Page 1

User’s Handbook

FF300

Electrical Circuits

Fault Finder

Page 2

Table of contents.

1 - Check out list

1 Check Out list Page 1

2 Start-up Page 1

3 Switching On and Off The FF300 Page 1

4 Setting the sensitivity level Page 2

5 How to use the probe Page 3

6 Locating Short Circuits Page 3

7 Wire tracing Page 4

8 Locating Current Leaks Page 4

9 Locating Open Circuits Page 5

10 Wire Identification Page 5

11 Hook Up Reference Chart Page 6

12 General Procedures Page 7

13 Special Tracing Procedures Page 8

14 Technical specifications Page 11

15 Care of the unit Page 12

16 Warranty Page 12

Caution

Very Important: Read this first

• For use only with DC voltage. Do not connect to circuits exceeding 36 volts DC

under any circumstances.

• DO NOT USE on AC voltage.

• Do not use on any circuit directly or indirectly connected to AC lines or any other

AC power source.

• Do not use with any component or part of the ignition system.

• Before using this device check the vehicle’s electrical wiring and disconnect any part

or subsystem sensitive to voltage and current pulses such as air bags, electronic

control modules, etc.

• Always follow the instructions and procedures indicated in the vehicle’s service

manual before attempting to disconnect any part or subsystem of the electrical

circuit.

Exceeding the limits listed above when using this apparatus, or not observing the

precautions listed above can expose you to physical injury and permanently damage

your instrument and parts and components of the vehicle under test.

The FF300 set consists of:

o FF300R FaultFinder receiver.

o FF300T FaultFinder transmitter.

o Factory supplied 9- volt alkaline batteries, type Duracell MN1604

o Foam padded polypropylene carrying case.

o User’s handbook.

If any of these parts are missing please contact your dealer immediately.

2 - Start Up

Both the FF300R and FF300T are factory supplied with batteries. To install the batteries

follow the steps below:

1. Open battery drawer at back of each unit.

2. Factory supplied batteries are in reversed disconnected position.

3. Remove the battery, turn it around and connect the battery observing the polarity

on the label at the bottom of the compartment, on both units.

4. Press the On/Off button on the FF300T (FaultFinder Transmitter), green LED will

light up. If green LED does not turn on, check the battery polarity and reinstall if

necessary. To turn the unit off, press the On/Off button again.

5. Press the On/Off button on the FF300R (FaultFinder Receiver), green LED will start

flashing. If the green LED does not flash, check the battery polarity and reinstall if

necessary. To turn the unit off press the On/Off button again.

3 - Switching On and Off the FF300 set

The FF300T – FaultFinder Transmitter is turned on and off by momentarily pressing

the the “ON/OFF” button, and it must be turned off manually after use by pressing the

On/Off button. Before storing the unit check to make sure that all lights are off, failure to

do so will result in a much shorter battery life.

The FF300R – FaultFinder Tracer can be turned on and off manually by momentarily

pressing the “On/Off” button, however after 3 minutes of not being used, it will turn off

automatically to conserve battery power. Turning the unit off manually will prolong battery life.

From time to time the batteries on both units will need to be replaced. When you notice a

dimming indicator light and level of the audio output, the batteries should be replaced with

a new set of 9-Volt alkaline batteries. To install the new batteries, replace the ones in the

units for the new batteries observing the polarity on the label at the bottom of the battery

compartment, and follow the instructions in the preceding section: 2 – Start Up.

Page 1

Page 3

4 - Setting the sensitivity level

The FF300R has three user selectable sensitivity ranges: ‘Low’, ‘Medium’ and ‘High’.

These ranges allow the technician to choose the degree of sensitivity most suitable to the

particular detection being performed.

4.1 Procedure to select the FF300R’s range :

1. Unit should be on, if not, turn it on by momentarily pressing the “ON/OFF” button.

2. Press and Hold “ON/OFF” button for approximately 3 seconds until a beeping

and flashing following the pattern below indicates that the desired sensitivity level

is set:

I- Low Sensitivity: single (1) flash and beep.

II- Medium Sensitivity : double (2) flash and beep.

III- High Sensitivity : Tripple (3) flash and beep.

