Page 1

™

Sewerooter T-3

Operating Instructions

For 1-1/4” through 3” and Most 4” lines

(30mm—100mm)

Your Sewerooter T-3 is designed to

give you years of trouble-free, profitable

service. However, no machine is better

than its operator.

Read, understand and follow all safety

warnings and instructions provided with

the product. Failure to follow the warnings

and instructions may result in electric

shock and/or serious injury. Save all warnings and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Page 2

Sewerooter T-3™

WARNING! Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury. Replacement

manuals are available upon request at no

charge, or may be downloaded from our website, www.drainbrain.com. Instructional videos

are available for download on our website, and

may be ordered. If you have any questions or

problems, please call General’s customer

service department at 412-771-6300.

SAVE THESE INSTRUCTIONS!

These instructions are intended to

familiarize all personnel with the safe

operation and maintenance

procedures for the Sewerooter T-3.

SAFETY SYMBOLS

Electric shock resulting in

death can occur if you plug

this machine into an improperly wired outlet. If the ground

wire is electrified, you can be

electrocuted by just touching

the machine, even when the

power switch is off. A ground

fault circuit interrupter will not protect you in this situation. Use a

UL approved tester to determine

if the outlet is safe.

Do not operate power tools in

explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which

may ignite the dust or fumes.

Only wear leather gloves.

Never use any other type of

glove, such as cloth, rubber, or

coated gloves. Never grasp a

rotating cable with a rag.

These items could become

wrapped around the cable and

cause serious injury.

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazard with a low level of risk which,

if not avoided, will result in minor or moderate injury.

Always wear safety glasses

and rubber soled, non-slip

shoes. Use of this safety equip-

ment may prevent serious injury.

Never operate machine with

belt guard removed. Fingers

can get caught between belt and

pulley.

Never operate machine without

the Guide Tube in place. Can

result in significant hand injury.

Do not overstress cables.

Overstressing cables may cause

twisting, kinking, or breaking of

the cable and may result in serious injury.

2

Page 3

Sewerooter T-3™

GENERAL SAFETY RULES

WARNING

Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire, and/or

serious injury.

SAVE THESE INSTRUCTIONS!

Work Area

1. Keep work area clean and well lit. Cluttered benches and dark

areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating

a power tool. Distractions can cause you to lose control.

Electrical Safety

1. Grounded tools must be plugged into an outlet, properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adapter plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tool should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

2. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

3. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

5. When operating a power tool outside use an outdoor exten-

sion cord marked “W-A” or “W”. These cords are rated for

outdoor use and reduce the risk of electric shock.

6. Test the Ground Fault Circuit Interrupter (GFCI) provided

with the power cord to insure it is operating correctly before

operating machine. Machine must have a properly functioning

ground fault circuit interrupter on the power cord. GFCI reduces

the risk of electric shock.

7. Extension cords are not recommended unless they are

plugged into a Ground Fault Circuit Interrupter (GFCI) found

in circuit boxes or outlet receptacles. The GFCI on the ma-

chine power cord will not prevent electric shock from the extension cords.

8. Only use proper three-wire extension cords in good condi-

tion which have three-prong grounding plugs and three-pole

receptacles which accept the tool’s plug. Use of damaged,

inferior, or other extension cords will not ground the tool. Increases the risk of electric shock and bodily injury or death.

9. Keep all electric connections dry and off the ground. Re-

duces the risk of electric shock.

10. DO NOT touch plugs or tools with wet hands. Reduces the

risk of electric shock.

Personal Safety

1. Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A mo-

ment of inattention while operating power tools may result in

serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Con-

tain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

3. Avoid accidental starting. Be sure switch is off before plug-

ging in. Carrying tools with your finger on the switch or plugging

in tools that have the switch on invites accidents.

4. Remove adjusting keys or wrenches before turning the tool

on. A wrench or key that is left attached to a rotating part of the

tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

6. Use safety equipment. Always eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions.

Tool Use and Care

1. Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to loss of control.

2. Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

3. Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

4. Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventative safety measures reduce the risk of starting the

tool accidentally.

5. Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

6. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely

to bind and are easier to control.

7. Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tool’s operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

8. Only use accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool may become hazardous when used on another tool.

Service

1. Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified repair

personnel could result in a risk of injury.

2. When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

3

Page 4

Sewerooter T-3™

SPECIFIC SAFETY RULES

This is the safety alert symbol. It is used to alert

1. Only wear leather gloves. Never use any other type of glove,

such as cloth, rubber, or coated gloves. Never grasp a rotating

cable with a rag. These items could become wrapped around the

cable and cause serious injury.

2. Never operate machine with belt guard removed. Fingers can

get caught between belt and pulley.

3. Never operate machine without Guide Tube in place. Can

result in significant hand injury.

4. Do not overstress cables. Keep leather-gloved hand on the

guide tube for control when machine is running. Overstressing

cables because of an obstruction may cause twisting, kinking, or

breaking of the cable and may result in serious injury.

5. Place the machine at a distance not greater than two feet

from the opening. Greater distances can result in cable twisting

or kinking.

6. Machine is designed for ONE-PERSON operation. Operator

must control foot switch and cable.

7. Do not operate machine in reverse (REV). Operating machine

in reverse can result in cable damage and is used only to back

cutting tool out of an obstruction.

8. Keep hands away from rotating drum. Do not reach into drum

unless machine is unplugged. Hand may be caught in the moving

parts resulting in serious injury.

9. Be careful when cleaning drains where cleaning chemicals

have been used. Avoid direct contact with skin and eyes. Drain

cleaning chemicals can cause serious burns as well as damage

the cable.

10. Do not operate machine if operator or machine is standing

in water. Will increase risk of electrical shock.

11. Wear safety glasses and rubber soled, non-slip shoes. Use

of this safety equipment may prevent serious injury.

12. Before starting each job, check that the cable in the drum is

not broken or kinked, by pulling the cable out and checking

for wear or breakage. Always replace worn out (kinked or bro-

ken) cables with genuine GENERAL replacement cables.

13. Only use this tool in the application for which it was de-

signed. Follow the instructions on the proper use of the machine. Other uses or modifying the drain cleaner for other appli-

cations may increase risk of injury.

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

Electric shock resulting in death can occur if you

plug this machine into an improperly wired outlet. If

the ground wire is electrified, you can be electrocuted

by just touching the machine, even when the power

switch is off. A ground fault circuit interrupter will not

protect you in this situation. Use a UL approved tester to

determine if the outlet is safe.

Do not overstress cables. Overstressing cables may

cause twisting, kinking, or breaking of the cable and may

result in serious injury.

Ground Fault Circuit Interrupter (GFCI)

Your machine is equipped with a ground fault circuit interrupter, which

protects you against shock if a short circuit should occur. Check that

receptacle is properly grounded. Test the GFCI before each use.

1. Plug into 120-volt receptacle.

2. Push test button. Indicator light will go out and power to machine

should cut off.

3. If light does not go out when test button is pushed, DO NOT USE

THE MACHINE until proper repairs can be made.

4. To restore power after test, push reset button. With the reset

button depressed, if the machine doesn't start, stops while running, or if the operator experiences a mild shock, DO NOT USE

THE MACHINE! Tag the machine out of service and take it to a

motor repair center or return it to the factory for repairs.

THE SECTION OF CORD BETWEEN THE WALL PLUG

AND THE GFCI IS NOT IN THE PROTECTED CIRCUIT.

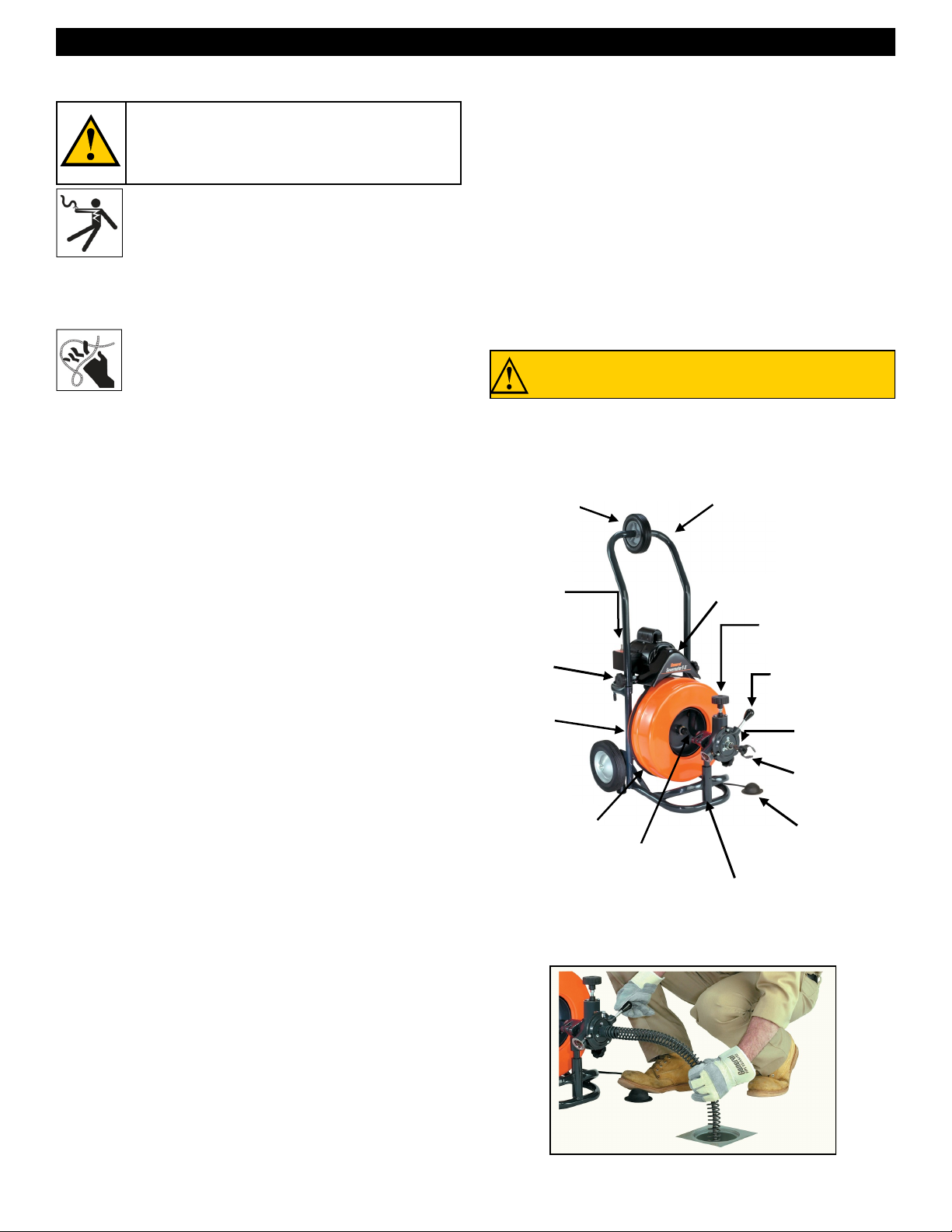

FEATURES

Truck

Loading

Wheel

Motor

Switch

Knob for

Folding

Handle

V-Belt

Drum

Distributor Tube

NOTE: Do not operate machine if warning labels on the switch box

and power cord are missing or illegible.

