Page 1

Operating Instructions for

General Cold-Shot™

F or 1/8" to 2" (10-60 mm) Metal and Plastic Pipes

Your Cold-Shot pipe freeze kit is

designed to give you years of trouble-free,

profitable service. However, no tool is better

than its operator. We therefore suggest you

read these instructions through carefully

before using your machine on the job. This

will enable you to operate the Cold-Shot more

efficiently and more profitably. Failure to

follow these instructions may cause personal

injury to operator or damage to equipment.

Basic Safety Instructions

Only use the Cold-Shot for the purpose for

which it was intended, with due attention to

the general safety and accident prevention.

Keep the work area clean. Clutter can be

dangerous.

Avoid dangerous flammable liquids or gases.

Provide adequate lighting at the workplace.

Wear suitable work clothes, keep long hair clear, take off jewelry and similar items.

Use personal safety equipment (e.g. safety glasses, rubber gloves).

Clamp the work piece securely; do not hold by hand.

Check the unit occasionally for damage, and to see that it is operating correctly.

Replace worn parts as early as possible.

Only use genuine GENERAL spare parts and accessories, for personal safety

reasons, to ensure correct operation of the Cold-Shot, and to preserve the basis for

the warranty claim.

All repair work must be performed only by an authorized repair facility.

Any unauthorized modifications of the Cold-Shot are prohibited for safety reasons

and will void the warranty.

Specific Safety Instructions

Carbon dioxide must be drawn from the cylinder in a liquid state in order to produce

dry ice. For this reason,

only cylinders equipped with a dip tube may be used.

Do not connect a pressure reducer to the cylinder.

Keep the cylinder in an upright position and secure it to prevent it from falling over.

The carbon dioxide cylinder must not be emptied completely.

Page 2

Do not interfere with nozzles, freeze heads or valves, including cylinder valves.

Work only in a well ventilated area

. Carbon dioxide is non-toxic and nonflammable but it is heavier than air and can therefore collect at ground level and

displace the air if ventilation is inadequate, giving rise to the danger of suffocation.

Wear eye protection or goggles.

Wear gloves.

Do not work with an open flame within 2 ft. (50 cm) of the freezing point.

Never hit a chilled freeze head with a hammer or other tool. A sharp blow will cause

it to fracture.

Keep other people, particularly children, well away. Dry ice causes burns if it comes

into contact with the skin. Once work is complete, any remaining dry ice in the

freeze heads must be carefully disposed of or placed in a covered refuse container.

Observe the safety instructions provided by the carbon dioxide supply company.

How the Cold-Shot Works

The Cold-Shot can be used to freeze all types of liquids, even at high pressure,

inside steel, copper, cast iron, lead, aluminum and plastic pipe in sizes ranging from

1/8" to 2" (10-60 mm).

The Cold-Shot uses commercially available carbon dioxide (CO²). You can

purchase or rent cylinders through your local welding supply house. Though any size

cylinder can be used, it is recommended that users purchase the largest cylinder size

possible.

Note: the CO² tank must have a dip tube.

The dip tube allows liquid rather

than gas to flow through the spiral hoses were it will expand to form Dry-ice inside the

freeze heads.

The ice pack which forms in the pipe is capable of withstanding a pressure of

approximately 7000 psi (500 bar). As the liquid freezes, a layer of frost will develop on

the surface of the pipe.