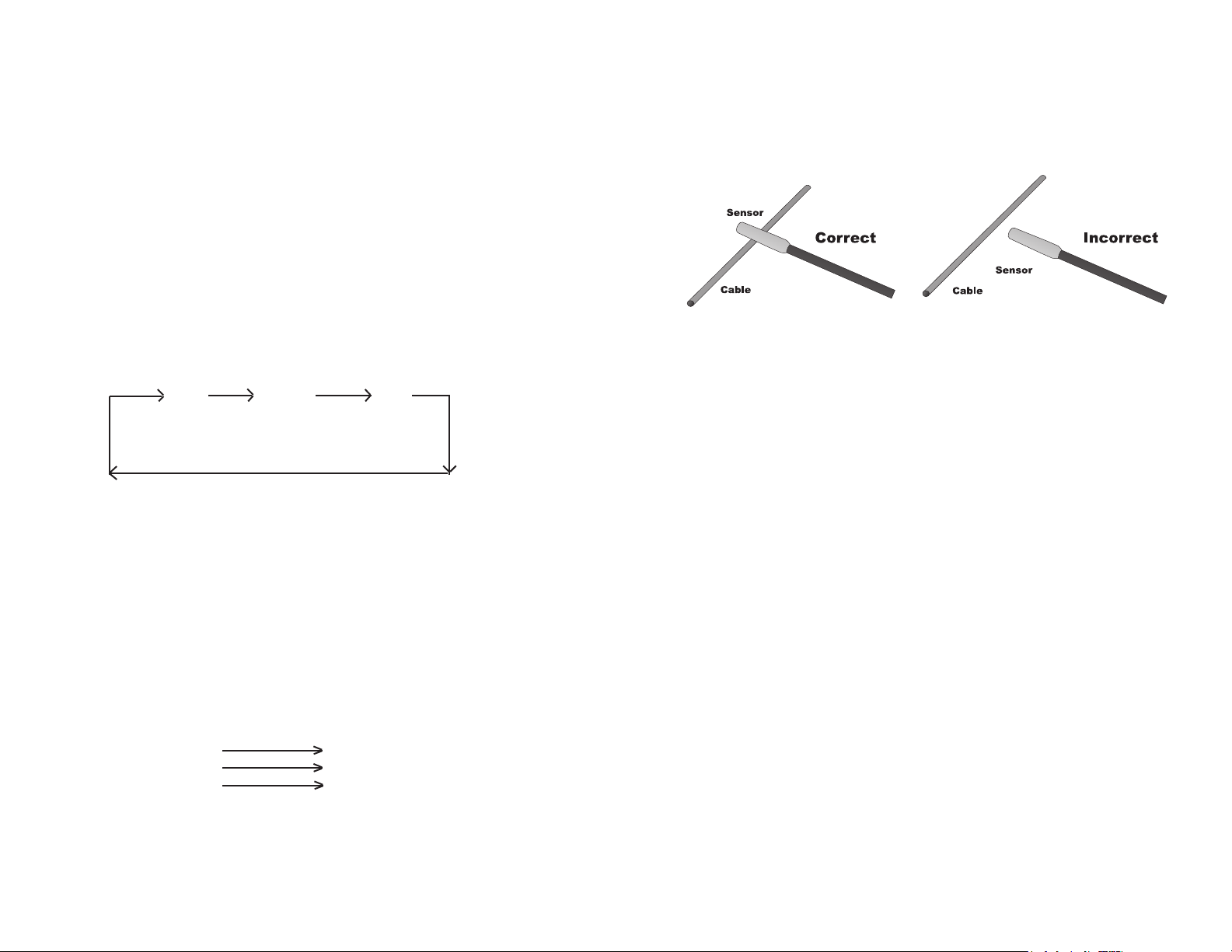

5 - How to use the probe:

The probe of the FF300R is built of coiled steel and can be bend as needed, in order to

reach wires in congested or difficult areas. Depending on the circuit characteristics and

sensitivity setting, the probe will pick-up the signal from the wire in a wide range of positions . However for the best possible range the FF300R’s probe tip (yellow cap) should

be positioned perpendicular ( at 90°) to the wire being traced and either above or below

it, as shown in Fig. 1 below.

Fig. 1 - Probe positioning

The sensitivity level is selected in the following it sequence:

LOW MEDIUM HIGH

Sensitivity Adjustment Sequence

For example: If the FF300R unit is set to HIGH, in order to set the sensitivity to

LOW follow the steps described in 1. and 2. of this section (above).

4.2 Checking the current sensitivity setting:

The FF300R’s current sensitivity setting is displayed when the unit is in stand-by mode (unit

on, with no audible signal). The high sensitivity setting generates a quick tripple flashing

of the green LED, a double flashing in the medium sensitivity range and a single flashing

indicates a low sensitivity level setting..

Standby green LED flashing pattern:

Green LED shows a: FF300R Tracer set to:

Single (1) flash Low sensitivity

Double (2) flash Medium sensitivity

Tripple (3) flash High sensitivity

When turned off, the FF300R will retain the last selected sensitivity setting.

6 - Locating Short Circuits

Refer to the Hook Up Reference Chart in Pag. 6.

6.1 Observe the limits and safety precautions at all times (refer to the begining of this

handbook).

