MH

8

Owner’s Manual

• Installation

• Use

• Maintenance

General Pump is a

member of the

Interpump Group

GENERAL PUMP

INDEX

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2. SYMBOL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

3. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

3.1 General warnings for safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

3.2 High pressure unit safety requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

3.3 Safety of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

3.4 General procedures for high pressure lance/gun operation . . . . . . . . . . . . . . .Page 4

3.5 Safety of maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

4. PUMP IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

5. TECHNICAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

6. DIMENSIONS AND WEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

7. GENERAL INFORMATION ABOUT SPECIFIC PUMP USE . . . . . . . . . . . . . . . . .Page 6

7.1 Water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

7.2 Maximum flow and pressure ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

7.3 Lowest operating RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

A member of the Interpump Group

MH SERIES

8. CONNECTION AND PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

9. PUMP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

9.1 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

9.2 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

9.3 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

9.4 Suction line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

9.5 Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

9.6 Delivery time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

10. START UP AND RUNNING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9

10.1 Before start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9

10.2 Starting up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9

10.3 Water leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9

11. MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

11.1 Crank mechanism maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

11.2 Fluid end maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

11.3 Pumping unit maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 12

12. SCREW CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

13. MAINTENANCE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

14. PUMP STOPPED FOR LONG TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

15. PRECAUTIONS AGAINST FREEZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

16. EXPLODED VIEWS AND PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

17. TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 17

Page 2

GENERAL PUMP

A member of the Interpump Group

MH SERIES

1. INTRODUCTION

MH high pressure water plunger pumps have been

designed for long life industrial duties and provided they

are correctly installed and maintained will give long

trouble-free operation. Read and understand this

manual before using your pump; it contains the

necessary information for the correct installation, use and

maintenance as well as some practical suggestion for

trouble shooting.

Upon receipt of your pump, inspect for overall good

condition and that no items are missing. Any missing

item or damage should be reported before installing

and starting the pump.

2. SYMBOL DESCRIPTIONS

Warning

Potential Danger

Read carefully and understand

the manual before operating

the pump

Danger

High Voltage

Danger

Wear protective mask

Danger

Wear goggles

3. SAFETY

3.1 General warnings for safe operation

The misuse of a high pressure water unit and the nonobservance of the pump installation and maintenance

instructions may cause serious damages and/or injuries

to people or properties or both.

Any Manufacturer/Operator requested to assemble/use

a high pressure water unit should be competent to do so,

should have the necessary knowledge on every high

pressure component installed in the unit and on the

precautions to be taken in order to guarantee the largest

safety margins during operation. No precaution, so far

as is reasonably practical, should be left out in the

interest of safety, both from the Manufacturer and the

Operator.

3.2 High pressure unit safety requirements

1. A safety valve should be installed in any delivery line

and should be sized to discharge or by-pass the

entire pump flow rate

2. High pressure unit components, with particular regard

for those units working outside, should be adequately

protected against rain, frost and heat.

3. Electric components and wiring should be provided

with an adequate degree of protection, able to protect

them against spray coming from any direction. They

should also be suitable for working in a wet

environment.

4. High pressure hoses and any other accessory under

pressure should be sized in accordance with the

maximum unit working pressure and must always

work within the safety margins indicated by the nose/

accessory Manufacturer.

5. High pressure hose ends should be fastened to a

steady object in order to prevent them from

dangerous sweeping around, should they burst or

come off their end fittings.

6. Proper safety guards should be provided to

adequately cover transmission joints, pulleys, belts or

auxiliary drives.

Danger

Wear protective gloves

Danger

Wear protective boots

Page 3

GENERAL PUMP

3.3 Safety of operation

The access into the area when a high pressure unit is

working should be strictly prohibited to unauthorized

personnel. The area should be suitably enclosed and its

perimeter, so far as is reasonably practical, cordoned

off and proper warning notices displayed in prominent

positions.

Personnel authorized to enter that area should have been

previously trained to do so and informed of the risks

arising from failures, misuse and any foreseeable

circumstance which may occur during operation. Before

starting the pump unit and bringing it up to pressure the

Operator is requested to carry out the following checks:

1. Make sure that a correct water supply to the pump

is provided.

2. Make sure that water inlet filters are properly clean.

3. Electrical components and wiring, with special

emphasis on connections, junction boxes, switches

and supply cables should be free from external

damage (i.e. exposed and broken wires) and

adequately protected against water.

4. High pressure hose should not show apparent

external wear and the fittings at both ends should be

free from signs of erosion or corrosion.

5. Make sure that all fluids (lubricating oil for pump and

engine, cooling water, hydraulic fluids) are at proper

levels and in good condition.

6. Make sure the safety guards are in good condition.

The work should stop immediately and the pressure must

be released in the event that leakage becomes apparent

or if any person becomes aware of an change in condition

or any hazard existing or being introduced. Any failure

must be promptly reported and then checked personnel.

3.4 General procedures for high pressure gun/lance

operation

1. The Operator should take reasonable care for the

safety of himself and of other persons who may be

affected by his acts or omission at work. His actions

should always be governed by his good sense and

responsibility.

