Page 1

™

DOWELING JIG KIT

#841

USER’S MANUAL

A

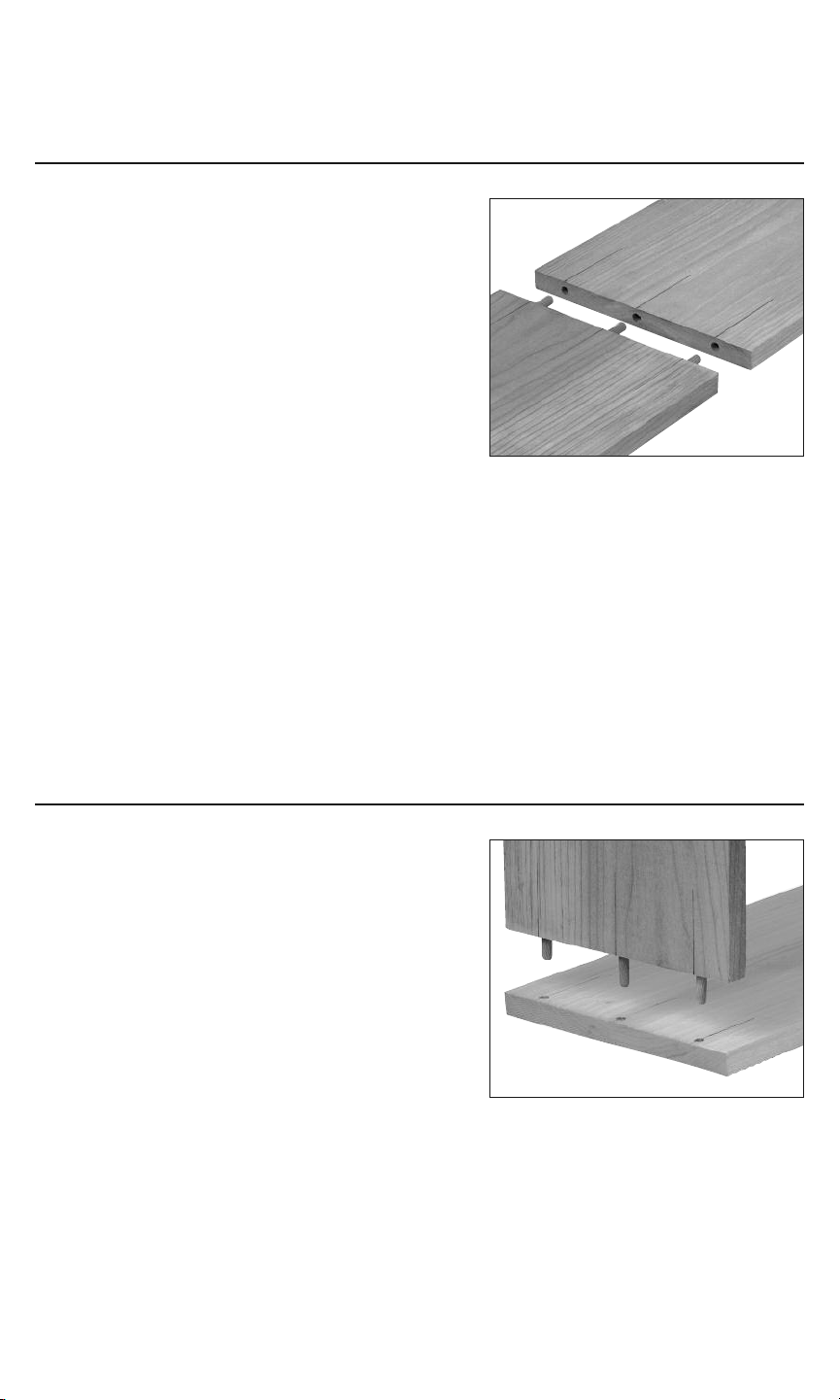

EDGE DOWELING / PERFORACIONES PARA ESPIGAS EN EL BORDE / GOUJONS LATÉRAUX

C

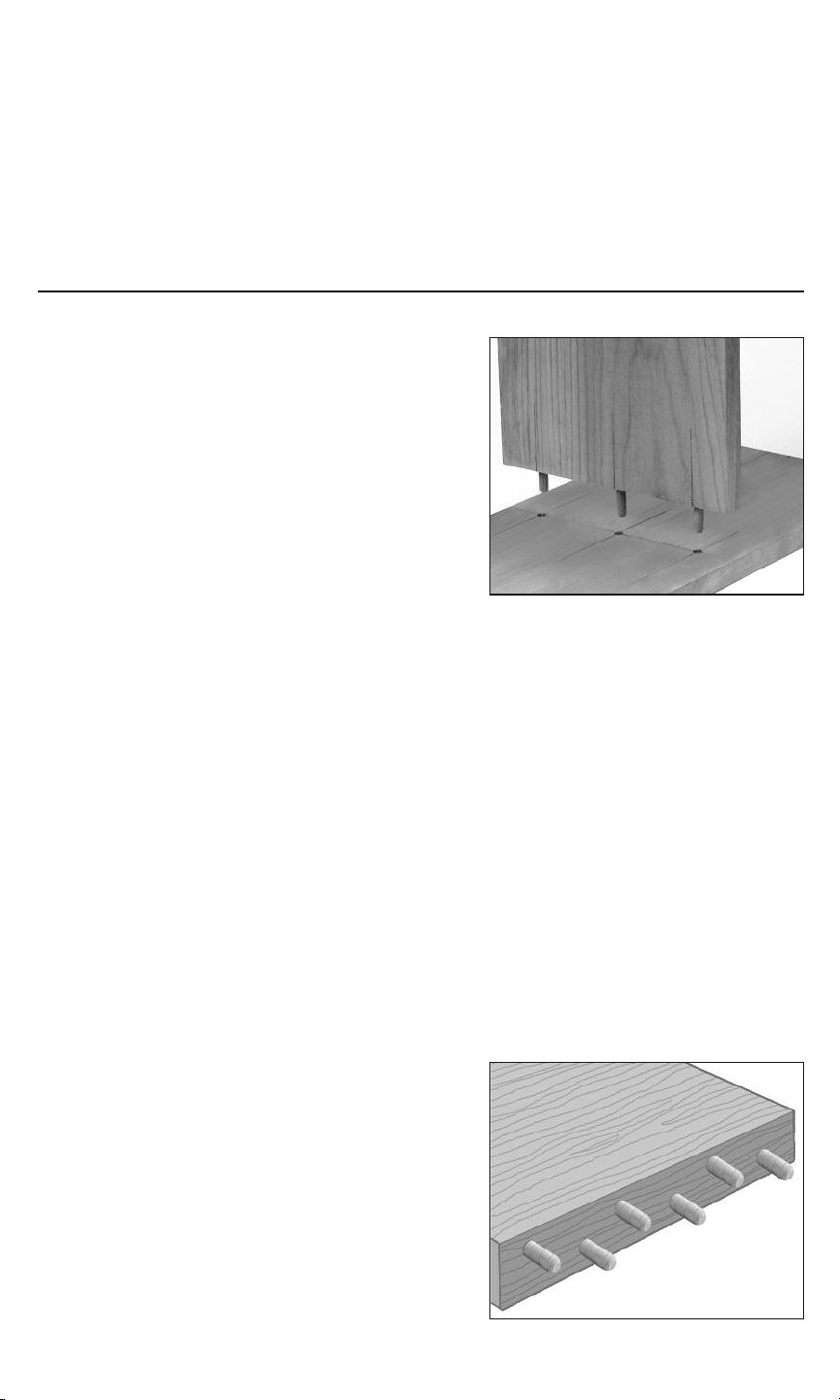

RIGHT ANGLE DOWELING /

PERFORACIONES PARA ESPIGAS EN ÁNGULO RECTO /

GOUJONS À ANGLE DROIT

B

D

SURFACE DOWELING /

EF

PERFORACIONES PARA ESPIGAS SOBRE SUPERFICIES /

GOUJONS EN SURFACE

Page 2

INSTRUCTIONS:

NOTE: In these instructions we will assume using 5/16" diameter dowels,

nominal 3/4" thick boards and drilling with the 5/16" drill bit.