6.2 Connect the FF300T (transmitter) in series with the short-circuited wire, making sure

one of the unit’s clips is connected to the circuit’s positive supply (or vice versa for

vehicles with positive supply connected to chassis). A fuse socket (in place of the

blown fuse), connector, etc. provides a convenient place as shown in Fig.2 and Fig.3

in page 7.

6.3 Switch the transmitter on by pressing the On/Off button and observe if the Red LED

on the FF300T is lighted up. If not check connections, power supply, and in the case

of having connected the unit to any place other than the fuse socket, check that the

circuit’s fuse is installed and in working condition (not open). If necessary replace

with a new fuse with the same ratings.

6.4 Switch the FF300R (tracer) on, and check if green LED starts flashing.

6.5 Verify that the FF300R is set to the low sensitivity level (single green LED Flash).

6.6 Slowly sweep the wire, conduit, etc., with tracer, ensuring the tracer’s probe is perpendicular and above or below the wire being traced and as close as possible to it

.

6.7 Follow the wire or check it at different points, starting from the transmitter and moving

towards the load (accessory, light , etc.) observing the positioning of the probe as

indicated above. Continue this procedure while the audio signal (beeping sound) and

visual signal (flashing Red LED light) indicates the integrity of the circuit. If beeping

and flashing slows or stops it indicates that the probe is either moving away from the

faulty wire or it has passed beyond the short circuit point.

6.8 If difficult or impossible to get the FF300R Tracer to pick-up any signal, then adjust

the sensitivity to HIGH, and check again if a signal is received.

6.9 Double check positioning the probe before and after the suspected place. If the short

circuit point has been found, the audio/visual indicators will show circuit integrity on

for one position, but not for the other.

Page 3Page 2

Page 4

6.10 The short circuit is located in the area where the audio/visual signal stops or

changes significantly.

6.11 When the test is completed, switch off the transmitter unit pressing the On/Off

button and disconnect from circuit.

Note: The closer the tracer probe is to the wire carrying the signal, the faster the beeping

and the flashing will be. Some times it will prove advantegous to reduce the sensitivity

level to pintpoint more accuratelly the faulty area.

7 - Wire tracing

Wire tracing hook up and procedures are essentially the same as for locating short

circuits. The transmitter sees the load (light, accessory, etc.) as the short circuit or

connection to ground. For wire tracing simply follow the wire with positive (beeping and

flashing) audio/visual indicator’s feedback on the tracer from source to load.

For step by step directions please refer to point 6– Locating Short Circuits, for some

hints and specific differences refer to the notes below:

The type and size of load connected to the circuit (impedance or resistance to ground)

determines the amount of current allowed to flow in the circuit. Small loads (low Wattage lamps, electronic systems, etc.) will reduce the range of the tracer accordingly.

In cases where the full range of the tracer is required to follow the wire, it may prove

advantageous to use one of the two methods described below:

• Tracing wires downstream (from supply to load): replacing the load for a full short

circuit allows the FF300 to work at its maximum capabilities. Before proceeding

remove all electrical power from the circuit, connect the FF300T in series with the

wire to trace, short circuit the load to ground (refer to Hook Up Reference Chart

Fig.2 and 3), then reconnect power and follow instructions in section 6 – Locating

Short Circuits.

• Tracing wires upstream (from load to supply): If more convenient, wires can also be

traced the other way around, by replacing the load with the FF300T (Fig. 4 of Hook

Up reference chart). To do this, first remove power from the circuit, disconnect load

and connect the FF300T in its place. Apply power to the circuit and follow instructions in section 6 – Locating Short Circuits.

8 – Locating Current Leaks

Hook up and procedures for locating current leaks are essentially the same as for locating short circuits. The transmitter sees the leak as a weak short circuit or connection

to ground. For locating a current leak simply follow the wire with positive (beeping and

flashing) audio/visual indicator’s feedback on the tracer, from source to leak location

(short circuit).

For step by step directions please refer to point 6 – Locating Short Circuits, for some

hints and specific differences refer to the notes below:

Current leak notes:

• The type and size of the leak in the circuit (impedance or resistance to ground)

determines the amount of current flowing in the circuit. Small leaks (i.e. low current)

will reduce the range of the tracer accordingly. In all cases the FF300R’s probe

should be positioned as close as possible to the wires, in order to maximize the

signal captured by the tracer, and set to a higher sensitivity level . For hook up refer

to the Hook Up Reference Chart Fig. 2 and 3 in Page 6.

9 - Locating Open Circuits

Refer to the Hook Up Reference Chart in Page 6.

9.1 Observe the limits and safety precautions at all times (refer to the begining of this

handbook)

9.2 Connect the FF300T (transmitter) in series with the open ended wire, making sure

one of the unit’s clips is connected to the circuit’s positive supply or ground . A fuse

socket ( with the fuse removed), connector, etc. provides a convenient place as shown

in Fig. 2, 3, 4 and 5 of the Hook Up Reference Chart.

