Page 1

Chimney Vent Hoods

Profile

49-80549 12-08 JR

Safety Instructions . . . . . . . . 2, 3

Operating Instructions

Light Controls . . . . . . . . . . . . . . . . . . . .4

Vent Controls . . . . . . . . . . . . . . . . . . . . .4

Care and Cleaning

Grease Filters . . . . . . . . . . . . . . . . . . . .5

Hood Lights . . . . . . . . . . . . . . . . . . . . . .6

Stainless Steel Surfaces . . . . . . . . . . .6

Installation Instructions

Installation Preparation . . . . . . . .7-13

Vented to the Outside . . . . . . . .14-17

Recirculating . . . . . . . . . . . . . . . . .18-22

Troubleshooting Tips . . . .23, 24

Consumer Support

Consumer Support . . . . . . . . . . . . . 26

Warranty . . . . . . . . . . . . . . . . . . . . . . . 25

Write the model and serial

numbers here:

Model # ________________

Serial #

________________

You can find them on a label

on the inside of the hood.

PV970

PV976

Owner’s Manual

and Installation

Instructions

ge.com

Page 2

SAFETY PRECAUTIONS

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING – TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer.

B. Before servicing or cleaning unit, switch

power off at service panel and lock the service

disconnecting means to prevent power from

being switched on accidentally. When the

service disconnecting means cannot be locked,

securely fasten a prominent warning device,

such as a tag, to the service panel.

C. Do not use this unit with any solid-state speed

control device.

D. This unit must be grounded.

CAUTION – For general ventilating use

only. Do not use to exhaust hazardous or explosive

materials and vapors.

CAUTION – To reduce risk of fire

and to properly exhaust air, be sure to duct air

outside. Do not vent exhaust air into spaces

within walls or ceilings or into attics, crawl

spaces or garages.

WARNING – TO REDUCE

THE RISK OF INJURY TO PERSONS IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING*:

A. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner.

BE CAREFUL TO PREVENT BURNS. If the flames

do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN—You may

be burned.

C. DO NOT USE WATER, including wet dishcloths

or towels—a violent steam explosion will result.

D. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher,

and you already know how to operate it.

2. The fire is small and contained in the area

where it started.

3. The fire department is being called.

4. You can fight the fire with your back

to an exit.

* Based on “Kitchen Fire Safety Tips

” published

by NFPA.

Consumer Support Troubleshooting Tips Operating Instructions Safety Instructions

Care and Cleaning

2

Page 3

Consumer Support

Troubleshooting TipsOperating Instructions

Safety Instructions

Care and Cleaning

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

READ AND SAVE THESE INSTRUCTIONS

SAFETY PRECAUTIONS

ge.com

WARNING – TO REDUCE THE RISK

OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high

settings. Boil overs cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low

or medium settings.

B.

Always turn hood ON when cooking on high

heat or when flambéing food (i.e. Crepes Suzette,

Cherries Jubilee, Peppercorn Beef Flambé).

C. Clean ventilating fans frequently. Grease should

not be allowed to accumulate on fan or filter.

D. Use proper pan size. Always use cookware

appropriate for the size of the surface element.

WARNING – TO REDUCE

THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must

be done by qualified person(s) in accordance

with all applicable codes and standards,

including fire-rated construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment

to prevent back drafting. Follow the heating

equipment manufacturer’s guidelines and

safety standards such as those published by

the National Fire Protection Association (NFPA),

the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE)

and the local code authorities.

C. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

D. Ducted fans must always be vented

to the outdoors.

WARNING – TO REDUCE THE RISK

OF FIRE, USE ONLY METAL DUCTWORK.

■ Do not attempt to repair or replace any

part of your hood unless it is specifically

recommended in this manual. All other servicing

should be referred to a qualified technician.

3

Page 4

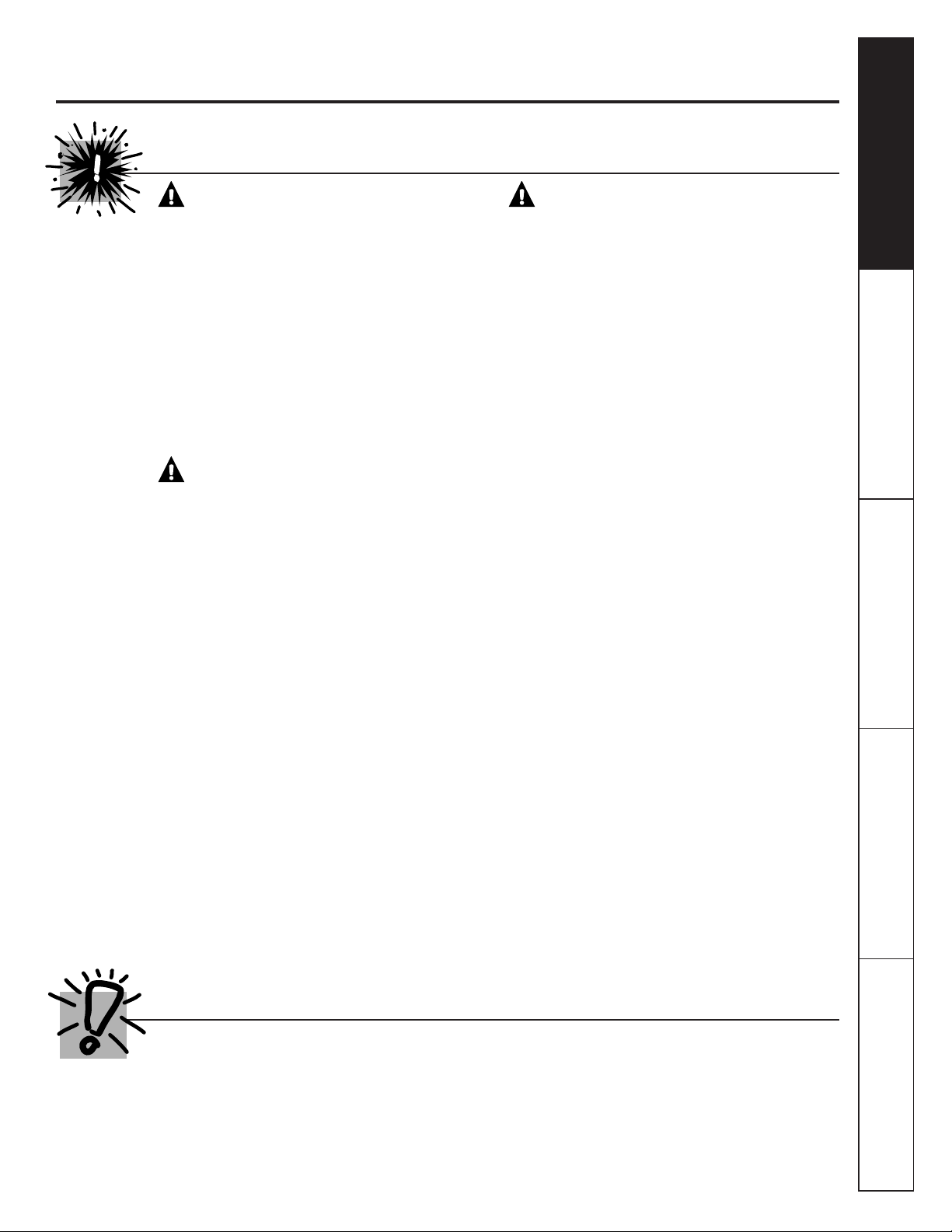

Using the hood controls.

Consumer Support

Troubleshooting Tips Operating Instructions Safety InstructionsCare and Cleaning

4

MEMORY/OFF. To set the memory:

A. Press the MEMORY/OFF button.

B. Set your desired fan and light settings.

C. Press the MEMORY/OFF button again to save

these settings.

With your desired settings in memory, press the

MEMORY/OFF button to restore the fan and light

levels to their saved settings. These settings will

remain in memory until they are changed or loss

of power occurs.

To turn off the hood, press the MEMORY/OFF

button.

LIGHT. Press + or – to increase or decrease light

level to desired setting. There are 2 light levels

(LOW, HIGH) and OFF. If you continue to press

the + or – buttons, the light will cycle back through

the settings.

NOTE: Please check the lamps to ensure only 20W

lamps (maximum) are installed.

FAN. Press + or – to increase or decrease fan

level to your desired setting. There are 4 fan levels

(LOW, MED, HIGH, BOOST) and OFF. If you continue

to press the + or – buttons, the fan will cycle back

through the settings.

NOTE: There is an audible “beep” each time

a button is pressed. This is normal.

NOTE: The collars around the buttons will illuminate

when pressed. This is normal. The collars will

automatically turn off if the hood is turned off.

HEAT SENSOR:

This hood is equipped with a heat sensor that will turn

on the fan if excessive temperatures are detected

(over 70 ˚C/158 ˚F) above the cooking surface. The hood

will return to its normal operation once the heat sensor

detects temperatures below 60 ˚C/140 ˚F.

NOTE: If the hood is OFF or on LOW fan speed,

the temperatures above 70 ˚C/158 ˚F are detected;

then the fan will automatically adjust to MED speed.

You may adjust the fan speed to HIGH or BOOST,

but you will not be able to adjust the fan speed to LOW

or OFF until temperatures below 60 ˚C/140 ˚F are detected.

NOTE: The collars around the buttons may not illuminate

if the heat sensor is activated. This is normal.

Page 5

Care and cleaning of the vent hood. ge.com

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part

of the vent hood.

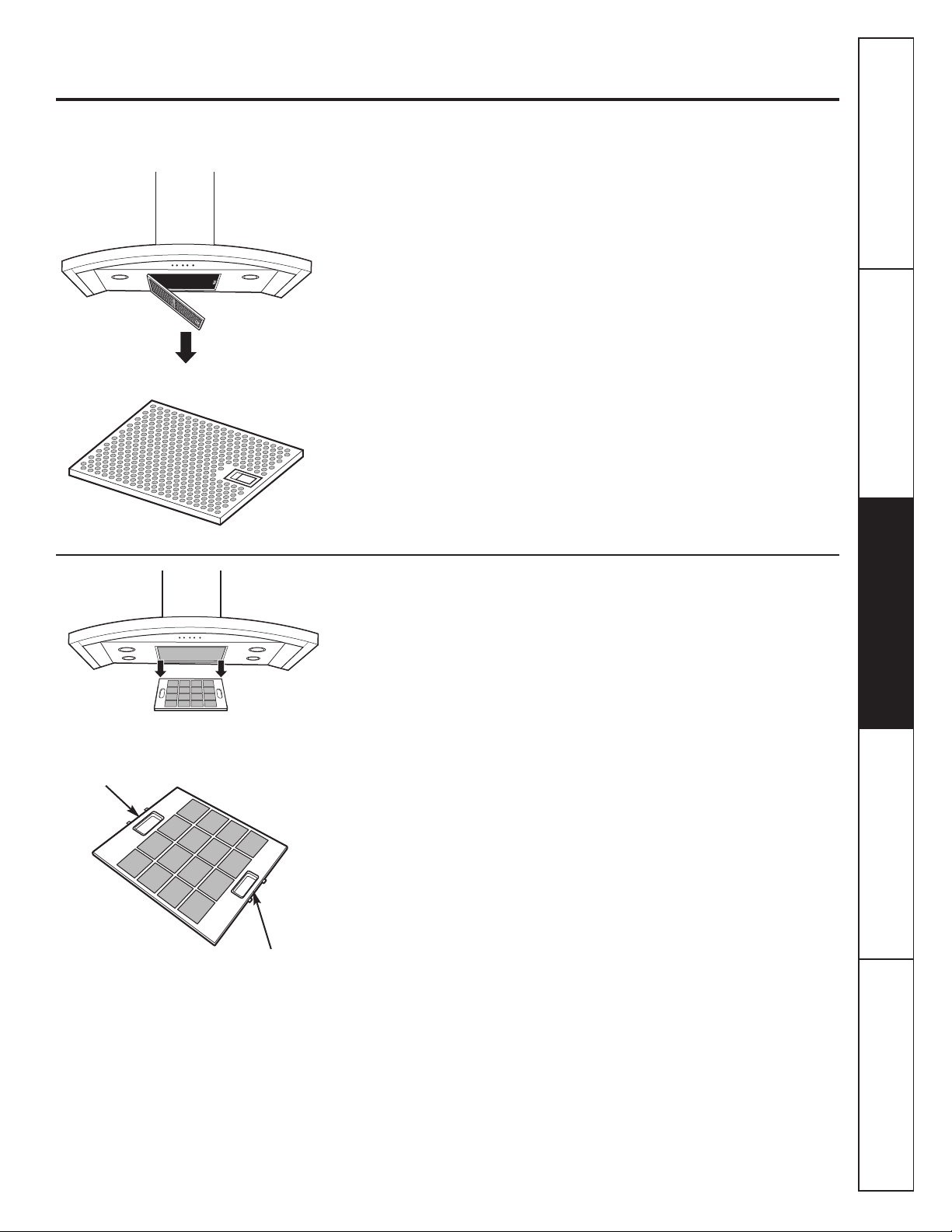

The metal filter traps grease

released by foods from the

cooktop. The filter also helps

prevent flames (from food, grease)

from damaging the inside

of the hood.

For this reason, the filter

must ALWAYS be in place when

the hood is in use. The grease filter

is dishwasher-safe and should be

cleaned every 6 months, or as

needed.

To remove:

Pull downward on the filter lock

to release the filter.

