Page 1

GEAppliances.com

Safety Instructions ............ 2-4

mm

mm

Operating Instructions

Automatic Icemaker ................ 10

Care and Cleaning ............. 12, 13

ClimateKeeper

with Dual Evaporators ............... 6

Drawers and Baskets ................ 9

Ice and Water Dispenser ....... 1O, 11

Refrigerator Doors .................. 8

Replacing the Light Bulbs ........... 14

Shelves and Bins .................... 7

Temperature Controls ............... 5

Water Filter ......................... 6

Model 42, 48

GE Profile COte a COte

Refr rs

La section francaise commence a la page 49

Installation Instructions

|

m_

Anti-Tip Brackets ................... 34

Dimensions, Clearances ............ 17

Door, Grille Panels .............. 36-38

Installation Space .................. 17

Leveling ........................... 35

Panel Dimensions .............. 21-30

Water Line ..................... 33, 34

Water Supply ...................... 39

Troubleshooting Tips ...... 42-44

Normal Operating Sounds .......... 41

Consumer Support

Consumer Support ........ Back Cover

Performance Data Sheet ........... 46

Warranty .......................... 45

Write the model and serial numbers

here:

Model #

Serial #

Find these numbers on a label inside

the refrigerator compartment at the

top on the right side,

225D2637PO01 49-60558-2 09- 74 GE

Page 2

IMPORTANT SAFETYINFORMATION.

READALL INSTRUCTIONSBEFOREUSING.

GEApp//ances Webs/te

For more information on your refrigerator's operation, visit www, GEAppliances.com or

call 800, GECARES {800, 432,2737), In Canada visit GEAppliances.ca or call 800, 567, 3344,

REFRIGERATOR SAFETY INFORMATION

_, This is the safety alert symbol, This symbol alerts you to potential hazards that can kill or hurt you and others, All safety

messages will follow the safety alert symbol and the word "DANGER","WARNING",or "CAUTION", These words are defined as;

Indicates a hazardous situation which if not avoided, will result in death or serious injury,

Indicates a hazardous situation which if not avoided, could result in death or serious injury,

lndicates a hazardous situation which if not avoided, could result in minor or moderate injury,

IMPORTANT SAFETY INSTRUCTIONS

I___ o reduce the risk of fire, explosion, electric shock, or injury when using your

refrigerator, follow these basic safety precautions:

This refrigerator must be properly installed and located in

accordance with the Installation Instructions before it is used,

Replace all parts and panels before operating,

Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance,

Because of potential safety hazards under certain conditions, we

strongly recommend against the use of an extension cord, However,

if you must use an extension cord, it is absolutely necessary that it

be a UL-listed (in the United States) or a CSA certified (in Canada),

3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the electrical rating of the cord be 15

amperes (minimum) and 120 volts,

To prevent suffocation and entrapment hazards to children, remove

the fresh food and freezer doors from any refrigerator before

disposing of it or discontinuing its use,

Do not allow children to climb, stand or hang on the door handles

or the shelves in the refrigerator, They could seriously it]jure

themselves,

Unplug the refrigerator :

• To disconnect power to the refrigerator, It cannot be turned off by

any setting on the control panel,

To clean, replace a burned out light bulb, or make repairs,

Note: Repairs must be performed by a qualified Service Professional,

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of injury when using your refrigerator, follow these basic

precautions,

In refrigerators with automatic ice makers, avoid contact with the

moving parts of the ejector mechanism, or with the heating element

that releases the cubes, Do not place fingers or hands on the

automatic ice making mechanism while the refrigerator is plugged

in,

Do not clean glass shelves or covers with warm water when they

are cold, Glass shelves and covers may break if exposed to sudden

temperature changes or impact, such as bumping or dropping,

Tempered glass is designed to shatter into many small pieces if it

breaks,

Keep fingers out of the "pinch point" areas; clearances between the

doors and between the doors and cabinet are necessarily small, Be

careful closing doors when children are in the area,

Do not touch the cold surfaces in the freezer compartment when

hands are damp or wet, skin may stick to these extremely cold

surfaces,

Do not refreeze frozen foods which have thawed completely,

Page 3

GEAppliances.com

INSTALLATION

_1( Explosion Hazard.

Keep flammable materials and vapors, such as gasoline, away from refrigerator.

Failure to do so can

result in fire, explosion, or death.

_/_ Tip Over Hazard.

This refrigerator is top heavy and must be handled with care. Failure to do so can result in the unit

tipping over and result in death or serious injury. Reference Installation Instructions for correct anti-tip

l bracket nsta at on.

CONNECTING ELECTRICITY

Electrical Shock Hazard.

Plug into a grounded 3-prong outlet

IDo not remove the ground prong

Do not use an adapter

Failure to follow these instructions can result in

death, fire, or electrical shock.

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with a 3-prong

(grounding) plug which mates with a standard 3-prong

(grounding) wall outlet to minimize the possibility of electric

shock hazard from this appliance,

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded,

Where a standard 2-prong wall outlet is encountered, it is

your personal responsibility and obligation to have it replaced

with a properly grounded 3-prong wall outlet, Do not use an

adapter,

The refrigerator should always be plugged into its own

individual electrical outlet which has a voltage rating that

matches the rating plate,

A 115 Volt AC, 60 Hz, 15- or 20-amp fused, grounded

electrical supply is required, This provides the best

performance and also prevents overloading house wiring

circuits which could cause a fire hazard from overheated

wires,

Never unplug your refrigerator by pulling on the power cord,

Always grip plug firmly and pull straight out from the outlet,

Repair or replace immediately all power cords that have

become frayed or otherwise damaged, Do not use a cord

that shows cracks or abrasion damage along its length or at

either end,

When moving the refrigerator away from the wall, be careful

not to roll over or damage the power cord,

DO NOT USEAN ADAPTERPLUG OR EXTENSIONCORD

(Adapter plugs not permitted in Canada)

Do not use an adapter plug to connect the refrigerator to a 2-prong outlet.

Do not use an extension cord with this appliance.

Page 4

IMPORTANT SAFETYINFORMATION.

READALL INSTRUCTIONSBEFOREUSING.

PROPER DISPOSAL OF YOUR OLD REFRIGERATOR

Suffocation and child entrapment hazard.

Remove fresh-food and freezer doors from the refrigerator, prior to disposal. Failure to do so can result

in child entrapment which can lead to death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past, Junked or abandoned refrigerators are

still dangerous even if they will sit for ']ust a few

days," If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents,

Before You Throw Away Your Old Refrigerator

or Freezer:

Take off the fresh food and freezer doors,

Leave the shelves in place so that children may not

easily climb inside,

READAND FOLLOWTills SAFETY/NFORMA-I-IONCAREFUILX

SAVETHESEINSTRUCTIONS

Refrigerants

All refrigeration products contain refrigerants,

which under federal law must be removed prior

to product disposal, If you are getting rid of an old

refrigeration product, check with the company

handling the disposal about what to do,

4

Page 5

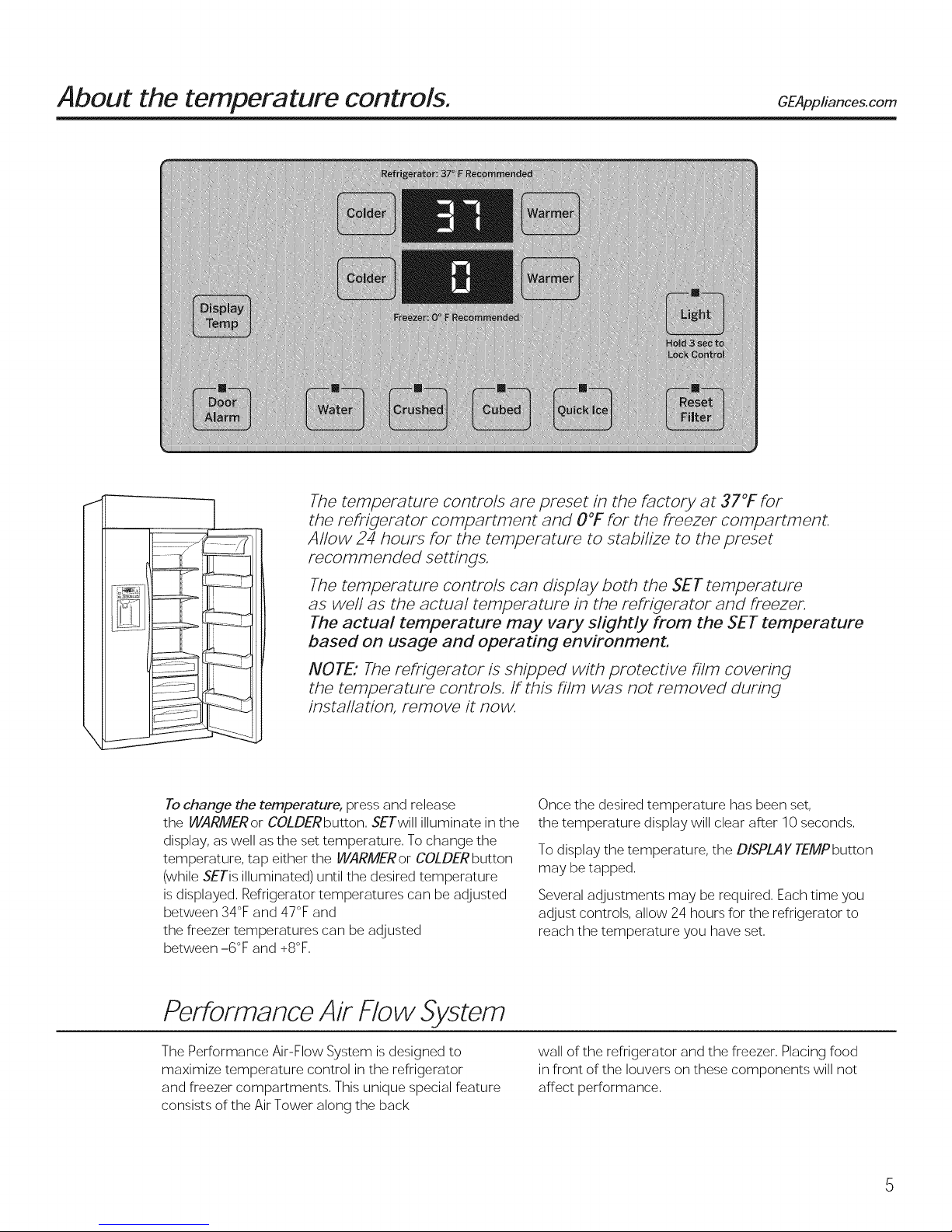

About the temperature controls. GEAppliances.com

The temperature controls are preset in the factory at 37°F for

the refrigerator compartment and O°F for the freezer compartment,

Aflow 24 hours for the temperature to stabilize, to the preset

recommended settings,

The temperature controls can display both the SET temperature

as well as the actual temperature in the refrigerator and freezer,

The actual temperature may vary slightly from the SET temperature

based on usage and operating environment.

NOTE: The refrigerator is shipped with protective film covering

the temperature controls, If this film was not removed during

installation, remove it now,

Tochange the temperature, press and release

the WARMERor COLDERbutton, SETwill illuminate in the

display, as well as the set temperature, To change the

temperature, tap either the WARMERor COLDER button

(while SETis illuminated) until the desired temperature

is displayed, Refrigerator temperatures can be adjusted

between 34°F and 47°F and

the freezer temperatures can be adjusted

between -6°F and +8°F,

Performance Air Flow System

Once the desired temperature has been set,

the temperature display will clear after 10 seconds,

Todisplay the temperature, the DISPLAYTEMPbutton

may be tapped,

Several adjustments may be required, Each time you

adjust controls, allow 24 hours for the refrigerator to

reach the temperature you have set,

The Performance Air-Flow System is designed to

maximize temperature control in the refrigerator

and freezer compartments, This unique special feature

consists of the Air Tower along the back

wall of the refrigerator and the freezer, Placing food

in front of the louvers on these components will not

affect performance,

Page 6

About ClimateKeeper with dual evaporators.

How it Works

The ClimateKeeper with dual evaporators system

features two evaporators-one for

the refrigerator and one for the Freezer,

This provides two separate cooling systems,and

separates the airflow between the fresh Foodand

freezer compartments during normal cooling

operations,

About the water filter.

Water filter cartridge Installing the filter cartridge

The water filter cartridge is located in the back upper right corner of [] Fillthe replacement cartridge with water from the tap

the refrigerator compartment, to allow for better flow from the dispenser immediately

When to reploce the filter on models []

with o replocement indicotor light

There is a replacement indicator light for the water fitter cartridge

on the dispenser.This light will turn orange to []

tell you that you need to replace the filter soon.

The filter cartridge should be replaced when the replacement

indicator light turns red or if the flow of water to the dispenser or

icemaker decreases.

When to replace the filter on models

without a replacement indicator light

The filter cartridge should be replaced every six months

or earlier if the flow of water to the dispenser or

icemaker decreases.

Theseparate airflow system minimizes

the mixing of air between the two compartments,

which reduces flesh Foododor transfer to improve

the taste of ice,

TheClimateKeepersystem also reduces

the number of defrosting cyclesin the freezer

evaporator, thereby reducing freezer burn.

after installation.

Line up the arrow on the cartridge and the cartridge holder. Place

the top of the new cartridge up inside the holder.

Do not push it up into the holder.

Slowly turn it to the right until the filter

cartridge stops. DO NOTOVERTIGHTEN.

Asyou turn the cartridge, it will

automatically raise itself into position.

Thecartridge will move about a ½ turn.

[] Runwater from the dispenser for 1-1/2 gallons (about three

minutes) to clear the system and prevent sputtering.

[] Pressand hold the RESETWATERFILTERpad (on some models) on

the dispenser for three seconds.

NOTE:A newly installed water filter cartridge may cause water

to spurt from the dispenser.