9.3 Make sure that the clips are firmly attached to their connection points, and switch

the transmitter on by pressing the On/Off button. Observe if the Green LED on the

FF300T is lighted up. In the case of having connected the unit to any place other than

the fuse socket, check that the circuit’s fuse is installed and in working condition (not

open). If necessary replace with a new fuse with same rating.

9.4 Switch the FF300R (tracer) on, and check if green LED starts flashing, and set if

nessesary the sensitivity level to “LOW”.

9.5 Slowly sweep the wire with the FF300R, ensuring the tracer’s probe is perpendicular

and above or below the wire being traced and as close as possible to it .

9.6 Follow the wire or check it at different points, starting from the transmitter and moving towards the load (accessory, light, etc.) observing the positioning of the probe as

indicated above. Continue this procedure while the audio signal (beeping sound) and

visual signal (flashing green LED light) indicates the integrity of the circuit. If beeping

and flashing slows or stops, it indicates that the probe is either moving away from the

wire or it has passed beyond the open, break or bad connection in the circuit.

9.7 If difficult or impossible to get the FF300R Tracer to pick-up any signal, then adjust

the sensitivity to” HIGH” and repeat again step 9.6.

9.8 Double check by positioning the probe before and after the suspected place. If the

open circuit point has been found, the audio/visual indicators will show circuit integrity

on one side, and not on the other.

9.9 At this point, where the audio/visual signal stops, you have found the open circuit.

9.10 When the test is completed, switch off the FF300T (transmitter) unit pressing the

On/Off button and disconnect from circuit. You may also switch the FF300R (tracer)

by pressing the On/Off button on the unit. However to conserve power, the FF300R

will automatically turn off after 3 minutes of not being used.

Note: The closer the tracer probe is to the wire carrying the signal, the faster the beeping

and the flashing will be.

10 - Wire identification

Refer to the Hook Up Reference Chart in Page 6.

Wiring can be identified by following the hook up and procedures for locating short circuits

or open circuits, depending on the particular configuration of the circuit.

• For identifying wires with load connected: Connect transmitter as described in section

‘6- Locating Short Circuits’ to the circuit to be identified. Then proceed to scan all suspected wiring with the FF300R’s probe until the flashing and beeping is at its maximum.

In the case of tightly packed wires( bundles, conduits, etc.), it may be necessary to

spread these apart to facilitate the identification process of a particular wire.

Page 5Page 4

Page 5

• For identifying wires without load connected: Connect transmitter as described in

section ‘9- Locating Open Circuits’,to the circuit to be identified. Then proceed to

scan all suspected wiring with the FF300R’s probe until the flashing and beeping is

at its maximum. In the case of tightly packed wires( bundles, conduits, etc.), it may

be necessary to spread these apart to facilitate the identification process of a particular wire.

12 - General Procedures

Short and Open Circuit operation – Differences:

The FF300 FaultFinder uses two different types of signals to trace either short or open

circuits. Understanding its differences, as explained in the following paragraphs will allow

you to make the most effective use of this versatile tool.

