also when changing bits, blades, cutters and other accessories.

16. USE ONLY RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use of improper accessories

may cause hazards.

17. AVOID ACCIDENTAL STARTING. Make sure switch is in “OFF” position before plugging in cord.

18. NEVER STAND ON A TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

19. CHECK FOR DAMAGED PARTS. Before further use of the router, a guard or other part that is damaged should be carefully checked to

ensure that it will operate properly and perform its intended function. Check for alignment of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

20. ROUTER TABLE DIRECTION OF FEED. Feed work into the cutter.

21. NEVER LEAVE THE ROUTER RUNNING UNATTENDED. Turn power off, and stay with router until it comes to a complete stop. Before leaving,

assure that power cannot be turned on accidentally. Use pad-locks, master switches, or remove start keys.

22. AVOID DRUGS, ALCOHOL, AND MEDICATION. Do not operate the a router while under the influence of drugs, alcohol or medication.

1

Page 2

OINTS TO NOTE BEFORE STARTING

P

• Ensure that the bit is sharp. Blunt tools cannot produce good quality work, and increase the risk of a kickback and machine overload.

• Advance the bit evenly and at a moderate pace to ensure longer bit life and to protect against overloads.

• Cut long sockets in stages if necessary to avoid any buildup of chips.

• After installation of a new milling bit make sure that it turns easily in the milling position.

• Check the operation and setting of the tool on a sample piece before using on good wood.

• Make sure both pieces of wood to be joined are perfectly flat by placing them against one another. Warped wood will cause an

unsatisfactory joint.

DOVETAIL JIG ASSEMBLY

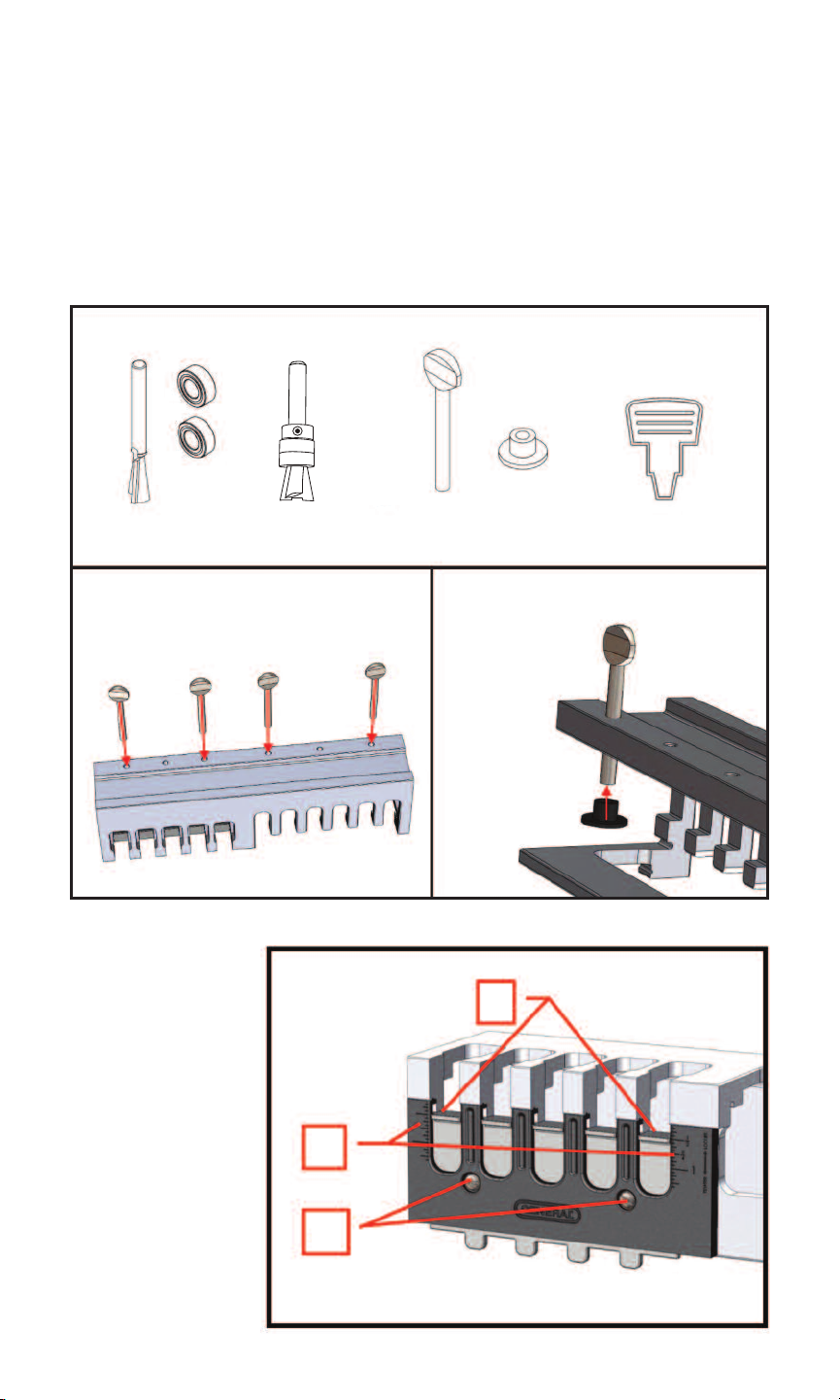

1. Remove all components from hardware bag and ensure that all are present and undamaged. (FIG.1)

. Install thumb screws into tapped holes as shown. Screw locations may be adjusted as needed. (FIG. 2)

2

3. Press non-marring ends onto thumbscrews. (FIG. 3)

or

FIG. 1

QTY. 2

QTY. 1

1/2" - OD

14º

1/2"x1/4"

Included bearings are 1/2" outside diameter (OD). Router sleeves or bushings can be substituted as long as they are also 1/2" OD.

Included router bit is 14° x 1/2". Other bits can be substituted providing they are also 1/2" diameter and their length is no greater than 3/4".

USING THE DEPTH GAUGE

The depth Gauge is used to set the

depth of the Dovetail Cutter during

router setup. It is also used to control

the length of the pins during cutting.

1. Loosen the two screws (A) on

the face of the depth gauge

2. Align the top surface (B) with

the desired measurement on

the ruled edges (C).

3. Tighten the two screws (A) to

lock the depth stop in position.