Removing the filter cortridge

If you are replacing the cartridge, first remove the old one

by slowly turning it to the left. Do not putI down on the cartridge. A

smatI amount of water may drip down.

CAUTION:Toreduce the riskassociated with property damage due

to water leakage, read and follow instructions before installation

and use of this system. Installation and use HaST comply with all

state and local plumbing codes.

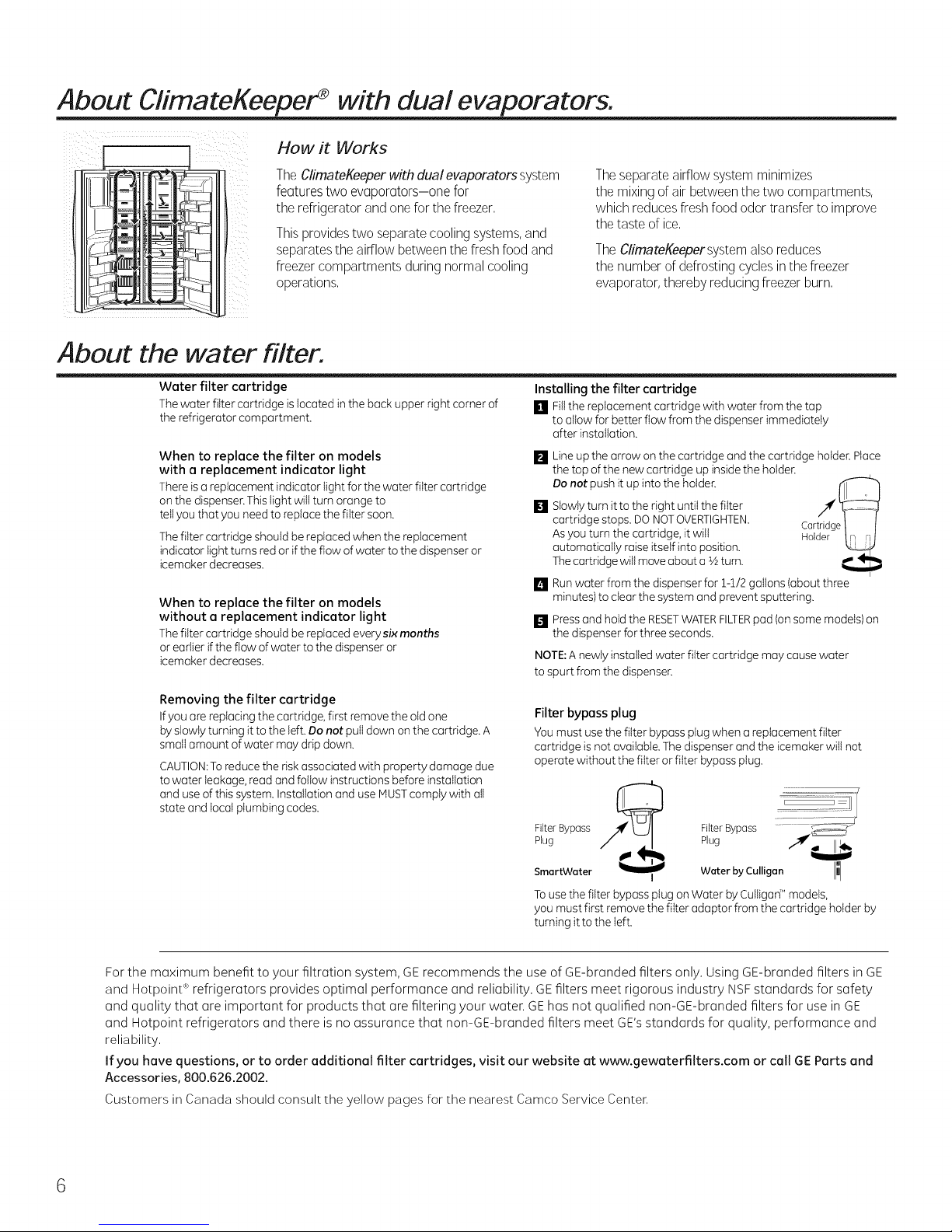

Filter byposs plug

You must use the filter bypass plug when a replacement filter

cartridge is not available. The dispenser and the icemaker will not

operate without the filter or filter bypass plug.

FilterBypass ,_ ]1 FilterBypass

Plug J_ Plug

SmortWater

Tousethe filter bypass plug on Water by Culligaff" models,

you must first remove the filter adaptor from the cartridge holder by

turning it to the left.

I Water byCulligon II I

For the maximum benefit to your filtration system, GE recommends the use of GE-branded filters only. Using GE-branded filters in GE

and Hotpoinff refrigerators provides optimal performance and reliability. GE filters meet rigorous industry NSFstandards for safety

and quality that are important for products that are filtering your waten GEhas not qualified non-GE-branded filters for use in GE

and Hotpoint refrigerators and there is no assurance that non-GE-branded filters meet GE'sstandards for quality, performance and

reliability.

Ifyou hove questions, or to order additional filter cartridges, visit our website at www.gewuterfilters.com or coil BE Parts and

Accessories, 800.626.2002.

Customers inCanada should consult the yellow pages for the nearest Camco Service Center.

Page 7

About the shelves and bins.

Not all features are on all models.

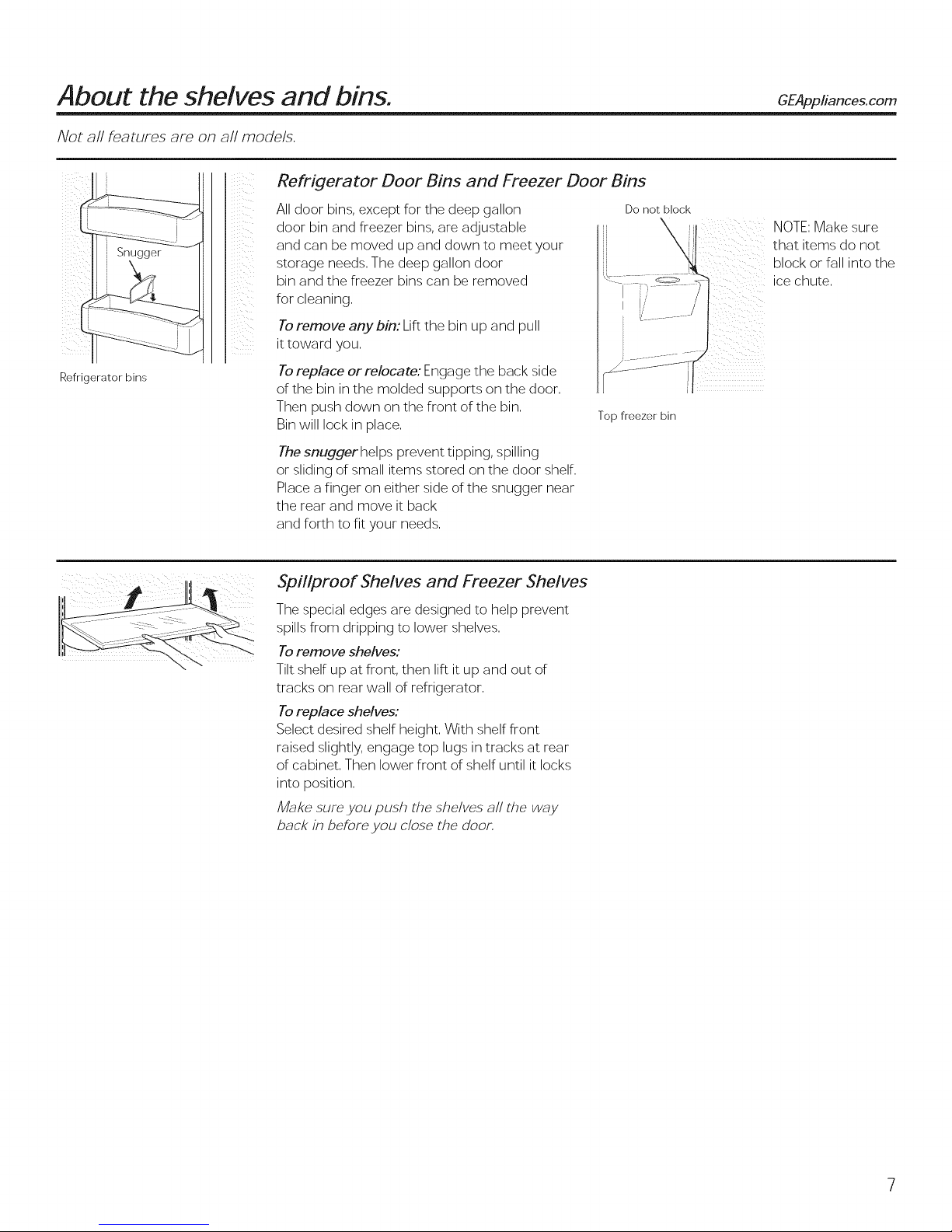

Refrigerator Door Bins and Freezer Door Bins

All door bins, except for the deep gallon

door bin and freezer bins, are adjustable

Snugger

and can be moved up and down to meet your

storage needs. The deep gallon door

bin and the freezer bins can be removed

for cleaning.

Toremove any bin: Lift the bin up and pull

it toward you.

GEAppliances.com

Do not block

} i block or fall into the

'_:::z z ......

[

j_!_ NOTE:Make sure

......... ice chute.

that items do not

? /

Refrigerator Dins

Toreplace or relocate: Engage the back side

of the bin in the molded supports on the door.

Then push down on the front of the bin.

Bin will lock in place.

The snuggerhelps prevent tipping, spilling

or sliding of small items stored on the door shelf.

Place a finger on either side of the snugger near

the rear and move it back

and forth to fit your needs.

Spillproof Shelves and Freezer Shelves

The special edges are designed to help prevent

spills from dripping to lower shelves.

Toremove shelves:

Tilt shelf up at front, then lift it up and out of

tracks on rear wall of refrigerator.

Toreplace shelves."

Select desired shelf height. With shelf front

raised slightly, engage top lugs in tracks at rear

of cabinet. Then lower front of shelf until it locks

into position.

M_?kesure you push the shelves aft the way

back in before you close the door,

Top freezer bin

Page 8

era tor doors.

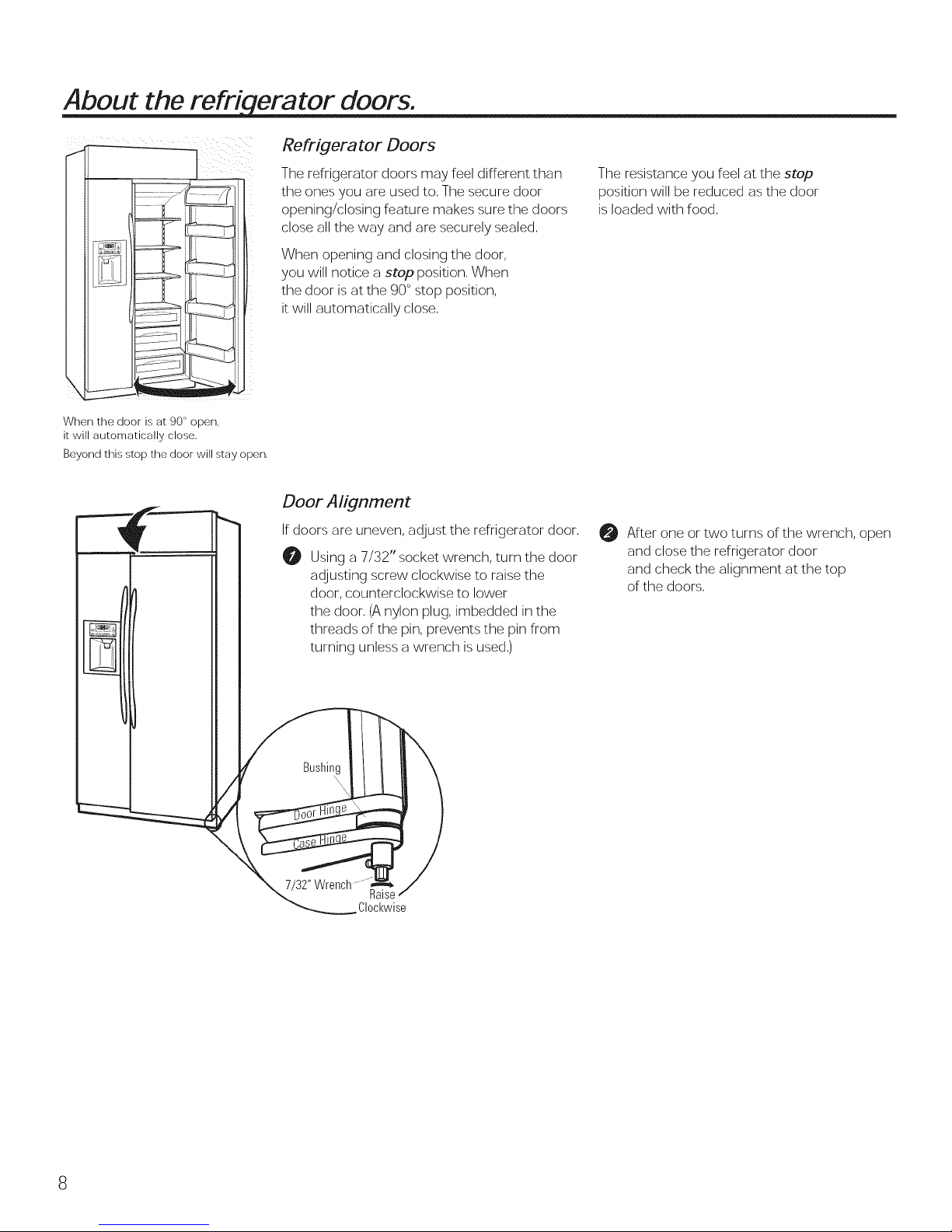

Refrigerator Doors

When the door is at 90" open,

it will automatically close.

