RMB2S THRU RMB4S

MINIATURE GLASS PASSIVATED SINGLE-PHASE SURFACE MOUNT

FAST RECOVERY BRIDGE RECTIFIER

Reverse Voltage - 200 to 400 Volts Forward Current - 0.5 Ampere

FEATURES

♦ Plastic package has Underwriters Laboratory Flammability

Classification 94V-0

♦ This series is UL recognized under Component Index,

file number E54214

♦ Glass passivated chip junctions

♦ High surge overload rating: 35A peak

♦ Saves space on printed circuit boards

♦ Fast recovery, low loss switching

♦ High temperature soldering guaranteed:

260°C/10 seconds at 5 lbs. (2.3kg) tension

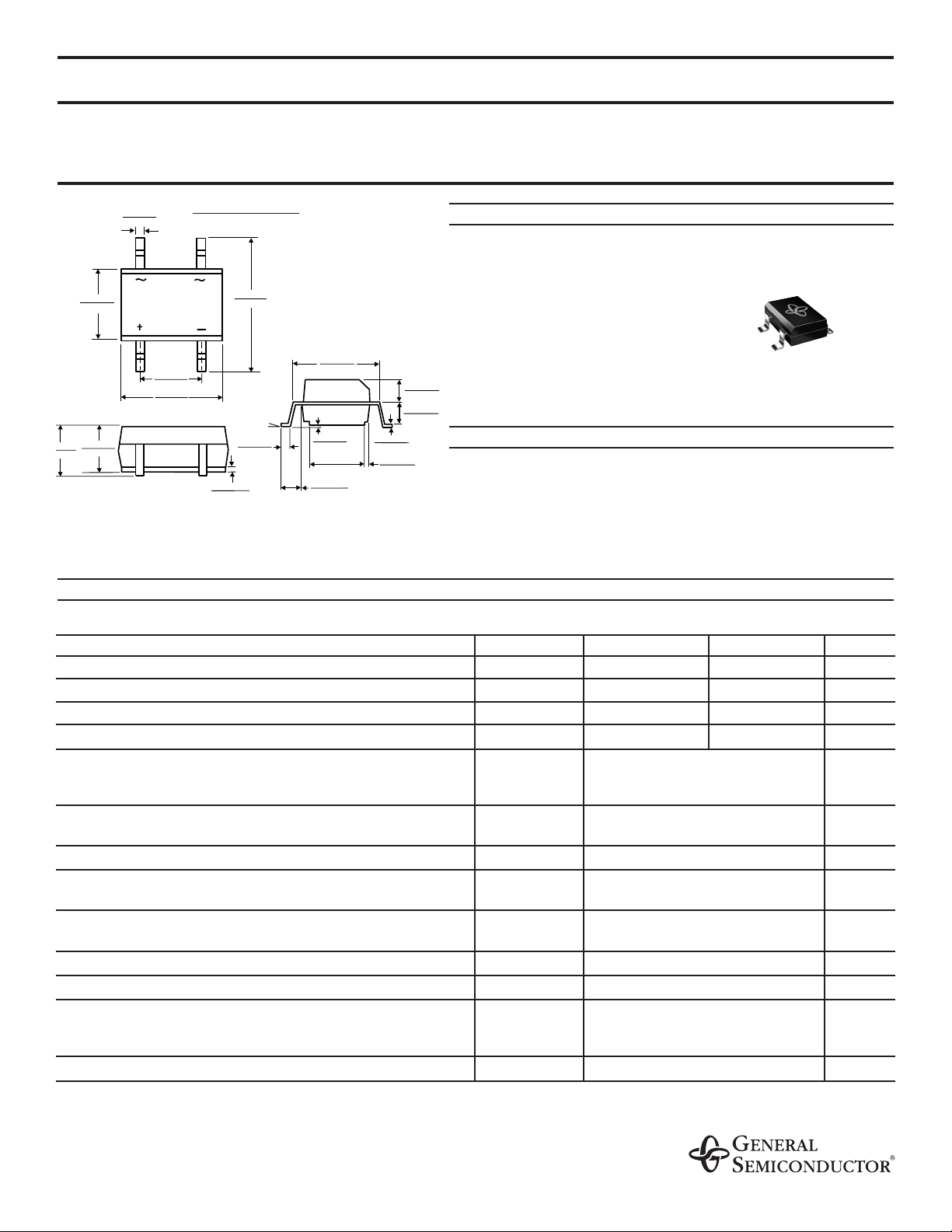

MECHANICAL DATA

Case: Molded plastic body over passivated junctions

Terminals: Plated leads solderable per MIL-STD-750,

Method 2026

Polarity: Polarity symbols marked on body

Mounting Position: Any

Weight: 0.0078 ounce, 0.22 gram

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified.

