Page 1

General Technologies Corp.

1. SAFETY RULES

This meter is designed for indoor use at temperatures between 0°C to 40°C and

•

altitudes up to 2,000m.

To ensure that the meter is used safely, follow all safety and operating instructions in

•

this operation manual. If the meter is not used as described in this operation manual,

the safety features of this meter might be impaired.

Do not use the meter if the meter or test leads look damaged ,or if you suspect that

•

the meter is not operating properly.

When using the instrument, keep your ngers behind the nger guards on the plastic

•

casing and probes.

Disconnect the live test lead before disconnecting the common test lead.

•

Make sure power is off before cutting, desoldering, or breaking the circuit wires. Small

•

amounts of current can be dangerous.

Do not apply more than 600 VDC or 600V AC rms between a terminal and ground.

•

To avoid electrical shock, use CAUTION when working above 60V DC or 25V AC rms.

•

Such voltages pose a shock hazard.

Never make measurements with the battery cover off.

•

To avoid electrical shock or damage to the meter, do not exceed the input limits.

•

2. INTERNATIONAL SYMBOLS

Important information Dangerous Voltages

see manual Continuity

AC Ground

DC Double Insulation

3. TECHNICAL SPECIFICATIONS

3.1 General Specifications

Display: 4 digits LCD, max. of 9999 display

Polarity: Automatic, (-) negative polarity indication

Zero adjustment: Automatic

Sample rate: 0.25 Sec., 0.05 Sec. for bar graph

Over range indication: “OL” is displayed

Power: 9-volt battery type NEDA 1604, IEC6F22

Battery life: Approx. 70 hours. (w/ alkaline batteries)

Dimension: 5.9”x2.95”x1.34” or 150x75x34 mm.

Weight: Approx. 8.9 Oz. or 252g (with battery).

Accesories: User’s Manual, Test Leads, Protective

Holster, Ha rd carriying ca se, K- type

temperature probe, Inductive pick-up and

9V battery.

3.2 Electrical Specifications

Accuracies are ±(% of reading + number of least signicant digits) at 23°C

•

±5°C, less than 75% RH. For DC/AC current measurement, the maximum current of 10 A is for 30 Sec. with 5 min. cool down between measurements.