Beyond this stop the door will stay open.

The refrigerator doors may feel different than

the ones you are used to, The secure door

opening/closing feature makes sure the doors

close all the way and are securely sealed,

When opening and closing the door,

you will notice a stop position, When

the door is at the 90°stop position,

it will automatically close,

Door A lignmen t

If doors are uneven, adjust the refrigerator door,

O Using a 7/32" socket wrench, turn the door

adjusting screw clockwise to raise the

door, counterclockwise to lower

the door, (A nylon plug, imbedded in the

threads of the pin, prevents the pin from

turning unless a wrench is used,)

The resistance you feel at the stop

position will be reduced as the door

is loaded with food,

@After one or two turns of the wrench, open

and close the refrigerator door

and check the alignment at the top

of the doors,

8

Page 9

About the drawers and baskets.

Not all features are on a// models.

GEAppliances.com

W

J

S

•_ i!/i_II

I

HU_|D|TY CONTROL

._ ......... ......................... Lo

L

Fruit and Vegetable Drawers

illi_

Excess water that may accumulate in the

bottom of the drawers should be wiped dry,

i I i

ii

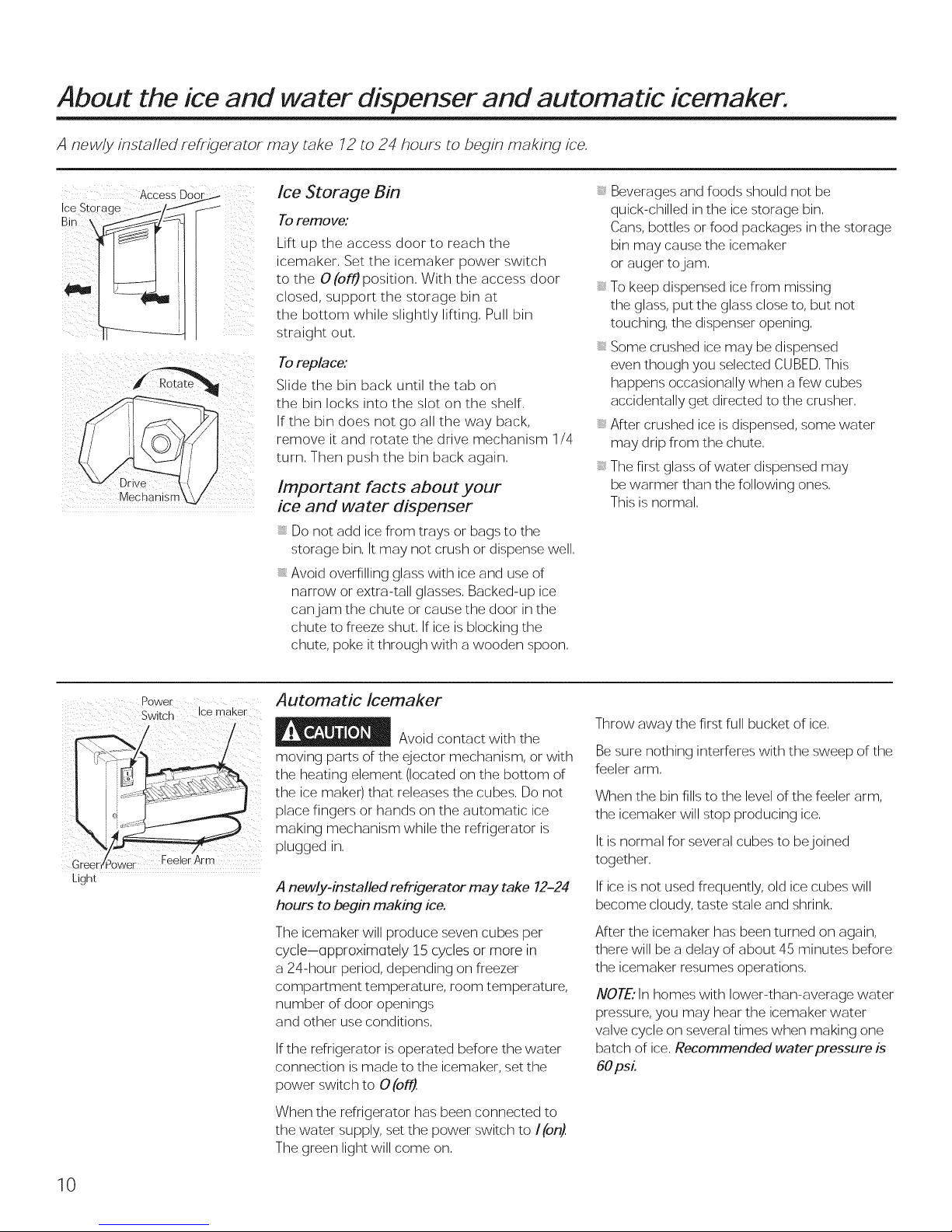

Adjustable Humidity Drawers

Slide the control all the way to the H/setting to

provide high humidity recommended for most

vegetables,

Slide the control all the way to the LO

setting to provide lower humidity levels

recommended for most fruits,

How to Remove and Replace the Drawers and Freezer Baskets

Toremove fresh food drawers: To replace fresh food drawers:

0 Pull the desired drawer out to the

stop position,

0 Lift up slightly on the front of the drawer,

Pullthe drawer slightly forward and

out of the refrigerator,

Tip the back rollers of the drawer behind the

rollers in the track,

Lower the front of the drawer into normal

position,

Slide the drawer to the back of the

refrigerator,

Toremove freezer baskets:

Pullthe desired basket out to the

stop position,

Lift up slightly on the front of the basket,

Pullthe basket slightly forward and

out of the freezer,

iI

iii

To replace freezer baskets:

Place the back corners in the rail

with the basket tilted up,

Lower the basket down to the normal

position,

Slide the basket to the back of the freezer,

9

Page 10

About the ice and water dispenser and automatic icemaker.

A newly insta//ed refrigerator may take 12 to 24 hours to begin making ice.

ce S_orage ./-

Bin _ __

AccessDoc/_

Drive

Mechanism

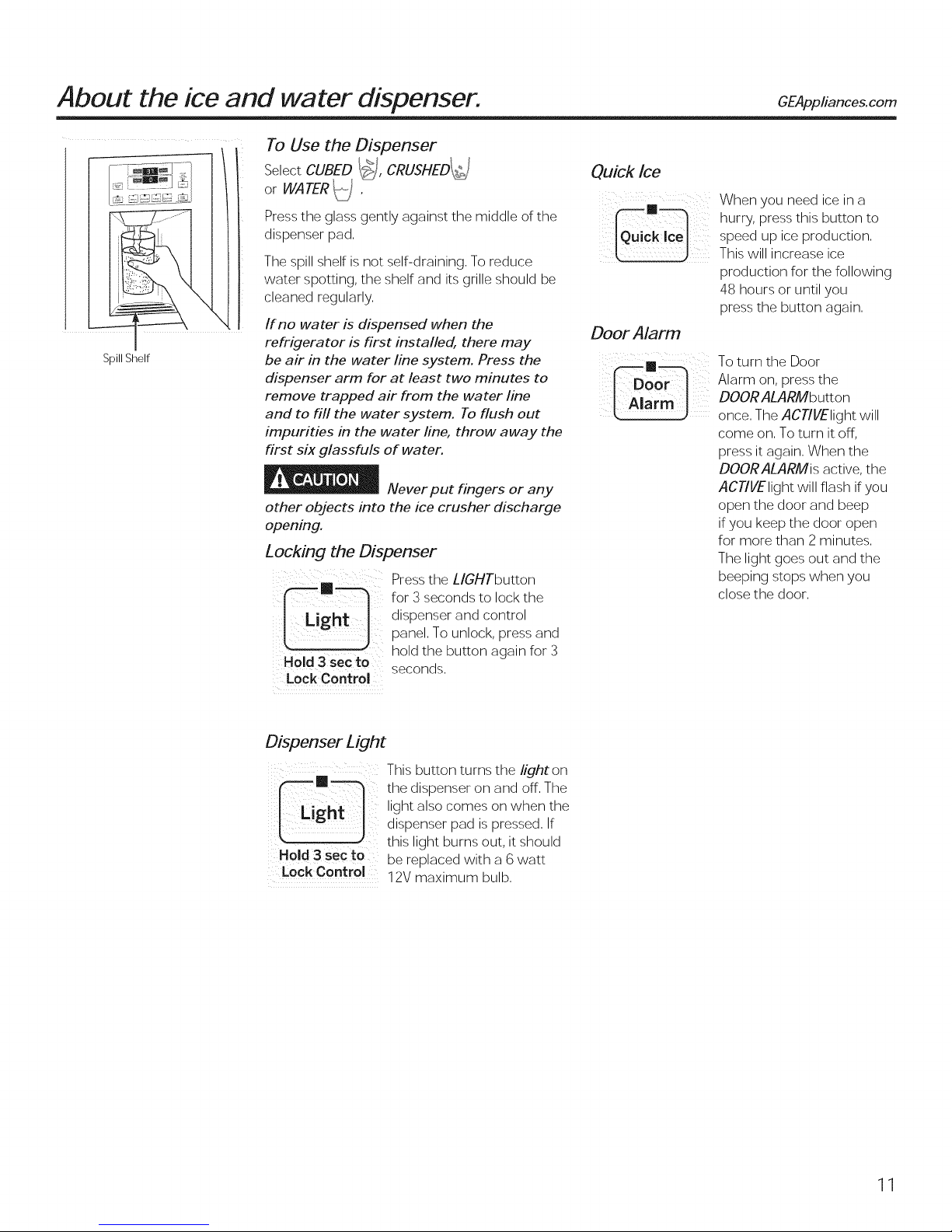

Ice Storage Bin

Toremove:

Lift up the access door to reach the

icemaker. Set the icemaker power switch

to the O (oft) position. With the access door

closed, support the storage bin at

the bottom while slightly lifting. Pull bin

straight out.

Toreplace:

Slide the bin back until the tab on

the bin locks into the slot on the shelf.

If the bin does not go all the way back,

remove it and rotate the drive mechanism 1/4

turn. Then push the bin back again.

Important facts about your

ice and water dispenser

Do not add ice from trays or bags to the

storage bin. It may not crush or dispense well.

, Avoid overfilling glass with ice and use of

narrow or extra-tall glasses. Backed-up ice

can jam the chute or cause the door in the

chute to freeze shut. If ice is blocking the

chute, poke it through with a wooden spoon.

Beverages and foods should not be

quick-chilled in the ice storage bin.

Cans, bottles or food packages in the storage

bin may cause the icemaker

or auger to jam.

To keep dispensed ice from missing

the glass, put the glass close to, but not

touching, the dispenser opening.

iiiiiiiiiiii_i_

Some crushed ice may be dispensed

even though you selected CUBED. This

happens occasionally when a few cubes

accidentally get directed to the crusher.

iiiiiii#_i_

After crushed ice is dispensed, some water

may drip from the chute.

iiiiiii#_i_

The first glass of water dispensed may

be warmer than the following ones.

This is normal.

Gre(

Light

Power

ce maker

Automatic Icemaker

Avoid contact with the

moving parts of the ejector mechanism, or with

the heating element (located on the bottom of

the ice maker) that releases the cubes. Do not

place fingers or hands on the automatic ice

making mechanism while the refrigerator is

plugged in.

A newly-installed refrigerator may take 12-24

hours to begin making ice.

The icemaker will produce seven cubes per

cycle-approximately 15 cycles or more in

a 24-hour period, depending on freezer

compartment temperature, room temperature,

number of door openings

and other use conditions.

If the refrigerator is operated before the water

connection is made to the icemaker, set the

power switch to O(off)

When the refrigerator has been connected to

the water supply, set the power switch to/(on)

The green light will come on.

Throw away the first full bucket of ice.

Be sure nothing interferes with the sweep of the

feeler arm.

When the bin fills to the level of the feeler arm,

the icemaker will stop producing ice.

It is normal for several cubes to bejoined

together.

If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

After the icemaker has been turned on again,

there will be a delay of about 45 minutes before

the icemaker resumes operations.

NOTE: In homes with lower-than-average water

pressure, you may hear the icemaker water

valve cycle on several times when making one

batch of ice Recommended water pressure is

60 psZ

10

Page 11

About the ice and water dispenser. GEAppliances.com

To Use the Dispenser

Spill Shelf

Select CUBED _, CRUSHEDI_;U

or WATEl?I_I .

Press the glass gently against the middle of the

dispenser pad,

The spill shelf is not self-draining, To reduce

water spotting, the shelf and its grille should be

cleaned regularly,

If no water is dispensed when the

refrigerator is first installed, there may

be air in the water line system, Press the

dispenser arm for at least two minutes to

remove trapped air from the water line

and to fill the water system, To flush out

impurities in the water line, throw away the

first six glassfuls of water,

_ Never put fingers or any

other objects into the ice crusher discharge

opening,

Locking the Dispenser

Press the LIGHTbutton

for 3 seconds to lock the

Quick Ice

When you need ice in a

hurry, press this button to

speed up ice production,

This will increase ice

production for the following

48 hours or until you

press the button again,

Door Alarm

m To turn the Door

[Alarm j DOORALARMbutton

once, The ACTIVElight will

come on, To turn it off,

press it again, When the

DOORALARMis active, the

ACTIVE light will flash if you

open the door and beep

if you keep the door open

for more than 2 minutes,

The light goes out and the

beeping stops when you

close the door,

dispenser and controlpanel, To unlock, press and

Hold 3 sec to seconds,

Lock Control

hold the button again for 3

Dispenser Light

This button turns the lighton

the dispenser on and off, The

light also comes on when the

dispenser pad is pressed, If

this light burns out, it should

Hold 3sec tO be replaced with a 6 watt

Lock Control 12V maximum bulb,

11

Page 12

Care and cleaning of the refrigerator.

