BS5205 man v.141110

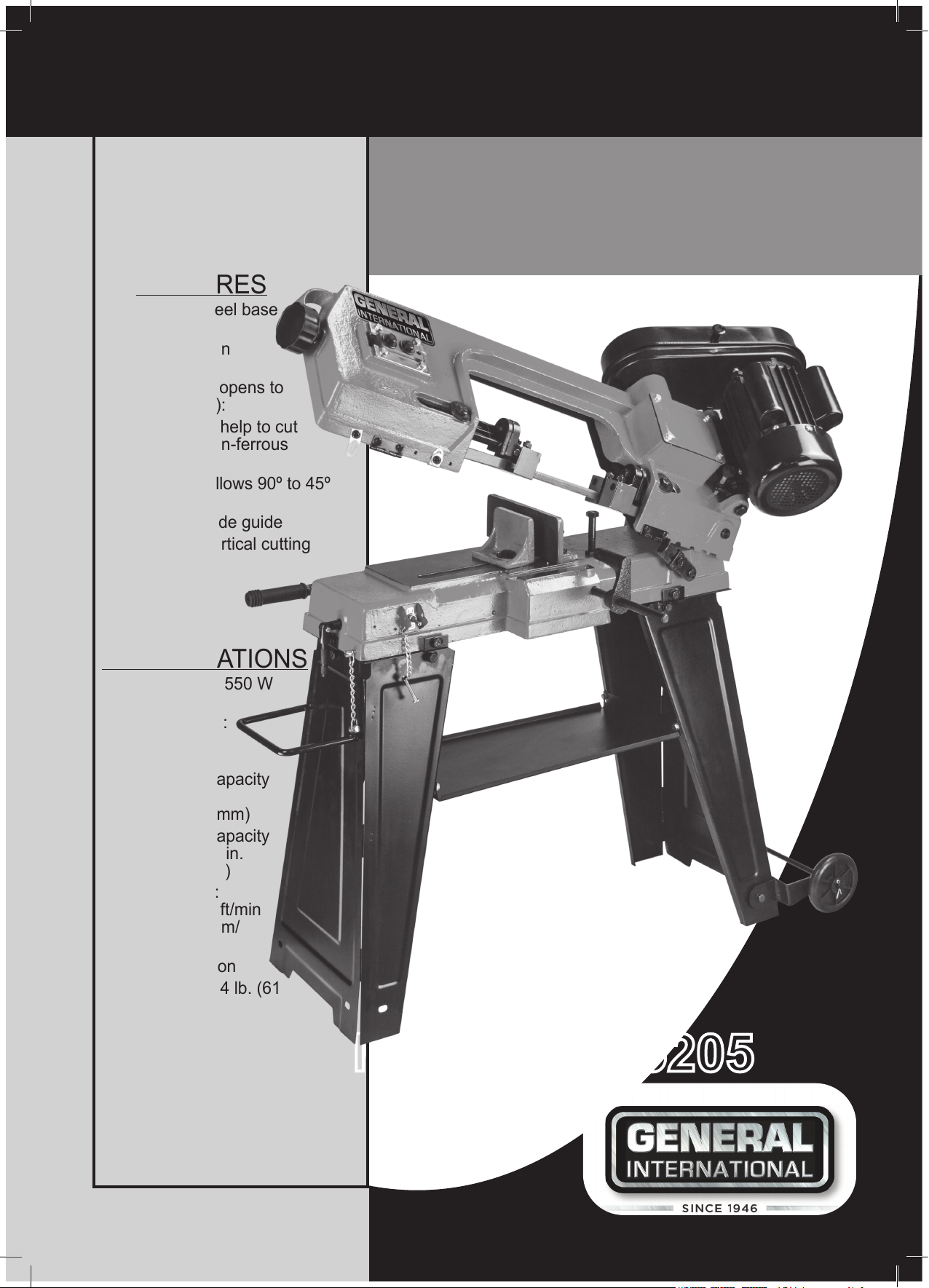

Model #

SETUP & OPERATION MANUAL

FEATURES

● Heavy duty steel base

with wheels

● Strong cast iron

head frame

● Cast iron vise opens to

6 in. (150 mm):

● Three speeds help to cut

ferrous and non-ferrous

metals

● Miter gauge allows 90º to 45º

cuts

● Adjustable blade guide

● Converts to vertical cutting

4-1/2 inch

Metal Cutting

Band Saw

SPECIFICATIONS

● 120 V ~ 60 Hz 550 W

motor:

● Blade included:

64-1/2 in.

(1638 mm)

● Max. cutting capacity

(round):

4-1/8 in. (105 mm)

● Max. cutting capacity

(square): 4 x 6 in.

(102 x 150 mm)

● Blade speeds:

80 / 120 / 180 ft/min

(24 / 36.5 / 55 m/

min)

● CSA certication

● Net weight: 134 lb. (61

kg)

BS5205

ENGLISH

THANK YOU

for choosing this General International machine. This tool has been

carefully tested and inspected before shipment and if properly used and

maintained, will provide you with years of reliable service. To ensure

optimum performance and trouble-free operation, and to get the most

from your investment, please take the time to read this manual before

assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic

function, and features of this tool as well as the set-up, maintenance and

identication of its parts and components. This manual is not intended

as a substitute for formal woodworking instruction, nor to offer the user

instruction in the craft of woodworking. If you are not sure about the safety

of performing a certain operation or procedure, do not proceed until you

can conrm, from knowledgeable and qualied sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for

future reference.

GENERAL® INTERNATIONAL

WARRANTY

All component parts of General® International products are carefully

inspected during all stages of production and each unit is thoroughly

inspected upon completion of assembly.

2-YEAR LIMITED WARRANTY

All products are warranted for a period of 2 years (24 months) from the

date of purchase. General® International agrees to repair or replace any

part or component which upon examination, proves to be defective in

either workmanship or material to the original purchaser during this 2-year

warranty period, subject to the “conditions and exceptions” as listed below.

Repairs made without the written consent of General International will void

the warranty.

DISCLAIMER

The information and specications in this manual pertain to the unit as

it was supplied from the factory at the time of printing. Because we are

committed to making constant improvements, General International

reserves the right to make changes to components, parts or features of

this unit as deemed necessary, without prior notice and without obligation

to install any such changes on previously delivered units. Reasonable care

is taken at the factory to ensure that the specications and information in

this manual corresponds with that of the unit with which it was supplied.

However, special orders and “after factory” modications may render some

or all information in this manual inapplicable to your machine. Further, as

several generations of this model of dust collector and several versions of

this manual may be in circulation, if you own an earlier or later version of

this unit, this manual may not depict your machine exactly. If you have any

doubts or questions contact your retailer or our support line with the model

and serial number of your unit for clarication.

TO FILE A CLAIM

To le a claim under our Standard 2-year Limited Warranty, all defective

parts, components or machinery must be returned freight or postage

prepaid to General® International, or to a nearby distributor, repair center

or other location designated by General® International. For further details

call our service department at 1-888-949-1161.

Along with the return of the product being claimed for warranty, a copy of

the original proof of purchase and a “letter of claim” must be included (a

warranty claim form can also be used and can be obtained, upon request,

from General® International or an authorized distributor) clearly stating

the model and serial number of the unit (if applicable) and including

an explanation of the complaint or presumed defect in material or

workmanship.

CONDITIONS AND EXCEPTIONS

This coverage is extended to the original purchaser only. Prior warranty

registration is not required but documented proof of purchase, i.e. a copy

of original sales invoice or receipt showing the date and location of the

purchase as well as the purchase price paid, must be provided at the time

of claim.

2

ENGLISH

141110

Warranty does not include failures, breakage or defects deemed after

inspection by General® International to have been directly or indirectly

caused by or resulting from; improper use, or lack of or improper

maintenance, misuse or abuse, negligence, accidents, damage in

handling or transport, or normal wear and tear of any generally considered

consumable parts or components.

Repairs made without the written consent of General® International will

void all warranty.

READ ALL INSTRUCTIONS

BEFORE OPERATING

SAVE THESE INSTRUCTIONS

Before attempting to operate your new tool, please read these instructions

thoroughly. You will need these instructions for the safety warnings,

precautions, assembly, operation, maintenance procedures, parts list and

diagrams. Keep your invoice with these instructions. Write the invoice

number on the inside of front cover. Keep the instructions and invoice in a

safe, dry place for future reference.

THE WARNINGS, CAUTIONS AND INSTRUCTIONS discussed

in this instruction manual cannot cover all possible conditions or

situations that could occur. It must be understood by the operator that

common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

IMPORTANT SAFETY

INSTRUCTIONS

The purpose of safety symbols is to attract your attention to possible

hazards. The safety symbols, and the explanations with them, deserve

your careful attention and understanding. The safety warnings do not, by

themselves, eliminate any danger. The instructions or warnings they give

are not substitutes for proper accident prevention measures.

DANGER! Indicates an imminently hazardous situation which, if not

avoided, will result in serious injury or death.

WARNING! Indicates an imminently hazardous situation which, if not

avoided, could result in serious injury or death.

CAUTION: Indicates an imminently risky situation which, if not avoided,

could result in minor injuries or slight injury. It may also be used to notify

the user to remain alert regarding unsafe practises which may cause

property damage.

3

ENGLISH

WARNINGS AND CAUTIONS

WEAR YOUR

FORESIGHT IS

BETTER THAN

NO SIGHT

Be sure to read, understand and follow all safety warnings and instructions

in the supplied operator’s manual.

WORK AREA

1. KEEP CHILDREN AND BYSTANDERS AWAY.

All children should be kept away from the work area. Don’t let them

handle machines, tools or extension cords. Visitors can be a distraction

and are difcult to protect from injury.

2. KEEP WORKING AREA CLEAN

and be sure adequate lighting is available. Cluttered areas invite

injuries.

3. AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep work area

well lit. Do not expose power tools to rain. Do not use the tool in the

presence of ammable liquids or gases.

4. STORE IDLE EQUIPMENT.

Store equipment in a dry area to inhibit rust. Equipment also should

be in a high location or locked up to keep out of reach of children and

untrained persons.

PERSONAL SAFETY

1. LEARN THE MACHINE’S APPLICATIONS AND LIMITATIONS,

as well as the specic potential hazards particular to this machine.

Follow available safety instructions and safety rules carefully.

2. DON’T OVERREACH.

Keep proper footing and balance at all times. Do not reach over or

across machines that are running.

3. STAY ALERT

Avoid distractions while operating this tool. Watch what you are doing.

Use common sense. Do not operate tool when you are tired. Do not

operate while under medication or while using alcohol or other drugs.

4. WEAR APPROPRIATE APPAREL

Do not wear loose clothing, gloves, bracelets, necklaces,or jewellery

while operating the tool. Wear face, eye, ear, respiratory and body

protection devices, as indicated for the operation or environment.

5. ALWAYS WEAR SAFETY GLASSES

Use ANSI approved safety glasses (in accordance with ANSI Z87.1-

2003.) Also use face or dust mask if cutting operation is dusty, and ear

plugs during extended periods of operation. Everyday eyeglasses have

only impact resistant lenses, they are NOT safety glasses.

6. WEAR BREATHING PROTECTION.

Use of this tool can generate and/or disperse dust, which may cause

serious and permanent respiratory or other injury. Many types of wood

are naturally toxic, especially in dust form. Wear a clean dust mask

if the work involves creating a lot of ne or coarse dust. Always use

NIOSH/OSHA-approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

7. WEAR HEARING PROTECTION,

especially from repeated exposure. This tool is loud. Proper hearing

protection should be worn (in accordance with ANSI S12.6-1997

R2002).

8. GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures. When your body is grounded

the risk of electric shock increases. When working wherever “live”

electrical wires may be encountered, try to ascertain whether there is

a danger of shock. Even so, DO NOT TOUCH ANY METAL PARTS

OF THE TOOL while using it. Hold the tool only by the plastic grip to

prevent electric shock if you contact a live wire.

9. ALWAYS DISCONNECT TOOL BEFORE SERVICING

and when changing accessories such as the blade.

10. ENSURE KEYS AND ADJUSTING WRENCHES ARE REMOVED

before turning power on. Left attached, these parts can y off a rotating

part and result in personal injury.

4

ENGLISH

141110

11. MAKE SURE THAT SWITCH IS IN “OFF” POSITION

before plugging in cord to reduce the risk of unintentional starts.

12. NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

13. KEEP HANDS WELL AWAY FROM CUTTING SURFACES

and all moving parts. Do not clear chips and sawdust away with

hands. Use a brush.

14. SECURE WORK.

Use clamps or a vise to hold the work. It’s safer than using your hands

and it frees both hands to operate the tool.

15. DISCONNNECT THE PLUG FROM POWER

before making any adjustments. Changing attachments or accessories

can be dangerous if the tool could accidentally start.

TOOL SAFETY

1. MAKE SURE ALL CUTTING TOOLS

are moving at operation speed before feeding.

2. DO NOT FEED THE MATERIAL TOO QUICKLY.

The tool will perform better and be safer working at the rate for which it

was designed.

3. NEVER LEAVE THE MACHINE WITH THE POWER ON.

4. DO NOT FORCE THE MACHINE.

It will do the job better and be safer at a rate for which it was designed.

Don’t force a small tool or attachment to do the work of a larger

industrial tool. Don’t use a tool for a purpose for which it was not

intended.

5. MAINTAIN TOOLS WITH CARE.

Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and safe performance. Follow instructions

for lubricating and changing accessories. Keep handles dry, clean and

free from oil and grease.

6. DISCONNNECT THE PLUG FROM POWER BEFORE MAKING ANY

ADJUSTMENTS.

Changing attachments or accessories can be dangerous if the tool

could accidentally start.

7. AVOID UNINTENTIONAL STARTING.

Be sure the switch is in the OFF position before plugging in. Do not

carry the tool with the power connected and your nger on the trigger.