All figure references are on the front & back covers.

EDGE DOWELING:

SETTING THE COLLAR AND DRILL DEPTH

FOR EDGE DOWELING

You will be drilling 3/4" deep dowel holes in each piece

so the 1-1/2" dowels will be equally centered into both

boards. In order to correctly position the drill collar, you

need to add the thickness of the jig plus the length of

the bushing (1") to the 3/4" depth. Thus, to also allow

for gluing, set the collar slightly longer than 1-3/4" from

the end of the drill (Fig. G).

PREPARING YOUR WORK PIECE

1. Draw location lines on the face of your work piece where the dowel holes are to be drilled.

Extend these lines at least 2 inches in from the edge (Fig. H).

2. Select the drill bushing that fits the dowel size you intend to use, and screw it into the long

side of the E•Z Pro Dowel Jig, using the hole that centers on the thickness of the stock

you are using (Fig. I).

3. Secure your work piece and attach the E•Z Pro Dowel Jig to the edge centering the

2" registration line in the appropriate “V” pointer as shown in (Fig. J).

4. Keeping the bushing in the same position re-align jig and drill holes for each dowel

position. Insert dowels, assemble dry to check for fit.

Apply glue to dowel pins or drilled holes for a permanent joint. Once assembled, wipe away

excess glue.

RIGHT ANGLE (CORNER)

DOWELING:

SETTING THE COLLAR AND DRILL DEPTH

FOR RIGHT ANGLE DOWELING

For the edge piece, you will be drilling a 1" deep hole

and/or the surface piece you will be drilling a 1/2" deep

hole to accommodate the 1-1/2" dowels.

Therefore, in order to correctly position the drill collar,

you need to add the thickness of the jig plus the length

of the bushing (1") to the respective depths before

drilling (2" and 1-1/2").

PREPARING YOUR WORK PIECE

Marking the pieces: Lay the 2 pieces to be joined on a flat surface and mark the drill hole

locations across each board (Fig. H). This will be the INSIDE of the joint.

For the edge doweled part:

1. Mark the board and select the appropriate bushing following the edge doweling

instructions (1) and (2) above.

2. Set the appropriate collar depth for edge drilling (2").

3. Drill your edge holes as above (Fig. B).

2

Page 3

For the surface doweled part:

1. Move the drill bushing to the corresponding location on the top of the E•Z Pro Dowel Jig

(Fig. D).

2. Secure your work piece accordingly; clamp the jig with the appropriate “V” pointer on the

location line (Fig. J).

3. Set your corresponding collar depth (1-1/2") and drill holes for each dowel position. Insert

dowels and assemble dry to check for fit.

Apply glue to dowel pins or drilled holes for a permanent joint. Once assembled, wipe away

excess glue.

SURFACE DOWELING:

NOTE: Surface doweling is the same as right angle

(corner) doweling, except you are not on

the edge.

SETTING THE COLLAR AND DRILL DEPTH

FOR SURFACE DOWELING

The collar settings and the drill depths will be the same

as for right angle doweling.

PREPARING YOUR WORK PIECE

1. In the case of bookcases or cabinets, prepare the

end of the shelf or partition as in EDGE DOWELING

( Fig’s A & B). Attach jig as in edge drilling (Fig. I) and drill holes.

2. On your vertical riser, mark a horizontal line across the full surface where the dowels will

be located (Fig. H). If not already marked, you can transfer the center locations from the

prepared edge to that horizontal line (Fig. K). Extend your marks at least 3-1/2" down the

face to make it visible for alignment to the bottom “V” pointer when the jig is positioned.

3. Mark the jig locating line 15/16" above and parallel to your doweling line (Fig. K). Align

your edge board on this line on the surface of your work piece and clamp both pieces

(Fig. L).

4. Place the Doweling Jig on its back with the thumbscrew toward you, and screw the

desired size drill bushing into the right hand, inside hole (Fig. F). (Note: this is the only

bushing hole to be used when surface doweling.)

