Page 1

General Technologies Corp.

CT8030

Professional Automotive Digital Multimeter

1. SAFETY RULES

This meter is designed for indoor use at temperatures between 0°C to 40°C and

•

altitudes up to 2,000m.

To ensure that the meter is used safely, follow all safety and operating instructions in

•

this operation manual. If the meter is not used as described in this operation manual,

the safety features of this meter might be impaired.

Do not use the meter if the meter or test leads look damaged ,or if you suspect that

•

the meter is not operating properly.

When using the instrument, keep your ngers behind the nger guards on the plastic

•

casing and probes.

Disconnect the live test lead before disconnecting the common test lead.

•

Make sure power is off before cutting, desoldering, or breaking the circuit wires. Small

•

amounts of current can be dangerous.

Do not apply more than 1000 VDC or 750V AC rms between a terminal and ground.

•

To avoid electrical shock, use CAUTION when working above 60V DC or 25V AC rms.

•

Such voltages pose a shock hazard.

Never make measurements with the battery cover off.

•

To avoid electrical shock or damage to the meter, do not exceed the input limits.

•

2. INTERNATIONAL SYMBOLS

Important information Dangerous Voltages

see manual Continuity

AC Ground

DC Double Insulation

3. TECHNICAL SPECIFICATIONS

3.1 General Specications

Display: LCD, 4¾ digits/40000 Counts (99999 for Hz

function) + 4 Digits/9999 Counts dual display

with 42 segments analog bargraph.

Polarity: Automatic, (-) negative polarity indication

Zero adjustment: Automatic

Sample rates

3¾ Digits: 5 times per Sec.

4¾ Digits: 1.25 times per Sec.

43 Seg. bar graph: 128 times per Sec

Over range indication: “

Operating Temperature: 0 to 35°C, 0 to 80% RH

0 to 50°C, 0 to 70% RH

Power Source: 9-volt battery type NEDA 1604, IEC6F22

Battery life: Approx. 70 hours. (w/ alkaline batteries)

Safety: Des igne d to co m ply wit h EN 6101 0-

E.M.C.: Meets EN55011 and EN582-1

Dimension: 7.32”x3.42”x1.39” or 186x87x35.5mm

without Holster

Weight: Approx. 13.8 Oz. or 390g (without Holster).

Accesories: User’s Manual, Test Leads, Back Probes,

OL” is displayed

1, UL3 111- 1, CSA C 22.2 No.1 010-1

and IEC1010-1 Installation category II,

Pollution degree 1

Alligator Clips, Protective Holster, Hard

Carriying Case, K-type Temperature Probe,

Inductive pick-up and 9V battery.