Cleaning the Outside

The spill shelf and the area beneath it should

be cleaned periodically with a mild liquid dish

detergent,

Dispenser drip area.

Dispenser pad. Before cleaning, lock the

dispenser by pressing the LOCK/LIGHT

button for 3 seconds to prevent activating the

dispenser, Clean with warm water and a mild

liquid dish detergent, Rinse thoroughly and wipe

dry, Unlock the dispenser by pressing the LOCK/

LIGHTbutton for 3 seconds,

Doorhand/es. Clean with a cloth dampened

with soapy water, Dry with a soft cloth,

Do not wipe the refrigeratorwith a soiled dish

cloth or wet towel, These may leave a residue

that can damage the finish, Do not use scouring

pads, powdered cleaners, bleach or cleaners

containing bleach because these products can

scratch and damage the finish,

The stainless steel doors and door handles

(on some models) can be cleaned with a

commercially available stainless steel cleaner,

Cleaners with oxalic acid such as Bar Keepers

Friend Soft Cleanser TM will remove rust, tarnish

and small blemishes, Use only a liquid cleanser

free of grit and rub in the direction of the brush

lines with a damp soft sponge, Do not use

appliance wax or polish on the stainless steel,

Cleaning the Inside

Turn off power at the circuit breaker or fuse

box before cleaning. If this is not practical,

wring excess moisture out of sponge or cloth

when cleaning around switches, lights or

controls,

Use warm water and baking soda solution-

about a tablespoon (15 ml) of baking soda

to a quart (1 liter) of water, This both cleans and

neutralizes odors, Thoroughly rinse and wipe

dry,

Other parts of the refrigerator, including door

gaskets, snack pan and vegetable drawers, ice

storage bin and all plastic parts, can be cleaned

the same way,

Do not wash the tray or any plastic refrigerator

parts in the dishwasher,

Do not clean glass shelves

or covers with warm water when they are

cold. Glass shelves and covers may break

if exposed to sudden temperature changes

or impact, such as bumping or dropping.

Tempered glass is designed to shatter into

many small pieces if it breaks.

12

Page 13

Preparing for Vacation

GEAppliances.com

For long vacations or absences, remove

food and unplug the refrigerator, Clean

the interior with a baking soda solution of one

tablespoon (15 ml) of baking soda to one quart

(1 liter) of water, Leave the doors open,

Set the icemaker power switch to the 0 (oft)

position and shut off the water supply to

the refrigerator,

Preparing to Move

Secure all loose items such as shelves and

drawers by taping them securely in place

to prevent damage,

Due to the weight and size

of this refrigerator, and to reduce the risk of

personal injury or damage to the product,

A MINIMUM OF4PEOPLEAREREQUIRED

TOBRING THEUNIT INTO THEHOMEAND

2 PEOPLEAREREQUIREDFORPROPER

INSTALLATION.

Be sure the refrigerator stays in an upright

position during moving,

If the temperature can drop below freezing,

have a qualified servicer drain the water supply

system to prevent serious property damage

due to flooding,

13

Page 14

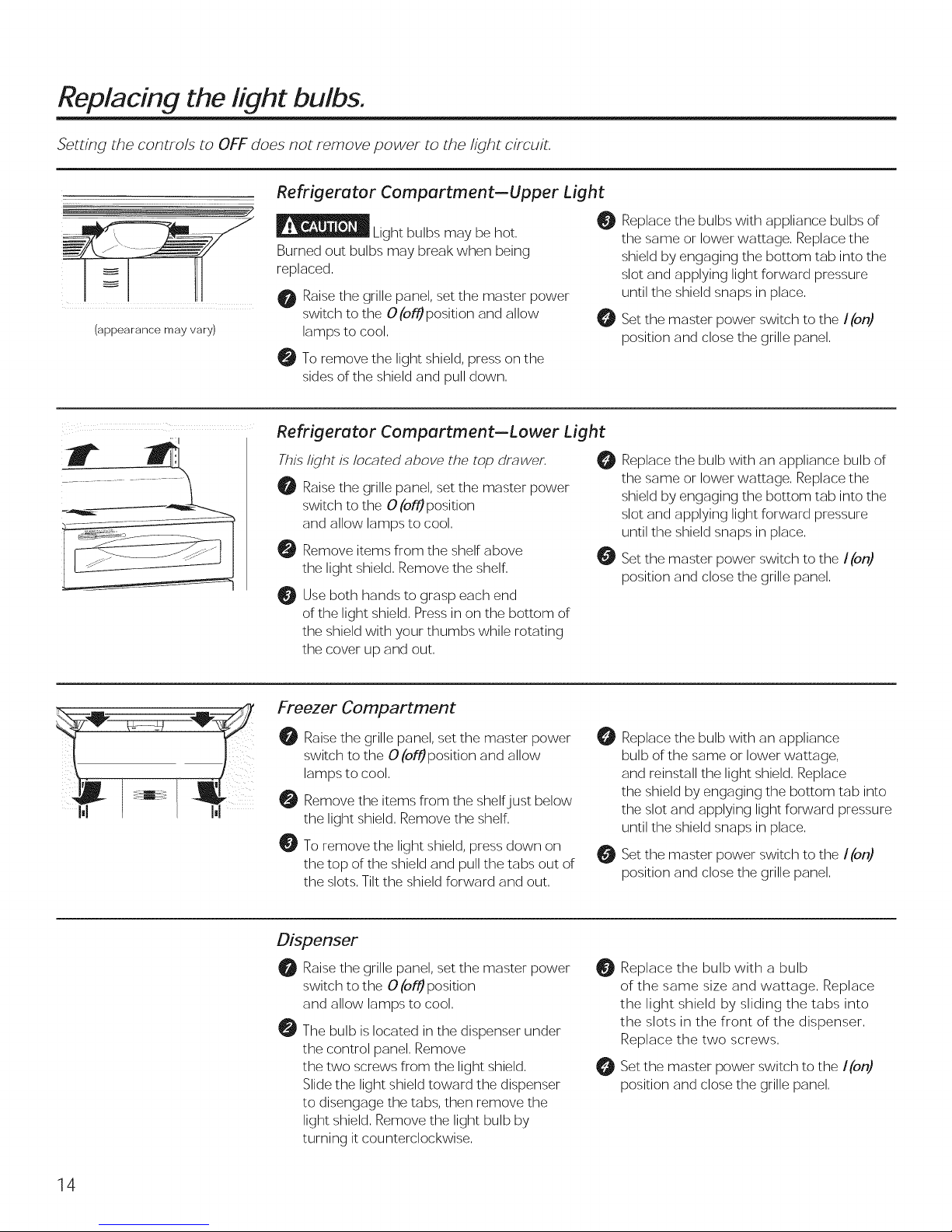

Replacing the light bulbs.

Setting the controls to OFF does not remove power to the fight circuit.

Refrigerator Compartment--Upper Light

(appearance may vary)

_ Light bulbs may be hot.

Burned out bulbs may break when being

replaced.

0 Raisethe grille panel, set the master power

switch to the O(off)position and allow

lamps to cool.

0 To remove the light shield, press on the

sides of the shield and pull down.

Refrigerator Compartment--Lower Light

This light is located above the top drawer,

Raisethe grille panel, set the master power

switch to the 0 (off) position

and allow lamps to cool.

Remove items from the shelf above

the light shield. Remove the shelf.

Use both hands to grasp each end

of the light shield. Press in on the bottom of

the shield with your thumbs while rotating

the cover up and out.

Replace the bulbs with appliance bulbs of

the same or lower wattage. Replace the

shield by engaging the bottom tab into the

slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the/(on)

position and close the grille panel.

Replace the bulb with an appliance bulb of

the same or lower wattage. Replace the

shield by engaging the bottom tab into the

slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the/(on)

position and close the grille panel.

Freezer Compartment

0

Raisethe grille panel, set the master power

switch to the 0 (off)position and allow

lamps to cool.

I

Remove the items from the shelf just below

the light shield. Remove the shelf.

To remove the light shield, press down on

the top of the shield and pull the tabs out of

the slots. Tilt the shield forward and out.

O

Replace the bulb with an appliance

bulb of the same or lower wattage,

and reinstall the light shield. Replace

the shield by engaging the bottom tab into

the slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the I(on)

position and close the grille panel.

Dispenser

Raise the grille panel, set the master power

switch to the 0 (off) position

and allow lamps to cool.

The bulb is located in the dispenser under

the control panel. Remove

the two screws from the light shield.

Slide the light shield toward the dispenser

to disengage the tabs, then remove the

light shield. Remove the light bulb by

turning it counterclockwise.

Replace the bulb with a bulb

of the same size and wattage. Replace

the light shield by sliding the tabs into

the slots in the front of the dispenser.

Replace the two screws.

Set the master power switch to the/{on)

position and close the grille panel.

14

Page 15

Installation

ilt-ln Side-By-Side

efrigerators

Instructio s

If you have questions, call 800.GE.CARES (800.432.2737) or visit our website at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit our webske at: www.geappliances.ca

PSB42YS,PSB42YG,PSB48YS,PSB48YG

BEFOREYOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT - Observe all governing

codes and ordinances,

Note to Installer - Be sure to leave these

instructions for the consumer's and local

inspector's use.

Note to Consumer - Keep these instructions

with your Owner's Manual for future reference.

Skill Level - Installation of this refrigerator

requires basic mechanical, carpentry and

plumbing skills. Proper installation is the

responsibility of the installer. Product failure

due to improper installation is not covered

under the GE Appliance Warranty.

See warranty information.

Completion Time - 90 minutes (new installations

require more time than replacement installations).

Due to the weight and size of this refrigerator,

and to reduce the risk of personal injury or

damage to the product, A MINIMUM OF 4 PEOPLE

ARE REQUIRED TO BRING THE UNIT INTO THE

HOME AND 2 PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

• These refrigerators are top-heavy and must

be secured to prevent the possibility of tipping

forward. Anti-Tip protection is required.

See Step 4 on page 34 for details.

• Usethis appliance only for its intended purpose.

• Immediately repair or replace electric power

supply cords that become frayed or damaged.

• Set the Master Power switch to the O (OFF)

position before cleaning or making repairs.

• Repairs should be made by a qualified service

technician.

For GE Profile TM local service in your area,

call 1.800.432.2737.

For GE Profile service in Canada,

call 1.800.561.3344.

For GE Profile Parts and Accessories,

call 1.800.626.2002.

GEAppliances.com (in Canada, geappliances.ca)

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

To reduce the risk associated with choking, do

not allow children under 3 years of age to have

access to small parts during the installation of this

product.

15

Page 16

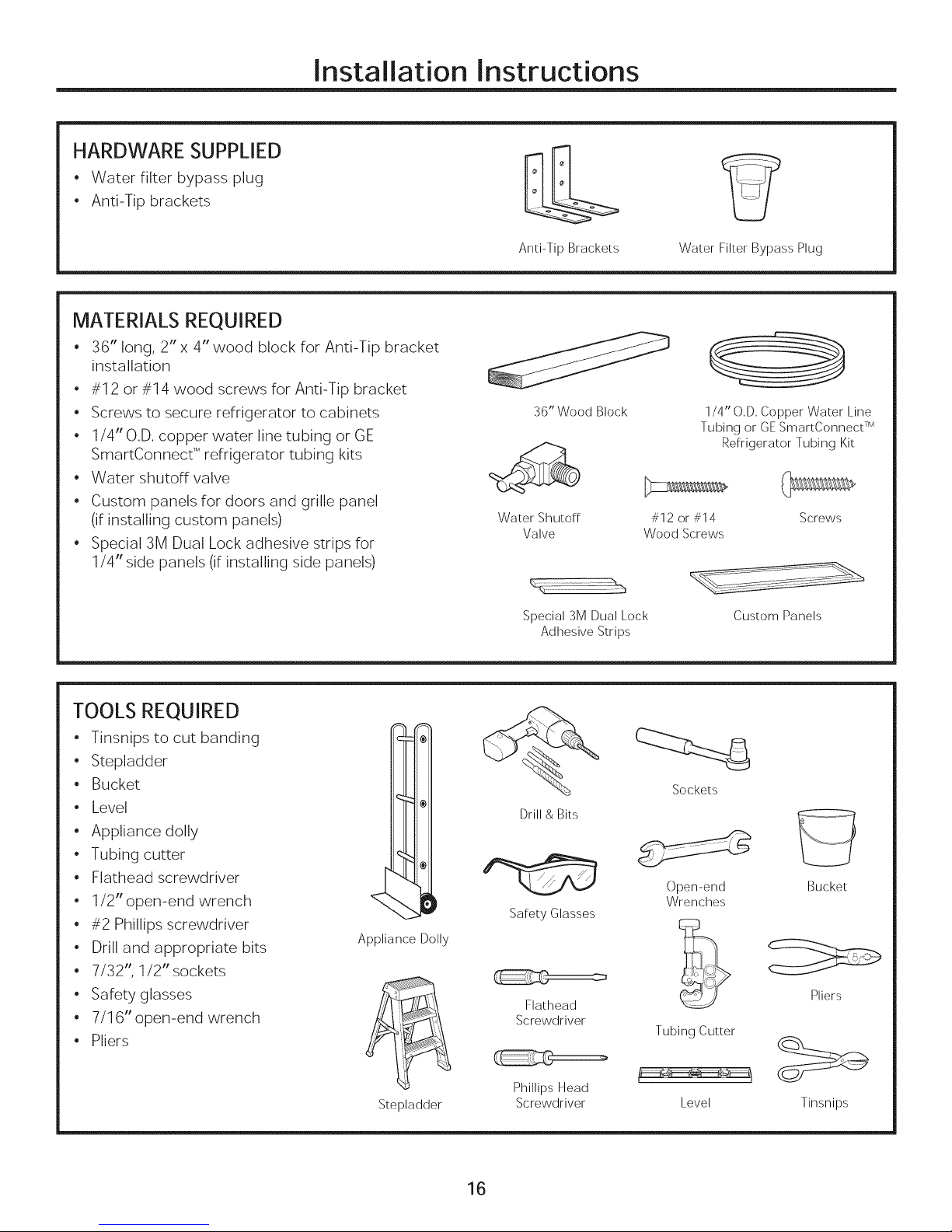

Installation Instructions

HARDWARE SUPPLIED

• Water filter bypass plug

• Anti-Tip brackets

MATERIALS REQUIRED

• 36" long, 2" x 4" wood block for Anti-Tip bracket

installation

• #12 or #14 wood screws for Anti-Tip bracket

• Screws to secure refrigerator to cabinets

• 1/4" O,D, copper water line tubing or GE

SmartConnecC refrigerator tubing kits

• Water shutoff valve

• Custom panels for doors and grille panel

(if installing custom panels)