To replace:

Fit the tabs at the end of the filter

into the slots in the left side of the

filter opening. Lift up the right side

of the filter and push gently until

the filter locks into place. Make

sure the filter lock is in the closed

position to secure the filter.

To clean, swish the filter in hot

soapy water and rinse in clean

water or wash it in the dishwasher.

Do not use abrasive cleansers.

NOTE: Some discoloration will occur

in the dishwasher.

Metal Grease Filter

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions Care and Cleaning

5

If the model is not vented to the

outside, the air will be recirculated

through a disposable charcoal filter

that helps remove smoke and odors.

The charcoal filter should be

replaced when it is noticeably dirty

or discolored (usually after 6 to 12

months, depending on hood usage).

NOTE: DO NOT rinse, or put charcoal

filter in an automatic dishwasher.

The charcoal filter cannot be

cleaned. It must be replaced.

Order Charcoal Filter WB02X11348.

To inquire about purchasing

replacement charcoal filters or to find

the location of a dealer nearest you,

please call our toll-free number:

National Parts Center

800.626.2002

To remove:

1. Remove the metal filter—see Metal

grease filter section.

2. Remove the charcoal filter by

pushing in on both locking tab

handles to release.

To replace:

1. Insert the charcoal filter into the

opening. Push the locking tab

handles toward the center and

release to engage the locking tabs.

2. Replace the metal filter—see Metal

grease filter section.

Charcoal Filter (for recirculating installation only)

Locking tab handle

Locking tab handle

Page 6

Consumer Support Troubleshooting Tips Operating Instructions Safety InstructionsCare and Cleaning

6

Care and cleaning of the vent hood.

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part

of the vent hood.

Do not use a steel wool pad;

it will scratch the surface.

To clean the stainless steel

surface, use warm sudsy water

or a stainless steel cleaner or polish.

Always wipe the surface in the

direction of the grain. Follow the

cleaner instructions for cleaning

the stainless steel surface.

To inquire about purchasing

stainless steel appliance cleaner

or polish, or to find the location

of a dealer nearest you, please call

our toll-free number:

National Parts Center

800.626.2002

ge.com

Stainless Steel Surfaces

Light Bulbs

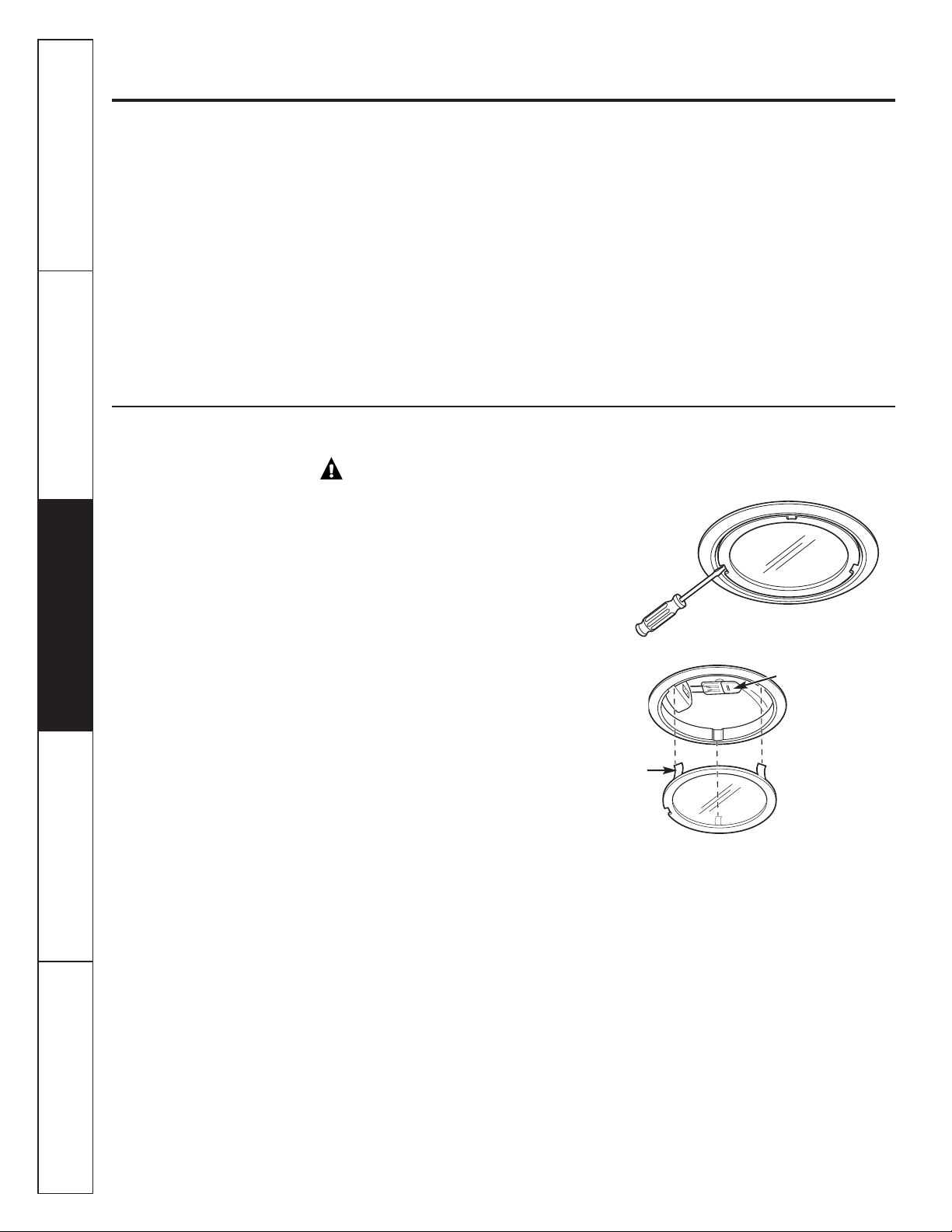

CAUTION:

Allow bulbs to cool before touching.

To change the light bulbs:

1. Remove the lamp lens cover by

inserting a small flat blade screwdriver

into each of the three slots and gently

prying it free.

NOTE: Do not remove the outer trim ring

(lamp assembly).

2. Wear gloves. Do not touch the bulb

with your bare fingers. Skin oils can

cause early lamp failure.

3. Grasp the bulb and pull it straight out.

4. Replace with the same wattage. Early

bulb failure and damage to or failure of

the transformer may occur if wattage

is too high.

These 12-volt, 20-watt halogen bulbs

with a G4 base are available at

specialty lighting stores and home

building centers.

To order replacement bulb no.

WB01X10239, contact the GE National

Parts Center at 1.800.626.2002 or

purchase from your local retailer.

5. Replace lamp lens cover by inserting

the three retaining tabs into the three

slots and pressing firmly in place.

Use a small flat blade screwdriver

to remove the lamp lens cover.

Outer trim ring

(lamp assembly)

Do not remove

Bulb

Removable inner

lamp lens cover

NOTE: Make sure the tabs are inserted into the slots.

Tab

Page 7

7

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

Installation

Chimney Vent

Hoods

Instructions

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT — Save these instructions

for local inspector’s use.

•

IMPORTANT — Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this vent hood requires

basic mechanical and electrical skills.

• Completion time –

Approximately 1 to 3 hours

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under the Warranty.

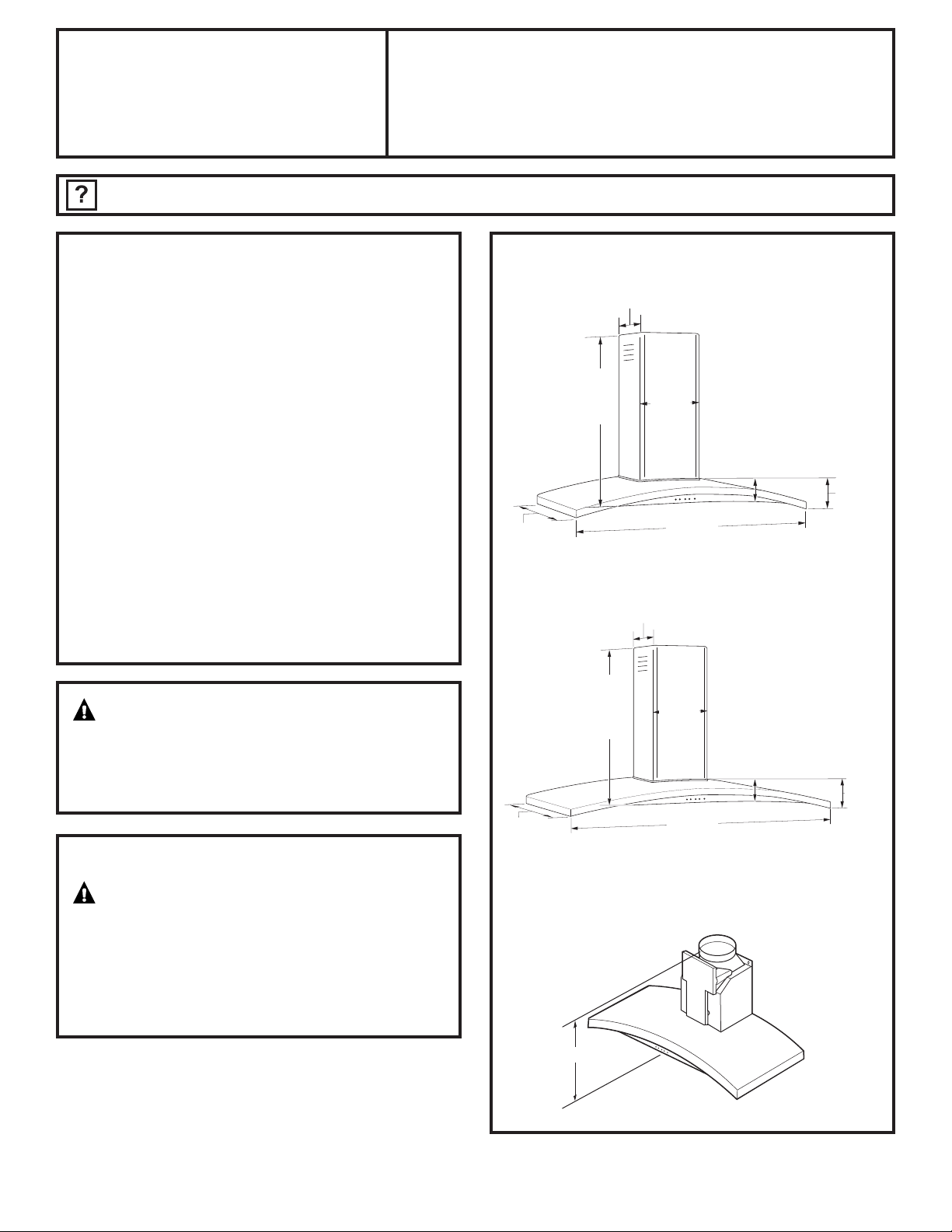

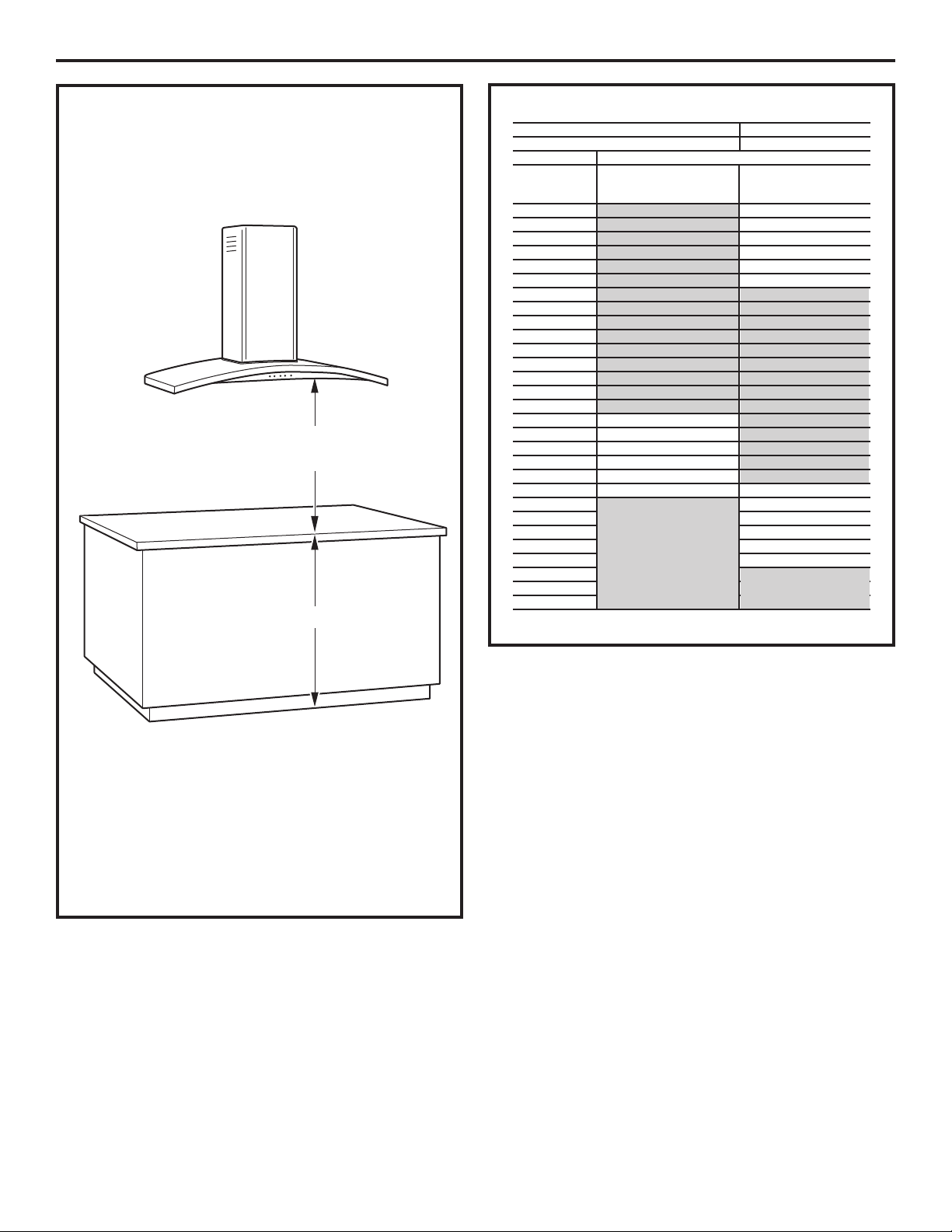

PRODUCT DIMENSIONS

FOR YOUR SAFETY:

WARNING — Before beginning the

installation, switch power off at service panel and

lock the service disconnecting means to prevent

power from being switched on accidentally. When

the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such

as a tag, to the service panel.

