General Pump TX-63 User Manual

GENERAL PUMPA member of the Interpump Group

8

SERVICING INSTRUCTIONS

SERVICING PUMP PROCEDURES

TX Series “63”

Triplex Plunger Pump

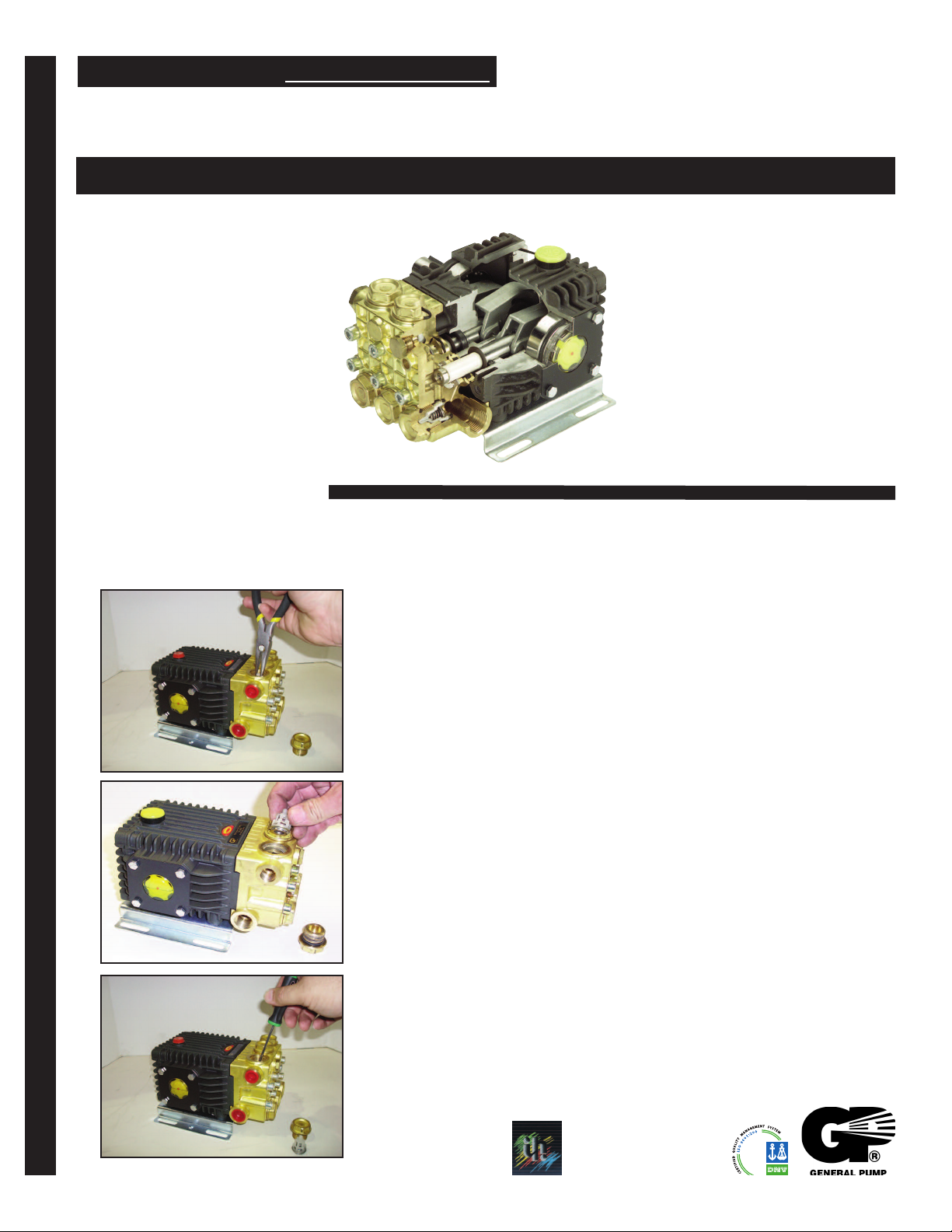

Valve Replacement: All inlet and discharge valves can be serviced without disrupting the inlet or discharge

plumbing. The inlet and discharge valves are identical in all 63 series models.

To service any valve:

1) Remove valve cap and examine o-ring. Replace o-ring if there is any

evidence of cuts, abrasions, distortion or wear.

2) Remove valve assembly (retainer, spring, valve, valve seat) from

valve cavity.

3) Remove valve seat o-ring from valve cavity.

4) Inspect manifold for wear or damage.

5) Install new o-ring in valve cavity.

TRIPLEX TRIPLEX

6) Insert valve assembly into valve cavity.

7) Replace valve cap and torque to specification.

NOTE: Only one valve kit is necessary to repair all the valves

in the pump. The kit includes new o-rings, valve seat, poppet, spring and

retainer. All are pre-assembled.