Page 1

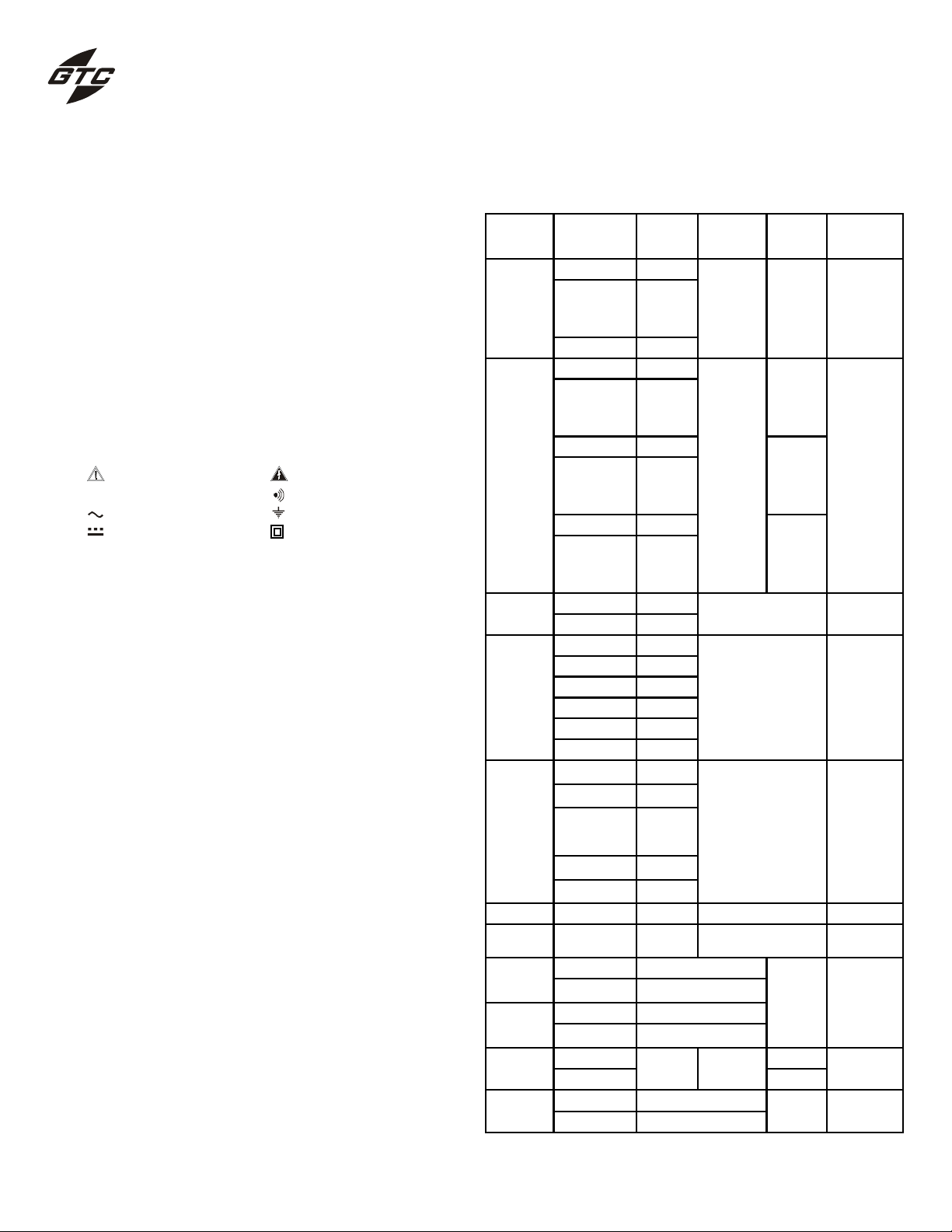

3.2 Electrical Specications

Accuracies are ±(% of reading + number of least signicant digits) at 23°C

•

±5°C, less than 75% RH. For DC/AC current measurement, the maximum

current of 10 A is for 30 Sec. with 5 min. cool down between measurements.

Function Range

40.00 mV

400.0 mV,

DC Voltage

AC Voltage

DC Current

AC Current

Resistance

Diode Test

Frequency

Multiport

Fuel

Injection

Single

Port Fuel

Injector

Tachometer

Dwell

4.000 mV,

40.00 V to

400.0 V

1000 V

40.00 mV

400.0 mV,

4.000 V,

40.00V,

400.0 V, 750V

40.00 mV

400.0 mV,

4.000 V,

40.00V,

400.0 V, 750V

40.00 mV

400.0 mV,

4.000 V,

40.00V,

400.0 V, 750V

4000 mA

10.00 A

4000 mA

10.00 A

4000 mA

10.00 A

4000 mA

10.00 A

40.00Ω

400.0Ω,

4.000 kΩ,

40.00 kΩ

400.00 kΩ

4.000 MΩ

40.00 MΩ

2.000 V

99.999 Hz to

20.000 kHz

0.05 - 250 mS

0.0 - 100 %

0.05 - 250 mS

0.0 - 100 %

120-20000 RPM

60-10000 RPM

0.0º - 360.0º 1.2º/krpm+1

0.0º - 100.0º 0.04º/krpm/cyl +2

A c c u -

racy

0.8%+6

0.1%+2

0.1%+4

1%+10

0.8%+4

3.5%+10

2.5%+5

4%+10

3.6%+8

1.2%+6

0.8%+4

1.2%+6

1.0%+3

2.5%+10

1.2%+3

3.5%+10

1.5%+5

0.5%+40

0.15%+4

0.15%+2

0.3%+2

1.5%+3

- < 3.2 V Test Voltage 600 Vrms

0.001%+4

0.04%/krpm +2

0.04%/krpm/cyl +2

2 RPM

Input

I m p e d -

ance

10 M

Ω,

30 pF

nominal

10 M

Ω,

30 pF

nominal

(100pF

nominal in

40 mV and

400 mV

Ranges)

0.03 V/A Voltage Burden

0.03 V/A Voltage Burden

<1.3 V Test Voltage

(<3.3 V in 40

400

Ω range)

1, 2, 20 and 200 Vrms

Selectable threshold

0.05mS+1

0.05mS+1

R e -

marks

50~60Hz

40 Hz to

1 kHz

1 kHz to

2 kHz

Ω and

Selectable

+/- Slope,

and

Number of

Cylinders

RPM 4

RPM 2

1 to 12

Cyl.

Overload

Protection

600 Vrms

600 Vrms

Fuse

Protected

Fuse

Protected

600 Vrms

600 Vrms

600 Vrms

600 Vrms

600 Vrms

Page 2

Audible Continuity Tester

+

-

RPM

4

RPM

2

RPM

2

RPM

4

Audible threshold : between 10Ω, and 60Ω.

•

Response time: 200μs.

•

O2 Sensor Tester

Application : For O2 Sensor dynamic test

•

Main Display : Symbolic waveform display of O2 Sensor

•

Mini display : Cross count per second parameter.

•

Sweep Rate : 10 per second.

•

Alternator tester

dynamic output.