• Special 3M Dual Lock adhesive strips for

1/4" side panels (if installing side panels)

Anti-Tip Brackets Water Filter Bypass Plug

36" Wood Block

Water Shutoff

Valve

#12 or #14

Wood Screws

1/4" O,D, Copper Water Line

Tubing or GE SmartConnect TM

Refrigerator Tubing Kit

Screws

TOOLS REQUIRED

• Tinsnips to cut banding

• Stepladder

• Bucket

• Level

• Appliance dolly

• Tubing cutter

• Flathead screwdriver

• 1/2" open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 7/32", 1/2" sockets

• Safety glasses

• 7/16" open-end wrench

• Pliers

Appliance Dolly

Special 3M Dual Lock

Adhesive Strips

Drill & Bits

Safety Glasses

Flathead

Screwdriver

Sockets

Open-end

Wrenches

Tubing Cutter

Custom Panels

Bucket

Pliers

Stepladder

16

Phillips Head

Screwdriver

Level

Tinsnips

Page 17

Installation Instructions

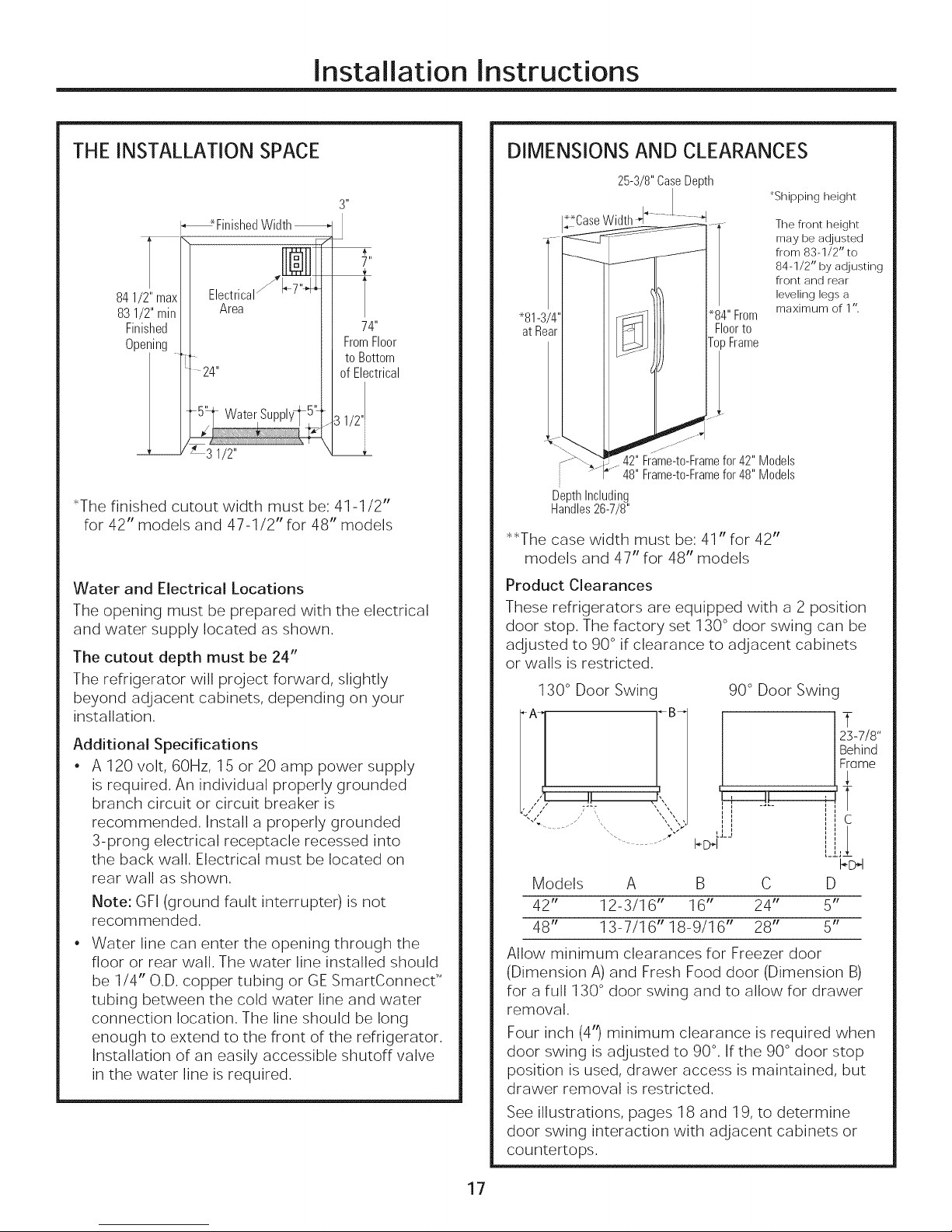

THE INSTALLATION SPACE

3"

I_Finished Width

÷

7"

÷

74"

FromFloor

to Bottom

ofElectrical

1/2"

_t___ V

*The finished cutout width must be: 41-1/2"

for 42" models and 47-1/2" for 48" models

Water and Electrical Locations

The opening must be prepared with the electrical

and water supply located as shown.

The cutout depth must be 24"

The refrigerator will project forward, slightly

beyond adjacent cabinets, depending on your

installation.

Additional Specifications

• A 120 volt, 60Hz, 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is

recommended. Install a properly grounded

3-prong electrical receptacle recessed into

the back wall. Electrical must be located on

rear wall as shown.

Note: GFI (ground fault interrupter) is not

recommended.

• Water line can enter the opening through the

floor or rear wall. The water line installed should

be 1/4" O.D. copper tubing or GE SmartConnecC

tubing between the cold water line and water

connection location. The line should be long

enough to extend to the front of the refrigerator.

Installation of an easily accessible shutoff valve

in the water line is required.

DIMENSIONS AND CLEARANCES

DepthIncluding

Handles26-7/8"

**The case width must be: 41" for 42"

models and 47" for 48" models

Product Clearances

These refrigerators are equipped with a 2 position

door stop. The factory set 130° door swing can be

adjusted to 90° if clearance to adjacent cabinets

or walls is restricted.

130 ° Door Swing 90 ° Door Swing

T

23-7/8"

Behind

Frame

A1IBI!

Models A B C

42" 12-3/16" 16" 24"

48" 13-7/16"18-9/16" 28"

Allow minimum clearances for Freezer door

(Dimension A) and Fresh Food door (Dimension B)

for a full 130 ° door swing and to allow for drawer

removal.

Four inch (4'_ minimum clearance is required when

door swing is adjusted to 90 °, If the 90 ° door stop

position is used, drawer access is maintained, but

drawer removal is restricted.

See illustrations, pages 18 and 19, to determine

door swing interaction with adjacent cabinets or

countertops.

T

c

D

5"

,,

17

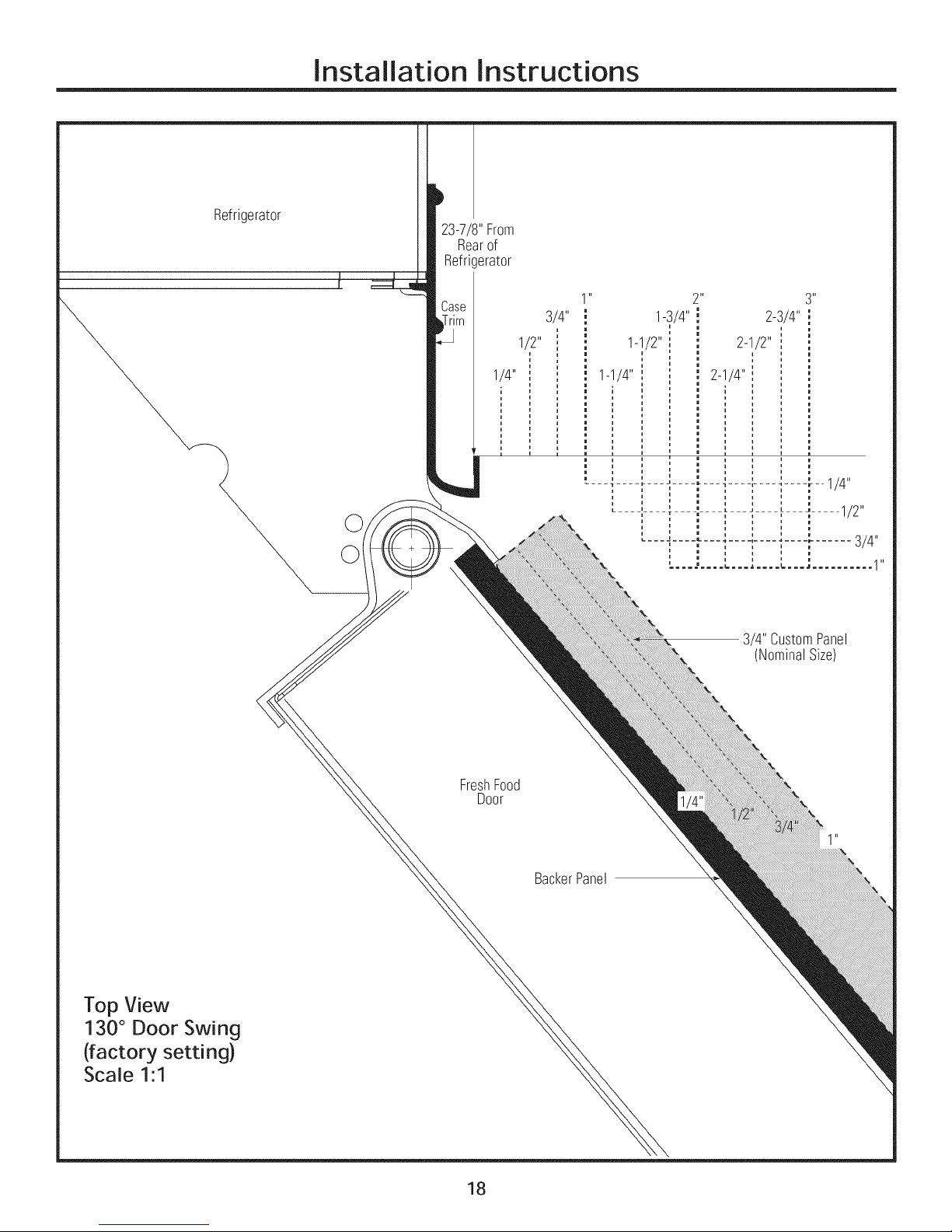

Page 18

Installation Instructions

Refrigerator

©

23-7/8"From

Rearof

Refrigerator

Csse

3/4" 2-3/4"

2-1/2"

u u

u

u

u

L

3/4"CustomPanel

(NominalSize)

Top View

130 ° Door Swing

(factory setting)

Scale 1:1

FreshFood

Door

BackerPanel

18

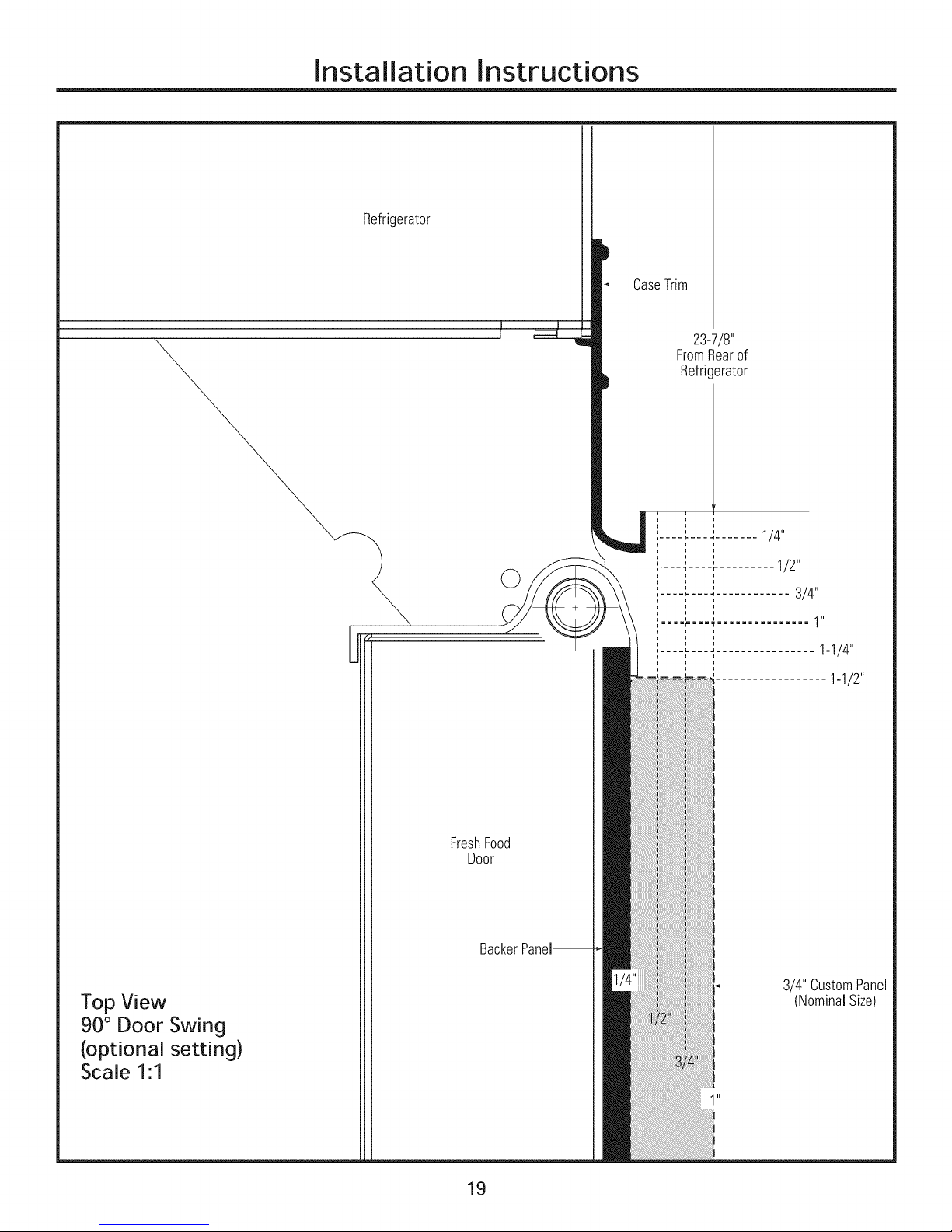

Page 19

Installation Instructions

Refrigerator

CaseTrim

23-7/8"