5. With the jig still on its back, slide its top edge to the clamped edge piece (Fig. F), or to the

marked line (Fig. K). Align the registration points on both ends of the jig with the extended

location lines, hold or clamp the jig firmly and drill your dowel hole.

Re-align the E•Z Pro jig and drill holes for each dowel position. Insert dowels; Assemble dry to

check for fit.

Apply glue to dowel pins or drilled holes for a permanent joint. Once assembled, wipe away

excess glue.

NOTE: When doweling stock that is greater than

1 inch thick, registration may be alternated

between the top and the bottom surfaces to

achieve balanced doweling (Fig. 1).

1

3

Page 4

INSTRUCCIONES:

NOTA: En estas instrucciones se utilizara la espiga de 5/16 de pulgada con una placa de

3/4 de pulgada de ancho y una broca de 5/16 de pulgada.

Todas las figuras de referencia están en la primera y última página del manual.

PERFORACION PARA ESPIGAS EN EL BORDE:

AJUSTE DEL COLLARÍN Y DE LA

PROFUNDIDAD DE PERFORACIÓN

Se necesita efectuar unas perforaciones de 3/4 de pulgada

de profundidad en cada pieza de manera que la guía para

la espiga de 1-1/2 pulgada esté centrada en ambas placas.

Para colocar el collarín de perforación en forma correcta,

necesita adicionar el ancho de la guía mas el largo del

cojinete (1 pulgada) a la profundidad de 3/4 de pulgada.

Además, necesitara espacio para la cola, ajuste el collarín a

un largo de un poco mas de 1-3/4 pulgada desde el

extremo del taladro (Fig. G).

PREPARACION DE LA PIEZA DE TRABAJO

1. Dibuje líneas de ubicación en el frente de la pieza a trabajar en el sitio en donde las

perforaciones para las espigas deben ser efectuadas. Extienda esas líneas al menos dos

pulgadas hacia el interior desde el borde (Fig. H).

2. Seleccione el cojinete de perforación que se ajuste al tamaño de la espiga que va a utilizar, y

atorníllelo en lado largo del juego de guías para espigas E•Z Pro, utilizando la perforación que

se centra en el ancho de la pieza que esta utilizando (Fig. I).

3. Asegure la pieza de trabajo y sujete el juego de guías para espigas E•Z Pro al borde,

centrando la línea de 2 pulgadas con el puntero en “V” adecuado (Fig. J).

4. Mantenga el cojinete en la misma posición, re-alinie la guía y efectúe las perforaciones para

cada posición de las espigas. Introduzca las espigas; ensamble sin cola para verificar el ajuste.

Aplique la cola a las espigas o al interior de las perforaciones para una unión permanente. Una

vez las piezas ensambladas, limpie el exceso de cola.

PERFORACIONES PARA ESPIGAS EN ANGULO RECTO

(ESQUINAS):

AJUSTE DEL COLLARIN Y DE LA

PROFUNDIAD DE LA BROCA

Para la pieza del borde necesita efectuar una perforación

de una pulgada y/o perforar la superficie

de la pieza a media pulgada para que las espigas de

1-1/2 pulgada ajusten.

Además, para colocar en forma correcta el collarín del

talado, se necesita adicionar el ancho de la guía de la

espiga mas el largo del cojinete (1 pulgada) a las

profundidades respectivas antes de efectuarlas perforaciones (2 y 1-1/2 pulgadas).

PREPARACION DE LA PIEZA DE TRABAJO

Marcado de las piezas: coloque las dos piezas a ensamblar sobre una superficie y marque la

ubicación de las perforaciones en cada tabla haciéndolas coincidir (Fig. H). Esto será el INTERIOR

de la unión.

Para la parte en donde irán las espigas:

1. Marque la tabla y seleccione el cojinete adecuado siguiendo las instrucciones anteriores (1) y

(2) para las guías del borde.