Preparation

1. Remove the seal from the carbon dioxide cylinder.

2. Screw connector with T-distributor on to cylinder (right-hand thread).

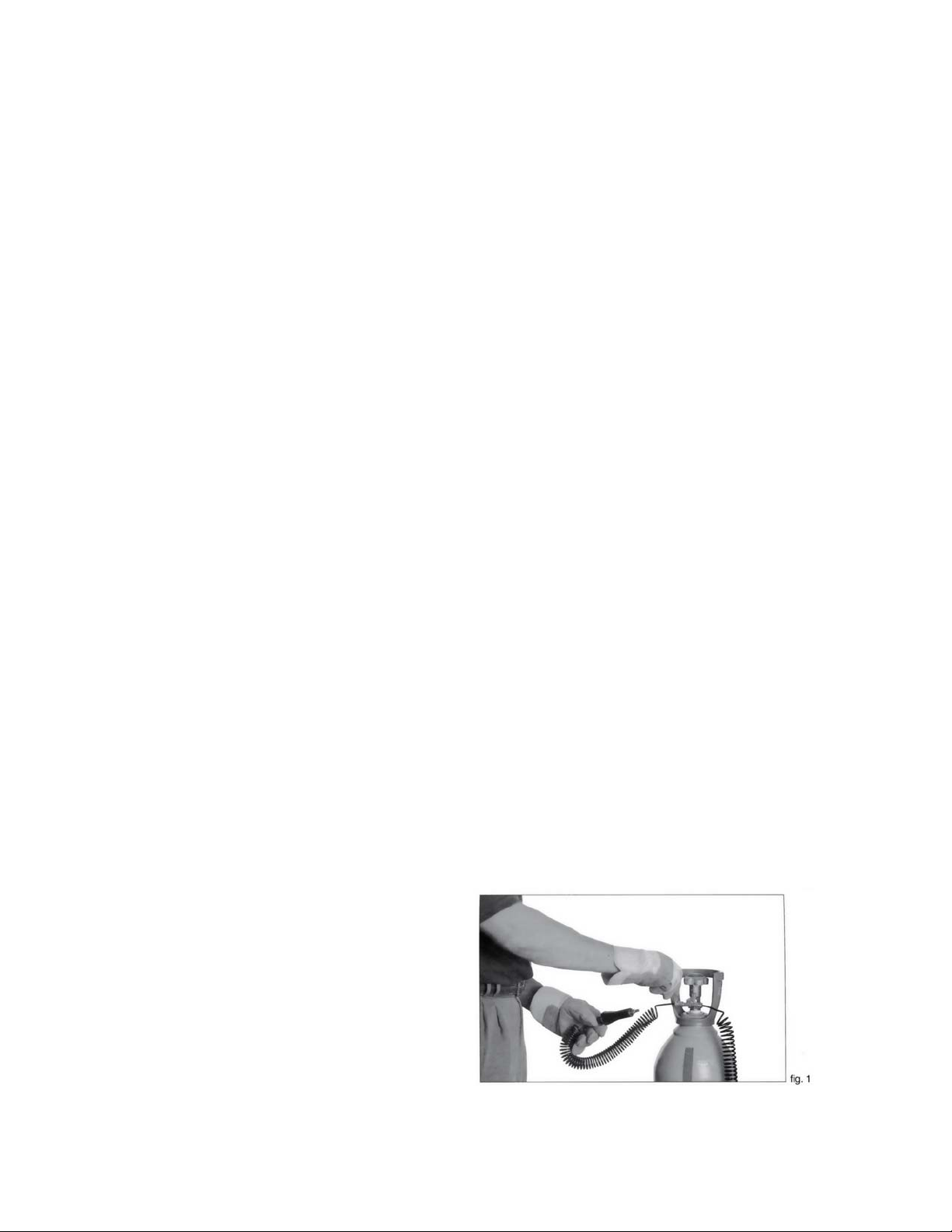

3. Screw spiral hoses on to the

T-distributor. (Fig. 1)

4. Choose freeze heads which

correspond to the size of the pipe to

be frozen.

2

Page 3

5. Place the freeze heads on the pipe and secure by tightening the knobs evenly,

using hex head wrench provided, to give a firm but not over tight hold. (Fig. 2)

6. Push each injector into the bore of the

freeze head until it is completely

inserted and resting against the stop,

then turn clockwise one quarter turn to

lock in place. (Fig. 3).

Operation

1. The liquid in the pipe can only be frozen

when it is no longer flowing. All pumps must

therefore be stopped and no liquid allowed to

escape from the pipe. Allow water to cool to

room temperature before freezing.

2. Fully open the cylinder valve.

The amount

of carbon dioxide required is controlled

automatically.

The liquid carbon dioxide

expands in the injector and forms dry ice

inside the freeze head with a temperature of

-110 F° (-79° C) and freezes the liquid

within the pipe.

3. After a brief period, frost will form on the pipe in the vicinity of the freeze heads.

(See table) If frost does not form in accordance with time given in the table, then

this indicates that the liquid within the pipe is still flowing or the water is too warm.

(Check that all pumps have been switched off and prevent any removal or outflow

of liquid)

4.

While work is in progress, the flow of carbon dioxide refrigerant must be

maintained.

To ensure a sufficient supply of refrigerant is available, a stand-by

cylinder is suggested. The only way to determine the amount of remaining carbon

dioxide is to weigh the cylinder. If it is necessary to change the cylinder during

work, it is essential that this procedure should be compete within 7 minutes to

prevent the ice pack from melting.

5. Once work is complete, close the cylinder valve and wait until the pressure in the

spiral hoses has returned to normal before removing them from valve. Once the

ice pack

has completely melted

, carefully unscrew and remove the injector at the

end of the spiral hoses from the freeze head, then remove the freeze head from

the pipe.

3

Page 4

Freezing times

The freezing times and carbon dioxide requirements given in the table below are

only to be regarded as general guidelines and are valid for a water temperature of

approximately 68 F° (20° C). The freezing times and refrigerant consumption

values will therefore vary for other temperatures. For freezing liquids in plastic

pipes much longer freezing times are generally required.

Freeze head size Material Freezing time Carbon dioxide

requirement

1/8" (10 / 12 mm) steel

copper

1/4" (15 mm) steel

copper

3/8" (18 mm) steel

copper

1/2" (22 mm) steel

copper

3/4" (28 mm) steel

copper

1" (35 mm) steel

copper

1-1/4" (42 mm) steel

copper

1 min.

1 min.

1 min.

2 min.

2 min.

3 min.

3 min.

5 min.

5 min.

7 min.

7 min.

10 min.

11 min.

14 min.

2 oz (60 g)

2¼ oz (65 g)

2½ oz (75 g)

4¾ oz (135 g)

5¼ oz (150 g)

7 oz (200 g)

8 oz (225 g)

11¾ oz (330 g)

12¼ oz (350 g)

15¾ oz (450 g)

17¾ oz (500 g)

23 oz (650 g)

24½ oz (700 g)

31¾ oz (900 g)

Number of

freezing

operations

possible per

20 lbs (10 kg)

cylinder per freeze

head

165

160

130

75

65

50

45

30

29

22

20

15

15

11

1-1/2" (54 mm) steel

copper

2" (60 mm) steel 29 min. 67 oz (1900 g) 5

Carbon Dioxide

Friendly to the environment: No.

C.F.C.

Important

Only use cylinders with dip tube.

!

16 min.

24 min.

37 oz (1050 g)

51 oz (1450 g)

Important

Insert Injector into the bore of

freeze head and rotate 1/4 turn

to lock in place.

!

General Wire Spring Co.

1101 Thompson Avenue

McKees Rocks, PA 15136

412/771-6300 Fax: 412/771-2771

4

10

7

C-CS-0504

Loading...

Loading...