CAUTION — Due to the weight

and size of these vent hoods and to reduce

the risk of personal injury or damage

to the product, TWO PEOPLE ARE REQUIRED

FOR PROPER INSTALLATION.

30" Models Require a 30" Wide Opening

*Height

to

Ceiling

19-3/4"

29-7/8"

2-1/2"

13-1/8"

10-7/8"

*Height

to

Ceiling

19-3/4"

35-7/8"

3-1/8"

13-1/8"

10-7/8"

36" Models Require a 36" Wide Opening

2-1/4"

* For supplied duct cover ceiling heights for vented installation

and recirculating installation, refer to the table on page 13.

17-1/2"

Allow 1" overlap

of duct.

2-3/8"

Page 8

8

Installation Preparation

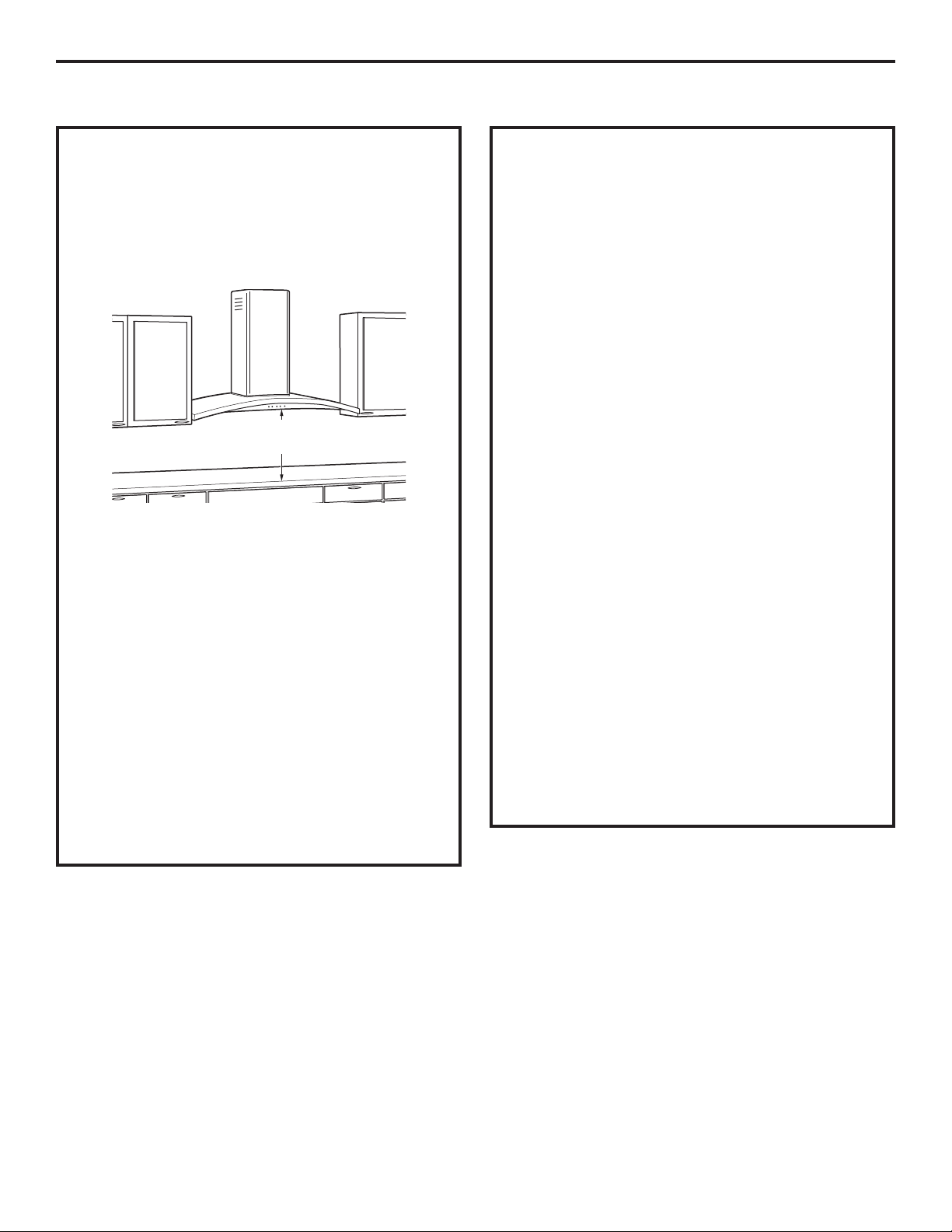

PREPARE TO INSTALL THE HOOD

INSTALLATION CLEARANCES

These vent hoods are designed to be installed

onto a wall. They may be installed beneath a soffit

or cabinet.

• Install these hoods 24" Min. to 30" Max. above

the cooking surface.

The vent hood must be installed 24" min.

and 30" max. above the cooking surface.

The hood installation height above the cooking

surface depends upon ceiling height and duct

cover limitations. The telescopic duct cover

conceals the ductwork running from the top

of the hood to the ceiling. For supplied duct cover

ceiling heights, see table on page 13.

Recirculation Kit:

Kit includes 1 air deflector and 1 charcoal filter

and is included with the hood.

NOTE: Installation height should be measured

from the cooking surface to the lowest part

of the hood. This hood may be installed onto a wall

and vented to the outdoors, or it can be installed

for recirculating operation. For recirculation

operation, a Recirculating Kit (included) is required.

24” Min.

30” Max.

ADVANCE PLANNING

Ductwork Planning

• This hood is designed to be vented vertically

through the ceiling. A duct transition piece is

supplied for vertical exhaust. Use locally supplied

elbows to vent horizontally through the rear wall.

See page 10.

• Determine the exact location of the vent hood.

• Plan the route for venting exhaust to the outdoors.

• Use the shortest and straightest duct route

possible. For satisfactory performance, duct run

should not exceed 100' equivalent length for any

duct configurations.

• Refer to “Duct Fittings” chart to compute

the maximum permissible length for duct runs

to the outdoors.

• Use metal ductwork only.

• A transition piece for 8" round duct is supplied.

Use 8" round duct.

• Install a wall cap or roof cap with damper

at the exterior opening. Order the wall or roof cap

and any transition and length of duct needed

in advance.

Wall Framing for Adequate Support

• This vent hood is heavy. Adequate structural

support must be provided. The hood must be

secured to vertical studs in the wall. See page 14.

• We strongly recommend that the vent hood with

duct cover be on site before final framing and

wall finishing. This will also help to accurately

locate the ductwork and electrical service.

Page 9

9

Installation Preparation

POWER SUPPLY

IMPORTANT – (Please read carefully)

WARNING:

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED.

Remove house fuse or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug

with this appliance. Follow National Electrical Codes

or prevailing local codes and ordinances.

Electrical supply

These vent hoods must be supplied with 120V,

60Hz, and connected to an individual, properly

grounded branch circuit, and protected by a 15

or 20 amp circuit breaker or time delay fuse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the above

requirements, call a licensed electrician before

proceeding.

• Route house wiring as close to the installation

location as possible in the ceiling or wall.

See page 14 for details.

• Connect the wiring to the house wiring

in accordance with local codes.

Grounding instructions

The grounding conductor must be connected

to a ground metal, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

WARNING: The improper connection

of the equipment-grounding conductor can result

in a risk of electric shock. Check with a qualified

electrician or service representative if you are in

doubt whether the appliance is properly grounded.

Page 10

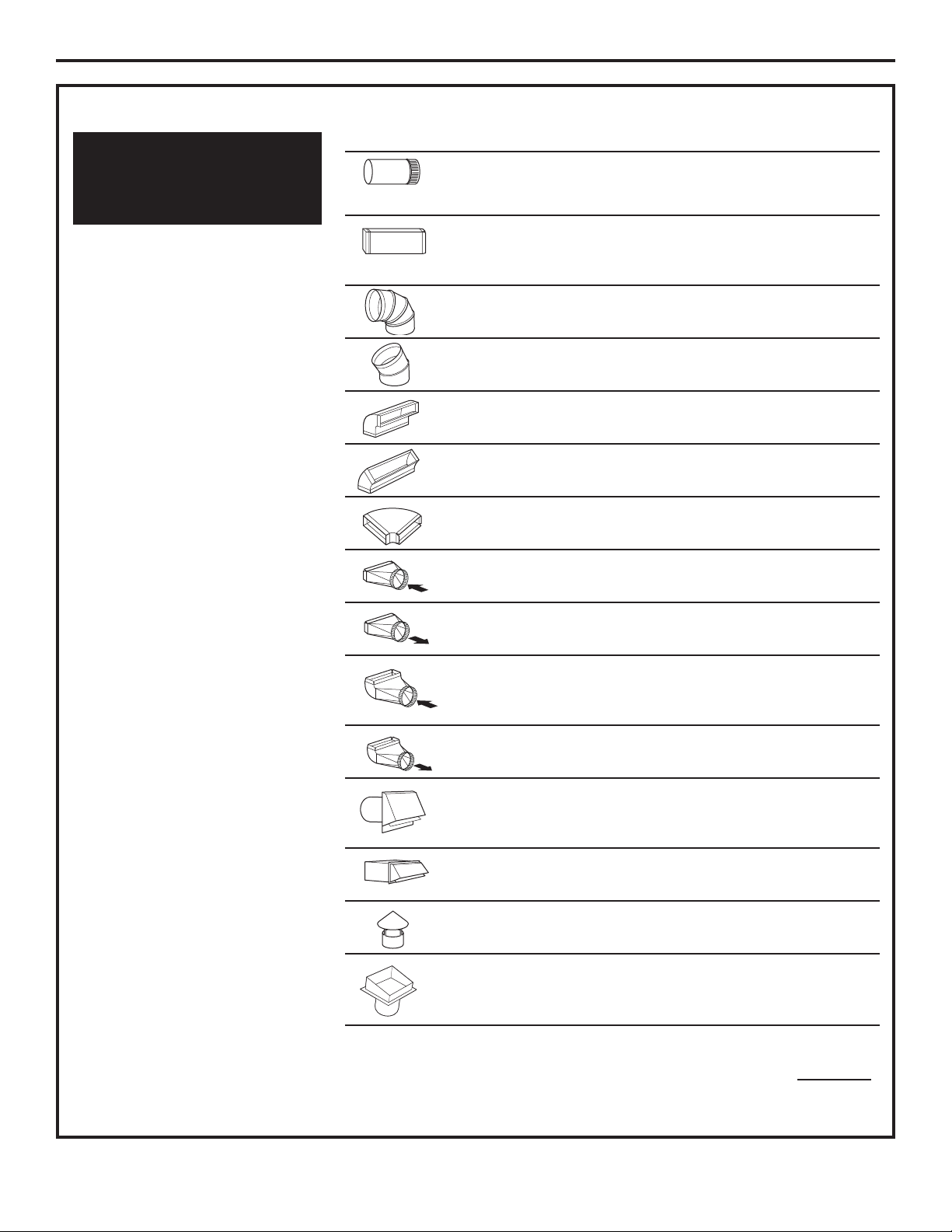

DUCT FITTINGS

This Hood Must Use an

8" Round Duct. It Can

Transition to a

3-1/4" x 12" Duct.

Use this chart to compute

maximum permissible lengths

for duct runs to outdoors.

NOTE: Do not exceed maximum

permissible equivalent lengths!

Maximum duct length:

100 feet.

Flexible ducting:

If flexible metal ducting is used,

all the equivalent feet values in

the table should be doubled.

The flexible metal duct should

be straight and smooth and

extended as much as possible.

DO NOT use flexible plastic

ducting.

NOTE: Any home ventilation

system, such as a ventilation hood,

may interrupt the proper flow

of combustion air and exhaust

required by fireplaces, gas

furnaces, gas water heaters and

other naturally vented systems.

To minimize the chance of

interruption of such naturally

vented systems, follow the

heating equipment manufacturer’s

guidelines and safety standards

such as those published by NFPA

and ASHRAE.

Total

Equivalent Quantity Equivalent

Duct Piece Dimensions Length* Used Length

8" Round, 1 ft.

straight (per foot

length)

3-1/4" x 12" 1 ft.

straight (per foot

length)

8" 90° elbow

17 ft.

