General Pipe Cleaners Kinetic Water Ram Installation Manual

™

Kinetic Water Ram

Operating Instructions

For 1-1/4” through 4”

(30mm—100mm)

Your Kinetic Water Ram is designed to

give you years of trouble-free, profitable

service. However, no machine is better

than its operator.

Read, understand and follow all safety

warnings and instructions provided with the

product. Failure to follow the warnings and

instructions may result in personal injury or

damage to equipment. Save all warnings

and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Pour français voir la page 7

Para ver el español vea la paginá 13

Kinetic Water Ram™

Always wear safety glasses and rubber

soled, non-slip shoes. Use of this safety

equipment may prevent serious injury.

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result in

serious personal injury. Replacement manuals are available upon request at no charge, or may be downloaded

from our website, www.drainbrain.com. Instructional videos are available for download on our website, and may

be ordered. If you have any questions or problems,

please call General’s customer service department at

412-771-6300.

SAVE THESE INSTRUCTIONS!

SAFETY SYMBOLS

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Never use the tool in a drain with a

chemical drain cleaner in it. Any hazard-

ous chemicals in the drain water should be

siphoned out or otherwise removed before

proceeding.

WHAT IS THE WATER RAM?

The Kinetic Water Ram easily clears debris, sediment, scale, and

grease in 1-1/4” to 4” drain lines. It’s an ideal tool for maintaining

apartment buildings, hotels, schools, universities, restaurants, hospi-

tals, RV and trailer parks, and other locations with multiple drains. It’s

safer than chemicals, cleaner than snakes, and less expensive and

more precise than CO2 cartridges.

The Water Ram is particularly effective when the stoppage is on the

far side of a drum trap or a series of difficult bends that would stop a

traditional plumbing snake.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazard with a low level of risk which,

if not avoided, will result in minor or moderate injury.

HOW DOES IT WORK?

The Kinetic Water Ram uses a burst of compressed air, which strikes

the column of water in the clogged pipe. The resulting shock wave,

called kinetic energy, hits the stoppage at a speed of approximately

4,700 feet per second, quickly clearing the blockage and flushing the

waste particles away. Since the shock wave travels so fast, it bypasses vents and stacks, and 98% of the force hits the clog head-on.

There’s no pressure build-up in the system, so pipes and joints aren’t

affected.

