General Pump LK Repair Manual

LLKK

Repair Manual

LK50-LK55-LK60

LK36-LK40-LK45

GENERAL PUMP

INDEX

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2. REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2.1 Repair of the Mechanical Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2.1.1 Dismantling the Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

2.1.2 Assembling the Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

2.1.3 Classes of Increase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 31

2.2 Repair of the Hydraulic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 31

2.2.1 Head Disassembly - Valve Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 31

2.2.2 Head Assembly - Valve Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 35

2.2.3 Disassembling the Plunger Unit - Supports - Seals . . . . . . . . . . . . . .Page 41

2.2.4 Assembly of the Plunger Unit - Suports - Seals . . . . . . . . . . . . . . . . .Page 44

3. SCREW CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 48

4. REPAIR TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 49

5. MAINTENANCE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 50

A member of the Interpump Group

LK SERIES

Page 2

GENERAL PUMP

A member of the Interpump Group

LK SERIES

1. INTRODUCTION

This manual contains the instructions for repairing LK Series pumps, and must be carefully read and

understood before performing any repair intervention on the pump. Correct use and adequate maintenance is

fundamental for the pump’s regular operation and long wear. General Pump declines any responsibility for

damage caused by the misuse or the non-observance of the instructions described in this manual.

2. REPAIR INSTRUCTIONS

2.1 Repair of the Mechanical Parts

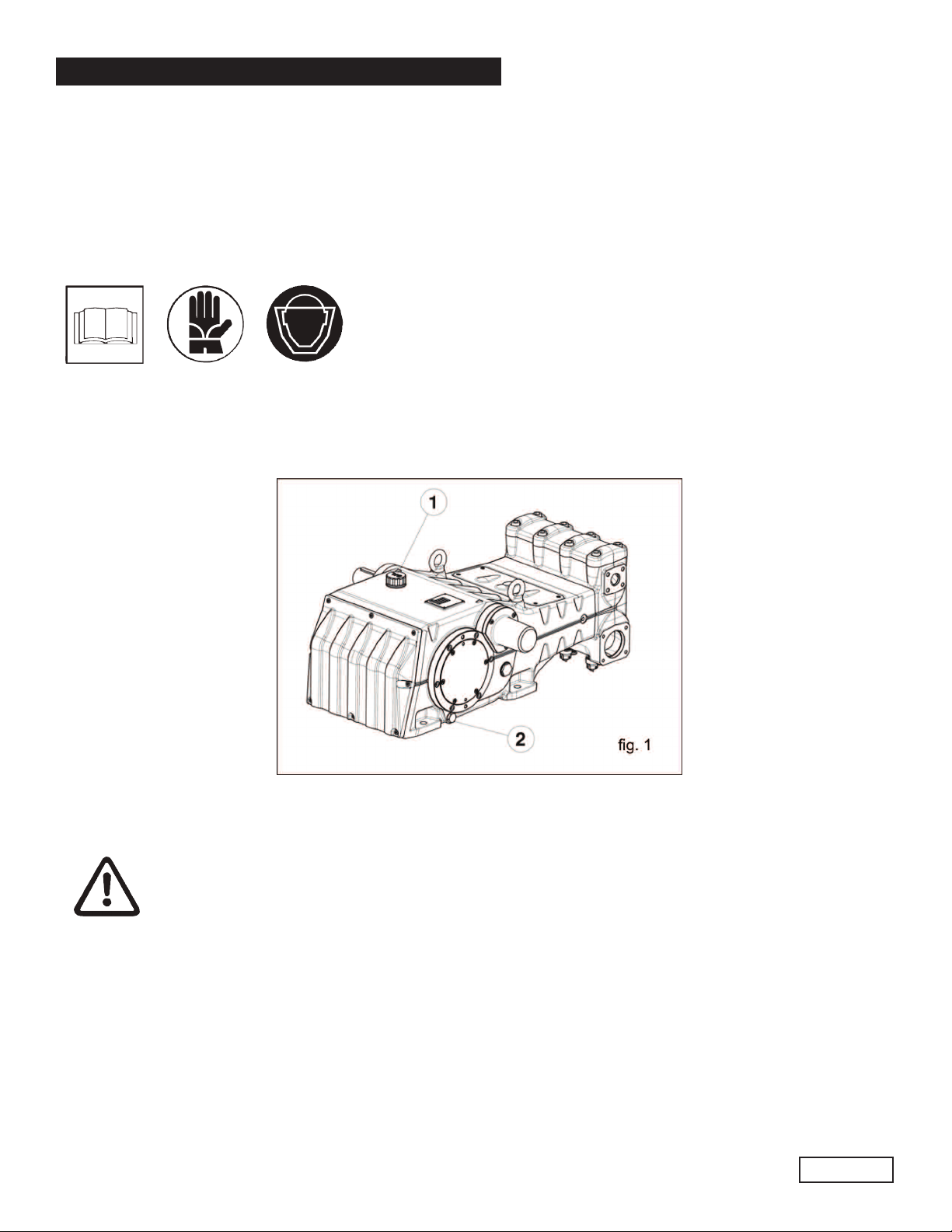

Repairs on the mechanical parts must be carried out after removing the oil from the crankcase. To remove the

oil, remove the oil fill plug, pos. 1, fig. 1 and then the drain plug, pos. 2, fig.1 present on both side of the

crankcase.

Exhausted oil must be collected in an appropriate container and disposed of in

an authorized location. Do not under any circumstances discard into the environment.

Page 3

GENERAL PUMP

2.1.1 Dismantling the Mechanical Parts

The correct sequence is the following:

Completely drain the oil of oil, as indicated in 2.1.

Remove the valve lifters from the head and the head from the pump casing as shown in 2.2.1 (from fig. 103 to

fig. 105).

Detach the upper inspection cover and the lower inspection cover by unscrewing the 4 attachment screws,

as shown in point 2.2.3 (fig. 129 and fig. 140). Slip off the O-rings and replace them if necessary.

Remove the three plungers and the liner/gasket support assemblies, as shown in 2.2.3 (fig. 138, fig. 141 and

fig. 142).

