HTCK3623S

8

Repair Manual

General Pump is a

member of the

Interpump Group

Ref 300935 Rev.A

09-13

GENERAL PUMP

INDEX

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2. REPAIR GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2.1 Repairing Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

2.1.1 Disassembly of Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

2.1.2 Reassembly of Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

2.1.3 Reduction Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.1.4 Disassembly/Reassembly of Bearings and Shims . . . . . . . . . . . . . . .Page 8

2.2 Repairing Hydraulic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11

2.2.1 Dismantling the Head-Valve Units . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11

2.2.2 Reassembling the Head-Valve Units . . . . . . . . . . . . . . . . . . . . . . . . .Page 12

2.2.3 Dismantling the Head-Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 13

2.2.4 Dismantling the Piston Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

2.2.5 Reassembling the Head-Seals-Piston Unit . . . . . . . . . . . . . . . . . . . . .Page 15

3. SCREW CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 16

4. REPLACING THE CONNECTING ROD FOOT BUSHING . . . . . . . . . . . . . . . . . .Page 17

A member of the Interpump Group

HTCK3623S

-Remove the piston guide seal rings as described below: . . . . . .Page 5

5. REPAIR TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 18

6. MAINTENANCE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 19

Ref 300935 Rev.A

09-13

Page 2

GENERAL PUMP

A member of the Interpump Group

HTCK3623S

1. INTRODUCTION

This manual describes the instructions for repair of the HTCK3623S, and must be carefully read and

understood before performing any repair intervention on the pump. Proper pump operation and longevity

depend on the correct use and maintenance. General Pump declines any responsibility for

damage caused by negligence or failure to observe the instructions described in this manual.

2. REPAIR INSTRUCTIONS

2.1 Repairing Mechanical Parts

Mechanical parts repair must be performed after the oil has been removed from the casing. To drain