Sewerooter T-3 shown with Guide Tube (Cat. #T3-GT)

4

Folding Handle

Belt Guard

Feed Pressure

Control Knob

Feed Control

Lever

Female

Connector

Cutter

Foot Pedal

Front Post

Page 5

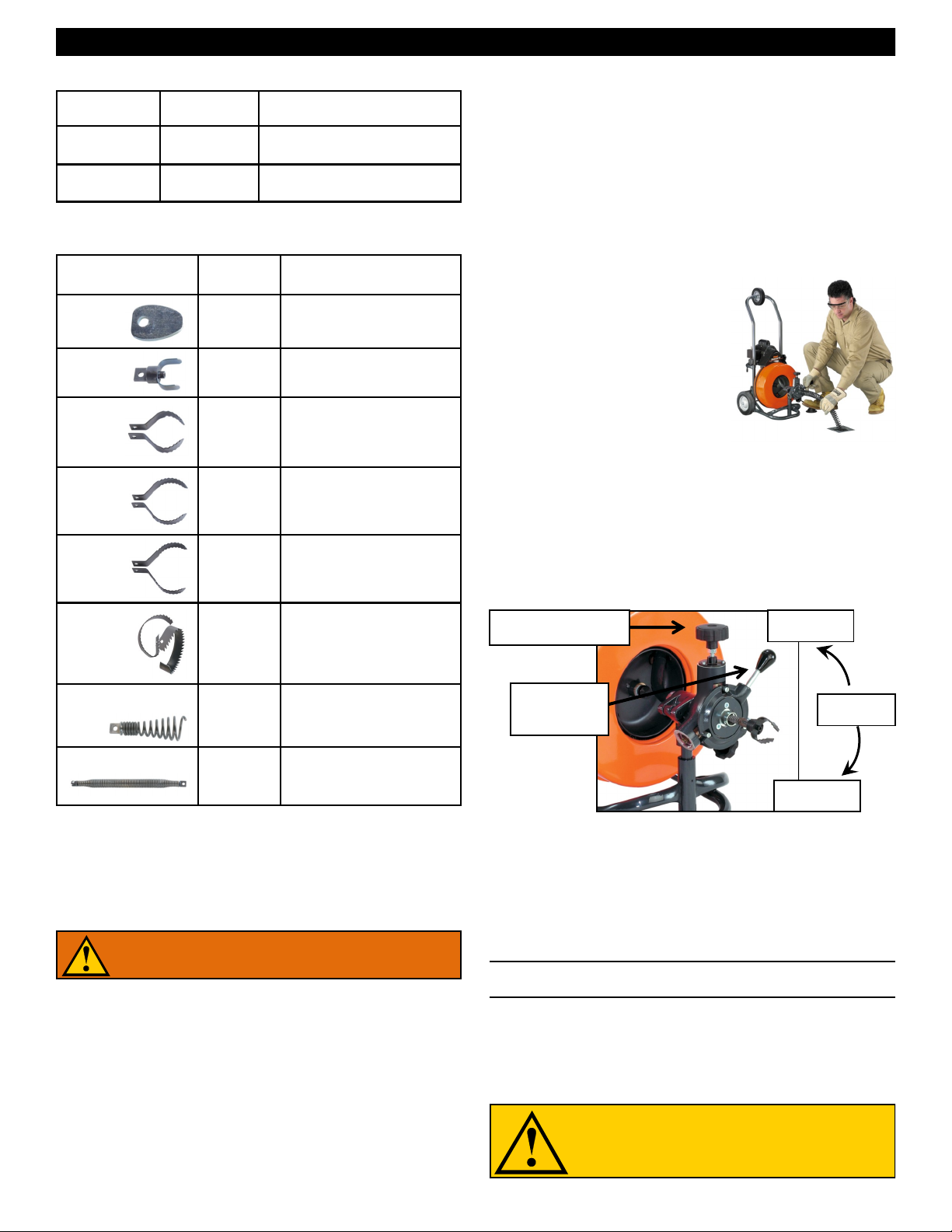

Cable Application Chart (Table 1)

Cable Size Pipe Size Typical Applications

1/2" 3" to 4"

3/8" 2" to 3"

Roof Stacks and Small Floor

Drains (No roots)

Roof Stacks, Laundry Lines and

Small Drains (No roots)

Cutter Application Chart (Table 2)

Cutter Cat. # Typical Applications

Arrow

Head

1-1/2”

U-Cutter

2” Side

Cutter

Blade

3” Side

Cutter

Blade

4” Side

Cutter

Blade

AH

1-1/2UC

2SCB

3SCB

4SCB

Starting tool, ideal for cutting

and scraping.

Starting tool, works well in

grease stoppages.

Finishing tool, for scraping

inside edges of pipe.

Finishing tool, for scraping

inside edges of pipe.

Finishing tool, for scraping

inside edges of pipe.

Sewerooter T-3™

4. Select the proper cutting tool (See Cutter Application Chart—

Table 2). A good tool to start with is the Arrow Head or 1-1/2” UCutter. After the line is opened, follow with larger blades, which

scrape the inside edges of the pipe, assuring a real cleaning job.

If you’re having difficulty getting around a P-trap or close bend,

attach the Flexible Leader (for 1/2" cable only).

5. Insert the cutter into the female connector at the end of the cable

and tighten the connecting screw and lock washer firmly in place.

OPERATION

1. Begin by pulling the cable from the

drum and sliding it into the drain as

far as it will go.

2. Tighten the knob at the top of the

Power Cable Feed so that the feed

roller presses against the cable. Be

sure not to over tighten since this

could cause excess cable wear.

Note: The Power Cable Feed is

designed for use with 3/8” and 1/2”

cables only.

3. The feed lever controls the feeding rate and direction of the cable. Move the lever down to feed the cable out of the drum. The

further the lever is moved downward, the faster the cable will

feed out. Move the lever up to retract the cable into the drum.

When the lever is in the middle (neutral) position, the cable will

spin in place.

3” Rotary

Saw

Blade

Retrieving

Tool

Flexible Leader

Note: There are no fixed rules for what cutter to use. If one tool doesn't

take care of a stoppage, simply try another.

3RSB

RTR-1

LE-1

Finishing tool, for cutting and

scraping.

To remove or retrieve loose

objects.

Tool for negotiating around

difficult bends.

OPERATION

SET-UP

MAKE SURE THE MOTOR SWITCH

IS IN THE ‘OFF’ POSITION!

1. Be sure the motor switch is in the off position.

2. Place machine at a distance of not greater than two feet of drain

opening. If you can’t place the machine this close to the drain

opening, run the cable through a pipe or a metal guide tube to

prevent cable whipping. The Sewerooter T-3 Guide Tube (T3GT) is ideal for this. Guide Tube Extensions (GTE) are also available.

3. Position the air foot pedal for easy accessibility. The machine is

designed for one-person operation. Be sure you can quickly remove your foot from the pedal in an emergency.

Feed Pressure Knob

Feed Control

Lever

4. Move the motor switch to the forward position. Then with a

gloved hand on the guide tube, depress the air foot pedal to start

machine.

5. Feed the cable into the line and against the obstruction with a

firm, even pressure. Adjust the feeding rate to the resistance

met. Do not force the cable – let the cutter do the work. The job

won’t get done any faster and you could damage the cable.

DO NOT USE TOO MUCH FORCE –

LET THE CUTTER DO THE WORK.

6. Don't leave too much slack in the cable since this will cause

whipping. If the cable starts to bend or build up too much twist,

release pressure on the foot pedal and rotate the drum in the

opposite direction to relieve the twist on the cable. Push any

excess cable back into the drum and then continue.

DO NOT ALLOW TOO MUCH SLACK IN THE CABLE

BETWEEN MACHINE AND DRAIN OPENING SINCE

THIS CAN CAUSE CABLE WHIPPING.

5

Reverse

Neutral

Forward

Page 6

Sewerooter T-3™

7. If you're having trouble getting around

tight bends, try putting the machine in

reverse while applying steady pressure. (If using Power Cable Feed,

putting motor in reverse will cause the

feed control lever to operate opposite

of normal.)

Don't run motor in reverse for more than a few seconds at a

time as this could cause tangling in the drum or kinking.

8. If you still can't get around the bend, you're probably using too

large a cable. Switch to a 3/8" diameter cable, or even a smaller

machine if necessary. (See Cable Application Chart—Table 1)

9. When the cable reaches the stoppage, put feed in neutral. Then

allow the cable to progress forward slowly, chewing into the stoppage as it goes. This slow forward movement will reduce stress

on the cable while doing a more thorough cleaning job. A back

and forth action often works best.

Hint: It's often helpful to have a small stream of water running in the

line to wash the cuttings away while the machine is in operation and

after.

10. Be careful not to let the cutter get caught in the stoppage as you

work through it. This can cause kinking and breaking of the cable. When you feel the cable starting to twist in your hands, stop

the machine and pull back on the cable. This will free the cutter

from the obstruction. Then allow the cable to move forward

slowly into the stoppage.

11. After the line has been opened, retract the cable by moving the

feed lever up. Make sure the motor switch is in the forward position. This is important to prevent the cable from tangling in the

drum or in the line.