Remove the three spray guard spacer rings and the spray guards, as shown in 2.2.3 (fig. 143 and fig. 144)

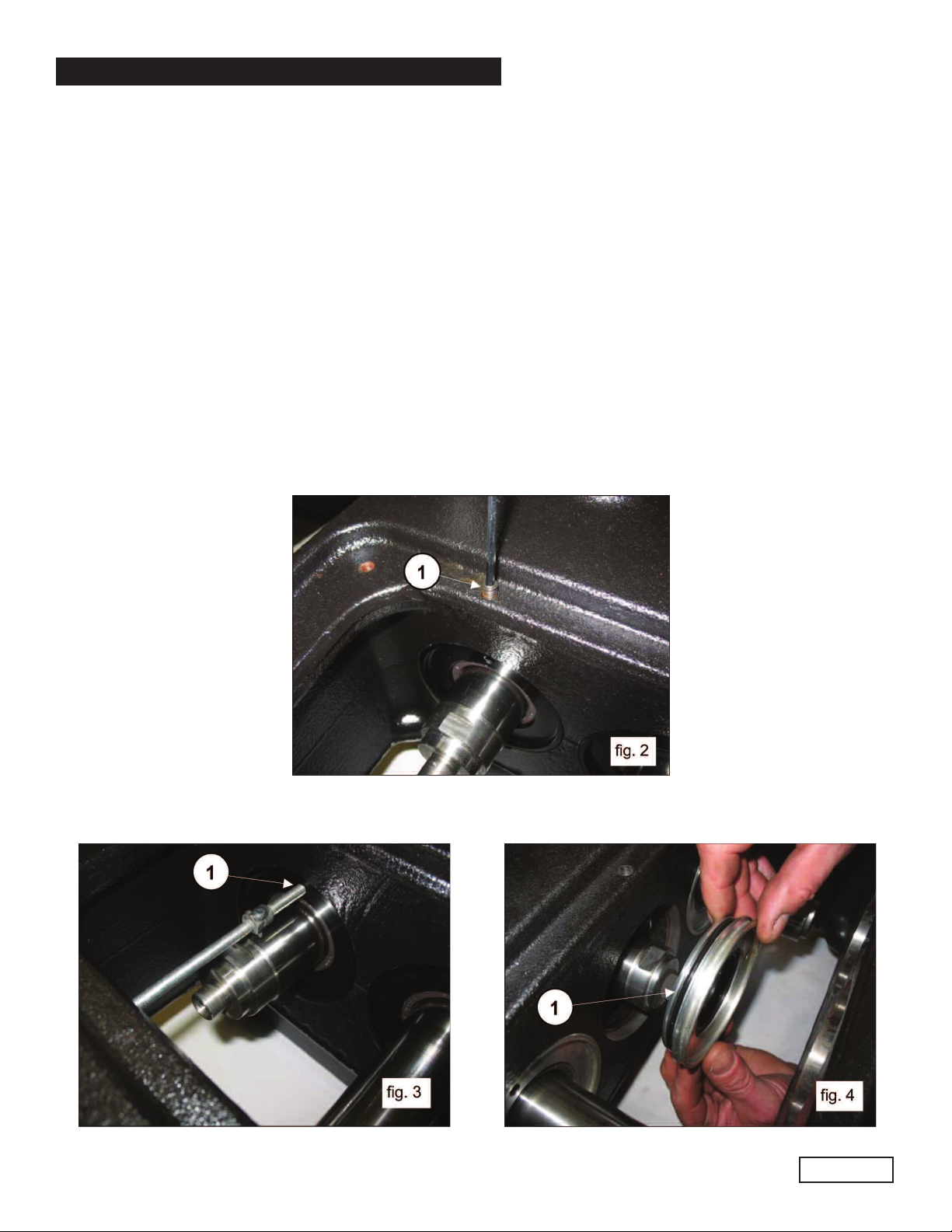

Unscrew the M6 locking grub screws from the three oil seal covers (pos.1, fig.2).

A member of the Interpump Group

LK SERIES

Screw in a threaded bar or an extractor M6 screw in the holes in the oil seal covers (pos. 1, fig.3) and

remove the covers from the pump assembly (pos. 1, fig. 4).

Page 4

GENERAL PUMP

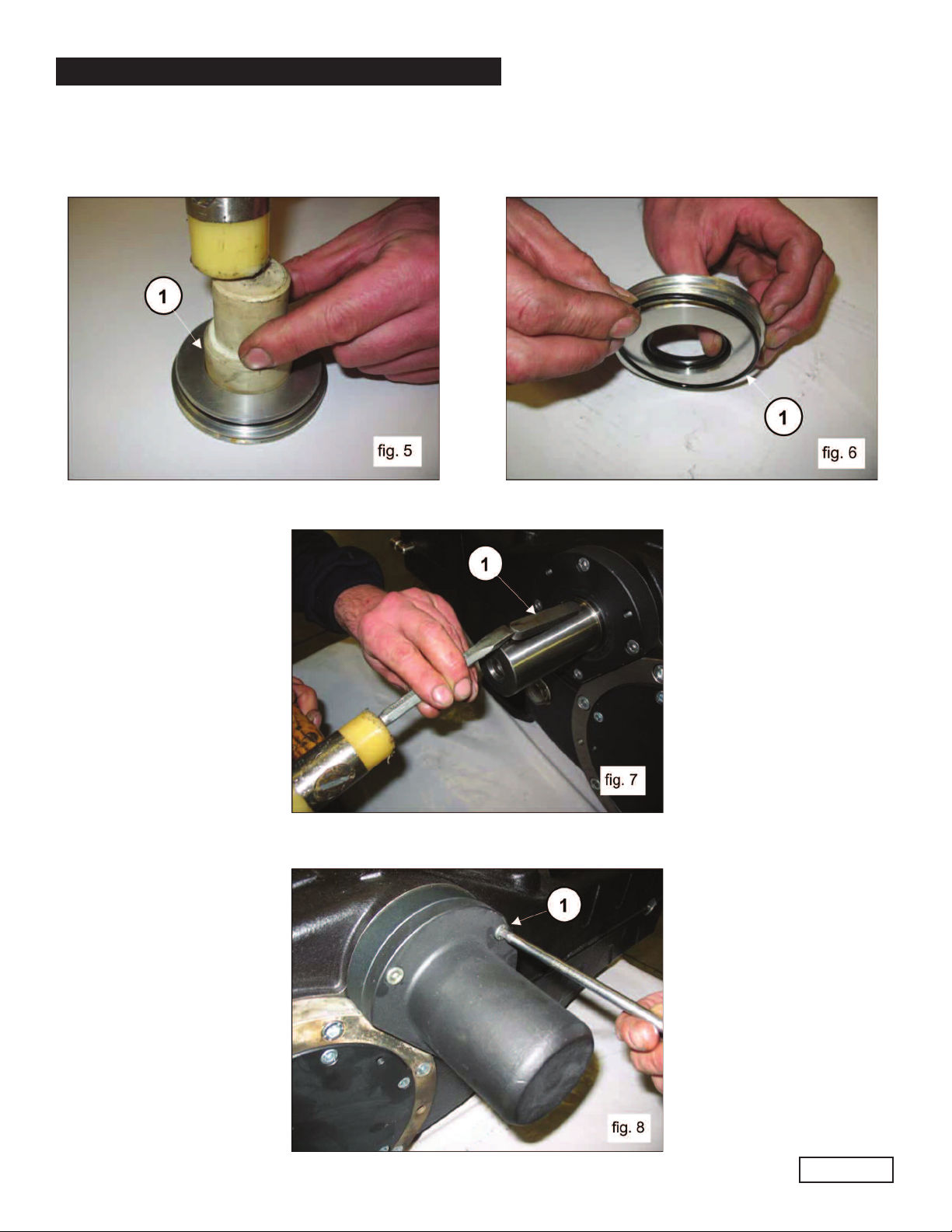

Take out the radial seal ring, (pos. 1, fig. 5) and the outside O-ring (pos.1, fig 6).

