Page 1

™

General D-25 Handy

Operating Instructions

For 1-1/4” through 3” lines

(30mm—75mm)

This tool is designed to give you years

of trouble-free, profitable service. However, no machine is better than its operator.

Read, understand and follow all safety

warnings and instructions provided with

the product. Failure to follow the warnings

and instructions may result in electric

shock and/or serious injury. Save all warnings and instructions for future reference.

SAVE THESE INSTRUCTIONS!

Pour français voir la page 5

Para ver el español vea la paginá 9

Page 2

D-25 Handy™

GENERAL SAFETY INSTRUCTIONS

WARNING! Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury. Replacement

manuals are available upon request at no

charge, or may be downloaded from our website, www.drainbrain.com.

If you have any questions or problems, please

call General’s customer service department at

412-771-6300.

Electric shock resulting in

death can occur if you plug

your drill into an improperly

wired outlet. If the ground wire

is electrified, you can be electrocuted by just touching the

machine, even when the power

switch is off. A ground fault cir-

cuit interrupter will not protect you

in this situation. Use a UL approved tester to determine if the

outlet is safe.

Do not operate power tools in

explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which

may ignite the dust or fumes.

SAVE THESE INSTRUCTIONS!

These instructions are intended to

familiarize all personnel with the safe

operation and maintenance

procedures for the D-25 Handy.

This is the safety alert symbol. It is

used to alert you to potential personal

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARINING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Only wear leather gloves.

Never use any other type of

glove, such as cloth, rubber, or

coated gloves. Never grasp a

rotating cable with a rag.

These items could become

wrapped around the cable and

cause serious injury.

Always wear safety glasses

and rubber soled, non-slip

shoes. Use of this safety equip-

ment may prevent serious injury.

Do not overstress cables.

Overstressing cables may cause

twisting, kinking, or breaking of

the cable and may result in serious injury.

CAUTION indicates a hazard with a low level of risk which,

if not avoided, will result in minor or moderate injury.

2

Page 3

Specific Safety Information

1. Only wear leather gloves. Never use any other type

of glove, such as cloth, rubber, or coated gloves.

Never grasp a rotating cable with a rag. These items

could become wrapped around the cable and cause

serious injury.

2. Be sure that your drill is plugged into a properly

grounded receptacle. If in doubt, check receptacle

before plugging in tool. Check the power cord to see

that there are no cuts or frays, and that the grounding

prong on the plug is still in place.

3. If the power cord supplied with your drill is not

long enough, be sure to use a 16 gauge heavy

duty extension cord no more than 50 feet long

and in good condition. Using lighter cords can re-

sult in severe power loss and motor overheating.

4. Place the tool as close as possible, but not more

than six inches from the opening. Greater distances can result in cable twisting or kinking.

5. Tool is designed for ONE-PERSON operation. Operator must control trigger switch and cable.

6. Never take hold of a rotating cable. Pull the cable

out, or push it back into the container by hand only

when the drill is stopped. When the drill is turning,

always have one hand controlling the trigger switch

and the other hand around the grip sleeve. Opera-

tor’s hand may be caught in the moving parts result-

ing in serious injury.

7. Be careful when cleaning drains where cleaning

chemicals have been used. Avoid direct contact

with corrosive drain cleaners. Drain cleaning chemicals can cause serious burns, as well as damage the

cable. Neutralize or remove corrosive drain cleaners

in the drain before starting the job.

8. Do not operate tool with electric drill if operator

or tool is standing in water. Will increase risk of

electrical shock.

9. Wear safety glasses and rubber soled, non-slip

shoes. Use of this safety equipment may prevent

serious injury.

10. Before starting each job, check that the cable in

the drum is not broken or kinked, by pulling the

cable out and checking for wear or breakage. Al-

ways replace worn out (kinked or broken) cables with

genuine GENERAL replacement cables.

11. Only use this tool in the application for which it

was designed. Follow the instructions on the proper

use of the tool. Other uses or modifying the drain

cleaner for other applications may increase risk of

injury.