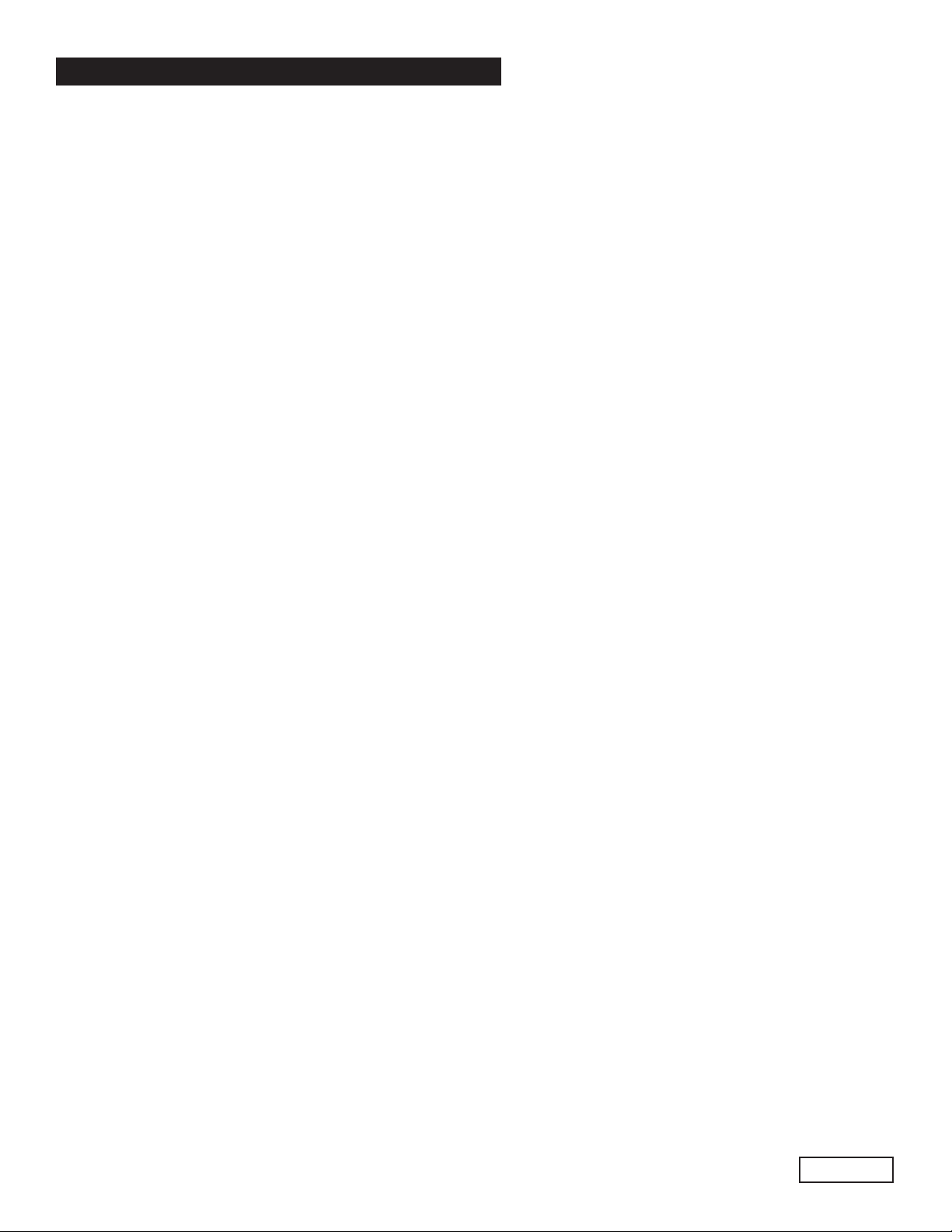

the oil, remove the oil dipstick, (1, fig. 1) and then the draining plug (2, fig. 1).

The oil must be placed in a suitable container and disposed of in special centers.

It absolutely must not be discarded into the environment.

Ref 300935 Rev.A

Page 3

09-13

GENERAL PUMP

A member of the Interpump Group

HTCK3623S

2.1.1 DISASSEMBLY OF MECHANICAL PARTS

The operations described must be performed after removing the hydraulic part, ceramic plungers and

splash guards from the pump (see 2.2.3 and 2.2.4).

Remove in the following order:

-the pump shaft tab

-the rear cover

-the connecting rod cap as follows:

unscrew the cap fixing screws, remove the connecting rod caps with their lower half-bearings

(fig. 2) paying attention to the numbered sequence during disassembly.

To avoid possible errors, caps and connecting rod shanks have been numbered on one side (fig. 2a, 1).

- the side covers using - for extraction - 3 fully threaded M6x50 screws,

inserting them in the threaded holes as indicated in fig. 3.