2. The Operator should wear suitable waterproof

protective clothing, having regard to the type of work

being undertaken. The clothing set should include

adequate hand protection, suitable boots able to

ensure proper grip on wet floors, helmet provided with

full face shield, waterproof garment providing full

cover to the Operator, including his arms.

As most water jets produce noise levels in excess of

A member of the Interpump Group

MH SERIES

90 dB(A) suitable ear protection is advised.

NOTE: it must be emphasized that whereas protective

clothing provides adequate protection against spray and

flying particles, it does not constitute complete protection

protection against the direct impact of the water jet.

Additional protections in the form of suitable metal shields

or barriers may be necessary for certain jetting operation.

3. In most jetting operations it is an accepted practice

to employ a team of Operators consisting of two

members at least, in order to provide mutual

assistance in case of need and to rotate their duties

in case of long and heavy work. While the first

Operator holds the gun, the second Operator attends

the pump unit, keeping close watch on the first

Operator for signs of difficulty or fatigue, and

watching the surrounding area for intrusion by other

persons or unsafe situations. If required, he will shut

off the pressure unit until it is safe to continue.

4. The area in which the work is to proceed should be

clear of loose items and debris to prevent

tripping and slipping hazards.

5. The water jet should be directed only and always

against the workpiece even during preliminary

operating tests prior to starting work.

6. Where applicable, proper side shields should be

suitable placed to safeguard personnel and

equipment against contact with grit or particles

removed by the water jet.

7. On no account must the Operator be distracted

during operation until the jet has been stopped.

Personnel having reason to enter the water jetting

area should wait until the jet is stopped and his

presence known.

8. Each team member must always be aware of the

actions and intentions of other team members in order

to prevent any dangerous misunderstanding occurring

during jetting operation.

9. The pump unit should not be started and brought up

to pressure unless each team member is in his

designated position, the nozzle directed to the

workpiece and the lance or gun securely held.

3.5 Safety of maintenance

Apart from the working pressure regulation no attempt

should be made to adjust any nut, hose, fitting, etc., while

that part of the system is under pressure. The pump

should be stopped and any pressure in the line released

prior to making any adjustments.

1. The high pressure water unit should be maintained in

accordance with the Manufacturer’s instructions.

2. The unit should be maintained only by competent

personnel

3. Service and maintenance should be carried out with

proper tools in order to prevent any damage on high

pressure connections and fittings.

4. Use of other than original spar parts is strictly

forbidden.