2. Ajuste la profundidad adecuada del collarín para perforar en el borde (2 pulgadas).

3. Efectúe las perforaciones del borde como indicado anteriormente (Fig. B).

4

Page 5

Para la superficie de la pieza con las espigas:

1. Mueva el cojinete de perforación al lugar correspondiente en la parte superior del juego de

guías E•Z Pro (Fig. D).

2. Asegure firmemente la pieza de trabajo; coloque el juego de guías con el puntero en “V” sobre

la línea marcada (Fig. J).

3. Ajuste la profundidad del collarín (1-1/2 pulgada) y efectúe las perforaciones para cada

espiga. Introduzca las espigas; ensamble sin cola para verificar el ajuste.

Aplique la cola a las espigas o a las perforaciones para una unión permanente. Una vez

ensamblado, limpie el exceso de cola.

ESPIGAS SOBRE UNA SUPERFICIE:

NOTA: las perforaciones para las espigas en superficie

se efectúan de la misma manera que para las espigas

en esquina solo que no se está en el borde.

AJUSTE DEL COLLARIN Y DE LA

PROFUNDIDAD DE PERFORACION PARA

LAS ESPIGAS SOBRE UNA SUPERFICIE

El ajuste del collarín y la profundidad de las perforaciones

serán las mismas que las perforaciones en ángulo recto.

PREPARACION DE LA PIEZA DE TRABAJO

1. En el caso de libreros o gabinetes, prepare el borde del entrepaño o travesaño como se indica

en ESPIGAS EN EL BORDE (Figuras A y B). Sujete el juego de guías como se indica en

perforaciones en el borde (Fig. I) y efectúe las perforaciones.

2. En el travesaño vertical marque una línea horizontal cruzando completamente la superficie en

donde se colocaran las espigas (Fig. H). Si aun no ha marcado, transfiera las posiciones

centrales del borde ya preparado a la línea horizontal (Fig. K). Extienda las marcas por lo

menos a 3-1/2 pulgadas a lo largo de la superficie para que sean visibles al alinear con el

puntero en “V” cuando coloque la guía de perforación.

3. Marque la línea para la guía unos 15/16 de pulgada por encima y en paralelo a la línea de

perforación para las espigas (Fig. K). Alinie el borde de la tabla sobre esta línea en la

superficie de la pieza de trabajo y sujete ambas piezas con una prensa (Fig. L).

4. Coloque el juego de guías de perforación para espigas sobre la parte trasera con el tornillo de

mano hacia usted. Atornille el cojinete de perforación deseado a la derecha, dentro del espacio

previsto (Fig. F). (Nota: este es el único espacio para cojinete que se utilizara al efectuar las

perforaciones.)

5. Con el juego de guías para perforación aun en su parte trasera, deslice la parte superior hacia

la pieza sujeta (Fig. F), o hacia la línea marcada (Fig. K). Alinie los puntos de referencia en

ambos lados del juego de guías con las líneas marcadas, sujete o coloque una prensa y

efectúe la perforación para la espiga.

Vuelva a alinear el juego de guías E•Z Pro y efectúe las perforaciones para cada posición de las

espigas. Introduzca las espigas y ensamble sin cola para verificar el ajuste.

Aplique cola en las espigas o en las perforaciones para una

unión permanente. Una vez ensamblado, limpie el exceso

de cola.

NOTA: Cuando la pieza en donde se colocarán las

espigas es de más de una pulgada de ancho, las

perforaciones para las espigas deben alternarse en la

superficie, arriba y abajo, para lograr un equilibrio en

el ajuste de las espigas (Fig. 1).

1

5

Page 6

INSTRUCTIONS :

REMARQUE :

5/16 po et l’épaisseur nominale de la planche est de 3/4 po. La mèche est aussi de 5/16 po.

Toutes les figures de référence se trouvent sur la première et dernière page de ce manuel.

GOUJONS LATÉRAUX :

RÉGLAGE DU COL ET DE LA PROFONDEUR

DE LA PERCEUSE POUR UN ASSEMBLAGE

AVEC GOUJONS LATÉRAUX

Perforer les trous pour les goujons à une profondeur de

3/4 po dans chaque pièce afin que le goujon de 1-1/2 po

soit centré dans les deux panneaux. Pour bien positionner

le col de la perceuse, il faut ajouter l’épaisseur du gabarit

et la longueur de la bague (1 po) à la profondeur de 3/4 po.

