General Semiconductor GI758, GI756, GI754, GI752, GI751 Datasheet

...

GI750 THRU GI758

HIGH CURRENT PLASTIC RECTIFIER

Reverse Voltage - 50 to 800 Volts Forward Current - 6.0 Amperes

FEATURES

♦ Plastic package has Underwriters Laboratory

Flammability Classification 94V-0

♦ High forward current capability

♦ Diffused junction

♦ Construction utilizes void-free

molded plastic technique

♦ High surge current capability

♦ High temperature soldering guaranteed:

250°C/10 seconds, 0.375" (9.5mm) lead length,

5 lbs. (2.3kg) tension

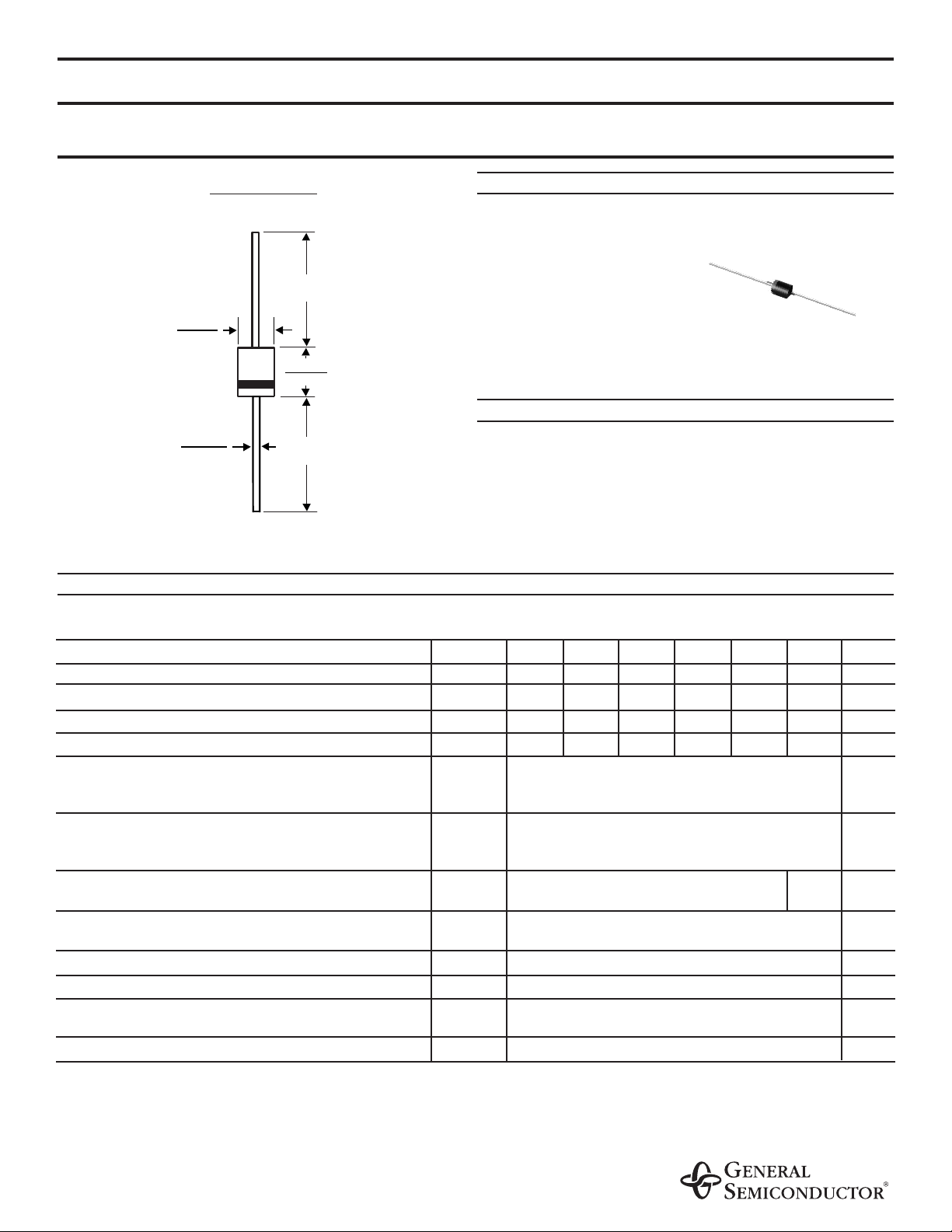

MECHANICAL DATA

Case: Void-free molded plastic body

Terminals: Plated axial leads, solderable per MIL-STD-750,

Method 2026

Polarity: Color band denotes cathode end

Mounting Position: Any

Weight: 0.07 ounce, 2.1 grams

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified.