1/4" - ID

QTY. 1

14º

1/2"x1/4"

C

FIG. 2

QTY. 4

1/4" - 20

QTY. 4 QTY. 1

FIG. 3

B

A

FIG. 4

2

Page 3

OUTER SETUP

R

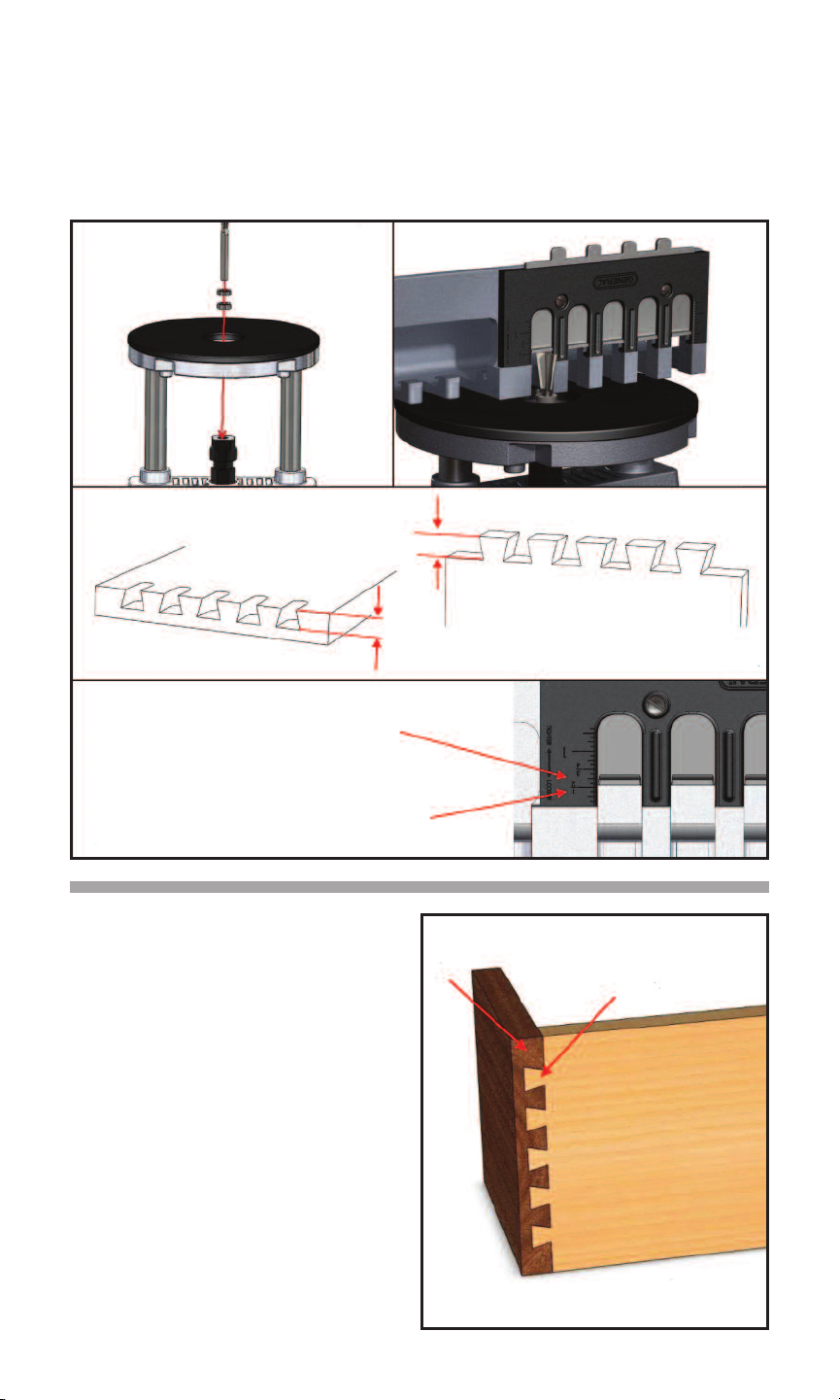

1. Insert the dovetail cutter with the fixed bearing into the router.

2. If the enclosed cutter is not of the fixed bearing type, install both bearings onto dovetail cutter and insert into Router. (FIG. 5)

3. Set the height of the Dovetail Cutter Bit using the Depth Gauge. (FIG. 6)

For instructions on setting the depth gauge see USING THE DEPTH GAUGE on page 2.

4. FIG. 7 shows the dimension of the dovetail joint that the cutter height affects.

5. The tightness of the joint (the fit between the two boards) can be adjusted by raising or lowering the height of the cutter as show in

FIG. 8. This will be described in greater detail later.

FIG. 5 FIG. 6

Setting a HIGHER bit height

will produce a TIGHTER joint.

Setting a LOWER bit height

will produce a LOOSER joint.

FIG. 8

CUTTING A HALF BLIND DOVETAIL JOINT

*The “PINS” side of the joint must be thicker than

1/2" for Half-Blind Joints

1. When cutting a half-blind dovetail joint, use the included

1/2" x 1/2" cutter and start with a bit height setting of 1/2".

2. Cut a test joint with scrap wood to confirm the fit of the joint.

If the boards do not fit together easily,the joint may be too

tight. The joint can be made looser or tighter by setting the

cutter depth shallower or deeper as shown in FIG. 8.

3. Begin with the “TAILS” side of the joint.

4. Center the board in the “TAILS” portion of the jig with the

outside face of the board facing inward. (FIG. 10)

5. Tighten the thumbscrews. CAUTION: DO NOT OVERTIGHTEN THE

THUMBSCREWS AS THIS HAS THE ABILITY TO WARP THE JIG.

6. Clamp the board to a workbench or secure it in a vice as

shown. (FIG. 11)

7. Cut the “TAILS” portion of the joint. Be sure to follow the jig

profile as the slots are wider than the cutter bearings. This is

to allow for a rough and a finish pass.

8. Now it is time to make the “PINS” side of the joint.

9. Set the depth gauge to the desired length of the “PINS”. This

should be slightly greater than the thickness of the wood used

for the “TAILS” board. (FIG. 12)