Page 4

GENERAL PUMP

A member of the Interpump Group

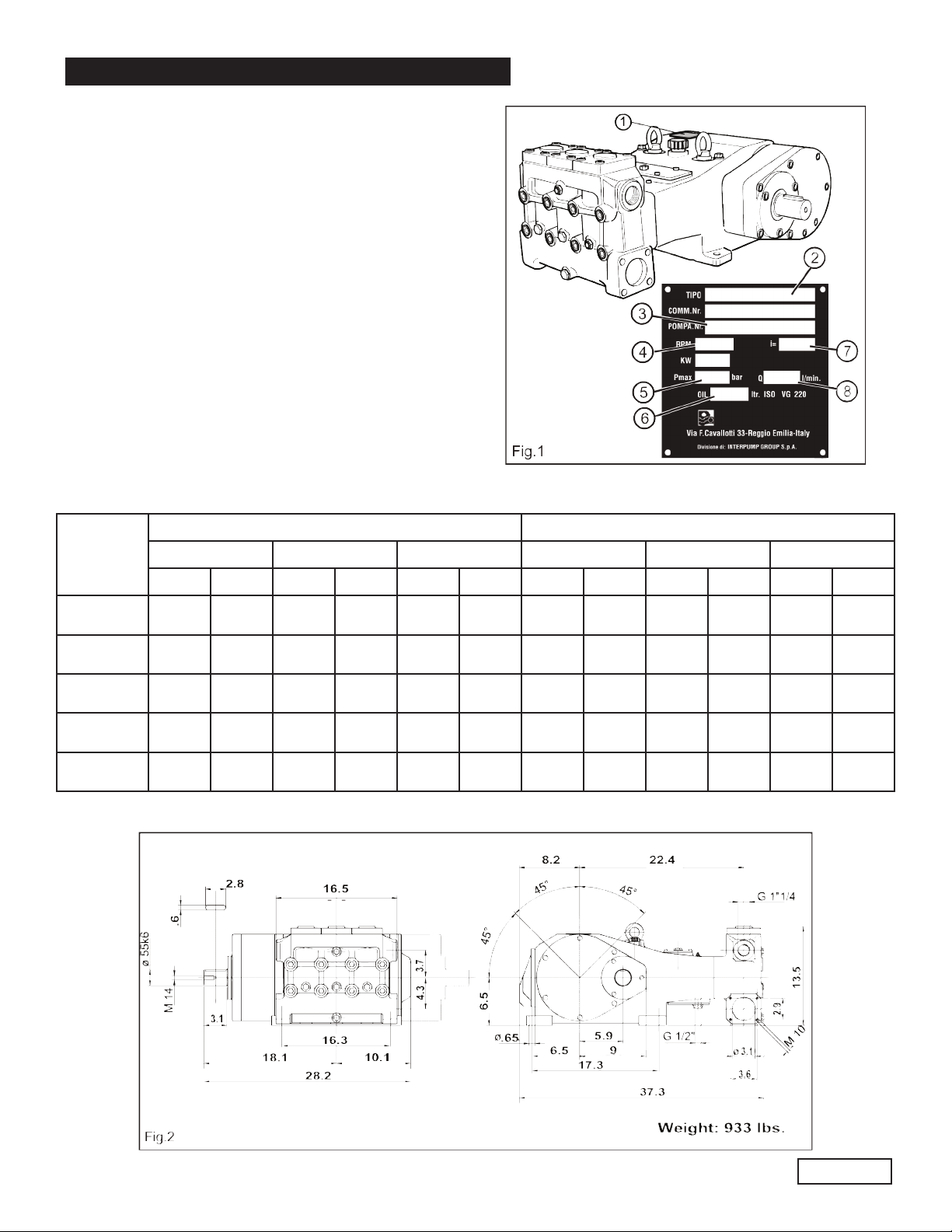

4. PUMP IDENTIFICATION

Each pump is fitted with a rating plate (see Fig. 1)

containing the following information:

2. pump model and version

3. serial number

4. max RPM

5. max operating pressure (bar)

6. oil capacity (ltr) and oil specification

7. gear box ratio

8. max flow rate (l/min)

Pump model, pump version and serial number should

be specified when ordering spare parts. Should the pump

be modified (i.e by changing the original version) than

any change should be mentioned on the rating plate for

future reference.

5. TECHNICAL FEATURES

MH SERIES

1800 RPM (R = 1:3.29) 1500 RPM (R = 1:2.65)

Model

MH45 49.4 187 4350 300 147 108 51.2 194 4350 300 152 112

MH50 61.0 231 3600 250 151 111 63.4 240 3500 240 151 111

MH55 74.0 280 2950 205 149 110 76.6 290 2900 200 152 112

MH60 88.0 333 2550 175 152 112 91.1 345 2400 165 149 110

MH65 103 391 2100 145 148 109 107 405 2050 140 148 109

Flow Rate Pressure Power Flow rate Pressure Power

GPM l/min PSI bar Hp kW GPM l/min PSI bar Hp kW

6. DIMENSIONS AND WEIGHT

Page 5

GENERAL PUMP

A member of the Interpump Group

MH SERIES

7. GENERAL INFORMATION ABOUT PUMP

USE

The MH pump has been designed to pump fresh filtered

water at room temperature.

7.1 Water temperature

Water temperature is critical for the pump life, the higher it

is, the more likely it is to crate cavitation, resulting in

premature seal and valve failures.

Below is the temperature chart

and relevant limitations:

<104oF

from

104oF

to

140oF

Water is considered to be at room

temperature.