8. KEEP GUARDS IN PLACE

and in working order. If a guard must be removed for maintenance or

cleaning, make sure it is properly attached before using the tool again.

9. DO NOT USE THE TOOL

if it cannot be switched on or off. Have your tool repaired

before using it.

10. CHECK FOR DAMAGED PARTS.

Before using this tool, any part that is damaged should be carefully

checked to determine that it will operate properly and perform its

intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mountings, and other conditions that

may affect its operation. Inspect screws and tighten any ones that

are loose. Any part that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise indicated

elsewhere in the instruction manual. Have defective switches replaced

by an authorized service center. Don’t use the tool if switch does not

turn it on and off properly.

11. OBTAIN ADVICE

from your supervisor, instructor or another qualied person if you are

not thoroughly familiar with the operation of this machine. Knowledge

is safety.

12. USE ONLY RECOMMENDED ACCESSORIES.

Use of accessories NOT recommended by General International may

result in a risk of injury.

5

ENGLISH

SERVICE

1. INSPECT AND MAINTAIN THE TOOL REGULARLY.

Have it repaired only by an authorized repair technician.

2. MAINTAIN TOOLS WITH CARE.

Keep tools sharp and clean for better and safer performance. Follow

instructions for lubricating and safe performance. Follow instructions for

lubricating and changing accessories. Keep handles dry, clean and free

from oil and grease.

3. ENSURE THAT THE VENTILATION OPENINGS

are kept clear of debris.

4. IF THE CORDSET IS DAMAGED HAVE IT REPAIRED

only by an authorized service center.

5. SERVICE AND REPAIRS SHOULD BE MADE BY QUALIFIED REPAIR

TECHNICIANS

at an authorized repair center. Improperly repaired tools could cause

serious shock or injury.

6. REPLACEMENT PARTS.

When servicing, use only the manufacturer’s recommended

replacement dentical replacement parts and accessories.

7. THE MANUFACTURER SHALL NOT BE LIABLE

for any changes made to the tool, nor for any damage resulting from

such changes.

SAFETY RULES SPECIFIC TO THIS EQUIPMENT

Because each shop situation is unique, no list of safety guidelines can

ever be complete. The most important safety feature in any shop is the

knowledge and good judgement of the user. Use common sense and

always keep safety considerations, as they apply to your individual shop

situation rst and foremost in mind. If you have any doubts about the

safety of an operation you are about to perform: STOP! Do not perform the

operation until you have validated from qualied individuals if the operation

is safe to perform and what is the safest method to perform it.

WARNING! To avoid mistakes that could cause serious, permanent

injury, do not plug the tool in until the following steps have been

completed:

Assembly and alignment

Learn the use and function of the on/off switch, feed control, depth

stop, belt tension and other adjustments.

Review and understanding of all safety instructions and operating

procedures in this manual.

Review of the maintenance methods for this tool.

1. READ THE WARNING LABELS ON THE TOOL.

2. AVOID UNINTENTIONAL STARTING.

Be sure the switch is in the OFF position before plugging in.

3. ALWAYS CHECK AND MAKE SURE TO REMOVE ANY ADJUSTING

KEYS OR WRENCHES

before turning the tool on. Left attached, these parts can y off a

rotating part and result in personal injury.

4. DO NOT OPERATE THIS MACHINE UNTIL IT IS COMPLETELY

ASSEMBLED

and installed according to the instructions. A machine incorrectly

assembled can cause serious injury.

NOTE: If any parts are damaged or missing, do not attempt to plug in

the power cord and turn the switch on until the damaged or missing parts

are obtained and are installed correctly.

5. NEVER CLIMB OR STAND ON THE TOOL.

Serious injury could occur if the tool tips. Do not store anything above

or near the tool where anyone might stand on the tool to reach them.

6. NEVER TURN THE MACHINE ON BEFORE

clearing the table/work area of all objects (tools, scraps of wood, etc.).

Flying debris is dangerous.

7. USE EXTRA SUPPORTS

6

ENGLISH

141110

(tables, saw horses, blocks, etc.) for any workpiece large enough to tip

when not held down to the work table.

8. DO NOT LEAVE THE WORK AREA UNTIL ALL MOVING PARTS

HAVE STOPPED.

Shut off the power to master switches. Childproof the workshop!

9. BEFORE STARTING,

be certain the motor, table, attachments and adjustment knobs are

secured.

10. NEVER TURN THE MACHINE ON

with the workpiece contacting the cutting surface. Workpiece may be

thrown and cause injury or damage.

11. PREVENT THE WORKPIECE

from contacting the blade before starting the tool. Loss of control of the

workpiece is dangerous.

12. DISCONNNECT THE PLUG FROM POWER BEFORE MAKING ANY

ADJUSTMENTS.

Changing attachments, making bit changes, adjustments or repairs or

accessories can be dangerous if the tool could accidentally start. Turn

off and unplug the drill press before moving it.

13. TURN THE MACHINE OFF,

disconnect the machine from the power source, when not in operation

and before leaving the machine. Clean the table/work area before

leaving the machine.

14. DO NOT LEAVE THE WORK AREA UNTIL ALL MOVING PARTS

HAVE STOPPED.

Shut off the power to master switches. Childproof the workshop!

15. TO FREE ANY JAMMED MATERIAL, TURN THE SWITCH OFF.

Unplug the tool. Wait for all moving parts to stop before removing the

jammed material.

16. SUPPORT THE WORKPIECE FIRMLY WITH A CLAMP,

vise, or work table when cutting. Hold the workpiece rmly. Loss of

control of the workpiece can result in injury.

17. PROPERLY SUPPORT LONG OR WIDE WORKPIECES.

If a workpiece overhangs the table so that it could fall or tip if not held,

clamp it to the table or provide auxiliary support(s). Loss of control of

the workpiece is dangerous.

18. SUPPORT ROUND WORK PROPERLY

Use V blocks to prevent it from rolling.

19. USE THE RECOMMENDED CUTTING SPEED

for the specic operation and workpiece material — check the label for

information

20. KEEP PULLEY COVER CLOSED

when not making belt adjustments.

21. USE ONLY ACCESSORIES DESIGNED FOR THIS TOOL

to avoid serious injury from thrown, broken parts or work pieces.

22. AVOID AWKWARD OPERATIONS AND HAND POSITIONS.

A sudden slip could cause a hand to move into the blade.

23. NEVER PERFORM LAYOUT, ASSEMBLY, OR SET-UP WORK ON

THE TABLE

/work area when the machine is running. A sudden slip could cause a

hand or hair to move into the blade Severe injury can result.

24. DO NOT GET DISTRACTED AND ALWAYS CONCENTRATE ON

WHAT YOU ARE DOING.

Use common sense. Never operate the machine when you are tired,

sick, or under the inuence of alcohol, or other drugs.

25. LOCK THE SWITCH IN THE “OFF” POSITION TO PREVENT

UNAUTHORIZED USE.

Someone else might accidentally start the machine and cause injury to

themselves.

26. FAILURE TO FOLLOW OPERATING INSTRUCTIONS AND SAFETY

PRECAUTIONS IN THIS INSTRUCTION MANUAL CAN RESULT IN

SERIOUS INJURY.

Read the manual before starting or operating this unit.

7

ENGLISH

27. KEEP THESE INSTRUCTIONS.

Refer to them frequently and use them to instruct other users. If you

loan someone this unit, also loan them the instructions.

HEALTH NOTICE: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contain chemicals

known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

─Lead from lead-based paints

─Crystalline silica from bricks and cement and other masonry products

─Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals, work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to lter out microscopic

particles.

ELECTRICAL

WARNINGS AND CAUTIONS

1. BEFORE CONNECTING THE MACHINE to the power source, verify

that the voltage of your power supply corresponds with the voltage

specied on the motor I.D. nameplate. A power source with greater

voltage than needed can result in serious injury to the user as well

as damage to the machine. If in doubt, contact a qualied electrician

before connecting to the power source.

2. MAKE SURE YOUR FINGERS

do not contact the terminals of the power cord plug when plugging in or

unplugging the saw.

3. GROUNDED TOOLS MUST BE PLUGGED INTO AN OUTLET THAT

ITSELF IS PROPERLY INSTALLED AND GROUNDED.

Grounding provides a low-resistance path to carry electricity to ground

away from the operator, should the tool malfunction electrically.

4. DO NOT ABUSE THE CORD.

Never carry your tool by the cord or pull on the cord to unplug it.

Protect the cord from potential sources of damage: heat, oil & solvents,

sharp edges, or moving parts. Replace damaged cords immediately.

5. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED

EXTENSION CORD.

An extension cord rated for outdoor use must be marked “W-A” or “W”.

6. THIS TOOL IS FOR INDOOR USE ONLY.

Do not expose electrical power tools to moisture. Rain or wet

conditions can cause water to enter the tool and lead to electric shock.

7. FOLLOW ALL LOCALLY APPLICABLE WIRING CODES

and recommended electrical connections to prevent shock or

electrocution.

POWER

POWER REQUIREMENTS

This tool is designed to operate on a properly grounded 120 volt, 60 Hz,

single phase, alternating current (AC) power source, fused with a 15 amp

time delayed circuit breaker. It is recommended that a qualied electrician

verify the ACTUAL VOLTAGE at the receptacle into which the tool will be

plugged and conrm that the receptacle is properly grounded. The use of

the proper circuit size can eliminate nuisance circuit breaker tripping when

using your tool.

CAUTION: do not operate this tool if the actual power source voltage is

less than 105 volts ac, or greater than 132 volts ac. Contact a qualied

electrician if this problem exists. Improper performance, and/or, damage

to the tool will result if operated on inadequate, or excessive power.

8

ENGLISH

141110

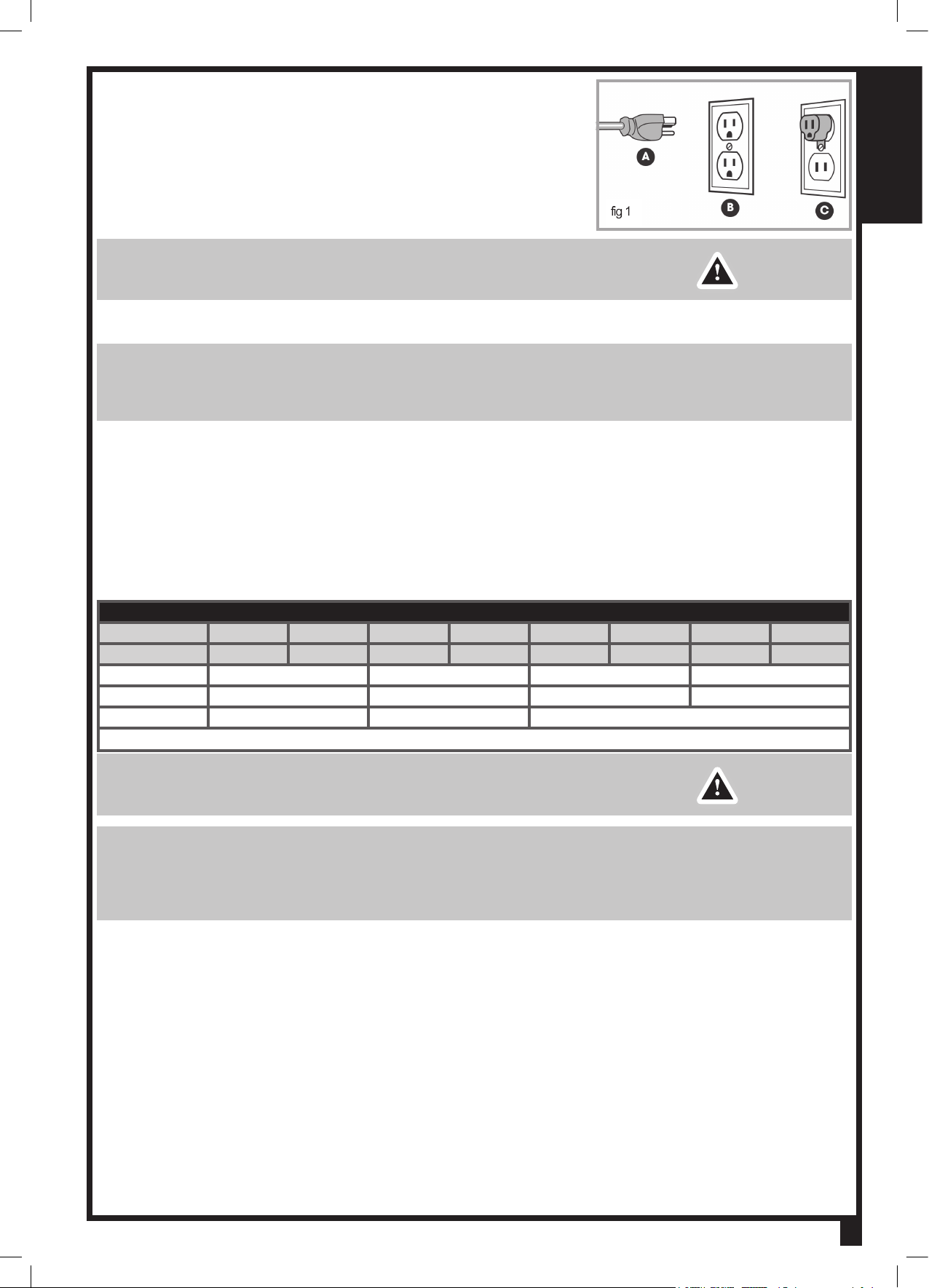

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit, grounding reduces

the risk of electric shock. The motor of this machine is wired for 120 V

single phase operation and is equipped with a 3-conductor cord and a

3-prong grounding plug to t a grounded type receptacle (B, g 1). Do not

remove the 3rd prong (grounding pin) to make it t into an obsolete 2-hole

wall socket or extension cord.