Ref 300935 Rev.A

09-13

Page 4

GENERAL PUMP

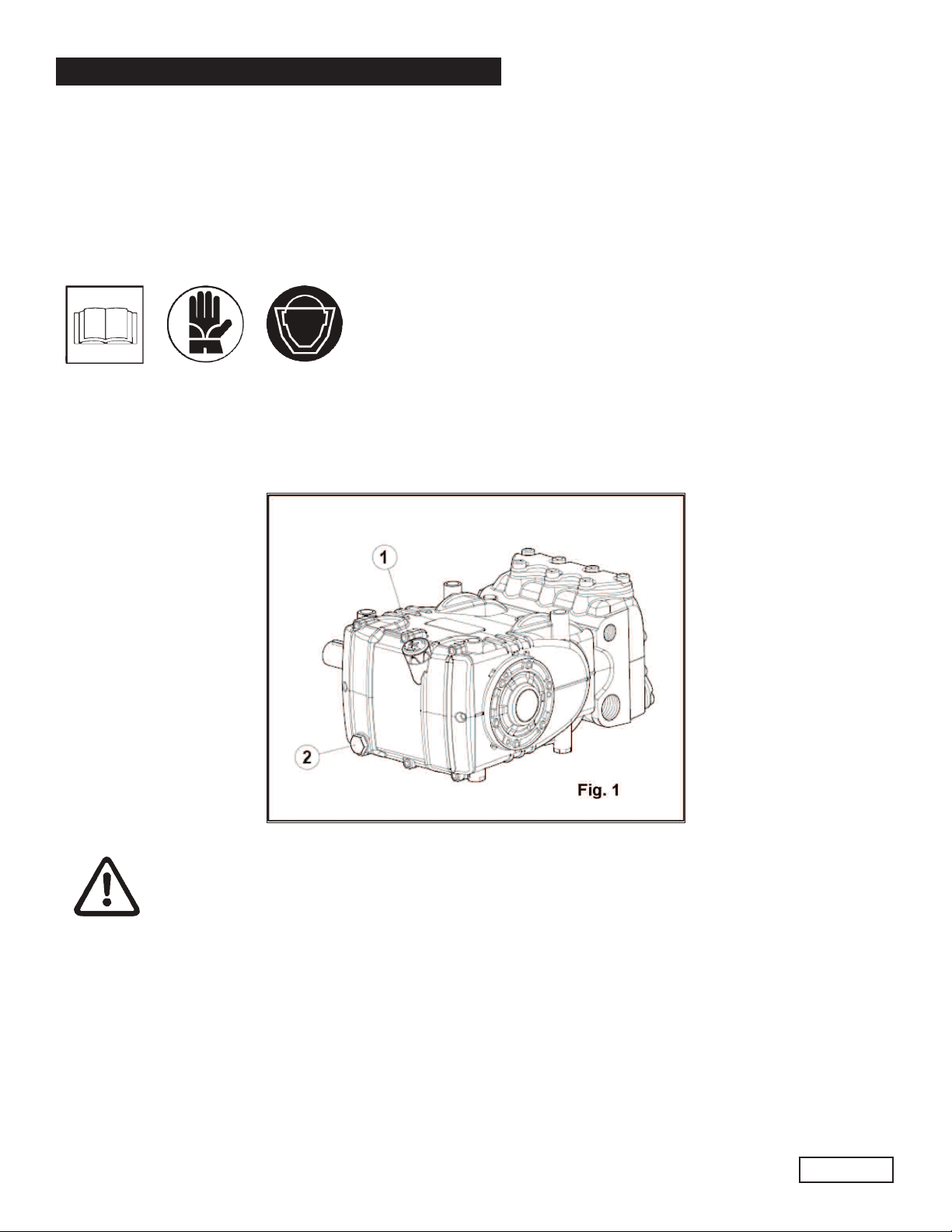

-push the plunger guides forward with their con-rods to facilitate side extraction of the pump shaft

as shown in fig. 4

-Remove the pump shaft

-Complete disassembly of the con-rod units by removing them from the pump casing and removing

the plunger guide pins

-Remove the pump shaft seal rings using common tools

-Remove the plunger guide seal rings as described below:

A member of the Interpump Group

HTCK3623S

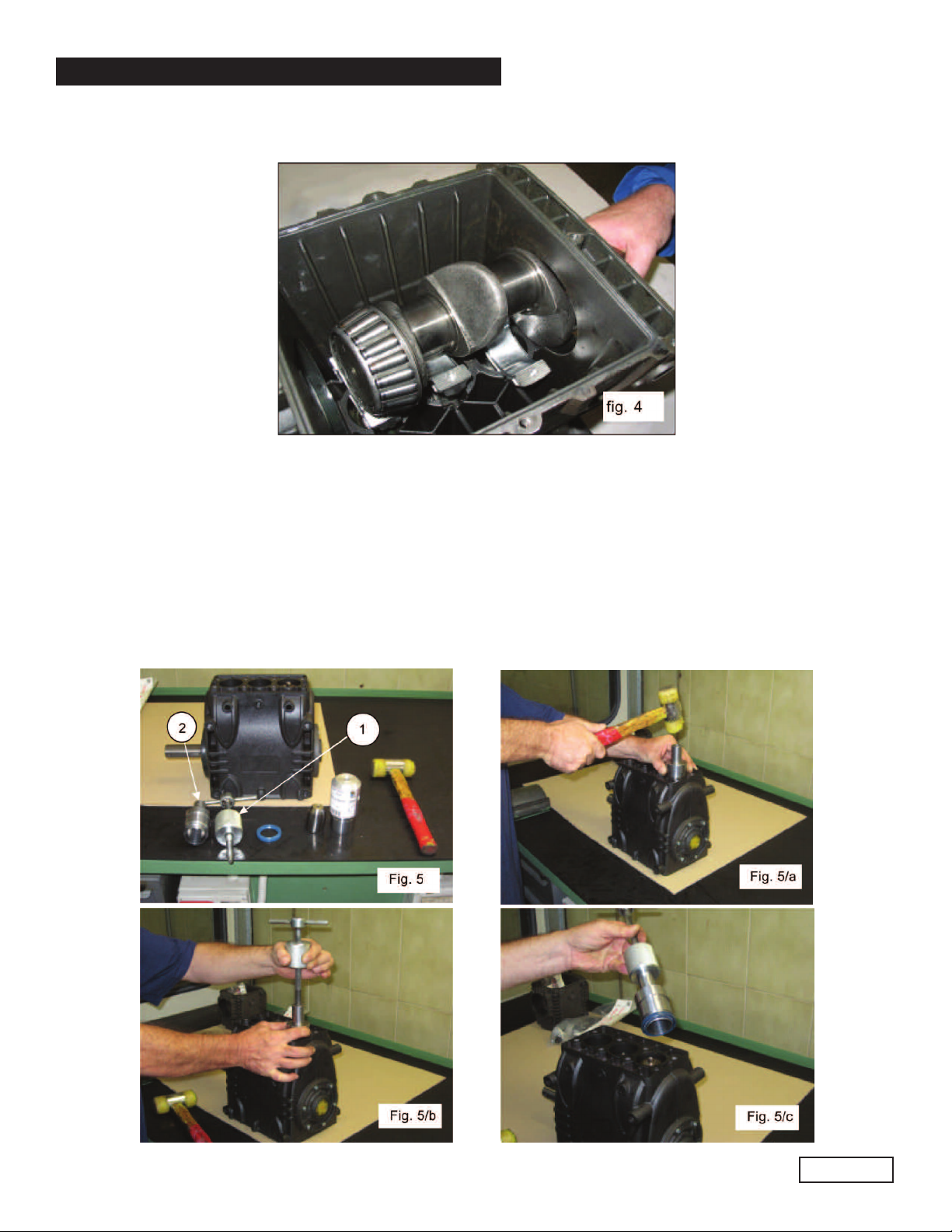

Use the extractor, p/n 26019400 (fig. 5, 1) and the gripper p/n 27503900 (fig. 5, 2). Insert the gripper as far as

possible onto the seal ring with the aid of a hammer (fig. 5a), subsequently screwing the extractor to the gripper, and use the extractor hammer (fig. 5b) until the ring to be replaced is removed (fig. 5c).

Ref 300935 Rev.A

09-13

Page 5

GENERAL PUMP

A member of the Interpump Group

HTCK3623S

2.1.2 REASSEMBLY OF MECHANICAL PARTS

After having checked that the casing is clean, proceed with assembly of the mechanical part as described

below:

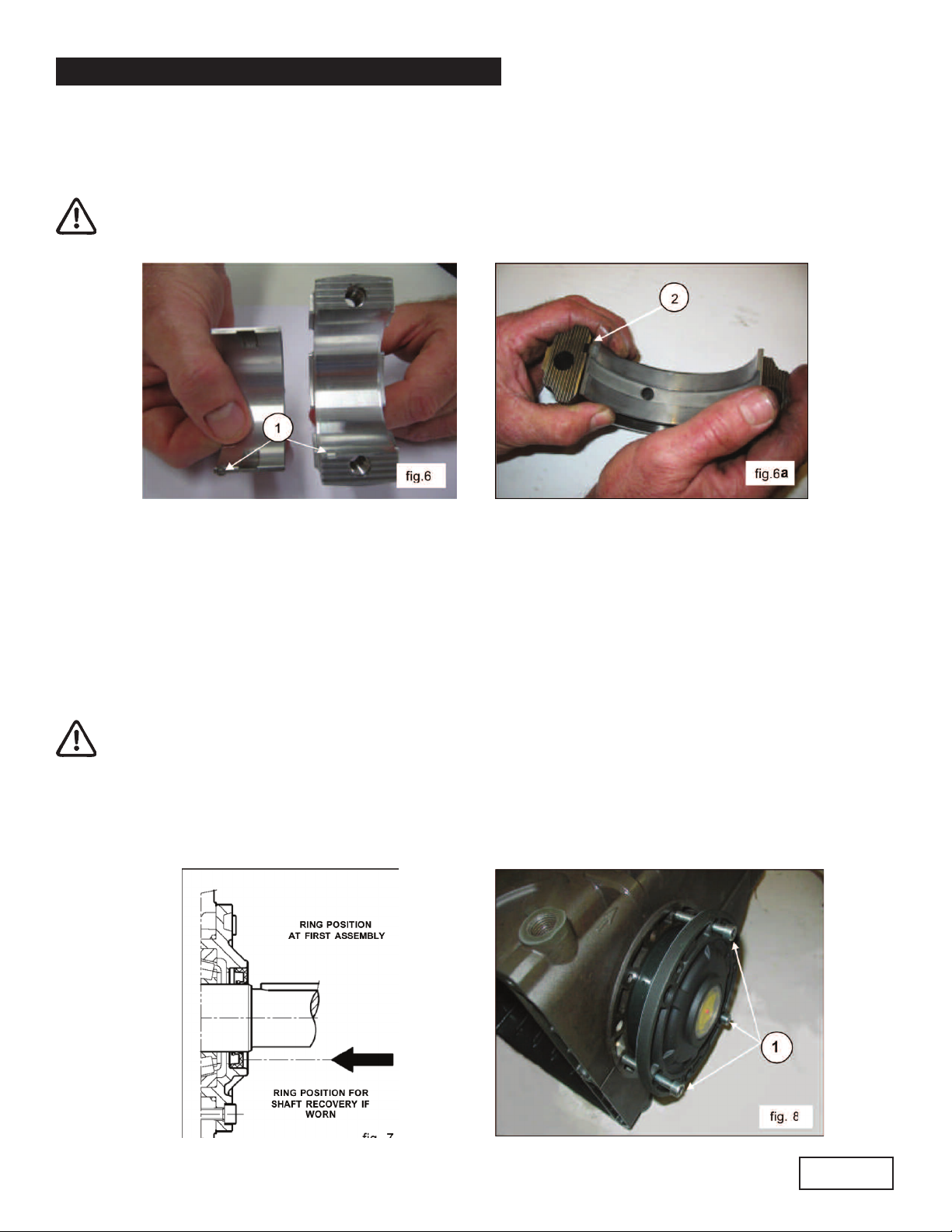

- Assemble the upper and lower half-bearings in their seats in the con-rods and caps.

Make sure that the reference marks on the upper half-bearings (fig.6, 1) and lower halfbearings (fig. 6a, 2) are positioned in their respective seats in the con-rod and cap.

-Insert the piston/con-rod guide units into the pump casing, directing the numbering on the con-rod

shank towards the top of the casing, taking care not to damage the piston guide seal rings.

To facilitate pump shaft insertion (without the tab), it is essential to repeat the operation performed during

disassembly, pushing the piston/con-rod guide units as far down as possible (paragraph 2.2.1).

-Before assembling the side cover on the PTO side, check the conditions of the radial ring lip seal and

relative contact area on the shaft.

If replacement is necessary, position the new ring using a tool p/n 27904500) as indicated in fig. 7.

If the pump shaft shows diametrical wear in the area of contact with the lip seal, in order to

prevent the grinding operation, it is possible to reposition the ring in abutment with the cover

as shown in fig. 7.

Before assembling the side covers, make sure there are O-rings on both of them and shim rings on the indicator side cover only. To facilitate filling of the first section and relative insertion of the covers on the casing,

we recommend using three partially threaded M6x40 screws (fig. 8,1), then completing the operation with the

screws supplied (M6x18).

Ref 300935 Rev.A

09-13

Page 6

Loading...

Loading...