D-25 Handy™

Operating Instructions

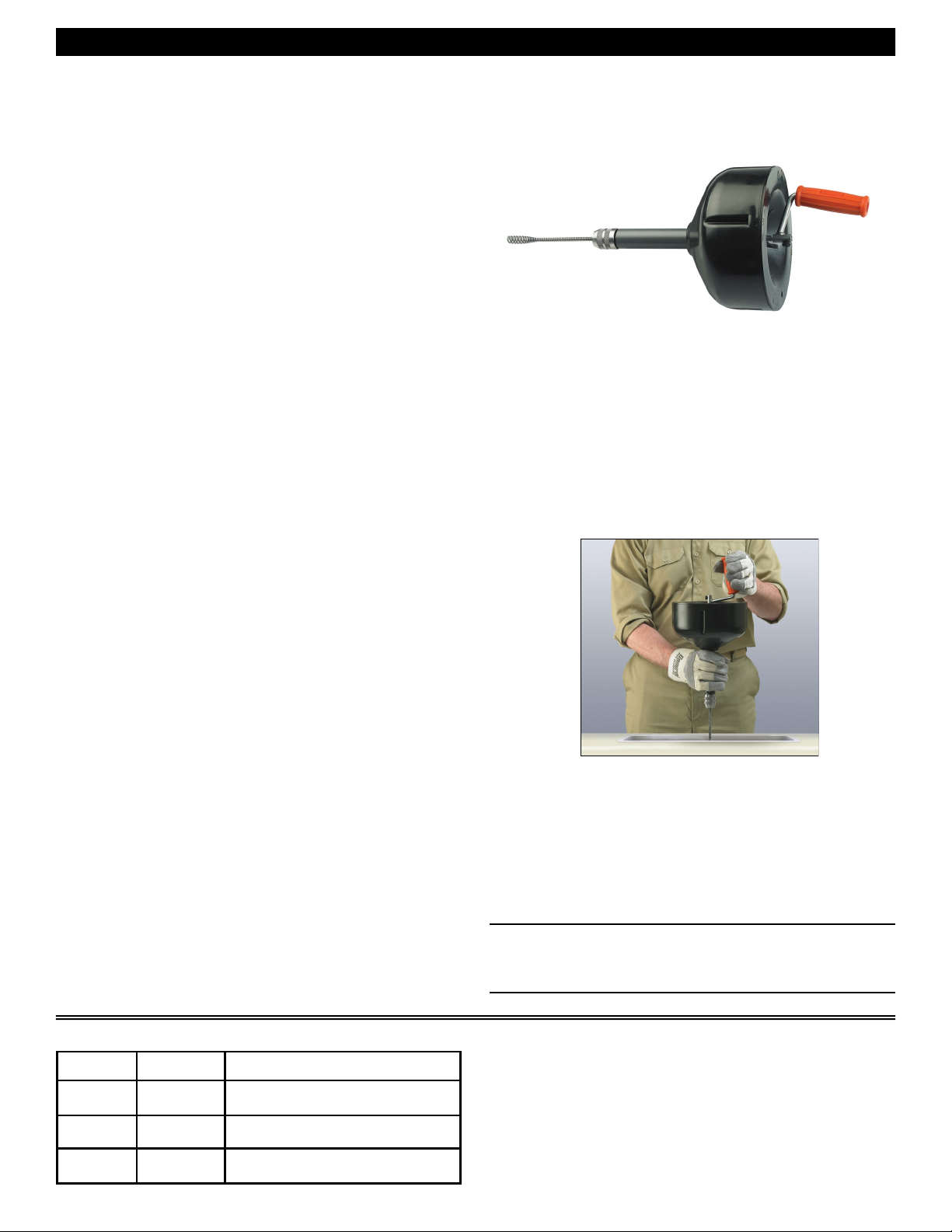

Manual Operation

1. Place tool as close as possible, but not more than six

inches from the drain opening. If you can’t place the

tool this close to the drain opening, run the cable

through a hose or pipe to prevent cable whipping.

2. Loosen the chuck. Insert the cable into the drain

opening as far as it will go. Tighten the chuck by

turning it in a counter-clockwise direction.

3. Turn the tool clockwise, using a slight forward pressure, until the exposed length of cable enters the

drain.

4. Loosen the chuck and pull the container back about

six inches.

5. Tighten chuck and repeat procedure until drain is

open.

6. When line is clear, retract cable while continuing to

rotate the container in the clockwise direction.

Hint: It's often helpful to have a small stream of

water running in the line to wash the debris away

while the tool is in operation and after.

CABLE APPLICATION CHART

Cable Size Pipe Size Typical Applications

1/4” 1-1/4" to 2" Small lines, tubs, and shower drains.

5/16" 1-1/2" to 2" Sinks, basins, and small drains.

3/8" 2" to 3" Stacks, toilets, small drains (No Roots).

Cables are available with either a regular basin plug head

(as pictured above) or an optional down head (as shown

on the cover) to help the cable get around tight bends.