2

Kinetic Water Ram™

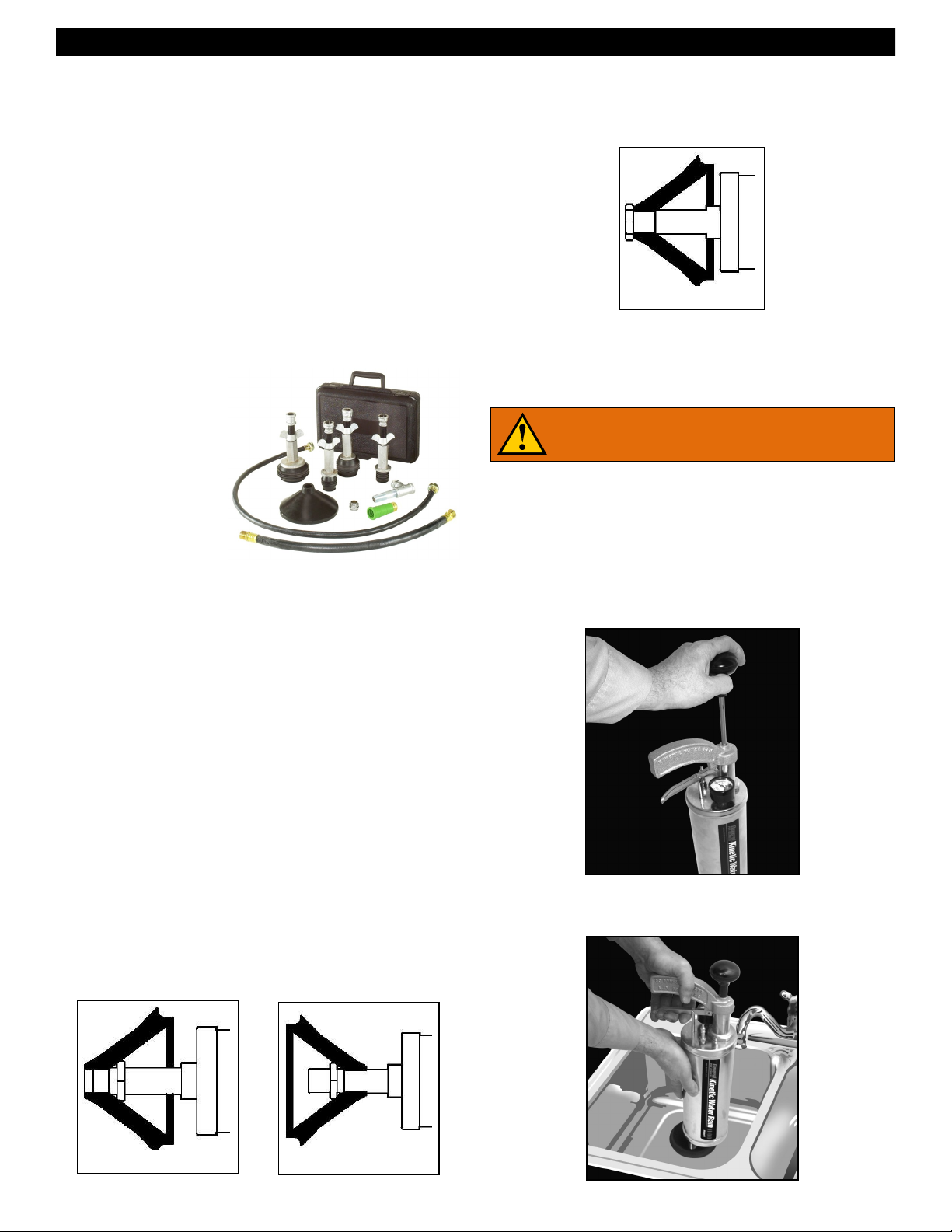

Figure 1 – CORRECT!

Figure 2 – INCORRECT!

Figure 3 – INCORRECT!

FEATURES

Built-in air compressor – The Ram pumps up very easily to

about 60 lbs. (4 bars).

Pressure Gauge – Though the pressure gauge can show up to

160 lbs. (11 bars) of pressure, do not use more than 80 lbs. (6

bars) to clear a line.

Schraeder Valve – For a higher charge of air, use the Schraeder

valve and an external compressor.

STANDARD ACCESSORIES

4” Tapered Rubber Cone – Fits 1-1/4’ to 3” drain openings.

Used in most applications.

Set of 5 Tapered Rubber Plugs – For use when a tighter fit is

required in the drain opening. Set includes 1-1/4“, 1-1/2“, 2“, 3“

and 4“ plugs.

Caulking Hose – For

use when the operator

is unable to tightly

seal the rubber plug

into the drain opening

due to the faucet

interfering with the

Ram.

OPTIONAL ACCESSORIES

Toilet Attachment – Enables you to position the cone in the bowl

to get a tighter seal. As a result, you can strike the blockage with

greater impact and no splash back.

6” Tapered Rubber Cone – Fits 1-1/4” to 4” drain openings.

Expansion Plugs – For use when a tighter seal is needed or when

high pressure is needed for clearing extreme blockages. They are

available in 1-1/2”, 2”, 3”, and 4” sizes.

Check Valve Assembly – For use when clearing slow draining

sinks and tubs. (Includes Water Supply Hose and Universal Faucet Adapter)

2. The point of the Rubber Cone should be a minimum of 1/4” be-

yond the end of the spindle.

3. Use the Lock Nut to hold the cone in place as shown in figure 1,

never as shown in figure 3.

OPERATION

ANY HAZARDOUS CHEMICALS IN THE DRAIN WATER SHOULD BE SIPHONED OUT OR OTHERWISE

REMOVED BEFORE PROCEEDING!