8" 45° elbow

10 ft.

3-1⁄4" x 12"

90° elbow 43 ft.

3-1/4" x 12"

45° elbow 26 ft.

3-1/4" x 12"

90° flat elbow 102 ft.

8" round to

3-1/4" x 12" transition 2 ft.

3-1/4" x 12" to 7"

round transition 5 ft.

8" round

to 3-1/4" x 12"

transition 90° elbow 6 ft.

3-1/4" x 12" to 8" round

round transition 90° elbow 13 ft.

8" Round

wall cap

with damper 32 ft.

3-1/4" x 12" wall cap

with damper 75 ft.

8" Round

roof cap 44 ft.

Round

roof vent 24 ft.

Installation Preparation

Total Duct Run

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by GE Evaluation

Engineering and reflect requirements for good

venting performance with any ventilation hood.

10

Page 11

Installation Preparation

REMOVE THE PACKAGING

CAUTION: Wear gloves to protect

against sharp edges.

• Remove the duct covers.

• Remove the hardware bag, literature package

and other boxed parts.

• Remove and properly discard the protective

plastic wrapping and other packaging materials.

• Remove packing foam from behind the blower.

11

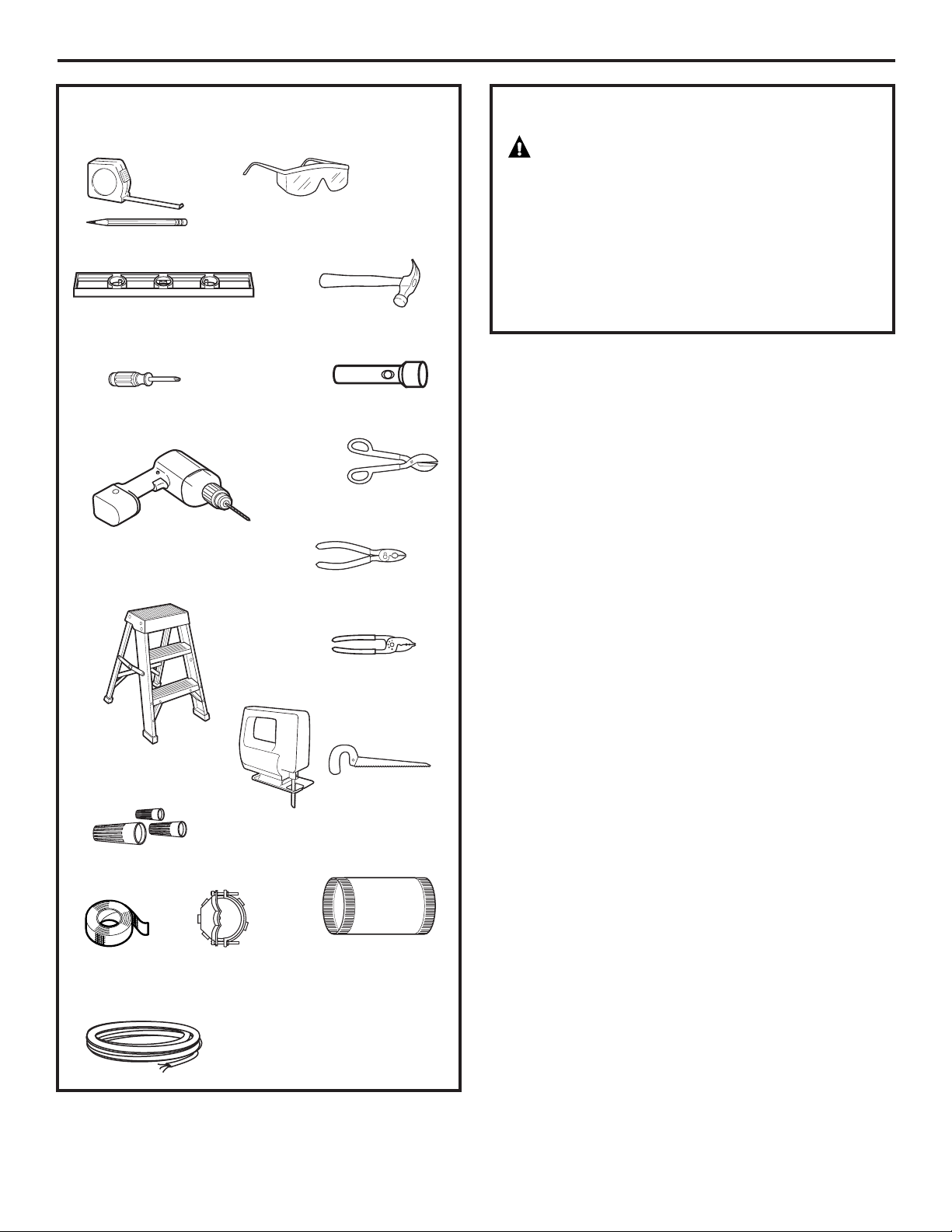

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

Pencil and tape measure

Pliers

Wire cutter/stripper

Metal snips

Spirit level

Aluminized

Duct tape

Safety glasses

120V 60Hz. 15 or 20 Amp,

2-wire with ground, properly

grounded branch circuit

Step ladder

Saber saw or Key Hole saw

Phillips screwdriver

Strain relief for

junction box

8" round metal

duct, length to

suit installation

Hammer

Electric drill with 3/16" bits,

#2 Phillips and flat head

Flashlight

UL listed wire nuts

Page 12

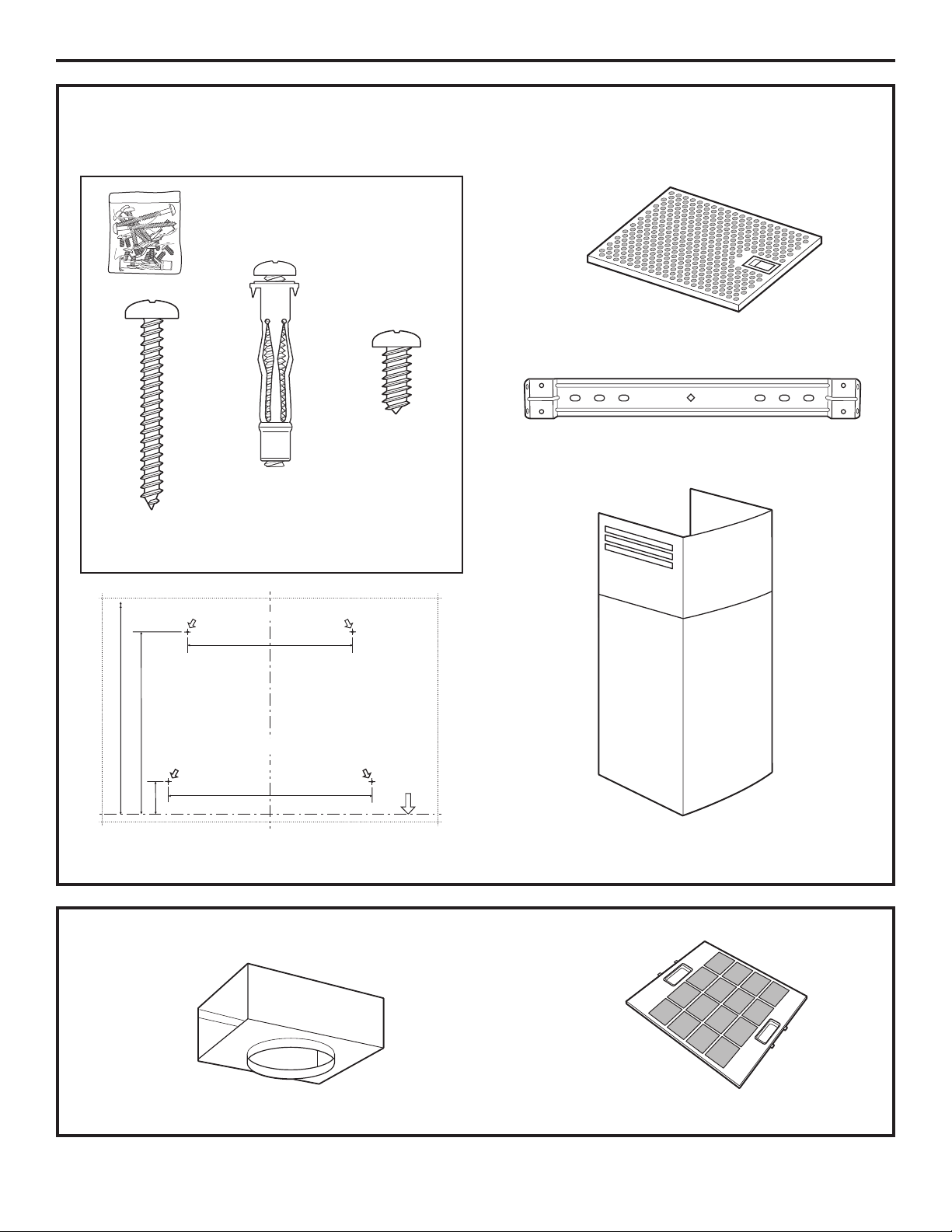

RECIRCULATING KIT (Included)

CHECK INSTALLATION HARDWARE

Locate the hardware package packed with the hood and check contents.

Installation Preparation

Stainless steel filter

Duct cover bracket

HARDWARE PACKAGE

Locate and count

screws

6 wood screws

(#10 1-3/4" long)

4 wall fasteners

(5/16")

(screw with

wall anchor)

8 duct cover

and air deflector

screws

(#8 thread forming

screw 3/8" long)

Charcoal filter

2-piece decorative

duct cover

Wall mount template

12

Air deflector

WALLVENT IS27-3/4" MIN.

ABOVE THEINSTALLATION

HEIGHT

11-7/16"

2"

Horizontal Line

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

10-1/8"

Ver

ti

cal C

e

nterline

MOUNTING TEMPLATE

C

L

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

12-1/2"

InstallationHeight

REAR WALL

ALIGN BOTTOMEDGE

WITH PENCILLINE

INDICATINGBOT TOM

OF THEHOOD

12-08JR

31-14772Printed inMexico

Page 13

13

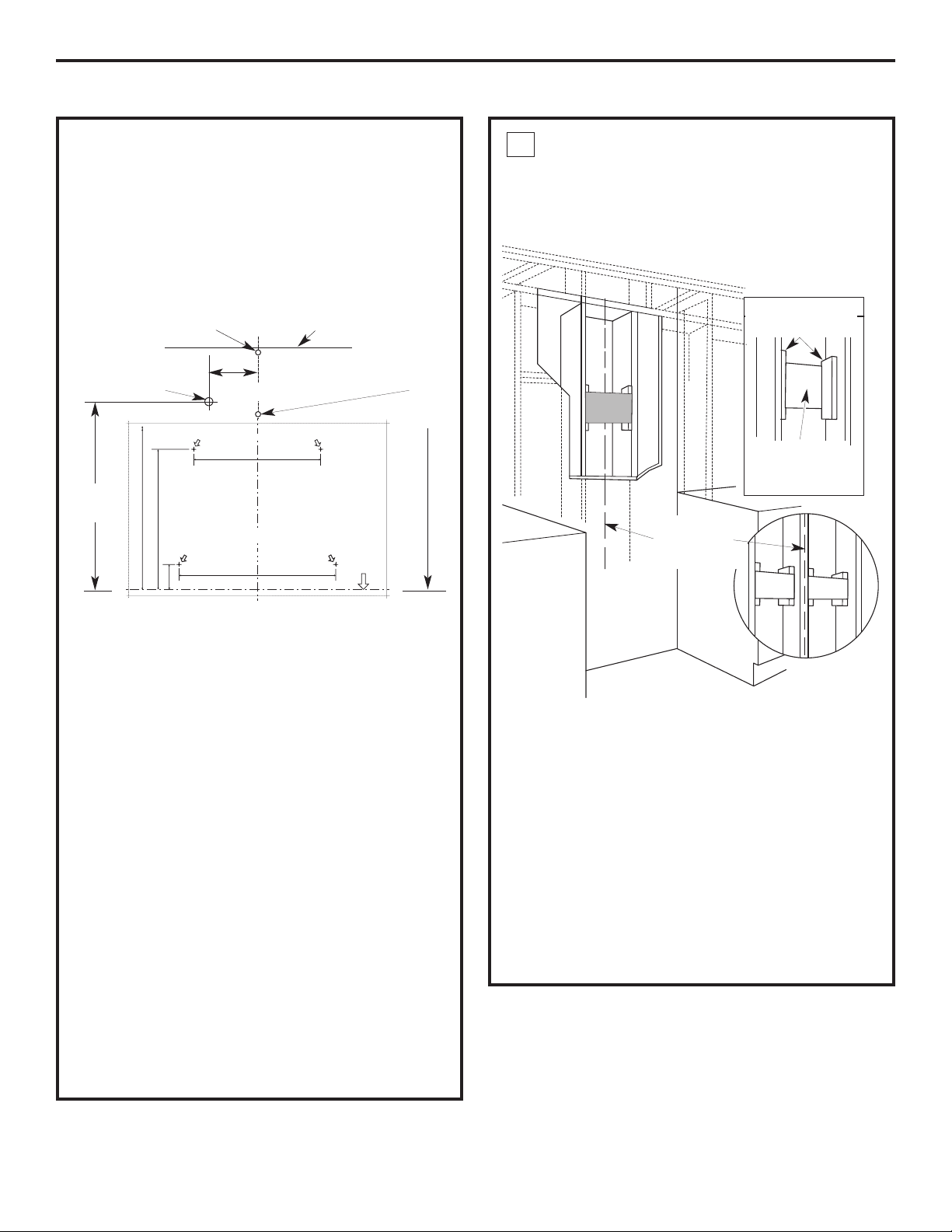

DETERMINE INSTALLATION HEIGHT

• Telescopic duct covers are provided to conceal

the ductwork running to the ceiling.