3

Page 4

D-25 Handy™

Operating Instructions

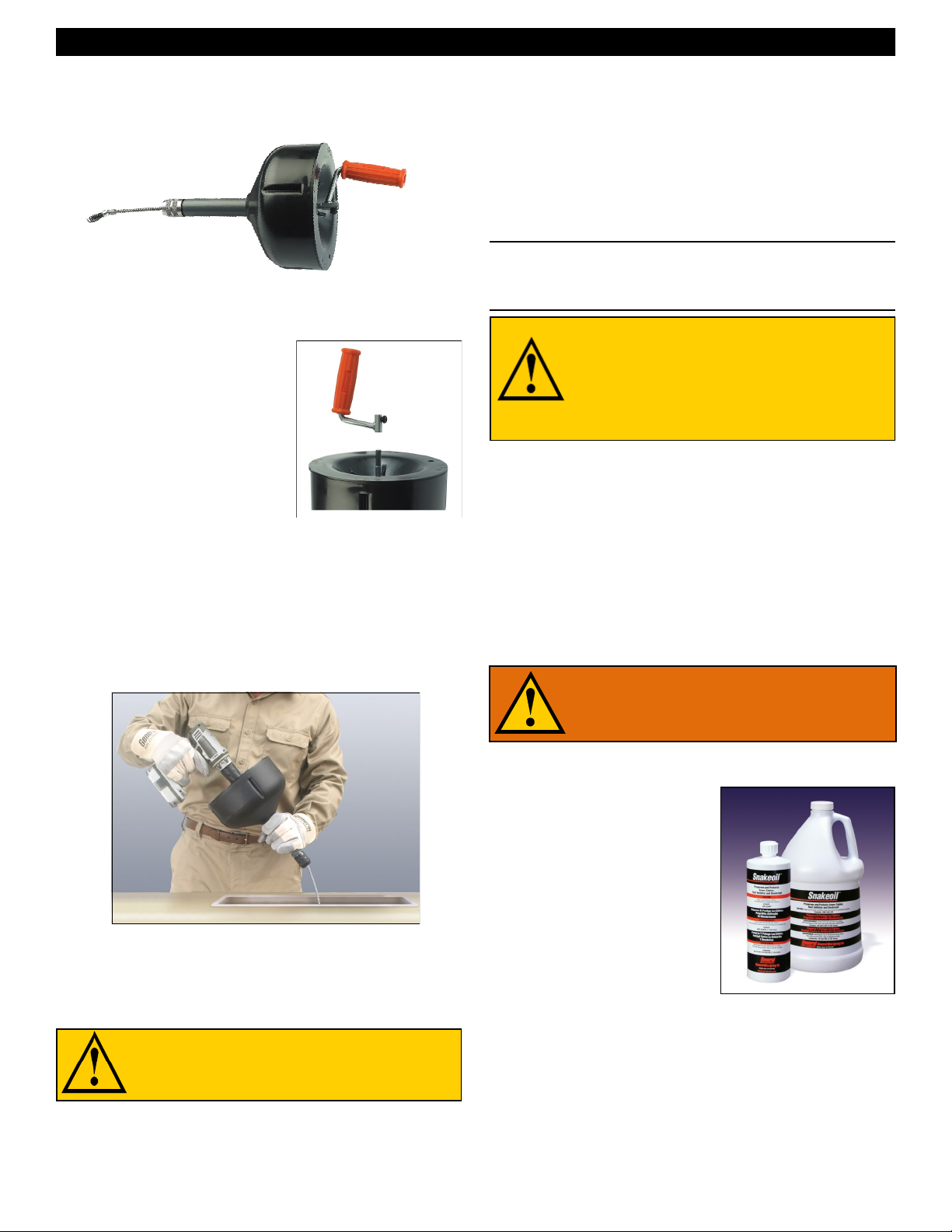

Drill Operation

1. To use the D-25 Handy manually, follow the instruc-

tions for Manual Operation.

2. To use with electric drill,

remove the turning handle

from the top of the container and slide the exposed spindle into the

chuck of your 3/8” double

-insulated, UL approved

drill only. Tighten drill

chuck securely.

3. Loosen container chuck.

Pull cable from container

and insert into drain.

4. Push cable in until resistance is met. Leave not more

than six inches of cable between tool and drain opening, then tighten chuck.

5. Grip drill handle securely in one hand, and grip

sleeve of D-25 in the other hand before squeezing

trigger switch. Drill switch must be in Forward position so that the container turns clockwise.

7. Release the trigger, loosen the container chuck and

pull back container about six inches. Tighten chuck

and repeat procedure until the stoppage is reached.

8. When you reach the stoppage, the cable may have

difficulty moving forward. Move the tool back and

forth until the cable has passed the obstruction.

9. When line is clear, retract cable while continuing to

run drill in forward direction. (Container rotates in the

clockwise direction.)

Hint: It's often helpful to have a small stream of

water running in the line to wash the debris away

while the tool is in operation and after.

DO NOT USE REVERSE TO PULL THE

CABLE OUT OF THE DRAIN. ALWAYS

RUN TOOL IN FORWARD. USE RE-

VERSE ONLY TO RELEASE CABLE

IF CAUGHT IN LINE.

Maintenance

To keep your tool operating smoothly, it is essential that

all bearings and bushings be lubricated. Oiling moving

parts is particularly important where tool comes in contact

with sand, grit and other abrasive material.

DISCONNECT TOOL FROM POWER

SOURCE BEFORE PERFORMING

MAINTENANCE ON TOOL!

6. Start will a slight pressure on the trigger for slow

speed. As more pressure is applied, the drum will

spin faster. With the drill running at the desired

speed, push the tool gently towards the drain.