1. Go to the drain or clean-out closest to the stoppage.

2. The Water Ram must hit a solid column of water, not air. If a pipe

is only partly blocked and drains slowly, turn the faucet wide open

so that water is supplied faster than it can drain off. If this doesn’t

provide enough water to create the required column of water, use

the Check Valve Assembly. (See “Clearing Slow Draining Sinks

and Tubs”)

3. Pump the Ram up to 10 lbs. (1 bar) of pressure to start.

Note: An Instructional Video is available. It covers operation of the Kinetic Water Ram as well as safety procedures.

Call 1-412-771-6300 for more information.

ASSEMBLY

1. Thread the 4” Rubber Cone onto the spindle with the point of the

cone facing downward as shown in figure 1, not with the point

facing the cylinder as shown in figure 2.

4. Wedge the tip of 4” Rubber Cone into the drain. If this will not pro-

vide a tight seal, use other attachments shown in Specific Applications.

3

Kinetic Water Ram™

5. To avoid splash back, press down firmly, putting your weight

behind the Ram. Then, SNAP trigger quickly for trip hammer effect.

6. Blockage will break up on impact.

7. If the blockage persists, gradually increase the pressure by 10 lb.

(1 bar) increments until the blockage has been cleared. Most lines

can be cleared using only 20 to 40 lbs (1.5 - 3 bars) of pressure.