FIG. 7

PINS

TAILS

FIG. 9

3

Page 4

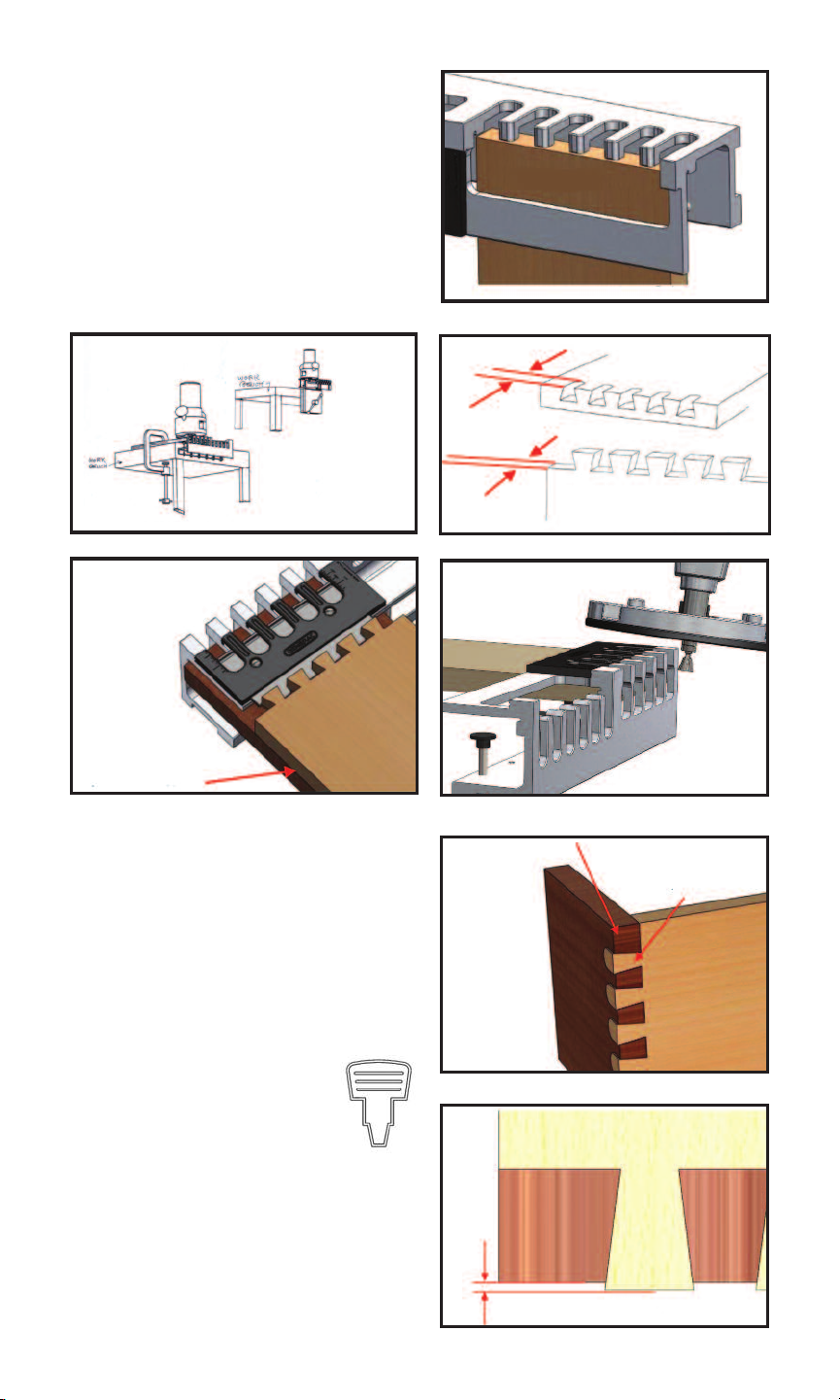

10. Loosely clamp the “PINS” wood into the jig with the outside face

pointing inward.

1. Insert the “TAILS” from previous cut into the teeth on the bottom of

1

adjuster plate. Position the wood to be cut by lining up the sides

with the first piece. (FIG. 13)

12. With the edges of both boards aligned; tighten the thumbscrews

NOTE THE CAUTION FROM STEP #5) and secure the stock to the

(

bench. Remove the “TAILS” board before proceeding.

13. Make all cuts. For this cut the router should ride on the surface of

the depth plate as shown in FIG. 14. Be sure to follow the jig profile

s the slots are wider than the cutter bearings. This is to allow for

a

rough and a finish pass.

a

14. Before gluing, fit the two sections together. The joint should be

tight and even with no gaps. If problems arise, file or trim the

joint to improve the fit.

NSIDE FACE

I

FIG. 10

FIG. 11

FIG. 13

SIDES LINE UP

CUTTING A FULL THROUGH DOVETAIL JOINT

*This requires a dovetail cutter bit with a depth greater than

the wood you are cutting.

The steps required to cut a full through joint (FIG. 15) are very similar

to those described in the previous section CUTTING A HALF BLIND

DOVETAIL JOINT, with the following exceptions:

FIG. 14

FIG. 15

FIG. 12

PINS

TAILS

1. When cutting the “TAILS” (FIG. 15) portion of the joint, set the bit

depth to slightly greater than the thickness of the “PINS” board.

This will ensure that the tails are slightly proud when fit and can

be sanded down for a flush fit. (FIG. 16)

2. When cutting the “PINS” portion of the joint, set the cutter depth

deeper (tighter) first and adjust to the desired joint fit.

CUTTING JOINTS WIDER THAN 6"

Joints over 6" wide must be cut in multiple

segments. To align the jig with the previous cut,

the aligning tool must be used.

1. Move the wood in the jig and position the last slot from the

previous cut in the last channel of the jig.

2. Loosely clamp the wood in the jig.

3. Insert the aligning tool into the slot to properly center the wood

with the jig. (FIG. 17)

4. Tighten the thumbscrews, (CAUTION: DO NOT OVERTIGHTEN),

and continue cutting.

5. Repeat as necessary.

FIG. 16

4

Page 5

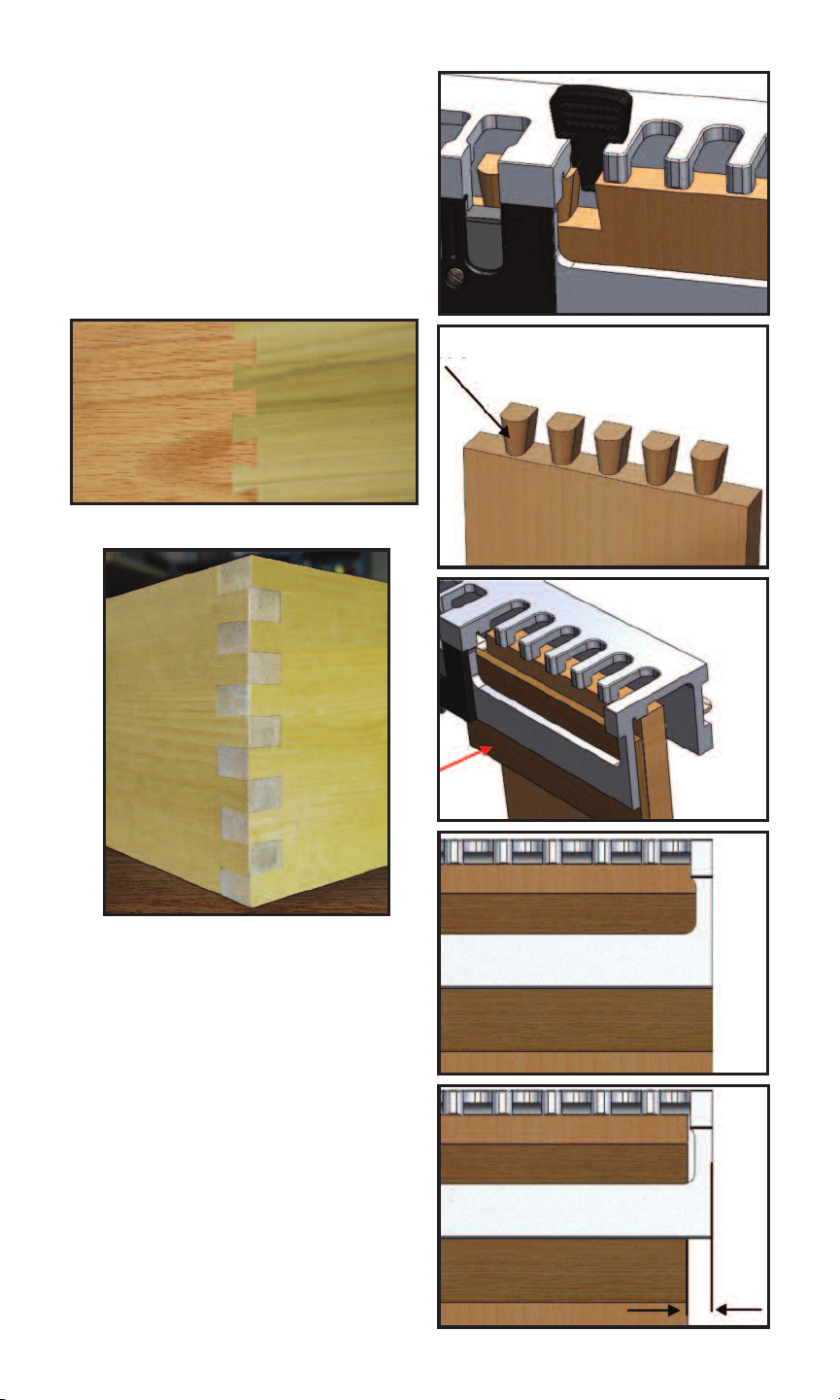

DGE JOINTING (FIG. 22)