CT8027

Professional Automotive Digital Multimeter

Function Range Accuracy

0.5%+6

0.5%+2

0.8%+2

1.5%+5

- < 3.5 V Test Voltage 600 Vrms

0.01%+2

0.04%/krpm +2

0.04%/krpm/cyl +2

2 RPM

2%+1

2%+2

Resistance

Diode Test

Frequency

Fuel

Injector

Tachometer

Dwell

Temperature

999.9Ω

9.999 kΩ,

99.99 kΩ

999.9 kΩ,

4.000 MΩ

40.00 MΩ

9.999 V

999.9Hz to

20.0 kHz

0.05 - 250 mS

0.0 - 100 %

0.05 - 250 mS

0.0 - 100 %

120-20000 RPM

60-10000 RPM

30-5000 RPM

0.0º - 360.0º 1.2º/krpm+1

0.0º - 100.0º 0.04º/krpm/cyl +2

-20º to 300ºC 3ºC+1

301º to 500ºC

0º to 572ºF 6ºF+2

573º to 932ºF

4. OPERATION

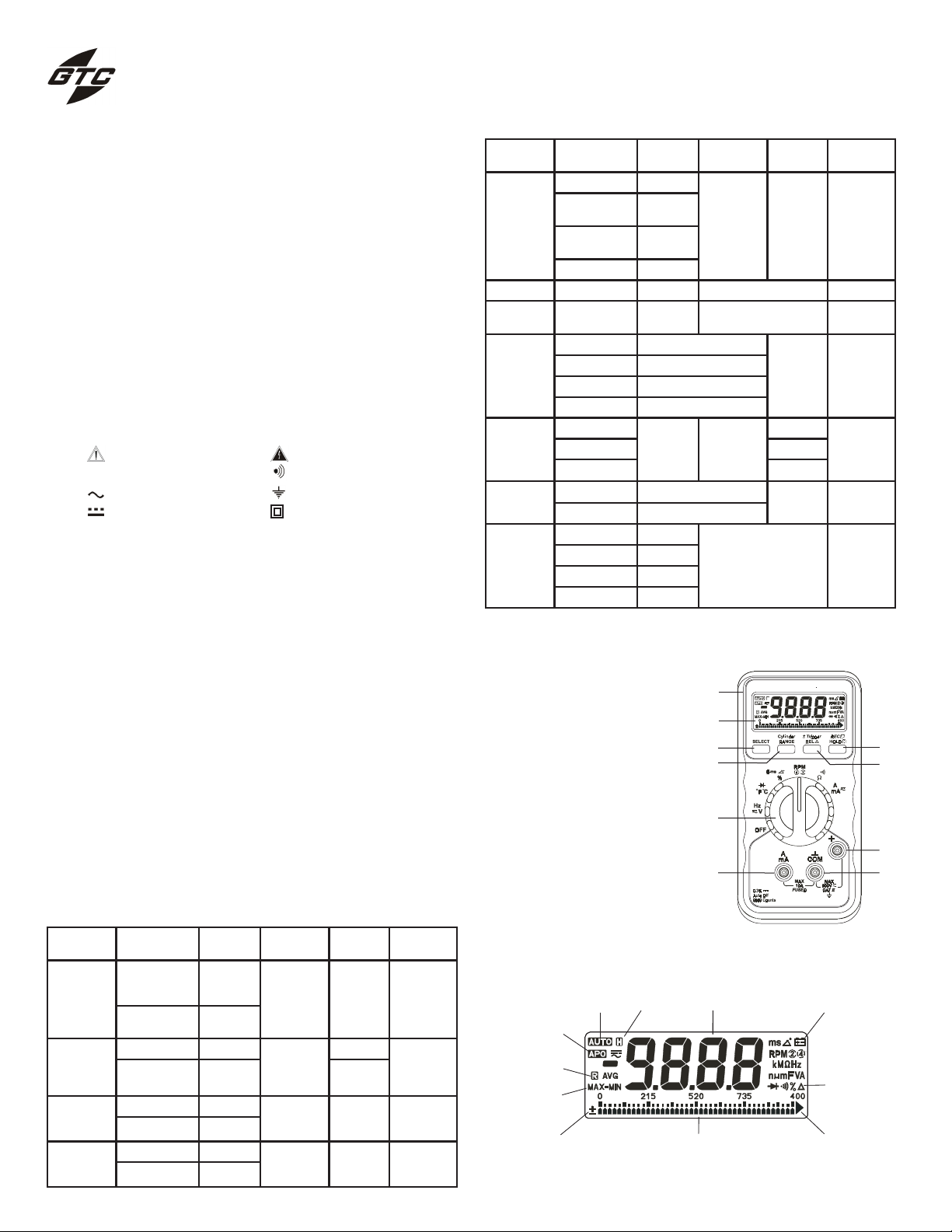

4.1 Instrument Description

1) Case

2) 4 Digit LCD display

3) Secondary Functions Button

4) Auto/Manual Select

5) Function Switch

6) Current Measurment Input

7) Common Input

8) Measurements Input

9) Trigger and Rel. Button

10) Hold and Max/Min. Button

Input

Impedance

-

1, 2, 20 and 200 Vrms

Selectable threshold

0.05mS+1

0.05mS+1

K-Type Thermocouple

1

2

3

4

5

6

Probe

Remarks

1.3 V

Max. Test

Voltage

(2.7 V in

999.9Ω

range)

Selectable

+/- Slope,

and

Number of

Cylinders

RPM 4

RPM 2

RPM 2M

1 to 12

Cyl.