8. Follow by flushing thoroughly with water to carry off waste particles.

SPECIFIC APPLICATIONS

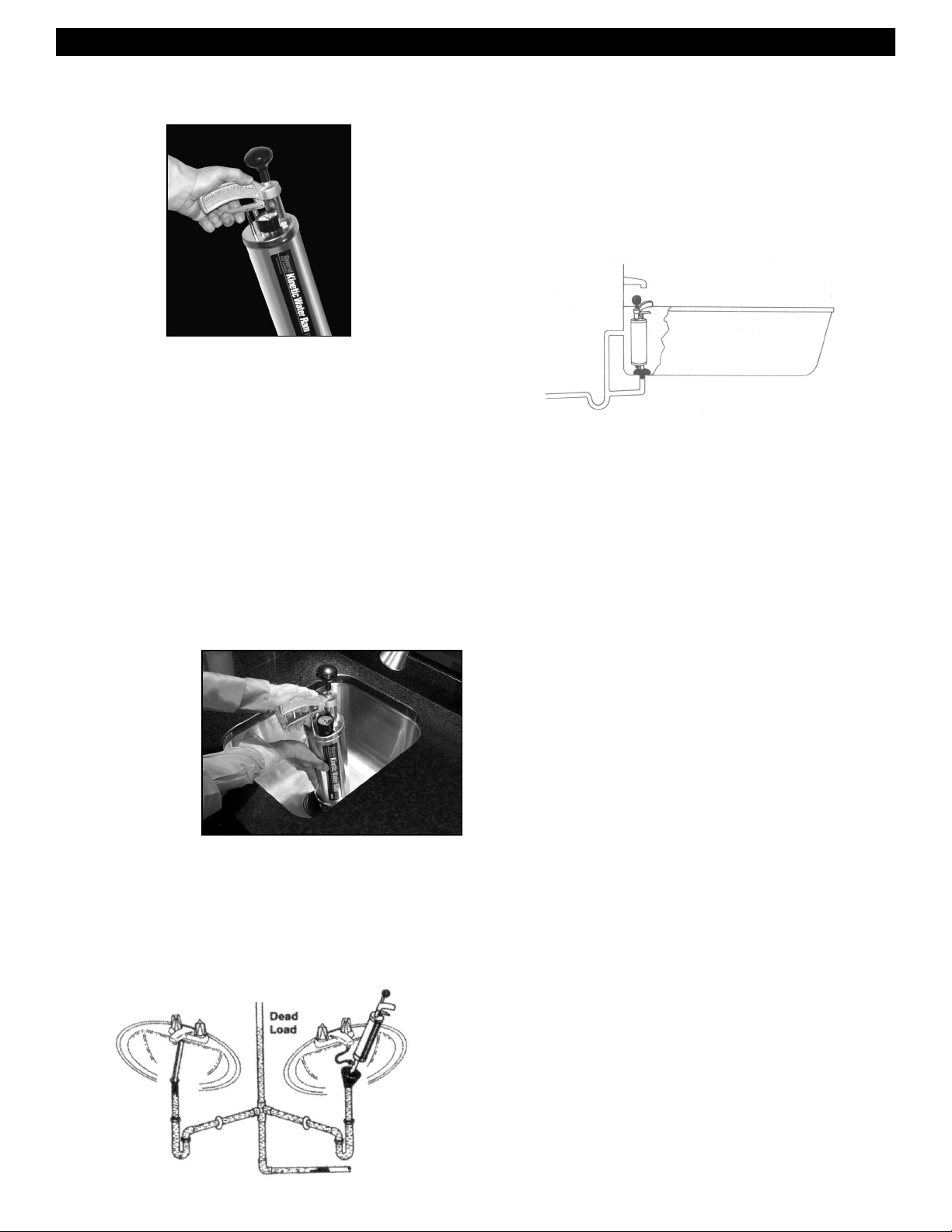

SINKS

In sinks you must block the overflow vent with a wet rag or towel before firing the Water Ram to prevent splash back. Apply pressure to

the rag or towel at the moment when you snap the trigger. There must

be some water in the basin, so that the nozzle of the Ram is under

water when placed in

the drain opening. Use

low pressure at first to

make sure you have

splash back under control, then increase in 10

lb. (1 bar) increments

until the stoppage has

been cleared. Flush the

line with warm water.

COMBINATION SINKS

To unclog double compartment sinks, use the Water Ram in the sink

section leading directly into the trap and stack. To avoid splash back,

seal off adjacent sink using an expansion plug. If you do not have an

Expansion Plug, block the adjacent drain by covering firmly with towel

or rag.

BATHTUBS

Remove the pop-up cover from tub drain and position the Water Ram.

Use low pressure at first to make sure splash back is under control.

Make sure there is some water in the tub so that the tip of the Ram is

under water when placed in the drain opening. If the water is draining

too quickly, see “Clearing Slow Draining Sinks And Tubs.”

If you’re having difficulty with splash back, follow the same procedure

as for clearing sinks. Remove the overflow screen and push 8 to 10

inches of thin, wet rag down the overflow and replace the screen.

In some tubs, excellent results can be obtained by combining the

caulking hose with the tapered Rubber Cone.

1. Unscrew the pop-up lever on the tub.

2. Thread the Lock Nut up the spindle two inches.

3. Thread the Rubber Cone back to the Lock Nut.

4. Thread the Caulking Hose onto the spindle, just in front of Cone.

5. Insert the Caulking Hose into the pop-up valve opening. This will

aim the kinetic force directly down the drain. Be sure to cover the

drain opening before snapping the trigger.

CLEARING SLOW DRAINING SINKS AND TUBS

Turn the faucet wide open so that water is supplied faster than it can

drain off. If this doesn’t provide enough water to create the required

column of water, use the optional Check Valve Assembly (G-CVK) as

follows:

1. Remove the 4” Rubber Cone from the end of the Water Ram.

2. Thread the Check Valve Attachment onto the end of the Ram.

3. Thread the 4” Rubber Cone, or the appropriate size Tapered Plug

or Expansion Plug, onto the end of the Check Valve Assembly.

4. Thread the Faucet Adapter or Threaded Adapter onto one end of

the Water Supply Hose, then attach it to the faucet. Thread the

other end of the hose to the Check Valve Assembly.

5. Place the tip of the Ram into the drain and pump it up to the desired pressure.

6. Turn the faucet wide open so that water is supplied faster than it

can drain off.

7. With the tip of the Rubber Cone firmly sealing off the drain opening, the water from the faucet flows through the Check Valve Assembly and enters the pipe, then rises in the stack or vent. This

creates a head pressure that helps the Ram clear the blockage.

8. Be sure to turn off the faucet before snapping the trigger.

4

Kinetic Water Ram™

TOILETS

Toilet bowls have an oval shaped opening that can make it difficult to

form a good seal around the 4” Rubber Cone. It often helps to stuff a

rag around the cone. A better solution is to use an optional Toilet Attachment (KR-CA).