E

1. In order to join two pieces of wood using a Dovetail-Joint the

ound-over created by the dovetail jig must be avoided. (FIG. 18)

r

2. Insert the first board into the “TAILS” section of the Dovetail Jig

along with a thin piece of scrap at least 1/4" thick to offset the

first board and the jig. (FIG. 19)

3. Align one edge of the board to be cut with the outside edge of

the jig. (FIG. 20)

4. Tighten the thumbscrews, (CAUTION: DO NOT OVERTIGHTEN),

and make all cuts.

5. Insert the second board into the jig along with the same scrap

wood and offset one edge of the board 1/2" from the outside

edge of the jig. (Fig. 21) This spacing will offset the “TAILS” of

the second board so that they align with the slots cut into the

first board.

IG. 17

F

FIG. 23

FIG. 22

ROUND-OVER

SCRAP

FIG. 18

FIG. 19

FIG. 20

CUTTING A BOX JOINT (FIG. 23)

For box jointing, use a 1/2" diameter straight bit with either a 1/2"

O.D. top guide bearing or a 1/2" O.D. guide sleeve insert in your router.

Set the depth of the cutter to equal, or slightly greater than the

thickness of the stock you’re joining.

Tip: Always make sure that the guide bearing or the guide sleeve

tracks in the guide slot.

To avoid the “round-over” part of the guide finger of the jig, use a

1/4" thick piece of scrap as a shim between the wood and the inner

surface of the jig to offset the board from the “round-over”. (FIG. 19)

Tip: If you’re doing more than one joint, you can use a piece of

double-face tape to hold the shim in place.

Cut the slots in the first board with the board edge set flush with the

right hand edge of the jig. (FIG. 20) Make the entry and exit cuts using

the left side of the guide slot only.

For the joining board, clamp it in the jig with its edge offset 3/8" in

from the right hand edge of the jig (FIG. 21), except use 3/8" offset

instead of 1/2". Make entry and exit cuts using the right side of the

guide slot only.

Dry fit the joint before gluing to be sure it is tight. If necessary, use a

wood mallet to bring the two parts together.

FIG. 21

3/8" offset for Box Joint

1/2" offset for Edge Joint

5

Page 6

ACCESORIO PARA COLA DE MILANO

No. 860

MANUAL DE INSTRUCCIONES

NORMAS DE SEGURIDAD PARA FRESADORA HOGAREÑA Y FRESADORAS DE MESA

1. CONOZCA SU FRESADORA. Lea cuidadosamente el manual del propietario antes de usarla. Aprenda sus aplicaciones y limitaciones así

también como los peligros potenciales específicos relativos a su uso.

2. MANTENGA LAS CUBIERTAS EN SU LUGAR y funcionando correctamente.

3. CONECTE TODAS LAS HERRAMIENTAS A TIERRA. La mayoría de las fresadoras tienen un enchufe de tres patas, y deben enchufarse en un

tomacorriente de tres orificios. Si utiliza un adaptador para conectarla a un tomacorriente de dos orificios, el cable de tierra del

adaptador debe conectarse a una toma de tierra adecuada, como el tornillo de montaje del tomacorriente. Nunca remueva la tercera

pata.

4. QUITE TODAS LAS LLAVES Y LAS PINZAS DE AJUSTE. Acostúmbrese a verificar que las llaves y pinzas de ajuste se hayan sacado de la

fresadora antes de usarla.

5. MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las áreas y bancos de trabajo abarrotados provocan accidentes.

6. EVITE LOS PELIGROS POTENCIALES. No utilice la fresadora en lugares húmedos o mojados ni las exponga a la lluvia. Mantenga el área de

trabajo bien iluminada.

7. MANTENGA ALEJADOS A LOS NIÑOS Y A LOS OBSERVADORES. Las distracciones pueden fácilmente causar accidentes – a usted y a los

demás.

8. HAGA SU LUGAR DE TRABAJO A PRUEBA DE NIÑOS. Use candados, interruptores maestros o quite las llaves de encendido.

9. NO FUERCE LA FRESADORA. Hará el trabajo mejor y de forma más segura a la velocidad para la cual fue diseñada.

10. USE LA INDUMENTARIA ADECUADA. No use ropa suelta, guantes, corbatas o joyas que puedan ser atrapadas por partes en movimiento. Le

recomendamos usar calzado antideslizante. Si tiene el cabello largo, use alguna cubierta para protegerlo.

11. USE GAFAS PROTECTORAS.

12. USE UNA MÁSCARA PARA LA CARA O CONTRA EL POLVO.

13. NO SE EXTIENDA DEMASIADO. Mantenga su superficie de apoyo y balance adecuado todo el tiempo.

14. MANTENGA SU FRESADORA EN ÓPTIMAS CONDICIONES. Mantenga las puntas de la fresadora afiladas y limpias para un rendimiento

mejor y más seguro. Siga las instrucciones para su lubricación y cambio de accesorios.

15. DESCONECTE SU FRESADORA ANTES DE HACERLE MANTENIMIENTO. También al limpiar las puntas, cuchillas, hojas y demás accesorios.

16. UTILICE ÚNICAMENTE LOS ACCESORIOS RECOMENDADOS. Consulte el manual del propietario acerca de los accesorios recomendados. El

uso de accesorios inadecuados puede ser peligroso.

17. EVITE LOS ARRANQUES ACCIDENTALES. Verifique que el interruptor esté en la posición “OFF” antes de enchufar el cable.

18. NUNCA SE PARE SOBRE UNA HERRAMIENTA. Podría sufrir heridas graves si se cae la herramienta o si entra en contacto accidentalmente

con la herramienta de corte.

19. VERIFIQUE QUE NO HAYA PARTES ROTAS. Antes de seguir usando la fresadora, una cubierta u otra parte dañada debe revisarse

cuidadosamente para verificar que funcione correctamente y que cumpla con su función específica. Verifique la alineación de las partes

móviles, roturas, montajes y cualquier otra cosa que pudiera afectar su funcionamiento. Una cubierta o cualquier otra parte dañada debe

ser correctamente reparada o reemplazada.

20. DIRECCIÓN DE ALIMENTACIÓN DE LA MESA FRESADORA. Alimente la pieza de trabajo hacia la fresadora.

21. NUNCA DEJE LA FRESADORA FUNCIONANDO DESATENDIDA. Apague la alimentación y permanezca con la fresadora hasta que se detenga

por completo. Antes de irse, asegúrese de que no pueda encenderse por accidente. Use candados, interruptores maestros o quite las

llaves de encendido.