De plus, pour permettre de coller les pièces, régler le col

pour qu’il soit un peu plus long que 1-3/4 po à partir de l’extrémité de la mèche (Fig. G).

PRÉPARATION DE LA PIÈCE

1. Tracer des lignes de repère sur la face de la pièce de bois où les trous pour les goujons seront

percés. Prolonger ces lignes d’au moins 2 po sur les côtés (Fig. H).

2. Choisir la bague de la perceuse qui convient à la taille du goujon qui sera utilisé et la visser

dans le côté long du gabarit à goujons E•Z Pro en utilisant le trou centré par rapport à

l’épaisseur de la pièce de bois utilisée (Fig. I).

3. Retenir la pièce de bois et fixer le gabarit à goujons E•Z Pro sur le côté en centrant la ligne de

2 po par rapport au pointeur en V approprié (Fig. J).

4. En gardant la bague dans la même position, réaligner le gabarit et percer un trou pour chaque

position des goujons. Insérer les goujons. Faire d’abord l’assemblage à sec afin de vérifier

l’ajustement.

Appliquer de la colle sur les goujons ou dans les trous afin d’obtenir un assemblage permanent.

Une fois les pièces assemblées, essuyer l’excès de colle

Dans les présentes instructions, les goujons utilisés ont un diamètre de

GOUJONS À ANGLE DROIT (COIN) :

RÉGLAGE DU COL ET DE LA PROFONDEUR DE LA PERCEUSE POUR UN

ASSEMBLAGE À ANGLE DROIT

Dans la pièce latérale, percer un trou de 1 po de

profondeur et/ou dans la pièce de surface, percer un trou

de 1/2 po de profondeur pour qu’il puisse contenir les

goujons de 1-1/2 po.

Pour bien positionner le col de la perceuse, il faut ajouter

l’épaisseur du gabarit et la longueur de la bague (1 po)

aux profondeurs respectives avant de faire le trou (2 po et

1-1/2 po).

PRÉPARATION DE LA PIÈCE

Marquage des pièces : étendre les deux pièces à assembler sur une surface plane et marquer

l’emplacement des trous sur chaque panneau (Fig. H). Ce sera l’INTÉRIEUR de l’assemblage.

Pour la partie avec les goujons sur le côté :

1. Marquer le panneau et choisir la bague appropriée selon les instructions pour goujons latéraux

(1) et (2) ci-dessus.

2. Régler la profondeur du col pour faire les trous latéraux (2 po).

3. Percer les trous latéraux comme ci-dessus (Fig. B).

6

Page 7

Pour la partie avec goujons en surface :

1. Placer la bague de la perceuse à l’endroit correspondant sur le dessus du gabarit à goujons

E•Z Pro (Fig. D).

2. Retenir la pièce en conséquence : serrer le gabarit avec le pointeur en V approprié sur la ligne

de repère (Fig. J).

3. Régler la profondeur du col correspondant (1-1/2 po) et percer des trous pour chaque position

des goujons. Insérer les goujons. Faire d’abord l’assemblage à sec afin de vérifier

l’ajustement.

Appliquer de la colle sur les goujons ou dans les trous afin d’obtenir un assemblage permanent.

Une fois les pièces assemblées, essuyer l’excès de colle.

GOUJONS EN SURFACE :

REMARQUE : Les goujons en surface s’installent de la

même façon que ceux à angle droit (coin), sauf que le

travail ne se fait pas sur le côté.

RÉGLAGE DU COL ET DE LA PROFONDEUR

DE LA PERCEUSE POUR UN ASSEMBLAGE

AVEC GOUJONS EN SURFACE

Les réglages du col et de la profondeur de la perceuse

seront les mêmes que pour l’assemblage à angle droit.

PRÉPARATION DE LA PIÈCE

1. Dans le cas d’une bibliothèque ou d’une armoire, préparer l’extrémité de la tablette ou de la

division selon l’installation de GOUJONS LATÉRAUX (Fig. A et B). Fixer le gabarit comme pour

faire des trous latéraux (Fig. I) et percer les trous.