DO NOT USE REVERSE TO PULL THE CABLE OUT

OF THE DRAIN. RUNNING MACHINE IN REVERSE

CAN CAUSE THE CABLE TO TANGLE IN THE DRUM.

12. When the cutter is near the drain opening, take your foot off the

pedal to stop drum rotation. Never retract the cutter from drain

while cable is rotating. The cable could whip and cause serious

injury.

SPECIAL OPERATIONS

IF CABLE GETS CAUGHT IN LINE

The motor can be reversed to free cable if it gets caught in the line.

(Note: if using Power Cable Feed, putting motor in reverse will cause

the feed control lever to operate opposite of normal.) Use the following procedure:

1. Move motor switch to reverse position.

2. Wearing leather gloves, retract cable while the drum is turning in

reverse.

3. When the cable is freed, slide excess cable back into drum.

4. Move the motor switch to the forward position again, and continue at Step 3 of the Operating Instructions.

DO NOT RUN MOTOR IN REVERSE FOR MORE THAN A

FEW SECONDS AT A TIME SINCE THIS COULD CAUSE

THE CABLE TO KINK OR TANGLE IN THE DRUM.

IF CABLE TANGLES IN DRUM

This is caused by using too much pressure when feeding the cable or

by feeding the cable while running the machine in reverse. To untangle cable, rotate drum in opposite direction. This will usually get the

cable to lie in the drum properly.

If cable has become severely tangled, which shouldn’t occur if used

properly, it can be straightened out by removing the distributor tube

from the drum. To do this:

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE UNTANGLING CABLES

1. Turn the drum until the distributor tube is pointing down.

2. While holding the tube firmly, loosen the knob on the front post.

3. Swing the hinged cap out of the way and lift out the tube. This

should free the cable. If not, continue to Step 4.

4. Reach into the center of the drum and unscrew the knob at the

center of the inner drum. Then, pull the inner drum forward off

the shaft and out of the drum.

5. After the cable has been untangled, reverse the above procedure

and reload the cable into the drum.

HOW TO REMOVE DRUM

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE EXCHANGING DRUMS!

1. Remove V-Belt. You can relieve the tension on the belt by pressing down on the motor, which is spring-loaded.

2. Hold distributor tube and loosen knob on front post. Then, open

hinged cap and lift out tube.

3. Reach behind the drum and locate the drum retaining latch.

While pulling the latch, pull the drum forward off of the machine.

4. To install the drum, simply reverse this procedure.

HOW TO INSTALL POWER CABLE FEED (PO-JR)

The Power Cable Feed gives you a “power-assist” when feeding ca-

bles in or pulling them out. When feeding, do not use too much force –

let the cutter do the work.

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE INSTALLING POWER CABLE FEED!

1. Slide the Power Cable Feed onto the

mounting stud located on the front post.

2. Align the mounting knob on the Feed

body with the flat spot on the stud.

3. Tighten knob firmly.

6

Page 7

Sewerooter T-3™

HOW TO INSTALL CABLES IN DRUM

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE INSTALLING CABLES IN DRUM!

1. Attach male connector of cable to the drum connecting cable

permanently connected to the drum. Be sure to tighten screw

and lock washer firmly.

2. Slip V-Belt off of drum. If using Power Cable Feed, loosen pressure knob on top.

3. Push the cable into the drum. As you load, turn the drum so that

the distributor tube is always pointed in the same direction. This

enables the cable to lie more evenly in the drum.

4. Be sure cable is going in proper

direction. To check, position distributor tube so that it's pointing

straight down. The cable should be

bending to the left as it comes out

of the back of the distributor tube.

1. Remove the feed pressure knob, cover screws, top cover, spring,

ball bearing and ball bearing holder. Note the positioning of these

parts to ease re-assembly. Remove the swing pin from the carrier. The top roller assembly can now be removed.

2. Remove the snap rings and thrust washers from the bottom

housing cylinders. Remove swing pins from carriers. The bottom

roller assemblies can now be removed.

3. Re-assembly is done in reverse order.

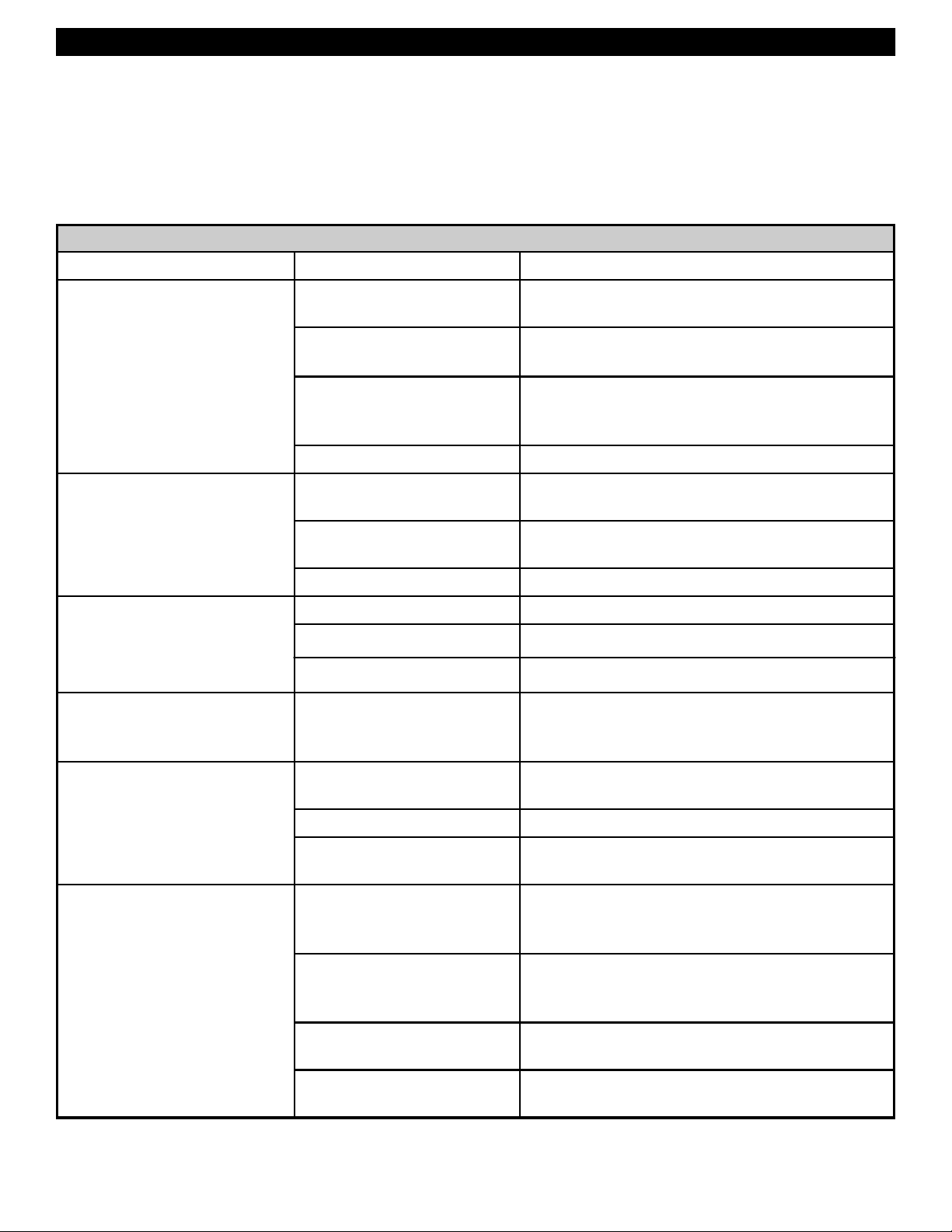

DAMAGED ROLLER

Excessive use may wear a roller to the point of failure. It is recommended that all three rollers be replaced at the same time (Cat # POJR-703). The replacement roller is an assembly consisting of one

Feed Roller, two Feed Roller Bearings, and two Bearing Spacers.

Note: The Bearing Spacers must be installed between the Carrier

and each Feed Roller Bearing (as illustrated below) in order to

ensure proper operation and to obtain maximum Feed Roller life.

NOTE: The cable must lay in the drum in the correct direction or it will

tangle in the drum.

MAINTENANCE

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE PERFORMING MAINTENANCE!

To keep your machine operating smoothly, it is essential that all bearings and distributor tube bushings be lubricated. Oiling moving parts is

particularly important where machine comes in contact with sand, grit

and other abrasive material.