To use the Toilet Attachment:

1. Remove the 4” Rubber Cone from the

end of the Water Ram.

2. Thread the Toilet Attachment onto the

end of the Ram. Tighten the Lock Nut

to secure the Toilet Attachment in

position.

3. Hold the Ram over the bowl and

press the Rubber Cone into the opening. Tilt it back to allow the cone to

seat properly.

Start with a small amount of pressure at first to make sure splash

back is under control. Press down firmly, putting your weight behind

the Ram and snap trigger. If low pressure is not successful, increase it

in 10 lb. (1 bar) increments until the line has been cleared.

If the toilet is only partly blocked, by an object such as a toothbrush or

pencil, loosely wad up a page of newspaper and stuff it into the bowl.

When the Ram is fired, the balled-up newspaper will break up the

blockage and clear the line.

EXTREME BLOCKAGES

If the line is severely blocked, insert the Caulking Hose furnished with

Water Ram into the drain opening. An excellent seal can be made by

caulking the hose into the drain by means of a wet rag. Then, while

you hold the hose down, fire the Ram using 30 to 40 lbs (2 - 3 bars) of

pressure.

In extreme stoppages, remove the trap, attach a half-inch reducing

coupling to drain pipe and connect the Ram. Attach the Water Supply

Hose between faucet and Check Valve Assembly on Ram. Turn on

faucet so that vent is filled with water. Two or three feet of water in the

vent or stack should be sufficient to clear the blockage. Be sure to

turn off the faucet before firing the Ram. Apply 50 to 75 lbs. (3.5 - 5

bars) of pressure. If pumping becomes difficult, attach an external

compressor to the Schraeder valve. Do not exceed 80 lbs. (6 bars).