SYMBOLS GI750 GI751 GI752 GI754 GI756 GI758 UNITS

Maximum repetitive peak reverse voltage V

RRM

50 100 200 400 600 800 Volts

Maximum RMS voltage V

RMS

35 70 140 280 420 560 Volts

Maximum DC blocking voltage V

DC

50 100 200 400 600 800 Volts

Maximum non-repetitive peak reverse voltage V

RSM

60 120 240 480 720 1200 Volts

Maximum average forward rectified current at

T

A

=60°C, P.C.B. mounting

(FIG. 1)

6.0

T

L

=60°C, 0.125" (3.18mm) lead length

(FIG. 2)

I

(AV)

22.0

Amps

Peak forward surge current

8.3ms single half sine-wave superimposed on I

FSM

400.0 Amps

rated load (JEDEC Method)

Maximum instantaneous forward voltage at 6.0A 0.90 0.95

100A

V

F

1.25 1.30

Volts

Maximum DC reverse current T

A

=25°C 5.0 µA

at rated DC blocking voltage T

A

=100°C

I

R

1.0 mA

Typical junction capacitance

(NOTE 1)

C

J

150.0 pF

Typical reverse recovery time

(NOTE 2)

t

rr

2.5 µs

Typical thermal resistance

(NOTE 3)

R

ΘJA

20.0

R

ΘJL

4.0

°C/W

Operating junction and storage temperature range T

J

, T

STG

-50 to +150 °C

NOTES:

(1) Measured at 1.0 MHz and applied reverse voltage of 4.0 Volts

(2) Reverse recovery test conditions:I

F

=0.5A, IR=1.0A, Irr=0.25A

(3) Thermal resistance from junction to ambient and from junction to lead at 0.375” (9.5mm) lead length,

P.C.B. mounted with 1.1 x 1.1” (30 x 30mm) copper pads

10/12/98

Case style P600

Dimensions are in inches and (millimeters)

1.0 (25.4)

MIN.

0.360 (9.1)

0.340 (8.6)

0.360 (9.1)

0.340 (8.6)

0.052 (1.32)

0.048 (1.22)

DIA.

1.0 (25.4)

MIN.