WARNING! BANDSAW MUST BE GROUNDED. Use a Ground Fault

Interrupter (GFI). Plug the power cord to a standard 120 volt receptacle

protected by a 20 amp circuit breaker.

If an adaptor plug is used (C, g 1), it must be attached to the metal screw

of the receptacle.

NOTE: The use of an adaptor plug is illegal in some areas, including

Canada. Check your local codes. If you have any doubts or if the

supplied plug does not correspond to your electrical outlet, consult a

qualied electrician before proceeding.

EXTENSION CORDS

If you nd it necessary to use an extension cord with your machine, use

only 3-wire extension cords that have 3-prong grounding plug and a

matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a

damaged extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage listed on the motor

I.D. plate. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The accompanying chart shows the correct

size extension cord to be used based on cord length and motor I.D. plate

amp rating.

Total Extension Cord Length

Amp Rating Feet Meters Feet Meters Feet Meters Feet Meters

25 8 50 15 100 30 125 40

3-10 amp 18 ga. 16 ga. 14 ga. 14 ga.

10.1 - 12 amp 16 ga. 16 ga. 14 ga. 14 ga.

12.1 - 16 amp 14 ga. 12 ga. Not Recommended

Use only UL or CSA approved extension cords

WARNING! Do not allow familiarity with your tool to make your

careless. Remember that a careless fraction of a second is sufcient to

inict severe injury.

IMPORTANT: The warnings, cautions and instructions detailed in this

manual cannot cover all possible conditions and situations that occur. It

must be understood by the operator that common sense and caution are

factors that cannot be built into this product, but must be supplied by the

operator.

9

ENGLISH

FUNCTIONAL DESCRIPTION

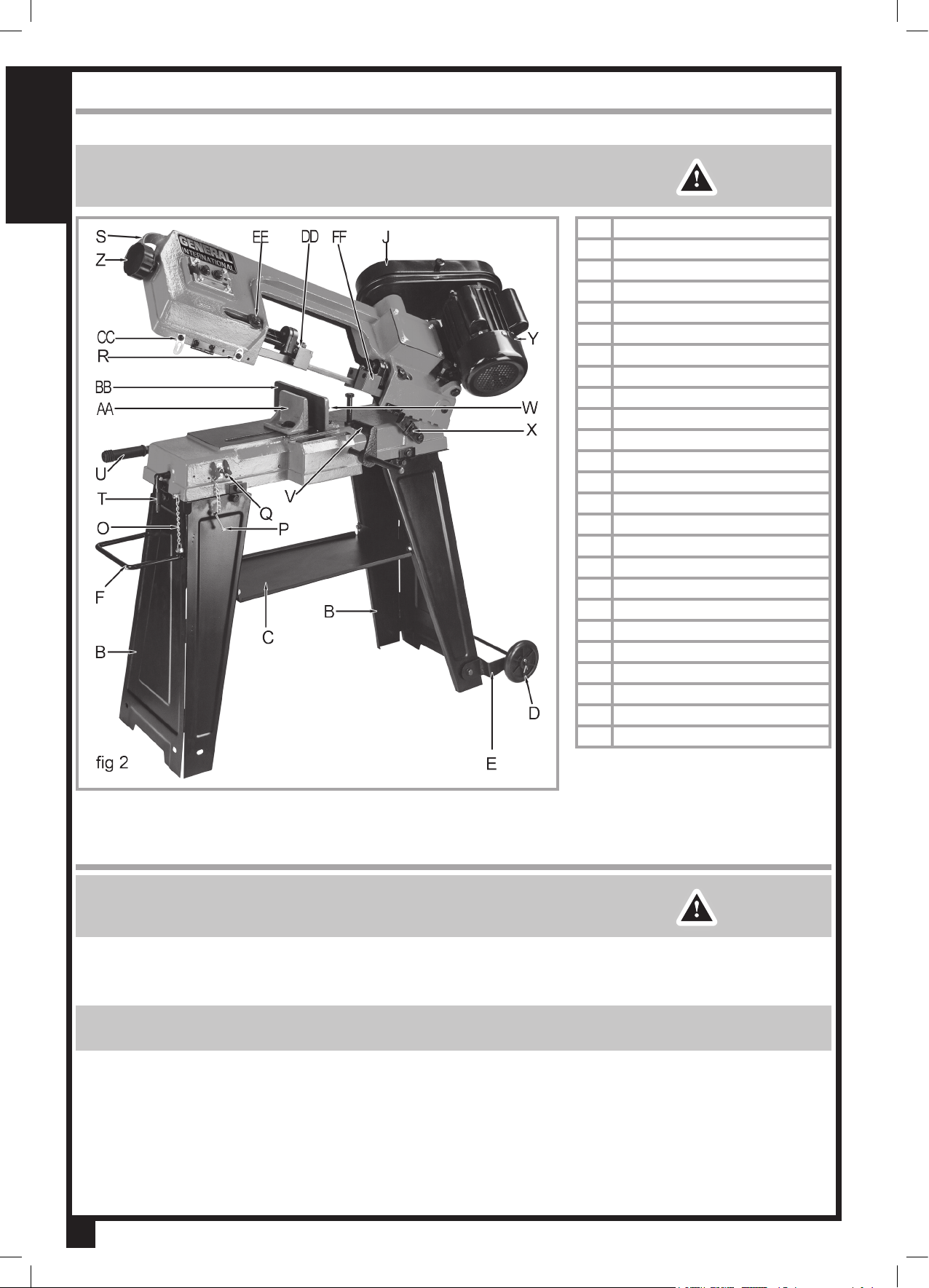

GETTING TO KNOW YOUR BAND SAW

WARNING! To avoid injury from accidental start, turn the switch off

and remove the plug from the power source outlet before making any

adjustments

B Leg assembly

C Tool tray

D Wheels

E Wheel frame

F Transport handle

J Pulley cover

K Work stop rod

O Lock chain

P Switch lock screw

Q Switch

R Switch tab

S Saw handle

T Vise handle

U Adjusting rod

V Work stop

W Miter lock handle

X Head support plate

Y Motor

Z Blade tension adjustment knob

AA Sliding vise plate

BB Mitering vise plate

CC Lock tab

DD Upper blade cover

EE Blade guard adjustment

FF Lower blade guard

UNPACKING

WARNING! Do not attempt to assemble the band saw, plug in the

power cord or turn on the switch if any parts are damaged or missing.

Failure to heed this warning could result in serious personal injury.

CONTENTS

Separate all parts from the packing materials and check carefully against

g 2 and the list below.

NOTE: Make certain all parts are accounted for before discarding any

packing material.

1. This tool comes partly assembled. It will be necessary to complete the

assembly.

2. Unpack and layout all the items and identify each one. Some items

listed below may be packed already assembled to each other.

10

ENGLISH

141110

A Band saw head assembly 1

B Leg assembly 2

C Tool tray 1

D Wheels 2

E Wheel frame 1

F Transport handle 1

G Worm gear pulley 1

H Motor shaft pulley 1

I V-belt 1

J Pulley cover 1

K Work stop rod 1

L Vertical cutting plate 1

M Vertical cutting support 1

N Accessory pack 1

ASSEMBLY PROCEDURE

WARNING! For your own safety, never connect the plug to the power

source outlet or insert the switch insert key until all the assembly steps

are complete and you have read and understood the entire owner's

manual.

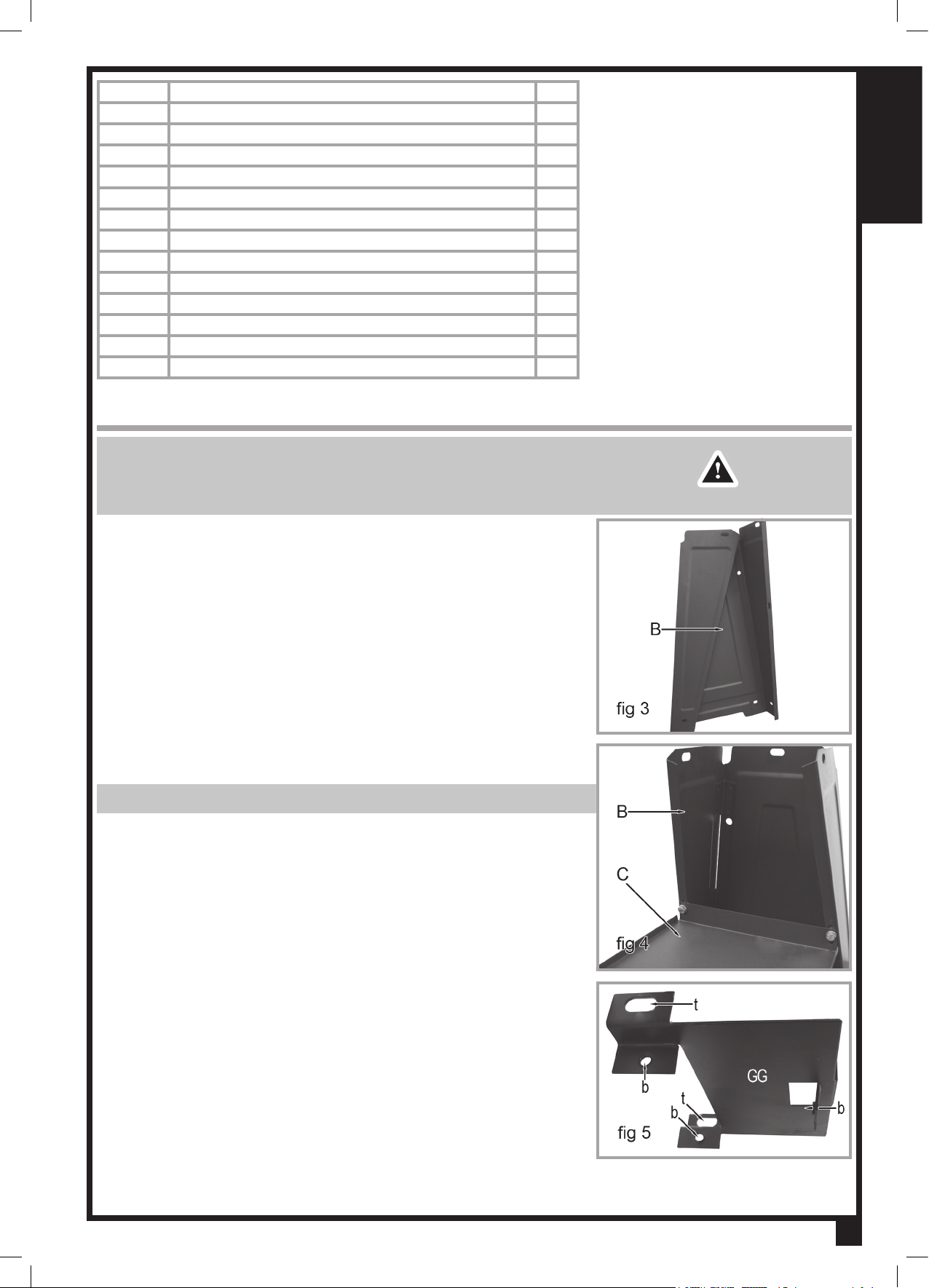

STAND

Attach the lower tray, wheels and transport handle in this order:

1. Locate the two 2 leg assemblies (B, g 2 & 3).

2. Locate the tool tray (C, g 2).

3. On both leg assemblies, open the hinged ap 90 degrees. (g 3)

4. Place the two 2 leg assemblies about 18" (45 cm) apart.

5. Place the tool tray with the edges pointing up, between the 2 leg

assembies.

6. At each end, align the holes of the tool tray with the holes in the edge of

the leg assembly.

NOTE: the legs should t equally well either way around.

7. Locate 8 M6 washers, 4 M6 hexagon nuts and 4 M6 x 10 hexagon head

bolts.

8. Place a washer onto each M6 x 10 hexagon head bolt.

9. Fully insert 1 hex head bolt with washer rst, through each of the 4

holes of the tool tray, then the holes of the leg assembly.

10. Slide a washer onto the threaded ends of each hex head bolt.

11. Place a hex nut onto each bolt.

12. Be sure the stand is symetrical and stable.

13. Fully tighten the 4 hexagon nuts and bolts.

BAND SAW CONNECTING PLATES

1. Locate the two connecting plates (GG, g 5) and place one connecting

plate on top of each leg assembly with the tabs inside.

2. Align the 3 bottom holes (b, g 5) of each connecting plate with the 3

holes at the tops of each leg assembly.