CABLE MAINTENENCE

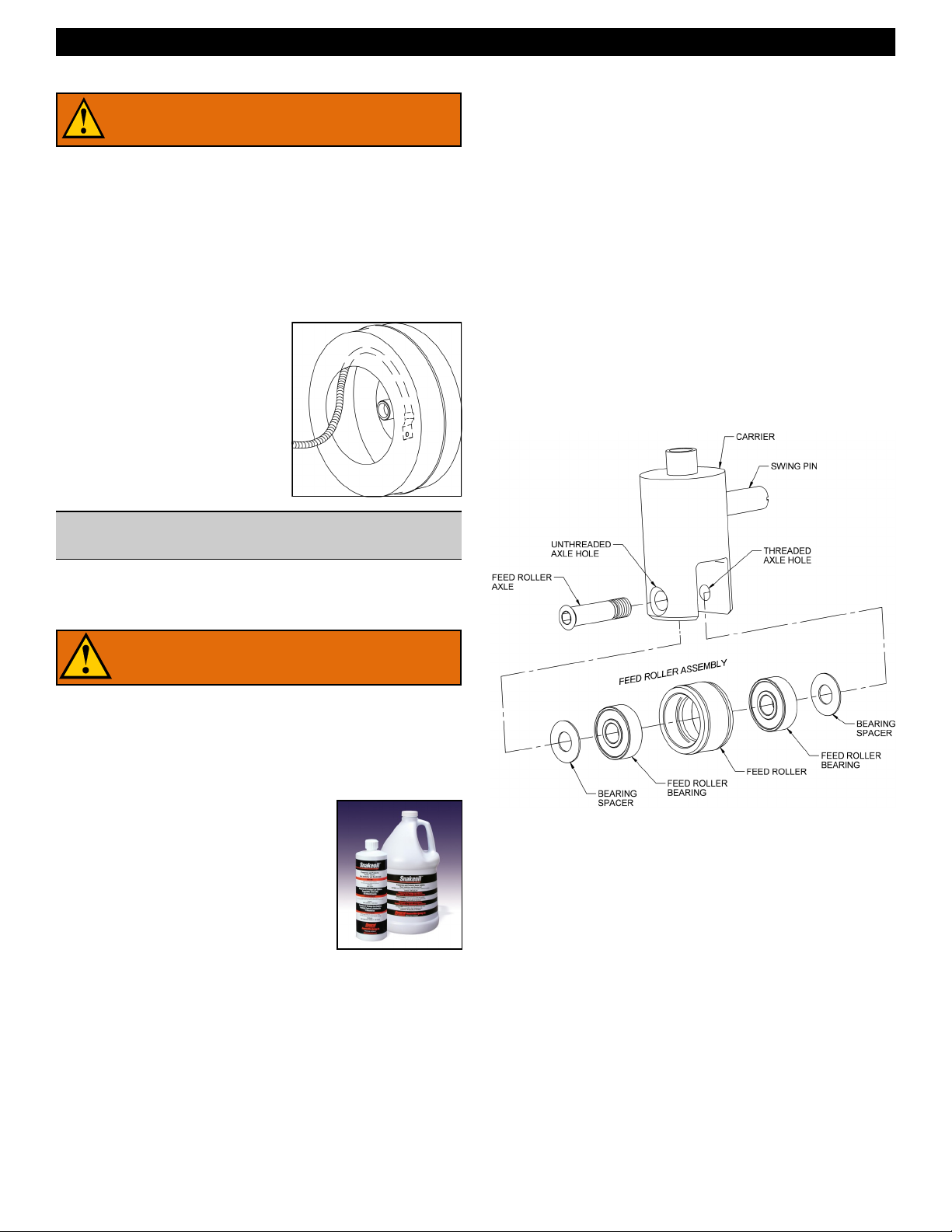

To get maximum service from your cables, be

sure that they are clean and well oiled. This not

only provides running lubrication but greatly

extends the life of the cables as well. Some

users periodically pour oil directly into the drum.

Then, as the drum turns, the cables get complete lubrication. Our SNAKE OIL is ideally

suited for this purpose, since it not only lubricates the cables, it deodorizes them as well.

FEED MAINTENANCE

Keep feed free of excessive soil and grit. It is recommended that the

feed be flushed with fresh water followed by a light oiling of the moving parts. No disassembly is normally required. Failure to feed can

usually be traced to the following possibilities:

DIRT ACCUMULATION

Over time, dirt can harden enough to stop roller rotation. Flushing with

water followed by liberal oiling can usually restore function. If disassembly is required, proceed as follows:

To Replace the Feed Roller Assembly:

1. Remove the Feed Roller Assembly by unscrewing and removing

the Feed Roller Axle.

2. For convenience, the components are assembled and wired

together at the factory. Before attempting to install the assembly,

hold the assembly together and remove the wire.

3. While still holding the Feed Roller Assembly together, insert it

into the slot opening of the Carrier.

4. In order to help align the Spacers and Bearings, insert a pencil

point or similar object through the un-threaded end of the Axle

hole in the Carrier. After removing the pencil point, continue to

maintain the alignment of the components.

5. The Feed Roller Axle should then be inserted through the same

un-threaded Axle hole and should continue to be guided through

the Spacers and Bearings to the threaded Axle hole on the other

side of the Carrier.

6. Securely tighten the Axle to the Carrier with a 3/16” allen wrench.

7

Page 8

Sewerooter T-3™

TANGLED CABLE

If a cable loops over itself in the drum, it will not feed properly. Remove and reload the cable to restore function. If the cable kinks, it is

evidence of abuse and results from the use of too much pressure or

use of the wrong size cable for the line. Do not force the cable — let

the cutter do the work.

TROUBLE SHOOTING GUIDE (Table 3)

Problem Probable Cause Solution

Cable kinks or breaks. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Too much slack between machine

and drain.

Cable used in wrong size drain line.

Cable exposed to acid. Clean and oil cables regularly.

Cable tangles in drum. Operator forcing the cable. Do not force the cable. Let the cutter do the work.

Machine running in reverse.

Distributor tube frozen. Lubricate distributor tube bushings.

Drum stops while foot pedal depressed.

Drum turns in one direction but not

other.

Ground fault circuit interrupter trips

and will not reset.

Hole in pedal or hose. Replace as required.

Hole in diaphragm switch.

Thermal overload activated.

Reverse switch failure. Replace reverse switch.

Damaged power cord or extension

cord.

Allow no more than two feet between machine and drain.

A cable that is too large or too small in diameter for a line is

more likely to kink. (Consult Table 1—Cable Applications.)

Do not run the machine in reverse to retract the cable from the

drain.

If no hole found in pedal or hose, replace diaphragm switch.

Allow motor to cool. Press reset button.

Replace cords.

Short circuit in motor. Take motor to authorized repair center.

Faulty ground fault circuit interrupter.

Failure to feed. Cable tangled in drum.

Feed misadjusted.

Feed roller frozen. Clean and lubricate feed rollers regularly. Replace worn rollers.

Worn cable. When cable coils wear flat, cable should be replaced.

Replace ground fault circuit interrupter.

Do not run machine in reverse. Use proper cable size. (Consult

Cable Application Chart—Table 1).

If feed tension knob is too loose the cable will slip. If it is too

tight the feed rollers will wear prematurely.

8

Page 9

Sewerooter T-3™ :

mode d’emploi

Pour les canalisations de 1-1/4 po à 3 po

et la plupart des canalisations de 4 po

(30 mm-100 mm)

Votre Sewerooter T-3 est conçu pour fournir

des années de service sans problème, et

générer des profits à long terme. Toutefois, le

bon fonctionnement et la durée de vie de

l’appareil dépendent de son opérateur.

Lisez, comprenez et respectez toutes les

consignes de sécurité et les instructions

fournies avec le produit. Ne pas respecter les

avertissements et les instructions fournies peut

entraîner un choc électrique et/ou des

blessures graves. Conservez en lieu sûr tous

les avertissements et instructions pour

référence ultérieure.

CONSERVEZ CES INSTRUCTIONS !

Page 10

AVERTISSEMENT ! Lire et comprendre

blessures, voire un accident mortel.

toutes les instructions. Le non-respect de

toutes les instructions listées ci-dessous peut

entraîner un choc électrique, un incendie et/ou

des blessures graves. Des manuels de remplacement sont disponibles sur demande sans

frais. Vous pouvez également les télécharger

depuis notre site Internet, www.drainbrain.com.

Des vidéos de formation sont disponibles en

téléchargement sur notre site Internet. Vous

pouvez également les commander. Si vous

avez des questions ou des problèmes, veuillez

appeler notre Service d’assistance à la

clientèle au (+1) 412-771-6300.

CONSERVEZ CES INSTRUCTIONS !

Ces instructions visent à familiariser tous

les employés avec l’utilisation et

l’entretien en toute sécurité de la

machine Sewerooter T-3.

SYMBOLES DE SÉCURITÉ

Voici le symbole d’alerte de sécurité.

Il sert à vous avertir des dangers

potentiels de blessures. Respecter

tous les messages de sécurité qui

suivent ce symbole pour éviter des

I

l peut se produire des chocs

électriques qui peuvent causer la

mort si vous branchez cet appareil

à une prise mal câblée. Si le fil de

terre est mis sous tension, vous

pouvez être électrocuté

simplement en touchant la

machine, même si le commutateur

est en position ARRÊT. Un

interrupteur GFCI ne vous protégera

pas dans cette situation. Utiliser un

testeur agréé UL pour déterminer si

la prise est sans danger.

Ne pas utiliser des outils

électriques dans une atmosphère

explosive, comme par exemple en

présence de liquides, de gaz ou de

poussières inflammables. Les

outils électriques produisent des

étincelles qui peuvent enflammer les

poussières ou les vapeurs.

Porter uniquement des gants en

cuir. Ne jamais utiliser d’autres

type de gant (en tissu, en

caoutchouc ou avec revêtement

ou enduit). Ne jamais saisir avec

un chiffon un câble en rotation.

Ces éléments pourraient s’entortiller

autour du câble et provoquer de

graves blessures.

Toujours porter des lunettes

otection et des chaussures

de pr

avec semelle en caoutchouc

antidérapante. Utiliser ces équipe-

ments de sécurité peut empêcher de

recevoir des blessures graves.

La

mention DANGER indique un danger qui présente un

haut niveau de risque : s’il n’est pas évité, il va causer la

mort ou des blessures graves.

La mention AVERTISSEMENT indique un risque qui

présente un niveau moyen de risque : s’il n’est pas évité, il

peut entraîner des blessures graves voire la mort.

La mention ATTENTION indique un danger qui présente un

niveau réduit de risque : s’il n’est pas évité, il va causer des

blessures moyennement graves ou bénignes.

10

Ne jamais utiliser la machine sans

le protège-courroie. Les doigts

peuvent se coincer entre la courroie

et la poulie.

Ne jamais utiliser la machine sans

le tube de guidage. Peut entrainer

des blessures importantes aux

mains.

Ne pas forcer les câbles. Une

tension excessive sur les câbles peut

causer leur torsion, leur vrillage ou

leur rupture, et peut entraîner des

blessures graves.

Page 11

RÈGLES GÉNÉRALES DE SÉCURITÉ

Lire et comprendre toutes les instructions. Le non-respect de

électrique, un incendie et/ou des blessures graves.

toutes les instructions listées ci-dessous peut entraîner un choc

CONSERVEZ CES INSTRUCTIONS !

Zone de travail

1.

Veiller à ce que la zone de travail reste propre et soit bien

éclairée. Des établis encombrés et des zones de travail dans

l’obscurité invitent les accidents.

2.

Ne pas utiliser des outils électriques dans une atmosphère

explosive, comme par exemple en présence de liquides, de gaz

ou de poussières inflammables. Les outils électriques produisent

des étincelles qui peuvent enflammer les poussières ou les vapeurs.

3.