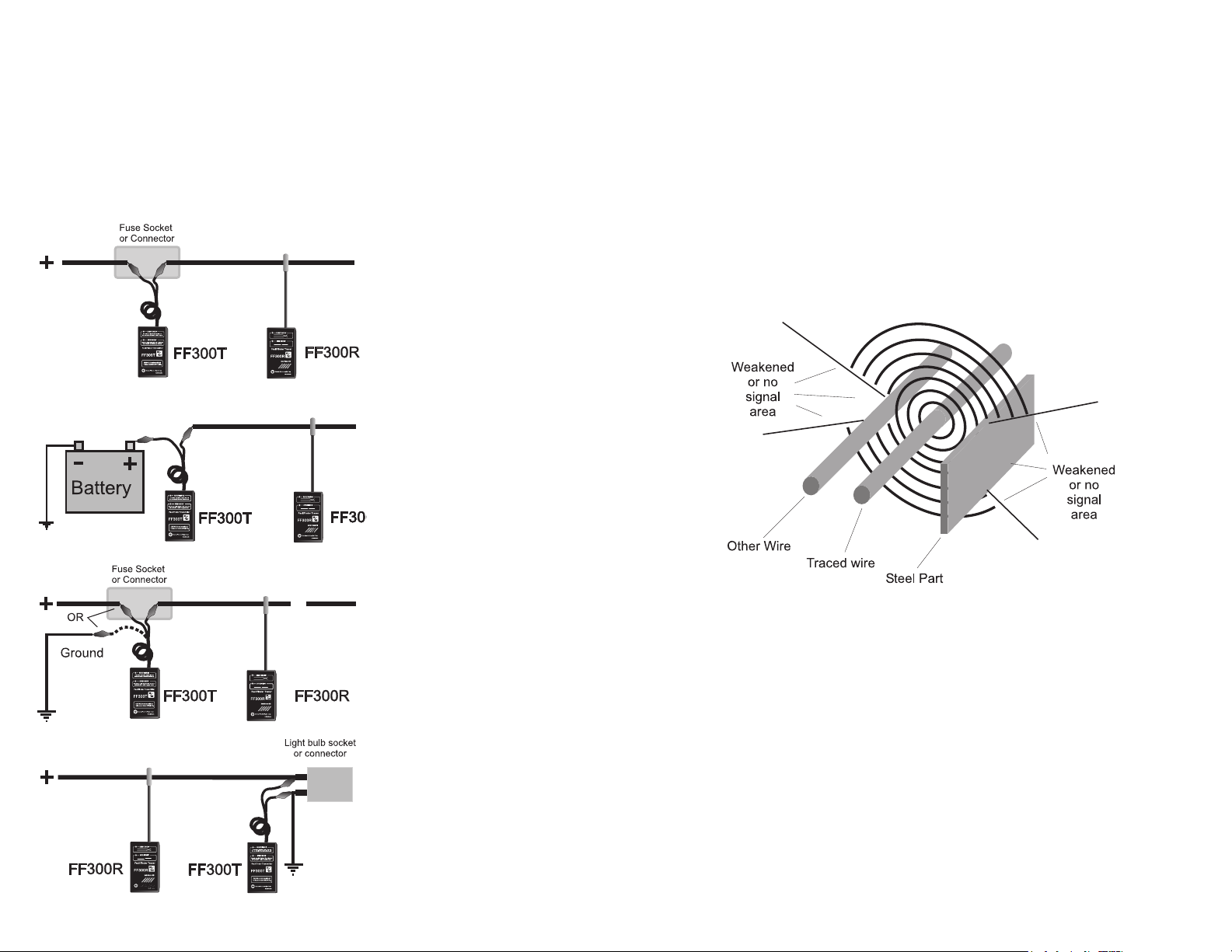

11- Hook up reference chart

12.1 Working with open circuits

On detection of an open circuit, the FF300T injects a special radio signal into the

circuit, which can be picked up by the FF300R (tracer) probe.

When tracing an open circuit, keep in mind that RF (radio frequency) signals injected

in the faulty wire being traced; will be easily absorbed by any other conductor nearby.

(ie: other wires, metal frames, etc.).

Fig.2 - Set up for tracing short or

open circuits, or location

of wiring

Fig.3 - Set up for tracing short

and open circuits, or

tracing wiring

Fig. 6 - Detection field when tracing open circuit with the FF300

Fig.4 - Set up for tracing open

circuits or identification

of wires

Fig.5 - Set up for upstream

tracing of open circuits

or location of wires

The effect of this absorption may vary from a reduction in the tracer’s range, to a total

shielding of the signal with no detection being possible at all (See Fig. 6).

In order to avoid confusing a shielded portion of the faulty wire with the actual fault

on it, the circuit should be checked on all possible sections to confirm that no signal

is picked up on one side of the suspected faulty section.

Hint: In some cases when tracing open circuits, connecting the FF300

transmitter’s clip with the slotted wire to the faulty wire, and the clip with the

flat wire to ground or positive supply will improve the tracer’s range.