• This hood can be installed for recirculating

operation. Recirculating Kit included with hood.

NOTE: Installation height should be measured from

the cooking surface to the straight portion of the

hood.

The vent hood must be installed 24" min. and

30" max. above the cooking surface. The hood

installation height, from the cooking surface to the

bottom of the hood, depends upon ceiling height

and duct cover limitations.

Installation Preparation

24" Min.

30" Max.

36" Min.

*Based on 36" countertop height

PV970, PV976

Upper Duct Cover 25.81

Lower Duct Cover 27.56

Counter to Hood Height

Actual *Possible

Ceiling *Possible VENTED RECIRCULATING

Height Installation Height Installation Height

7' 11" 24" to 30" 24"

8' 0" 24" to 30" 24" to 25"

8' 1" 24" to 30" 24" to 26"

8' 2" 24" to 30" 24" to 27"

8' 3" 24" to 30" 24" to 28"

8' 4" 24" to 30" 24" to 29"

8' 5" 24" to 30" 24" to 30"

8' 6" 24" to 30" 24" to 30"

8' 7" 24" to 30" 24" to 30"

8' 8" 24" to 30" 24" to 30"

8' 9" 24" to 30" 24" to 30"

8' 10" 24" to 30" 24" to 30"

8' 11" 24" to 30" 24" to 30"

9' 0" 24" to 30" 24" to 30"

9' 1" 24" to 30" 24" to 30"

9' 2" 25" to 30" 24" to 30"

9' 3" 26" to 30" 24" to 30"

9' 4" 27" to 30" 24" to 30"

9' 5" 28" to 30" 24" to 30"

9' 6" 29" to 30" 24" to 30"

9' 7" 30" 25" to 30"

9' 8" 26" to 30"

9' 9" 27" to 30"

9' 10" 28" to 30"

9' 11" 29" to 30"

10' 0" 30"

10' 1"

10' 2"

10' 3"

Page 14

14

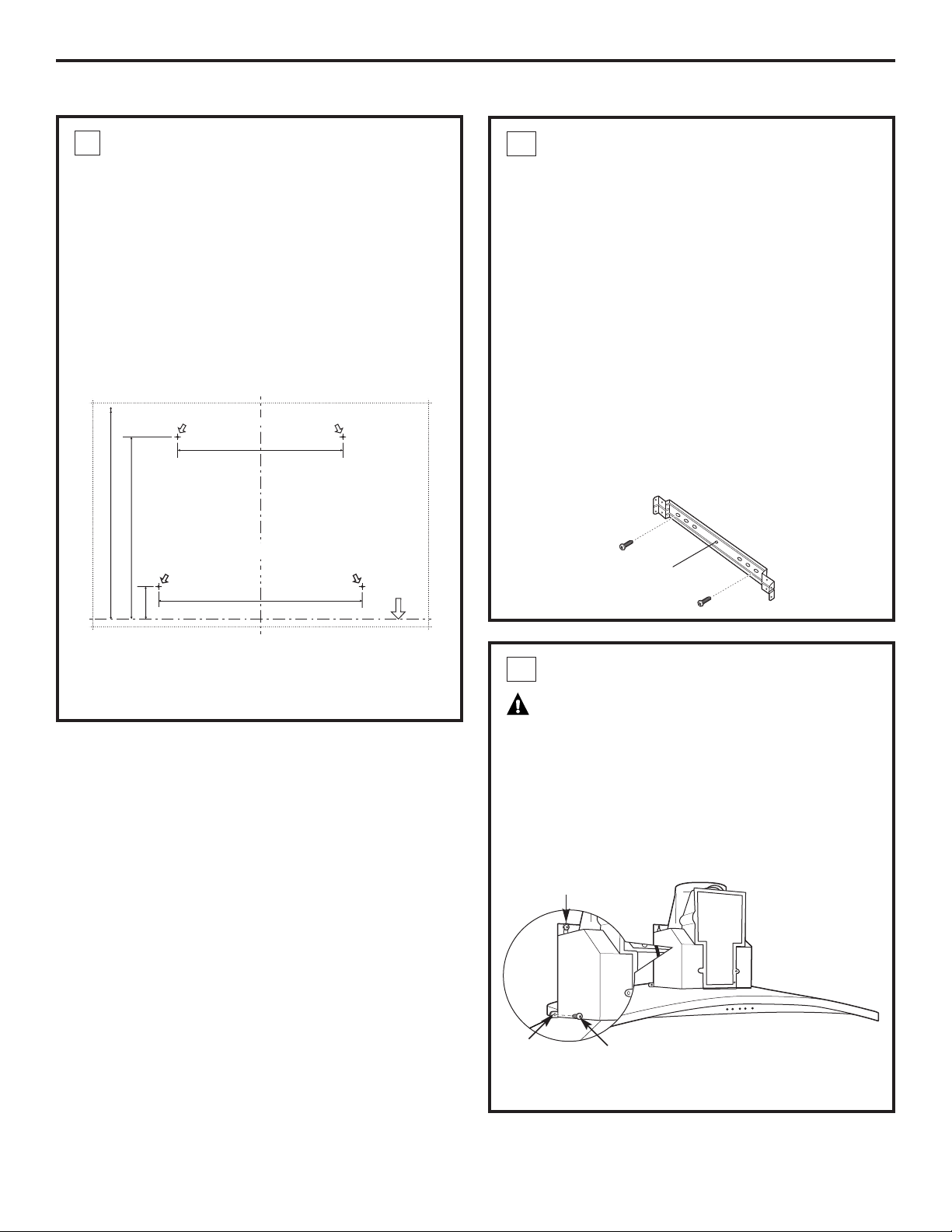

INSTALL FRAMING

FOR HOOD SUPPORT

IMPORTANT— Framing must be capable

of supporting 100 lbs.

If drywall is present, mark the screw hole locations

for the top mounting brackets. Remove the template.

• Cut away enough drywall to expose 2 vertical studs

at the bracket location indicated on the template.

• Install a horizontal support at least 1" x 12"

between two wall studs at the mounting screw

location. The horizontal support must be flush with

the room side of the studs. Use cleats behind both

sides of the support to secure to wall studs.

NOTE: 2 horizontal supports will be needed if there

is a stud located between the horizontal screw

locations (see figure).

IMPORTANT: Reinstall drywall for an even mounting

surface.

1

Installation Instructions

Centerline of

installation

space

View from

rear cleats

1" x 12" min.

mounting

support

DUCTWORK, WIRING LOCATIONS

Determine the exact location of the vent hood.

• Locate the template packed with the literature.

– Measure 36" from the floor to the top of the cooking

surface. Add hood installation height determined on

pages 8 and 13. Mark that location.

– Use a level to draw a straight pencil line on the wall.

– Tape the template in position along the penciled

line. CHECK TO BE SURE THE TEMPLATE IS LEVEL.

Ceiling ducting:

If ductwork will vent straight up to the ceiling:

• Use a level to draw a line straight up, from

the centerline on the template to the ceiling.

• Measure 5" from the back wall to the centerline

of an 8-1/2" hole on the ceiling.

NOTE: If drywall is not present, add drywall thickness

to the 5" dimension.

Wall Ducting:

If ductwork will vent to the rear:

• Use a level to draw a line straight up from

the centerline on the template.

• Measure at least 27-3/4" above the pencil line

that indicates the bottom installation height,

to the centerline of an 8-1/2" dia. duct hole.

(Hole may be elongated for duct elbow.)

HOUSE WIRING LOCATION:

• The junction box is located on the top left side

of the hood.

• Wiring should enter the back wall at least 18" above

the bottom of the hood and within 5" of the left side

of the centerline.

INSTALLATION—VENTED TO THE OUTSIDE

8-1/2" min. opening for ductwork

Ceiling

House Wiring

Location

C

L

5"

18"

Min.

Wall vent

27-3/4" min.

above

installation

height

5" c enterline to wall

WALLVENT IS27-3/4" MIN.

ABOVETHE INSTALLATION

HEIGHT

11-7/16"

DRILL2 (TWO)3/16" PILOTHOLESTHROUGH STUDSOR REARWALLSUPPORT

DRILL2 (TWO)3/16" PILOTHOLESTHROUGH STUDSOR REARWALLSUPPORT

2"

HorizontalLine

10-1/8"

Ver

ti

calC

e

nterline

REAR WALL

MOUNTING TEMPLATE

C

L

ALIGN BOTTOMEDGE

WITH PENCILLINE

INDICATINGBOTTOM

12-1/2"

InstallationHeight

OF THEHOOD

31-14772Printed inMexico

12-08JR

Page 15

Installation Instructions

INSTALL DUCT BRACKET

The duct bracket should be installed against the back wall

and flush with the ceiling; the point where the ceiling meets

the wall should be level for the bracket and duct cover to fit

flush. This bracket will hold the duct cover in place at the top.

Secure the bracket to the wall:

• Align the diamond centerline cutout on the bracket

with the penciled centerline on the wall.

• Mark 2 screw hole locations in the wall.

• Drill 1/8" pilot holes in the marked locations.

• If pilot holes do not enter wood studs, enlarge the holes

to 3/8" and install metal wall fastener anchors (provided).

• If mounting directly to a masonry wall, obtain appropriate

#10 masonry screw anchors. Drill and install per the

fastener supplier’s instructions.

• Drive screws, by hand, into the fasteners to allow anchors

to expand. Remove the screws.

• Secure the bracket to the wall with wood screws and/or

fasteners.

3

INSTALL HOOD MOUNTING SCREWS

The two upper mounting screws must enter the horizontal

support or wall studs.

• With the template taped in place, use a punch to mark

mounting bracket screw locations.

• Drill 1/8" pilot holes in 4 of the punched locations

in the lower bracket. If the bottom 2 pilot holes do not enter

wood, enlarge the holes to 3/8” and install metal wall

fastener anchors (provided).

• Remove the template.

• Install the 2 top mounting screws, leave 1/4" gap between

the screw head and the wall. This will allow the keyhole

slot on the hood frame to engage the screw head.

IMPORTANT:Use the mounting screws provided.

DO NOT USE DRYWALL SCREWS.

• Check to be sure the mounting screws are horizontally level.

2

Centerline cutout

MOUNT THE HOOD

WARNING: 2 people are required to lift

and position the hood onto the mounting screws.

• Lift the hood onto the mounting screws.

• If using a wall fastener, make sure the washer is in front

of the flange and not behind it. Check with a level before

tightening the screws.

• Install lower screws to pull the hood tight against the wall.

4

Tighten

screws

Install

screws

15

Bottom

screw

location

WALLVENT IS27-3/4" MIN.

ABOVE THEINSTALLATION

HEIGHT

11-7/16"

2"

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

Ver

ti

cal C

e

nterline

C

L

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

Horizontal Line

10-1/8"

MOUNTING TEMPLATE

12-1/2"

InstallationHeight

REAR WALL

ALIGN BOTTOMEDGE

WITH PENCILLINE

INDICATINGBOT TOM

OF THEHOOD

31-14772Printed inMexico

12-08JR

Page 16

16

Installation Instructions

INSTALLATION—VENTED TO THE OUTSIDE

CONNECT DUCTWORK

• Remove shipping tape from the damper.

• Install ductwork, making connections

in the direction of airflow as illustrated.

• Push duct over the exhaust outlet and damper.

• Secure joints in ductwork with sheet metal screws.

• Wrap all duct joints and the flange connections

with aluminized duct tape for an airtight seal.

CAUTION:Do not use sheet metal

screws at the hood flange connection. Doing so will

prevent proper damper operation. Seal connection

with tape only.

5

Duct tape

over seam

and screw

Screw

Airflow

CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING: If house wiring is not 2-wire

with a ground wire, a ground must be provided

by the installer. When house wiring is aluminum,

be sure to use U.L. approved anti-oxidant compound

and aluminum-to-copper connectors.

• Remove the 6 screws on the junction box cover

and the knockout on the top left side.

• Secure the house wiring to the junction box with

a strain relief (not provided).

• Connect the white lead to the branch circuit white lead.

• Connect the black lead to the branch circuit black lead.

• Connect the green/yellow lead to the branch

circuit green lead or bare ground lead.

• Secure all the connections with wire nuts on each

electrical connector.

• Push the wires into the junction box and replace

the cover. Be sure the wires are not pinched.

• Secure the junction box cover with the 6 original

screws.

6

Junction

box cover

Knockout

Page 17

Installation Instructions

INSTALL DUCT COVERS

• Remove protective plastic

covering.

• Assemble duct covers

according to application.

NOTE: The inside duct cover has vent

holes on one end. The holes are intended

for use when the hood is installed for

recirculating purposes. Slide the upper duct cover

into the folded ends of the lower duct cover.

• Place the decorative duct covers on top of the hood.

7

Mounting

screws

Lower duct

cover seat

Duct cover bracket

Lower duct

cover

Upper duct

cover

Duct cover

attachment tabs

17

• Extend the inner duct cover upward to the ceiling

bracket.