11

ENGLISH

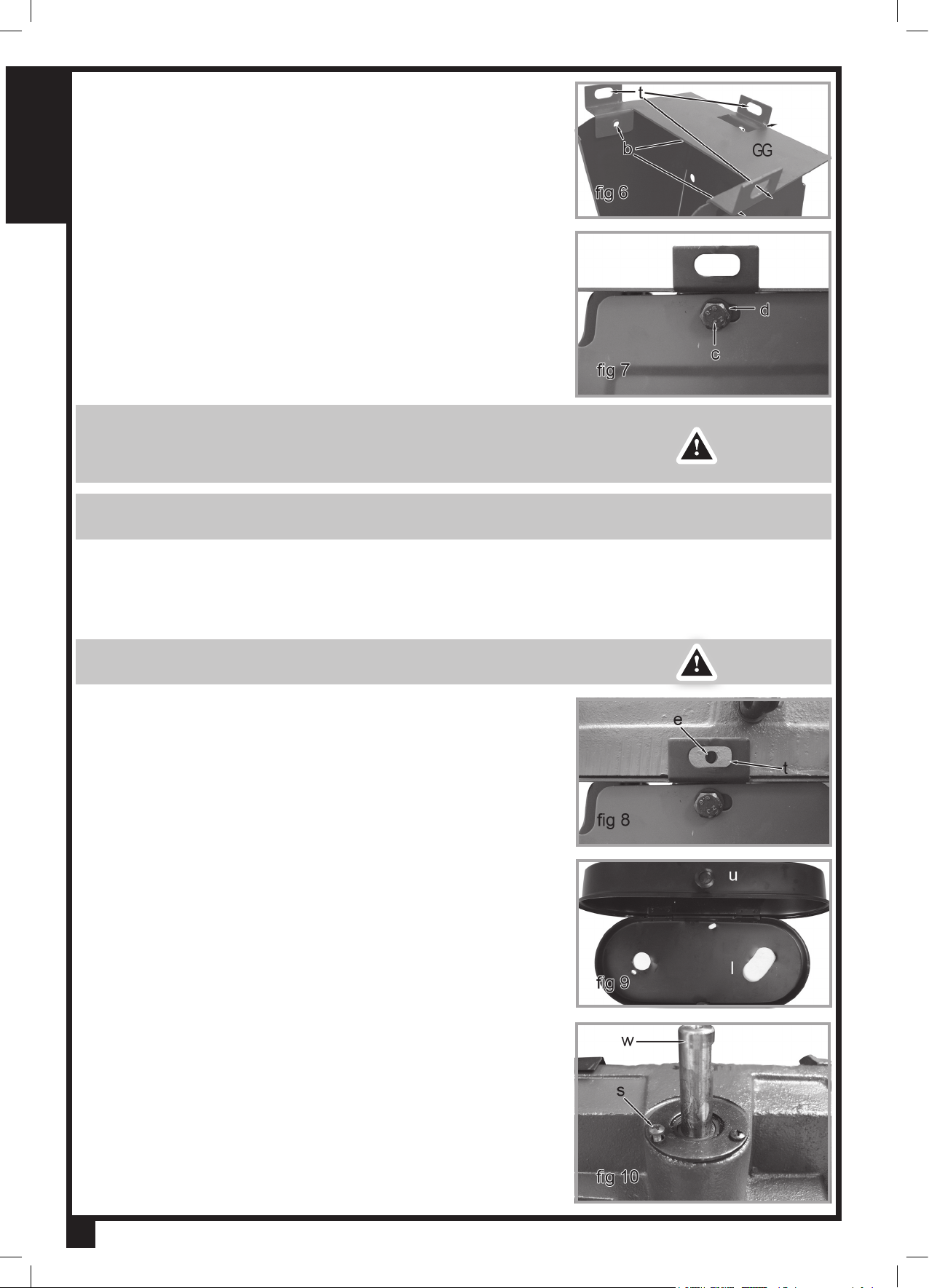

3. Place the 3 bottom tabs of the connecting plates inside the leg

assemblies (b, g 6).

4. Locate 6 M8 washers (d, g 7), and 6 M8 x 16 hexagon head bolts (c,

g 7).

5. Place a washer onto each hexagon head bolt.

6. Hand thread each hex head bolt, rst through the leg assembly, then

into the one of the two connecting plates (g 7).

7. Do not fully tighten any of the 6 hexagon head bolts at this time; this will

be done later.

BAND SAW HEAD MOUNTING

WARNING! This item is very heavy. We strongly suggest that two

people be used to unpack and assemble this band saw. Using proper

lifting methods and the help of another person, lift the band saw head

assembly and place it between the brackets of both connecting plates.

NOTE: The band saw head may be placed with the motor facing either

direction on the stand assembly.

1. Locate the 3 holes at either end of the base of the band saw head

assembly.

2. With the help of another person, adjust the band saw head assemblyso

as to align the 3 holes of the band saw head with the 3 brackets and

holes (t, g 5 & 6) of each connecting plate.

CAUTION: The head assembly is heavy (about 55 lb. / 25 kg) and you

will require assistance from a second person.

3. Locate 6 M8 x 25 hexagon head bolts and 6 M8 washers.

4. Place one washer on each hexagon head bolt.

5. Thread one hexagon head bolt through each hole of the connecting

plate bracket (t, g 8), then into the base of the band saw head head

assembly (e, g 8).

PULLEY SYSTEM ASSEMBLY

1. Locate the complete pulley cover. The complete pulley cover consists of

the pre-assembled lower pulley cover (l, g 9) and the upper pulley

cover (u, g 9).

2. Locate the worm gear shaft (w, g 10) on the band saw head assembly.

3. Locate the M4 x 8 screw (s, g 10), which is already in place near the

worm gear shaft .

4. Un-thread and remove the M4 x 8 screw.

12

ENGLISH

141110

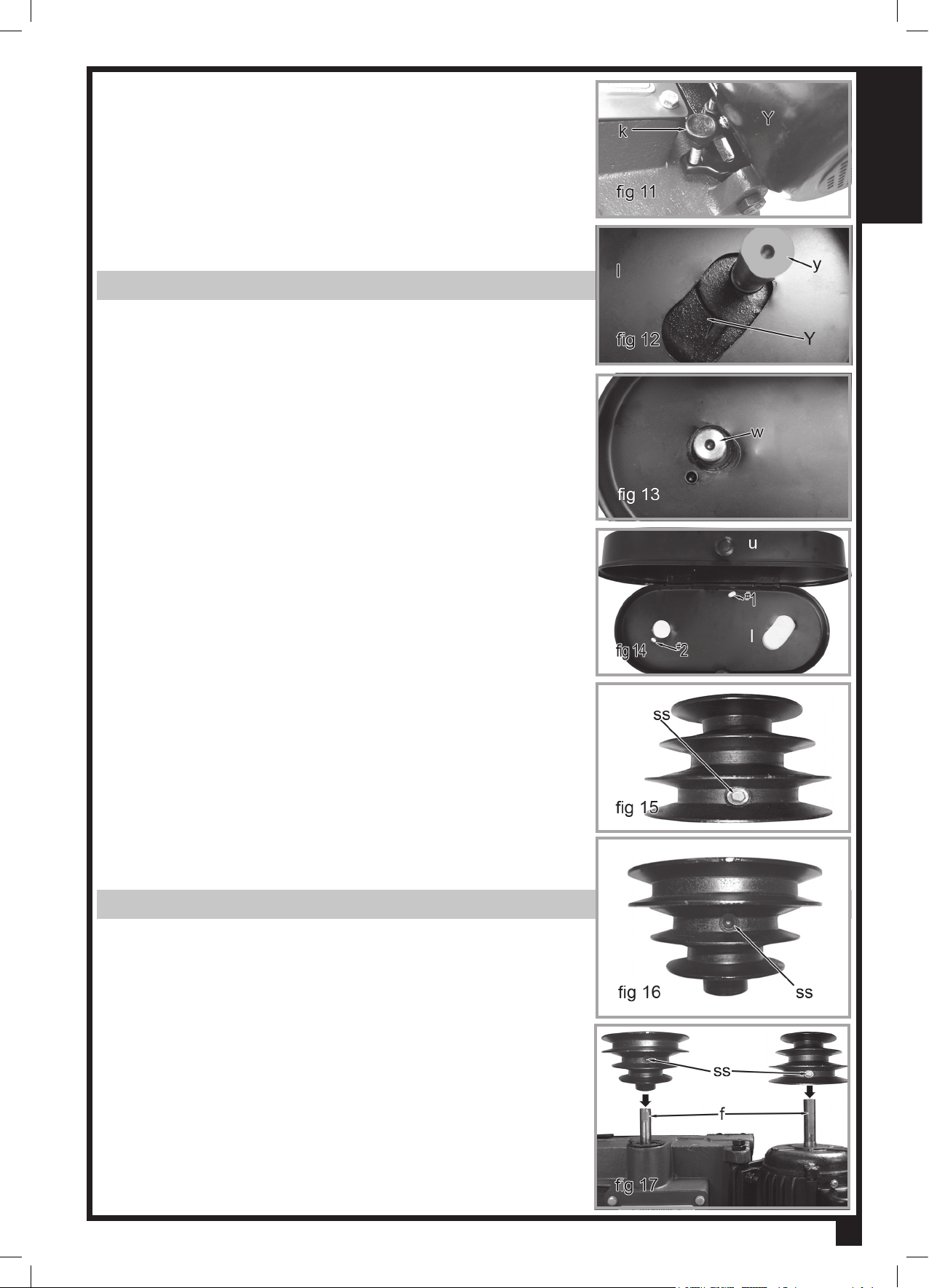

5. Locate the motor adjusting knob (k, g 11).

6. Loosen, but do not fully unscrew, the motor adjusting knob by rotating it

counter-clockwise.

7. Slide the kidney shaped hole of the lower pulley cover (l, g 12) over the

shaft (y, g 12) of the motor (Y, g 12).

NOTE: The motor rests on a hinge.

8. Raise the motor to allow for the needed slack to place the pulley cover

onto the worm gear shaft.

9. Slide the round hole of lower pulley cover onto the worm gear shaft (g

13).

1. Inside the pulley cover are 2 holes. These holes are used to mount the

pulley cover (g 14)

2. Align hole #1 with the pre-drilled hole on the band saw.

3. Locate and slide an M6 rubber washer under both holes, 1 and 2, of the

pulley cover.

4. Locate 1 M6 x 12 cross head screw.

5. Screw the cross head (Phillips) screw through hole #1 and the rubber

washer, fully securing the pulley cover in place.

6. Re-insert the M4 x 8 screw in hole #2 and through the rubber washer.

This screw was removed in step 4 of this section.

7. Locate the motor pulley and worm gear pulley.

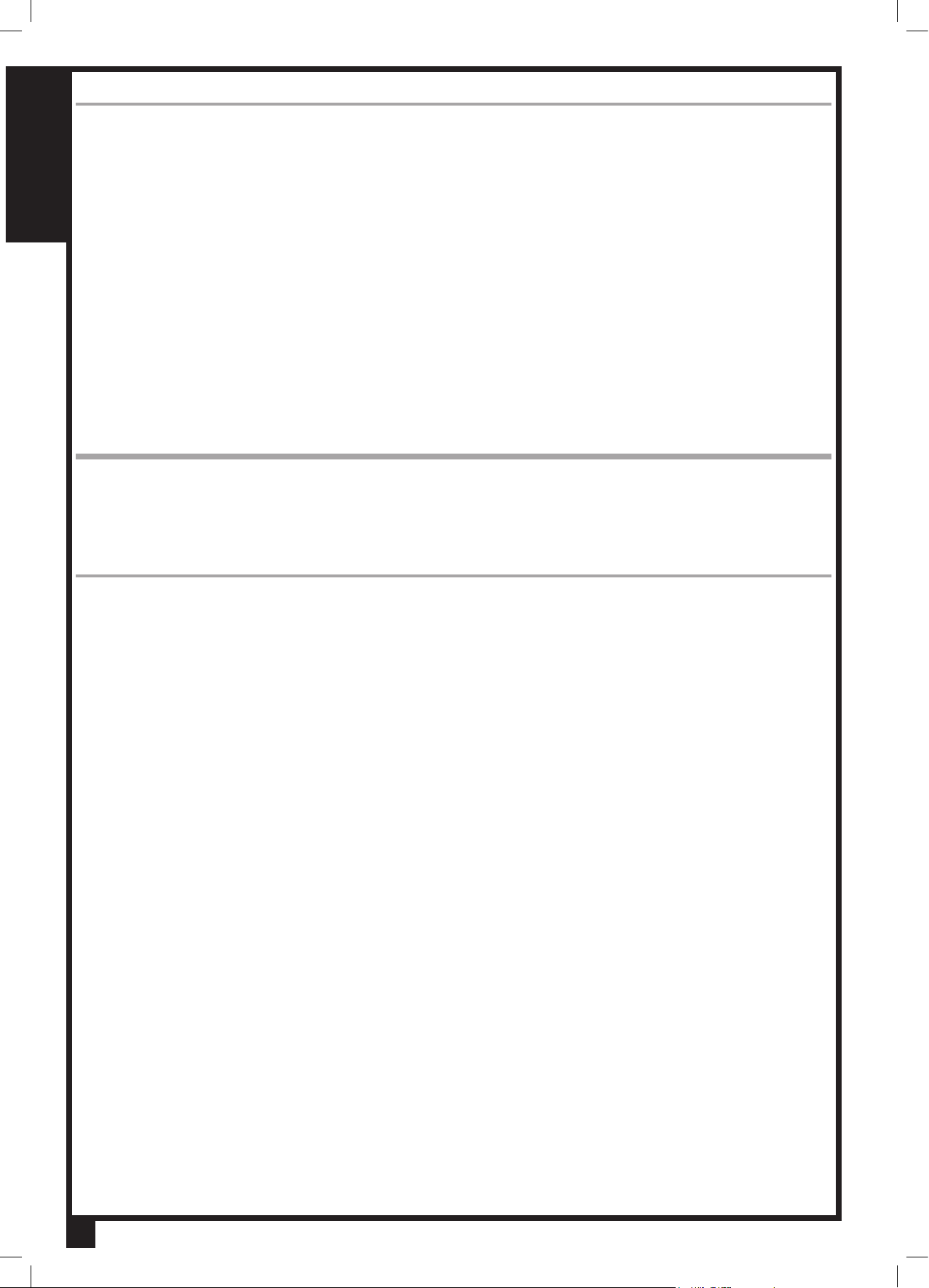

8. Locate the 2 M8 x 12 set screws; 1 in the motor pulley (ss, g 15) and 1

in the worm gear pulley (ss, g 16).

9. Place the motor pulley onto the motor shaft and align the set screw (ss,

g 17) of the motor pulley with the atted surface of the motor shaft (f,

g 17).

10. Place the worm gear pulley onto the worm gear shaft and align the set

screw of the worm gear pulley (ss, g 17) with the atted surface of the

worm gear shaft (f, g 17).

NOTE: In g 17, the pulley cover has been removed for clarity.

11. Raise and lower each pulley until they are visually ush with each other.

12. Fully tighten both of the set screws with the provided hex wrench.

13

ENGLISH

13. Locate the V-Belt.

14. Lift the hinged motor and place the V-belt around the top grooves of

both the motor pulley and the worm gear pulley.