A beep sound will alert the user on each

signicant cross count edge

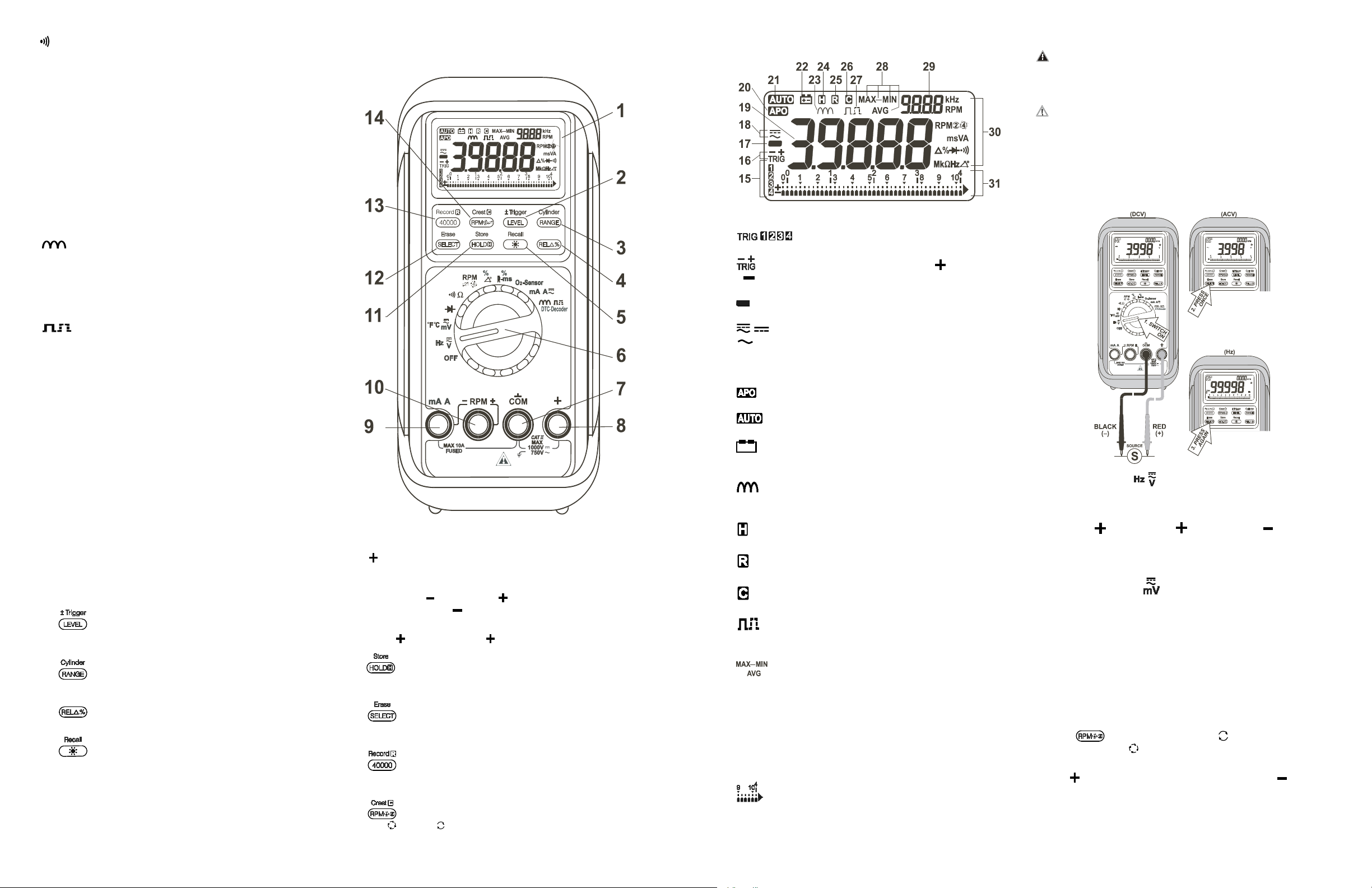

4.2 Display Description

15. : These annunciators indicate trigger level status.

4.3 Measurement Procedures

CAUTION: Maximum Input Voltage is 750Vrms,do not exceed

this rating to avoid personal injuries or damage to the

instrument. The FUNCTION switch should be set to

the range you want to test before the operation.

CAUTION: Always ensure that the correct terminals are used for

the type of measurement to be made. Avoid making

connections to “live” circuits whenever possible.When

making current measurements ensure that the circuit

is not “live” before opening it in order to connect the

test leads.