Tenir les personnes présentes, les enfants et les visiteurs

éloignés quand vous utilisez un outil électrique. Des distractions

peuvent vous en faire perdre le contrôle.

Sécurité électrique

1.

Les outils avec mise à la terre doivent être branchés dans une

prise qui a été correctement installée et reliée à la terre

conformément aux codes et règlements locaux. Ne jamais retirer

la broche de terre ni modifier la fiche d’aucune façon. Ne pas

utiliser d’adaptateur de prise. Vérifier avec un électricien qualifié si

vous avez des doutes quant à savoir si la prise est correctement

mise à la terre. Si l’outil subit un dysfonctionnement électrique ou se

casse, la mise à la terre assure un chemin à faible résistance pour

disperser l’électricité sans blesser l’utilisateur.

2.

Éviter de toucher avec toute partie du corps les surfaces mises

à la terre telles que tuyaux, radiateurs, cuisinières et

réfrigérateurs. Il y a un risque accru de choc électrique si votre

corps est relié à la terre.

3.

Ne pas exposer les outils électriques à la pluie ou à l’humidité.

De l’eau qui pénètre dans un outil électrique augmente le risque

d’électrocution.

4.

Protéger le cordon. Ne jamais transporter les outils en les tenant

par le cordon, ne jamais tirer sur le cordon pour retirer la fiche d’une

prise murale. Éloigner le cordon de la chaleur, de l’huile, des arêtes

tranchantes ou des éléments mobiles. Remplacer immédiatement

tout cordon endommagé. Les cordons endommagés augmentent le

risque de choc électrique.

5.

Lorsque vous utilisez un outil électrique à l’extérieur, utiliser

une rallonge électrique extérieure marquée « W-A » ou « W ».

Ces cordons sont conçus pour une utilisation à l’extérieur et

réduisent le risque de choc électrique.

6.

Tester le disjoncteur différentiel de fuite à la terre (DDFT - ou

interrupteur GFCI) fourni avec le cordon d’alimentation pour

assurer son bon fonctionnement avant d’utiliser la machine. La

machine doit être équipée sur le cordon d’alimentation d’un

disjoncteur différentiel qui fonctionne correctement. Le disjoncteur

différentiel GFCI réduit le risque de choc électrique.

7.

Éviter d’utiliser des rallonges électriques, sauf si elles sont

branchées à une prise ou à un boîtier d’alimentation équipé d’un

disjoncteur différentiel de fuite à la terre (DDFT - GFCI). Le

disjoncteur différentiel sur le cordon d’alimentation de machine

n’empêchera pas les chocs électriques provenant des rallonges.

8.

Utiliser uniquement des rallonges trifilaires appropriées, en bon

état, qui sont équipées de prises de terre, et des prise murales

tripolaire qui sont compatibles avec la fiche de l’outil. Utiliser des

rallonges inappropriées, endommagées ou de qualité inférieure ne

permettra pas de mettre l’outil à la terre. Le risque d’électrocution et

de blessures corporelles ou de mort est augmenté.

9.

Veiller à ce que toutes les connexions électriques restent bien

au sec, et ne touchent pas le sol. Cela réduit le risque de choc

électrique.

10.

NE PAS toucher les prises ou les outils avec les mains

mouillées. Cela réduit le risque de choc électrique.

Sécurité personnelle

1.

Rester vigilant, regarder bien ce que vous faites et faire preuve

de jugement lorsque vous utilisez un outil électrique. Ne pas

utiliser d’outils lorsque vous êtes fatigué(e) ou sous l’influence

de drogues, d’alcool ou de médicaments. Un moment d’inattention

lors de l’utilisation d’un outil électrique peut entraîner des blessures

corporelles graves.

2.

Porter des vêtements appropriés. Ne pas porter de vêtements

amples ni des bijoux. Sécuriser des cheveux longs. Tenir vos

cheveux, les vêtements et les gants éloignés des éléments en

mouvement. Les vêtements amples, les bijoux et les cheveux longs

peut être capturés par les pièces mobiles.

3.

Éviter les démarrages accidentels. Assurez-vous que

l’interrupteur est en position ARRÊT avant de brancher

l’appareil. Le transport de l’appareil avec le doigt sur l’interrupteur ou

le branchement des outils quand l’interrupteur est en position

MARCHE invite les accidents.

4.

Enlever tout outil de réglage ou autre avant d’allumer l’outil. Un

outil qui reste attaché à une partie rotative de l’outil peut entraîner

des blessures corporelles.

5.

Ne pas se pencher trop en avant. Veiller à maintenir un bon

équilibre et vérifier où vous poser les pieds. Un bon équilibre et

une base stable permettent de mieux contrôler l’outil dans des

situations inattendues.

6.

Utiliser les équipements de sécurité. Toujours porter des

protections oculaires. Selon les conditions, utiliser un masque

antipoussière, des chaussures de sécurité antidérapantes, un casque

ou une protection auditive.

Utilisation et entretien des outils

1.

Utiliser des pinces ou autre moyen approprié pour fixer

l’ouvrage sur une base stable. Tenir l’ouvrage à la main ou contre

votre corps n’est pas suffisamment stable et peut conduire à une

perte de contrôle.

2.

Ne pas forcer l’outil. Utiliser l’outil approprié pour votre

application. L’outil approprié va effectuer le travail requis mieux et de

manière plus sûre s’il est utilisé au niveau de charge pour lequel il est

conçu.

3.

Ne pas utiliser l’outil si l’interrupteur ne le met pas en marche ou

ne l’arrête pas. Tout outil qui ne peut pas être contrôlé par son

commutateur est dangereux et doit être réparé.

4.

Débrancher la fiche de la source d’alimentation avant d’effectuer

tout réglage, avant de changer les accessoires ou avant de

ranger l’outil. Ces mesures de sécurité préventives réduisent les

risques que l’outil se mette en marche accidentellement.

5.

Ranger les outils hors de portée des enfants et des personnes

inexpérimentées quand ils ne sont pas en cours d’utilisation. Les

outils sont dangereux dans les mains d’utilisateurs sans expérience

ou formation.

11

Page 12

6.

Voici le symbole d’alerte de sécurité. Il sert à

voire un accident mortel.

Il peut se produire des chocs électriques qui peuvent

Ne pas forcer les câbles. Une tension excessive sur les

Entretenir les outils avec soin. Veiller à ce que les outils

tranchants restent bien aiguisés et sont propres. Des outils bien

entretenus, avec des lames bien affutées, sont moins susceptibles de

se coincer et sont plus faciles à contrôler.

7.

Examiner les outils pour vérifier qu’il n’y a pas de mauvais

alignement ou de grippage des pièces mobiles, que les pièces

ne sont pas cassées, ou pour déceler toute autre condition qui

pourrait nuire au fonctionnement de l’outil. Si nécessaire, faire

réparer l’outil avant de l’utiliser. De nombreux accidents sont

causés par le mauvais entretien des outils.

8.

Utiliser uniquement les accessoires recommandés par le

fabricant pour le modèle spécifique de votre outil. Des

accessoires pouvant convenir à un certain outil peuvent se révéler

dangereux lorsqu’ils sont utilisés avec un autre outil.

Service

1.

L’outil ne doit être entretenu ou réparé que par un réparateur

qualifié. Toute réparation ou tout entretien effectué par un réparateur

non qualifié pourrait entraîner un risque de blessure.

2.

Pour l'entretien ou les réparations, veiller à utiliser des pièces

détachées identiques en remplacement. Suivre les instructions

notées dans la section Entretien de ce manuel. Utiliser des pièces

non autorisées ou ne pas suivre les instructions d’entretien peut créer

un risque d’électrocution ou de blessures.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

vous avertir des dangers potentiels de blessures.

Respecter tous les messages de sécurité qui

suivent ce symbole pour éviter des blessures,

causer la mort si vous branchez cet appareil à une

prise mal câblée. Si le fil de terre est mis sous

tension, vous pouvez être électrocuté simplement en

touchant la machine, même si le commutateur est en

position ARRÊT. Un interrupteur GFCI ne vous

protégera pas dans cette situation. Utiliser un testeur

agréé UL pour déterminer si la prise est sans danger.

câbles peut causer leur torsion, leur vrillage ou leur

rupture, et peut entraîner des blessures graves.

1.

Porter uniquement des gants en cuir. Ne jamais utiliser d’autres

type de gant (en tissu, en caoutchouc ou avec revêtement ou enduit).

Ne jamais saisir avec un chiffon un câble en rotation. Ces éléments

pourraient s’entortiller autour du câble et provoquer de graves

blessures.

2.

Ne jamais utiliser la machine sans le protège-courroie. Les doigts

peuvent se coincer entre la courroie et la poulie.

3.

Ne jamais utiliser la machine sans le tube de guidage. Peut

entraîner des blessures importantes aux mains.

4.

Ne pas forcer les câbles. Garder la main protégée par un gant en

cuir sur le tuyau-guide pour le contrôler quand la machine est en

marche. Une tension excessive sur les câbles (par exemple, en cas

d’obstruction résistante) peut causer leur torsion, leur vrillage ou leur

rupture, et peut entraîner des blessures graves.

5.

Ne pas placer l’appareil à plus de 60 cm (2 pi) de l’ouverture. Une

distance plus grande augmente les risques de torsion ou de vrillage.

6.

La machine est conçue pour être opérée par UNE SEULE

PERSONNE. L’opérateur doit contrôler la pédale de commande et le

câble.

7.

Ne pas utiliser la machine en marche arrière (« REV »). Utiliser la

machine en marche arrière, peut endommager le câble ; à n’utiliser

strictement que pour récupérer un outil de découpe coincé dans une

obstruction.

8.

Tenir les mains éloignées de tout tambour en rotation. Ne pas

insérer la main dans le tambour si la machine n’est pas d’abord

débranchée. La main peut être prise dans les éléments mobiles, ce

qui entraînera des blessures graves.

9.

Faire preuve de prudence lors du débouchage des drains dans

lesquels on a utilisé des produits chimiques de nettoyage. Évitez

tout contact direct avec la peau et les yeux. Les produits chimiques

utilisés pour le nettoyage des tuyauteries peuvent causer des

brûlures graves et endommager le câble.

10.