FromRearof

Refricerator

P

©

FreshFood

Door

i

i

u u

' -I- 1/2"

u u

i u

',..................... 3/4"

i i

i i i

i i

',.... _---4 ............... 1"

i i

i i i

i i

......... I................ 1-1/4"

i

i i i

u i

J

' 1/4"

i

i

1-1/2"

Top View

90 ° Door Swing

(optional setting)

Scale 1:1

3/4" CustomPanel

(NominalSize)

19

Page 20

Installation Instructions

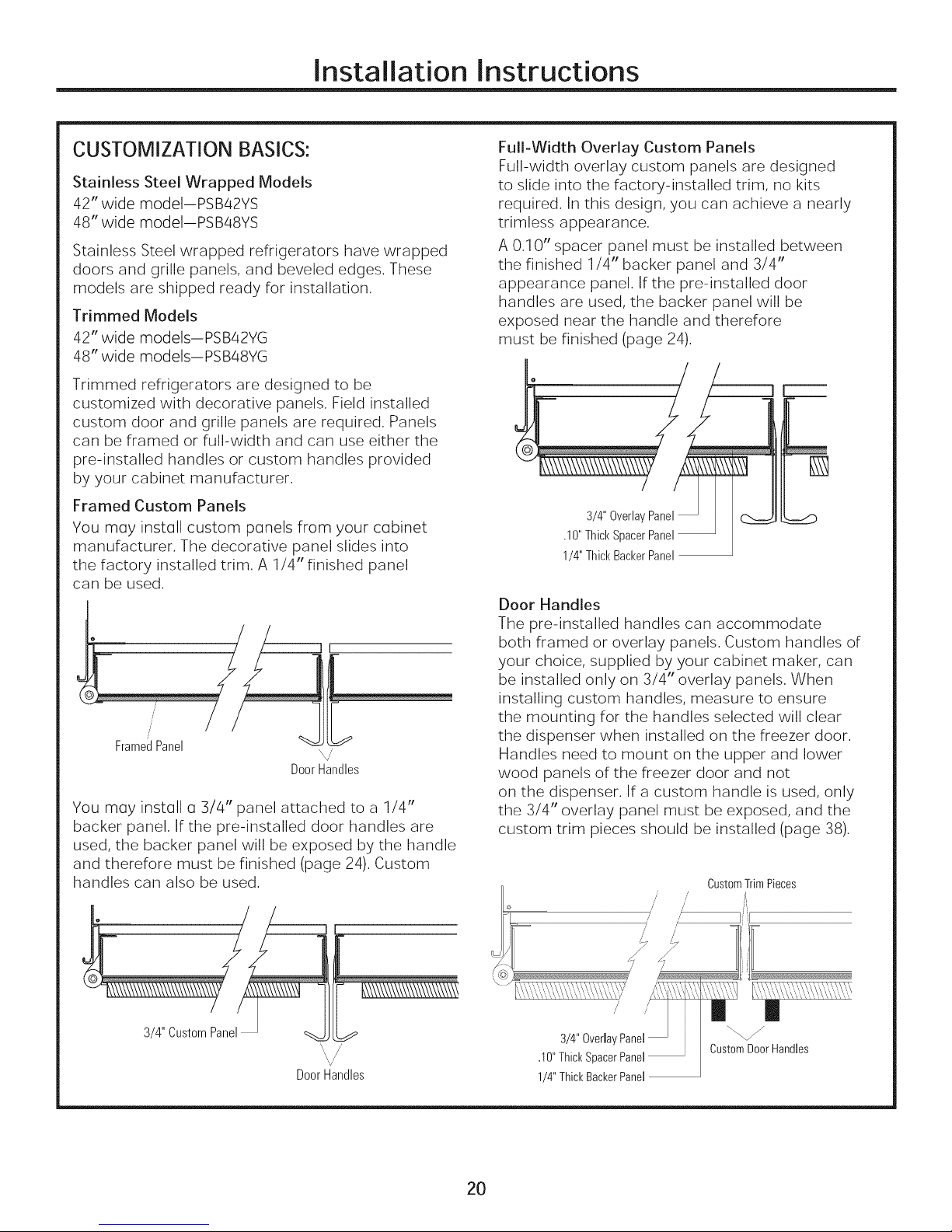

CUSTOMIZATION BASICS:

Stainless Steel Wrapped Models

42" wide modeI--PSB42YS

48" wide modeI--PSB48YS

Stainless Steel wrapped refrigerators have wrapped

doors and grille panels, and beveled edges. These

models are shipped ready for installation.

Trimmed Models

42" wide models--PSB42YG

48" wide models--PSB48YG

Trimmed refrigerators are designed to be

customized with decorative panels. Field installed

custom door and grille panels are required. Panels

can be framed or full-width and can use either the

pre-installed handles or custom handles provided

by your cabinet manufacturer.

Framed Custom Panels

You may install custom panels from your cobinet

manufacturer. The decorative panel slides into

the factory installed trim. A 1/4" finished panel

can be used.

FramedPanel

You may install a 5/4" panel attached to a 1/4"

backer panel. If the pre-installed door handles are

used, the backer panel will be exposed by the handle

and therefore must be finished (page 24). Custom

handles can also be used.

Full-Width Overlay Custom Panels

Full-width overlay custom panels are designed

to slide into the factory-installed trim, no kits

required. In this design, you can achieve a nearly

trimless appearance.

A 0.10" spacer panel must be installed between

the finished 1/4" backer panel and 3/4"

appearance panel. If the pre-installed door

handles are used, the backer panel will be

exposed near the handle and therefore

must be finished (page 24).

[]

3/4" OverlayPanel

.10" Thick SpacerPanel

1/4" Thick Backer Panel

Door Handles

The pre-installed handles can accommodate

both framed or overlay panels. Custom handles of

your choice, supplied by your cabinet maker, can

be installed only on 3/4" overlay panels. When

installing custom handles measure to ensure

the mounting for the handles selected will clear

the dispenser when installed on the freezer door.

Handles need to mount on the upper and lower

wood panels of the freezer door and not

on the dispenser. If a custom handle is used, only

the 3/4" overlay panel must be exposed, and the

custom trim pieces should be installed (page 38).

CustomTrimPieces

DoorHandles

2O

3/4" OverlayPanel

.10"ThickSpacerPanel

1/4"ThickBackerPanel

CustomDoorHandles

Page 21

Installation Instructions

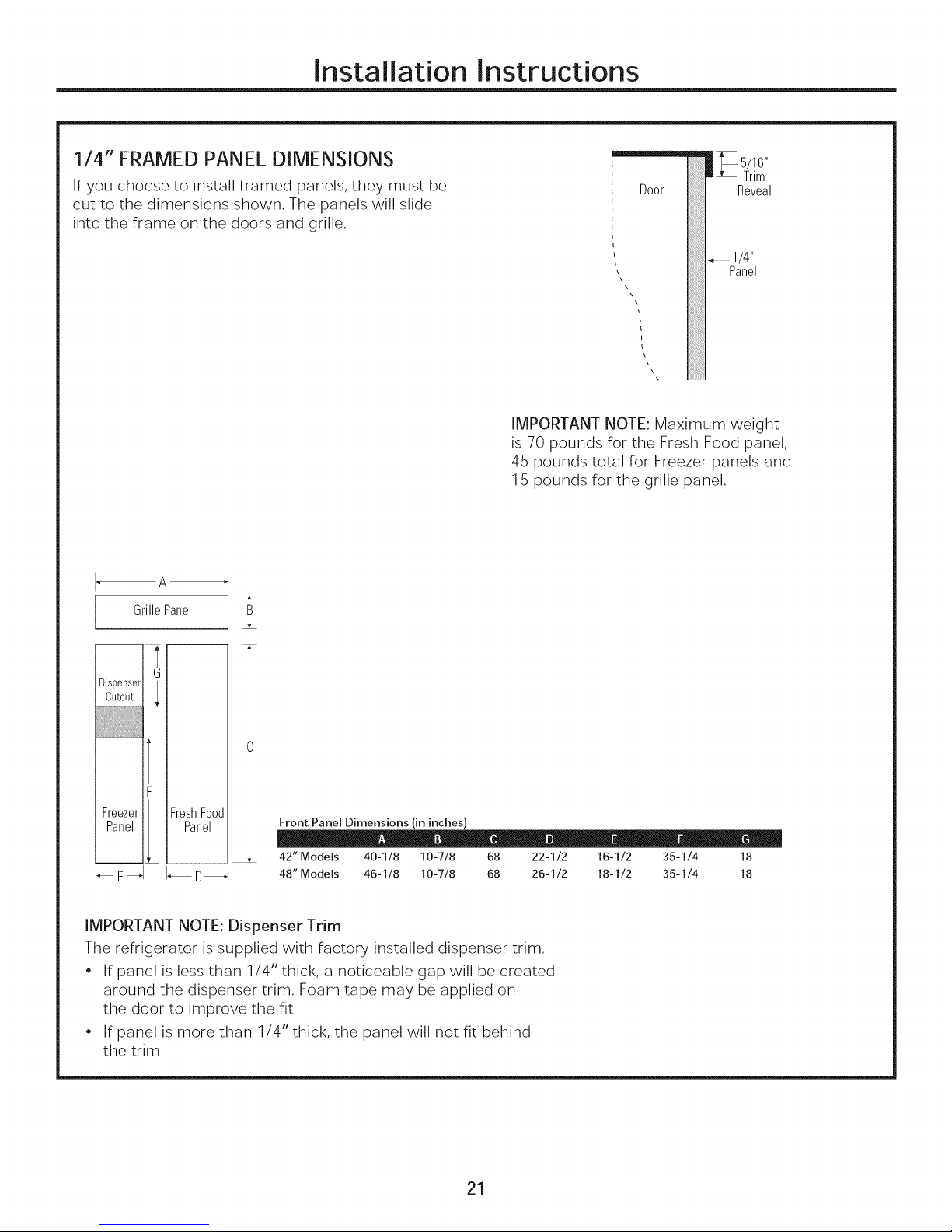

114" FRAMED PANEL DIMENSIONS

If you choose to install framed panels, they must be

cut to the dimensions shown. The panels will slide

into the frame on the doors and grille,

A

GrillePanel

5/16"

Door

i

i

3!!i Trimiii Reveal

\

\

\

Panel

1141/4"

IMPORTANT NOTE: Maximum weight

is 70 pounds for the Fresh Food panel,

45 pounds total for Freezer panels and

15 pounds for the grille panel.

FreshFood

Panel

E--I _D_

Front Panel Dimensions (in inches)

42" Models 40-1/8 10-7/8 68 22-1/2 16-1/2 35-1/4 18

48" Models 46-1/8 10-7/8 68 26-1/2 18-1/2 35-1/4 18

IMPORTANT NOTE: Dispenser Trim

The refrigerator is supplied with factory installed dispenser trim.

• If panel is less than 1/4" thick, a noticeable gap will be created

around the dispenser trim. Foam tape may be applied on

the door to improve the fit.

• If panel is more than 1/4" thick, the panel will not fit behind

the trim.