2. Sur le montant, marquer une ligne horizontale d’un côté à l’autre de la surface où les goujons

seront insérés (Fig. H). Si elle n’est pas déjà marquée, il est possible de transférer les repères

du centre présents sur le côté préparé à ceux de la ligne horizontale (Fig. K). Prolonger les

marques d’au moins 3-1/2 po vers le bas de la surface afin de la rendre visible pour l’aligner

avec le pointeur en V du bas lorsque le gabarit sera en place.

3. Marquer la ligne de repère du gabarit à 15/16 po au-dessus de la ligne des goujons et

parallèlement à celle-ci (Fig. K). Aligner le panneau latéral sur cette ligne à la surface de la

pièce et serrer les deux pièces (Fig. L).

4. Placer le gabarit à goujons sur le dos (la vis à oreille vers soi) et visser la bague de la perceuse

de la taille désirée dans le côté droit, à l’intérieur du trou (Fig. F). (Remarque : il s’agit du seul

trou de bague à utiliser pour l’assemblage avec goujons en surface.)

5. Laisser le gabarit sur le dos et glisser son côté supérieur vers la pièce latérale serrée (Fig. F),

ou vers la ligne marquée (Fig. K). Aligner les points de repère sur les deux extrémités du

gabarit avec les lignes de repère, puis retenir ou serrer fermement le gabarit et percer les

trous pour les goujons.

Réaligner le gabarit à goujons E•Z Pro et percer les trous

pour chaque position de goujon. Insérer les goujons. Faire

d’abord l’assemblage à sec afin de vérifier l’ajustement.

Appliquer de la colle sur les goujons ou dans les trous afin

d’obtenir un assemblage permanent. Une fois les pièces

assemblées, essuyer l’excès de colle.

REMARQUE : Lorsque le l’épaisseur du bois à

goujonner est supérieure à 1 po, la position des

goujons peut être alternée entre le dessus et la base

des surfaces afin qu’il y ait équilibre (Fig. 1).

1

7

Page 8

G

H

SETTING THE COLLAR /

AJUSTE DEL COLLARÍN DE PERFORACIÓN /

RÉGLAGE DU COL

EDGE ALIGNMENT /

ALINEAR LOS BORDES /

ALIGNEMENT LATÉRAL

MARKING YOUR WORK PIECE /

MARCADO DE LA PIEZA DE TRABAJO /

MARQUAGE DE LA PIÈCE

I

RIGHT ANGLE BUSHING & ALIGNMENT / COJINETE PAR

ÁNGULO RECTO Y ALINEAMIENTO / ALIGNEMENT ET

EMPLACEMENT DE LA BAGUE À ANGLE DROIT

DOWEL LOCATIONS LINE /

LÍNEA DE POSICIÓN PARA

LAS PERFORACIONES DE

LAS ESPIGAS / LIGNE

D’EMPLACEMENT DES

GOUJONS

JIG LOCATING LINE / LÍNEA DE

POSICIÓN PARA EL JUEGO DE

GUÍAS DE PERFORACIÓN PARA

ESPIGAS / LIGNE D’EMPLACEMENT

DU GABARIT

J

INSIDE ANGLE TRANSFER MARKING / TRANSFERIR

LAS MARCAS DEL INTERIOR DEL ÁNGULO /

MARQUAGE DU TRANSFERT DE L’ANGLE INTÉRIEUR

GENERAL TOOLS & INSTRUMENTS

80 White Street New York, NY 10013-3567

PHONE (212) 431-6100 FAX (212) 431-6499 TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com www.generaltools.com

Specifications subject to change without notice

©2012 GENERAL TOOLS & INSTRUMENTS

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

KL

SURFACE RULE MARKING /

MARCADO DE LA SUPERFICIE CON UNA REGLA /

MARQUAGE DE LA SURFACE À LA RÈGLE

841 User’s Manual

MAN#841 2/22/12

Loading...

Loading...