DO NOT USE THE CONTINUOUS RUN

BUTTON. DRILL SPEED MUST NOT

EXCEED 550 RPM.

CABLE MAINTENENCE

To get maximum service from

your cables, be sure that they

are clean and well oiled. This

not only provides running

lubrication but greatly extends

the life of the cables as well.

Some users periodically pour

oil directly into the drum.

Then, as the drum turns, the

cables get complete lubrication. Our SNAKE OIL is ideally suited for this purpose,

since it not only lubricates the

cables, it deodorizes them as

well.

4

Page 5

™

General D-25 Handy

Manuel d’instructions

Pour canalizations de 1 1/4 à 3 pources

(30mm—75mm)

Votre débouchoir Handy est conçu pour

vous procurer de nombreuses années de service fiable et rentable. Toutefois aucun appareil ne peut donner son plein rendement si

l'opérateur ne le connaît pas à fond.

Lisez, comprenez et respectez toutes

les consignes de sécurité et instructions fournies avec ce produit. Le fait de ne pas suivre

ces consignes et instructions risquerait de

provoquer une électrocution et/ou des blessures graves. Conservez ces documents pour

future référence.

CONSERVEZ CES INSTRUCTIONS !

Page 6

D-25 Handy™

CONSIGNES DE SÉCURITÉ

GÉNÉRALES

AVERTISSEMENT! Lisez attentivement toutes les instructions. Le fait de ne pas suivre

toutes les instructions risque de provoquer une

électrocution, un incendie et/ou des blessures

graves. Des manuels de rechange peuvent

être obtenus gratuitement sur demande, ou

téléchargées à partir de notre site Internet,

www.drainbrain.com. Des films d'instruction

peuvent également être téléchargés de notre

site Internet ou nous être commandés. En cas

de question ou de problème, veuillez contacter

le service clientèle de General au 412-771-

6300.

CONSERVEZ CES INSTRUCTIONS !

L'appareil doit être branché

dans une prise correctement

mise à la terre. À défaut de suivre ces instructions, il peut

s'ensuivre un choc électrique

et la mort. Si le fil de mise à la

terre est électrifié, vous pouvez

être électrocuté par un simple

contact avec l'appareil et ce,

même si l’interrupteur est à Ar-

rêt (Off). Dans ce cas, le disjoncteur de fuite à la terre ne peut pas

vous protéger. Utilisez un testeur

certifié UL pour vérifier si la prise

de courant est sécuritaire.

N'utilisez jamais des outils motorisés dans une atmosphère

explosive générée par des liquides inflammables, des gaz

ou de la poussière. Les outils

électriques provoquent des étin-

celles qui risquent d’enflammer la

poussière ou les vapeurs.

Ces instructions ont pour objet de fa-

miliariser tous les employés avec l’u-

tilisation et l’entretien sans danger

du D-25 Handy.

Ce symbole de sécurité vous avertit

de l’existence d'un danger pour votre

DANGER signale un danger de haut risque qui, s’il n’est

pas évité, entraînera des blessures graves ou mortelles.

AVERTISSEMENT signale un danger de risque moyen qui,

s’il n’est pas évité, peut entraîner des blessures graves ou

mortelles.

MISE EN GARDE signale un danger de faible risque qui,

s’il n’est pas évité, peut entraîner des blessures de faible

ou moyenne gravité.

sécurité personnelle. Respectez toutes les consignes de sécurité suivant

ce symbole afin d’éviter des blessu-

res graves ou mortelles.

Ne portez que des gants en

cuir. N’utilisez aucun autre ty-

pe de gants, en tissu, caoutchouc ou enduit. Ne saisissez

jamais un câble en mouvement

avec des gants en tissu ou un

chiffon; ces matériaux peuvent

s’enrouler autour du câble et cau-

ser des blessures graves.

Portez toujours des lunettes de

sécurité et des chaussures à

semelles de caoutchouc antidérapantes. L'emploi de ces

équipements de sécurité peut

empêcher des blessures graves.

Ne forcez jamais les câbles

exagérément. Une tension ex-

cessive peut causer la torsion, le

vrillage ou la rupture du câble et

pourrait provoquer des blessures

graves.

6

Page 7

D-25 Handy™

CONSIGNES DE SÉCURITÉ PARTICULIÈRES

1. Portez uniquement des gants en cuir. N’utilisez

jamais d’autres types de gants, tels que gants en

toile, en caoutchouc ou en tissu enduit. Ne saisissez

jamais un câble en rotation avec un chiffon. Ces objets peuvent se prendre dans le câble et provoquer

un accident grave.

2. Assurez-vous que l'outil soit branché dans une

prise de courant correctement mise à la terre. En

cas de doute, vérifiez la prise avant d'y brancher l'outil. Vérifiez que le cordon électrique n'est pas coupé

ou effiloché, et que la broche de mise à la terre est

encore bien en place.