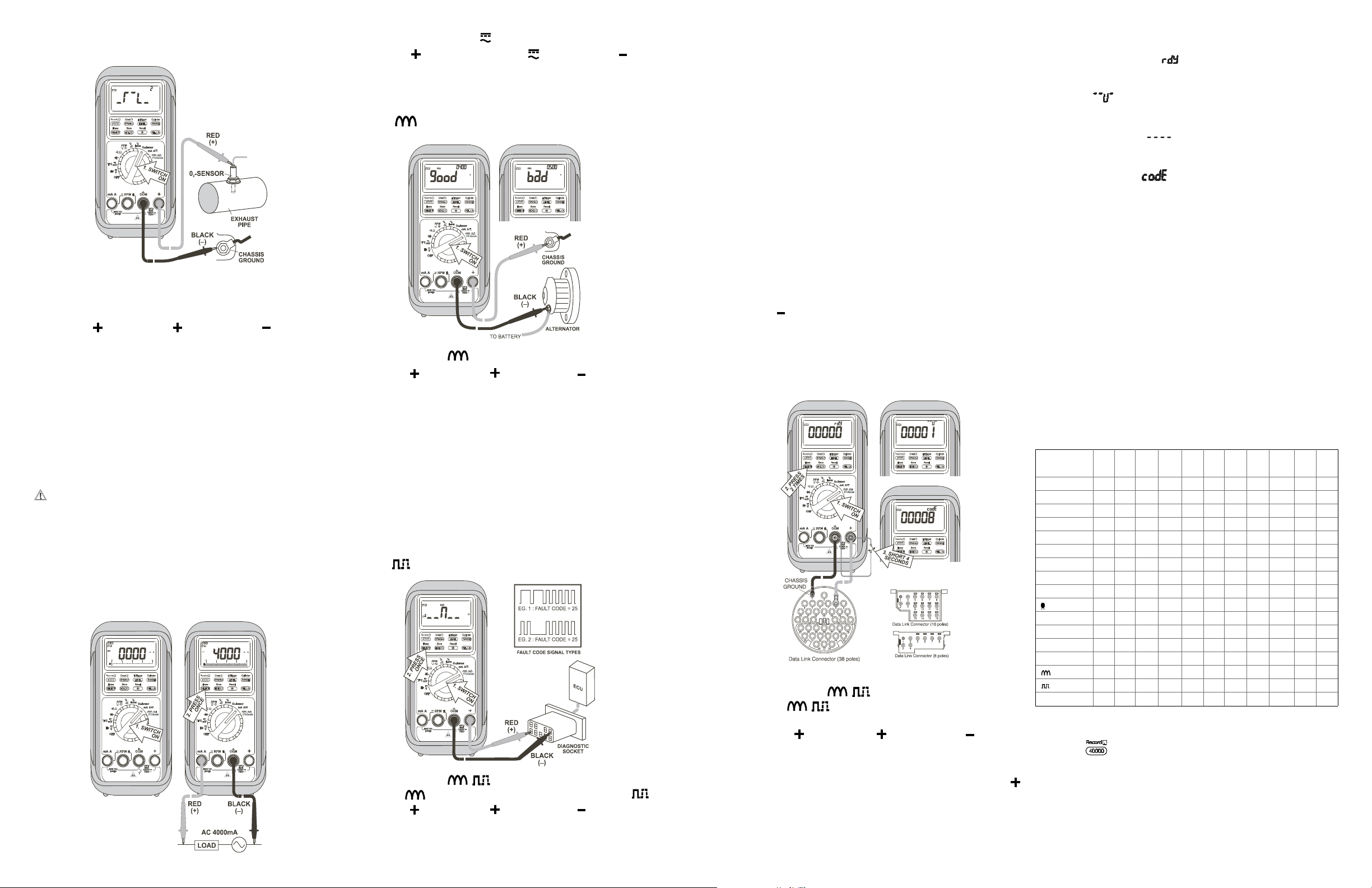

4.3.1 DC/AC Voltage Measurement

Application : For quick go / no go test on alternators

•

Threshold : The display indicates "bad" and the

•

Fault Code Detector

Application : For blink type fault code detection

•

Display : The display indicates a symbolic pulse and

•

Threshold : 4.5VDC with selectable positive or negative

•

DTC (Diagnostic Trouble Code) Decoder

Application : A replacement of the Impulse Counter Scan

•

beeper turns on when the measured

ripple voltage is greater than 0.45VAC.

the beeper turns on when the blink code

pulse is detected.

pulse trigger (by ±Trigger button).

Tool as specified in the Mercedes-Benz

Diagnostic Trouble Code Reference Guide

to scan the DTC Code readout automatically

on the Mercedes-Benz car series.

4. OPERATION

4.1 Instrument Description

: Input Socket for all functions except Current and TACH

8-

functions.

16.

17.

18.

19. DATA : Main digital readings of data being measured.

20.

21.

22.

23.

24.

25.

: These annunciators indicate positive ( ) or negative

( ) Trigger Slope is selected.

: Negative polarity symbol.

:

annunciator indicates direct current (DC) is selected.

annunciator indicates alternating current (AC) is selected.

: This annunciator indicates Auto Power Off is enabled.

: This annunciator indicates Autoranging.

: Low Battery alert, replace the battery as soon as possible

to ensure accuracy.

: This annunciator indicates the Alternator tester function

is selected.

: This annunciator indicates data HOLD function is activated.

: This annunciator indicates the Record function is activated.

Set rotary switch to position.

•

Default at DC. Press SELECT button momentarily to select AC,

•

and press again to select

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect test leads to voltage source and observe the digital display

•

for the readout.

Hz if required.

1- LCD Display: 4-3/4digit 40000 count 4 digits 9999 count dual display.

2-

3- : Pushbutton to select Auto/Manual ranging in most

4-

5- : Pushbutton. Press momentarily to turn on the display

6- Rotary Switch: Turns the power ON and OFF and selects

7-

: Pushbutton, press momentarily to select trigger levels,

or press and hold for 1 second to toggle between positive and

negative trigger slopes.

functions, or number of cylinders in Dwell function.

: Pushbutton to select relative zero and relative

percentage change.

backlight, or press and hold for 1 second to recall stored data.

measuring functions.

COM Input Socket: Common (Ground Reference) Input

connector for all functions except TACH function.

mA A/RPM : Input Jack ( ) for current function, and

9-

ground reference (

RPM : INPUT JACK ( ) FOR RPM FUNCTION

10-

11-

12- : Pushbutton. press momentarily to select secondary

13- : Pushbutton. press momentarily to toggle between

14- : Pushbutton. press momentarily to toggle between

Page 2

: Pushbutton. Press momentarily to activate hold, or

press and hold for 1 second to store the data displayed for

later recall

functions, or press and hold for 1 second to erase all stored

datas

40,000 and 4000 counts modes, or press and hold for 1

second to activate record function

and

second to activate Crest function

) input Jack for RPM function.

in RPM function, or press and hold for 1

26.

: This annunciator indicates the Crest function is activated.

27.

28.

29.

30.

31.

: This annunciator indicates the Fault Code Detector

function is activated.

: This annunciators indicate MAX (Maximum), MIN

(Minimum), MAX-MIN (Maximum minus Minimum), or AVG

(Average) reading is being displayed.

DATA : Secondary display for Dual Display data.

kHz : These annunciators indicate the function being selected

and/or the appropriate measurement units.

: Analog bar graph with overload ag, polarity and scale.

Set rotary switch to position for voltage application below

•

0.4V with similar operation procedures.

Refer (4-2) for enabling dual display RPM function.

•

Hz Function: 4 trigger levels selectable through the LEVEL push

button for advanced applications in this function. Also refer to section

5.8 of this manuals for more details.

4.3.2 DUAL DISPLAY RPM Function

Set the meter to the corresponding primary function. See note

•

below for function availability.

Press button to toggle to

•

engine, or to

Insert output plug of inductive pick up with the positive (red) into

•

RPM

Clamp the inductive pick up to a spark plug wire with the arrow

•

sign facing the spark plug. Make sure that the pick up jaws are

completely closed.