21

Page 22

Installation Instructions

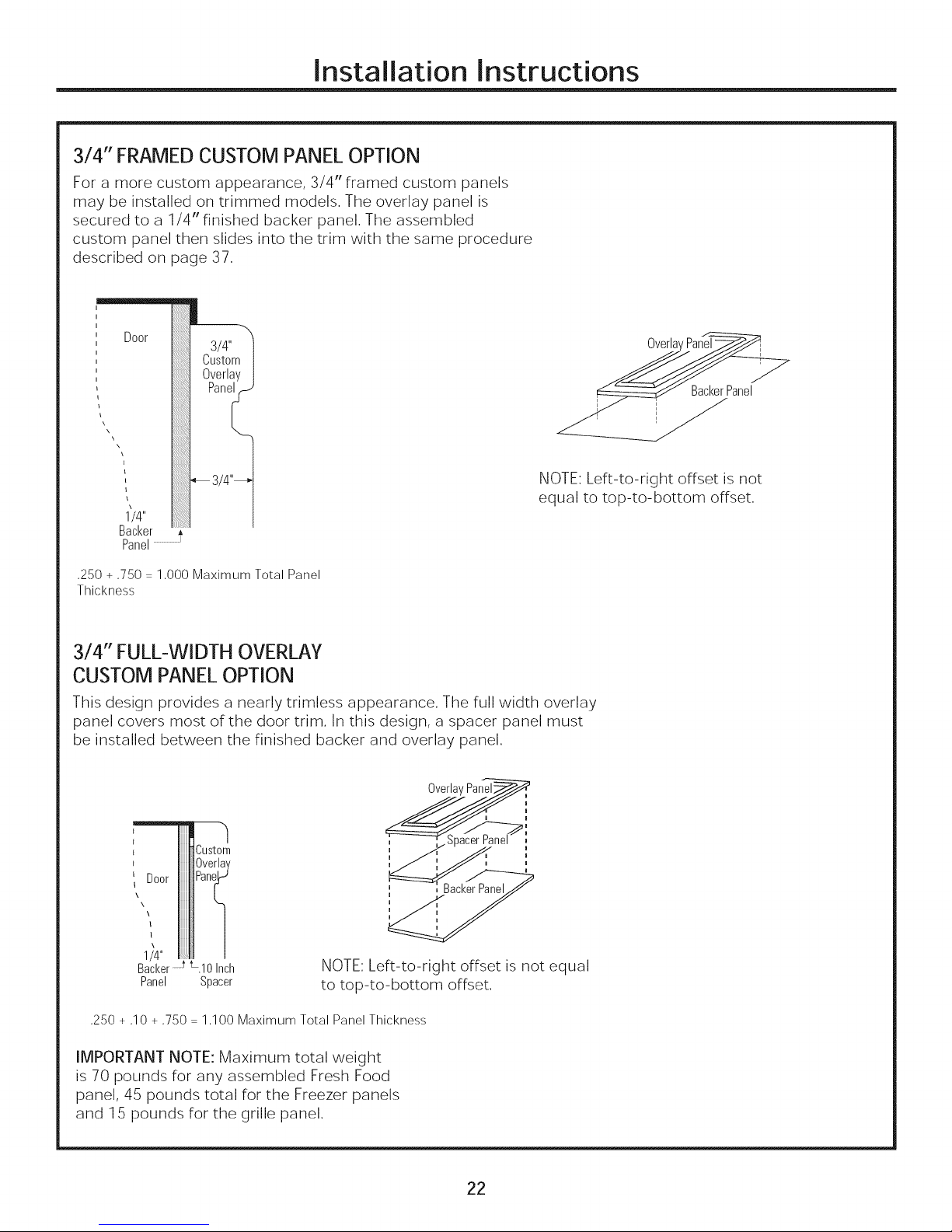

3/4" FRAMEDCUSTOMPANEL OPTION

For a more custom appearance, 3/4" framed custom panels

may be installed on trimmed models. The overlay panel is

secured to a 1/4" finished backer panel. The assembled

custom panel then slides into the trim with the same procedure

described on page 37.

Door

\\

1/4"

Backer _.

Panel

NOTE: Left-to-right offset is not

equal to top-to-bottom offset.

,250 + ,750 = 1,000 Maximum Total Panel

Thickness

3/4" FULL-WIDTH OVERLAY

CUSTOMPANEL OPTION

This design provides a nearly trimless appearance. The full width overlay

panel covers most of the door trim. In this design, a spacer panel must

be installed between the finished backer and overlay panel.

OverlayPanel:,

Custom

, BackerPanel

Door _Vr_e_

1/4"

Backer _.10 Inch

Panel Spacer

,250 + ,10 + ,750 = 1,100 Maximum Total Panel Thickness

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

IMPORTANT NOTE: Maximum total weight

is 70 pounds for any assembled Fresh Food

panel, 45 pounds total for the Freezer panels

and 15 pounds for the grille panel.

22

Page 23

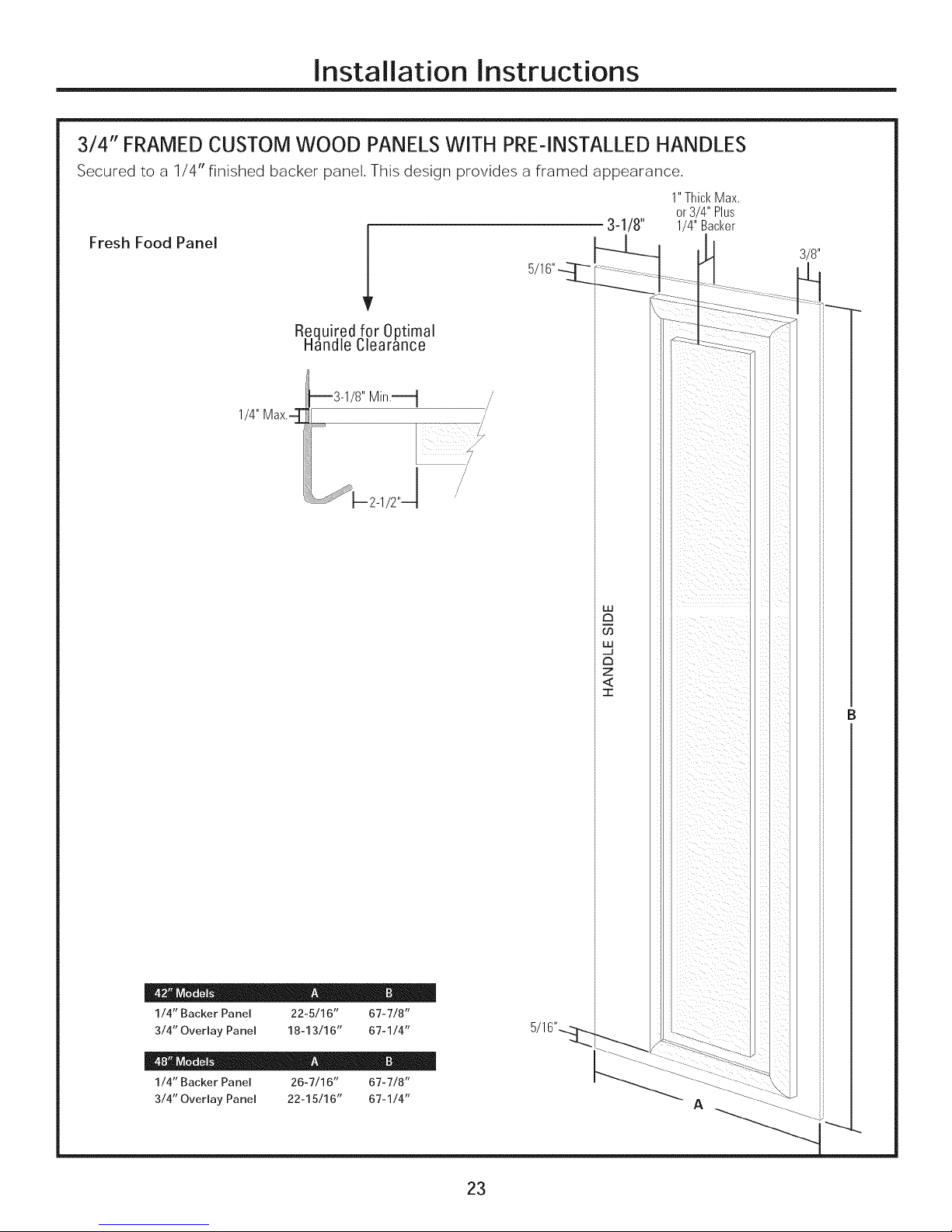

Installation Instructions

3/4" FRAMED CUSTOM WOOD PANELSWITH PRE-INSTALLED HANDLES

Secured to a 1/4" finished backer panel. This design provides a framed appearance.

1"ThickMax.

or3/4"PIus

Fresh Food Panel

1/4" Max.-_

Required for Optimal

Nandle Clearance

3-1/8" 1/4"Backer

1/4" Backer Panel 22-5/16" 67-7/8"

3/4" Overlay Panel 18-13/16" 67-1/4"

1/4" Backer Panel 26-7/16" 67-7/8"

3/4" Overlay Panel 22-15/16" 67-1/4"

B

A

23

Page 24

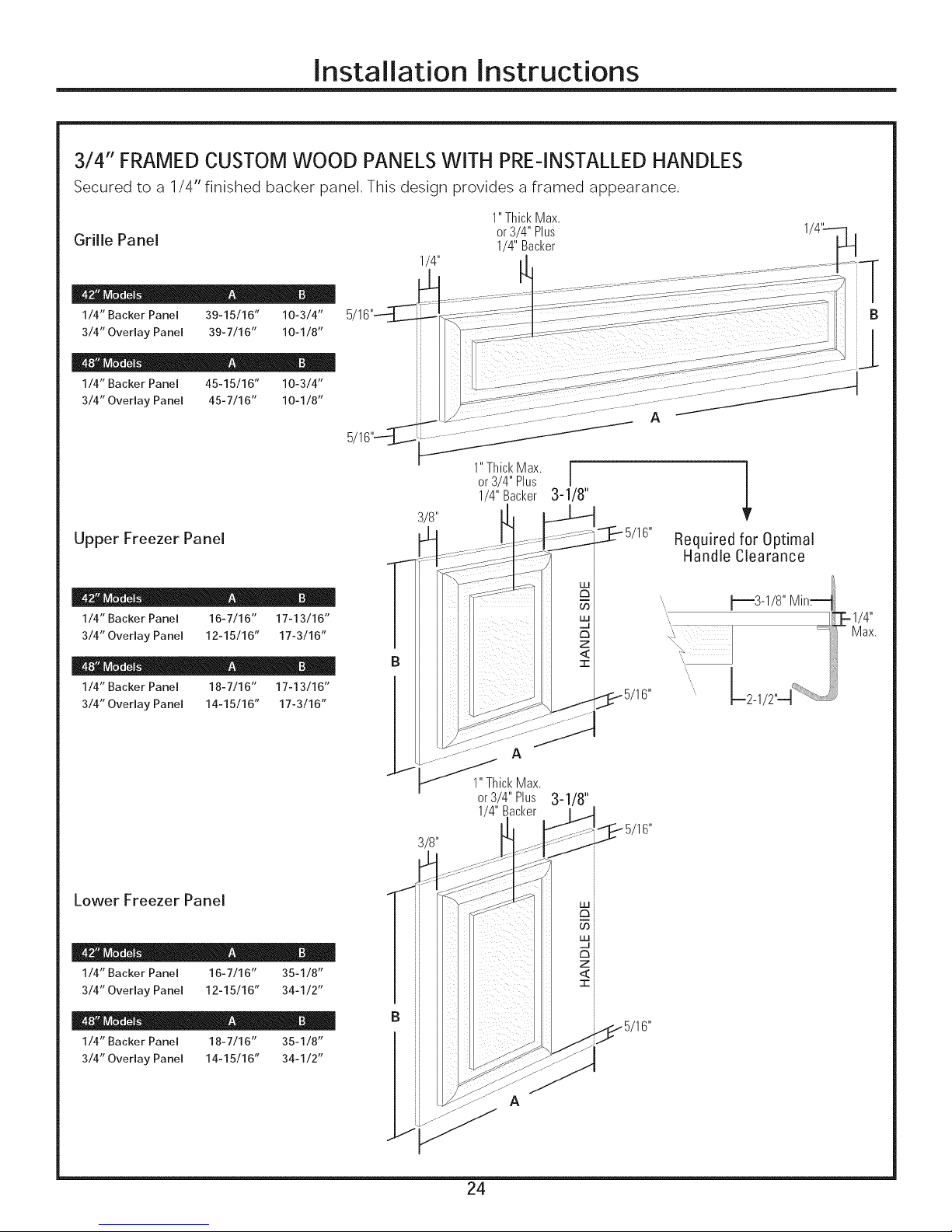

Installation Instructions

3/4" FRAMED CUSTOM WOOD PANELSWITH PRE-INSTALLED HANDLES

Secured to a 1/4" finished backer panel. This design provides a framed appearance.

1"ThickMax.