3. Si le cordon d'alimentation de l'outil n'est pas

suffisamment long, vous pouvez utiliser une rallonge pour usage intensif en bon état de calibre

16 et ne dépassant pas 15 m (50 pi). Un cordon de

calibre plus petit peut entraîner une importante chute

de puissance et la surchauffe du moteur.

4. Placez l’appareil le plus près possible du drain, à

une distance de 15,24 cm maximum. Une distance

plus grande risque de conduire à une torsion ou un

vrillage du câble.

5. Cet appareil est prévu pour être utilisé PAR UNE

PERSONNE seulement à la fois. L’utilisateur doit

contrôler la gâchette et le câble.

6. Ne saisissez jamais un câble en mouvement. Ne

saisissez le câble pour le sortir de son logement

ou l'y rentrer que lorsque le moteur est arrêté.

Lorsque le moteur tourne, ayez toujours une

main sur la gâchette et l'autre main autour de la

poignée bouclier conique. La main de l’utilisateur

risque de se prendre dans des pièces en mouvement, ce qui peut entraîner des blessures graves.

7. Faites attention lorsque vous nettoyez un drain

dans lequel des produits chimiques ont été utilisés. Évitez tout contact direct avec les produits de

débouchage de drain corrosifs. Ces produits chimiques peuvent causer des blessures à l'opérateur et

endommager le câble. Neutralisez ou évacuez les

produits de nettoyage corrosifs des tuyaux avant

d'utiliser l'outil.

8. Ne faites pas fonctionner la machine si elle ou

l'utilisateur se trouve sur un sol inondé. Ceci aug-

menterait le risque d’électrocution.

9. Portez toujours des lunettes de sécurité et des

chaussures à semelle en caoutchouc antidérapant. L'emploi de ces équipements de sécurité peut

empêcher des blessures graves.

10. Avant chaque utilisation, vérifiez que le câble

n'est ni cassé ni emmêlé à l'intérieur du tambour,

en extrayant le câble et en vérifiant qu'il n'est pas

usé ni cassé. Remplacez toujours les câbles usés

(entortillés ou cassés) par des câbles de remplace-

ment GENERAL authentiques.

11. N’utiliser cet outil que pour la tâche à laquelle il

est destiné. Suivez le mode d’emploi. Toute autre

utilisation ou la modification du débouchoir pour d’autres applications risquent d’augmenter le risque de se

blesser.

FICHE D’APPLICATION DES CÂBLES

Taille du

Câble

1/4”

(6.35 mm)

5/16"

(7.94 mm)

3/8"

(9.5 mm)

Taille du Tuyau Application Typique

1-1/4" à 2"

(31.75 à 50.8 mm)

1-1/2" à 2"

(38.1 à 50.8 mm)

2" to 3"

(50.8 à 76.2 mm)

Petits Conduits,Bains, Douches

Eviers, Bassins et petits renvois

Évents, Toilettes et petits renvois

DIRECTIVES D'UTILISATION

Fonctionnement Manuel

1. Placez la machine à une distance de 15,24 cm maxi-

mum de l’ouverture du drain. Si ceci n’est pas possi-

ble, faites passer le câble à travers un tuyau ou une

conduite pour éviter que le câble ne fouette.

2. Desserrer le mandrin. Sortir le câble du récipient et

insérer la tête d’alésage dans le renvoi. Il sera possi-

blement nécessaire de tourner la tête du câble au

travers les croisillons de la crépine.

3. Tourner l’outil dans le sens des aiguilles d’une mon-

tre et enfoncer avec une légère pression avant

jusqu’à ce que la section exposée du câble pénètre

le renvoi.

4. Desserrer le mandrin et reculer le récipient d’environ

6 pouces (15cm).

5. Serrer le mandrin et répéter le procédé jusqu’à ce

que le renvoi soit dégagé.

6. Lorsque le conduit est libre, rétracter le câble toujours en tournant le récipient dans le sens des aiguilles d’une montre.

Truc: Il peut être avantageux de faire couler un filet

d'eau dans la canalisation pendant et après l'utilisation

de l'appareil, pour dégager les débris coupés par le couteau.

7

Page 8

D-25 Handy™

INSTRUCTIONS SUR L’OPÉRATION

Percer l'opération

1. D’utiliser le D-25 Handy manuellement, suivez les

instructions pour le Fonctionnement Manuel.

2. Retirer la poignée du dessus du

récipient et glisser la tige exposée dans le mandrin de la perceuse. Bien serrer le mandrin.

ATTENTION: Utiliser une per-

ceuse 3/8” à isolation double

reconnue par UL seulement.

3. Desserrer le mandrin du réci-

pient. Sortir le câble du récipient

et l’insérer dans le renvoi.

4. Enfoncer le câble jusqu’à ce qu’une résistance soit

sentie. Garder environ 6 pouces (15cm) de câble

entre l’outil et l’ouverture du renvoi, ensuite serrer le

mandrin.