15. Lower the hinged motor.

16. The band saw is now set at a speed of 80 f.p.m. (24 m/min).

17. Fully tighten the motor adjusting knob (k, g 11) by rotating it clockwise.

NOTE: By tightening the adjusting knob, the v-belt is fully tightened on

the pulleys.

18. Tension is correct when the belt deects by about 1/2 an inch (13 mm)

at their center of run when using reasonable thumb pressure.

19. Close band saw upper pulley cover.

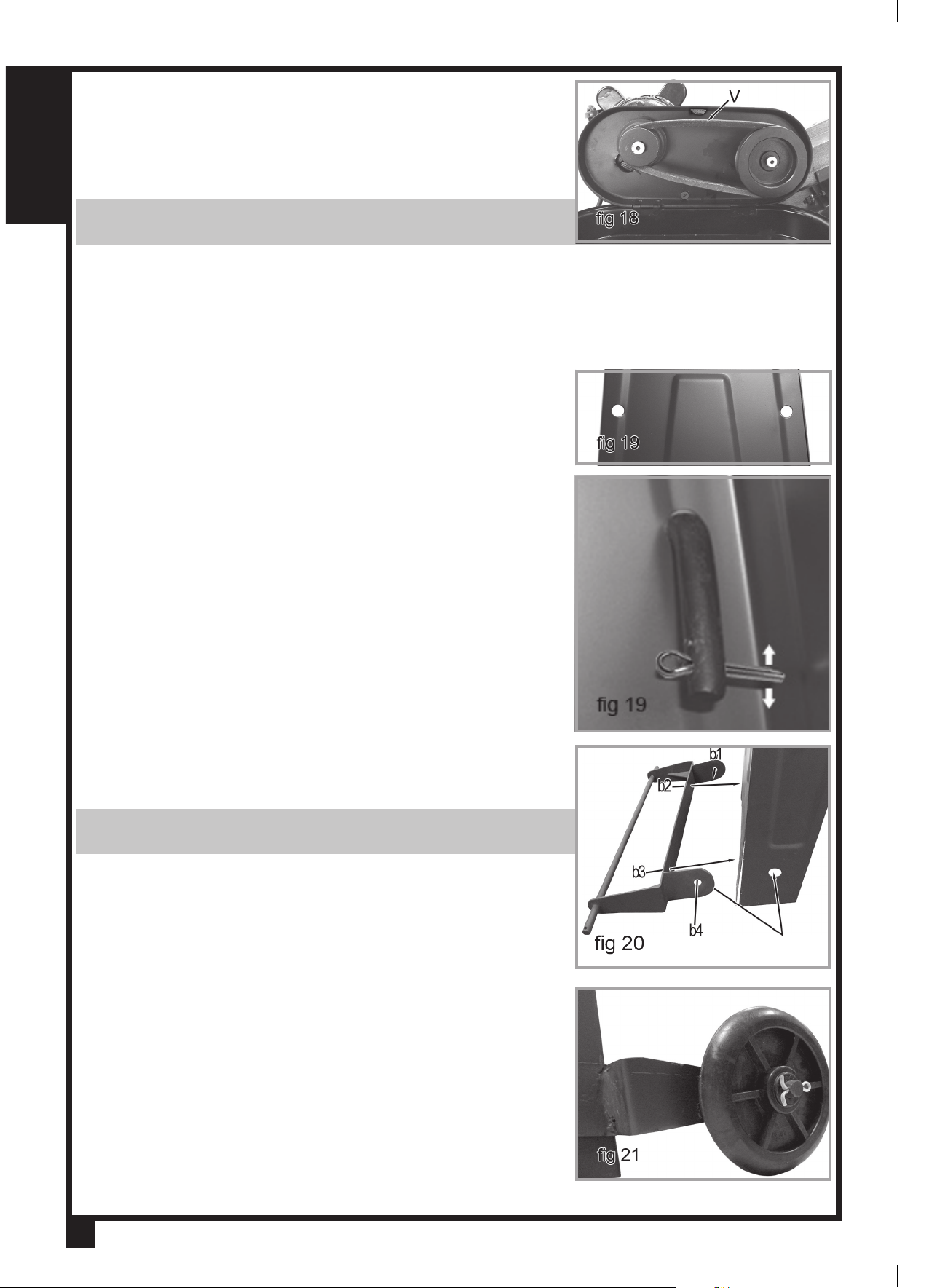

TRANSPORT HANDLE

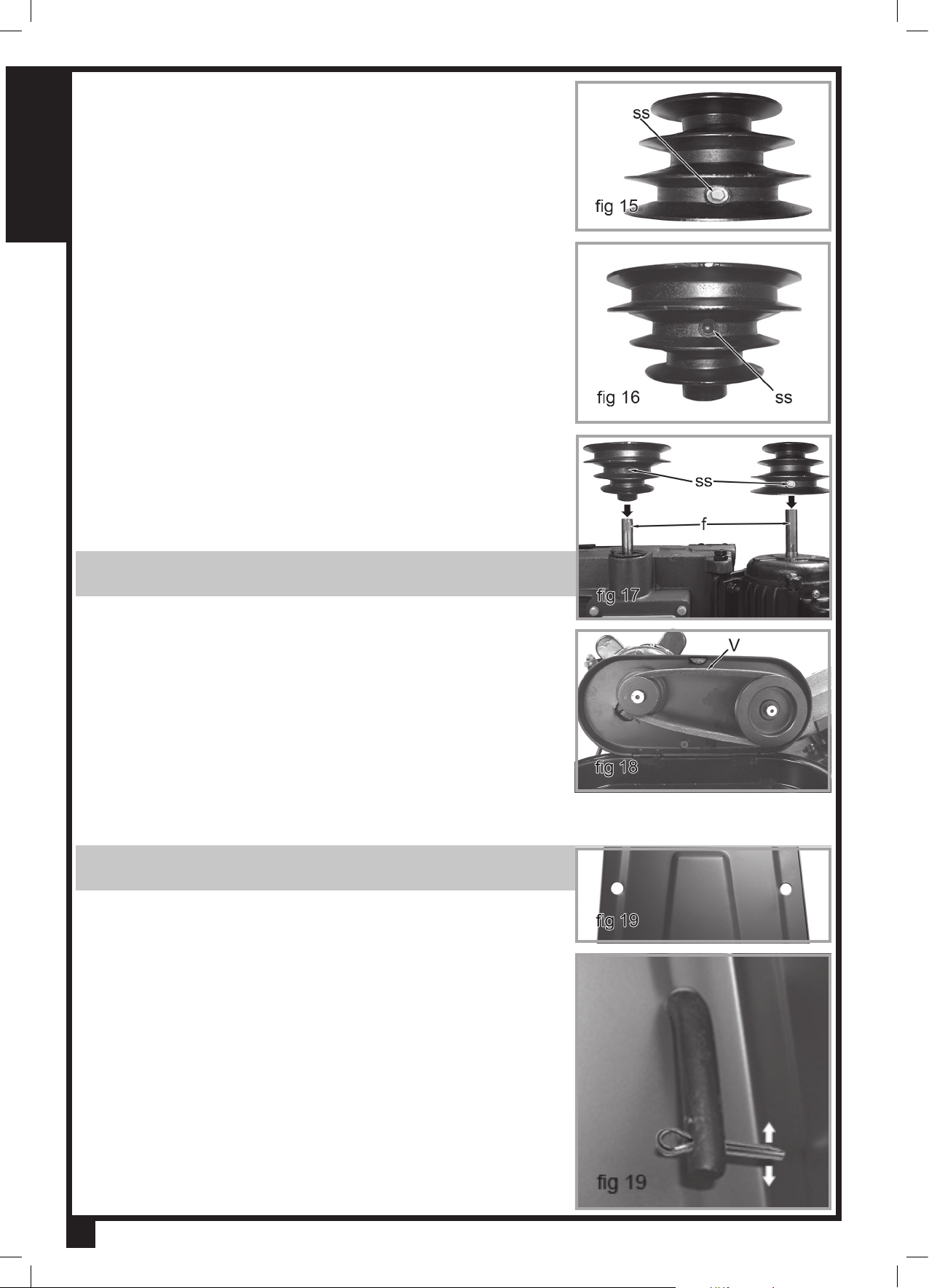

1. Locate the transport handle.

2. Place the ends of the transport handle through the 2 holes of the leg

assembly at the opposite side of the motor (g 18).

3. Locate two 3 x 18 cotter pins.

4. Place a cotter pin through the hole at each end of the oor stand handle;

now located inside the oor stand.

5. Using pliers, wrap 1 leg of each cotter pin around the transport handle

(g 19 shows one side of the handle inside the leg assembly).

6. Wrap the other leg of each cotter pin, in the opposite direction, around

the transport handle.

WHEELS

1. Locate the wheel frame (E, g 2).

2. Place the wheel frame against the bottom of the oor stand.

NOTE: Install the wheel frame on the same end of the band saw as the

motor.

3. Align the holes of the wheel frame with the holes of the oor stand.

When aligning the holes, make sure the wheel frame is level with the

ground.

4. Locate 8 M8 washers, 4 M8 hexagon nuts and 4 M8 x 16 hexagon head

bolts.

5. Place a washer onto each hexagon head bolt.

6. Insert one hexagon head bolt with washer, rst through each hole of the

wheel frame, then into the oor stand, for a total of 4 bolts.

7. Place a washer onto the threaded ends of each inserted bolt.

8. Fully thread and tighten a hexagon nut onto the threaded ends of each

inserted bolt.

9. Locate 2 wheels and two 3 x 18 cotter pins.

10. Slide 1 wheel onto each side of the wheel frame axle.

11. Insert 1 cotter pin into each hole of the wheel frame axle.

12. Using pliers, wrap the 1 leg of the cotter pin around the axle (g 21).

13. Wrap the other leg of the cotter pin, in the opposite direction, around

the axle.

14

ENGLISH

141110

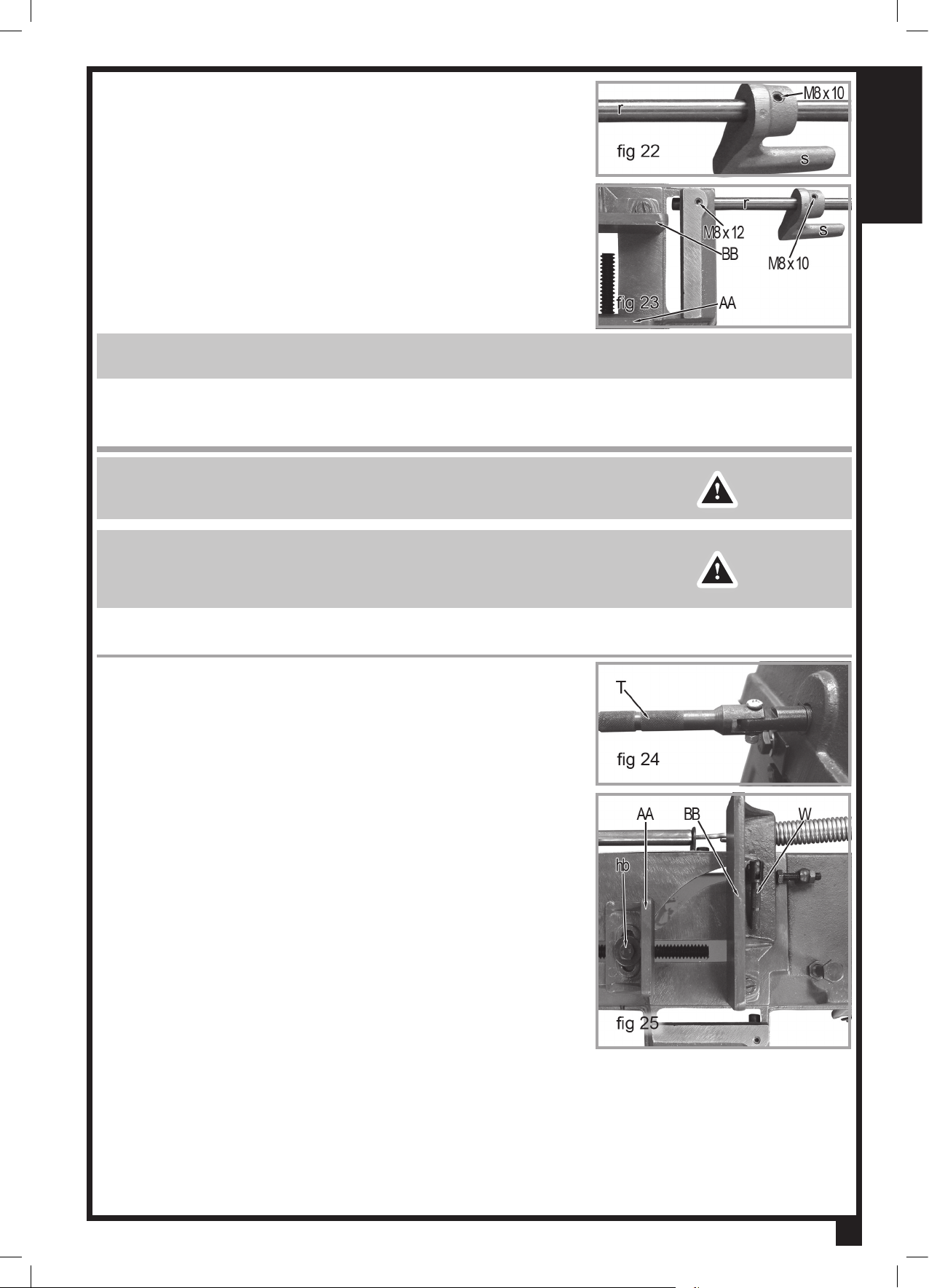

WORK STOP

A work stop can be used to cut multiple work pieces to equal length without

having to re-measure each piece individually.