SYMBOLS RMB2S RMB4S UNITS

Device marking code R2 R4

Maximum repetitive peak reverse voltage V

RRM

200 400 Volts

Maximum RMS voltage V

RMS

140 280 Volts

Maximum DC blocking voltage V

DC

200 400 Volts

Maximum average forward output rectified

current at T

A

=30°C - on glass-epoxy P.C.B.

(NOTE 1)

I

(AV)

0.5 Amp

- on aluminum substrate

(NOTE 2)

0.8

Peak forward surge current 8.3msec single half sinewave superimposed on rated load (JEDEC Method)

I

FSM

30.0 Amps

Rating for fusing (t<8.3ms) I

2

t 5.0 A2sec

Maximum instantaneous forward voltage drop

per leg at 0.4A

V

F

1.25 Volts

Maximum DC reverse current at T

A

=25°C 5.0

rated DC blocking voltage per leg T

A

=125°C

I

R

100

Maximum reverse recovery time

(NOTE 3)

t

rr

150 ns

Typical junction capacitance per leg

(NOTE 4)

C

J

13.0 pF

Typical thermal resistanceper leg

(NOTE 1)

R

ΘJA

85.0

(NOTE 2)

R

ΘJA

70.0 °C/W

(NOTE 1)

R

ΘJL

20.0

Operating junction and storage temperature range T

J

, T

STG

-55 to +150 °C

NOTES:

(1) On glass epoxy P.C.B. mounted on 0.05 x 0.05" (1.3 x 1.3mm) pads

(2) On aluminum substrate P.C.B. with an area of 0.8 x 0.8" (2.0 x 2.0mm) mounted on 0.05 x 0.05” (1.3 x 1.3mm) solder pad

(3) Reverse recovery test conditions: I

F

=0.5A, IR=1.0A, Irr=0.25A

(4) Measured at 1.0 MHz and applied reverse voltage of 4.0 Volts

0.029 (0.74)

0.017 (0.43)

0-8

o

0.049 (1.24)

0.039 (0.99)

0.062 (1.57)

0.058 (1.47)

0.016 (0.41)

0.006 (0.15)

0.018 (0.46)

0.014 (0.36)

0.008 (0.20)

0.004 (0.10)

0.117 (2.97)

0.107 (2.72)

0.058 (1.47)

0.054 (1.37)

0.252 (6.40)

0.272 (6.90)

0.106 (2.70)

0.090 (2.30)

0.0075 (0.19)

0.0065 (0.16)

0.105 (2.67)

0.095 (2.41)

0.195 (4.95)

0.179 (4.55)

0.144 (3.65)

0.161 (4.10)

0.205 (5.21)

0.195 (4.95)

4 (2.90)

0.038 (0.96)

0.019 (0.48)

Case Style MBS

Dimensions in inches and (millimeters)