Overload

Protection

600 Vrms

600 Vrms

600 Vrms

600 Vrms

600 Vrms

600 Vrms

10

9

8

7

Function Range Accuracy

999.9 mV,

DC Voltage

AC Voltage

DC Current

AC Current

9.999 V,

99,99V

600 V 0.3%+5

999.9 mV 2.5%+5 10 MΩ,

9.999 mV,

99.99 V

4000 mA

10.00 A

4000 mA

10.00 A

0.3%+3

2.5%+5 50~500Hz

1.2%+6

0.8%+4

2.5%+10

1.2%+3

Input

Impedance

10 MΩ,

16MΩ for

999.9 mV

range

16MΩ for

999.9 mV

range

0.03V/A

Burden

Voltage

0.03V/A

Burden

Voltage

Remarks

- 600 Vrms

50~200Hz

-

-

Overload

Protection

600 Vrms

10 A - 250V

Fast Acting

Fuse

10 A - 250V

Fast Acting

Fuse

4.2 Display Description

Autoranging Hold

Auto Power Off

Record

Function

Max./Min.

and Average

Bar Graph/Trigger Polarity

Digital

Readout

Analog

Bar Graph

Low Battery

Relative

Measurement

Bar Graph

Overflow

Page 2

4.3 Measurement Procedures

CAUTION: Maximum Input Voltage is 600Vrms,do not exceed

this rating to avoid personal injuries or damage to the

instrument. The FUNCTION switch should be set to

the range you want to test before the operation.

CAUTION: Always ensure that the correct terminals are used

for the type of measurement to be made. Avoid

making connections to “live” circuits whenever

possible.When making current measurements ensure that the circuit is not “live” before opening it in

order to connect the test leads.

Measuring

resistance

and

continuity

M e as u r in g

Voltages

The measurement will be shown in the LCD Display when the

•

probe are connected. For Continuity Test a continuous beeping

sound indicates that the measured resistance is < 100 Ω.

4.3.4 Frequency measurement

Connect the black test lead to the “COM” socket and red test lead

•

to the “+” socket.

Set the FUNCTION switch to the “ V Hz” function.

•

The instrument default to VDC measurement. To measure

•

frequency press the SELECT button momentarily twice, and the

Hz will appear on the display.

Connect the read probe into the “+” input and the black probe

•

into the “COM” input.

When the frequency function is selected, the trigger level defaults

•

to 1 Volt. If the readings are unstable or if there is not reading at

all, it maybe be necesary to change the trigger level. To change

the trigger level, press the “RANGE” button once to display the

selected level, and then press the “RANGE” button within 1

second. Every time the button is pressed the trigger level will

change to the next value (1V, 2V, 20V and 200V).

Connect the test leads across the source or circuit under

•

measurement. Readout will show on the LCD display.

4.3.5 Tach (RPM) Measurement

4.3.1 DC/AC Voltage measurement

Connect the black test lead to the “COM” socket and red test lead

•

to the “+” socket.

Set the FUNCTION switch to the “ V Hz” function.

•

The instrument default to DC measurement. To measure AC

•

Voltages press the SELECT button momentarily.

• Connect the read probe into the “+” input and the black probe

into the “COM” input.

Connect the test leads across the source or load under

•

measurement. Readout will show on the LCD display.

4.3.2 DC Current measurement

Connect the black test lead to the “COM” socket and red test lead

•

to the “A mA” input connector. .

Set the FUNCTION switch to the “mA A ” function.

•

Connect the test leads in series with the source or load under

•

measurement.

The instrument default to DC measurement. To measure AC

•

Current press the SELECT button momentarily.

Connect the test leads in series with the source or load under

•

measurement. Readout will show on the LCD display.

4.3.3 Resistance measurement and Continuity Test

CAUTION: Maximum Input Voltage for this function is 600 Vrms

do not exceed this rating to avoid personal injuries or

damage to the instrument. Also ensure there is no

power applied to the component or circuit and all

capacitors are discharged.

Connect the black test lead to the “COM” socket and red test lead

•

to the “+” socket.

Set the FUNCTION switch to the “Ω ” position. The instrument

•

will default to Resistance measurement, to select the Continuity

Test function press the “SELECT” button momentarily.

Connect the test leads across the componet or circuit under

•

measurement.

Taking Tach

Readings

Connect the black lead plug of the inductive pick-up into the

•

“COM” socket and red lead plug to the “+” socket.

Set the FUNCTION switch to the position.

•

Press the SELECT button to select through “RPM ” for 4

•

strockes, “RPM ” for 2 strockes and DIS, and “RPM M” for 2

strockes with waste spark ignition system engines.