22. EVITE LAS DROGAS, EL ALCOHOL Y LA MEDICACIÓN. No use la fresadora cuando esté bajo la influencia de drogas, alcohol o medicación.

6

Page 7

UNTOS IMPORTANTES ANTES DE COMENZAR

P

• Verifique que la punta esté afilada. Las herramientas desafiladas no pueden producir trabajo de buena calidad e incrementan el riesgo de

ontragolpes y sobrecarga de la máquina.

c

• Haga avanzar la punta de forma pareja y a una velocidad moderada para prolongar la vida de la punta y protegerla contra sobrecargas.

• Haga los cortes largos en etapas si es necesario, para evitar la acumulación de aserrín.

• Luego de instalar una punta fresadora nueva verifique que se mueva libremente en su posición de trabajo.

• Verifique el funcionamiento y ajuste de la herramienta en una pieza de prueba antes de usarla en la pieza final.

• Verifique que las dos piezas de madera a unir sean perfectamente planas colocando una contra la otra. La madera arqueada resultará en

una unión insatisfactoria.

ONJUNTO DE COLA DE MILANO

C

1. Saque todos los componentes de la bolsa y verifique que no falte nada y que no estén dañados. (Fig. 1)

2. Instale los tornillos de ajuste manual en los orificios roscados como se indica. Se puede cambiar la ubicación de los tornillos si es

necesario. (Fig. 2)

3. Presione los extremos sin marcas con los tornillos de ajuste manual. (Fig. 3)

o

14º

CANT. 2

1/2" - DE

1/4" - DI

CANT. 1

1/2"x1/4"

Los rodamientos incluidos tienen 1/2" de diámetro externo (DE). Se pueden sustituir las mangas o cojinetes de la fresadora siempre y

cuando tengan 1/2" de DE.

La punta de fresadora incluida

es de 14° x 1/2". Se puede sustituir

por otras puntas siempre y cuando

también tengan 1/2" de diámetro y

no sean más largas que 3/4".

USANDO EL MEDIDOR DE

PROFUNDIDAD

El medidor de profundidad se usa

para ajustar la profundidad del corte

de cola de milano durante el ajuste de

la fresadora. También se usa para

controlar la longitud de las clavijas

durante el corte.

1. Afloje los dos tornillos (A) de la

cara del medidor de profundidad.

2. Alinee la superficie superior (B) con

la medida deseada del borde

graduado (C).

3. Ajuste los dos tornillos (A) para

trabar el tope de profundidad en su

lugar.

CANT. 1

14º

1/2"x1/4"

CANT. 4

1/4" - 20

FIG. 2

CANT. 4 CANT. 1

B

C

A

FIG. 3

FIG. 4

7

Page 8

JUSTE DE LA FRESADORA

A

1. Inserte la fresa para cola de milano con el cojinete fijo en la fresadora.

2. Si la fresa que se adjunta no es del tipo de cojinete fijo, instale ambos cojinetes en la fresa para cola de milano e insértela en la fresadora.

(FIGURA 5)

3. La Fig. 7 muestra la dimensión de la unión de cola de milano afectada por la altura de la cuchilla de corte.

4. Se puede ajustar cuán estrecha será la unión (cuanto juego tendrán las partes) subiendo o bajando la altura de la hoja de corte como se

muestra en la Fig. 8. Esto se describe en mayor detalle más adelante.

FIG. 5 FIG. 6

Ajustando la punta HACIA ARRIBA

producirá una unión MÁS AJUSTADA.

Ajustando la punta HACIA ABAJO

producirá una unión MÁS FLOJA.

FIG. 8

CORTANDO UNA UNIÓN COLA DE MILANO INVISIBLE

* El lado de las “CLAVIJAS” de la unión debe ser más grueso que

1/2" para uniones invisibles

1. Al cortar una unión cola de milano invisible, use la hoja de corte

de 1/2" x 1/2" incluida y comience con una profundidad de punta

de 1/2".

2. Haga una unión de prueba con madera de desecho para confirmar

el encastre de la unión. Si las placas no se encastran fácilmente,

la unión puede ser demasiado ajustada. Se puede hacer la unión

más floja o más ajustada ajustando la profundidad de corte hacia

arriba o hacia abajo como se muestra en la Fig. 8.

3. Comience por el lado de las “COLAS” de la unión.

4. Centre la placa en la porción de las “COLAS” con la cara externa

de la placa mirando hacia adentro (Fig. 10).

5. Ajuste los tornillos manuales. PRECAUCIÓN: NO AJUSTE DE MÁS

LOS TORNILLOS MANUALES YA QUE PODRÍA ARQUEAR EL

CONJUNTO.

6. Fije la placa a un banco de trabajo o asegúrela en una prensa

como se muestra (Fig. 11).

7. Corte el lado de las “COLAS” de la unión. Asegúrese de seguir el

perfil de la plantilla ya que las ranuras son más anchas que los

rodamientos de las cuchillas. Esto permite hacer una pasada

rápida y una de acabado.

8. Ahora es el momento de hacer el lado de las “CLAVIJAS” de la

unión.

FIG. 7

CLAVIJAS

COLAS

FIG. 9

8

Page 9

9. Ajuste el medidor de profundidad a la longitud deseada de las

“CLAVIJAS”. Esta debe ser levemente mayor que el espesor de la

madera usada para la placa de las “COLAS”. (Fig. 12).

10. Ajuste levemente la madera de las “CLAVIJAS” en el dispositivo

con la cara externa apuntando hacia adentro.

11. Inserte las “COLAS” del corte anterior en los dientes de la parte

nferior de la placa de ajuste. Coloque la madera a cortar

i

alineando los lados con la primera pieza. (Fig. 13).

12. Con los bordes de ambas placas alineados, ajuste los tornillos

manuales (VER EL AVISO DE PRECAUCIÓN DEL PASO #5) y asegure

l conjunto al banco de trabajo. Saque la placa de las “COLAS”

e

ntes de proceder.

a

13. Haga todos los cortes. Para este corte, la fresadora debe

deslizarse por la superficie de la placa de profundidad como se

muestra en la Fig. 14. Asegúrese de seguir el perfil de la plantilla

ya que las ranuras son más anchas que los rodamientos de las

uchillas. Esto permite hacer una pasada rápida y una de

c

acabado.

14. Antes de encolarla, encastre las dos partes entre sí. La unión debe

quedar ajustada y pareja, sin espacios. Si surge algún problema,

lime o rebaje la unión para mejorar su encastre.

FIG. 12

FIG. 13

FIG. 11

FIG. 14

CARA INTERNA

IG. 10

F

LADOS ALINEADOS

CORTANDO UNA UNIÓN COLA DE MILANO PASANTE

* Esto requiere una punta de corte cola de milano más profunda que

la madera que esté cortando.