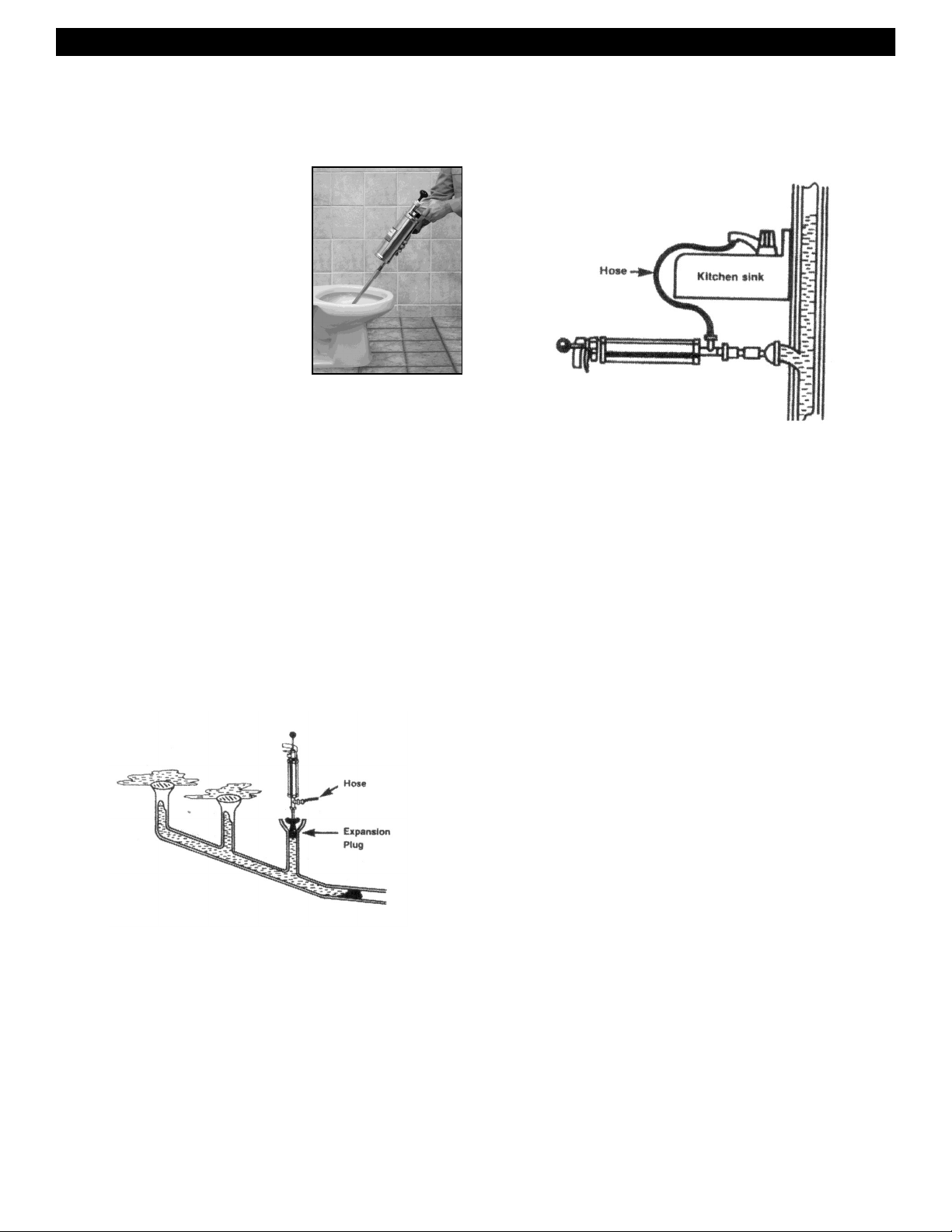

TWO TO FOUR INCH SEWERS

When the Water Ram is used at the cleanout or floor drain, connect

the Ram to an Expansion Plug. If you encounter a 4” floor drain that is

a bit oversized for the 4” Expansion Plug, wrap a piece of gasket rub-

ber around the expansion plug and make a snug fit before tightening

the plug.

Where there is more than one drain opening, always apply the Ram

where the water backs up first. Use the Check Valve Assembly to add

water to the line. (See “Clearing Slow Draining Sinks And Tubs.”) Do

not discharge the Ram until the water appears on the floor at the next

opening. Other drain openings should be covered to protect against

splash back.

MAINTENANCE

The leather seal (G-15) in the Water Ram’s pump should be oiled

every 3 to 6 months to keep it from drying out. This can be done by

lifting the pump rod up and then applying a few drops of neat’s foot

(leather) oil through the air hole.

The seals in the pump will wear with time and use. If the Ram has

difficulty holding pressure, you can easily replace all the seals at the

same time using the Ram Repair Kit (Cat # KRRK).

The best method for cleaning rubber accessories is to wash them in

hot water with soap or detergent.