Open the Inductive Pick-up clamp and insert a spark plug wire

•

inside, observing that the arrow on the Inductive Pick-up points

to the spark plug, and then close the clamp making sure that the

clamp jaws are completely close. The RPM will be shown in the

LCD Display when the engine is running.

4.3.6 Dwell Angle Measurement

Connect the black test lead to the “COM” socket and red test lead

•

to the “+” socket.

Set the FUNCTION switch to the “ %” position, and press

•

the SELECT button once to select the Dwell function.

The Number of cylinders defaults to 4 (4-\). Press the “Cylinder

•

/RANGE” switch to display the cylinders setting, and immediately

press the button again to select the number of cylinders (1

through 12) of the engine under test.

Page 3

Measuring

Dwell

Connect the black test lead to the vehicle ground or negative (-)

•

terminal of the battery, and the red test lead to the breaker point of

the distributor or negative (-) terminal of the ignition coil.

To display Dwell as a percentage (%), press the “SELECT” button

•

once. To display reading in degrees again, press the “SELECT”

button twice.

To change the trigger level and slope please refer to Section 4.4.4

•

and 4.4.5 of this manual.

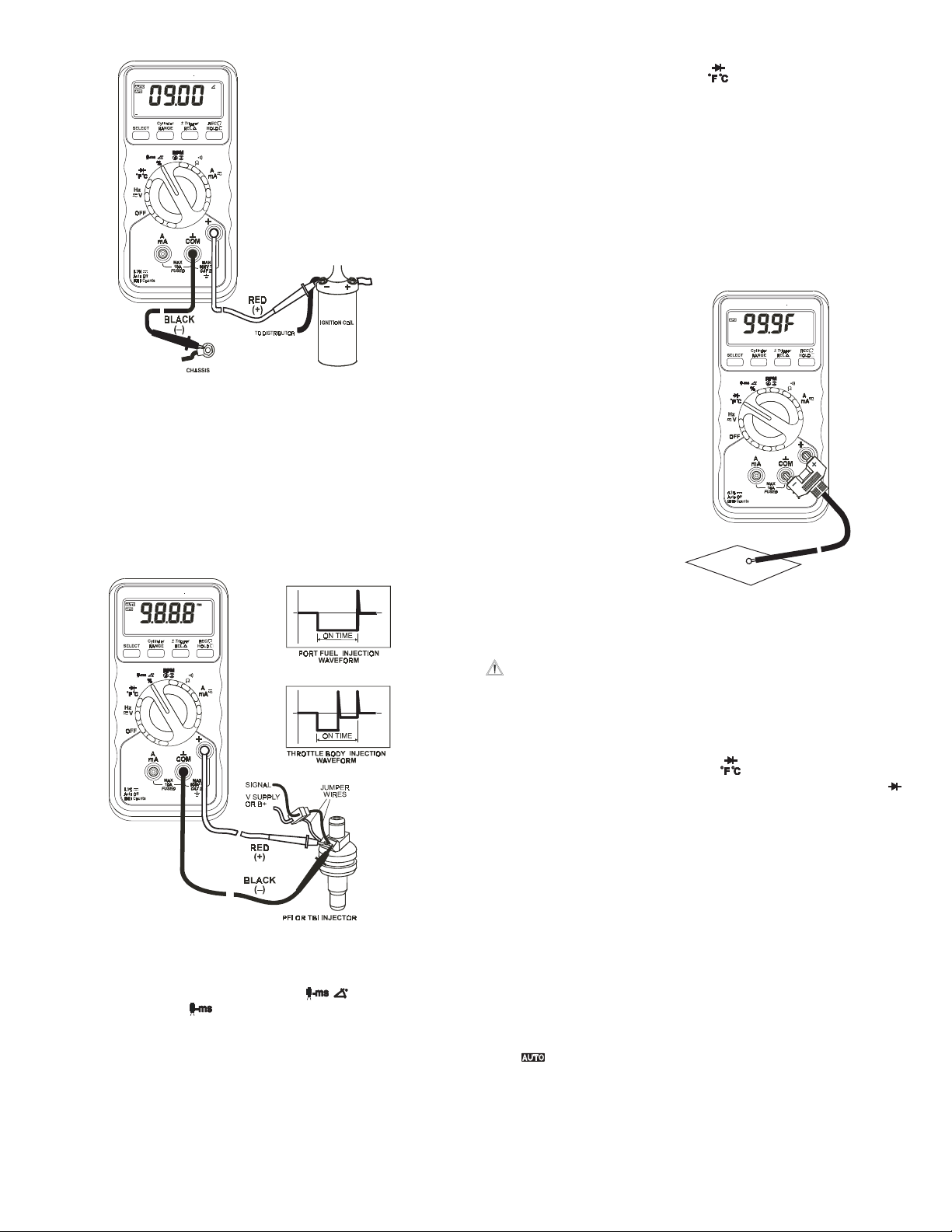

4.3.8 Temperature Measurement

Set the FUNCTION switch to the “ ” position.

•

The instrument defaults to ºC units, to select ºF units press the

•

“SELECT” button once. To return to ºC units press the “SELECT”

button twice.

Connect the K-type thermocouple probe connector into the “COM”

•

and “+” sockets observing the polarity of the connector and

socket.

Make contact between the thermocouple at the end of the

•

probe the object to measure. To obtain accurate temperature

measurements, the contact between the probe and the object to

measure should be maintained for a few seconds until the readout

on the display becomes stable.

Measuring

Temperature

4.3.7 Fuel Injector (Pulse Width) Measurement

•

•

•

•

• This function applies to both Port Fuel Injectors (PFI) and Throttle

Measuring

Pulse Width on

EFI

systems

Connect the black test lead to the “COM” socket and red test lead

to the “+” socket.

Set the FUNCTION switch to the “ %” position, the

instrument default to , with units in ms (milliseconds).

Connect the black test lead to the signal wire terminal of the fuel