Los pasos necesarios para cortar una unión pasante (Fig. 15) son muy

parecidos a los descritos en la sección anterior CORTANDO UNA

UNIÓN COLA DE MILANO INVISIBLE. Con las siguientes excepciones:

1. Al cortar las “COLAS” de la unión, ajuste la profundidad de la punta

a un poco más que el espesor de la madera de las “CLAVIJAS”.

Esto asegurará que las colas queden levemente más profundas al

encastrarlas y se podrán lijar para que queden al ras. (Fig.16)

2. Al cortar las “CLAVIJAS” de la unión, ajuste primero la profundidad

de corte un poco más profunda (ajustada) y ajústela hasta el

encastre deseado de la unión.

CORTANDO UNIONES MÁS ANCHAS

QUE 6"

Las uniones de más de 6" deben cortarse en varios

segmentos. Para alinear el dispositivo con el corte

anterior, deberá usar la herramienta de alineación.

1. Mueva la madera dentro del dispositivo y

coloque la última ranura del corte anterior en el último canal

del dispositivo. (Fig. 17)

2. Ajuste levemente la madera en el dispositivo.

3. Inserte la herramienta de alineación en la ranura para centrar

correctamente la madera con el dispositivo.

4. Ajuste los tornillos manuales (PRECAUCIÓN: NO ADJUSTE DE MÁS

LOS TORNILLOS MANUALES) y haga todos los cortes.

5. Repítalo como sea necesario.

FIG. 15

CLAVIJAS

COLAS

FIG. 16

9

Page 10

ENSAMBLADURA DE BORDES

1. Para poder unir dos piezas de madera usando una junta de cola de

milano, deberá evitar el redondeado creado por el dispositivo de

cola de milano. (Fig. 18)

. Inserte la primera tabla en la sección “COLAS” de la plantilla para

2

colas de milano, con un pedazo delgado de al menos 1/4" de

espesor para ajustar la primera tabla y la plantilla. (FIGURA 19)

. Alinee un extremo de la placa a cortar con el borde externo del

3

ispositivo. (Fig. 20)

d

4. Ajuste los tornillos manuales (PRECAUCIÓN: NO ADJUSTE DE MÁS

LOS TORNILLOS MANUALES) y haga todos los cortes.

. Inserte la segunda tabla en la plantilla con la ayuda del mismo

5

pedazo de madera y ajuste un borde de la tabla a 1/2" del borde

externo de la plantilla. Este espaciado ajustará las “COLAS” de la

segunda tabla para que se alineen con las ranuras cortadas en la

primera tabla. (FIGURA 21)

FIG. 22

FIG. 23

REDONDEADO

FIG. 17

FIG. 18

FIG. 19

CORTE DE UNA ENSAMBLADURA DE CAJA

Para ensambladuras de caja utilice una broca recta de 1/2” de

diámetro, con un cojinete de guía superior de 1/2” de diámetro

externo o un encastre de casquillo guía de 1/2” de diámetro externo

en su fresadora. Establezca la profundidad de la fresa a un espesor

igual o ligeramente mayor al material que está uniendo.

Consejo: Siempre asegúrese de que el cojinete guía o el casquillo guía

se encuentre en la ranura de la guía.

Para evitar la parte “redondeada” del dedo de la guía de la plantilla,

use un pedazo de madera de 1/4” de espesor como cuña entre la

madera y la superficie interna de la plantilla para desplazar la parte

“redondeada” de la tabla (figura 19, página 5).

Consejo: Si está realizando más de una ensambladura, puede utilizar

un pedazo de cinta adhesiva de doble cara para mantener las cuñas

en su lugar.

Corte las ranuras en la primera tabla con el borde de la tabla montado

con el borde derecho de la plantilla (consulte la figura 20, página 5).

Realice los cortes de entrada y salida utilizando únicamente el lado

izquierdo de la ranura guía.

Para la tabla de unión, sujétela en la plantilla con su borde ajustado a

3/8” del borde del lado derecho de la plantilla (consulte la figura 21,

página 5, excepto que use un desplazamiento de 3/8” en lugar de uno

de 1/2”). Realice los cortes de entrada y salida utilizando únicamente

el lado derecho de la ranura guía.

Coloque la unión antes de colocarle pegamento para asegurarse de

que esté apretada. Si resulta necesario, utilice un mazo de madera

para unir ambas partes.

DESECHO

FIG. 20

Wood is flush to edge of jig

FIG. 21

Desplazamiento de 3/8" para ensambladura de caja

Desplazamiento de 1/2" para ensambladura de bordes

10

Page 11

GABARIT EN QUEUE D’ARONDE

No. 860

MANUEL D’INSTRUCTIONS

RÈGLES DE SÉCURITÉ POUR UNE TOUPIE PORTATIVE ET LES TOUPIES UTILISÉES AVEC UNE TABLE À TOUPIE

1. APPRENEZ À CONNAÎTRE VOTRE TOUPIE. Lisez soigneusement le manuel de l'utilisateur avant de l’utiliser. Apprenez les usages ainsi que

les limitations de la toupie et les dangers potentiels faisant partie de son utilisation.

2. GARDEZ L’ÉCRAN PROTECTEUR en place et en bon état.

3. TOUS LES OUTILS DOIVENT ÊTRE MIS À LA TERRE. La plupart des toupies sont équipées d'une prise à trois broches, et il doit être branché

dans une prise électrique à trois trous. Si un adaptateur est utilisé pour ajuster une prise à deux broches, le crochet de l’adaptateur doit

être attaché à un sol connu, tel que la prise qui retient la vis. N'enlevez jamais la troisième broche.

4. ENLEVER TOUTES LES CLÉS DE RÉGLAGE Prenez l’habitude de vérifier que les clés de réglage sont enlevées de la toupie avant de le faire

fonctionner.

5. GARDEZ L’AIRE DE TRAVAIL PROPRE. Les endroits et les établis encombrés attirent les accidents.

6. ÉVITEZ D’ÉVENTUELS DANGERS. N’utilisez jamais votre toupie dans des endroits humides ou mouillés ou les exposer au soleil. Garder

votre surface de travail bien éclairée.

7. GARDEZ LES ENFANTS ET LES VISITEURS À DISTANCE. Les distractions peuvent facilement conduire à des accidents – vôtres ou des

autres.

8. TRANSFORMEZ VOTRE ATELIER À L'ÉPREUVE DES ENFANTS. Utilisez des cadenas, interrupteurs centraux ou enlevez les clés de

démarrage.

9. NE FORCEZ PAS LA TOUPIE. Il fera le travail plus efficacement et de façon plus sécuritaire au régime pour lequel il a été fabriqué.

10. PORTEZ DES VÊTEMENTS APPROPRIÉS. Pas de vêtements amples, gants, cravates ou bijoux puisqu'ils peuvent s'accrocher à des pièces en

mouvement. Les chaussures antidérapantes sont recommandées. Portez une protection pour les cheveux pour couvrir les cheveux longs.

11. UTILISEZ DES LUNETTES DE SÉCURITÉ.

12. UTILISEZ UN PROTECTEUR FACIAL OU UN MASQUE ANTI-POUSSIÈRE.

13. N’UTILISEZ PAS SUR DE TROP GROS OBJETS. Maintenez votre bon appui et restez en équilibre en tout temps.

14. GARDEZ VOTRE TOUPIE EN EXCELLENT ÉTAT. Gardez les mèches de toupie bien aiguisés et propres pour la meilleure performance et la

plus sécuritaire. Suivez les instructions de lubrication et de changement des accessoires.