Remove the lug from the PTO shaft (pos. 1, fig. 7)

A member of the Interpump Group

LK SERIES

Unscrew the attachment screws from the shaft end cover (pos. 1, fig. 8) and slip the cover off the PTO shaft.

Page 5

GENERAL PUMP

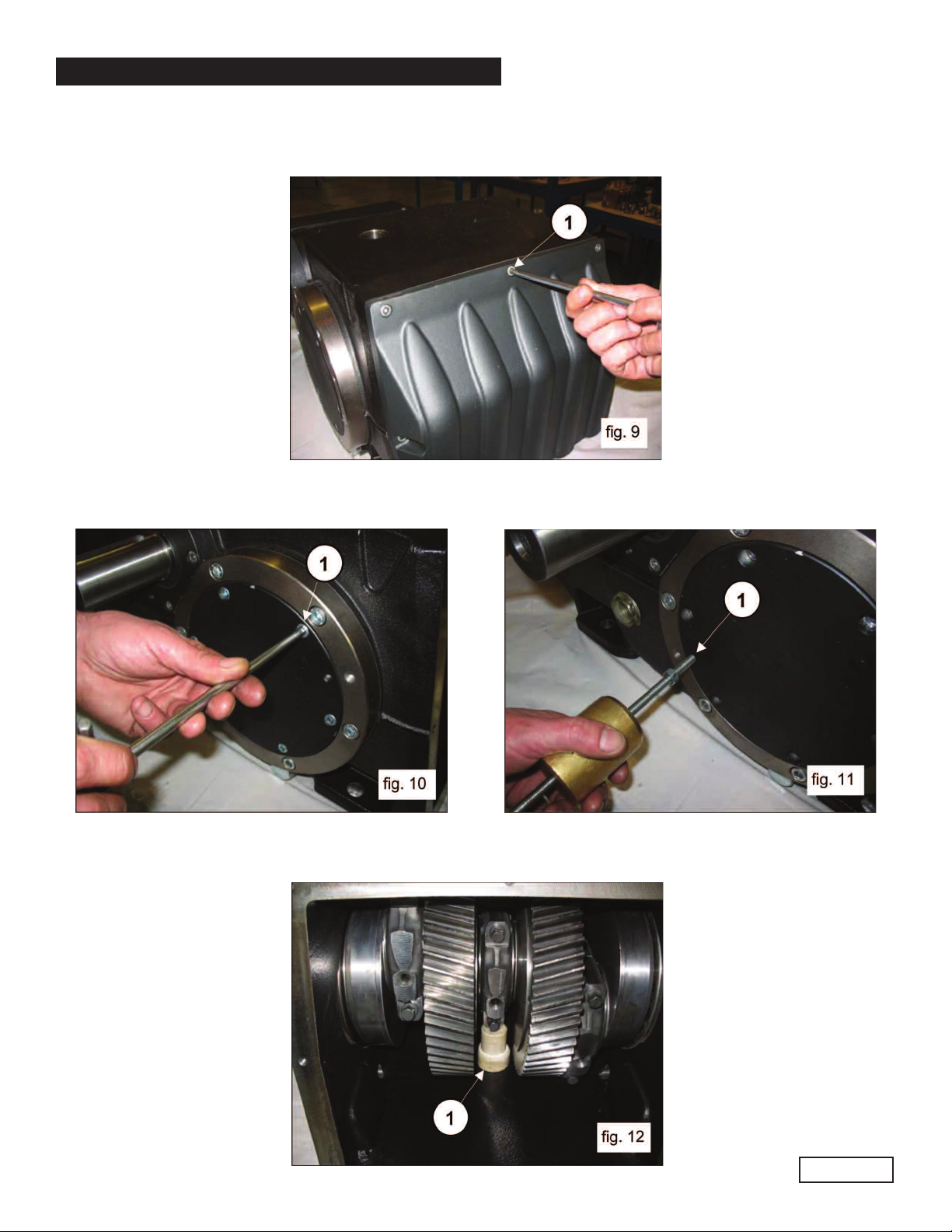

Unscrew the crankcase cover attachment screws (pos. 1, fig. 9) and remove it. Slip off the O-ring and replace

it if necessary.

Now remove the two bearing covers by unscrewing the screws (pos. 1, fig10). To help with their removal, use

2 M8 grub screws or screws (pos. 1, fig 11) as extractors. Slip off the O-ring and replace if necessary.

A member of the Interpump Group

LK SERIES

Insert a shim under the shank of the central connecting rod, to stop the rotation of the crankshaft

(pos. 1, fig. 12).