•

Secure with 2 screws to the duct cover bracket.

•

Remove the packing material from the filter

opening.

• Locate the screw holes on the inside front edge

of the opening. Install 2 screws to secure the lower

duct cover to the hood.

Screw holes

INSTALL METAL GREASE FILTER

• Remove the protective film on the grease filter.

NOTE: The charcoal filter is not required for this

installation.

• Fit the tabs at the end of the filter into the slots

in the left side of the filter opening. Lift up the

right side of the filter and push gently until the

filter locks into place. Make sure the filter lock

is in the closed position to secure the filter.

• To remove the filter, pull downward on the filter

lock to release.

8

FINALIZE INSTALLATION

• Check to be sure all tape and packaging materials

have been removed.

• Refer to the Operating Instructions in this manual

to operate the hood.

9

Page 18

Installation Instructions

18

INSTALLATION—RECIRCULATING

DUCTWORK, WIRING LOCATIONS

• Determine the exact location of the vent hood.

• Locate the template packed with the literature.

• Measure 36" from the floor to the top of the cooking

surface. Add hood installation height determined on

pages 8 and 13. Mark that location.

• Tape the template in position along the penciled line.

CHECK TO BE SURE THE TEMPLATE IS LEVEL.

• Use a level to draw a line straight up, from

the centerline on the template to the ceiling.

HOUSE WIRING LOCATION:

• The junction box is located on the top left side

of the hood.

• Wiring should enter the back wall at least 18"

above the bottom of the hood, and within 5"

of the centerline.

INSTALL FRAMING

FOR HOOD SUPPORT

IMPORTANT: Framing must be capable

of supporting 100 lbs.

If drywall is present, mark the screw hole locations

for the top mounting brackets. Remove the template.

• Cut away enough drywall to expose 2 vertical studs

at the bracket location indicated on the template.

• Install a horizontal support at least 1" x 12"

between two wall studs at the mounting screw

location. The horizontal support must be flush with

the room side of the studs. Use cleats behind both

sides of the support to secure to wall studs.

NOTE: 2 horizontal supports will be needed if there

is a stud located between the horizontal screw

locations (see figure).

IMPORTANT: Reinstall drywall for an even mounting

surface.

1

Ceiling

House Wiring

Location

C

L

5"

18"

Min.

View from

rear cleats

1" x 12" min.

mounting

support

Centerline of

installation

space

5" c enterline to wall

WALLVENT IS27-3/4" MIN.

ABOVETHE INSTALLATION

HEIGHT

11-7/16"

DRILL2 (TWO)3/16" PILOTHOLES THROUGHSTUDSOR REARWALL SUPPORT

DRILL2 (TWO)3/16" PILOTHOLES THROUGHSTUDSOR REARWALL SUPPORT

2"

HorizontalLine

10-1/8"

Ver

ti

calC

e

nterline

C

L

12-1/2"

REAR WALL

MOUNTING TEMPLATE

InstallationHeight

ALIGN BOTTOMEDGE

WITH PENCILLINE

INDICATINGBOTTOM

OF THEHOOD

31-14772Printed inMexico

12-08JR

Page 19

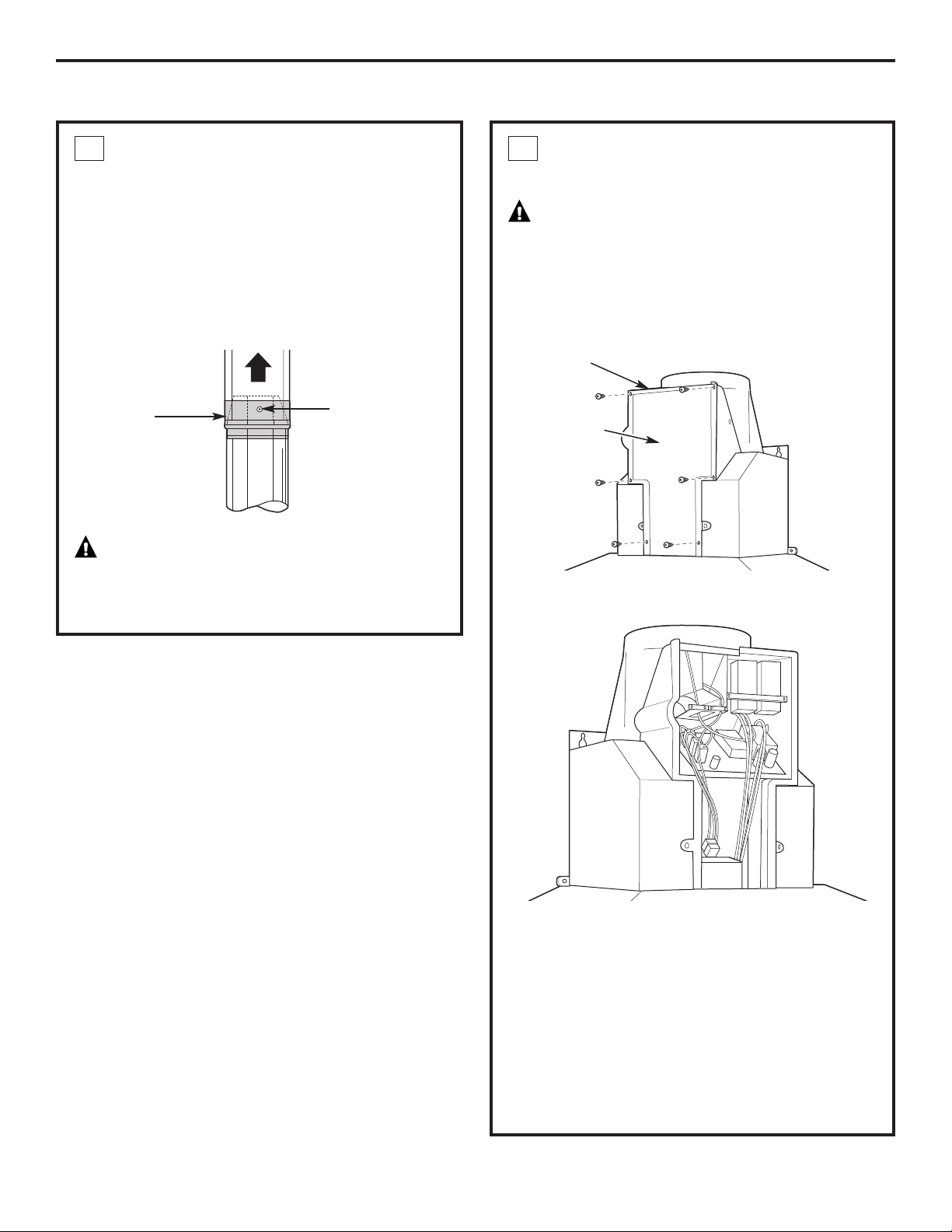

INSTALL DUCT BRACKET

AND DEFLECTOR

The duct bracket should be installed against the back

wall and flush with the ceiling; the point where the

ceiling meets the wall should be level for the bracket

and duct cover to fit flush. This bracket will hold

the duct cover in place at the top.

Secure the bracket to the wall:

• Align the diamond centerline cutout on the bracket

to the penciled centerline on the wall.

• Mark 2 screw hole locations in the wall.

• Drill 1/8" pilot holes in the marked locations.

• If pilot holes do not enter wood studs, enlarge

the holes to 3/8" and install metal wall fastener

anchors (provided).

• If mounting directly to a masonry wall, obtain

appropriate #10 masonry screw anchors. Drill

and install per the fastener supplier’s instructions.

• Drive screws, by hand, into the fasteners to allow

anchors to expand. Remove the screws.

• Secure the bracket to the wall with wood screws

and/or fasteners.

• Assemble the air deflector accessory to the duct

cover bracket with the 4 assembly screws provided.

DO NOT tighten screws. This is a temporary

installation.

3

Installation Instructions

INSTALL HOOD MOUNTING SCREWS

The mounting screws must enter the horizontal

support or wall studs.

• With the template taped in place, use a punch

to mark mounting bracket screw locations.

• Drill 1/8" pilot holes in 4 of the punched locations

in the lower bracket. If the bottom 2 pilot holes do

not enter wood, enlarge the holes to 3/8” and install

metal wall fastener anchors (provided).

• Remove the template.

• Install the 2 top mounting screws; leave 1/4" gap

between the screw head and the wall. This will allow

the keyhole slot on the hood frame to engage the

screw head.

IMPORTANT:Use the mounting screws provided.

DO NOT USE DRYWALL SCREWS.

• Check to be sure the mounting screws are

horizontally level.

2

Centerline cutout

19

WALLVENT IS27-3/4" MIN.

ABOVE THEINSTALLATION

HEIGHT

11-7/16"

2"

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

Ver

ti

cal C

e

nterline

C

L

DRILL 2 (TWO) 3/16"PILOT HOLESTHROUGH STUDSOR REARWALL SUPPORT

Horizontal Line

10-1/8"

MOUNTING TEMPLATE

12-1/2"

InstallationHeight

REAR WALL

ALIGN BOTTOMEDGE

WITH PENCILLINE

INDICATINGBOT TOM

OF THEHOOD

31-14772Printed inMexico

12-08JR

Page 20

Installation Instructions

20

SIZE AND CUT DUCT PIECE

• Measure from the bottom of the air deflector

to the top of the hood as shown. Reduce that

dimension by 1" to facilitate installation.

The duct will cover and overlap the deflector

and the exhaust outlet in the hood.

• Remove the air deflector from the duct cover

bracket.

• Cut the duct piece to size and slip onto the bottom

of the deflector.

• Place the assembled deflector and duct over

the exhaust outlet.

• Hold the assembly against the duct bracket.

• Drive 2 screws into each side of the bottom

of the deflector and into the bracket.

• Use duct tape to seal duct to the deflector

and at the exhaust outlet.

5

Measure

length

Duct

length

Deflector

INSTALLATION—RECIRCULATING

MOUNT THE HOOD

WARNING: 2 people are required to lift

and position the hood onto the mounting screws.

• Lift the hood onto the mounting screws.

• If using a wall fastener, make sure the washer

is in front of the flange and not behind it. Check

with a level before tightening screws.

• Install lower screws to pull the hood tight against

the wall.

4

Tighten

screws

Install

screws

Bottom

screw

location

Page 21

21

Installation Instructions

CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING: If house wiring is not 2-wire

with a ground wire, a ground must be provided

by the installer. When house wiring is aluminum,

be sure to use U.L. approved anti-oxidant compound

and aluminum-to-copper connectors.

• Remove the 6 screws on the junction box cover

and the knockout on the top left side.

• Secure the house wiring to the junction box

with a strain relief.

• Connect the white lead to the branch circuit white lead.

• Connect the black lead to the branch circuit black lead.

• Connect the green/yellow lead to the branch

circuit green lead or bare ground lead.

• Secure all the connections with wire nuts on each

electrical connector.

• Push the wires into the junction box and replace

the cover. Be sure the wires are not pinched.

• Secure the junction box cover with the 6 original

screws.

6

Junction

box cover

INSTALL DUCT COVERS

• Remove protective plastic

covering.

• Assemble duct covers

according to application.

NOTE: The upper duct cover

has vent holes on one end

intended for use when the hood

is installed for recirculating

purposes. Be sure the vented

end is at the top; the vent holes

will be visible in this installation.

Slide the upper duct cover into

the folded ends of the lower duct cover.

• Place the decorative duct covers on top of the hood.

• Extend the inner duct cover upward to the ceiling

bracket.

•

Secure with 2 screws to the duct cover bracket.

•

Remove the packing material from the filter opening.

• Locate the screw holes on the inside front edge

of the opening. Install 2 screws to secure the lower

duct cover to the hood.

7

Mounting screws

Vent holes

Lower duct

cover seat

Duct cover

support bracket

Lower duct

cover

Upper duct

cover

Duct cover

attachment tabs

Knockout

Screw holes

Page 22

Installation Instructions

INSTALL FILTERS

Charcoal Filter

Insert the charcoal filter into the opening.

Push the latch on both sides toward the center

and engage the flange.

Metal Grease Filter

• Remove the protective film on the grease filter.

• Fit the tabs at the end of the filter into the slots

in left side of the filter opening. Lift up the right

side of the filter and push gently until the filter

locks into place. Make sure the filter lock is

in the closed position to secure the filter.

• To remove the filter, pull downward on the filter

lock to release.

8

FINALIZE INSTALLATION

• Remove all tape and packaging materials.

• Refer to the Operating Instructions in this manual

to operate the hood.

9

22

INSTALLATION—RECIRCULATING

Page 23

Consumer Support

Troubleshooting TipsOperating Instructions

Safety Instructions

Care and Cleaning

Before you call for service…

Troubleshooting Tips

Save time and money! Review the chart below first

and you may not need to call for service.

Problem Possible Causes What To Do

Fan/Light does not A house fuse may be blown • Replace fuse or reset circuit breaker.

operate when either or a circuit breaker tripped.

button is pressed

Fan does not operate The blower connector is loose •Disconnect power to the unit. Remove the filters

when fan + or – buttons or not plugged into its mating and look up at the blower. If the blower connector

or MEMORY/OFF button connector. plug is loose or you see the connector dangling,

is pressed the installer failed to plug it in securely. See the

Installation Instructions for the plug location and how

to plug in the connector.

Loud or abnormal Wrong duct size used in •This hood requires 8" ducting and a maximum duct

airflow noise installation. length of 100 equivalent feet to perform optimally.