Ref 300685 Rev. B

General Pump

is a member of

the Interpump Group

02-12

TX Series “63”

Servicing Instructions

GENERAL PUMPA member of the Interpump Group

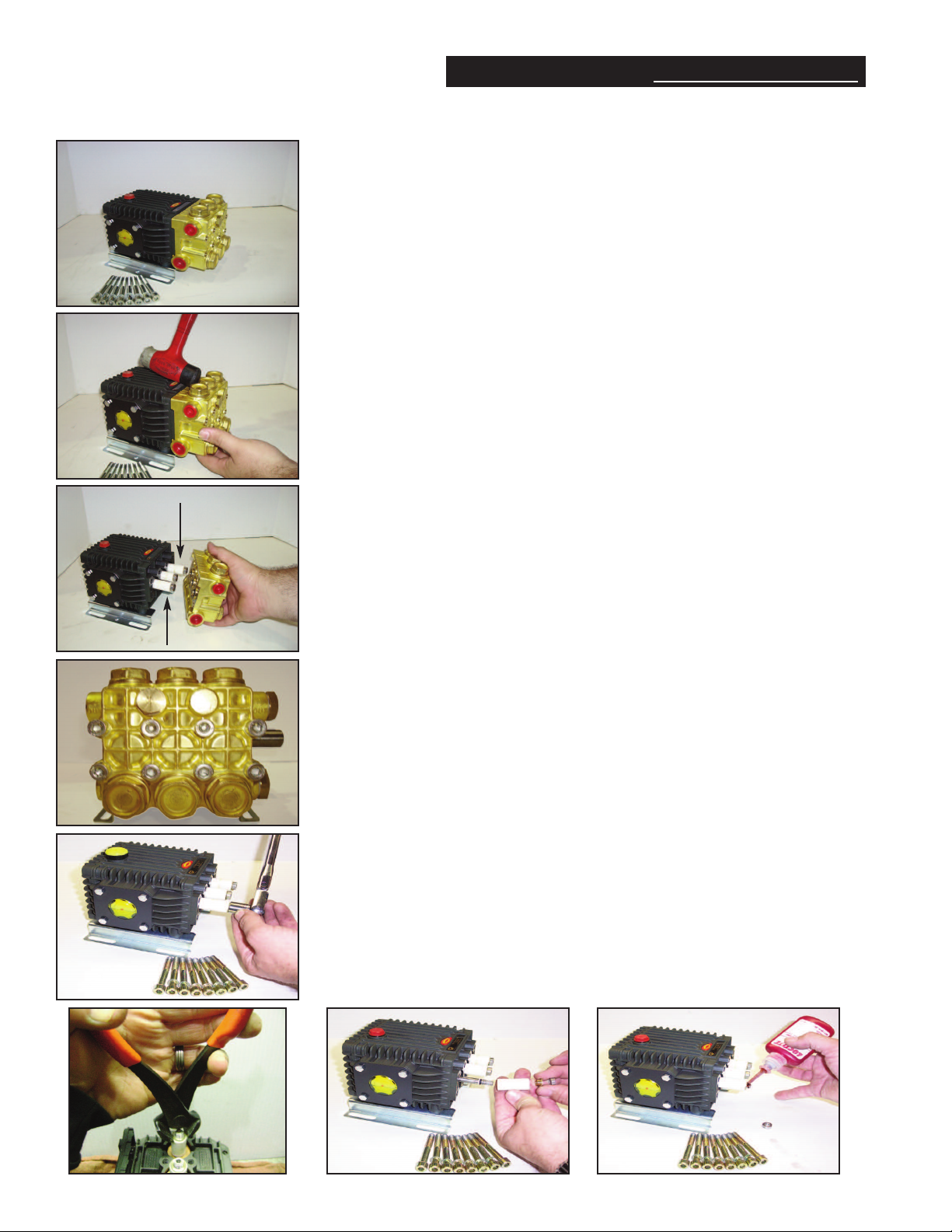

Removing/Installing Manifold:

1) Remove fasteners retaining manifold.

2) Separate manifold from crankcase.

Note: it may be necessary to rotate the crankshaft, or tap the manifold

lightly with rawhide mallet to loosen the manifold from crankcase.

Caution: When sliding head from crankcase use caution not to damage

plungers.

3) The seal assemblies may come off with the manifold. At this point

examine the ceramic plungers. Plunger’s surface should be smooth

and free from scoring, pitting, or cracks; if not, replace.

4) Coat each plunger with grease.

5) Align outside pistons in the forward position.

6) Reinstall manifold and torque to specifications per sequence

described below.

TORQUE SEQUENCE FOR TIGHTENING MANIFOLD:

14 67

5328

• Install all manifold bolts finger tight.

• Torque to 10 foot pounds in sequence as shown.

• Next torque to specification; again, in sequence.

Replacing ceramic plungers:

1) Remove the stainless steel fasteners retaining the plungers.

2) Remove the brass bushing and ceramic plunger from piston rod.

3) If copper slinger washer comes off with plunger, be certain this is

replaced before new plunger is installed.

4) Install new o-ring and Teflon back-up ring on piston rod.

NOTE: a film of grease on the outside of the o-ring insures a better

installation.

5) Slide new plunger over the piston rod, insert new brass

bushing.

6) Apply a drop of removable anaerobic thread sealant to

threads of piston rod.

7) Install the stainless steel fasteners retaining the plungers

and torque to specifications.

Ref 300685 Rev. B

02-12

Loading...

Loading...