Ne pas utiliser la machine si l’opérateur ou la machine doit se trouver dans l’eau.

11.

Porter des lunettes de protection et des chaussures avec

semelle en caoutchouc antidérapante. Utiliser ces équipements

de sécurité peut empêcher de recevoir des blessures graves.

12.

Avant de commencer une intervention, vérifier que le câble

dans le tambour n’est pas cassé ni vrillé. Pour ce faire, tirer

sur le câble pour l’extraire du tambour et vérifier l’usure et

rechercher toute cassure éventuelle. Toujours remplacer un

câble usé (vrillé ou cassé) par un câbles de remplacement

GENERAL authentique.

13.

N’utiliser cet outil que pour la tâche pour laquelle il a été

conçu. Suivre les instructions concernant l’utilisation

correcte de la machine. Toute autre utilisation ou toute

modification du déboucheur pour d’autres applications peut

augmenter les risques de blessures.

Disjoncteur différentiel de fuite à la terre (DDFT ou interrupteur GFCI)

Votre machine est équipée d’un disjoncteur différentiel de fuite à la terre

qui vous protège contre les chocs électriques en cas de court-circuit.

Vérifier que la prise est correctement mise à la terre. Tester le disjoncteur

différentiel avant chaque utilisation.

1.

Brancher à une prise de courant 120 volts.

2.

Enfoncer le bouton d’essai. Le témoin lumineux s’éteint et

l’alimentation électrique à la machine doit se couper.

3.

Si le témoin lumineux ne s’éteint pas lorsque le bouton est enfoncé,

NE PAS UTILISER L’APPAREIL jusqu'à ce qu’il a pu être réparé.

4.

Pour rétablir le courant après l’essai, appuyer sur bouton de

réarmement. Quand le bouton de réarmement a été appuyé, si la

machine ne démarre pas, si elle s’arrête en cours de fonctionnement

ou si l’utilisateur ressent un léger choc, NE PAS UTILISER

L’APPAREIL ! Étiqueter la machine pour signaler qu’elle est horsservice. Portez-la à un centre de réparation pour moteurs électriques,

ou renvoyez-la à l’usine pour réparation.

12

Page 13

CARACTÉRISTIQUES

Diamètre du câble

Taille du tuyau

Applications typiques

1/2 po

3 po à 4 po

Colonnes de plomberie et petits

3/8 po

2 po à 3 po

Colonnes de plomberie, tuyauteries

Tête de

découpe

No Cat

Applications typiques

la

Lame de

coupe

latérale

Lame de

coupe

latérale

Lame de

coupe

latérale

Lame scie

circulaire

3

Outil de

récupération

Guide flexible

Tableau d’application des têtes de découpe (tableau 2)

REMARQUE : ne pas utiliser la machine si les étiquettes de mise en

garde sur le boîtier de l’interrupteur et sur le cordon d’alimentation ont

disparues ou sont illisibles.

Tête de

lance

1-1/2 po

U-Cutter

po

- 2 po

- 3 po

- 4 po

-

AH

1-1/2UC

2SCB

3SCB

4SCB

3RSB

RTR-1

LE-1

Outil de démarrage, idéal pour

découpe et le grattage.

Outil de démarrage, utile pour

les bouchons de graisse.

Outil de finition, pour gratter

l’intérieur du tuyau.

Outil de finition, pour gratter

l’intérieur du tuyau.

Outil de finition, pour gratter

l’intérieur du tuyau.

Outil de finition, découpe et

raclage.

Pour récupérer des objets

perdus dans la canalisation.

Outil pour négocier dans les

courbes difficiles.

Sewerooter T-3 illustré avec son tuyau-guide (no cat. T3-GT)

Tableau d’utilisation des câbles (tableau 1)

drains (pas de racines)

d’évacuation de buanderie et petits

Note : il n’y a pas de règle absolue qui dicte quelle lame utiliser. Si un outil

ne débouche pas la canalisation, en essayer simplement un autre.

FONCTIONNEMENT

Installation

1.

Assurez-vous que l’interrupteur du moteur est en position

« ARRÊT » !

2.

Ne pas placer l’appareil à plus de 60 cm (2 pi) de l’ouverture du

drain. Si vous ne pouvez pas placer la machine à proximité de

l’ouverture du drain, faire passer le câble par un tube ou un tuyauguide métallique afin d’éviter l’effet coup de fouet du câble. Le tuyauguide Sewerooter T-3 (T3 - GT) a été conçu pour cette tâche. Des

extensions de tuyau-guide (Guide Tube Extensions - GTE) sont

également disponibles.

3.

Positionner la pédale là où elle sera facilement accessible. La

machine est conçue pour être opérée par une seule personne.

Assurez-vous que vous pouvez enlever rapidement le pied de la

pédale en cas d’urgence.

4.

Sélectionner l’outil de coupe correct (voir le tableau d’application des

lames — Tableau 2). Un bon outil pour commencer est la tête de

lance ou la lame U-Cutter de 1-1/2 pouces. Une fois que l’obstruction

est percée, continuer avec les plus grandes lames. En grattant

l’intérieur des canalisations, elles assurent un meilleur nettoyage. En

13

Page 14

cas de difficultés à passer un siphon ou une courbe serrée, attacher

le guide flexible (pour câble de 1/2 po uniquement).

5.

Insérer l’outil de coupe dans le connecteur femelle au bout du câble

et serrer la vis et la rondelle-frein de raccordement en veillant à ce

que les deux soient bien bloqués.

FONCTIONNEMENT

1.

Commencer en tirant le câble du

tambour et en le glissant dans le drain

jusqu’à ce qu’il arrive en butée.

2.

Serrer la molette située sur le

Dispositif d’entraînement motorisé

pour que le rouleau d’alimentation se

retrouve en appui contre le câble.

Veiller à ne pas trop serrer la molette,

car cela pourrait provoquer l’usure

excessive du câble. Note : le Dispositif

d’entraînement motorisé de câble est conçu pour une utilisation avec

des câbles de 3/8 po et 1/2 po uniquement.

3.

Le levier d’alimentation contrôle la vitesse de déroulement et la

direction du câble. Pousser le levier vers le bas pour faire dévider le

câble du tambour. Plus vous poussez loin le levier vers le bas, plus

vite le câble va se dévider. Tirer le levier vers le haut pour faire

reevenir le câble dans le tambour. Quand le levier est en placé en

position centrale (point mort), le câble tourne sans avancer.

7.

Si vous rencontrez des difficultés à faire passer l’outil dans les

parties courbes de la tuyauterie, essayer de mettre la machine en

marche arrière tout en appliquant une

pression constante. (En cas d’utilisation

du Dispositif d’entraînement motorisé, si

vous mettez le moteur en marche

arrière, le levier de commande de

l’alimentation opèrera à l’inverse de sa

fonction normale.)

pas faire tourner le moteur en

Ne

marche arrière pendant plus de

quelques secondes à la fois car cela pourrait provoquer des

emmêlements dans le tambour ou un vrillage du câble.

8.

Si vous ne parvenez toujours pas à faire négocier les courbes au

câble, vous utilisez probablement un câble d’un diamètre trop grand.

Sélectionner un câble de 3/8 po, ou même peut-être une plus petite

machine. (Voir le tableau d’utilisation des câbles (tableau 1)

9.

Quand le câble atteint l’obstruction, mettre la machine au point mort.

Laisser alors avancer le câble lentement vers l’avant. L’outil va

pénétrer dans le bouchon en avançant. Ce mouvement lent en avant

va réduire la tension sur le câble tout en permettant d’effectuer un

travail de nettoyage plus approfondi. Il est souvent utile de lui faire

effectuer un mouvement de va-et-vient pour un meilleur résultat.

Astuce : il est souvent utile de laisser couler un filet d’eau dans la

canalisation pour entraîner les débris pendant et après l’opération de

la machine.

4.

Mettre le commutateur du moteur en position MARCHE AVANT.

Poser une main protégée par un gant en cuir sur le tuyau-guide.

Appuyer sur la pédale de contrôle pour démarrer la machine.

5.

Dévider le câble dans le drain jusqu’à ce qu’il arrive en butée contre

l’obstruction : utiliser une pression ferme et sans à-coups. Ajuster le

taux d’alimentation en fonction de la résistance rencontrée. Ne pas

forcer le câble — laisser l’outil faire le travail. Le travail ne sera pas

accompli plus rapidement et vous pourriez endommager le câble.

NE PAS UTILISER TROP DE FORCE –

LAISSER L’OUTIL FAIRE LE TRAVAIL.

6.

Ne pas laisser trop mou dans le câble, car cela entraînerait un effet

de fouet. Si le câble commence à se plier ou à se vriller, relâcher la

pression sur la pédale et faire tourner le tambour dans la direction

opposée pour soulager l’effet de torsion sur le câble. Repousser tout

excédent de câble dans le tambour, puis continuer.

10.

Veiller à ne pas laisser la lame se coincer dans le bouchon pendant

que l’outil se fraye un passage dans l’obstruction. Ceci peut causer le

vrillage et la rupture du câble. Quand vous sentez que le câble

commence à se vriller entre vos mains, arrêter la machine et faire

revenir le câble en arrière. La lame se libèrera de l’obstruction. Faire

alors de nouveau avancer le câble lentement vers l’avant dans le

bouchon.

11.

Après que la canalisation a été ouverte, récupérer le câble en

déplaçant le levier vers le haut. Assurez-vous que l’interrupteur du

moteur est en position « marche avant ». Ceci est important pour

empêcher le câble de s’emmêler dans le tambour ou dans les

tuyauteries.

12.

Quand l’outil se rapproche de l’ouverture du drain, enlever le pied de

la pédale pour arrêter la rotation du tambour. Ne jamais retirer l’outil

de coupe du drain pendant que le câble est en rotation. Le câble

risque de fouetter et de causer des blessures graves.

14

Page 15

OPÉRATIONS SPÉCIALES

REMARQUE :

SI LE CÂBLE SE COINCE DANS LA CANALISATION

Le moteur peut être mis en marche arrière pour libérer le câble s’il se

coince dans la canalisation. (Remarque : en cas d’utilisation du Dispositif

d’entraînement motorisé, si vous mettez le moteur en marche arrière, le

levier de commande de l’alimentation opèrera à l’inverse de sa fonction

normale.) Pour libérer le câble :

1.