injector, and the red test lead to the positive supply wire terminal of

the fuel injector.

To display pulse width as a percentage (%) or duty cycle, press

the “SELECT” button twice. To display reading in ‘ms’ units again,

press the “SELECT” button again.

Body Injectors TBI). To change the trigger level and slope please

refer to Section 4.4.4 and 4.4.5 of this manual.

4.4 Other Functions

4.4.1 Diode Test

CAUTION: Maximum Input Voltage for this function is 600

Vrms, do not exceed this rating to avoid personal

injuries or damage to the instrument.

Connect the black test lead to the “COM” socket and red test lead

•

to the “+” socket.

Set the FUNCTION switch to the “ ” position. The instrument

•

will default to temperature measurement in ºC units, to select

(diode test) press the “SELECT” button twice.

Forward voltage drop test: Connect the test leads across the

•

diode observing the polarity: red probe to the anode (+) of the

diode and black test lead to the cathode (-) of the diode under test.

The readout of a good silicon diode should be between 0.4 to 0.9

V. A readind outside this range may indicate a defective diode.

Reverse Voltage test: Connect the test leads across the diode

•

observing the polarity: red probe to the Catode (-) of the diode and

black test lead to the anode (+) of the diode under test. A diode in

good condition should produce a “OL“ reading, other reading may

indicate a damaged or defective diode.

4.4.2 Manual and Autoranging Operation

To lock the present range, press the “RANGE” button once, and

•

the display indicator will turn off. Pressing the “RANGE” button

will step through the ranges. Pressing and holding the “RANGE”

button for 1 second or more will restore the meter to autorange

mode.

NOTE: When the instrument is in Record, Hold or Relative mode,

•

pressing the “RANGE” button will cause the meter to exit these

operations.

•

Page 4

4.4.3 Relative measurements

Pressing the “REL ” button once enter the relative measurement

•

mode. In this mode the instrument offsets all the following

measurements with the value present at the time the relative mode

was entered.

The relative mode can be used conmbined with any other function,

•

including MAX, MIN, MAX-MIN and AVG readings of the RECORD

function.

Pressing the “REL ” button again exits this function.