1. Locate the work stop. This includes the work stop rod (r), the work stop

(s) and the M8 x 10 hexagon socket set screw (see g 22).

2. Locate M8 x 12 set screw, already installed in the band saw base.

3. Push the work stop rod into the hole located below this M8 x 12 set

screw. (See a view looking down at the vise assembly, g 23)

4. Tighten the M8 x 12 set screw (clockwise) to secure the work stop rod in

place.

5. Using the provided hex wrench, loosen, do not remove, the hexagon

socket set screw located in the work stop itself.

6. Swing up and slide the work stop to the desired length to be cut by

measuring the distance from the work stop to the blade.

NOTE: always perform a test cut on a piece of scrap material after

making adjustments to the tool.

7. Using the provided hex wrench, tighten the hexagon socket set screw.

OPERATING INSTRUCTIONS

WARNING! Before using this machine, the operator should carefully

read over this operation manual and acquaint himself with the

construction, controls and drive system of the band saw.

WARNING! Always disconnect the tool from power source before

making any adjustments, storing, servicing, or changing accessories.

Such preventative safety measures reduce the risk of starting the tool

accidentally.

CLAMPING A WORK PIECE

This tool comes with a vise for securing your work piece. For larger work

pieces, seek out additional vises or clamps. The vise is designed to be

used for horizontal cuts only.

SECURE AN ITEM FOR CUTTING

1. Raise and lock the band saw head in the vertical position using the head

support plate (X, g 2).

2. Locate the vise handle (T, g 2 & 24).

3. Rotate the vise handle counter-clockwise until there is enough room

for your work piece between the sliding vise plate (AA, g 25) and the

mitering vise plate (BB, g 25).

4. Locate the M10 x 30 hexagon head bolt (hb. g 25).

5. Loosen the M10 x 30 hexagon head bolt by rotating it counterclockwise. This will allow for a tighter clamp later.

6. Place the work piece between both of the vise plates.

7. Rotate the vise handle clockwise until the sliding vise plate clamps the

work piece against the mitering vise plate.

8. Fully tighten the hexagon head bolt.

15

ENGLISH

SETTING CUT ANGLE

CUTTING SPEEDS

WARNING! Always disconnect the tool from power source before

making any adjustments, storing, servicing, or changing accessories.

Such preventative safety measures reduce the risk of starting the tool

accidentally.

The General International 4-1/2 Inch Metal Cutting Band Saw can cut at

any angle up to 45 degrees.

1. Locate the miter scale on the backside of the band saw (m, g 26).

2. Locate the miter lock handle (W, g 26).

3. Rotate the miter lock handle counter-clockwise to loosen the mitering

vise plate (BB, g 26).

4. Swivel the mitering vise plate to the desired angle by aligning the

mitering vise plate with the numbered degree on the miter scale.

5. Fully tighten the lock handle by rotating it clockwise.

6. Rotate the vise handle (T, g 24) counter-clockwise until there is enough

room for your work piece between the sliding vise plate and the mitering

vise plate.

7. Loosen the hexagon head bolt, which locks the sliding vise plate in

place, by rotating it counter-clockwise. This will allow for a tighter clamp

later.

8. Place the work piece between both of the vise plates.

9. Rotate the vise handle clockwise until the sliding vise plate clamps the

work piece against the mitering vise plate.

10. Fully tighten the hexagon head bolt on the sliding vise plate (hb, g 27).

CUTTING

BLADE SPEED─ BELT POSITION

When using your band saw, always change the blade speed to best suit

the material being cut.

1. Decide what speed is best based on the material being cut.

MATERIALS BEING CUT SPEED

Stainless steel

Alloy steel

Bearing bronzes

Mild steel

Hard brass

Bronze

Soft brass

Aluminum

Other light materials

2. Fully loosen the motor adjusting knob by rotating it counter-clockwise.

3. Open the pulley cover.

4. Lift the hinged motor, releasing tension on the v-belt.

5. Move the v-belt up or down along the grooves of the pulleys to the

desired speed.

80 ft./min.

24 m/min

120 ft./min.

37 m/min

180 ft./min.

55 m/min

80 FPM (24 m/min)

120 FPM (37 m/min)

180 FPM (55 m/min)

Worm gear pulley Motor pulley

6. Lower the hinged motor.

7. Fully tighten the motor adjusting knob to increase belt tension.

8. Close the pulley cover.

16

ENGLISH

141110

FEED RATE─ ADJUSTING ROD

The adjusting rod is used to control the pressure and speed of the band

saw head as it lowers and cuts through the work piece.

1. Locate the adjusting rod (U, g 2 & 28). The adjusting rod tightens or

loosens a counter-balancing spring governing the weight that the head

exerts on the blade..

2. Turning the adjusting rod clockwise will increase the spring tension and

cause the band saw to cut more slowly into the work piece, effectively

reducing the feed rate.

3. Turning the adjusting rod counter-clockwise increases the effect of

gravity and allows the band saw head to cut more quickly into the work

piece.

NOTE: Adjusting rod tech tip: before cutting, make sure the adjusting

rod is fully tightened. Perform a test cut on a scrap piece that is the same

metal and thickness as your work piece. Loosen the adjusting rod as

needed to allow for a cleaner and more controlled cut. This will improve

the quality of cut and prolong the life of your blade.

HORIZONTAL CUTTING

WARNING! When cutting metal, the area of the cut may be sharp and

can cause damage to property and self. Be extremely careful when

handling.

This saw uses a single blade, running on 2 wheels.

1. Unhook the lock chain (O, g 2) from the lock tab, releasing the saw

head for use.

2. Once you have set your band saw to an appropriate speed for the

material and secured your work piece in the vise, locate the switch (Q,

g 29), the switch safety lock screw (P, g 29) and remove the lock

screw by unscrewing the safety nut (n, g 29).

3. Using the band saw handle (S, g 2), raise the band saw to the vertical

position.

NOTE: make sure the head support plate (X, g 2) is in the down

position.

4. Keeping one hand on the band saw handle, ip the switch up to the on

position.

5. Allow the band saw to reach full speed before starting any cuts.

6. Using the band saw handle, lower the band saw to the horizontal

position; thus cutting into the work piece (g 30).

7. Once the band saw begins cutting into the work piece, let go of the

band saw handle. Do not apply any pressure to the band saw. Allow the

pressure set by the adjusting rod to continue cutting through the work

piece.

8. The switch tab (R, g 31) will turn off the tool after the cut has been

made by physically placing the switch in the off position.

9. After making a cut, allow the blade to come to a complete stop before

making any adjustments.

10. Replace the switch safety screw and safety nut.

VERTICAL CUTTING─ SETUP

One of the features of this saw is the ability to be used as a vertical band

saw. To change to the vertical cutting position:

1. Unhook the lock chain (O, g 2) from the lock tab, releasing the saw

head for use.

2. Using the band saw handle (S, g 2), gently raise the band saw head 90

degrees into the upright position. Do not release the band saw handle

until the band saw head is in the full upright position.

3. Locate the head support plate (X, g 2) at the base of the band saw

head assembly near the motor. Rotate the support plate clockwise to

help prevent the band saw head from falling (X, g 32).

17

ENGLISH

4. Locate the blade back safety cover (bc, g 33).

5. Locate the plum screw (p, g 33) on the blade back safety cover.

6. Fully remove plum screw by rotating it counter-clockwise.

7. Open the blade back safety cover.

8. Locate the lower blade guard (FF, g 2, 33 & 34).

9. Locate the two M6 x 12 cross head screws (cs, g 34) on the blade

guard.

NOTE: These screws are already in place on this tool.

10. Unscrew and remove the 2 cross head screws from blade guard.

11. Remove the blade guard by sliding it up and away from the bearings it

covers.

12. Close the blade back cover and replace the plum screw.

13. Locate the vertical cutting plate (HH, g 35).

14. Locate the vertical cutting plate support (ps, g 36), an M6 x 12 cross

head screw, an M6 hexagon nut and an M6 washer.

15. Insert the cross head screw down through hole #1, g 35 of the vertical

cutting plate.

16. Place the support plate onto the threaded end of the cross head screw

as it protrudes below the cutting plate.

17. Place a washer onto the threaded end of the cross head screw.

18. Hand-tighten a hexagon nut onto the cross head screw (g 37).

19. Slide the cutting plate around the blade along the blade slot.

20. Locate the M10 x 35 bolt on the band saw head.

21. Loosen, do not fully remove, the M10x35 bolt.

22. Slide the forked end of the support plate around the threads of the bolt,

behind the washer. (g 38)

23. Fully tighten the bolt.

24. Thread and fully tighten 2 M6 x 12 cross head screws through the

cutting plate (holes #2 & #3, g 35) into the lower blade guard /bearing

mount.

NOTE: These screws (cs, g 34) were removed in step 10.

25. Fully tighten the hexagon nut installed in step 18, above.

18

ENGLISH

141110

WARNING! When cutting metal, the area of the cut may be sharp and

can cause damage to property and self. Be extremely careful when

handling.

CUTTING IN VERTICAL ORIENTATION

1. Identify and mark the cutting path on the work piece.

2. Remove the switch lock screw by unscrewing the safety nut.

3. Pull out the switch safety screw.

4. Flip the switch up to the ON position.

5. Place the work piece on the vertical cutting plate.

6. Allow the band saw to reach full speed before making any cuts.

WARNING! Keep hands clear of blade at all times.

7. With one hand on each side of work piece, slowly guide the work piece

into the blade (g 39).

NOTE: Do not apply excessive pressure. Forcing the blade through

your work piece puts unnecessary strain on the motor. Too much

force will likely produce unwanted cut quality and will wear the blade

prematurely.

8. After the cut has been made, turn off the band saw.

9. Replace the switch safety screw and safety nut.

MAINTENANCE

WARNING! Always disconnect the tool from power source before

making any adjustments, storing, servicing, or changing accessories.

Such preventative safety measures reduce the risk of starting the tool

accidentally.

CHANGING THE BLADE

1. Raise the band saw head to the vertical position (g 40)..

2. Locate the support plate (X, g 40) at the base of the band saw near the

motor.

3. Rotate the support plate clockwise to help prevent the band saw head

from falling. (See also g 32)

4. Locate the switch tab (R, g 40).

5. Locate the M6 x 12 cross head screw (s, g 40) holding the switch tab.

6. Remove the screw and the switch tab.

7. Locate the plum screw (p, g 33 & 40) and remove it, turning it counter-

clockwise.

8. Open the blade back cover.

9. Locate the upper blade cover (DD, g 40).

10. Locate the two M6 x 12 cross head screws that hold it in place.

11. Unscrew these 2 screws and remove the upper blade cover by pulling

down on it.

12. Locate the lower blade guard (FF, g 41) and the two 2 M6 x12 cross

head screws (cs, g 41)

13. Unscrew the two screws from the blade guard and remove it.

19

ENGLISH

14. Rotate the blade tension adjustment knob counter-clockwise to allow

the blade to slip off the rear blade wheel (r, g 42) and the front blade

wheel (f, g 42).

15. Remove the old blade.

16. Place a new new 64-1/2 inch (1638 mm) blade between the bearings of

the lower blade guard (b, g 43).

17. Slide the blade around the top of the rear blade wheel.

18. Continue to slide the blade around the bottom of the front blade wheel.

19. Turn the blade tension knob clockwise until no blade slippage occurs.

20. Place 2-3 drops of oil onto the blade near the bearings.

21. Replace the blade guard and fasten with the cross head screws

removed in step 11.

22. Replace the blade cover and fasten with the cross head screws

removed in step 13.

23. Close the blade back safety cover.

24. Replace the plum screw.

25. Replace the switch tab with the cross head screw removed in step 6.

NOTE: The Switch Tab should be able to turn off Switch when placed in

the horizontal position.

This band saw comes with a 1/2 inch x 0.025 x 64-1/2 inch minimum (651/2 inch max,) 14 TPI (teeth per inch) general use blade.

Additional Blades in the 14 to 24 tooth sizes are available at your local

dealer. For thinner work pieces, use a Blade with a higher teeth per inch

count. When cutting, a minimum of 3 teeth should be in contact with the

work piece at all times.

LUBRICATION

The Drive Gears run in an oil bath and should not require a lubricant

change more often than once a year. To change lubricant:

1. Place a small pan under the right lower corner of the gear box.

2. Lower the band saw head to the horizontal position.

3. Remove the four M6 x 10 hexagon head bolts used to keep the gear

box cover in place (g 44).

4. Remove the gear box cover.

5. Slowly raise the band saw to the vertical position until all of the oil ows

out and into the pan.

6. Lower the band saw back to the horizontal position.

7. Fully ll the gear box with a 90 weight oil.

8. Use a soft rag to wipe up excess oil and foreign matter that may have

spilled.

9. Replace the gear box cover and tighten the bolts.

20

ENGLISH

141110

BLADE TRACKING

This adjustment has been completed and tested under power at the

factory. The need for adjustment should rarely occur when the saw is used

properly. If tracking goes out of adjustment, the blade will leave the wheel

and damage may result. Should the Blade Tracking need adjustment,

contact the General International Technical Service Department.

Keep your tool in good condition by adopting a regular

maintenance program. Before each use, make a general examination of

the saw.

PREVENTIVE MAINTENANCE

● Keep your tool in good condition by adopting a regular maintenance

program.

● Before use, examine the general condition of your tool. Inspect blades,

switches, tool cord and extension cord for damage.

● Check for loose screws, misalignment, binding of moving parts,

improper mounting, broken parts, and any other condition that may

affect its safe operation. If abnormal noise or vibration occurs, turn the

tool off immediately and have the problem corrected before further use.

● Do not use a damaged tool.

● Never disassemble the tool or try to do any rewiring on the tool’s

electrical system. Contact General International for all repairs.

● Clean dust and debris from vents.