5

Kinetic Water Ram™

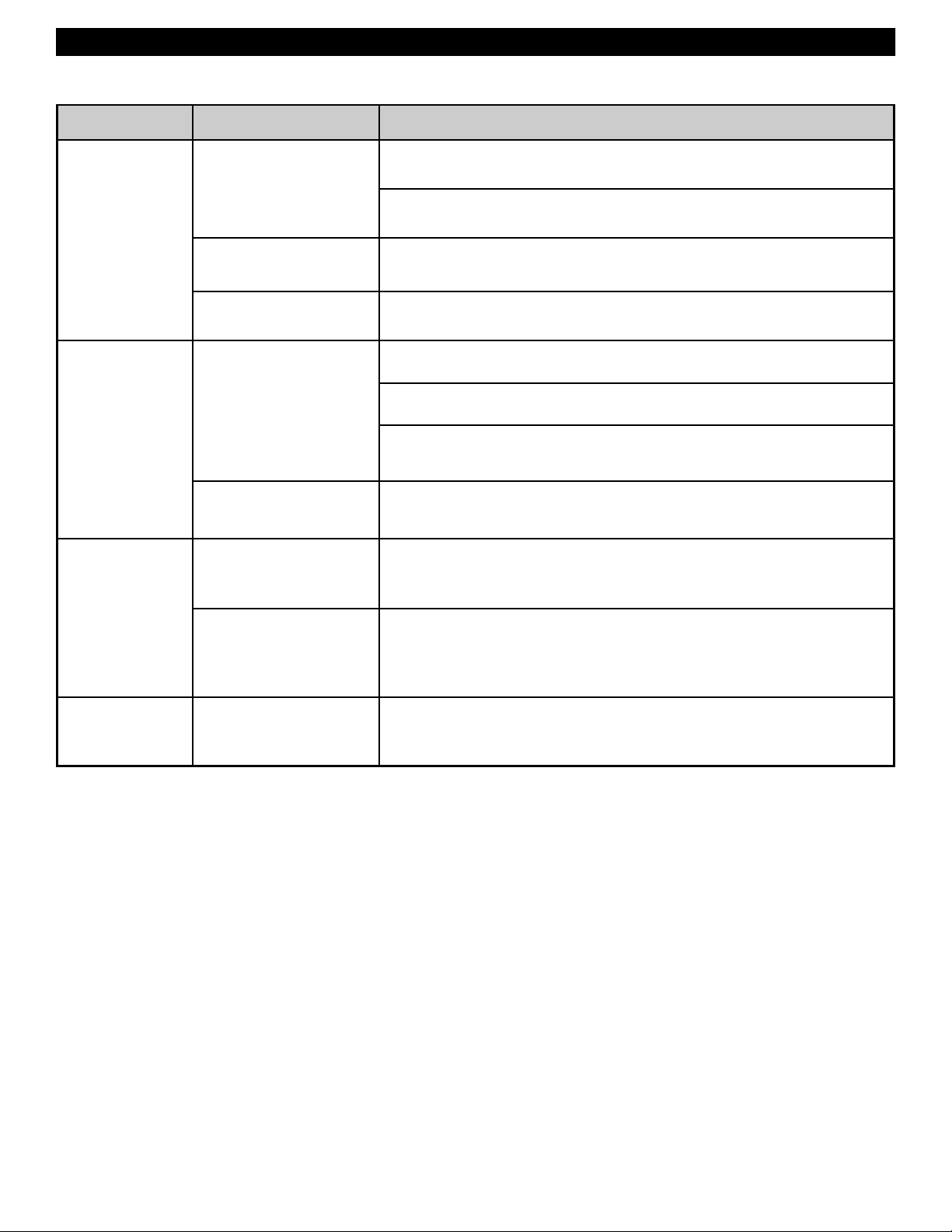

TROUBLE SHOOTING GUIDE

Problem Probable Cause Solution

Cannot clear

drain.

Getting splash

back.

Ram will not pump

up to pressure.

No water in drain.

Not enough pressure.

Ram is not at the correct

drain opening.

Seal is not tight enough Push down on Ram as it is being fired for a tighter seal.

Overflow or other drain is not

covered.

Dry leather seal.

Water must be in the drain. Open water faucet to allow drain to back up. Turn off before firing Ram.

Use optional Check Valve Assembly (G-CVK) to provide water in slow draining sinks

and tubs.

Increase pressure in 10 lb. increments until stoppage is cleared. If pumping becomes

difficult, attach external compressor to Schraeder valve. Do not exceed 80 lbs.

Ram must be used at the closest drain opening to the stoppage.

Use Tapered Plugs or Expansion Plug for a tighter seal.

Wedge a rag around the Rubber Cone or Caulking Hose for odd shaped openings, or

wrap a strip of rubber around an Expansion Plug to increase the diameter.

Cover overflow in sink or other drain opening in combination sinks.

Leather seal must be lubricated every 3 to 6 months to keep it from drying out. To do

so, lift the pump rod and apply a few drops of neat’s foot (leather) oil to the seal through

the air hole.

Ram will not hold

pressure.

Worn leather seal.

Worn seals.

If the leather seal is completely worn, it must be replaced. It is recommended that the

Valve Seat Washer (G-10) be replaced at the same time. Be sure to clean the inside of

the Air Pump Cylinder (G-18) and Pump Bottom Cap (G-8) of any oil and residue before

reassembling unit.

Seals will wear over time. All seals may easily be replaced at the same time using the

Ram Repair Kit (Cat # KRRK). Be sure to clean the inside of the Air Pump Cylinder (G-

18) and Pump Bottom Cap (G-8) of any oil and residue before reassembling unit.

6

Loading...

Loading...