•

4.4.4 Trigger Level selection

When measuring Frequency, Dwell or Pulse Width, and the

•

readings are unstable or if there is not reading at all, it maybe be

necesary to change the trigger level.

To change the trigger level, press the “RANGE” button once to

•

display the selected level, and then press the “RANGE” button

within 1 second. Every time the button is pressed the trigger level

will change to the next value (1V, 2V, 20V and 200V).

4.4.5 Trigger Slope selection

The slope function is useful when performing Dwell and Pulse

•

Width (Fuel Injector) measurements. For example, if you are

measuring a signal with 10% duty cycle when the trigger is set

to +, the same waveform will show a duty cycle of 90% when the

trigger is set to .

To Toggle between Trigger + and , press and hold the + Trigger

•

(REL ) for 1 second or more.

4.4.6 Hold Display Data

Pressing the “HOLD” button, will toggle the hold display funcion on

•

and off.

When the HOLD function is activated, the readout on the display

•

will be maintained or ‘freezed’ until the function is turned off by

pressing the “HOLD” button again.

4.4.7 Record Mode

Pressing the “REC ” button for 1 second or more will activate the

•

RECORD mode, and the indicator will appear in the display.

When the RECORD function is activated, the instrument will beep

•

when a new maximum or minimum is detected.

To read the MAX, MIN, MAX-MIN and AVG, press the REC

•

button to step through the recorded measurements.

Pressing the “REC ” button again for 1 second or more will exit

•

the RECORD mode.

4.4.8 Auto Power Off

This function is included to extend the battery life when the

•

instrument is not in use.

The instrument will turn OFF automatically and sound a warning

•

beep, after approxiamtely 4 minutes of no activity (i.e. rotary

switch or buttons operations, or no significant meter reading

changes), .

The instrument is turned automatically ON if the FUNCTION

•

switch is operated.

5. MAINTENANCE

CAUTION: Before attempting battery removal or replacement,

disconnect test leads and remove the instrument from

any energized circuit to avoid shock hazard.

5.1 Battery Replacement

To replace the battery, remove the 3 screws of the back cover (back

•

of the case), and lift the end of the case nearest to the input sockets,

until it unsnaps from the case top. Remove the battery.

Replace with a new 9 V alkaline battery type NEDA 1604 or IEC6F22

•

observing the proper polarity from the diagram on the label inside

the battery compartment.

Reinstall the case cover, ensuring that all gaskets are properly

•

seated, and that the snaps on the case top (near the LCD Display)

are engaged. Replace and tighten the securing screws.

5.2 Fuse replacement

To replace the fuse, remove the 3 screws of the back cover (back of

•

the case), and lift the end of the case nearest to the input sockets,

until it unsnaps from the case top.

Replace new fuse only with the identical type and rating.

•

F2=10A: Type IEC60127-2 or UL248-14 (6.3x25.4mm)

fast acting fuse, rated at 10A/250V.

Reinstall the case cover, ensuring that all gaskets are properly

•

seated, and that the snaps on the case top (near the LCD Display)

are engaged. Replace and tighten the securing screws.

5.3 Cleaning And Storage

Periodically wipe the case with a soft damp cloth and mild house-

•

hold cleanser. Do not use abrasives or solvents. Ensure that no

water gets inside the instrument to prevent possible shorts and

damage.

• If the instrument is not to be use for long periods of time ( 60 days or

more) to avoid damage due to battery leakage, remove the battery

from the instrument and store it separately.

6. WARRANTY

One year limited warranty, excluding batteries and fuses. For details see Standard Warranty Information in our webpage or request

a printed copy.

4.4.9 External power lines noise filtering

When the RECORD function is activated, the instrument will turn

•

off the AUTO POWER OFF function, and the indicator in the

display will not show.

To read the MAX, MIN, MAX-MIN and AVG, press the REC

•

button to step through the recorded measurements.

Pressing the “REC ” button again for 1 second or more will exit

•

the RECORD mode.

General Technologies Corp.

#121 - 7350 72nd Street Tel.: (604) 952-6699

Delta, BC Fax: (604) 952-6690

Canada V4G 1H9 www.generaltechnologies.net

© Copyright 2001 General Technologies

Loading...

Loading...