Page 6

GENERAL PUMP

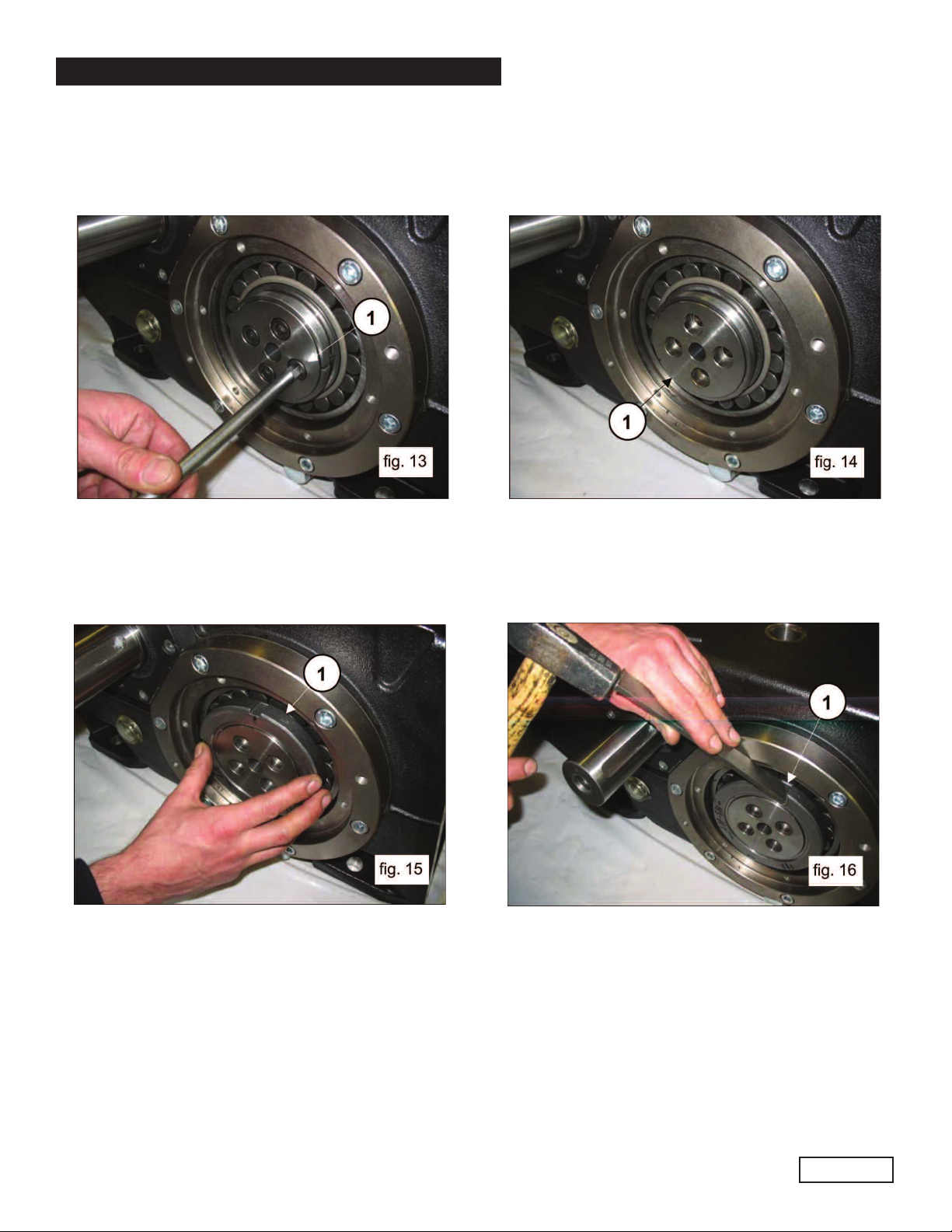

Unscrew and take out the bushing locking flange attachment screws, from both sides (pos. 1, fig. 13). The

bushing locking flanges must be left in position (pos. 1, fig. 14).

A member of the Interpump Group

LK SERIES

On one side, screw a ferrule (type SKF KM20) onto the pressure bushing (pos. 1, fig. 15), and then unblock

the bushing using a striking hammer (pos. 1, fig 16), but do not remove it. Repeat the operation on the other

side.

Remove the shim from under the shank of the central connecting rod.

Page 7

GENERAL PUMP

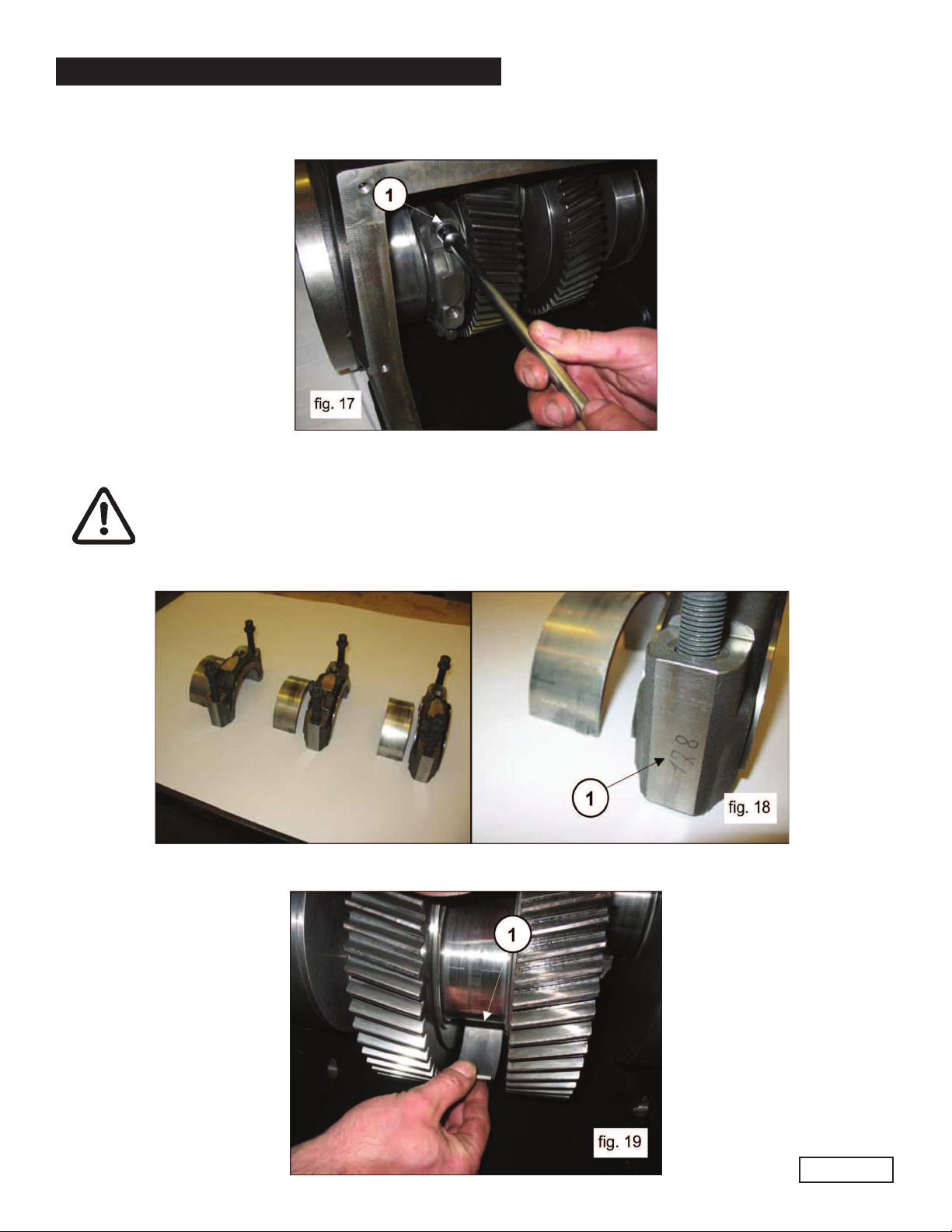

Unscrew the connecting rod screws (pos.1, fig. 17).