Observe the secondary digital display for RPM readings.

•

Page 3

jack and the negative (black) into the RPM jack.

for 4-stroke engine.

for 2-stroke and DIS

Page 3

Note: 1- This function is available to primary functions: DCV, ACV,

Temperature Probe

RPM

4

2

RPM

2

RPM

4

Hz, Dwell, Fuel injection detector, & Duty cycle.

2- When trigger level selection is required for advanced

applications, use main display RPM function. See (4.3.6)

for more details.

4.3.3 TEMPERATURE Function

4.3.4 DIODE TEST function

Set rotary switch to .

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect the test leads as shown and observe the digital display.

•

Normal forward voltage drop (forward biased) for a good silicon

•

diode is between 0.400V to 0.900V. A reading higher than that

indicates a leaky diode (defective). A zero reading indicates

a shorted diode (defective). An ‘

(defective).

Reverse the test leads connections (reverse biased) across the

•

diode.

The digital display shows ‘OL’ if the diode is good. Any other

•

readings indicate the diode is resistive or shorted (defective).

OL’ indicates an open diode

4.3.5 Ω RESISTANCE, CONTINUITY Functions

Connect the test leads as shown and observe the digital display.

•

Default at Ω. Press SELECT button momentarily to select

•

Continuity function.

A continuous beep tone indicates a complete wire. This is useful

•

for checking wiring connections and operation of switches.

4.3.6 RPM function (main display)

Set rotary switch to .

•

Press

•

engine, or to

Insert output plug of inductive pick up with the positive (red) into

•

RPM

Clamp the inductive pick up to a spark plug wire with the arrow

•

sign pointing the spark plug. Make sure that the pick up jaws are

completely closed.

Observe the digital display for RPM readings.

•

button to toggle to

for 4-stroke engine.

jack and the negative (black) into the RPM jack.

for 2-stroke and DIS

Set rotary switch to .

•

Default at 4 cylinders ( ). Press cylinder (RANGE) button

•

momentarily to display the cylinder setting on the secondary

display, and press momentarily again within one second to select

the number of cylinders from 1 through 12 to match the engine

under test.

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect the test leads as shown and observe the digital display.

•

Press SELECT button momentarily to display DWELL reading in

•

terms of percentage if required.

Refer (4-2) for convenient dual display RPM function.

•

Adjust the dwell angle according to the procedures outlined in your

•

vehicle service manual.

Note: 1- Re-check the timing whenever the dwell angle has been

2- 4 trigger levels selectable through LEVEL push button for

adjusted.

advanced applications in this function. Also refer (5-8) for

more details.

4.3.8 FUEL INJECTION DETECTOR Function

Set rotary switch to position

•

Press SELECT button momentarily two times to select temperature

•

function.

Without any temperature probe plugged into the input terminals

•

(detect automatically by the meter), the secondary digital display

displays the meter internal temperature reading in °C & °F

alternatively.

Insert the banana plug type-K temperature bead probe (standard

•

accessory) with correct

jack where negative (

use a plug adapter (optional accessory) with banana pins to typeK socket to connect other standard type-K mini plug temperature

probes.

Touch the end of the thermo probe to the measurement surface

•

and observe the digital display with °C in the main display, and °F

in the second display.

polarities. Positive ( ) plugs into

) plugs into COM input jack. You can also

CAUTION: Maximum Input Voltage for this function is 600 Vrms

Set rotary switch to Ω

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack

Page 4

do not exceed this rating to avoid personal injuries

or damage to the instrument. Also ensure there is no

power applied to the component or circuit and all

capacitors are discharged.

Note: 4 trigger levels selectable through LEVEL push button, for

advanced applications in this function. Also refer (5.8) for

more details.

4.3.7 DWELL Function

Set rotary switch to -ms.

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect the test leads as shown and observe the digital display.

•

Press SELECT button momentarily to display ms reading in terms

•

of percentage (%) if required.

Refer (4-2) for convenient dual display RPM function.

•

Note: 1. This

2. 4 trigger levels selectable through LEVEL push button for

3. The fuel injection frequency can be displayed on the

Page 5

-ms function applies to both Port Fuel Injectors (PFI)

which operate with a single on time pulse and Throttle Body

Injectors (TBI) which operate with twin pulses.

advanced applications in this function. Also refer (5.8) for

more details.

secondary display by pressing the

button.

Page 4

4.3.9 O2-SENSOR TESTER Function

Set rotary switch to O

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect test leads to the O

•

the digital display.

The main digital display shows a symbolic waveform of the O2

•

sensor dynamic output.

The secondary digital display shows the cross count per second

•

parameter, and a beep sound will alert the user on each cross

count edge being detected. Nominal cross count number is 1 to

3 for a good O

more active the O2 sensor is.

-Sensor position.

2

sensor dynamic output and observe

2

sensor. The higher the cross count number, the

2

4.3.9 mA and A Functions

CAUTION: Do not measure any circuit that draws more than

the current rating of the protection fuse. If the fuse

blows, replace it with the proper fuse. Failure to

do this may result in injury or damage to the meter.

Do not attempt a current measurement where the

open circuit voltage is above 600V. Suspected

open circuit voltage must be checked with voltage

functions. Voltage output current clamp adaptors are

recommended to use with the meter voltage functions

for making high current measurements.

Set rotary switch to mA A .

•

Insert red ( ) test lead into mA A jack and black ( ) test

•

lead into COM input jack..

Defaults at DC. Press SELECT button momentarily to select AC.