feed the plunger pump with a centrifugal

pump supplying at least twice the plunger

pump volume at 30 to 45 PSI

reduce pump rated RPM by 30% to 50%

Make sure the crankshaft turns as

indicated by the arrows located neat the

drive shaft projection

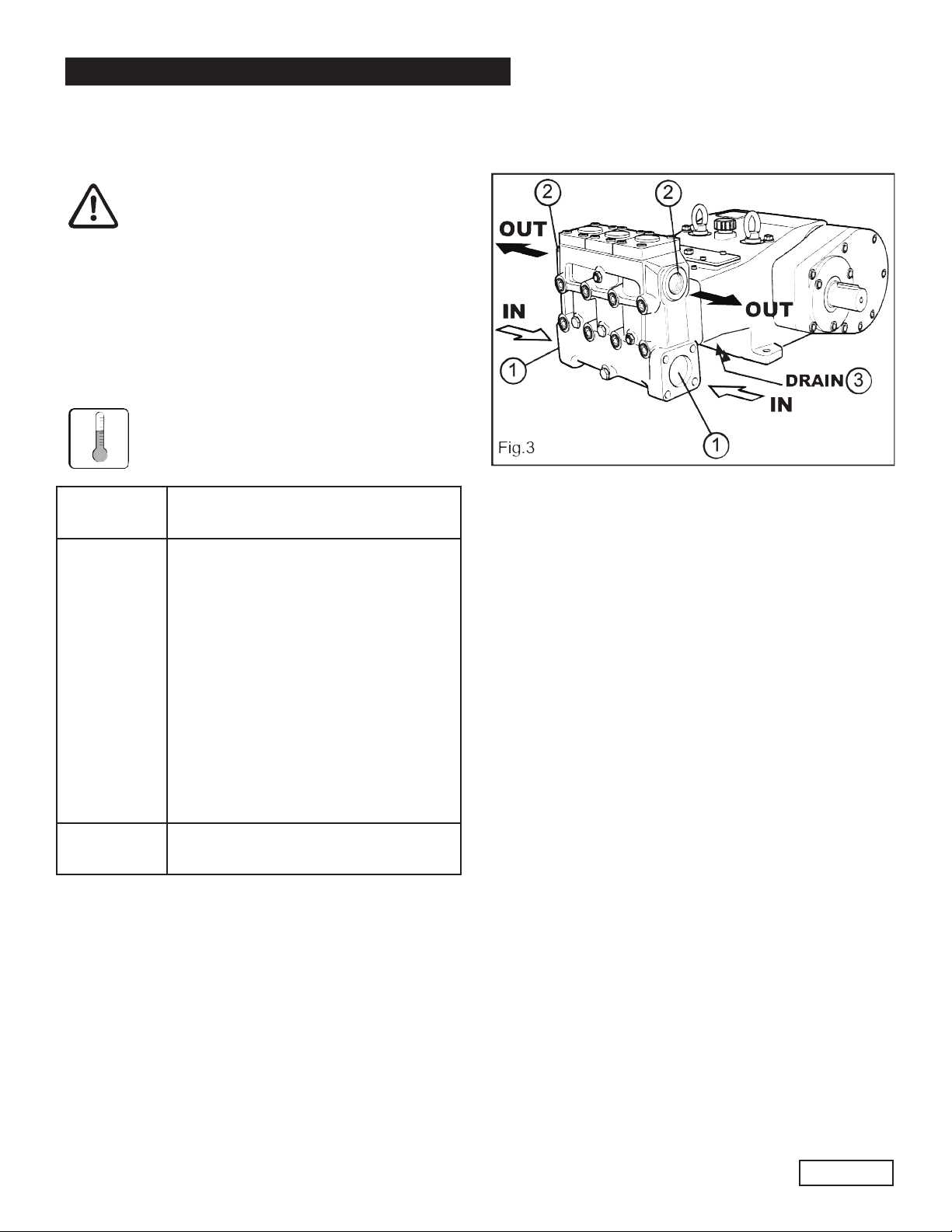

8. CONNECTIONS AND PLUGS

MH pumps are provided with (Fig. 3):

1 - 2 inlet ports IN Ø 3”-NPT

Suction line connection to any of the two inlet ports is

acceptable, the port not being used should be sealed

with the correct plug.

2 - 2 outlet ports OUT 1-1/4” NPT

3 - 1 hole DRAIN provided underneath the crankcase

and designed to drain out the water leakage of the

pressure packings. This hole must always be left

open (see paragraph 10.3 Fig. 7-page 9).

>140oF

7.2 Max flow and pressure ratings

The performance data indicated in the catalog and on the

rating plate refer to the maximum performance of the

pump. The use of the pump below the rated performances

does not allow the drop in power absorbed to be balanced

by altering the pressure or volume of the pump above its

maximum value.

7.3 Lowest operating RPM

The lowest operating speed of the crankshaft for all

MH’s (all versions is 350 RPM.

standard pump not suitable, contact our

Customer service Department

Page 6

GENERAL PUMP

A member of the Interpump Group

MH SERIES

9. PUMP INSTALLATION

9.1 Positioning

The pump should be installed flat on a rigid base by

means of the four feet Ø 16.5 mm.

The base should be rigid enough to avoid any

misalignment of flexing of flexing of the

pump/transmission coupling axis due to the torque involved

during operation.

On no account should the pump be installed in such a

way its fluid end rests on the base where the pump

is mounted. The fluid end should be left free and not

subjected to any force (Fig. 4).

9.2 Direction of rotation

Fig 5 shows the correct direction of rotation looking at the

pump from the fluid end side. Two arrows stamped on

the crankcase nearby the crankcase provide the

information as well.

9.3 Water connections

In order to isolate the high pressure equipment from the

pump vibrations it is suggested, where applicable, to use

flexible hoses for both suction and delivery lines at least

for the first length. The flexible suction hose must be

rigid enough to prevent it from collapsing during the

suction stroke, when a partial vacuum may occur.

9.4 Suction line

Plunger pumps are not self priming therefore a positive

suction head should always be provided. Information for

the correct suction line:

1. Internal diameter should be at least 3”, in any

point, possibly larger depending on the drop in

pressure due to the length and shape of the line.

2. Should be as straight as possible minimizing changes

in size and direction and positioned in such a way

to allow air pockets and bubbles to escape.

3. Should be perfectly airtight.

4. Should be completely free from 90oelbows, diameter

reductions, counter slopes, “T” connections and

should not be connected to other pipelines.

5. Should positioned in such a way to prevent the pipe

emptying after the pump stops.

6. Do not use high pressure flexible hoses for the

suction line.

7. Do not use high pressure hydraulic fittings like 90

elbows, high pressure adapters, high pressure 3 or

4 way nipples and so on.

8. Do not install any kind of detergent injector along the

suction line.

9. Do not install standing valves, check valves or other

kind of one-way valves.