PATENT PENDING PATENT PENDING PATENT PENDING

9/8/98

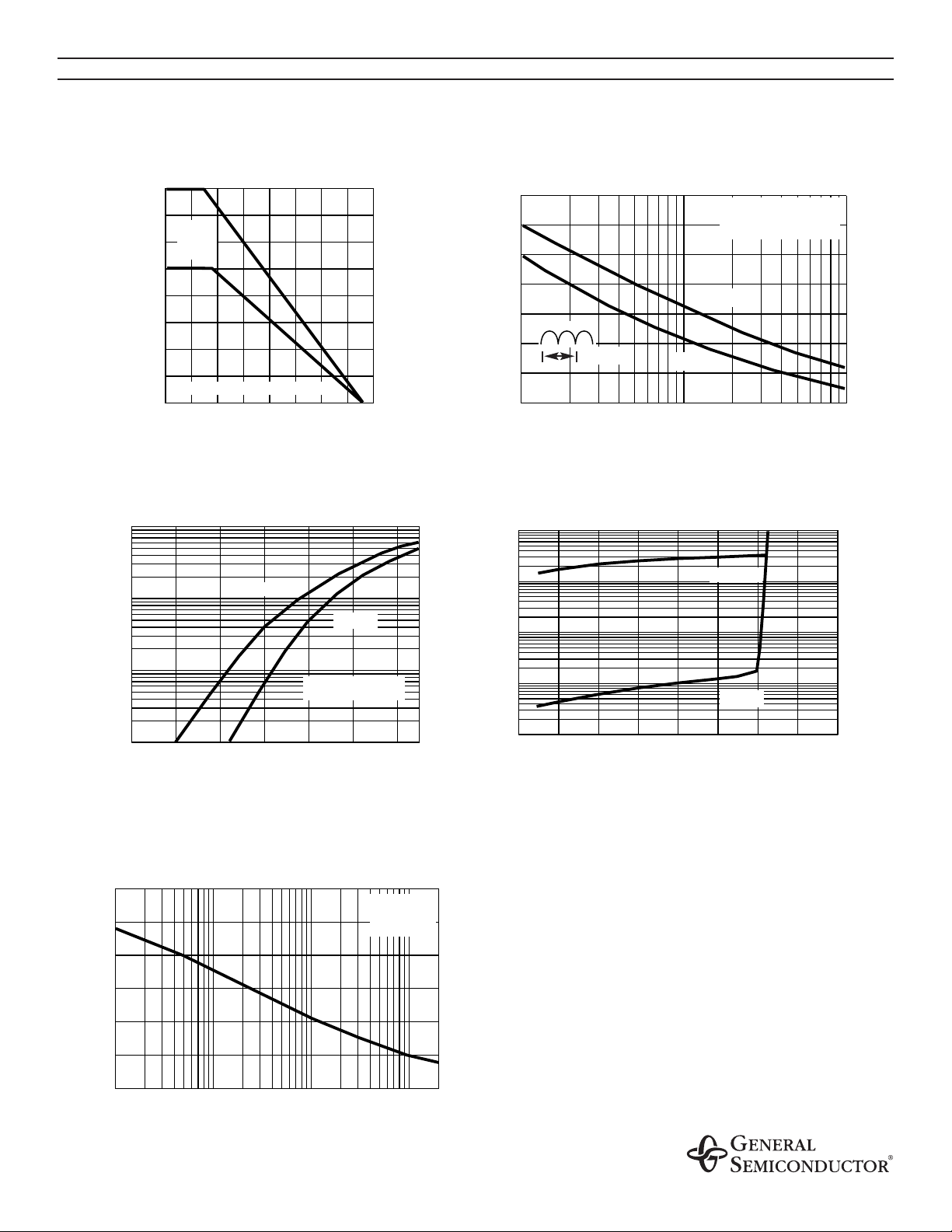

RATINGS AND CHARACTERISTIC CURVES RMB2S THRU RMB4S

FIG. 1 - DERATING CURVE FOR OUTPUT

RECTIFIED CURRENT

AMBIENT TEMPERATURE, °C

PEAK FORWARD SURGE CURRENT,

AMPERES

FIG. 2 - MAXIMUM NON-REPETITIVE PEAK FORWARD SURGE

CURRENT PER LEG

NUMBER OF CYCLES

AVERAGE FORWARD RECTIFIED CURRENT,

AMPERES

FIG. 3 - TYPICAL FORWARD VOLTAGE

CHARACTERISTICS PER LEG

FIG. 4 - TYPICAL REVERSE LEAKAGE CHARACTERISTICS

PER LEG

FIG. 5 - TYPICAL JUNCTION CAPACITANCE

PER LEG

INSTANTANEOUS FORWARD CURRENT,

AMPERES

INSTANTANEOUS REVERSE LEAKAGE CURRENT,

MICROAMPERES

JUNCTION CAPACITANCE, pF

INSTANTANEOUS FORWARD VOLTAGE,

VOLTS

PERCENT OF RATED PEAK REVERSE

VOLTAGE, %

REVERSE VOLTAGE, VOLTS

TA=40°C

SINGLE HALF SINE-WAVE

(JEDEC Method)

TJ=125°C

TJ=25°C

TJ=25°C

f=1.0 MHz

Vsig=50mVp-p

TJ=150°C

TJ=25°C

PULSE WIDTH=300µs

1% DUTY CYCLE

f=60 H

Z

f=50 H

Z

1.0 CYCLE

GLASS

EPOXY

P.C.B.

RESISTIVE OR INDUCTIVE LOAD

10

1

0.1

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0 20 40 60 80 100 120 140 160

35

30

25

20

15

10

5.0

0

1

10

100

10

1

0.1

100

0.01

30

25

20

15

10

5.0

0

0.1

0.8

0.6

0.4

0.2

1

1.0 1.2

10

1.4

100

200

0.01

020

40

80 100 120 140 160

60

Loading...

Loading...