15. DÉBRANCHEZ VOTRE TOUPIE AVANT DE FAIRE LE SERVICE. Faites-le aussi lorsque vous changez les mèches, les lames, les couteaux, et

les autres accessoires.

16. UTILISER DES ACCESSOIRES RECOMMANDÉS UNIQUEMENT. Consultez le manuel de l’utilisateur pour les accessoires recommandés.

L'utilisation d'accessoires non recommandés peut causer des risques.

17. ÉVITER LES DÉMARRAGES ACCIDENTELS. Assurez-vous que les interrupteurs soient à la position d’arrêt (OFF) avant de brancher au

cordon.

18. NE MONTEZ JAMAIS SUR UN OUTIL. Des blessures graves pourraient se produit si l’outil est penché ou si l’outil de coupage est en

contact accidentellement.

19. VÉRIFIER SI LES PIÈCES SONT ENDOMMAGÉES. Avant d'utiliser la toupie, une protection ou une autre partie endommagée doit être

inspectée soigneusement pour s'assurer d'une opération adéquate et d'un fonctionnement normal. Soyez attentifs à tout alignement des

pièces en mouvement, à tout bris, montage ou à toute autre condition préjudiciable au bon fonctionnement de l’outil. Un protège-lame ou

toute autre partie qui est endommagée doit être correctement réparée ou remplacée.

20. DIRECTION DE LA TABLE À TOUPIE DU MÉCANISME D’ALIMENTATION. Mâchez le travail dans le couteau.

21. NE LAISSEZ JAMAIS LA TOUPIE EN MARCHE SANS SURVEILLANCE. Mettez-le en arrêt et restez avec la toupie jusqu’à ce qu’il soit en arrêt

complètement. Avant de partir, assurez-vous que l’alimentation ne puisse pas être activée accidentellement. Utilisez des cadenas,

interrupteurs centraux ou enlevez les clés de démarrage.

22. ÉVITEZ LES DROGUES, L’ALCOOL ET LES MÉDICAMENTS. N’utilisez pas la toupie si vous êtes sous l'influence de drogues, d'alcool, ou de

médicaments.

11

Page 12

OINTS À REMARQUER AVANT DE COMMENCER

P

• Assurez-vous que la mèche est aiguisée. Les outils épointés ne peuvent pas produire une bonne qualité de travail, et augmentent le risque

e recul et de surcharge de la machine.

d

• Passez la mèche de manière uniforme et à un rythme modéré pour vous assurer une durée de vie de la mèche plus longue et pour la

protéger contre les surcharges.

Coupez des longues douilles en étapes si nécessaire, afin d'éviter toute accumulation des croustilles.

•

• Après l’installation de la nouvelle mèche de moulage, assurez-vous qu’elle tourne facilement en position de moulage.

• Vérifiez le fonctionnement et le réglage de l’outil sur un échantillon avant de l’utiliser sur le bon bois.

• Assurez-vous que les deux morceaux de bois à assembler sont parfaitement plat en les plaçant l’un contre l’autre. Du bois gauchi

provoquera un joint insatisfaisant.

ASSEMBLAGE DE GABARIT DE QUEUE D’ARONDE

1. Enlevez tous les composants de la valise de matériel et assurez-vous qu'ils sont tous là et intacts. (fig.1)

2. Installez les vis à oreille dans les trous filetés comme illustré. Les endroits des vis peuvent être ajustés au besoin. (fig. 2)

3. Appuyez les extrémités de protection sur les vis à oreilles. (fig. 3)

u

o

QTÉ. 1

1/2"x1/4"

Les coussinets inclus possèdent un diamètre extérieur de 1/2 po (OD). Les manchons de toupie ou les coussinets sont interchangeables en

autant qu'ils possèdent un diamètre extérieur (OD) identique de 1/2 po.

Comprend une mèche à toupie de

14° x 1/2 po. D'autres mèches

peuvent être interchangeables à

condition qu'ils possèdent un

diamètre de 1/2 po et que la longueur

ne soit pas supérieure à 3/4 po.

UTILISER L’INDICATEUR

D’ENFONCEMENT

L’indicateur d’enfoncement est utilisé

pour régler la profondeur du couteau

de queue d’aronde lors de la

configuration de la toupie. Il est aussi

utilisé afin de contrôler la longueur

des iges lors du coupage.

1. Desserrez les deux vis (A) sur la

face de l’indicateur d’enfoncement.

2. Alignez la surface supérieure (B)

avec la mesure désirée sur le bord

réglementé (C).

3. Serrez les deux vis (A) pour

verrouiller l’arrêt de la profondeur

à la bonne position.

14º

QTE. 2

1/2" - OD

1/4" - DI

QTE. 1

14º

1/2"x1/4"

QTE. 4

1/4" - 20

FIG. 2

QTE. 4 QTE. 1

FIG. 3

B

C

A

FIG. 4

12

12

Page 13

ÉGLAGE DE LA TOUPIE

R

1. Insérez la fraise pour queues d’aronde avec le support fixe dans la toupie.

2. Si la fraise fournie n’est pas de type à support fixe, installez les supports sur la fraise et insérez l’ensemble dans la toupie. (FIG. 5)

3. La fig. 7 montre les dimensions du joint de queue d’aronde qui est influé par la hauteur du couteau.

4. La contraction du joint (l’adéquation entre les deux tableaux) peut être réglée en augmentant ou en réduisant la hauteur des couteaux

comme illustré dans la fig. 8. Ceci sera décrit plus en détail plus tard.

FIG. 5 FIG. 6

Régler la mèche avec une hauteur PLUS ÉLEVÉE

Régler la mèche avec une hauteur MOINS ÉLEVÉE

causera un joint PLUS SERRÉ.

causera un joint PLUS DESSERRÉ.

FIG. 8

COUPER UN JOINT DE QUEUE D'ARONDE SEMI-AVEUGLE

* Le côté des « TENONS » du joint doit être plus épais que 1/2 po

pour les joints semi-aveugles.

1. Lorsque vous coupez un joint de queue d’aronde semi-aveugle,

utilisez le couteau inclus de 1/2 po x 1/2 po et commencez avec

un réglage de la hauteur de la mèche de 1/2 po.

2. Coupez un joint d’essai avec un petit morceau de bois pour

confirmer l’adéquation du joint. Si les tableaux ne s’ajustent pas

ensemble facilement, le joint est peut-être trop serré. Le joint

peut être plus desserré ou plus serré en réglant la profondeur de

coupe moins ou plus profonde comme montré dans la fig. 8.

3. Débutez avec le côté « QUEUES » du joint.

4. Centrez la plaque dans la portion « QUEUES » du serre-joint,

la face extérieure de la plaque vers l'intérieur (fig. 10).

5. Serrez les vis à serrage à la main. MISE EN GARDE : NE PAS TROP

SERRER LES VIS À SERRAGE À la MAIN CAR CELLES-CI PEUVENT

AVOIR UN EFFET DE GAUCHISSEMENT SUR LE

SERRE-JOINT.