•

Connect the test leads as shown and observe the digital display.

•

4.3.10 ALTERNATOR TESTER Function

Typical fault code output triggering procedure is to short (close

•

circuit) the two trigger pins of the diagnostic socket and then turn

the ignition key to the ON position. DO NOT start the engine.

Location of the diagnostic socket, signal pins assignment, signal

•

type, and procedures of triggering & clearing the fault code may

be varied with car models. Consult your vehicle service manual

for manufacturer's specications. The display indicates a symbolic

pulse and the beeper turns on when the blink code pulse is

detected.

Time interval between pulse signals and duration of pulse signal

•

represent the blink type fault code numbers.

As an example, some car manufacturers use long pulse for the rst

•

code digit, and short pulse for the second code digit. In this case,

2 long 'Beeps' followed by 5 short 'Beeps' represented

fault code

number 25. As another example, some car manufacturers use

6- Trigger the DTC readout by Shorting (close circuit) the 2 signal

7- During scanning the meter secondary display indicates a pulse

If the DTC scanning is not successful, the meter secondary

If the DTC scanning is successful, the meter secondary display

8- Read and note DTC readout displayed on the LCD Display "1" =

same time interval between pulse signals on the same code digit,

and with longer time interval to separate the code digits. In this

9- Repeat procedure in step 6. If there are no further faults in the

case 2 short 'Beeps' followed by a quiet interval and then followed

by 5 short 'Beeps' represented fault code number 25.

Please note that in some car models, fault code signal output is

•

preceded by leading pulse signals.

As a typical procedure for clearing the fault code stored in the

•

memory. Turn the ignition key to the OFF position. Disconnect the

negative (

) battery terminal from the car electrical system for

10- Repeat procedure in step 9 until the rst DTC displayed is

11- Eliminate (repair) all noted faults (DTC readout) of the car

12- After eliminating a fault, the respective DTC may be cleared

about 1 minute, and the fault code will be cleared from memory.

Some car models require specic procedure to clear the fault code

stored, consult your vehicle service manual for details.

Set rotary switch to

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Start the engine and operate it at about 2000 rpm.

•

Connect the test leads as shown and observe the digital display.

•

A reading of 0.45V (typical) or less indicates that the alternator and

•

the associated rectier diodes are in good condition, and ‘good’ will

4.3.12 DTC-DECODER Function

*Note: Consult your Mercedes Benz Diagnostic Trouble Code

Reference Guide for signal pins assignments and engine precondition

procedures before triggering the

different from car model to model, and function to function.

5. ADVANCED OPERATION

See table below for feature availability on each function.

be displayed on the LCD. A display ‘bad’ together with continuous

beep sound indicate any of the following faults may exist:

- Defective rectier diode(s).

- Defective Alternator coils.

- Opened coil or rectier connections.

- Neutral of 3-phase Y-connection alternator accidentally

grounded to chassis.

4.3.11 FAULT CODE DETECTOR Function

1- Set rotary switch to DTC-Decoder

2- Default at . Press SELECT button two times to select

DTC-Decoder

3- Insert Red (

) test lead into jack and black ( ) test lead

into COM input jack

4- *Connect the test leads to the signal pins of the data link

connector. This function is a replacement of the impulse counter

Set rotary switch to DTC-Decoder.

•

Default at . Press SELECT button momentarily to select

•

Insert red ( ) test lead into jack and black ( ) test lead into

•

COM input jack.

Connect the test leads to the fault code signal pins of the diagnostic

•

socket and then trigger the fault code output.

scan tool with wire connections COM for black (bk), and

for yellow (yw) as specied in the Mercedes-Benz Diagnostic

Trouble Code Reference Guide. Since the meter is powered by

internal battery, connection of the impulse counter red (rd) wire

(to B+) for external power is not required

5- *Set Engine at idle

Page 6 Page 7

5.1 40,000 COUNTS HIGH RESOLUTION Mode

Press the button momentarily to enter the 4-3/4 digit high

resolution slow mode with a maximum display at 40,000 counts.

Press the button momentarily again to return to 3-3/4 digit fast

mode. In 3-3/4 digit fast mode, the digital display updates 5 times per

second nominal to give you the maximum measuring speed. In 43/4 digit slow mode, the digit display updates 1.25 times per second

nominal to give you smooth readings as well as the full accuracy of

the meter.

pins of the data link connector for about 4 seconds until the

secondary LCD shows "

". Then the meter is ready to scan

the DTC readout automatically.

symbol "

", and the beeper turns on when a DTC pulse is

detected.

display will indicate "

" to alert the user. Re-check the wire

connections, and start the trigger process again.

will indicate code "

" with 4 beep sounds, and the main

display indicates the correct DTC readout.

no fault stored, Greater than "1" = fault in system.

system, the previously displayed DTC will be displayed.

repeated.

according to troubleshooting chart and diagnostic tests.

by repeating procedure on step 6 to get the

DTC readout, and

then short the 2 signal pins for another 6 to 10 seconds, then

the

DTC displayed is cleared. Please note that each DTC

displayed must be cleared individually.

DTC readout. They might be

Data

Range

Function

DC Voltage

AC Voltage

Temperature

DC Current

AC Current

Resistance

RPM

Frequency

Duty Cycle

-ms

Dwell

O2 Sensor

Continuity

Diode

Alternator Test

Fault Code

DTC Decoder

40,000

Hold

Lock

Count

Relative Record

• • • • • • • •

• • • • • • • •

• • • • •

• • • • • • •

• • • • • • •

• • • • • •

• • • • •

• • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • •

• • • • •

• • • • •

• • •

• • •

• • •

Crest

(Peak)

+/-

Trigger

Trigger

Level

No. of

Cylinders

Dual

Display

Store

Recall

Page 5

5.1 SECONDARY FUNCTION Selection

RPM

4

RPM

2

5.6 CREST (Instantaneous Peak Value) Mode

5.9 TRIGGER Selection

Press the button momentarily to select the secondary functions

of a selected rotary switch position.