Using smaller duct pipe or longer equivalent lengths

of duct pipe will cause improper venting. GE service

technicians cannot correct this issue if installed

improperly.

Fan fails to circulate air Obstructions in duct work. •Make sure nothing is blocking the vent. Make sure

or moves air slower your wall or roof cap has a blade or door.

than normal and/or fan

Damper blade on wall or roof •Make sure damper swings freely. Damper blades may

is making loud or

cap may not be open. flip over and will not fully open when this happens.

abnormal airflow noise

Adjust to original position.

Metal grease filter and charcoal •Clean the metal grease filter and replace charcoal

filter (if present) may be dirty. filter (if present). See Care and Cleaning of the Vent

Hood.

The hood controls are Control logic confused. •Disconnect power to the hood by resetting the circuit

not operating correctly breaker. Wait 30 seconds to allow controls to reset.

Early bulb failure Replacing bulbs with bare hands.•Replace bulbs while wearing gloves to keep skin oils

off bulbs.

•Bulb wattage is too high. Replace with correct

wattage.

Hood does not appear The memory feature of this •Follow procedures for setting the MEMORY/OFF

to operate when the hood has not been set. This is button. Adjust the Fan and Light settings to your

MEMORY/OFF button normal. preference.

is pressed. All collars

around the push buttons

are illuminated.

23

Page 24

24

Consumer Support Troubleshooting Tips Operating Instructions Safety InstructionsCare and Cleaning

Before you call for service…

Troubleshooting Tips

Save time and money! Review the chart below first

and you may not need to call for service.

Problem Possible Causes What To Do

Fan turned on by itself The heat sensor is activated. •This is normal when temperatures below the hood

and is in MED setting. are exceeding the heat sensor limits. Remove the heat

The fan setting can be source under the hood or wait until the hood cools to

adjusted but not to OFF. appropriate levels. The hood will automatically turn

itself off or return to its original setting once the heat

sensor detects the temperature has reached a safe

condition.

A collar around a push Push button may be stuck. • Check affected push button and ensure that it is not

button is not illuminating stuck. Call for service if problem persists.

when pressed.

Two or more collars Two or more push buttons • Check affected push buttons and ensure that they

around the push buttons may be stuck. are not stuck. Call for service if problem persists.

are not illuminating

when pressed.

Sequential presses This is normal. It is a feature •No action required.

of the LIGHT or FAN of the hood that the LIGHT

buttons will change and FAN buttons will cycle

the setting from lowest around through the settings

setting to OFF, to so that you can easily set

highest setting, to OFF, the controls to your desired

to the lowest setting. setting.

Page 25

GE Range Hood Warranty.

For The Period Of: GE Will Replace:

One Year Any part of the range hood which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor

original purchase and in-home service to replace the defective part.

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused,

or used for other than the intended purpose

or used commercially.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Damage caused after delivery.

■ Product not accessible to provide required service.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available,

you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service

Location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule

service on-line, visit us at ge.com, or call 800.GE.CARES

(800.432.2737). Please have serial number and model number

availa ble when calling for service.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Consumer Support

Troubleshooting TipsOperating Instructions

Safety Instructions

Care and Cleaning

25

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided

in this Limited Warranty. Any implied warranties, including the implied warranties of merchantability

or fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

Page 26

Register Your Appliance ge.com

Register your new appliance on-line—at your convenience! Timely product registration will allow for

enhanced communication and prompt service under the terms of your warranty, should the need arise.

You may also mail in the pre-printed registration card included in the packing material.

Consumer Support.

GE Appliances Website

ge.com

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order parts or even schedule service on-line.

Schedule Service ge.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

Real Life Design Studio ge.com

GE supports the Universal Design concept—products, services and environments that can be used by

people of all ages, sizes and capabilities. We recognize the need to design for a wide range of physical and

mental abilities and impairments. For details of GE’s Universal Design applications, including kitchen design ideas

for people with disabilities, check out our Website today. For the hearing impaired, please call 800.TDD.GEAC

(800.833.4322).

Extended Warranties ge.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty

is still in effect. You can purchase it on-line anytime, or call 800.626.2224 during normal business hours.

GE Consumer Home Services will still be there after your warranty expires.

Parts and Accessories ge.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone

at 800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

Contact Us ge.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Printed in Mexico

26

Page 27

Campanas de ventilación

de chimenea

Profile

49-80549 12-08 JR

Instrucciones

de Seguridad . . . . . . . . . . . . . . 2, 3

Instrucciones de Operación

Controles de la luz . . . . . . . . . . . . . . .4

Controles de la ventilación . . . . . . .4

Cuidado y limpieza

Filtros de grasa . . . . . . . . . . . . . . . . . .5

Luces de la campana . . . . . . . . . . . .6

Superficies de acero inoxidable . . .6

Instrucciones de instalación

Preparación para

la instalación . . . . . . . . . . . . . . . . .7-13

Ventilación hacia

el exterior . . . . . . . . . . . . . . . . . . .14-17

Recirculación . . . . . . . . . . . . . . . .18-22

Consejos para

la identificación y solución

de problemas . . . . . . . . . . . . .23, 24

Apoyo al cliente

Apoyo al cliente . . . . . . . . . . . . . . . . 26

Garantía . . . . . . . . . . . . . . . . . . . . . . . 25

Escriba los números

de modelo y de serie aquí:

Modelo # ______________

Serie #

________________

Usted puede encontrarlos en

una etiqueta ubicada en la parte

interna de la campana.

PV970

PV976

Manual del Propietario

e Instrucciones

de Instalación

ge.com

Page 28

PRECAUCIONES DE SEGURIDAD

INFORMACIÓN IMPORTANTE DE SEGURIDAD.

LEA TODAS LAS INSTRUCCIONES ANTES DE SU USO.

ADVERTENCIA – PARA REDUCIR

EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA

O LESIONES A PERSONAS, CUMPLA CON LOS

SIGUIENTES PUNTOS:

A. Utilice esta unidad sólo de la manera concebida

por el fabricante. Si tiene alguna pregunta,

comuníquese con el fabricante.

B. Antes de realizar reparaciones o limpiar

la unidad, desconecte la energía del panel

de servicio y bloquee los medios de desconexión

para evitar el accionamiento de la energía

de manera accidental. Cuando los medios

de desconexión de servicio no pueden

bloquearse, coloque sobre el panel de servicio

un dispositivo de advertencia bien visible, como

una etiqueta.

C. No utilice esta unidad con ningún dispositivo

de control de velocidad de estado sólido.

D. Esta unidad debe contar con conexión a tierra.

PRECAUCIÓN – Sólo para

ventilación general. No lo utilice para ventilar

materiales o vapores peligrosos o explosivos.

PRECAUCIÓN – Para reducir

el riesgo de incendio y para eliminar el aire

de escape correctamente, asegúrese de dirigir el aire

del conducto hacia el exterior. No ventile el aire

de escape en espacios dentro de paredes

o cielorrasos o en áticos, huecos sanitarios o garajes.

ADVERTENCIA – PARA REDUCIR

EL RIESGO DE LESIONES A PERSONAS SI SE

PRODUCE UN INCENDIO DE GRASA EN LA ESTUFA,

CUMPLA CON LOS SIGUIENTES PUNTOS*:

A. APAGUE LAS LLAMAS con una tapa que ajuste

bien, una plancha para galletas o bandeja

de metal, y luego apague el quemador.

TENGA CUIDADO A FIN DE EVITAR QUEMADURAS.

Si las llamas no se apagan de inmediato, SALGA

DE LA VIVIENDA Y LLAME AL DEPARTAMENTO

DE BOMBEROS.

B. NUNCA LEVANTE UNA SARTÉN EN LLAMAS—

Usted puede quemarse.

C. NO UTILICE AGUA, incluyendo repasadores

o toallas húmedos—se provocará una violenta

explosión de vapor.

D. Utilice un extintor SÓLO si:

1. Usted sabe que cuenta con un extintor Clase

ABC y ya sabe cómo utilizarlo.

2. El incendio es pequeño y se contuvo

en el área donde comenzó.

3. Se está llamando al departamento

de bomberos.

4. Usted puede combatir el incendio con

su espalda apuntando hacia una salida.

* Basado en “Consejos de seguridad sobre incendio

en la cocina” publicado por NFPA.

2

Apoyo al Cliente

Solucionar Problemas

Instrucciones

de Operación

Instrucciones

de Seguridad

Cuidado y Limpieza

Page 29

LEA Y SIGA ESTA INFORMACIÓN DE SEGURIDAD CUIDADOSAMENTE.

LEA Y GUARDE ESTAS INSTRUCCIONES

PRECAUCIONES DE SEGURIDAD

ge.com

ADVERTENCIA – PARA REDUCIR

EL RIESGO DE UN INCENDIO DE GRASA SOBRE

UNA ESTUFA:

A. Nunca deje unidades de superficie desatendidas

en configuraciones de calor elevadas. Los

alimentos que hierven y se derraman provocan

humo y derrames grasosos que pueden

prenderse fuego. Caliente los aceites lentamente

en configuraciones bajas o medias.

B.

Siempre encienda (ON) la campana cuando

cocine con configuraciones elevadas o cuando

flambee alimentos (por ej., Crepes Suzette, cerezas

Jubilee, carne flambeada a la pimienta en grano).

C. Limpie los ventiladores con frecuencia.

No debe permitirse la acumulación de grasa

en el ventilador o en el filtro.

D. Utilice el tamaño de recipiente adecuado.

Siempre utilice recipientes de cocción

apropiados para el tamaño del elemento

de superficie.

ADVERTENCIA – PARA REDUCIR

EL RIESGO DE INCENDIO, DESCARGA

ELÉCTRICA O LESIONES A PERSONAS, CUMPLA

CON LOS SIGUIENTES PUNTOS:

A. El trabajo de instalación y el cableado eléctrico

deben realizarlo personas calificadas

en cumplimiento con todos los códigos

y normas aplicables, incluyendo construcción

con clasificación para incendios.

B. Se necesita suficiente aire para una combustión

y escape de gases adecuados a través

de la ventilación (chimenea) de equipamiento

de combustión de combustible para evitar

la contracorriente. Siga las pautas y normas

de seguridad de fabricante del equipamiento

de calefacción, tales como las publicadas por

la Asociación Nacional de Protección contra

Incendios (NFPA), la Sociedad Estadounidense

de Ingenieros en Calefacción, Refrigeración

y Aire Acondicionado (ASHRAE) y las autoridades

de códigos locales.

C. Cuando realice cortes o perforaciones dentro

de paredes o cielorrasos, no dañe el cableado

eléctrico y otros servicios públicos ocultos.

D. Los sistemas de conductos siempre deben

contar con una salida al exterior.

ADVERTENCIA – PARA REDUCIR

EL RIESGO DE INCENDIO, SÓLO UTILICE

CONDUCTOS DE METAL.

■ No intente reparar o cambiar ninguna pieza

de su campana a menos que esté

específicamente recomendado en este manual.

Cualquier otro servicio debe realizarlo un técnico

calificado.

3

Apoyo al Cliente

Solucionar Problemas

Instrucciones

de Operación

Instrucciones

de Seguridad

Cuidado y Limpieza

Page 30

Cómo usar los controles de la campana.

4

MEMORY/OFF (memoria/apagado).

Para configurar la memoria:

A. Presione el botón MEMORY/OFF.

B. Ingrese las configuraciones deseadas

de ventilación y de luz.

C. Presione el botón MEMORY/OFF de nuevo para

guardar estas configuraciones.

Con sus configuraciones deseadas en la memoria,

presione el botón MEMORY/OFF para restablecer

los niveles de ventilación y de luz a sus

configuraciones guardadas. Estas configuraciones

permanecerán en la memoria hasta que se

modifiquen u ocurra un corte de energía.

Para apagar la campana, presione el botón

MEMORY/OFF.

LIGHT (luz). Presione + o – para subir o bajar el nivel

de luz hasta la configuración deseada. Hay dos

niveles de luz (LOW [bajo], HIGH [alto]) y OFF

(apagado). Si continúa presionando los botones

+ o – , la luz se desplazará a través de las

configuraciones.

NOTA: Controle que sólo se instalen bombillas

de 20 vatios (máximo).

FAN (ventilador). Presione + o – para subir o bajar

el nivel del ventilador hasta la configuración

deseada. Hay 4 niveles de ventilación (LOW, MED

[medio], HIGH, BOOST [impulso]) y OFF. Si continúa

presionando los botones + o – , el ventilador

se desplazará a través de las configuraciones.

NOTA: Puede oírse un pitido cada vez que

se presiona un botón. Esto es normal.

NOTA: Los collarines ubicados alrededor

de los botones se iluminan cuando se presionan

los botones. Esto es normal. Los collarines

se apagan en forma automática cuando se apaga

la campana.

SENSOR DE CALOR:

Esta campana cuenta con un sensor de calor que

enciende el ventilador si se detectan temperaturas

excesivas (más de 70 ˚C/158 ˚F) sobre la superficie

de cocción. La campana volverá a su funcionamiento

normal una vez que el sensor de calor detecte

temperaturas por debajo de 60 ˚C/140 ˚F.

NOTA: Si la campana está OFF o en una velocidad de

ventilación LOW, se detectan temperaturas por encima

de 70 ˚C/158 ˚F; luego el ventilador se ajustará

automáticamente a la velocidad MED. Usted puede

ajustar la velocidad de ventilación a HIGH o BOOST,

pero no podrá ajustar la velocidad del ventilador a LOW

o OFF hasta que se detecten temperaturas por debajo

de 60 ˚C/140 ˚F.