10. Make sure that the feed tank capacity and the water

minimum level do not give rise to turbulence at the

tank outlet port, which, in turn, might create

cavitation at the pump.

11. Do not connect the by-pass line from the valve directly

to the pump suction line.

12. The water flow from the valve should be directed back

in the tank. Make sure that the by-pass and tank

feeding flows to not give rise to turbulence at the

tank outlet port, which, in turn, might create

cavitation at the pump. Proper baffle plates should

be provided inside the tank.

13. Before connecting the suction line to the pump inlet

port make sure the pipe is perfectly clean inside.

o

Page 7

GENERAL PUMP

A member of the Interpump Group

MH SERIES

9.5 Filtration

All pumps require a suitable filter. The filter should be

installed as close as possible to the pump, should allow

easy inspection and have the following characteristics:

1. The filter capacity should be at least three times the

rated pump volume.

2. Filter port diameters should not be smaller than the

pump inlet ports.

3. Filtration degree in between 50 and 80 mesh (360

to 200 microns.

IMPORTANT NOTE: In order to properly safeguard the

pump it is very important to plan cleaning of the filter

with a frequency depending on the water quality,

filtration degree and number of hours of each

application.

9.6 Delivery line

For a correct delivery line comply with the following

instructions:

1. The first length of delivery hose should be flexible

in order to isolate the pump vibrations from the

rest of the system.

2. Use only high pressure hoses and fittings able to

guarantee the largest possible safety margins in

any working conditions.

3. A suitable relief valve should be installed in the

delivery line.

4. Use glycerine filled pressure gauges, as the most

suitable for pulsating loads.

5. When designing the delivery line, take into proper

account the unavoidable drop in pressure, due to

its length and size.

6. If necessary, the effects of the pump pulsations

can be reduced by installing a proper pulsation

dampener in the pressure line.

Page 8

GENERAL PUMP

A member of the Interpump Group

MH SERIES

10. START UP AND RUNNING PROCEDURES

10.1 Before start up

Before start up make sure that the following conditions

have been complied with:

1. Suction line should be connected: the pump must

never run dry.

2. Suction line must be perfectly air-tight.

3. Any ON-OFF valve in between the pump and water

source should be open and make sure the water

gets into the pump freely.

4. Set the pressure line in dump mode in order to let

the air in the pump get out easily thus facilitating

the pump priming.

5. Make sure all suction/delivery line connections are

fully tightened.

6. Joint alignment, belt tightening and PTO shaft

inclination tolerances should remain within the

values indicated by the transmission Manufacturer.

7. Make sure the oil level is correct.

Note: in case the pump has not run for a long period of

time check the suction and delivery valves for scaling

(see paragraph 11.2).

10.3 Water leakage

During operation a small amount of water (a few drops a

minute) is released from the pump fluid end; this leakage

is designed to provide lubrication for the pressure

packings. The leakage is drained out of the pump

through a hole in the lower cover (Fig. 7).

This hole must always be kept open.

10.2 Starting up

1. Pump and motor/engine should start offload, set the

regulating valve to zero or set the pressure line in

dump mode by means of proper dumping devices.

2. When starting the pump up for the first time or after

every wiring re-connection check for the proper

direction of rotation.

3. Check that the rotating speed does not exceed the

rated value.

4. Before putting the pump under pressure let it run for

some time until the oil flows freely.

5. Before stopping the pump release the pressure from

the system by operating the dump device or by

releasing the regulating valve and reduce RPM to a

minimum (diesel applications).

Note: in case of feeding by a centrifugal pump, make sure

that the plunger pump start only when the correct

inlet pressure is provided.

Page 9

GENERAL PUMP

A member of the Interpump Group

MH SERIES

11. MAINTENANCE INSTRUCTIONS

11.1 Crank mechanism maintenance.

Check oil level on a weekly basis by means of the two

oil dipsticks (1, Fig. 8) provided with notches for min.

and max. levels.

If necessary, top up from the oil plug 3, Fig. 8

Check the oil when cold and change the oil when still

hot (pump still at working temperature.).

In order to drain the oil from the pump remove the

magnetic plug 2, Fig. 8.

At every oil change clean the magnetic plug 2, Fig. 8 and

check the lower cover of Fig. 7 for grease

sediments or deposits.

11.2 Fluid end maintenance

The fluid end does not require periodical maintenance.

Service operations are limited to valve inspection

and/or replacement, when necessary.

In order to remove the valves:

Loosen and remove the valve cover screws. 1, Fig. 9

OIL CHANGES Hours Qty.

First Change 50

Subsequent

Changes

Oil should be changed at least once a year.

Recommended oils:

BRAND TYPE

AGIP ACER 220

ARAL MOTANOL HP 220

AVIA AVILUB RSL 220

BP ENERGOL HL 220

CASTROL ALPHA ZN 220

ESSO NUTO 220

FINA SOLNA 220

IP HYDRUS 220

MOBIL DTE OIL BB

SHELL TELLUS C 220

TEXACO REGOL OIL 220

TOTAL CORTIS 220

500

14.8

quarts

Oil

Type

ISO

220

Tighten the two grub screws, 1, Fig. 10 of each valve

cover until the complete valve unit moves upward

enough to allow easy extraction.