5. Dans une main prendre une bonne prise sur la

poignée de la perceuse et de l’autre main retenir la

bague de rétention de la D-25 avant d’appuyer sur la

gachette de la perceuse. La perceuse doit être en

position de marche avant afin que le récipient tourne

dans le sens des aiguilles d’une montre.

7. Relâcher la gachette, desserrer le mandrin du réci-

pient et reculer le récipient d’environ 6 pouces

(15cm). Serrer le mandrin et répéter le procédé

jusqu’à ce que l’obstruction soit atteint.

8. Lorsque l’obstruction est atteinte, il est possible que

le câble avance avec plus de difficulté. Bouger l’outil

en mouvement avant/arrière jusqu’à ce que le câble

passe l’obstruction.

9. Lorsque le conduit est libre, rétracter le câble toujours avec la marche avant de la perceuse. (Le réci-

pient tourne dans le sens des aiguilles d’une mon-

tre.)

Truc: Il peut être avantageux de faire couler un filet

d'eau dans la canalisation pendant et après l'utilisation

de l'appareil, pour dégager les débris coupés par le couteau.

PAS DE MARCHE ARRIÈRE POUR

RÉTRACTER LE CÂBLE DU RENVOI.

UTILISER LA MARCHE ARRIÈRE SEU-

LEMENT POUR LIBÉRER LE CÂBLE

S’IL SE COINCE DANS LE CONDUIT.

ENTRETIEN

Afin de s’assurer que l’outil fontionne toujours bien, tous

les roulements et câbles doivent être lubrifiés. La lubrification des pièces mobiles est particulièrement importante

lorsque la machine vient en contact avec le sable, le gravier et autres matières abrasives

6. Commencer avec une légère pression sur la gachet-

te pour une vitesse lente. Lorsque plus de pression

est appliquée sur la gachette, le récipient tourne plus

rapidement. Une fois la perceuse à la vitesse désir-

ée, pousser l’outil légèrement vers le renvoi.

N’UTILISER PAS LE BOUTON DE VE-

RROUILLAGE ROUGE. LA VITESSE

DE LA PERCEUSE NE DOIT PAS

EXCÉDER 550 TOURS/MINUTE.

DÉCONNECTEZ L'APPAREIL DE SA

SOURCE D'ALIMENTATION ÉLECTRIQUE AVANT TOUT ENTRETIEN !

ENTRETIEN DES CÂBLES

Pour obtenir un rendement

maximal des câbles, assurez-vous qu'ils soient propres et bien lubrifiés. Cela

est nécessaire à leur utilisation et prolonge grandement

leur durée. Certains utilisateurs versant périodiquement de l'huile directement

dans le tambour. Alors,

quand le tambour tourne, le

câble est complètement lubrifié. Notre huile SNAKE

OIL est idéale à cette fin puisqu'elle désinfecte et désodorise tout en lubrifiant.

8

Page 9

™

General D-25 Handy

Instrucciones de Operación

Para lineas de 1 1/4 à 3 pulgadas

(30 a 75mm)

Esta herramienta está diseñada para darle

años de servicio rentables y sin problemas. Sin

embargo, no hay máquina que sea mejor que

el operario.

Lea, entienda y cumpla con todas las advertencias de seguridad e instrucciones que vienen

con el producto. Si no se siguen todas estas

advertencias e instrucciones se pueden producir descargas eléctricas y/o graves lesiones.

Guarde todas las advertencias e instrucciones

como referencias futuras.

¡GUARDE ESTAS INSTRUCCIONES!

Page 10

D-25 Handy™

REGLAS GENERALES

DE SEGURIDAD

ADVERTENCIA: Lea y entienda todas las

instrucciones. Si no se siguen todas las instruc-

ciones que se indican a continuación pueden producirse descargas eléctricas, incendios y/o graves

lesiones corporales. El usuario puede solicitar manuales de repuesto de forma gratis o puede descargarlos en nuestro sitio web en

www.drainbrain.com. También hay videos de ins-

trucciones que pueden descargarse de nuestro

sitio web, o que pueden pedirse. Si tiene preguntas

o problemas, comuníquese con el Departamento

de Servicio al Cliente de General, llamando al 412-

771-6300.

¡GUARDE ESTAS INSTRUCCIONES!

Estas instrucciones están concebidas pa-

ra que todo el personal quede familiariza-

do con los procedimientos de operación

y mantenimiento seguros de D-25 Handy.

Este es un símbolo de alerta de seguridad. Se utiliza para alertar al usuario

ante aquellos posibles peligros que

pueden causar una lesión personal.

Obedezca todos los mensajes de seguridad asociados a este símbolo

para evitar posibles lesiones o la

muerte.