● Keep the tool handles clean, dry and free of oil or grease.

● Use only mild soap and damp cloth to clean your tool since certain

cleaning agents and solvents are harmful to plastics and other insulated

parts. Some of these harmful solvents include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia,

and household detergents containing ammonia.

STORAGE

● When storing your 4-1/2 inch metal cutting band saw,be sure to loosen

the tension on the blade. Rotate the blade tension adjustment knob

counter-clockwise to loosen blade tension and preserve the life of your

blade and tool.

● Be sure the tool is turned off and the switch safety screw in place.

● Unplug the tool from any power sources.

● Protect electrical cord from damage (such as being stepped on or

driven over). Wrap all cords loosely around the motor.

● Place a blanket or sheet over the tool making sure the blade is covered.

Place your tool in a cool, dry, safe, and indoor location.

WARNING! Never use ammable or combustible solvents around tools.

WARNING! To reduce the risk of injury, electric shock and damage to

the tool, never immerse your tool in liquid or allow liquid to ow inside the

tool.

NOTE: SERVICE AND REPAIRS should be made by qualied repair

technicians at an authorized repair center. Improperly repaired tools

could cause serious shock or injury.

NOTE: REPLACEMENT PARTS. When servicing, use only the

manufacturer’s recommended replacement dentical replacement parts

and accessories.

21

ENGLISH

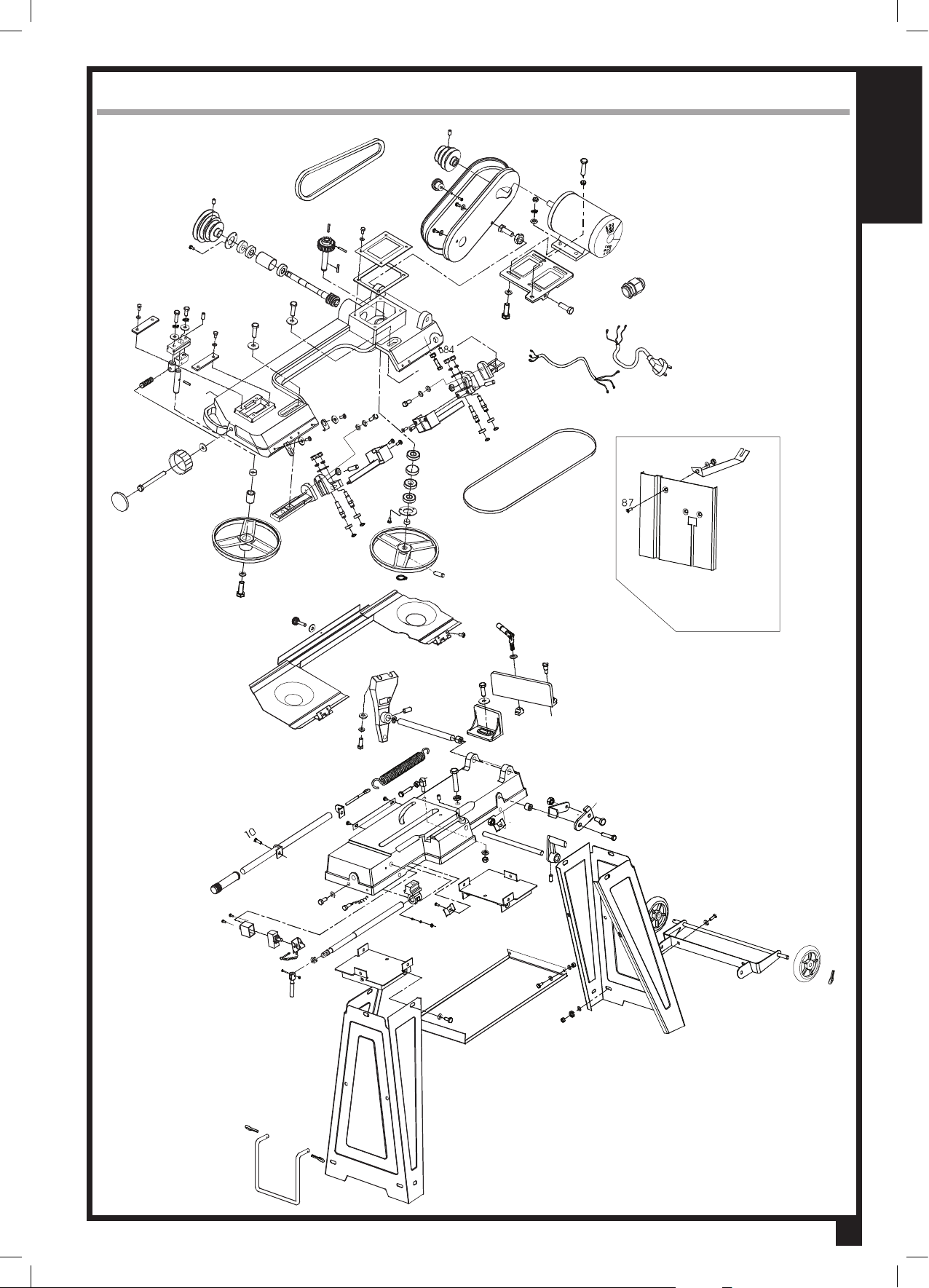

PARTS LIST

NO. DESCRIPTION Q T Y.

001 Floor stand handle 1

002 Cotter pin 3 x 18 4

003 Hexagon Head screw M8 x 20 1

004 Washer 8 29

005 Floor stand 2

006 Connecting plate 2

007 Hexagon nut M8 17

008 Wheel frame 1

009 Lower blade guard 1

010 Hexagon head screw M8 x 16 14

011 Spring washer 8 18

012 Wheel 2

013 Hexagon socket headless

screw M8 x 8

014 Handle 1

016 Thrust washer 13 1

017 Lead screw 1

018 Vise nut 1

019 Lock chain 1

020 Switch 1

021 Switch box 1

022 Screw M4 x 8 11

023 Star washer 4 1

024 Switch safety plate 1

025 Switch safety screw 1

026 Wire relief retainer 2

027 Cross head screw M6 x 12 5

028 Stock stop rod 1

029 Stock stop 1

030 Hexagon head screw M8 x 40 2

031 Support plate 1

032 Support plate cover 1

033 Bushing 2

034 Movable vise plate 1

035 Arc sliding plate 1

036 Mitering vise plate 1

037 Screw 1

038 Lock handle 1

039 Knob 1

040 Hexagon head screw M10

x 30

041 Big washer 10 4

042 Big Washer 8 11

043 Screw M8 x 12 2

044 Pivot 1

045 Pivoting rod 1

046 Hexagon head screw M12

x 65

047 Hexagon thin nut M12 2

NO. DESCRIPTION Q T Y.

048 Stop screw 1

049 Spring 1

050 Screw M8 x 25 6

051 Spring adjusting screw 1

052 Rear nut plate 1

053 Scale 1

054 Cross head screw M5 x 8 2

055 Bed 1

056 Hexagon head screw M8 x 30 9

057 Front nut plate 1

058 Adjusting rod 1

059 Adjusting hold cover 1

2

1

1

060 Blade back safety cover 1

061 Plum screw 1

062 Washer 6 16

063 Big Washer 6 4

064 Blade wheel (rear) 1

065 Sliding bearing 1

066 Upper blade guard 1

067 Screw M10 x 35 2

068 Hexagon head screw M6 x 20 1

069 Lock chip 1

070 Cross head screw M6 x 10 1

071 Bearing 6000 2Z 6

072 Guide pivot (left) 2

073 Thrust washer 10 4

074 Guide pivot (right) 2

075 Shaft 2

076 Upper blade cover 1

077 Switch cut off screw 1

078 Ball bearing 6002 2Z 4

079 Bearing bushing 1

080 Oil seal 2

081 Blade wheel bearing cover 1

082 Bushing 1

083 Blade wheel (front ) 1

084 Hexagon socket headless

screw M6 x 12

085 Thrust washer 15 1

086 Blade 1

087 Cross head screw M6 x 12 4

088 Lower blade cover 1

091 Lower pulley cover 1

092 Upper pulley cover 1

093 Motor pulley 1

094 Motor 1

095 Motor cord 1

096 Strain relief 1

1

NO. DESCRIPTION Q T Y.

097 Supply cord 1

098 Vertical cutting support plate 1

099 Vertical cutting plate 1

100 Hexagon nut M6 6

101 Motor mount plate 1

102 Screw M12 x 35 1

104 Key 5 x 5 x 25 2

105 Spring pin 4 x 26 1

106 Transmission wheel shaft 1

107 Transmission gear 1

108 Gear box gasket 1

109 Gear box cover 1

110 Hexagon head screw M6 x 10 8

111 Hexagon head screw (with

hole)

112 Worm gear shaft 1

113 Bearing bushing 1

114 Bearing cover 1

115 Worm gear pulley 1

116 Blade tension sliding guides 2

117 Screw M6 x 12 4

118 Hexagon head screw M8 x 20 1

119 Blade tension sliding plate 1

120 Sliding plate draw block 1

121 Spring pin 4x20 1

122 Blade wheel shaft 1

123 Shaft block 1

124 Spring 1

125 Blade tension adjustable knob 1

126 Body frame 1

127 Tool plate 1

128 V-belt 1

131 Cross head screw M4 x 20 1

132 Nut M4 1

133 Hex head screw M10 x 100 1

134 Adjust knob cover 1

135 Washer 4 1

136 Lower guide frame 1

137 Upper guide frame 1

138 Adjust support plate 1

139 Pivoting rod bushing 1

140 Cross head screw M5 x 12 1

141 Adjusting knob 1

142 Rubber washer 6 2

143 Cross head screw M5 x 10 2

144 Washer 10 1

1

22

ENGLISH

141110

SCHEMATIC DRAWING

43

27

85

1 09

1 09

56

139

49

93

39

10 8

100

42

88

87

82

44

43

7

30

22

13 5

6

140

27

142

136

68

71

11

72

71

43

73

13

22

40

41

33

46

47

7

4

7

26

4

10

78

79

78

80

81

45

48

18

70

23

1 17

116

1 24

62

1 34

1 19

1 23

42

122

133

1 28

43

41

10 4

11 0

107

78

1 12

67

63

7

69

11

61

58

13 2

1 06

4

50

24

16

27

63

7

13 7

4

11

60

6363

77

72

52

4

71

19

105

104

71

54

62

56

27

42

11

76

75

74

71

22

73

73

83

8383

42

11

56

51

54

53

55

17

3

11

42

12 0

1 25

64

1 18

41

143

117

62

1 16

59

1 14

65

42

10

21

80

78

1 13

67

41

12 6

33

66

57

20

25

131

14

1 15

22

56

11

1 21

111

42

56

74

144

92

75

71

73

47

141

91

7

7

11

4

9

86

38

35

34

7

32

28

13

6

62

1 10

12 7

94

101

10

96

97

10 0

63

98

99

30

10

4

8

12

2

102

95

37

36

31

138

29

1 00

4

7

11

2

2

1

5

23

ENGLISH

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Excessive blade breakage Work piece is loose in vise Clamp work securely

Incorrect speed or feed Adjust blade speed or feed rate

Blade tooth spacing too great Use a slower blade speed and higher

Incorrect blade tension Adjust tension to just where blade does

Blade is in contact with workpiece before

starting saw

Blade rubs on wheel ange Adjust wheel alignment

Mis-aligned guide bearings Adjust bearings

Premature blade dulling Teeth too coarse Use ner tooth count

Speed is too high Decrease speed

Inadequate feed pressure Decrease spring tension (turn rod

Hard spots or scale on material Reduce speed, increase feed pressure

Blade twist Replace with a new blade, and adjust

Unusual wear on side or back of blade Blade guides are worn Replace

Blade guide bearings not adjusted

properly

Blade guide bearing bracket is loose Tighten

Tooth loss on blade Teeth are too coarse for the work Use ner tooth count

Too heavy pressure & too slow speed Decrease pressure, increase cutting

Vibrating or chattering work piece Clamp work securely

Teeth clogging Use coarser blade, use a brush to clear

Motor runs hot Blade tension too high Reduce tension on blade

Drive belt tension too high Reduce tension on belt

Gears need lubrication Check oil bath

Cut is binding the blade Decrease feed pressure and blade

Bad cuts (off square) Feed pressure too high Increase spring tension with adjusting

Guide bearings improperly adjusted Adjust bearing clearance to 0.001 inch

Inadequate blade tension Increase blade tension

Dull blade Replace blade

Speed incorrect Adjust speed

Blade guides spaced out too much Tighten blade guides gap

Blade guide assembly loose Tighten

Blade track too far away from wheel

anges

Bad cuts (too rough) Too much speed or feed Decrease

Blade is too coarse Replace with ner blade

Blade tension is loose Tighten

Blade is twisting Cut is binding the blade Decrease feed pressure

Too much blade tension Decrease

TPI blade

not slip on wheel

Allow saw to come up to speed before it

comes into contact with material

counter-clockwise)

blade tension

Adjust

speed

away chips

speed

rod

or less.

Retrack blade

24

BS5205 man v.141110

Modèle #

MANUEL D’INSTRUCTIONS ET D’ASSEMBLAGE

DEPUIS

Scie à ruban pour

métaux de 4-1/2 po

CARACTÉRISTIQUES

● Robuste base d’acier

avec roues

● Cadre de coupe en

fonte solide

● Étau de fonte avec

ouverture de 6 po (150

mm)

● 3 vitesses de coupe

aidant à couper les métaux

ferreux et non ferreux

● Indicateur de coupe d’onglet de

90º à 45º degrés

● Guide de lame ajustable

● Coupe verticale

SPÉCIFICATIONS

● Moteur :

120 V ~ 60 Hz 550 W

● Lame :

64-1/2 po

(1638 mm)

● Capacité de coupe

maximum (rond) :

4-1/8 po (105 mm)

● Capacité de coupe

maximum (droit) :

4 x 6 po

(102 x 150 mm)

● Vitesse de la lame :

80/120/180 pi/min

(24/36.5/55 m/min)

● Certication CSA

● Poids net :

134 lb (61 kg)

BS5205

FRANÇAIS

NOUS VOUS REMERCIONS

d’avoir choisi une machine de General International. Cette outil a été

soigneusement testée et inspectée avant de vous être expédiée, et

moyennant une utilisation et un entretien adéquats, elle vous procurera

un service able pendant de nombreuses années. An d’obtenir un

rendement optimal et une utilisation sans problème, et d’optimiser

votre investissement, veuillez prendre le temps de lire ce manuel avant

d’assembler, d’installer et d’utiliser l’unité.