Valve components of each

valve unit are screwed

together in one single block

and therefore they can be

easily serviced, replaced

and installed back

in place. Separating the

various components of the

valve unit is carried out by

means of simple tools as

shown in Fig. 11, 12 and

13 on the next page.

Page 10

GENERAL PUMP

A member of the Interpump Group

MH SERIES

Should excessive scaling inside the fluid end hinder the

valve extraction open one of the two lateral inlet ports,

remove the three plugs 1, Fig. 15, insert our special tool

p/n F200030090 (2, Fig. 15), or a corresponding one,

and push the valve unit out as shown in Fig. 15.

Check the valve components for wear and replace where

necessary.

Every time valves are inspected all o-rings of the valve

units and valve covers should be replaced.

Reassemble the valve units and fit them

back in the fluid end. Valve cover screws

should be tightened with a torque wrench

set for 86.7 ft. lbs.

Page 11

GENERAL PUMP

11.3 Pumping unit maintenance

The only maintenance operation required for the pumping

unit is the pressure packings greasing through the proper

greasers (1, Fig. 16).

Greasing should be carried out at even intervals

at least every 100 hours by means of a hand pump.

Stop greasing when the pump trigger becomes harder

to operate: that means the grease chamber is full. Use

top quality silicone grease (i.e. DANKELL OCILIS 250,

penetration coefficient 290 or a corresponding one).

A member of the Interpump Group

MH SERIES

Loosen and remove the plunger screws (1, Fig. 18).

Periodically check the amount of water drained out by

the pump through the hole provided in the lower cover

(Fig. 7, page 9). It clearly shows the pressure packing

state of wear; replace them if water dripping becomes

continuous and not intermittent.

For inspecting the pumping unit remove the head by

loosening the eight head screws (1, Fig 17).

Remove the upper cover by loosening the four screws

(1, Fig. 19).

Push the plungers forward by rotating the crankshaft,

then introduce our tool pn/ F200030060 (or equivalent)

in between the piston guide and the packing support

(1, Fig. 20).

Page 12

GENERAL PUMP

With the tool in place, rotate the crankshaft until the

packing support is pushed out together with plungers

and cylinders (Fig. 21). Repeat the operation for each

pumping unit.

A member of the Interpump Group

MH SERIES

Remove the wipers from the piston guides (1, Fig. 22

and Fig. 23).

Separate the pumping unit components and check them

for wear. Pressure packing replacement is carried out

by hand without need of special tools (Fig. 24)

A little bit of grease helps when sliding the packings into

the packing support. Pressure packings and o-rings

should always be replaced at every disassembling of

the pumping unit.

In order to fit the new scraper in place shape it manually

as shown in Fig. 25.

VERY IMPORTANT! The scraper is provided with an

internal lip which performs the correct scraping effect only

if oriented toward the fluid end. See window inside Fig. 25.

Put the pumping unit components together and fit them

back in the pump crankcase. Tighten the plunger screws

(1, Fig. 18) with a torque wrench set for 72.3 ft. lbs.

Grease the pressure packings through the greasers (2,

Fig. 23) by means of a hand pump. Stop greasing when

the pump trigger becomes hard to operate: that means the

grease chamber is full. Head back in place, head screws

tightened at 260.3 ft. lbs.

Page 13

GENERAL PUMP

A member of the Interpump Group

MH SERIES

12. SCREW CALIBRATION

Screw calibration is to be carried out by

means of a torque wrench only:

DESCRIPTION Ft. Lbs. N-m Kgm.

Valve cover

screws

Head Bolts 260.3 353 36

Plunger bolts 72.3 98 10

Connecting Rod

Screws

86.7 117.6 12

54.2 73.5 7.5

13. MAINTENANCE TOOLS

The following tools are designed to

facilitate mounting and dismounting

operations of some pump components:

for disassembling:

-packing support extractor F200030060

-main gear (gear box) F200030010

15. PRECAUTIONS AGAINST FREEZING

In the risk of freezing the following

precautions should be taken:

- After use drain the entire suction and delivery lines

(filter included) by means of discharging devices,

provided and positioned specifically for this purpose

along the lowest point of the lines.

- Run the pump only for a few seconds in order to

drain the water collected inside the fluid end.

Or when applicable

- Add a recommended amount of anti-freeze into the

water tank and run the pump until the anti-freeze

works all through the system.

- valve extractor F200030090

14. PUMP STOPPED FOR LONG TIME

Before starting the pump for the very first

time after a long period from the date of

shipment check for the correct oil level,

check the valves as indicated in chapter

11 and then comply with the starting

procedures indicated in chapter 10. When

a long inactivity is scheduled drain the

entire suction and delivery line and then

run the pump dry only for a few seconds

in order to drain out the water collected

inside the fluid end.

If a pump is frozen or appears frozen ON NO ACCOUNT

SHOULD THE PUMP BE OPERATED until the entire

system has been thawed out.