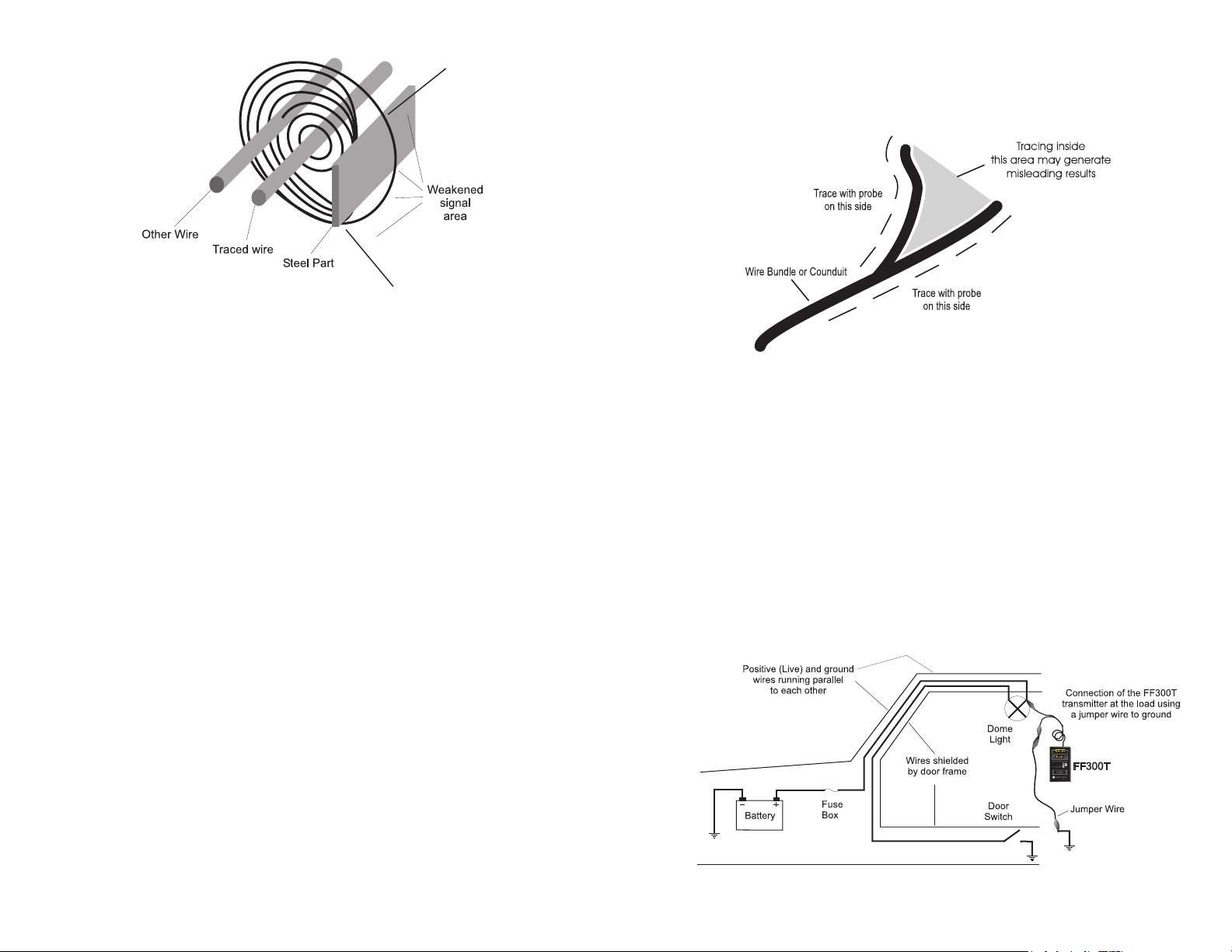

12.2 Working with short circuits (and tracing circuits)

When the FF300T detects a short circuit (or closed circuit), it injects pulses of

electrical current in the wires, which generate magnetic fields. Unlike radio signals,

magnetic fields are not easily absorbed by nearby conductors and therefore can be

picked up by the FF300R (tracer) probe in a wider range of situations (See Fig. 7).

Page 7Page 6

Page 6

Fig. 7 - Detection field when tracing short-circuits with the FF300

12.3 Some circuit characteristics that may affect the tracing of a wire:

• Electromagnetic loop size and geometry, etc. may affect the range of the

FF300’s. For example for circuits in which the live and ground (return) wire run

parallel and close to each other in the same circuit. The two magnetic fields

interaction may weaken the signal, thereby reducing the FF300 range.

• Wires enclosed or tightly lining the metal frame or body of the vehicle, (i.e.:

door frames, etc.), have the same effects as having the live and ground wires

running in parallel in the same circuit since, the metal frame or vehicle body will

be acting as a ground wire. Another unfavorable factor may be due to the channeling effect steel parts have on magnetic fields. These two cases, individually

or combined, will reduce and sometimes impede the tracing of the wire sections

affected.

Hint: Whenever possible the short circuit mode of operation should be used, be-

cause it provides with the best tracing capabilities.

13 - Special Tracing procedures

• In all cases, first set the FF300R at the lower sensitivity level and increase it as nec-

essary. Proceed as indicated in the sections of this User’s Manual applicable to your

situation.

• Always after locating a probable fault area, verify several points in the wires on both

sides (before and after) the suspected area. The signal should be present at only one

side of the fault (open or short). This procedure will help avoid confusing a signal loss

with the actual trouble point.

Because the probe may be picking up the signal from the other nearby branch (the one

with the wire actually being traced). To avoid following the wrong path, the branches

should be swept maintaining the probe outside the apex area between the split, as

shown in figure 8 below.

8 - Tracing Wires inside bundles and conduits

Careful attention should be paid to the beeping and flashing speed of the tracer unit

indicators, as these provide the necessary feedback to evaluate the proximity of the

wire being traced.