Dismantle the small ends of the connecting rods with the half-bearings. During the operation take particular

care to note the order in which the parts are removed

The connecting rod small ends and the big end halves must be reassembled in exactly the

same order and pairings in which they were dismantled.

A member of the Interpump Group

LK SERIES

To prevent any errors, small ends and big end halves are numbered on one side (pos. 1, fig. 18).

Advance the three big end halves as far as possible in the direction of the head. Slip off the three upper halfbearings of the beg end halves (pos. 1, fig 19).

Page 8

GENERAL PUMP

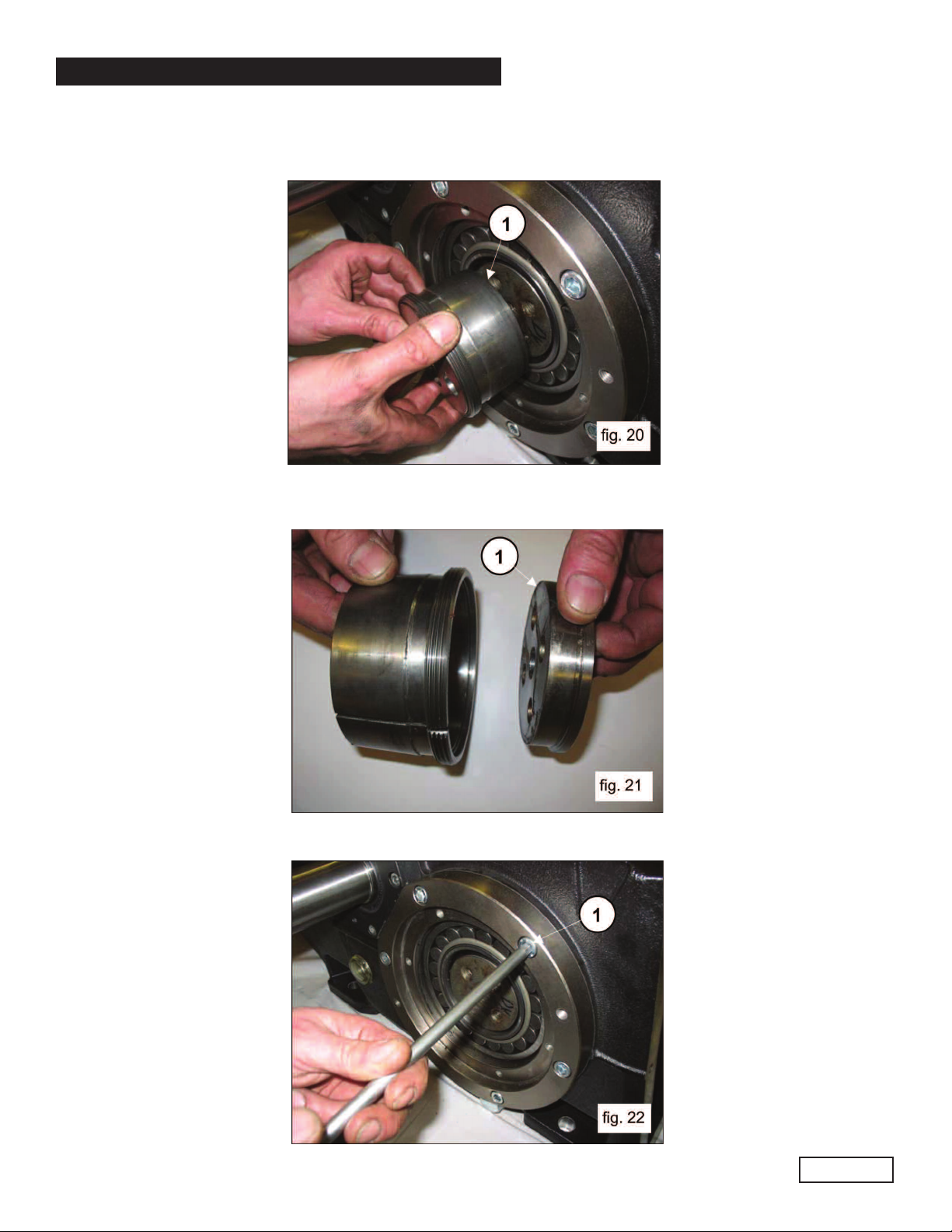

Take out both of the pressure bushings (pos. 1, fig. 20).

Separate the bushing locking flange from the pressure bushing (pos. 1, fig. 21).

A member of the Interpump Group

LK SERIES

Unscrew the screws of the two bearing support covers (pos. 1, fig. 22).

