GENERAL PUMPA member of the Interpump Group

8

SERVICING INSTRUCTIONS

SERVICING PUMP PROCEDURES

TC Series “60”

Triplex Plunger Pump

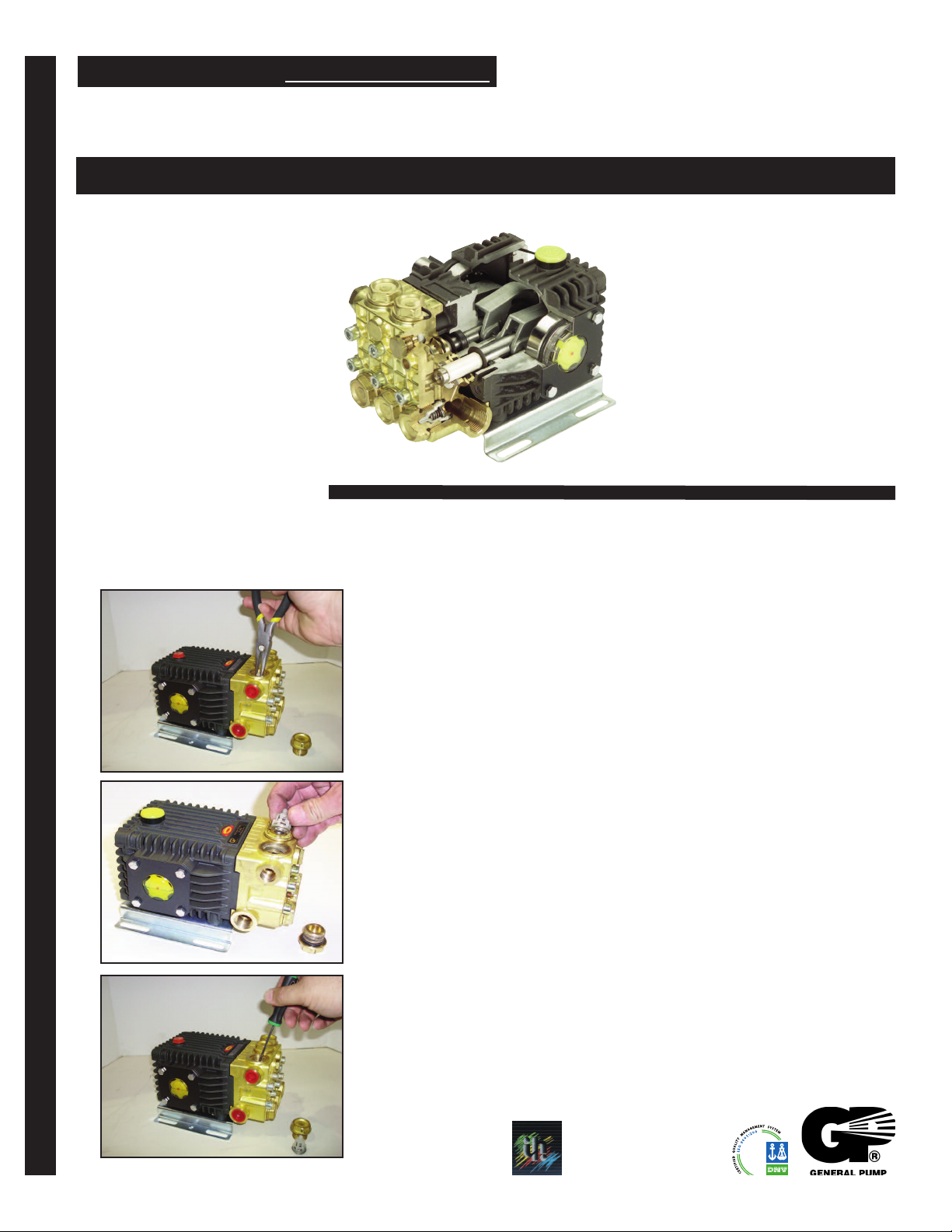

Valve Replacement: All inlet and discharge valves can be serviced without disrupting the inlet or discharge

plumbing. The inlet and discharge valves are identical in all 63 series models.

To service any valve:

1) Remove valve cap and examine o-ring. Replace o-ring if there is any

evidence of cuts, abrasions, distortion or wear.

2) Remove valve assembly (retainer, spring, valve, valve seat) from

valve cavity.

3) Remove valve seat o-ring from valve cavity.

4) Inspect manifold for wear or damage.

5) Install new o-ring in valve cavity.

TRIPLEX TRIPLEX

6) Insert valve assembly into valve cavity.

7) Replace valve cap and torque to specification.

NOTE: Only one valve kit is necessary to repair all the valves

in the pump. The kit includes new o-rings, valve seat, poppet, spring and

retainer. All are pre-assembled.