Placer le commutateur du moteur en position Marche arrière.

2.

En protégeant vos mains avec des gants de cuir, rentrer le câble

pendant que le tambour tourne en sens inverse.

3.

Lorsque le câble est libéré, rentrer le câble en excès dans le tambour.

4.

Replacer le commutateur du moteur en position Marche avant, et

reprendre les opération à l’étape 3 du mode d’emploi.

4.

Il suffit d’inverser cette procédure pour installer le tambour.

COMMENT INSTALLER LE DISPOSITIF D’ENTRAÎNEMENT MOTORISÉ (PO-JR)

Le Dispositif d’entraînement motorisé vous fournit une assistance

quand vous alimentez ou récupérez les câbles. Ne pas utiliser trop de

force – laisser l’outil faire le travail.

1.

Faire glisser le Dispositif d’entraînement

motorisé de câble sur le goujon de montage

situé sur le support avant.

2.

Aligner la molette de montage située sur le

corps du dispositif d’entraînement sur le

méplat de la tige filetée.

3.

Bien serrer la molette.

SI LE CÂBLE S’EMMÊLE DANS LE TAMBOUR

La cause est que l’opérateur a appliqué trop de pression en alimentant

le câble, ou a poussé le câble alors que la machine fonctionnait en

marche arrière. Pour démêler le câble, faire tourner le tambour dans la

direction inverse. Dans la plupart des cas, le câble va se remettre en

place correctement dans le tambour.

ble se retrouve complètement emmêlé, ce qui ne se produira

Si le câ

pas si l’appareil est utilisé correctement, il peut être remis en état en

déposant le tuyau de distribution du tambour. Pour ce faire :

1.

Faire tourner le tambour jusqu'à ce que le tuyau de distribution est

orienté vers le bas.

2.

Tout en maintenant fermement le tuyau, desserrer la molette située

sur le support avant.

3.

Faire basculer le capuchon pour l’écarter et sortir le tuyau. Cela devrait

libérer le câble. Si ce n’est pas le cas, passer à l’étape 4.

4.

Passer la main au milieu du tambour et dévisser la molette au centre du

tambour interne. Ensuite, extraire le tambour interne en le tirant pour le

faire glisser sur l’arbre jusqu’à ce qu’il soit en dehors du tambour.

5.

Une fois le câble démêlé, inverser la procédure ci-dessus et

recharger le câble dans le tambour.

COMMENT FAIRE POUR DÉPOSER LE TAMBOUR

COMMENT INSTALLER LE CÂBLE DANS LE TAMBOUR

1.

Attacher le connecteur mâle du câble au câble de raccordement

connecté au tambour. Veiller à bien bloquer la vis et la rondelle.

2.

Glisser la courroie en V du tambour. Si vous utilisez un Dispositif

d’entraînement motorisé, desserrer la molette de contrôle de la

pression située sur le haut.

3.

Pousser le câble dans le tambour. Pendant le chargement du

tambour, le faire tourner afin que le tuyau de distribution soit toujours

orienté dans la même direction. Cela permet au câble de se répartir

plus uniformément dans le tambour.

4.

Veiller à ce que le câble soit orienté

dans la bonne direction. Pour

vérifier, positionner le tuyau de

distribution afin qu’il pointe vers le

bas. Le câble doit se diriger vers la

gauche en sortant par l’arrière du

tuyau de distribution

le câble doit être orienté dans le tambour dans le bon

sens pour éviter qu’il ne s’emmêle dans le tambour.

.

1.

Retirer la courroie en V. Vous pouvez soulager la tension sur la

courroie en appuyant sur le moteur, qui est monté sur ressort.

2.

Tenir avec la main le tuyau de distribution et desserrer la molette

située sur le support avant. Ensuite, ouvrir le capuchon et sortir le

tuyau.

3.

Passer la main derrière le tambour et localiser le loquet de

verrouillage du tambour. Tout en maintenant le loquet ouvert, tirer sur

le tambour vers l’avant pour l’extraire de la machine.

ENTRETIEN

Pour maintenir votre appareil en état de marche optimal, il est essentiel

que tous les roulements et tous les coussinets du tube distributeur soient

bien lubrifiés. Il est particulièrement important de bien huiler les pièces en

mouvement là où la machine rentre en contact avec du sable, des

poussières agressives et autres matériaux abrasifs.

15

Page 16

ENTRETIEN DU CÂBLE

ROULEMENT

DU ROULEAU

Pour assurer une longue durée de vie aux

câbles, veiller à ce qu’ils soient propres et bien

lubrifiés. Non seulement la lubrification assure

un fonctionnement plus fluide, mais cela

prolonge également considérablement la

durée de vie des câbles. Certains utilisateurs

versent à intervalle régulier de l’huile

directement dans le tambour. Quand le

tambour tourne, le câble est complètement

lubrifié. Notre huile SNAKE OIL est

parfaitement adaptée à cet usage : en effet, non

seulement elle lubrifie les câbles,

mais elle les désodorise également.

E

NTRETIEN DU SYSTÈME D’ALIMENTATION

Veiller à ce que le système d’alimentation ne soit pas couvert de manière

excessive de boues et de matières abrasives. Il est recommandé de rincer

le système à l’eau douce puis de lubrifier sans excès les pièces en

mouvement. Aucun démontage n’est normalement requis. Si le câble ne

se dévide pas correctement, c’est en général pour les raisons suivantes :

ACCUMULATION DE SALETÉ

Au fil du temps, les saletés peuvent suffisamment durcir et empêcher les

rouleaux de tourner. Un rinçage à l’eau suivi d’une bonne lubrification peut

généralement restaurer le fonctionnement du système. Si un démontage

est nécessaire, procéder comme suit :

1.

Déposer la molette de contrôle de la pression d’alimentation, la vis

du capot, le capot, le ressort, le roulement à billes et le logement du

roulement à billes. Noter le positionnement de ces pièces pour

faciliter le remontage. Retirer la goupille du corps du système. Le

bloc supérieur du système de roulement peut maintenant être

déposé.

2.

Déposer les circlips et les rondelles de butée des cylindres inférieurs.

Déposer les goupilles des supports. Les blocs inférieurs du système

de roulement peuvent maintenant être déposés.

3.

Le remontage se fait dans l’ordre inverse.

ROULEAU ENDOMMAGÉ

Une utilisation excessive peut user un rouleau et le mener à la

défaillance. Il est recommandé de remplacer les trois rouleaux en même

temps (no Cat. PO-JR-703). Le rouleau de remplacement consiste en

un bloc composé d’un rouleau d’alimentation, de deux roulements pour

rouleau d’alimentation et de deux entretoises de butée.

Note : les entretoises doivent être installées entre le support et

chaque roulement du rouleau (comme illustré ci-dessous) afin

d’assurer le bon fonctionnement et pour obtenir la durée de vie

maximale pour le rouleau.

Pour remplacer le bloc rouleau d’alimentation :

1.

Retirer le bloc rouleau en dévissant et en déposant l’axe du rouleau.

2.

Pour plus de commodité, les composants sont assemblés et

maintenus en place par un fil métallique à l’usine. Avant d’essayer

d’installer le bloc, retirer le fil en tenant fermement les composants

pour qu’ils ne se séparent pas.

3.

Tout en tenant toujours fermement les composants, insérer le bloc

dans l’ouverture du support.

4.

Pour aligner les entretoises et les roulements, insérer une pointe de

crayon ou un objet similaire dans l’extrémité non filetée de

l’ouverture pour l’axe du support. Après avoir retiré la pointe de

crayon, continuer à maintenir les éléments bien alignés.

5.

L’axe du rouleau d’alimentation doit alors être inséré par cette même

ouverture non filetée. Il doit passer les entretoises et les roulements

pour ressortir par le trou d’axe fileté de l’autre côté du support.

6.

Bien serrer l’axe dans le support avec une clé Allen de 3/16 po.

CÂBLE EMMÊLÉ

Si un câble fait une boucle sur lui-même dans le tambour, il ne va pas

pouvoir se dévider correctement dans le drain. Retirer et recharger le

câble pour le remettre en place. Si le câble se vrille, c’est qu’il a été forcé

et que l’utilisateur a utilisé une pression trop forte, ou a choisi le mauvais

diamètre de câble pour la canalisation. Ne pas forcer le câble — laisser

l’outil faire le travail.

16

Page 17

GUIDE DE DÉPANNAGE (Tableau 3)

Problème

Cause probable

Solution

Câble vrillé ou cassé.

L’opérateur force le câble.

Ne pas forcer sur le câble. Laisser l’outil faire le travail.

Trop de mou entre la machine et le

drain.

Ne pas installer la machine à plus de 30 cm (2 pi) du drain.

Mauvais diamètre de câble pour la taille

Un câble qui est trop grand ou trop petit pour la canalisation est

câbles (tableau 1).

Le câble a été exposé à des

Nettoyer et lubrifier régulièrement les câbles.

Le câble s’emmêle dans le tambour

L’opérateur force le câble.

Ne pas forcer sur le câble. Laisser l’outil faire le travail.

Machine fonctionnant en marche

arrière.

Ne pas faire fonctionner la machine en marche arrière pour retirer

le câble de la canalisation.

Tuyau de distribution bloqué.

Lubrifier les bagues de tuyau de distribution.

Le tambour s’arrête alors que la

pédale est enfoncée.

Il y a une fuite dans le tuyau ou

dans la pédale.

Remplacer si nécessaire.

Fuite dans le commutateur à

diaphragme.

Si aucune fuite n’est notée à la pédale ou dans le tuyau,

remplacer le commutateur à diaphragme.

Protection contre surcharge

thermique activée.

Laisser refroidir le moteur. Appuyer sur le bouton de réarmement.

Le tambour tourne dans un sens,

mais pas dans l’autre.

Défaillance du commutateur de

marche arrière.

Remplacer le commutateur de marche arrière.

Le disjoncteur différentiel de fuite à

Cordon d’alimentation ou rallonge

endommagé.

Remplacer le cordon ou la rallonge.

Court-circuit dans le moteur.

Emporter le moteur dans un centre de service agréé.