Ce manuel vise à vous familiariser avec l’utilisation sécuritaire, les

fonctions élémentaires et les caractéristiques de cette scie ainsi qu’avec

le réglage, l’entretien et l’identication de ses parties et composantes. Il

n’est pas conçu pour remplacer un enseignement théorique sur le travail

ni pour offrir à l’utilisateur une formation en la matière. En cas de doute

concernant la sécurité d’une opération ou d’une procédure, demandez

l’aide d’une personne qualiée avant d’entamer le travail.

Une fois que vous avez lu ces instructions, conservez ce manuel aux ns

de consultation ultérieure.

GARANTIE DE

GENERAL® INTERNATIONAL

Toutes les composantes des machines de General® International sont

soigneusement inspectées durant chacune des étapes de production, et

chaque unité est inspectée en profondeur une fois l’assemblage terminé.

GARANTIE STANDARD

LIMITÉE DE 2 ANS

En raison de son engagement envers la qualité et la satisfaction du

consommateur, General® International accepte de réparer ou de remplacer

toute pièce qui, suite à l’examen, se révèle défectueuse quant aumatériel

et au ni d’exécution pour une période de 2 ans (24 mois) suivant la date

d’achat. Pour se prévaloir de la garantie, l’acheteur doit retourner toutes

les pièces défectueuses port payé à General® International.

Les réparations effectuées sans le consentement écrit de General®

International annuleront la garantie.

CLAUSE DE NON-RESPONSABILITÉ

L’information et les caractéristiques présentées dans ce manuel se

rapportent à la machine telle qu’elle est sortie de l’usine au moment de

mettre sous presse. En raison de son souci d’amélioration constante,

General International se réserve le droit de modier des composantes, des

pièces ou des caractéristiques de la machine si cela est jugé nécessaire,

sans préavis et sans obligation d’effectuer ces modications sur les

machines déjà vendues. On prend soin de s’assurer à l’usine que les

caractéristiques et l’information présentées dans ce manuel correspondent

à la machine avec laquelle il est fourni.

Toutefois, en raison de commandes spéciales et de modications réalisées

“hors de l’usine,” une partie ou la totalité de l’information contenue dans

ce manuel peut ne pas s’appliquer à votre machine. De plus, comme il se

peut que plusieurs générations de ce modèle de scie.

et plusieurs versions de ce manuel soient en circulation, il est possible que

ce manuel ne décrive pas exactement votre machine si vous possédez

une version antérieure ou ultérieure. Si vous avez des doutes ou des

questions, veuillez communiquer avec votre détaillant ou notre

ligne de soutien technique et mentionner le numéro de modèle et de série

de votre machine an d’obtenir des éclaircissements.

DEMANDE DE RÉCLAMATION

Pour présenter une demande de réclamation en vertu de notre Garantie

Standard Limitée de 2 ans, ou en vertu de notre Garantie Limitée à Vie,

toute pièce, composante ou machinerie défectueuse doit être retournée,

port payé, à General® International, ou encore à un distributeur, un centre

de réparation ou tout autre emplacement situé près de chez vous et

désigné par General® International. Pour plus d’informations ou si vous

avez besoin d’aide pour remplir une demande de réclamation, contactez

notre département de service au 1-888-949-1161.

Une copie de la preuve d’achat originale ainsi qu’une lettre (un formulaire

26

FRANÇAIS

141110

de réclamation de garantie peut vous être fourni sur demande par

General® International ou par un distributeur agréé) spéciant clairement le

modèle et le numéro de série de l’unité (si applicable), et faisant état de la

plainte ou du défaut présumé, doivent être jointes au produit retourné.

CONDITIONS ET EXCEPTIONS

Cette couverture ne s’applique qu’au premier acheteur. Un enregistrement

préalable de la arantie n’est pas requis. Par contre, une preuve d’achat –

soit une copie du coupon de caisse ou du reçu original, sur lequel gnt la

date et le lieu d’achat ainsi que le prix payé – doit être fournie lors de la

réclamation.

La Garantie ne couvre pas les défaillances, bris ou défauts qui, après

examen par General® International, sont considérés comme étant

directement ou indirectement causés par ou résultant de: une utilisation

incorrecte, un entretien inadéquat ou l’absence d’entretien, un usage

inapproprié ou abusif, la négligence, un accident, des dommages survenus

durant la manutention ou le transport, ou encore l’usure normale ou la

détérioration des pièces et composantes considérées, de façon générale,

comme étant des consommables.

Les réparations effectuées sans le consentement écrit de General®

International annuleront toute garantie.

LISEZ TOUTES LES INSTRUCTIONS

AVANT L’UTILISATION

CONSERVEZ CES INSTRUCTIONS

Avant d’essayer de faire fonctionner votre nouvel outil, veuillez lire

les instructions au complet. Vous aurez besoin de ces instructions

pour les avertissements de sécurité, les précautions, l’assemblage, le

fonctionnement, les procédures d’entretien, la liste des pièces et les

schémas des pièces. Gardez votre facture avec ces instructions. Écrivez

votre numéro de facture à l’intérieur de la page couverture. Gardez les

instructions ainsi que la facture dans un endroit sûr et sec pour référence

future.

LES AVERTISSEMENTS, LES PRÉCAUTIONS ET LES

instructions discutés dans ce manuel ne peuvent pas couvrir toutes les

conditions et les situations qui pourraient survenir. L’utilisateur se doit de

comprendre que le bon sens ainsi que la prudence sont des facteurs qui

ne peuvent être incorporés dans ce produit, mais peuvent être fournis

par l’utilisateur lui-même.

REGLES DE SÉCURITÉ ET

DIRECTIVES

L’objectif des symboles de sécurité est d’attirer votre attention sur les

risques potentiels. Les symboles de sécurité, ainsi que les explications les

accompagnant, nécessitent votre attention et votre compréhension. Les

avertissements de sécurité n’éliminent pas d’eux-mêmes tous les dangers.

Les instructions ou les avertissements qu’ils donnent ne sont pas un

remplacement aux mesures de prévention d’accident appropriées.

DANGER!

évitée, causera de sérieuses blessures ou la mort

AVERTISSEMENT!

elle n’est pas évitée, pourrait causer de sérieuses blessures ou la mort.

ATTENTION: Indique une situation à risque imminent, laquelle si elle

n’est pas évitée, peut causer des blessures mineures ou des blessures

légères. Il peut aussi être utile de demeurer alerte au sujet des pratiques

non sécuritaires qui pourraient causer des dommages à la propriété.

Indique une situation à risque imminent, laquelle si elle n’est pas

.

Indique une situation à risque imminent, laquelle si

27

FRANÇAIS

AVERTISSEMENTS ET

PRÉCAUTIONS

Assurez-vous de lire, comprendre et suivre tous les avertissements et

consignes de sécurité dans le manuel de l'opérateur.

ZONE DE TRAVAIL

1. TENEZ LES ENFANTS ELOIGNÉS.

Assurez-vous que les visiteurs sont maintenus à une distance

sécuritaire de la zone de travail.

2. GARDER LE LIEU DE TRAVAIL PROPRE

et assurez-vous qu'un éclairage adéquat est disponible.

3. ÉVITEZ LES ENVIRONNEMENTS DANGEREUX

Ne pas utiliser d'outils électriques dans des endroits humides ou

mouillés. Garder la zone de travail bien éclairée. Ne pas exposer les

outils électriques à la pluie. Ne pas utiliser l'outil dans la présence de

liquides ou gaz inammables.

4. RANGEZ VOTRE ÉQUIPEMENT

Rangez la machine dans un endroit sec pour empêcher la rouille. La

scie devrait également être dans un endroit verrouillé ou à garder hors

de portée des enfants et des personnes non qualiées.

SÉCURITÉ PERSONNELLE

1. APPRENDRE LES APPLICATIONS ET LES LIMITES

de la machine ainsi que les risques spéciques à cette machine.

Suivez les instructions de sécurité disponibles et les règles de sécurité

attentivement.

2. NE PAS TROP SE PENCHER

Garder une position correcte en tout temps.

3. DEMEURER ALERTE

Regardez ce que vous faites. Utilisez votre bon sens. Ne pas utiliser

l'outil lorsque vous êtes fatigué. Ne pas l'utiliser sous médication ou si

vous avez consommer de l'alcool ou d'autres drogues.

4. PORTEZ DES VÈTEMENTS APPROPRIÉS.

Ne portez pas de vêtements amples, gants, bracelets, colliers, bijoux

lors de l'utilisation de l'outil. Porter un masque ou un dispositif de

protection pour les yeux, les oreilles, les voies respiratoires et pour le

corps comme indiqué dans le fonctionnement de l’appareil.

5. PORTEZ TOUJOURS DES LUNETTES DE SÉCURITÉ.

Utilisez également un masque anti- poussière si le sablage soulève de

la poussière, et des bouchons d'oreille pendant de longues périodes

de fonctionnement. Les lunettes ordinaires ont des verres résistant aux

chocs, ils NE SONT PAS des lunettes de sécurité.

6. PORTEZ UNE PROTECTION RESPIRATOIRE.

L'utilisation de cet outil peut produire et / ou répandre de la poussière,

ce qui peut entraîner des problèmes respiratoires graves et

permanents ou d'autres blessures. De nombreux types de bois sont

naturellement toxiques, surtout sous forme de poussière. Porter un

masque anti-poussière propre si le travail consiste à créer beaucoup

de poussière ne ou grossière. toujours utiliser NIOSH / OSHA

approuvé une protection respiratoire appropriée pour l’exposition à la

poussière. Diriger les particules loin du visage et du corps.

7. PORTEZ UNE PROTECTION AUDITIVE,

Spécialement si exposé à répétition. Cet outil est bruyant. Des

protections auditives devraient être portées. (en accord avec ANSI

S12.6-1997R2002).

8. ATTENTION AUX DÉCHARGES ÉLECTRIQUES

Éviter tout contact corporel avec des surfaces en mises à la terre. Par

exemple: tuyaux, radiateurs, cuisinières, réfrigérateurs. Quand votre

corps est en mis à la terre le risque de choc électrique augmente.

Lorsque l'on travaille, il est possible d’avoir certains ls électriques

avec courant autour de vous, tentez de déterminer si il y a un danger

de choc. NE TOUCHEZ PAS LES PARTIES MÉTALIQUES DE

L'OUTIL tout en l'utilisant. Tenez l'outil par la poignée en plastique pour

éviter un choc électrique si vous venez en contact avec un l sous

tension.

PORTEZ VOS

PRÉVOYANCE EST

MIEUX QUE DE

NE PAS VOIR

28

FRANÇAIS

141110

9. TOUJOURS DÉBRANCHER L’OUTIL AVANT DE FAIRE

L’ENTRETIEN

et changer les accessoires tels que la lame.

10. VÉRIFIER QUE LES CLÉS ET MOLETTES DE RÉGLAGE SONT

RETIRÉES

avant la mise sous tension, laisser en place ces pièces peuvent

s'envoler au démarrage et entraîner des blessures.

11. ASSUREZ-VOUS QUE LE COMMUTATEUR EST EN POSITION

ARRET «OFF»

avant de brancher le cordon pour réduire le risque de départs

involontaires.

12. NE JAMAIS MONTER SUR L'OUTIL

De graves blessures peuvent se produire si l'outil bascule ou si la lame

de coupe est accidentellement en contact avec vous.

13. GARDER LES MAINS LOIN DES SURFACES DE COUPE

et toutes les pièces mobiles. Ne pas enlever la sciure ou la poussière

avec mains. Utilisez une brosse.

14. SÉCURISER VOTRE PIÈCE À TRAVAILLER.

Utilisez des pinces ou un étau pour maintenir la pièce. Il est plus

sûr que d'utiliser vos mains et il libère les deux mains pour faire

fonctionner l'outil.

15. DÉBRANCHER LE CORDON D’ALIMENTATION

avant de faire des ajustements. Modication des pièces jointes

ou accessoires peuvent être dangereux si l'outil démarrait

accidentellement.

LA SÉCURITÉ DE L’OUTIL

1. ASSUREZ-VOUS QUE L’OUTIL

est à sa vitesse d’opération avant de présenter une pièce pour La

coupe.

2. NE PAS ALIMENTER TROP RAPIDEMENT.

L'outil a de meilleures performances et sera plus sécuritaire s’il

travaille à la vitesse pour lequel il a été conçu.

3. NE JAMAIS LAISSER LA MACHINE SOUS TENSION

4. NE PAS FORCER LA MACHINE.

Elle fera mieux son travail et plus sûrement à une vitesse pour laquelle

il a été conçu. Ne forcez pas un petit outil ou accessoire pour faire le

travail d'un plus grand outil industriel. Ne pas utiliser un outil pour un

usage pour lequel il n'a pas été prévu

5. ENTRETENIR LES OUTILS AVEC SOIN.

Garder les outils affûtés et propres pour un meilleur rendement.

Suivre les instructions pour la lubrication et pour une performance

sécuritaire. Suivez les instructions pour la lubrication et pour le

changement des accessoires. Gardez la poignée sèche, propre et

exempte d'huile et de graisse.