RATINGS AND CHARACTERISTIC CURVES GI750 THRU GI758

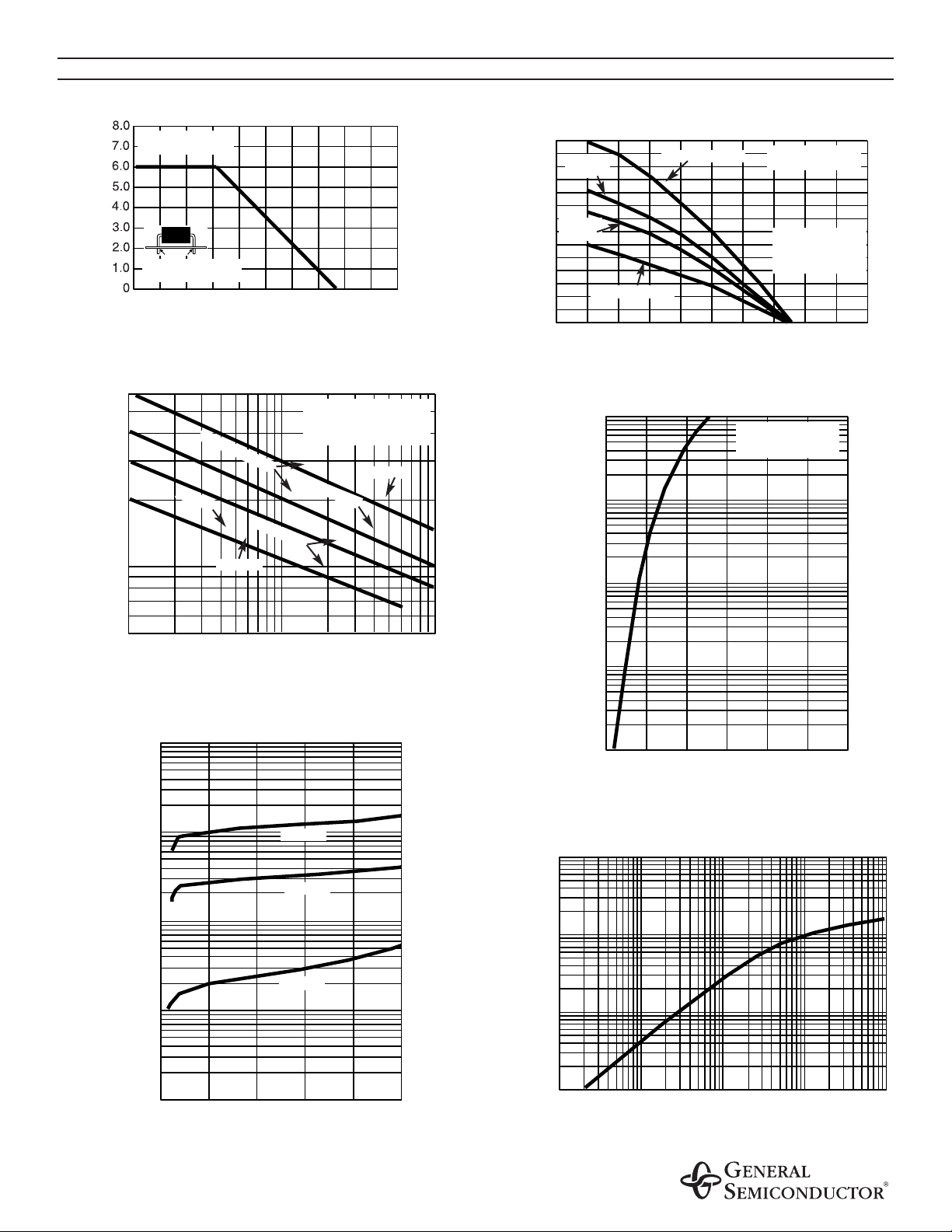

FIG.1 - MAXIMUM FORWARD CURRENT

DERATING CURRENT

AMBIENT TEMPERATURE, °C

AVERAGE FORWARD RECTIFIED CURRENT,

AMPERES

60 HZRESISTIVE or

INDUCTIVE LOAD

AVERAGE FORWARD CURRENT,

AMPERES

LEAD TEMPERATURE, °C

TJ=25°C

PULSE WIDTH=300µs

1% DUTY CYCLE

FIG. 2 - MAXIMUM FORWARD CURRENT DERATING

CURVE

FIG. 3 - MAXIMUM PEAK FORWARD SURGE CURRENT

NUMBER OF CYCLES AT 60 H

Z

PEAK FORWARD SURGE CURRENT

AMPERES

TJ=150°C

NON-REPETITIVE

REPETITIVE

TJ=25°C

1.1 x 1.1” (30 x 30mm)

COPPER PADS

T

J

=25°C

T

J

=150°C

L=0.625”(15.8mm)

L=0.125” (3.18mm)

60 HZRESISTIVE or

INDUCTIVE LOAD

BOTH LEADS

ATTACHED to HEAT

SINKS with LENGTH

as SHOWN “L”

L=0.25”

(6.35mm)

L=0.375”

(9.5mm)

TJ=100°C

TJ=125°C

TJ=25°C

V

RRM

may be APPLIED

BETWEEN EACH CYCLE of

SURGE, the T

J

NOTED is T

J

PRIOR to SURGE

INSTANTANEOUS FORWARD VOLTAGE,

VOLTS

FIG. 4 - TYPICAL INSTANTANEOUS

FORWARD CHARACTERISTICS

INSTANTANEOUS FORWARD CURRENT,

AMPERES

FIG. 6 - TYPICAL TRANSIENT THERMAL IMPEDANCE

t, PULSE DURATION, sec.

TRANSIENT THERMAL IMPEDANCE, °C/W

FIG. 5 - TYPICAL REVERSE CHARACTERISTICS

PERCENT OF RATED PEAK REVERSE VOLTAGE, %

INSTANTANEOUS REVERSE CURRENT,

MICROAMPERES

600

0 20 40 60 80 100 120 140 160 180 200

28

24

20

16

12

8.0

4.0

0

0 20 40 60 80 100 120 140 160 180 200

100

10

100

50

1

100

10

1

10

1

100

0.1

0.01

0.6 0.8 1.0 1.2 1.4 1.6 1.8

100

10

0.1

0.01

20

0

40

60

80

100

0.1

1

0.01

0.1

1

10

100

Loading...

Loading...