NOTA: Los collarines ubicados alrededor de los botones

pueden no iluminarse si se activa el sensor de calor. Esto

es normal.

Apoyo al Cliente

Solucionar Problemas

Instrucciones

de Operación

Instrucciones

de Seguridad

Cuidado y Limpieza

Page 31

Cuidado y limpieza de la campana de ventilación. ge.com

Asegúrese de que la energía eléctrica esté apagada y que todas las superficies estén frías antes de limpiar

o arreglar cualquier pieza de la campana de ventilación.

El filtro metálico atrapa la grasa

liberada por los alimentos desde

la estufa. El filtro también ayuda

a evitar que las llamas (de los

alimentos, grasa) dañen la parte

interna de la campana.

Por esta razón, el filtro debe estar

SIEMPRE en su lugar cuando la

campana esté en funcionamiento.

El filtro de grasa es apto para

lavavajillas y debe limpiarse cada

6 meses, o según sea necesario.

Para quitar:

Tire hacia abajo la traba del filtro

para liberarlo.

Para volver a colocar:

Coloque las lengüetas del extremo

del filtro dentro de las ranuras del

lado izquierdo de la abertura del

filtro. Levante el lado derecho del

filtro y presione ligeramente hasta

que el filtro se trabe en su lugar.

Verifique que la traba del filtro se

encuentre en la posición cerrada

para asegurar el filtro.

Para limpiar el filtro, utilice agua

jabonosa caliente y enjuague con

agua limpia o lávelo en el

lavavajillas. No utilice productos

de limpieza abrasivos.

NOTA: En el lavavajillas se

producirá una leve decoloración.

Filtro de grasa metálico

5

Si el modelo no tiene ventilación al

exterior, el aire se recirculará a través

de un filtro de carbón desechable

que ayuda a remover humo y olores.

El filtro de carbón debe cambiarse

cuando esté evidentemente sucio

o decolorado (usualmente después

de 6 a 12 meses, dependiendo del

uso de la campana).

NOTA: NO enjuague o coloque el

filtro de carbón en el lavavajillas

automático.

El filtro de carbón no puede

limpiarse. Debe cambiarse.

Solicite el filtro de carbón

WB02X11348.

Para consultar sobre la compra

de filtros de carbón de repuesto

o para encontrar la ubicación

del distribuidor más cercano

a su domicilio, llame a nuestro

número gratuito:

Centro nacional de piezas

800.626.2002

Para quitar:

1. Quite el filtro metálico—ver la

sección Filtro de grasa metálico.

2. Quite el filtro de carbón

presionando sobre las dos manijas

de las lengüetas de bloqueo.

Para volver a colocar:

1. Introduzca el filtro de carbón

dentro de la abertura. Presione

las manijas de las lengüetas

de bloqueo hacia el centro

y libérelas para sujetar

las lengüetas de bloqueo.

2. Vuelva a colocar el filtro metálico—

ver la sección Filtro de grasa

metálico.

Filtro de carbón (sólo para instalación con recirculación)

Manija de la lengüeta de bloqueo

Manija de la lengüeta de bloqueo

Apoyo al Cliente

Solucionar Problemas

Instrucciones

de Operación

Instrucciones

de Seguridad

Cuidado y Limpieza

Page 32

6

Cuidado y limpieza de la campana de ventilación.

Asegúrese de que la energía eléctrica esté apagada y que todas las superficies estén frías antes de limpiar

o arreglar cualquier pieza de la campana de ventilación.

No utilice almohadillas de acero

porque rayan la superficie.

Para limpiar la superficie de acero

inoxidable, utilice agua tibia

jabonosa o un limpiador o lustrador

de acero inoxidable. Siempre limpie

la superficie en dirección de la veta.

Siga las instrucciones del producto

para limpiar la superficie de acero

inoxidable.

Para consultar sobre la compra

de limpiadores o lustradores

de aparatos de acero inoxidable,

o para encontrar la ubicación del

distribuidor más cercano, llame

a nuestro número gratuito:

Centro nacional de piezas

800.626.2002

ge.com

Superficies de acero inoxidable

Bombillas de luz

PRECAUCIÓN:

Antes de tocarlas, espere a que las bombillas

se enfríen.

Para cambiar las bombillas de luz:

1. Quite la tapa de la bombilla

introduciendo un destornillador plano

dentro de las tres ranuras y liberándolas

con cuidado.

NOTA: No quite el anillo exterior

(montaje de la bombilla).

2. Utilice guantes. No toque la bombilla

con las manos desnudas. Los aceites

de la piel pueden provocar una falla

temprana de la bombilla.

3. Tome la bombilla y quítele directamente

hacia afuera.

4. Coloque una bombilla de repuesto

del mismo vataje. Si el vataje es muy

elevado pueden producirse daños

prematuros de la bombilla o daños

o fallas en el transformador.

Estas bombillas halógenas de

12 voltios, 20 vatios con una base G4

se encuentran disponibles en tiendas

especializadas en iluminación y centros

de construcción.

Para solicitar una bombilla de repuesto

N° WB01X10239, comuníquese con

el Centro nacional de piezas GE

al 800.626.2002 o adquiérala

en su minorista local.

5. Vuelva a colocar la tapa de la bombilla

introduciendo las tres lengüetas de

retención dentro de las tres ranuras

y presionando firmemente en su lugar.

Utilice un destornillador plano para

quitar la tapa de la bombilla.

Anillo exterior

(montaje de la bombilla)

No lo quite

Bombilla

Tapa de la bombilla

interior desmontable

NOTA: Asegúrese de que las lengüetas estén colocadas

en las ranuras.

Lengüeta

Apoyo al Cliente

Solucionar Problemas

Instrucciones

de Operación

Instrucciones

de Seguridad

Cuidado y Limpieza

Page 33

7

¿Preguntas? Llame al 800.GE.CARES (800.432.2737) o visite nuestro sitio Web en: ge.com

Instrucciones

Campanas de ventilación

de instalación

de chimenea

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

•

IMPORTANTE — Guarde estas

instrucciones para el uso de inspectores locales.

•

IMPORTANTE — Cumpla con todos los

códigos y ordenanzas vigentes.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el Consumidor.

• Nota al consumidor – Conserve estas

instrucciones para referencia futura.

• Nivel de capacidad – La instalación de esta

campana de ventilación requiere capacidades

mecánicas y eléctricas básicas.

• Tiempo de finalización – Aproximadamente

de 1 a 3 horas.

• El instalador tiene la responsabilidad de efectuar

una instalación adecuada.

• La Garantía no cubre las fallas del producto

debido a una instalación incorrecta.

DIMENSIONES DEL PRODUCTO

PARA SU SEGURIDAD:

ADVERTENCIA — Antes de comenzar

la instalación, desconecte la energía del panel de

servicio y bloquee los medios de desconexión para

evitar el accionamiento de la energía de manera

accidental. Cuando los medios de desconexión

de servicio no pueden bloquearse, coloque sobre

el panel de servicio un dispositivo de advertencia

bien visible, como una etiqueta.

PRECAUCIÓN — Debido al peso

y tamaño de estas campanas de ventilación y para

reducir el riesgo de lesiones personales o daños

al producto, SE NECESITAN DOS PERSONAS PARA

REALIZAR UNA INSTALACIÓN CORRECTA.

Los modelos de 30" requieren una abertura de 30" de ancho

*Altura

hasta el

cielorraso

19-3/4"

29-7/8"

2-1/2"

13-1/8"

10-7/8"

*Altura

hasta el

cielorraso

19-3/4"

35-7/8"

3-1/8"

13-1/8"

10-7/8"

Los modelos de 36" requieren una abertura de 36" de ancho

2-1/4"

* Para las alturas del cielorraso de las cubiertas del conducto

provistas para instalación ventilada e instalación con

recirculación, consulte la tabla de la página 13.

17-1/2"

Deje 1

"

de superposición

para el conducto.

2-3/8"

Page 34

8

Preparación para la instalación

PREPARACIÓN PARA INSTALAR LA CAMPANA

ESPACIO DE INSTALACIÓN

Estas campanas de ventilación están diseñadas

para instalarse sobre una pared. Pueden instalarse

debajo de un sofito o gabinete.

• Instale estas campanas de 24" mínimo o 30"

máximo sobre la superficie de cocción.

La campana de ventilación debe instalarse a un

mín. de 24" y un máx. de 30" sobre la superficie

de cocción. La altura de instalación de la campana

sobre la superficie de cocción depende de la altura

del cielorraso y las limitaciones de la cubierta del

conducto. La cubierta plegable oculta los

conductos que van desde la parte superior de la

campana hasta el cielorraso. Para las alturas de

cielorraso de las cubiertas de conductos, consulte

la tabla de la página 13.

Kit de recirculación:

El kit incluye 1 deflector de aire y 1 filtro de carbón

y se incluye con la campana.

NOTA: La altura de instalación debe medirse desde

la superficie de cocción hasta la parte más baja de

la campana. Esta campana puede instalarse sobre

una pared y ventilarse hacia el exterior, o puede

instalarse para que realice una operación de

recirculación. Para la operación de recirculación,

se requiere un kit de recirculación (incluido).

24" Mín.

30" Máx.

PLANIFICACIÓN PREVIA

Planificación de conductos

• Esta campana está diseñada para ventilarse

en forma vertical a través del cielorraso. Se

suministra una pieza de transición de conductos

para escape vertical. Utilice codos suministrados

en forma local para ventilación horizontal

a través de la pared trasera. Ver página 10.

• Determine la ubicación exacta de la campana

de ventilación.

• Planifique el recorrido de la salida de ventilación

hacia el exterior.

• Utilice el recorrido de conductos más corto y más

recto posible. Para un desempeño satisfactorio,

el recorrido de los conductos no debe superar

una longitud equivalente a los 100 pies para

ninguna configuración de conductos.

• Consulte la tabla “Accesorios de conductos” para

calcular la longitud máxima permisible para

recorridos de conductos hacia el exterior.

• Sólo use conductos de metal.

• Se suministra una pieza de transición para

conductos redondos de 8". Utilice un conducto

redondo de 8".

• Instale una cubierta de pared o casquete

de techo con un regulador de tiro en la abertura

exterior. Solicite por adelantado la cubierta

de pared o el casquete de techo y cualquier

transición o longitud de conducto necesarios.

Armazones de pared para un soporte adecuado

• Esta campana de ventilación es pesada. Debe

contarse con un soporte estructural adecuado.

Esta campana debe fijarse a columnas verticales

en la pared. Ver página 14.

• Recomendamos enfáticamente que la campana

de ventilación con cubierta del conducto se

encuentre en el lugar antes de colocar los

armazones y efectuar el acabado de la pared.

Esto también ayudará a ubicar con precisión

los conductos y el servicio eléctrico.

Page 35

9

Preparación para la instalación

SUMINISTRO DE ENERGÍA

IMPORTANTE – (Tenga a bien leer cuidadosamente)

ADVERTENCIA:

PARA SEGURIDAD PERSONAL, ESTE APARATO DEBE

CONECTARSE A TIERRA DE MANERA ADECUADA.

Quite el fusible o abra el interruptor de circuitos

antes de comenzar la instalación.

No utilice un cable de extensión o un enchufe

adaptador con este artefacto. Siga los Códigos

Eléctricos Nacionales o códigos y ordenanzas

locales vigentes.

Suministro eléctrico

Estas campanas de ventilación deben contar

con un suministro de 120V, 60Hz, deben estar

conectadas a un circuito derivado individual con

una adecuada conexión a tierra y deben contar

con la protección de un interruptor de circuitos

o un fusible con retraso de 15 o 20 amperios.

• El cableado debe ser de 2 hilos con conexión

a tierra.

• Si el suministro eléctrico no cumple con los

requisitos anteriores, llame a un electricista con

licencia antes de continuar.

• Dirija el cableado doméstico lo más cerca posible

a la ubicación de la instalación, en el cielorraso

o pared trasera. Ver página 14 para más detalles.

• Conecte el cableado al cableado doméstico

en cumplimiento con los códigos locales.

Instrucciones de conexión a tierra

El conductor a tierra debe conectarse a un metal

con conexión a tierra, un sistema de cableado

permanente o una terminal o conductor de

conexión a tierra del equipamiento en la campana.

ADVERTENCIA:Una conexión

inadecuada del conductor de conexión a tierra

del equipamiento puede provocar un riesgo

de descarga eléctrica. Consulte a un electricista

calificado o representante de servicio técnico

si tiene dudas sobre la correcta conexión a tierra

del artefacto.

Page 36

ACCESORIOS PARA

CONDUCTOS

Esta campana debe usar

un conducto redondo de 8".

Puede conectarse a un

conducto de 3-1/4" x 12".

Utilice esta tabla para calcular

las longitudes máximas

permitidas para recorridos

de conductos hacia el exterior.

NOTA: ¡No supere las longitudes

equivalentes máximas permitidas!

Longitud máxima de conducto:

100 pies.

Conductos flexibles:

Si se utilizan conductos flexibles

de metal, todos los valores

equivalentes en pies de la tabla

deben duplicarse. El conducto

flexible de metal debe ser recto

y liso y debe extenderse lo

máximo posible.

NO USE conductos flexibles

de plástico.

NOTA: Cualquier sistema

de ventilación doméstico, como