Ref 300875 Rev. A

General Pump

is a member of

the Interpump Group

02-12

TC Series “60”

Servicing Instructions

GENERAL PUMPA member of the Interpump Group

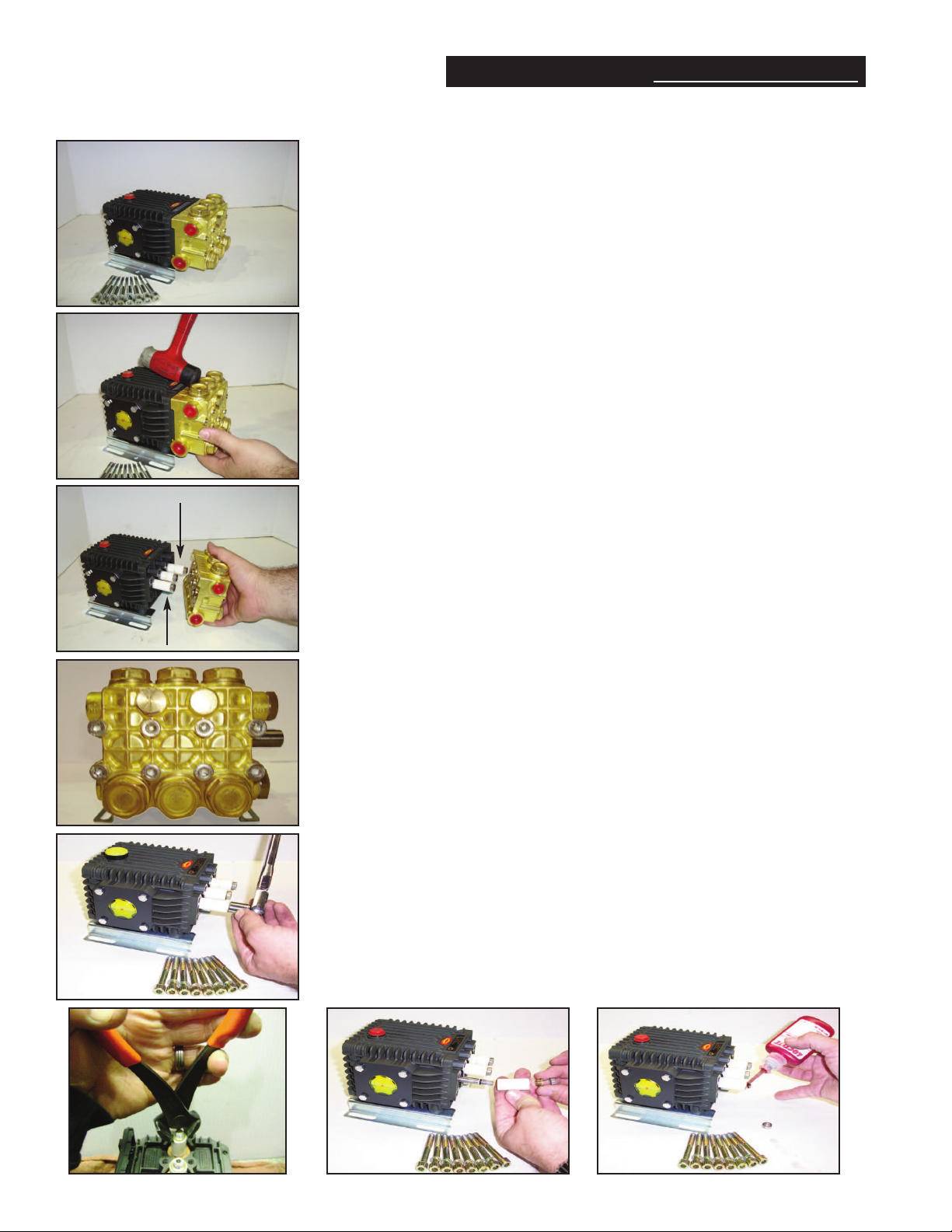

Removing/Installing Manifold:

1) Remove fasteners retaining manifold.

2) Separate manifold from crankcase.

Note: it may be necessary to rotate the crankshaft, or tap the manifold

lightly with rawhide mallet to loosen the manifold from crankcase.

Caution: When sliding head from crankcase use caution not to damage

plungers.

3) The seal assemblies may come off with the manifold. At this point

examine the ceramic plungers. Plunger’s surface should be smooth

and free from scoring, pitting, or cracks; if not, replace.

4) Coat each plunger with grease.

5) Align outside pistons in the forward position.

6) Reinstall manifold and torque to specifications per sequence

described below.

TORQUE SEQUENCE FOR TIGHTENING MANIFOLD:

14 67

5328

• Install all manifold bolts finger tight.

• Torque to 10 foot pounds in sequence as shown.

• Next torque to specification; again, in sequence.

Replacing ceramic plungers:

1) Remove the stainless steel fasteners retaining the plungers.

2) Remove the brass bushing and ceramic plunger from piston rod.

3) If copper slinger washer comes off with plunger, be certain this is

replaced before new plunger is installed.

4) Install new o-ring and Teflon back-up ring on piston rod.

NOTE: a film of grease on the outside of the o-ring insures a better

installation.

5) Slide new plunger over the piston rod, insert new brass

bushing.

6) Apply a drop of removable anaerobic thread sealant to

threads of piston rod.

7) Install the stainless steel fasteners retaining the plungers

and torque to specifications.