6. Fixez la plaque dans l'étrier d'un établi ou fixez-la solidement

dans un étau, tel qu'illustré (fig. 11).

7. Coupez la portion « QUEUES » du joint. Assurez-vous de suivre le

profil du serre-joint puisque les fentes sont plus larges que les

coussinets. Cela permet une coupe rude et de finition.

8. Vous pouvez maintenant faire le côté « TENONS » du joint.

9. Ajustez la jauge de profondeur à la longueur désirée de

« TENONS ». Elle devrait être légèrement plus longue que

l'épaisseur du bois utilisé pour les planches « QUEUES » (fig. 12).

FIG. 7

TENONS

QUEUES

FIG. 9

1313

Page 14

10. Fixez doucement les « TENONS » de bois dans le serre-joint, la face

extérieure pointant vers l'intérieur.

1. Insérez les « QUEUES » des coupes précédentes dans la dent

1

inférieure de la plaque d'ajustement. Positionnez le bois à couper en

l'alignant avec les côtés de la première pièce (fig. 13).

12. Les rebords maintenant alignés des deux côtés de la planche, serrez

es vis à la main (VOYEZ LA MISE EN GARDE À L'ÉTAPE NO. 5) et fixez

l

l'assemblage à l'établi. Retirez les « QUEUES » de planche avant de

continuer.

13. Effectuez toutes vos coupes. Pour cette coupe, la toupie devrait

atiner à la surface de la plaque de profondeur, tel qu'illustré à la

p

igure 14. Assurez-vous de suivre le profil du serre-joint car les

f

fentes sont plus larges que les coussinets. Cela permet une coupe

rude et de finition.

14. Avant de coller, ajustez les deux sections ensemble. Le joint doit

être serré et même sans ouvertures. Si un problème arrive,

iguisez ou taillez le joint pour améliorer la forme.

a

ACE INTÉRIEURE

F

FIG. 10

FIG. 12

FIG. 13

CÔTÉS ALIGNÉS

COUPER UN JOINT DE QUEUE D’ARONDE COMPLET

* Ceci exige une mèche de couteau de queue d’aronde avec une

profondeur plus grande que celle du bois que vous coupez.

Les étapes exigées pour couper un au complet (fig. 15) sont très

similaires à celles décrites dans la section précédente COUPER UN

JOINT DE QUEUE D'ARONDE SEMI-AVEUGLE. Avec les exceptions

suivantes:

1. Lorsque vous coupez des « QUEUES » du joint, réglez la profondeur

de la mèche un peu plus grande que l’épaisseur des « TENONS ».

Ceci assurera que les queues soient un peu plus fières lors de

l’ajustement et peuvent être poncées pour les accoter directement.

(fig. 16)

2. Lorsque vous coupez les « TENONS » du joint, réglez premièrement

la profondeur du couteau plus profond (plus serré) et puis ajustez

à la forme désirée du joint.

FIG. 11

FIG. 14

FIG. 15

TENONS

QUEUES

COUPER DES JOINTS PLUS GRANDS QUE

6 PO

Les joints de plus de 6 po de large doivent être coupés

en plusieurs segments. Pour aligner le gabarit avec la

coupe précédente, l’outil d’alignement doit être utilisé.

1. Déplacez le bois dans le gabarit et positionnez la dernière fente

de la coupe précédente dans la dernière chaîne du gabarit.

2. Serrez, pas très fort, le bois dans le gabarit.

3. Insérez l’outil d’alignement dans la fente afin de bien centrer

le bois dans le gabarit. (fig. 17)

4. Fixez la plaque dans l’étrier d’un éstabli et faites toutes les coupes.

5. Répétez si nécessaire.

FIG. 16

14

Page 15

OINT BOUT À BOUT DES RIVES

J

1. Afin de joindre deux morceaux de bois en utilisant un joint de

queue d’aronde, le cercle créé par le gabarit de queue d’aronde doit

être évité. (fig. 18)

. Insérez la première planche dans la partie « QUEUES » du gabarit

2

de queue d’aronde avec une fine pièce de déchet d’au minimum

1/4" (6,4 mm) d’épaisseur pour décaler la première planche et le

gabarit. (FIG. 19)

. Alignez un bord du tableau à couper avec le bord extérieur du

3

abarit. (fig. 20)

g

4. Fixez la plaque dans l’étrier j’un éstabli et faites toutes les coupes.

. Insérez la deuxième planche dans le gabarit avec le même déchet

5

de bois et décalez un des bords de la planche de 1/2" (1,3 cm) du

bord extérieur du gabarit. Cet écart décalera les « QUEUES » de la

deuxième planche afin qu'elles s’alignent avec les fentes

découpées dans la première planche. (FIG. 21)

FIG. 22

FIG. 23

CERCLE

IG. 17

F

FIG. 18

FIG. 19

DÉCOUPAGE D’UN ASSEMBLAGE À QUEUES DROITES

Pour une coupe tenon, utilisez une mèche droite de 1/2” (1,3 cm) de

dia. ext. avec soit un palier-guide supérieur de 1/2” (1,3 cm) ou une

douille-guide de 1/2” (1,3 cm) de dia. ext. dans votre toupie. Réglez la

profondeur de la fraise à la même épaisseur ou légèrement

supérieure au bois que vous assemblez.

Conseil : Assurez-vous toujours que le palier-guide ou la douille-guide

suive bien la fente du guide.

Pour éviter la partie « arrondie » du doigt de guidage du gabarit,

utilisez une pièce de déchet de 1/4” (6,4 mm) d’épaisseur entre le

bois et la surface intérieure du gabarit pour décaler la planche de la

partie « arrondie » (figure 19, page 5).

Conseil : Si vous réalisez plus d’un assemblage, vous pouvez utiliser

un peu d'adhésif double-face pour maintenir la cale en place.

Découpez les fentes dans la première planche avec le bord de la

planche affleurant avec le bord du côté droit du gabarit (voir fig. 20,

page 5). Réalisez les découpes d’entrée et de sortie en utilisant le

côté gauche de la fente de guidage uniquement.

Pour la planche d’assemblage, fixez-la dans le gabarit avec son bord

décalé de 3/8” (1 cm) du bord droit du gabarit (voir fig. 21, page 5,

mais en utilisant un décalage de 3/8” au lieu de 1/2”). Réalisez les

découpes d’entrée et de sortie en utilisant le côté droit de la fente de

guidage uniquement.

Accommodez bien l’assemblage avant de l’encoller pour être sûr qu'il

soit serré. Si nécessaire, utilisez un maillet en bois pour rapprocher

les deux pièces.

PETIT

MORCEAU

Décalage de 3/8" (1 cm) pour l’assemblage

à queues droites

Décalage de 1/2" (1,3 cm) pour assemblage

bout à bout

15

FIG. 20

FIG. 21

Page 16

GENERAL TOOLS & INSTRUMENTS

™

80 White Street, New York,NY10013-3567

PHONE (212) 431

-

6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

860 User’s Manual

Specifications subject to change without notice

©2010 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

™

MAN#860 2/10

16

Loading...

Loading...