5.1 BACK LIGHT

Press and hold the button momentarily to toggle the backlight

on and off. The backlight will also be off 55 seconds after each

activation automatically to extend battery life.

5.4 Selection

In the RPM function, the meter defaults to

4-stroke engine. Press

for DIS or 2-stroke engine.

button momentarily to toggle to

for conventional

5.5 RECORD Mode

Perform measurements as described in BASIC OPERATION.

Press and hold the

Record mode, the LCD annunciators turn on. The meter

beeps when new maximum or minimum reading is detected. Press

the button momentarily to read throughout the Maximum (MAX),

Minimum (MIN), Maximum minus Minimum (MAX-MIN), and

Average (AVG) readings. Press the button for 1 second or more to

exit

Record mode.

With the Auto-Ranging Record mode, you can easily track intermittent

signals, capture turn-on/ turn-off surges, and monitor line voltage

changes over a much wider dynamic range with the best resolution. It

largely surpasses single range recording which is easily over-owed,

or with insufcient resolution. The meter features a fast single range

sampling speed of 50ms for MAX, MIN, MAX-MIN and AVG readings.

The faster the sampling speed, the more accurate the measurement

of surges, spikes and sags will be. The true average AVG feature

calculates all readings taken over time continually.

Notes: 1- Auto Power Off feature will be disabled automatically in

2- To retain the readings after measurements, use

this mode

function to stop updating the measurements before

disconnecting the test leads. Use similar pushbutton

procedures described above to read throughout the locked

readings

button for 1 second or more to activate

HOLD

Page 8 Page 9

Perform measurements as described in BASIC OPERATION.

Press and hold the button for 1 second or more to activate

Crest mode with LCD annunciators MAX turn on. Press the button

momentarily to read throughout the Maximum (MAX), Minimum

(MIN), and Maximum minus Minimum (MAX-MIN) readings. Press

the button for 1 second or more to exit Crest mode. With the Crest

mode, you can capture transient signal crest voltage (instantaneous

peak value) as short as 1ms.

Note: 1- Auto Power Off feature will be disable automatically in this

mode.

2- To retain the readings after measurements, use

function to stop updating the measurements before

disconnecting the test leads. Use similar pushbutton

procedures described above to read throughout the locked

readings.

5.7 HOLD Function

Press the button momentarily to activate the hold function

with LCD annunciator turns on. Press momentarily again to

release. When in normal measuring modes, the hold feature freezes

the display for later view. When in

however, the hold function stops updating the measurements, and

you can read throughout the locked

AVG readings. Release the hold function to continue RECORD or

CREST.

RECORD or CREST mode,

MAX, MIN, MAX-MIN, and

5.8 TRIGGER LEVEL Selection

The meter is set at carefully selected trigger levels, and as power

up default on individual functions for most applications. However,

car signal levels under test may vary due to aging of components,

abnormal conditions, and different design from different car

manufacturers.

Therefore, a Trigger level selection function is designed to provide

more exibility to cope with your applications. The 4 trigger levels

provided are carefully selected and tested to include all of the

extreme conditions, and you virtually do not need more. More trigger

levels may decrease the ease of use and increase the measuring

uncertainty as you may encounter in some old technology.

If your measuring reading is unstable, select lower sensitivities (higher

trigger level number) by pressing the

your measuring reading shows zero, select higher sensitivities (lower

trigger level number).

LEVEL button momentarily. If

HOLD

Trigger or is to identify whether the on or off portion of the

signal under test is of measuring interest. For example, as in duty

cycle function, if you get a reading of 10% in the trigger

portion), you then will get a reading of 90% in trigger

portion).

To toggle between trigger

button for 1 second.

and , Press and Hold the

(off

(on

5.10 MANUAL or AUTO RANGING

Press the button momentarily to select manual ranging, and

•

the meter will remain in the range it was in with LCD annunciator

turns off. Press the button momentarily again to step

through the ranges. Press and hold the button for 1 second or

more to resume auto-ranging. In

Press the button momentarily to display the cylinder setting

•

on the secondary display, and press momentarily again within one

second to select the number of cylinders from 1 through 12 to

match the engine under test.

Dwell function.

5.11 DATA STORE, RECALL & ERASE

This feature stores the whole display data in memory for later recall.

The memory will remain even in auto-power-off mode, and can also

be recalled while you are in another meter function. The memory will

be erased if the rotary switch is switched to the OFF position.

Press the button for 1 second to store the displaying

•

information. The LCD will show "

to conrm storage. You can store up to 18 datas by repeating this

procedure.

Press the button for 1 second to recall the last stored data.

•

The LCD will show "

displaying the recalled data. The annunciator

to identify that the recalled data is being displayed. Then press the

button momentarily to retrieve other stored datas.

Press any other buttons momentarily EXCEPT to resume

•

measurement. Press and Hold the

Erase all the stored data.

" and the last memory data number before

" and the memory data number

will then turn on

button for 1 second to

5.12 RELATIVE Modes

Press the button momentarily to enter the Relative Zero

•

( ) mode with LCD annunciator turns on. Relative zero allows the

user to offset the meter measurements with a relative reference

value. Practically all display readings can be set as relative

reference value including MAX, MIN, MAX-MIN, and AVG readings

of RECORD functions.