Si enchufa la máquina en un

tomacorriente alambrado incorrectamente se puede producir

una descarga eléctrica, que

puede resultar en la muerte. Si

el alambre de conexión a tierra

está vivo, usted puede ser

electrocutado con sólo tocar la

máquina, incluso cuando el

interruptor de potencia esté

apagado. En esta situación, un

interruptor de circuito de falla de

la conexión a tierra no lo protegerá. Use un probador aprobado

por UL para determinar si el tomacorriente está bien protegido.

No opere herramientas mecánicas en atmósferas explosivas,

como por ejemplo en presencia

de líquidos, gases o polvos inflamables. Las herramientas

eléctricas generan chispas que

pueden encender el polvo o los

vapores.

Use sólo guantes de cuero.

Nunca use ningún otro tipo de

guante, como por ejemplo los

de tela, caucho o recubiertos.

Nunca agarre con un trapo un

cable que esté girando. Estos

artículos podrían enredarse en el

cable y causar graves lesiones.

PELIGRO indica un peligro con un alto nivel de riesgo que

si no se evita resultará en la muerte o en una lesión grave.

ADVERTENCIA indica un peligro con un nivel medio de

riesgo que si no se evita podría resultar en la muerte o en

una lesión grave.

PRECAUCIÓN indica un peligro con un bajo nivel de riesgo que si no se evita resultará en una lesión de grado menor o moderado.

Use siempre gafas de seguridad y calzado antideslizante

con suela de goma. El uso de

este equipo de seguridad puede

evitar graves lesiones.

No tense en exceso los cables.

La tensión excesiva de los cables

puede causar la torcedura, formación de dobleces o rotura del

cable y puede producir graves

lesiones.

10

Page 11

D-25 Handy™

INFORMACIÓN DE SEGURIDAD ESPECÍFICA

1. Use sólo guantes de cuero. Nunca use ningún otro

tipo de guante, como por ejemplo los de tela, caucho

o recubiertos. Nunca agarre con un trapo un cable

que esté girando. Estos artículos podrían enredarse

en el cable y causar graves lesiones.

2. Asegúrese de que la unidad esté enchufada en

un receptáculo correctamente conectado con tierra. Si tiene dudas, revise el receptáculo antes de

enchufar la máquina. Revise el cordón eléctrico para

ver que no haya cortes o desgaste y que el diente de

conexión con tierra del enchufe todavía esté en su

lugar.

3. Si el cordón eléctrico que viene con la máquina

no es lo suficientemente largo, asegúrese de utilizar una extensión de calibre 16 que no tenga

más de 50 pies y esté en buen estado. El uso de

cordones más livianos puede producir una grave

pérdida de energía y recalentamiento del motor.

4. Coloque la máquina a una distancia de no más de

seis pulgadas del orificio del desagüe. Distancias

mayores pueden hacer que el cable se tuerza o doble.

5. La máquina está diseñada para ser operada por

UNA SOLA PERSONA. El operario está obligado a

controlar el interruptor del disparador y el cable.

6. Nunca agarre un cable que está girando. Saque o

meta el cable en el envase con la mano solamente

cuando el motor esté detenido. Cuando el motor esté

girando, tenga siempre una mano controlando el disparador y la otra agarrando el protector de la agarradera. Las piezas móviles pueden atrapar las manos

del operario y causarle así una lesión grave.

7. Evite el contacto directo con limpiadores de de-

sagües que sean corrosivos. La exposición a esos

productos químicos puede causar lesiones al operario y dañar el cable. Neutralice o quite los limpiadores de desagüe corrosivos que estén en el desagüe

antes de comenzar.

8. No opere la máquina si el operario o la máquina

están parados sobre el agua. Ello aumentará el

riesgo de descarga eléctrica.

9. Use gafas de seguridad y calzado antideslizante

con suela de goma. El uso de este equipo de segu-

ridad puede evitar graves lesiones.

10. Antes de comenzar cada trabajo, compruebe que

el cable en el tambor no esté roto ni doblado,

sacándolo y revisando si presenta desgaste o

roturas. Reemplace siempre los cables gastados

(que tienen dobleces o están rotos) por cables de

repuesto GENERAL auténticos.

11. Utilice esta herramienta sólo en la aplicación pa-

ra la que fue diseñada. Siga las instrucciones sobre

uso adecuado de la herramienta. Otros usos o la modificación del limpiador de desagües para otras aplicaciones pueden aumentar el riesgo de lesiones.

Cuadro de aplicaciones de cables

Calibre del

cable

1/4 pulg

6.3 mm

5/16 pulg

7.9 mm

3/8 pulg

9.5 mm

Tamaño de

la tubería

1-1/4 a 4 pulg

30 mm a 50 mm

1-1/2 a 2 pulgadas

38 mm a 50 mm

2 a 3 pulgadas

50 mm a 75 mm

Aplicaciones típicas

Desagües de duchas, tinas y

líneas pequeñas.

Fregaderos, lavamanos y desagües pequeños.

Bajantes, retretes, desagües

pequeños (sin raíces).