Page 9

GENERAL PUMP

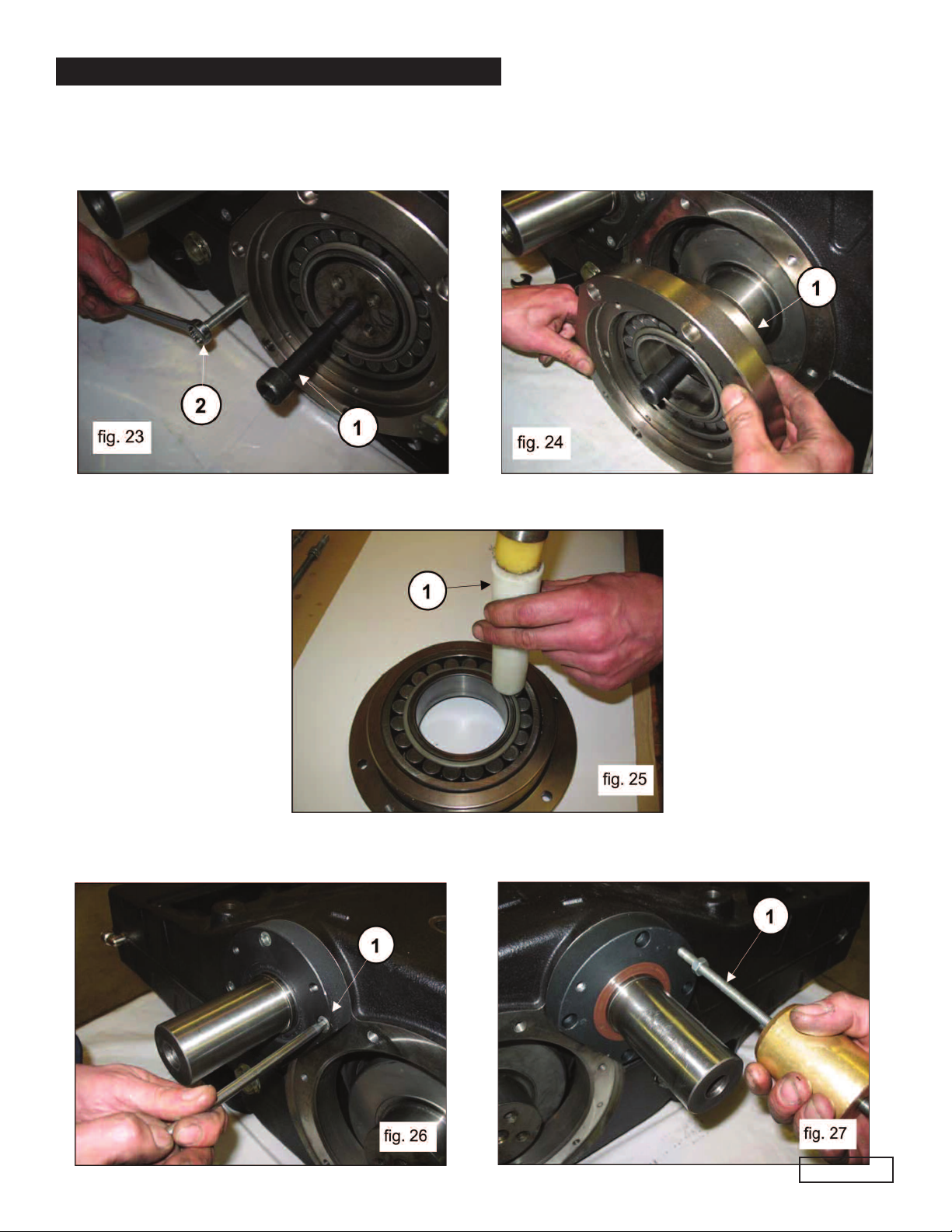

Apply an M16 threaded pin to one end of the crankshaft (pos. 1, fig. 23) and, while keeping it raised, take out

the bearing support cover complete with bearing and O-ring (pos. 1, fig. 24). To help with their removal, use 2

M10 grub screws or screws (pos. 2, fig. 23) as extractors. Repeat the operation on the other side

Lay the crankshaft on the bottom of the crankcase. Separate the bearing support cover from the bearing,

using a striking hammer (pos. 1, fig. 25).

A member of the Interpump Group

LK SERIES

Unscrew the attachment screws of the left and right PTO bearing cover (pos. 1, fig. 26) and slip the two covers off the PTO shaft. To help with their removal, use 3 M8 grub screws or screws (pos. 1, fig. 27) as

extractors.

Page 10

GENERAL PUMP

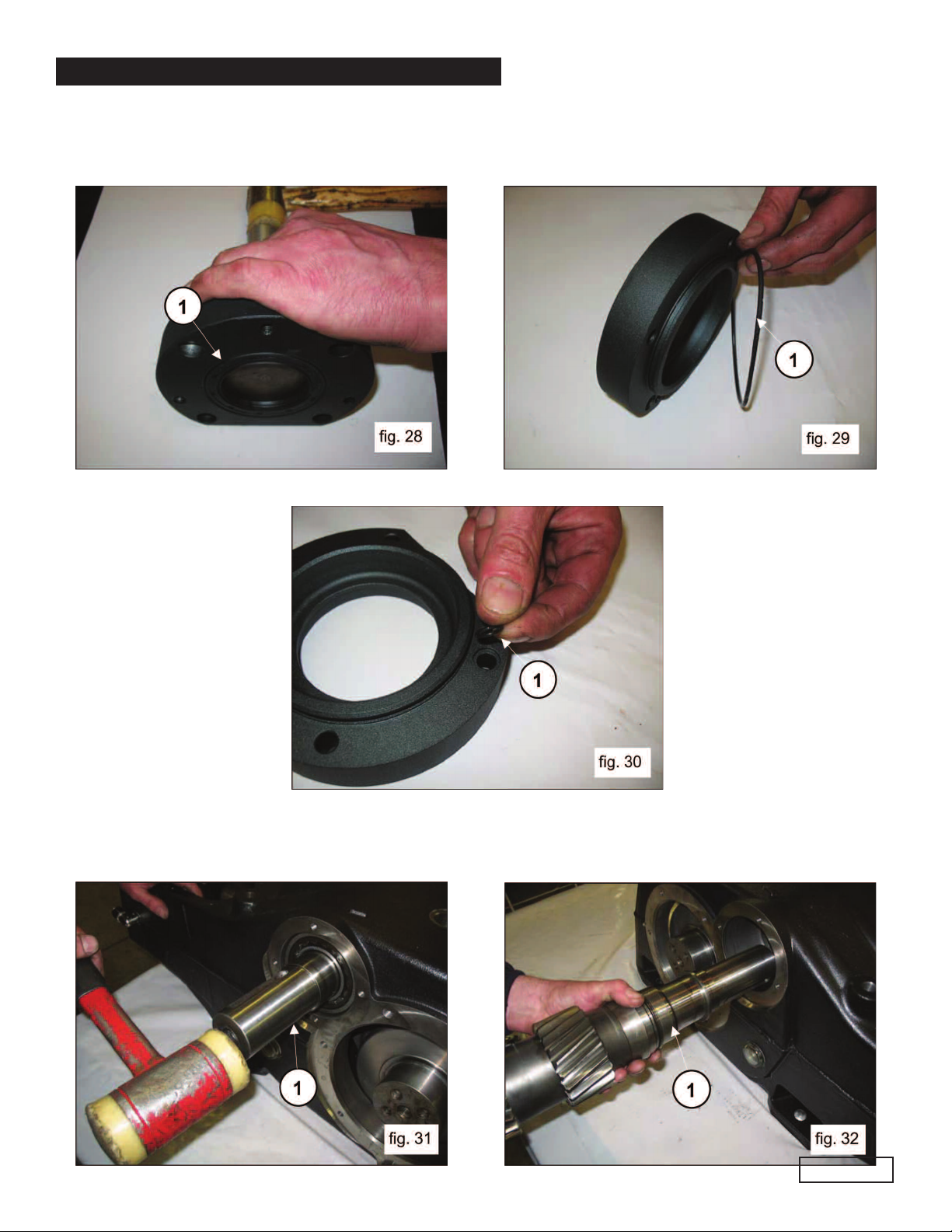

Take out the radial seal ring (pos. 1, fig. 28) and the outside O-ring (pos. 1, fig. 29) and the lubrication hole

O-ring (pos. 1, fig. 30)

A member of the Interpump Group

LK SERIES

Roll back the three connecting rods as far as possible (until they touch the crankshaft). Using a striking

hammer or mallet (pos. 1, fig. 31), take out the PTO crankshaft from either one of the two sides

(pos. 1, fig. 32).

