Page 1

General Technologies Corp.

�

�

�

TA105

Laser Optical Tachometer

1. SAFETY RULES

This Instrument is designed for indoor use at temperatures

•

between 32°F to 122°F (0°C to 50°C), altitudes up to 6500 ft.

(2,000 m), and 10% to 90% relative humidity.

To ensure that the instrument is used safely, follow all safety and

•

operating instructions in this manual. If the instrument is not used

as described in this operation manual, the safety features of this

device might be impaired.

• To avoid personal injuries and damage to the instrument use

extreme caution when working around hot or moving objects or

machinery like: radiators, exhaust manifolds, catalytic converters,

drive belts, fly wheels, etc.

2. INTERNATIONAL SYMBOLS

Important information

Refer to the User’s Manual

CAUTION: Laser Radiation

AVOID DIRECT EYE EXPOSURE

1mW Output at 630-670 nm

Class II Laser Product

3. TECHNICAL SPECIFICATIONS

3.1 General Specifications

Display: 5 digits 0.7” (16mm) LCD, Max. of

99999 display, with measuring unit indicator and Laser On Target indicator

Resolution: ±(0.05%+1 Digit)

Operating Temperature: 32°F to 122°F (0°C to 50°C)

Response time: 0.5 sec. (over 120 RPM)

Range Selection: Auto Ranging

Memory: Max. Value, Min. Value and Last

Distance to target: 2” to 20” (50 mm to 500 mm)

Laser Pointer: Laser Diode, < 1mW output

Power Source: 4 x 1.5 V type AA/UM3 or equivalent

Battery life: Approx. 5 hours.(w/alkaline batteries)

Dimensions: 6.3”x 2.8”x 1.5” (160 x 72x 37 mm)

Weight: 6.96 oz. (200 g) with battery.

Accesories: Soft Pouch, 23.5” (600 mm) long reflec-

Value stored automatically in memory

wavelength 630-670 nm, Class II

tive tape,4 x 1.5 V alkaline battery, and

User’s Manual

4. OPERATION

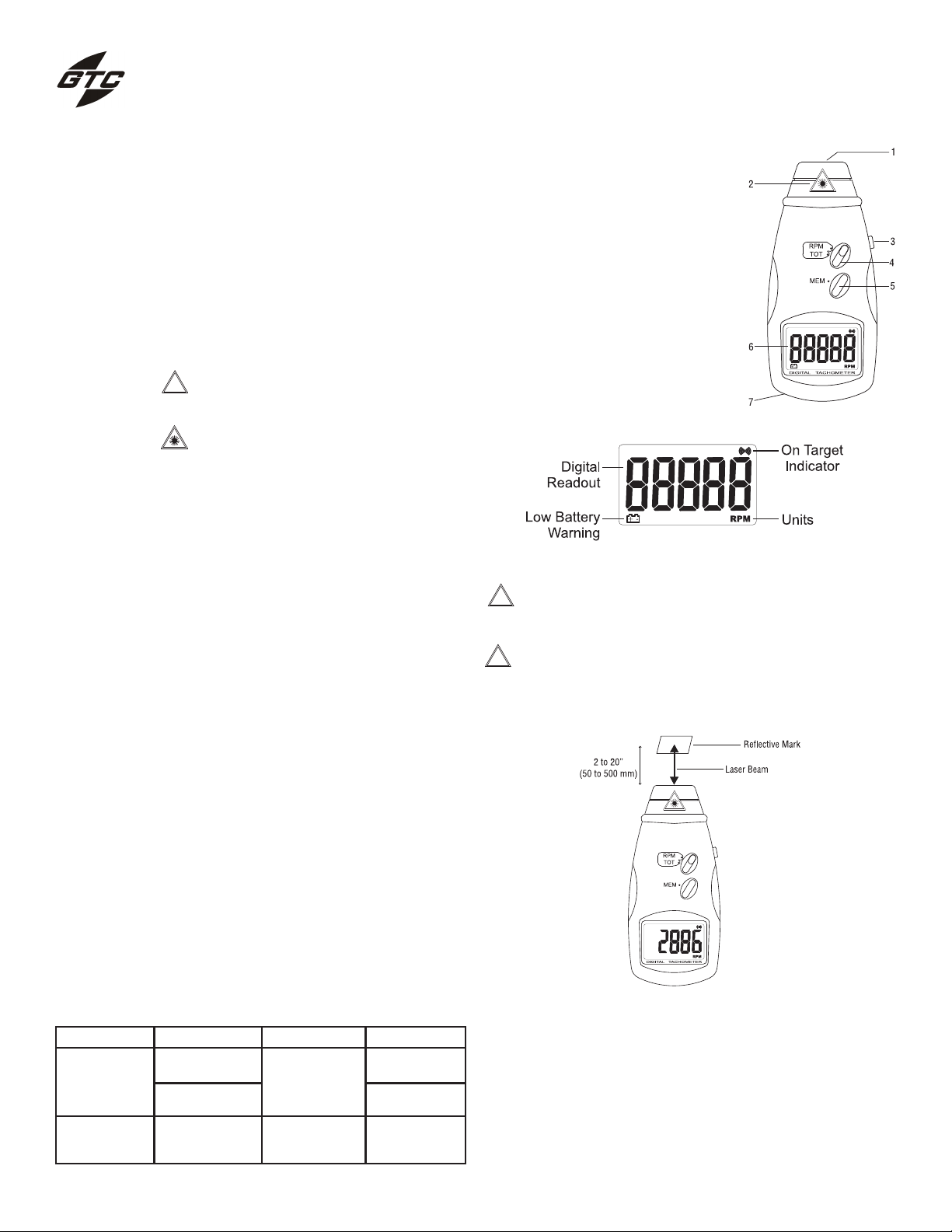

4.1 Instrument Description

1) Laser output

2) Laser warning symbol

3) Measurement button

4) Function switch

5) Memory button

6) Digital display

7) Battery compartment cover

4.2 Display Description

4.3 Measurement Procedures

CAUTION: Avoid contact with moving and hot

components, to prevent personal

injury or damage to the instrument.