Press the button momentarily again to enter the Relative

•

Percentage Change (%) mode with LCD annunciators % turn on.

In this mode, the readings show relative percentage changes with

respect to the relative reference value. It simplies zero, peaking,

nulling measurements, and is excellent for ne adjustments and

comparison.

Press and hold the button for 1 second or more to exit relative

•

modes and resume normal measurements.

5.13 AUTO POWER OFF (APO)

The Auto Power Off (APO) mode turns the meter OFF automatically

to extend battery life after 5 minutes of inactivities. The meter turns

back ON if the rotary switch is turned. Activities are specied as:

1- Rotary switch or push button operations.

2- Signicant measuring data readings.

When entering the Record or Crest mode, the Auto Power Off will be

disabled automatically, and the LCD annunciator will be off.

The Auto Power Off feature can be disabled manually as a poweron option by pressing the

The LCD annunciator will be off during operation. For maintenance

testing purposes, the Auto Power Off timing can be shortened to 5

seconds by pressing the

Note: 1. Stored data remains after Auto Power Off, BUT will be

erased if the rotary switch is switched to the OFF position

2. Always turn the rotary switch to the OFF position when the

meter is not in use. The meter will produce a beep sound

to alert the user while turning off automatically

button while turning the meter on.

button while turning the meter on

5.14 LINE FILTER FREQUENCY 50 Hz or 60 Hz

selection

The line lter frequency can be selected as a power-on option.

Press the button while turning the meter on to display the

•

set frequency.

Press the button for 50 Hz or press the button for 60

•

Hz selections.

Then press the button to store the selected frequency.

•

Selecting the appropriate line lter frequency to cope with your line frequency

can maximize the meter's noise rejection ability. This feature is normally

only available in expensive bench top

multimeter.

Page 6

conditions of operation, the series fusible resistors will be blown off

(become high impedance) to protect the user and the instrument.

Most measuring functions through this terminal will then be open

circuit. The series fusible resistors and the spark gaps should then be

replaced by qualified technician. Refer to the LIMITED WARRANTY

section for obtaining warranty or repairing service.

9. LIMITED WARRANTY

With the exception of the batteries and the fuse, this instrument is

warranted against defects of material or workmanship which develop

within a period of one (1) year after the date of purchase by the

original owner. Proof of date of purchase will be required when

applying for repair or replacement under this guarantee. For this

reason, we strongly suggest that you keep your sales receipt safely

in your intrument storage case.

6. MAINTENANCE

WARNING: To avoid electrical shock, disconnect the meter

from any circuit, remove the test leads from the

input jacks and turn OFF the meter before opening

the case. Do not operate with open case. Install only

the same type of fuse or equivalent.

6.1 Battery and Fuse Replacement

6.1.1 Battery Replacement

Battery: Single 9V battery NEDA1604, JIS006P or IEC6F22; or 9V

alkaline battery NEDA1604A, JIS6AM6 or IEC6LF22.

Loosen the 2 screws from the battery access door of the case bottom.

Lift the battery access door and thus the battery compartment up.

Replace the battery. Re-fasten the screws

6.1.2 Fuse Replacement

In the event a aw develops in any of the units, please return it to

your dealer who will arrange repair or replacement. The manufacturer

will either repair or replace the tool ( at the manufacturer’s option)

free of charge providing the instrument is still under warranty. If the

warranty has expired, there will be a repair charge payable to your

dealer when you pick up the unit. When a unit has been repaired

or replaced under warranty, the replacement unit will extend the

warranty period of the original unit for six (6) months after the date of

replacement or until the original warranty expires, whichever is the

longest period. This warranty shall not apply to any problem, failure

or damage caused by improper use or inadequate maintenance

or care.

The manufacturer shall not be obligated to provide service under

this warranty or to repair damage resulting from attempts by

unauthorized persons to repair or service the units, other than to

replace the batteries, or to repair damage resulting from improper

use. Specifically if there is evidence of an attempt to open the units

the warranty is void.

Any implied warranties arising out of the sale of the units including

but not limited to implied warranties of merchantability and tness for

a particular purpose are limited in duration to the above mentioned

one (1) year period, and the manufacturer shall not be liable for loss

of use of the instrument or other incidental damages, expenses or

economic loss. Some jurisdictions do not allow limitations on how

long implied warranties last or the exclusion or limitation of incidental

or consequential damages, so the above may not apply to you.

Fuse: 15A/600V, IR 100kA, F fuse for mA/A current input.

Loosen the 4 screws from the case bottom. Lift the end of the case

bottom nearest the input jacks until it unsnaps from the case top.

Replace the blown fuse. Replace the case bottom, and ensure that

all the gaskets are properly seated and the two snaps on the case

top (near the LCD side) are engaged. Re-fasten the screws.

7. Cleaning and Storage

Periodically wipe the case with a damp cloth and mild detergent; do

not use abrasives or solvents. If the meter is not to be used for periods

of longer than 60 days, remove the battery and store it separately.

8. Troubleshooting

If the instrument fails to operate, check battery, fuses, leads, etc.,

and replace as necessary. Double check operating procedure as

described in this user’s manual. If the instrument voltage-resistance

input terminal has subjected to high voltage transient (caused by

lightning or switching surge to the system) by accident or abnormal

Page 10

General Technologies Corp.

#121 - 7350 72nd Street Tel.: (604) 952-6699

Delta, BC Fax: (604) 952-6690

Canada V4G 1H9 www.generaltechnologies.net

© Copyright 2003 General Technologies

Loading...

Loading...