Page 11

GENERAL PUMP

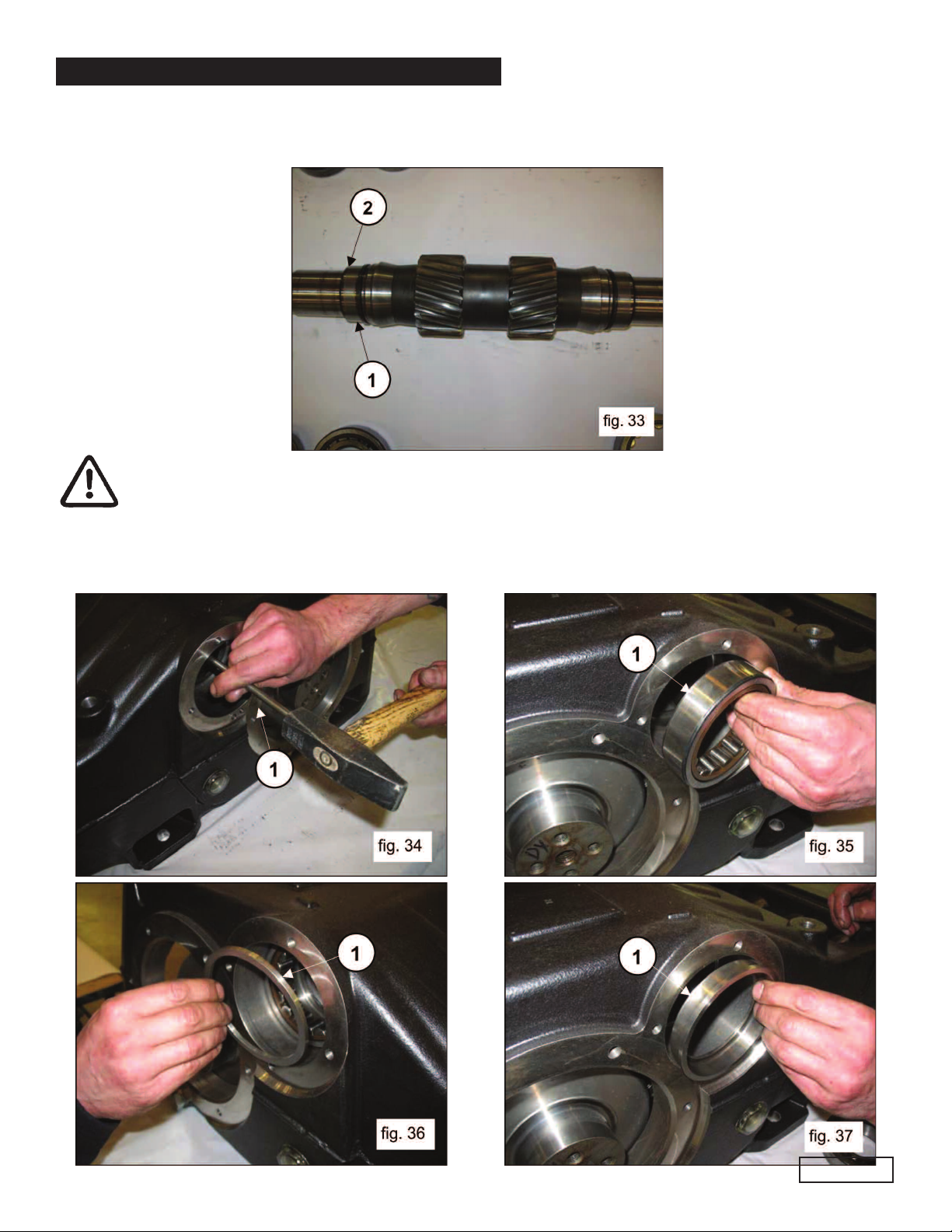

Slip the internal bearing rings off the PTO shaft (pos. 1, fig. 33) and also slip off the two internal bearing

spacers (pos. 2, fig. 33).

The internal and external bearing rings must be reassembled in exactly the same order

and pairings in which they were dismantled.

A member of the Interpump Group

LK SERIES

Using a sufficiently long bar (pos. 1, fig. 34) and a striking hammer, take the bearing rings out of the pump

casing (pos. 1, fig. 35), along with the external spacer (pos. 1, fig. 36) and the bearing lubrication bushing

(pos. 1, fig. 37).