CAUTION: Laser Radiation is emitted

Avoid direct eye contact

4.3.1 RPM Measurement

3.2 Measurement Specifications

Accuracies are ±(% of reading + number of least significant dig-

•

its) at 23°C ±5°C ambient temperature, with less than 75% RH.

Function Range Acuracy Resolution

2.5 to 999.9 RPM

RPM

1000 to 99,999 RPM 1 RPM

TOT

(total revolutions)

1 to 99,999 RPM

±(0.05%+1 Digit)

±(0.05%+1 Digit)

0.1 RPM

1 RPM

Apply a reflective mark or a piece of reflective tape to the

•

rotating object under measurement.

Slide the function switch to the “RPM” position

•

Press the measurement button and aim the light beam to the

•

reflective mark or tape on the rotating object.

Verify that the “On Target Indicator“ appears on the display,

•

indicating that the instrument is detecting the rotation of the

object and the reflective mark on it.

Proceed to read the RPM on the digital display.

•

Page 2

4.3.2 TOT (Total revolutions) function

Apply a reflective mark or a piece of reflective tape to the

•

rotating object under measurement.

Slide the function switch to the “TOT” position

•

Press the measurement button and aim the light beam to the

•

reflective mark or tape on the rotating object.

Verify that the “On Target Indicator“ appears on the display,

•

indicating that the instrument is detecting the rotation of the

object and the reflective mark on it.

Proceed to read the total revolutions on the digital display.

•

4.3.3 Reflective marks

Cut a 1/2” length of the reflective tape provided, peel off the

•

back to expose the adhesive, and attach it to the rotating part

or shaft to measure, observing the following recommendations:

- The non-reflective area must always be smaller that the

reflective piece of tape.

- If the object or shaft to measure is reflective, it must first be

covered with a black tape or painted black before attaching

the reflective tape.

- Before applying the tape ensure that the surface is clean

and smooth

4.3.4 Very low RPM measurements

The response time will vary with the rotational speed being

measured. Therefore when measuring very slow rotating parts, it

may be advantageous to follow the procedure below to increase

the update rate of the measurement:

Depending on the size of the rotating object or shaft,

•

attach multiples reflective marks, evenly spaced along its

circumference.

Proceed to measure RPM as described in 4.3.1, and divide the

•

reading by the number of reflective marks, in order to obtain the

correct RPM.

5. MAINTENANCE

5.1 Battery Replacement

When the battery is low and needs to be replaced, the “Low Bat-

•

tery Warning” symbol will appear on the lower left hand side of

the display.

To replace the battery, remove the screw and open the battery

•

compartment cover (located at the back of the unit), and remove

the battery.

Replace with 4 x 1.5 V type AA/UM3 or equivalent observing the

•

proper polarity of each battery as indicated at the bottom of the

battery compartment.

Close the battery cover, and replace the screw.

•

5.2 Cleaning

5.2.1 Lens cleaning

Debris or dirt on the lens may cause obstruction and impede the

working of the tachometer. If this occurs, either wipe the lens with

a Q-tip (moistened with water only) or blow off the loose particles

with clean compressed air. Do not use solvent on the lenses, as it

may become damage.

5.2.2 Exterior cleaning

Periodically wipe the case with a soft damp cloth and mild household

cleanser. Do not use abrasives or solvents. Ensure that no water gets

inside the instrument to prevent possible shorts and damage.

6. WARRANTY

One year limited warranty, excluding batteries and fuses. For

details see Standard Warranty Information on our web page or you

may request a printed copy.

4.4 Other Functions

4.4.1 Display Hold

The instrument will automatically hold the last reading

•

immediately after the “On Target Indicator” on the display

turns off, and hold it while the “Measurement button” is pressed.

4.4.2 MEM function

In every measuring cycle (pressing the measuring button,

obtaining a reading, and then releasing the button), the instrument

will automatically store in its internal memory the Maximum,

Minimum and Last value. To retrieve the values in memory follow

the procedure described below:

With the instrument off press and hold down the “MEM” button

•

to display the Maximum value stored in memory. Display

screens will alternate between “UP” (maximum) and the stored

maximum reading. Note the value and release the “MEM”

button.

Pressing and holding again the “MEM” button will display the

•

Minimum value stored in memory. Display screens will alternate

between “dn” (minimum) and the stored minimum reading. Note

the value and release the “MEM” button.

Pressing and holding again the “MEM” button will display

•

the last reading value stored in memory. Display screens

will alternate between “LA” (Last reading) and the stored last

reading value. Note the value and release the “MEM” button.

This memory retrieval cycle will keep repeating in the order

detailed above.

Notes: The values stored in memory will be retained until a new

Removing the batteries, or low batteries will cause all

measurement cycle is performed.

values stored in memory to be erased.

General Technologies Corp.

#121 - 7350 72nd Street Tel.: (604) 952-6699

Delta, BC Fax: (604) 952-6690

Canada V4G 1H9 www.generaltechnologies.net

© Copyright 2004 General Technologies

Loading...

Loading...