13.2 How to increase the pick up range when tracing wires

• When tracing or identifying wires connected to lightly loaded circuit (low currents), these

reduces the range of pick up significantly. A possible solution is after connecting the

FF300T - transmitter in series with the circuit to trace, is to replace the load (light

bulb, module, etc.) with a direct connection to ground. This allows the FF300T to inject

a more powerful signal easier to detect.

• For the cases in which it is suspected the layout of the wires is the cause of a very dif-

ficult to pick up or weak signal, a dramatic increase of the range can be accomplished

by “spreading” the circuit.

13.1 Wire bundles and conduits:

Special care should be given in the case of tracing a wire inside a bundle or conduit

when there is a split. In this case it may be possible to follow the wrong branch for a

short distance and still receive a positive audio/visual indication.

Fig. 9 - Simplified dome light circuit hook up for wire tracing

Page 9Page 8

Page 7

This is achieved by means of connecting a jumper wire between the live wire (preferably

at a termination point in the circuit such as a light bulb socket or a switch, etc.), and a

ground point somewhere else in the vehicle ( see Fig. 9). This last metod should be

used only as “last resource” and with the FF300R set to low sensitivity, as it may make

the pinpoint of the precise location more difficult due to the much increased range.

• Always verify that the FF300T is connected in series with the circuit being tested and

that its red indicator light is on, as this confirms a proper connection and will limit the

amount of current flowing in the circuit.

14 - Technical specifications

FF300T Transmitter

Voltage range: 6 to 36 Volts.

Indicator: Green LED indicator for Power On or Open Circuits.

Red Led LED indicator for short circuits.