Page 12

GENERAL PUMP

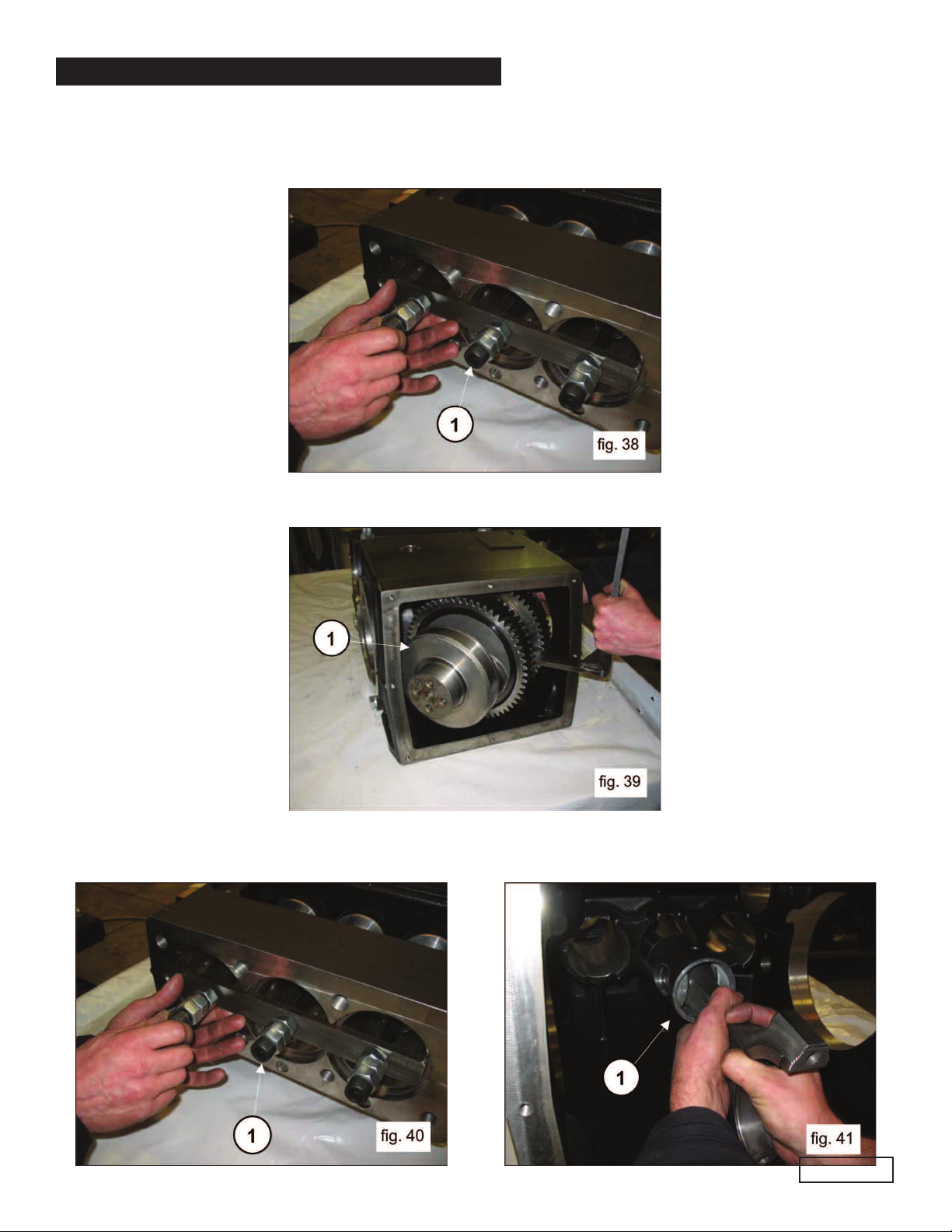

Advance the big end halves in the direction of the hydraulic part and lock them in place using the special

tool (p/n F27566200) (pos. 1, fig. 38).

Move the crankshaft from the lower part of the casing (pos. 1, fig. 39).

A member of the Interpump Group

LK SERIES

Proceed to unscrew the screws of the device (p/n) F2756620) to unlock the connecting rods (pos. 1, fig. 40)

and then take out the connecting rod/piston head assemblies from the rear opening of the casing (pos. 1, fig.

41).

Page 13

GENERAL PUMP

Couple the big end halves to the small ends that were previously dismantled, with reference to their

numbering scheme (pos. 1, fig. 42).

Remove the two pin-locking Seeger rings using the correct tool (pos. 1, fig. 43).

A member of the Interpump Group

LK SERIES

Page 14

GENERAL PUMP

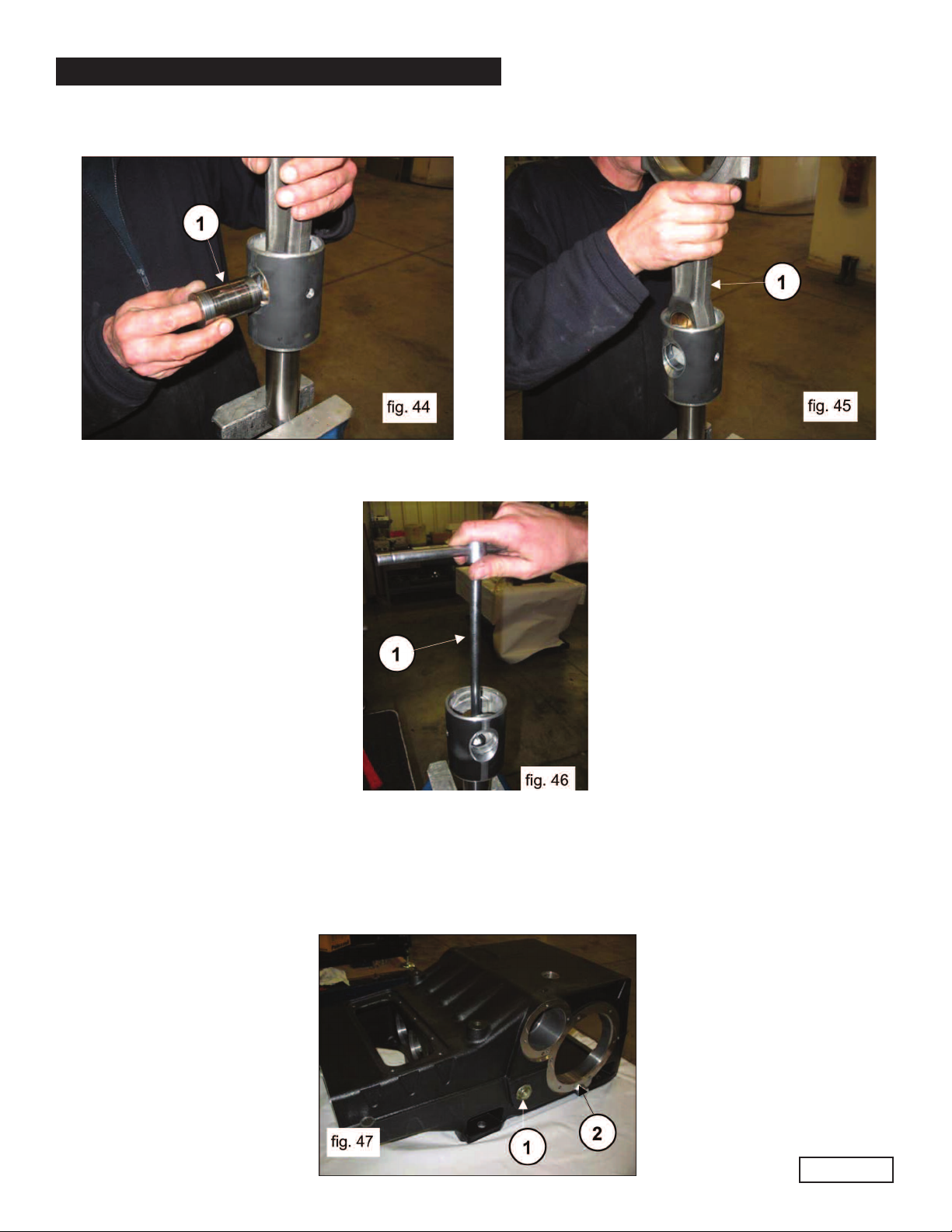

Slip out the pin (pos. 1, fig 44) and take out the connecting rod (pos. 1, fig. 45).

To separate the stem from the piston head, it is necessary to unscrew the hexagonal-head M10 screw using

a no. 17 socket wrench (pos. 1, fig. 46).

A member of the Interpump Group

LK SERIES

Complete the disassembly of the mechanical parts by removing the oil level lights and the eyebolts.

2.1.2 Assembling the Mechanical Parts

Proceed with the assembly, following the reverse of the procedure shown in 2.2.1/ The correct sequence is as

follows:

Attach the two oil level lights and the two oil drain plugs (pos. 1 and 2, fig. 47).

Page 15

Loading...

Loading...