Page 14

GENERAL PUMP

16. EXPLODED VIEW AND PARTS LIST

A member of the Interpump Group

MH SERIES

Page 15

GENERAL PUMP

A member of the Interpump Group

Item Part # Description QTY.

1 F080100200 Gearbox body 1

2 F872047006 Lockwasher Ø12 8

3 F871131100 Screw M12 x 40 6

4 F052000060 Driven gear 1500 RPM (Z53) 1

F052000080 Driven gear 1800 RPM (Z56) 1

5 F030000080 Retaining flange 1

6 F042000000 Flange screw retainer 1

7 F871024107 Screw M10 x 25 2

8 F872126004 Retaining pin Ø 12 x 40 3

9 F871125109 Screw M10 x 45 8

10 F871121151 Screw M8 x 16 13

063100070Pinion cover

11F

080600090Gasket, pinion cover

12F

881080028Seal, Ø 60x80x10

13F

811110012Bearing

14F

063100050Cover, gearbox

15F

080600080Gasket, gearbox

16F

17 F872098009 Key, pinion gear 1

F872097013 Key, pinion gear Ø48 1

18 F052000070 Pinion 1500 RPM (Z20) MH 1

052000090Pinion 1800 RPM (Z17) MH

F

F052000190 Pinion 1500 RPM (Z20) Ø48 1

052000200Pinion 1800 RPM (Z17) Ø48

F

19 F811110006 Bearing 1

20 F871131107 Screw, M12 x 50 2

21 F812000000 Bearing, connecting rod 3

22 F872046006 Lock washer Ø12 6

23 F035000070 Connecting rod bolt 6

24 F040000030 Lower cover 1

25 F871115152 Screw, M6 x 14 16

26 F080600070 Gasket, lower cover 1

27 F060100180 Crankcase 1

28 F811110021 Bearing 1

29 F080600050 Gasket, side 2

30 F801057002 Magnetic plug, G 1/2” 1

31 F872043002 Aluminum washer Ø1/2” 4

32 F063400500 Rear cover 1

33 F080600040 Gasket, rear cover 1

34 F001000000 Oil level dipstick 2

35 F872041501 Washer Ø3/8” 2

36 F872026003 Eye bolt M 16 2

37 F030000030 Washer, eyebolt 2 - 4

38 F801054027 Vented plug G 1” 1

39 F881010116 O-ring, Ø29.82 x 2.62 4

40 F801056002 Plug G 1/2” 1

41 F040000010 Top cover 1

42 F080600060 Gasket, top cover 1

43 F872101009 Key 1

44 F050000000 Crankshaft 1

45 F811111014 Bearing 1

46 F811920014 Bearing retainer bushing 1

47 F872069016 Washer MB16 1

48 F872020016 Nut KM16 1

49 F871131103 Screw M12 x 30 8

50 F063400460 Side cover 1

51 F801077003 Grease fitting M10 x 1 3

52 F250000040 Complete connecting rod 3

53 F250001080 Complete piston guide 3

54 F872142015 Retainer pin Ø 5 x 36 3

55 F071000050 Wrist pin Ø 35 3

56 F881081001 Oil seal Ø 35 x 47 x 8.5 Spec. 3

57 F881010128 O-ring Ø 72.69 x 2.62 3

58 F063400480 Oil seal cover 3

59 F205000010 Flinger washer 3

60 F024202600 Plunger MH45 3

F024200270 Plunger MH50 3

REPAIR KITS

2, 6, 12, 13, 16, 22, 26, 29, 31, 33, 35,

39, 42, 47, 51, 54, 56, 57, 61, 67, 68,

73, 74, 79, 84, 85, 89, 90, 92, 93, 94

Item MH45 MH50 MH55 MH60 MH65

61, 64, 85, 89, 90, 92, 93 F1190 F1191 F1192 F1193 F1194

31, 67, 68, 73, 94, 94 F1195

F1196 F1197 F1198 F1199 F1200

MH SERIES

Item Part # Description QTY.

60 F024200280 Plunger MH55 3

F024200290 Plunger MH60 3

F024200330 Plunger MH65 3

61 F872040004 Washer Ø 14 Spec. 3

871135518Screw M14 x 140 inox MH45

62F

871135510Screw M14 x 80 inox MH50, 55, 60, 65

F

208005230Valve assembly

63 F

871245356Set screw M10 x 20

64 F

871135102Screw M14 x 40

65F

063002400Valve cover

66 F

881112003Anti-extrusion ring

1

1

1

1

1

1

1

1

67 F

881011252O-ring Ø 70 x 4 Spec.