Ref 300875 Rev. A

02-12

TC Series “60”

Servicing Instructions

GENERAL PUMPA member of the Interpump Group

Replacing packings:

1) Remove manifold from crankcase.

2) Insert proper extractor collet through main seal retainer.

Tighten collet and extract retainers, packings and

head rings.

3) Apply grease to the packing assembly before installing in

cylinders.

4) Install packing assembly into manifold

5) Repeat this sequence for each cylinder.

6) Align outside pistons in forward position.

7) Coat each plunger with grease.

8) Install manifold and torque retainers to specifications.

Recommended Tools/Supplies:

1) 100783 Complete Extraction Kit

Includes the following tools:

2530016 handle 2530020 15mm sleeve

2530017 bolt 2530021 18mm sleeve

2530018 pin

2) 190446 Oil Drain Kit

3) 100295 General Pump Series 100 Oil (1-16 oz. bottle)

100214 General Pump Series 100 Oil (6-16oz. bottles)

100216 General Pump Series 100 Oil (24-16 oz. bottles)

GGEENNEERRAALL PPUUMMPP

Phone: (651)686-2199 • Fax: (800)535-1745 • e-mail: sales@gpcompanies.com • www.generalpump.com

1174 Northland Drive • Mendota Heights, MN 55120

Ref 300875 Rev. A

02-12

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Pulsation

Low pressure

Pump runs extremely rough,

pressure very low.

Water leakage from under

manifold. Slight leakage.

Oil leak between crankcase

and pumping section.

Valve stuck open. Check all valves, remove foreign matter.

Faulty pulsation damper.

Worn nozzle. Replace nozzle, of proper size.

Belt slippage. Tighten or replace; use correct belt.

Air leak in inlet plumbing. Disassemble, reseal and reassemble.

Relief valve stuck; partially plugged or

improperly adjusted valve seat worn.

Inlet suction strainer clogged or improperly sized.

Worn packing. Abrasives in pumped fluid

or severe cavitation. Inadequate water.

Fouled or dirty inlet or discharge valves. Clean inlet and discharge valve assemblies.

Worn inlet, discharge valve blocked or dirty.

Leaky discharge hose.

Restricted inlet or air entering the inlet plumbing.

Inlet restrictions and/or air leaks. Stuck

inlet or discharge valve.

Worn packing. Install new packing.

Cracked plunger. Replace plunger(s).

Worn crankcase piston rod seals. O-rings

on plunger retainer worn.

Check precharge; if low, rechargeit or install a new one.

Clean, adjust relief valve; check for worn and dirty

valve seats. Kit available.

Clean. Use adequate size. Check more frequently.

I

nstall proper filter. Suction at inlet manifold must be limited

to lifting less than 20 feet of water or -8.5 PSI vacuum.

Replace worn valve seats and/or discharge hose

Proper size inlet plumbing; check for air tight seal

Replace worn cup or cups, clean out foreign material,

replace worn valves.

Replace crankcase piston rod seals. Replace

o-rings.

Oil leaking in the area of

crankshaft.

Excessive play in the end of

the crankshaft pulley.

Water in crankcase.

Oil leaking from underside

of crankcase.

Oil leaking at the rear portion

of the crankcase.

Loud knocking noise in pump.

Frequent or premature failure

of the packing.

Worn crankshaft seal or inproperly

installed oil seal o-ring.

Bad bearing.

Worn main bearing from excessive

tension on drive belt.

May be caused by humid air condensing i

nto water inside the crankcase

Worn packing and/or piston rod sleeve,

o-rings on plunger retainer worn.

Cracked plunger Replace plunger(s).

Worn crankcase piston rod seals. Replace seals.

Scored piston rod. Replace piston rod.

Damaged crankcase, rear cover o-ring,

drain plug o-ring, or sight glass o-ring.

Pulley loose on crankshaft. Check key and tighten screw.

Broken or worn bearing on rod(s). Replace bearing or rod(s).

Valve stuck open or shut, or not opening enough.

Scored, damaged or worn plunger. Replace plungers.

Overpressure to inlet manifold. Reduce inlet pressure.

Abrasive material in the fluid being pumped. Install proper filtration on pump inlet plumbing.

Excessive pressure and/or temperature

of fluid being pumped.

Overpressure of pump. Reduce pressure.

Running pump dry. Do not run pump without water.

Upstream chemical injection.

Remove oil seal retainer and replace damaged

o-ring and/or seals.

Replace bearing and any spacer or cover damaged

by heat.

Replace crankcase bearing and/ or

tension drive belt.

Change oil intervals. Use General Pump SAE 30

non-detergent oil.

Replace packing. Replace o-rings.

Replace cover or-ring, drain plug o-ring, or sight

glass o-ring.

Replace bad valve.

Check pressures and fluid inlet temperature; be

sure they are within specified range.

Use downstream chemical injection.

GGEENNEERRAALL PPUUMMPP

Phone: 651.686.2199 • Fax: 800.535-1745 • e-mail: sales@gpcompanies.com • www.generalpump.com

1174 Northland Drive • Mendota Heights, MN 55120

Ref 300875 Rev. A

02-12

Loading...

Loading...