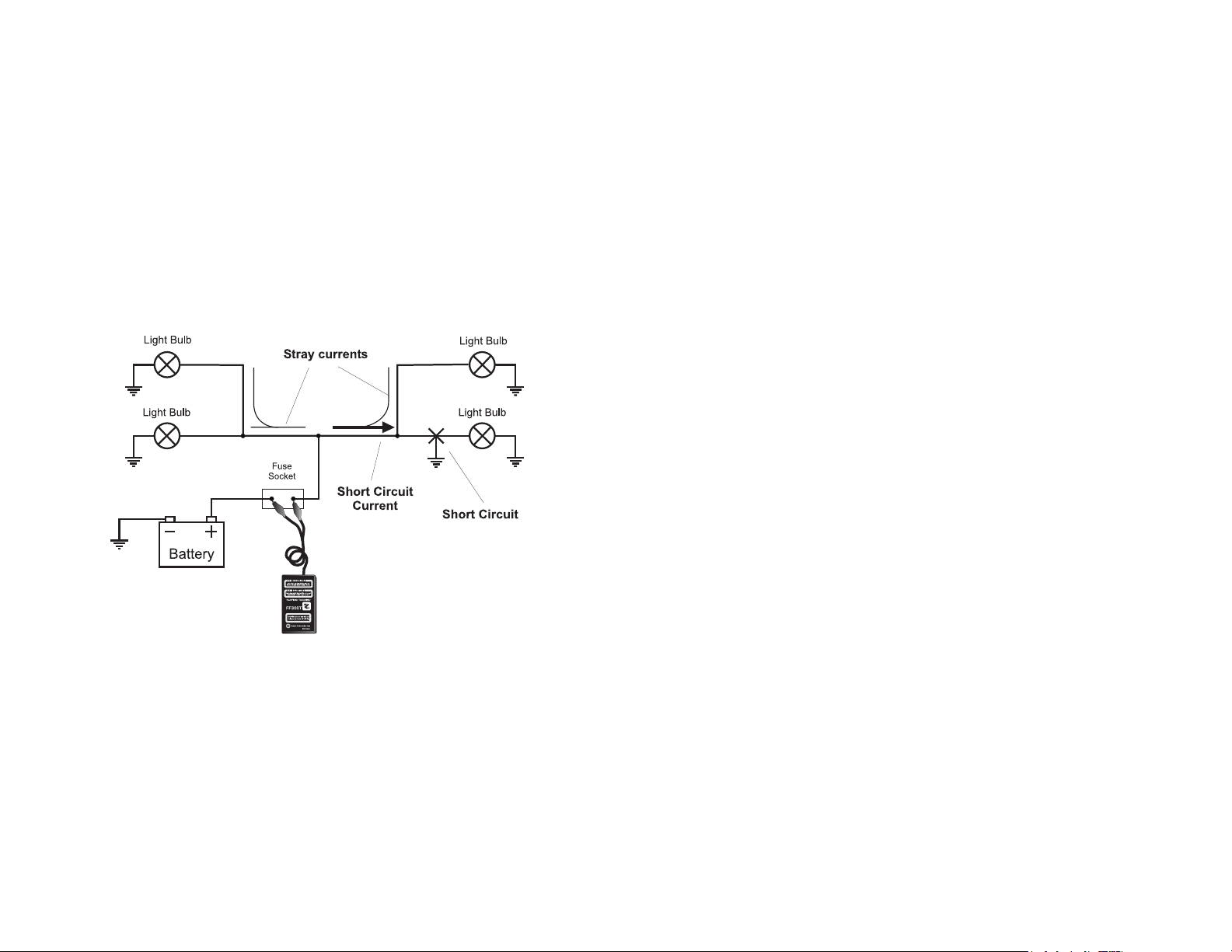

13.3 Circuits with multiple loads or branches

When tracing circuits connected to, or which are powering multiple loads and/or

branches (See Fig. 10), and when these circuits are active or live, the bulk of the current injected into the circuit by the FF300T will be directed to the short circuited branch

of the circuit. However smaller amounts of current (or stray currents) will flow to the

other branches as long as these provide a path to ground (i.e. close the circuit).

Power source: 9-volt alkaline battery. Duracell MN1604 or equivalent.

Connector: Two 5 Amp. universal micro-clips with auto polarity

and 18” long cable.

Battery life: approx. 50 hours of use.

FF300R Tracer

Tracer Sensitivity: 3 User selectable levels (Low, Medium and High)

Tracer probe: Flexible 9” gooseneck insulated steel probe.

Indicator: Green LED indicator for Power On and Open Circuits.

Red LED indicator for short circuits.

Audio signal for shorts and opens.

Variable flashing and modulated audible signal.

Power source: 9-volt alkaline battery. Duracell MN1604 or equivalent.

Battery life: Approx. 50 hours of use.

Fig. 10 - Schematic of a single circuit with multiples loads

These stray currents present in the non-shorted branches of the circuit, and depending

on the circuit configuration and physical layout of the wires, could be picked up by

the FF300R (receiver), making the tracing procedures confusing, and even misleading.

The simplest and most effective way to deal with these cases, is to disconect or remove all the loads from the circuit being traced (i.e. remove the light bulbs in example

shown above).

Page 11Page 10

Page 8

15 - Care of the Unit

The FaultFinder is a precision instrument and should be treated as such. Damage

caused by mistreatment is not covered by the warranty.

Keep the units in their carrying case when not in use and do not subject to dampness or

severe heat or cold. Do not use the units in the rain, if they should accidentally get wet.

Dry off with a clean paper towel before storing away.

Protect the units from contact with any solvents. Never clean with a solvent or petroleum

based medium such as gasoline, as these chemicals may attack the plastic parts and

cause permanent damage. Never use an abrasive cleaner. Cleaning should be limited

to wiping with a clean damp paper towel with a small amount of soap if required. Dry the

units thoroughly after any cleaning.

The unit is a sealed instrument and contains no user serviceable parts other than the

battery which can be replaced by opening the drawer on the back of the units. Opening

other parts of the units will void the warranty.

16 - Warranty

With the exception of the batteries, your FaultFinder is warranted against defects of material or workmanship which develop within a period of one (1) year following the date of

purchase by the original owner. Proof of date of purchase will be required when applying

for repair or replacement under guarantee. For this reason, we strongly suggest that you

keep your sales receipt safely in your FaultFinder storage case.

In the event a flaw develops in the FaultFinder, please return it to your dealer who will

arrange repair or replacement. The manufacturer will either repair or replace the tool (

at the manufacturer’s option) free of charge providing the FaultFinder is still under warranty. If the warranty has expired, there will be a repair charge payable to your dealer

when you pick up the unit. When a unit has been repaired or replaced under warranty,

the replacement unit will continue the warranty period of the original unit for six (6)

months after the date of replacement or until the original warranty expires, whichever is

the longest period. This warranty shall not apply to any defect, failure or damage caused

by improper use or inadequate maintenance or care.

The manufacturer shall not be obligated to provide service under this warranty or to

repair damage resulting from attempts by unauthorized persons to repair or service

the FaultFinder, other than to replace the battery; or to repair damage resulting from

improper use. Specifically if there is evidence of an attempt to open the FaultFinder the

warranty is void.

Any implied warranties arising out of the sale of the FaultFinder including but not limited

to implied warranties of merchantability and fitness for a particular purpose are limited in

duration to the above one (1) year period, the manufacturer shall not be liable for loss of

use of the FaultFinder or other incidental damages, expenses or economic loss.

Some Jurisdictions do not allow limitations on how long implied warranties last or the

exclusion or limitation of incidental or consequential damages, so the above may not

apply to you.

Page 12

Page 9

Part # FF300M9909EN

© 1999 General Technologies Corp.

Printed in Canada

Loading...

Loading...