68F

021200280Discharge valve guide

69 F

090200050Discharge valve spring

70 F

082200060Discharge valve poppet

71 F

205000110Discharge valve seat

72 F

73 F881011168 O-ring Ø 72 x 3 Spec. 3

74 F881011161 O-ring Ø 56 x 3 Spec. 6

75 F021200260 Inlet valve guide 3

090200040Inlet valve spring

76F

082200050Inlet valve poppet

77 F

78 F081200060 Inlet valve seat 3

79 F872041300 Gasket washer Ø 1/4” 8

80 680115 Plug NPT 1/4” 8

81 F871151172 Screw M20 x 200 8

82 F164000400 Manifold 1

83 F084000010 Plug 1/2” NPT 3

84 F881011054 O-ring Ø 96 x 2 9

85 F881011253 O-ring Ø 72 x 4 Spec. 3

86 F062200170 Cylinder MH45 3

F062200180 Cylinder MH50 3

F062200190 Cylinder MH55 3

F062200200 Cylinder MH60 3

F062200210 Cylinder MH65 3

87 F031300120 Spacer MH45 3

F031300050 Spacer MH50 3

F031300060 Spacer MH55 3

F031300070 Spacer MH60 3

F031300080 Spacer MH65 3

88 F031200110 Head ring MH45 3

F031200210 Head ring MH50 3

F031200220 Head ring MH55 3

F031200230 Head ring MH60 3

F031200250 Head ring MH65 3

89 F881020012 Packing MH45 6

F881020014 Packing MH50 6

F881020015 Packing MH55 6

F881020016 Packing MH60 6

F881020017 Packing MH65 6

90 F881011163 O-ring Ø 59.5 x 3 MH45 3

F881011165 O-ring Ø 65 x 3 MH50 3

F881011167 O-ring Ø 69.5 x 3 MH55 3

F881011169 O-ring Ø 76 x 3 MH60 3

F881011170 O-ring Ø 80 x 3 MH65 3

91 F022300290 Packing support MH45 3

F022300300 Packing support MH50 3

F022300310 Packing support MH55 3

F022300320 Packing support MH60 3

F022300330 Packing support MH65 3

92 F881011053 O-ring Ø 80 x 2 3

93 F881061017 Scraper MH45 3

F881061018 Scraper MH50 3

F881061019 Scraper MH55 3

F881061021 Scraper MH60 3

F881061023 Scraper MH65 3

94 F010500290 Anti-extrusion ring 6

Also Included:

F1201 Inlet flange, closed

F1299 Inlet flange, open, 3” NPT

680096 Drain valve kit

Page 16

3

3

3

6

2

1

3

3

3

3

3

3

3

3

3

GENERAL PUMP

17. TROUBLE SHOOTING

A member of the Interpump Group

MH SERIES

THE PUMP DOES NOT PRODUCE ANY

NOISE: the pump is not primed

and is running dry!

- No water in the inlet line

- The valves are blocked

- The pressure line is closed and does

not allow the air to get out the fluid

end.

THE PUMP KNOCKS:

- Air suction.

- Insufficient feeding:

- bends, elbows and fittings along the

suction line throttle the amount of

water which passed through.

- too small inlet filter.

- dirty inlet filter.

- the feeding pump, where provided is

not of the suitable type or provides

insufficient pressure or volume.

- The pump is not primed due to

insufficient feeding or the delivery line

is closed during start up.

- The pump is not primed because some

valves are stuck (i.e pump inactivity

for long time).

- Jammed or worn out valves.

- Worn out pressure packings.

- The pressure regulating valve does not

work properly.

- Clearance in the drive system.

- RPM are higher than rated.

THE PUMP DOES NOT DELIVER THE

RATED VOLUME:

- Insufficient feeding (due to the cause

listed above).

- RPM are less than rated.

- Excessive amount of water by-passed

by the pressure regulating valve.

- Worn out valves

- Excessive leakage from pressure

packings

INSUFFICIENT PUMP PRESSURE:

- The nozzle is (or has become) too large.

- RPM are less than rated

- Excessive leakage from pressure

packings

- Excessive amount of water by-passed

by the pressure regulating valve or

faulty valve operation.

- Worn out valves.

EXCESSIVE WATER LEAKAGE FROM

THE PUMP:

- Pressure packing are excessively worn

out (due to normal wear or excessive

cavitation).

- Worn out plungers

OVERHEATED PUMP:

- The direction of rotation is not correct.

- Pump is overloaded (pressure or RPM

over the rated values).

- The oil level is too low or the oil is not of

a suitable type or fully used

- Water in the oil

- Excessive belt tension or incorrect

alignment of the joint (where provided).

- Excessive inclination of the pump

during operation.

PIPE VIBRATIONS OR KNOCKING:

- Air suction.

- The pressure regulating valve does not

work properly.

- The by-pass line is undersized.

- Jammed up valves.

- Drive transmission motion is irregular.

Page 17

GENERAL PUMP

MAINTENANCE LOG

OIL CHANGE

GREASE

PACKING

REPLACEMENT

A member of the Interpump Group

MH SERIES

HOURS & DATE

PLUNGER

REPLACEMENT

VALVE

REPLACEMENT

GP Companies, Inc.

1174 Northland Drive

Mendota Heights, MN 55120

Phone:651.686.2199 Fax: 800.535.1745

www.generalpump.com email: sales@gpcompanies.com

Ref 300019 Rev.C

08/07

Page 18

Loading...

Loading...