INSTRUCCIONES DE OPERACIÓN

Manual de funcionamiento

1. Coloque la herramienta a una distancia de no más de

seis pulgadas del orificio del desagüe. Si no puede

colocar la herramienta tan cerca orificio de desagüe,

pase el cable a través de una manguera o tubería para evitar que se golpee.

2. Suelte el mandril. Inserte el cable en el orificio de de-

sagüe lo más profundo que pueda. Apriete el mandril

girándolo en el sentido contrario a las mancillas del

reloj.

3. Gire la herramienta en el sentido de las manecillas del

reloj utilizan una ligera presión hacia adelante hasta

que la parte expuesta del cable entre en el desagüe.

4. Afloje el mandril y jale el envase alrededor de seis pul-

gadas.

5. Apriete el mandril y repita el procedimiento hasta que

el desagüe corra libremente.

6. Cuando la cañería quede despejada, retraiga el cable

sin dejar de girar el envase en el sentido de las manecillas del reloj.

Consejo: Suele ser útil tener un pequeño flujo de agua

en la línea para eliminar los residuos de cortaduras

mientras la máquina está en operación y después de

ello.

11

Page 12

D-25 Handy™

INSTRUCCIONES DE OPERACIÓN

Perforar la Operación

1. Para usar el D-25 Handy manualmente, siga las ins-

trucciones indicadas para Manual de funcionamiento.

2. Para usar el talado eléctrico, retire la manecilla girato-

ria de la parte de arriba del envase y meta el husillo expuesto

en el mandril de su taladro de

3/8”, que debe ser solamente un

taladro aprobado por UL con

aislamiento doble. Apriete firmemente el mandril.

3. Afloje el mandril del envase. Jale

el cable del envase e insértelo

en el desagüe.

4. Empuje el cable hasta que sienta resistencia. Deje

seis pulgadas de cable entre la herramienta y el orificio del desagüe, y luego apriete el mandril.

5. Agarre la manecilla del taladro firmemente con una

mano y el manguito del taladro con la otra antes de

apretar el interruptor del gatillo. El interruptor del tala-

dro debe encontrarse en la posición “Forward” (hacia

adelante) para que el envase gire en el sentido de las

manecillas del reloj.

7. Libere el gatillo, afloje el mandril del envase y jale el

envase alrededor de seis pulgadas. Apriete el mandril y repita el procedimiento hasta que el desagüe

corra libremente.

8. Es posible que cuando llegue a la obstrucción, el

cable tenga dificultades continuar moviéndose hacia

adelante. Mueva la herramienta hacia adelante y

hacia atrás hasta que el cable pase la obstrucción.

9. Cuando la línea quede despejada, retraiga el cable

sin detener el taladro que está moviéndose en la dirección hacia adelante. (El envase gira en el sentido

de las manecillas del reloj).

Consejo: Suele ser útil tener un pequeño flujo de agua

en la línea para eliminar los residuos de cortaduras

mientras la máquina está en operación y después de

ello.

NO UTILICE REVERSA PARA SACAR

EL CABLE DEL DESAGÜE. SIEMPRE

HAGA FUNCIONAR LA HERRAMIEN-

TA HACIA ADELANTE. USE REVERSA

SÓLO PARA LIBERAR EL CABLE SI

ÉSTE QUEDA ATRAPADO EN LA

LÍNEA.

MANTENIMIENTO

Para mantener su máquina operando sin problemas, es

esencial que todos los rodamientos y bujes estén lubricados. La lubricación de las piezas móviles es particularmente importante si la máquina debe entrar en contacto

con arena, arenisca y otros materiales abrasivos.

6. Comience ejerciendo una ligera presión en el gatillo

para obtener una velocidad baja. En la medida que

aumente la presión, el tambor girará más rápidamente. Cuando el taladro esté funcionando a la velocidad

deseada, empuje la máquina cuidadosamente hacia

del desagüe.

NO UTILICE EL BOTÓN DE

FUNCIONAMIENTO CONTINUO. LA

VELOCIDAD DEL TALADRO NO DEBE

EXCEDER LAS 550 RPM.

General Wire Spring Co.

1101 Thompson Avenue

McKees Rocks, PA 15136

412-771-6300 www.drainbrain.com

DESCONECTE LA MÁQUINA DE LA

FUENTE DE ALIMENTACIÓN ANTES DE

DARLE CUALQUIER MANTENIMIENTO!

MANTENIMIENTO DEL CABLE

Para obtener el máximo de servicio de los cables, asegúrese de que estén limpios y bien lubricados. Esto no sólo

proporciona lubricación continua, sino que también prolonga

en gran medida la vida útil de

los cables. Algunos usuarios

periódicamente echan aceite

directamente en el tambor. Así,

al girar el tambor, los cables se

lubrican completamente. Nuestro ACEITE SNAKE es ideal

para esto, dado que no sólo

lubrica los cables sino también

los desodoriza.

© General Wire Spring Co. 2014 C-D25OI-0714

Loading...

Loading...