Disjoncteur différentiel de fuite à

GFCI) défectueux.

Remplacer le disjoncteur différentiel de fuite à la terre (DDFT)

L’alimentation du câble ne s’effectue

Câble emmêlé dans le tambour.

Ne pas faire fonctionner la machine en marche arrière. Utiliser le

(tableau 1).

Alimentation mal réglée.

Si la molette de contrôle de la pression d’alimentation n’est pas

rouleaux d’alimentation vont s’user prématurément.

Rouleau d’alimentation bloqué.

Nettoyer et lubrifier régulièrement les rouleaux d’alimentation.

Remplacer les rouleaux usés.

Câble usé.

Quand le câble commence à avoir des aplats, le câble doit être

remplacé.

la terre (DDFT) se déclenche et ne

se réinitialise pas.

de canalisation.

matières acides.

la terre (DDFT - interrupteur

plus susceptible de se vriller. (Voir le tableau d’utilisation des

pas correctement.

câble de bonne taille. (Voir le tableau d’utilisation des câbles

assezz serrée, le câble va glisser. Si elle est trop serrée, les

17

Page 18

Page 19

Para tuberías de 1-1/4” a 3” y la mayoría de

Sewerooter T-3

™

Instrucciones de operación

Su Sewerooter T-3 está diseñado para

darle años de servicio beneficioso sin

problemas. No obstante, ninguna máquina es

mejor que su operador.

Lea, entienda y siga todas las

advertencias de seguridad e instrucciones

proporcionadas con el producto. De no seguir

las advertencias e instrucciones se puede

provocar una descarga eléctrica y/o lesiones

graves. Guarde todas las advertencias e

instrucciones como referencia en el futuro.

¡GUARDE ESTAS INSTRUCCIONES!

las tuberías de 4” (30 a 100 mm)

Page 20

¡ADVERTENCIA! Lea y entienda todas las

Sewerooter T-3™

Lea y entienda el manual

del operador antes de usar

esta máquina. De no seguir

las instrucciones de

operación podría produje la

muerte o lesiones graves.

ADVERTENCIA

ADVERTENCIA

Este es el símbolo de alerta de

seguridad. Se usa para alertar a las

personas sobre posibles peligros de

lesiones personales. Obedezca todos

los mensajes de seguridad que siguen

este símbolo para impedir posibles

lesiones o la muerte.

instrucciones. De no seguir las advertencias

citadas se puede provocar una descarga

eléctrica, un incendio y/o lesiones personales

graves. Se dispone de manuales de repuesto

gratuitos a petición o se pueden descargar de

nuestro sitio web, www.drainbrain.com. Se

dispone de vídeos de instrucción para

descargar de nuestro sitio web y se pueden

pedir. Si tiene dudas o problemas, llame por

favor al departamento de servicio al cliente de

General al 412-771-6300.

¡GUARDE ESTAS INSTRUCCIONES!

Estas instrucciones tienen como fin

familiarizar a todo el personal con la

operación segura y los

procedimientos de mantenimiento

para el Sewerooter T-3.

SÍMBOLOS DE SEGURIDAD

Se puede producir una descar-ga

eléctrica que provoque la

muerte si se enchufa esta máquina a una toma eléctrica cableada incorrectamente. Si el

cable a tierra tiene corriente, es po

sible la electrocución al tocar la

máquina, aun cuando el i

nterruptor de encendido esté en

apagado. Un interruptor de pé

rdidas accidentales a tierra no le

protegerá en esta situación. Use un

probador aprobado por UL pa ra

determinar si la toma es seg ura.

No haga funcionar las herramientas eléctricas en atmósferas explosivas, como en presencia de líquidos, gases o

polvo inflamables. Las herramientas eléctricas produce chis-

pas que pueden inflamar el polvo o

los humos.

Lleve puestos solamente guan-tes

de cuero. No use nunca ningún

otro tipo de guante, como

tela, goma o guantes

recubiertos. No agarre nunca

un cable giratorio con un trapo. Tal

vez estos artículos podrían

envolverse alrededor del cable y

provocar lesiones graves.

PELIGRO

PELIGRO indica un peligro con un alto nivel de riesgo que,

si no se evita, resultará en lesiones graves o la muerte.

ADVERTENCIA

ADVERTENCIA indica un peligro con un nivel de riesgo

intermedio que, si no se evita, podría resultar en lesiones

graves o la muerte.

PRECAUCIÓN

PRECAUCIÓN indica un peligro con un bajo nivel de

riesgo que, si no se evita, resultará en lesiones menores o

moderados.

Lleve puestas siempre gafas de

seguridad y zapatos antirresbaladizos con suela de goma. El

uso de estos equipos de

seguridad puede impedir lesiones

graves.

No haga funcionar nunca la

máquina con el protector de

correa retirado. Los dedos

pueden quedar atrapados entre la

correa y la polea.

Nunca opere la máquina sin el

tubo guia en su lugar. Puede

provocar lesiones significativas en la

mano.

No someta los cables a una

fatiga excesiva. Someter a los

cables a una fatiga excesiva

puede provocar torceduras,

retorcimientos o roturas del cable y

causar lesiones graves.

20

Page 21

REGLAS DE SEGURIDAD GENERAL

Sewerooter T-3™

ADVERTENCIA

Lea y entienda todas las instrucciones. De no seguir las

advertencias citadas se puede provocar una descarga eléctrica,

un incendio y/o lesiones graves.

¡GUARDE ESTAS INSTRUCCIONES!

Área de trabajo

1.

Mantenga el área de trabajo limpia y bien iluminada. Los

bancos desorganizados y las áreas oscuras pueden provocar

accidentes.

2.

No haga funcionar las herramientas eléctricas en atmósferas

explosivas, como en presencia de líquidos, gases o polvo

inflamables. Las herramientas eléctricas crean chispas que

pueden inflamar el polvo o los humos.

3.

Mantenga alejados a observadores, niños y visitantes

mientras opera una herramienta eléctrica. Las distracciones

pueden hacer que pierda el control.

Seguridad eléctrica

1.

Las herramientas conectadas a tierra deben enchufarse en

una toma correctamente instalada y conectada a tierra

según todos los códigos y ordenanzas. No quite nunca la

clavija a tierra ni modifique el enchufe de cualquier manera.

No use ningún enchufe adaptador. Verifique con un

electricista capacitado si tiene dudas sobre la conexión a

tierra correcta de la toma. Si la herramienta funciona

eléctricamente de forma incorrecta o si deja de funcionar, la

conexión a tierra proporciona una vía de resistencia baja para

llevar la electricidad lejos del usuario.

2.

Evite el contacto del cuerpo con superficies conectadas a

tierra, como tuberías, radiadores, hornos y refrigeradores.

Hay un mayor riesgo de descarga eléctrica si su cuerpo está

conectado a tierra.

3.

No exponga las herramientas eléctricas a la lluvia ni

condiciones húmedas.. Si entra agua en la herramienta

eléctrica, se aumentará el riesgo de descarga eléctrica.

4.

No abuse el cordón. No use el cordón nunca para llevar las

herramientas ni para sacar el enchufe de una toma. Mantenga el

cordón alejado del calor, del aceite, de los bordes afilados y de

las piezas móviles. Reemplace los cordones dañados

inmediatamente. Los cordones dañados aumentan el riesgo de

descarga eléctrica.

5.

Al operar una herramienta eléctrica fuera use un cordón de

alargamiento marcado “W-A” o “W”. Estos cordones están

homologados para el uso fuera y reducen el riesgo de una

descarga eléctrica.

6.

Pruebe el interruptor de pérdidas accidentales a tierra

proporcionado con el cordón eléctrico para verificar su

operación correcta antes de operar la máquina. La máquina

debe tener un interruptor de pérdidas accidentales a tierra que

funcione debidamente en el cordón eléctrico. Este interruptor

reduce el riesgo de descarga eléctrica.

7.

No se recomienda el uso de cordones de alargamiento a

menos que estén enchufados a un interruptor de pérdidas

accidentales a tierra encontrado en las cajas de circuitos o

los receptáculos de las tomas. Este interruptor en el cordón

eléctrico de la máquina no impedirá una descarga eléctrica de

los cordones de alargamiento.

8.

Use solamente cordones de extensión de tres cables correctos

en buenas condiciones que tengan enchufes de conexión a

tierra de tres clavijas y receptáculos de tres polos que aceptan

el enchufe de la herramienta. El uso de cordones de

alargamientos dañados, inferiores u otro no conectarán la

herramienta a tierra. Se aumenta el riesgo de descarga eléctrica y

lesiones corporales o la muerte.

9.

Mantenga todas las conexiones eléctricas secas y por encima

del suelo. Se reduce el riesgo de descarga eléctrica.

10.

NO toque los enchufes ni las herramientas con las manos

mojadas. Se reduce el riesgo de descarga eléctrica.

Seguridad personal

1.

Permanezca alerta, mire lo que hace y use el sentido común

al operar una herramienta eléctrica. No use la herramienta

cuando esté cansado o bajo la influencia de drogas, alcohol

o medicamentos. Un momento de falta de atención al operar

herramientas eléctricas puede provocar lesiones personales

graves.

2.

Vístase correctamente. No lleve puesta ropa holgada ni

artículos de joyería. Recójase el cabello largo. Mantenga su

cabello, ropa y guantes alejados de las piezas móviles. La

ropa holgada, los artículos de joyería o el cabello largo pueden

quedar atrapados en piezas móviles.

3.

Evite el arranque por accidente. Asegúrese de que el

interruptor esté en apagado antes de enchufar. Si se

transportan herramientas con un dedo en el interruptor o se

enchufa una herramienta con el interruptor en encendido se

pueden provocar accidentes.

4.

Quite las llaves de ajuste o los interruptores antes de

encender la herramienta. Una llave o chaveta que quede

conectada a una pieza giratoria de la herramienta puede

provocar lesiones personales.

5.

No estire demasiado el brazo. Mantenga la postura y el

equilibrio apropiados en todo momento. La postura y el

equilibrio apropiados facilitan un mejor control de la herramienta

en situaciones inesperadas.

6.

Use equipos de seguridad. Lleve puestos siempre

protectores para los ojos. Se deben usar una máscara contra