Grille Panel

1/4" Backer Panel 39-15/16" 10-3/4"

3/4" Overlay Panel 39-7/16" 10-1/8"

1/4" Backer Panel 45-15/16" 10-3/4"

3/4" Overlay Panel 45-7/16" 10-1/8"

5/1

I/4"

.Li

or3/4" PIus

1/4" Backer

A

Upper Freezer Panel

1/4" Backer Panel 16-7/16" 17-13/16"

3/4" Overlay Panel 12-15/16" 17-3/16"

1/4" Backer Panel 18-7/16" 17-13/16"

3/4" Overlay Panel 14-15/16" 17-3/16"

Lower Freezer Panel

1"ThickMax. [

or 3/4" Plus

1/4"Backer 3-1/8"

A

11 __1" Thicl<Max.

or3/4"PIus

1/4" Backer

/

3-1/8"

Required for Optimal

Handle Clearance

",. _--3-1/8" Minm

", _-I/4"

' L2 -4

.... -1/2"

/16"

Max

1/4" Backer Panel 16-7/16" 35-1/8"

3/4" Overlay Panel 12-15/16" 34-1/2"

1/4" Backer Panel 18-7/16" 35-1/8"

3/4" Overlay Panel 14-15/16" 34-1/2"

'16"

A

24

Page 25

Installation Instructions

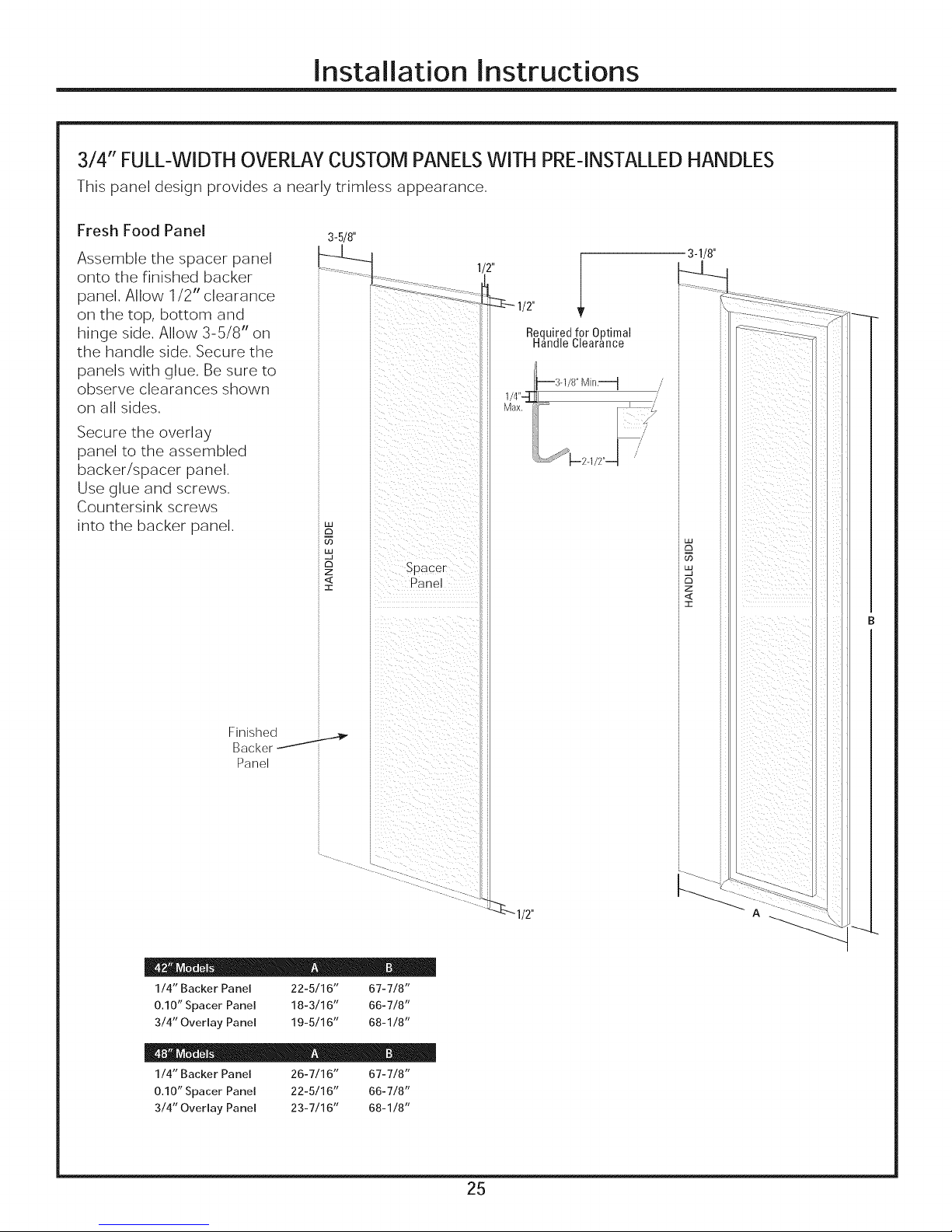

3/4" FULL-WIDTH OVERLAYCUSTOMPANELSWITH PRE-INSTALLEDHANDLES

This panel design provides a nearly trimless appearance.

Fresh Food Panel

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2" clearance

on the top, bottom and

hinge side. Allow 3-5/8" on

the handle side. Secure the

panels with glue. Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel.

3-5/8"

'5

zo spacer-

Panel

1/2"

Required for Optimal

Nandle Clearance

3-1/8"

Finished

Backer

Panel

iiiiiiii_i_il i I x_i_ill

1/4" Backer Panel 22-5/16" 67-7/8"

0.10" Spacer Panel 18-3/16" 66-7/8"

3/4" Overlay Panel 19-5/16" 68-1/8"

1/4" Backer Panel 26-7/16" 67-7/8"

0.10" Spacer Panel 22-5/16" 66-7/8"

3/4" Overlay Panel 23-7/16" 68-1/8"

1/2"

25

Page 26

Installation Instructions

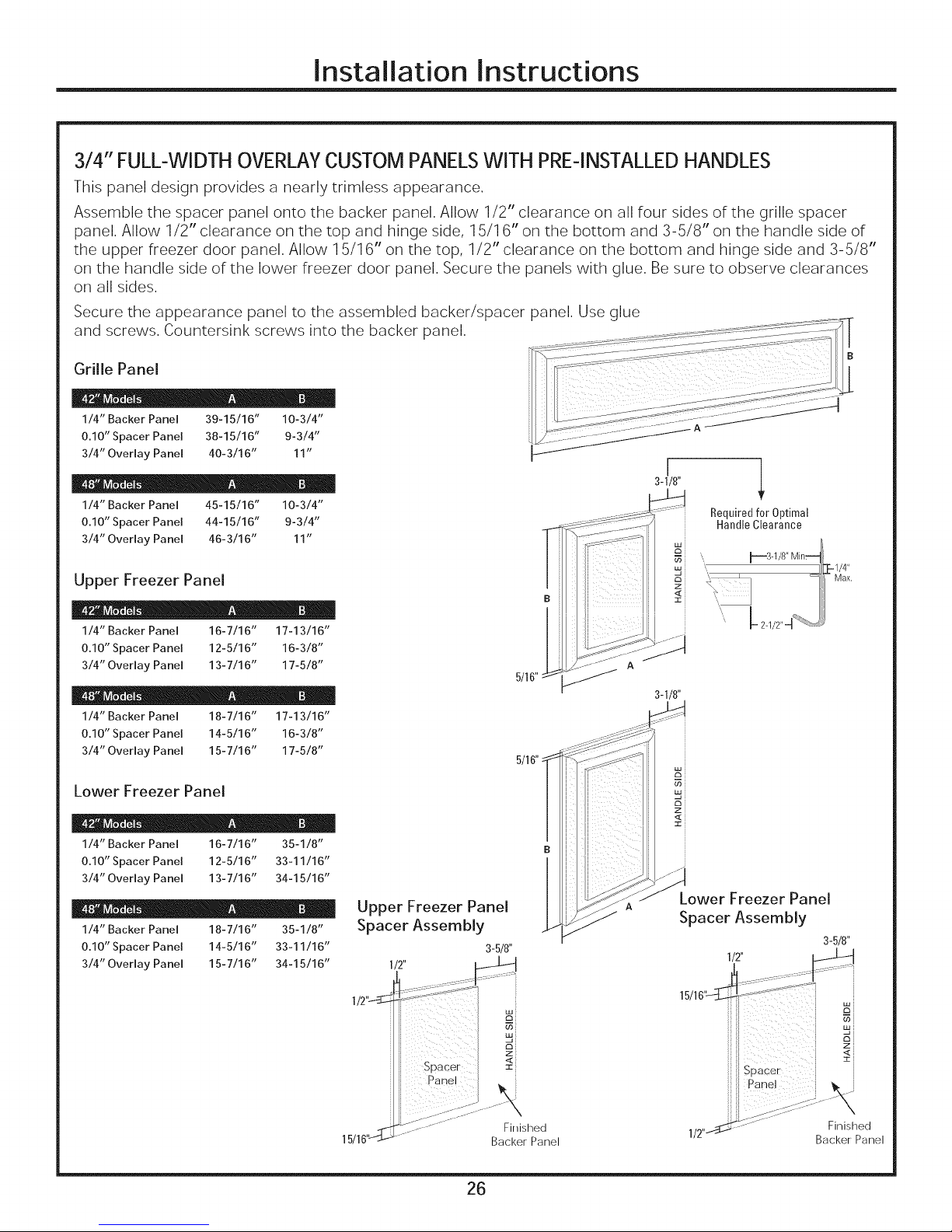

3/4" FULL-WIDTH OVERLAYCUSTOMPANELSWITH PRE-INSTALLEDHANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2" clearance on all four sides of the grille spacer

panel. Allow 1/2" clearance on the top and hinge side, 15/1 6" on the bottom and 3-5/8" on the handle side of

the upper freezer door panel. Allow 15/1 6" on the top, 1/2" clearance on the bottom and hinge side and 3-5/8"

on the handle side of the lower freezer door panel. Secure the panels with glue. Be sure to observe clearances

on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

I/4" Backer Panel 39-15/16" 10-3/4"

0.10" Spacer Panel 38-15/16" 9-3/4"

3/4" Overlay Panel 40-3/16" 11"

I

3-1/8"

1/4" Backer Panel 45-15/16" 10-3/4"

0.10" Spacer Panel 44-15/16" 9-3/4"

3/4" Overlay Panel 46-3/16" 11"

Required for Optimal

HandleClearance

D}

,, _'-3ol/8" Min4i

Upper Freezer Panel

I/4" Backer Panel 16-7/16" 17-13/16"

0.I0" Spacer Panel 12-5/16" 16-3/8"

3/4" Overlay Panel 13-7/16" 17-5/8"

1/4" Backer Panel 18-7/16" 17-13/16"

0.10" Spacer Panel 14-5/16" 16-3/8"

3/4" Overlay Panel 15-7/16" 17-5/8"

Lower Freezer Panel

1/4" Backer Panel 16-7/16" 35-1/8"

0.10" Spacer Panel 12-5/16" 33-11/16"

3/4" Overlay Panel 13-7/16" 34-15/16"

1/4" Backer Panel 18-7/16" 35-1/8"

0.10" Spacer Panel 14-5/16" 33-11/16"

3/4" Overlay Panel 15-7/16" 34-15/16"

Upper Freezer Panel

Spacer Assembly

3-5/8"

5/16"

5/16" _-

zi

A

3-1/8"

Lower Freezer Panel

Spacer Assembly

3-5/8"

1/2"

m_

o3_

wi

Ji

tm_

zi

:z:i

15/ Backer Panel

Finished

26

1/2

Finished

Backer Panel

Page 27

Installation Instructions

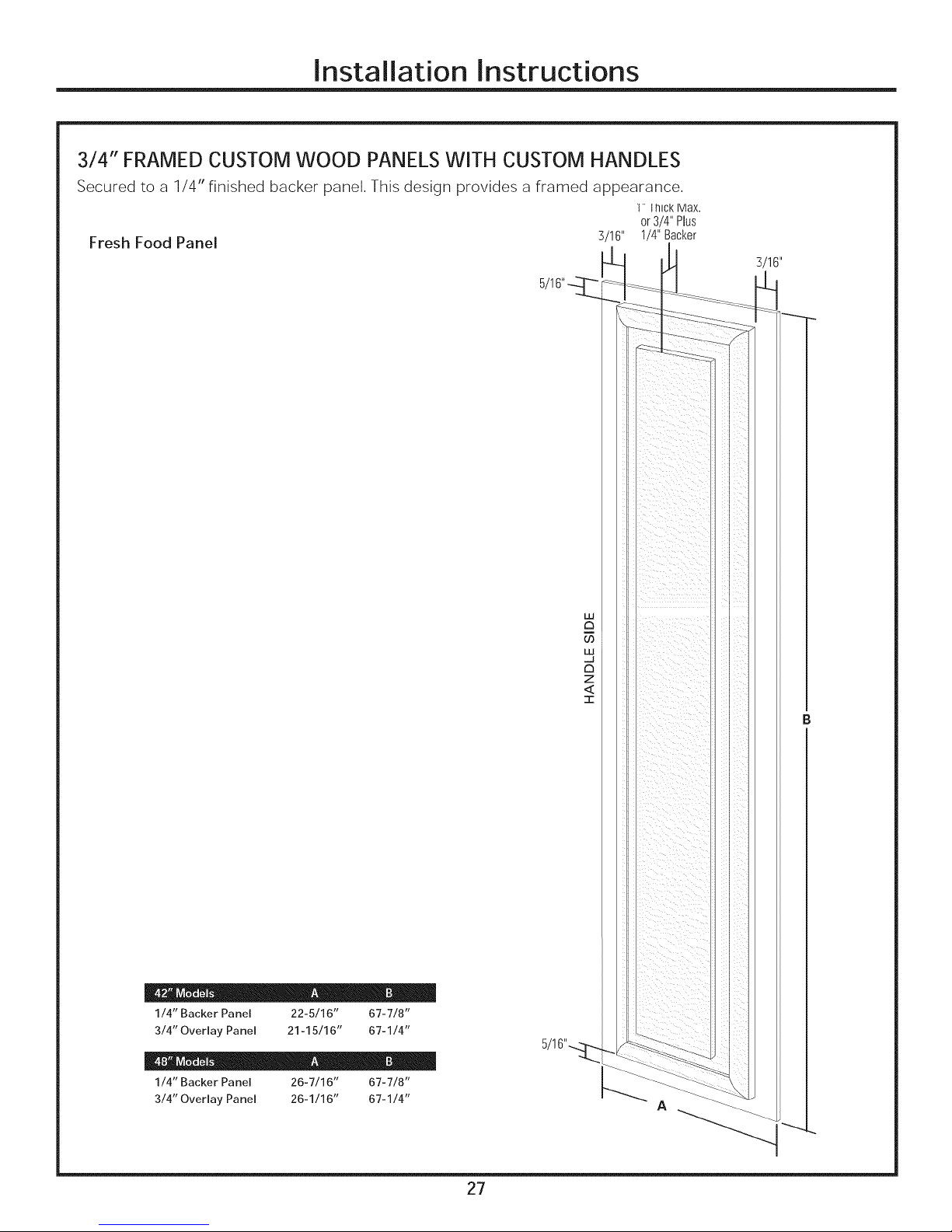

3/4" FRAMED CUSTOM WOOD PANELSWITH CUSTOM HANDLES

Secured to a 1/4" finished backer panel. This design provides a framed appearance,

1 tiqlck IVtax.

or3/4"Plus

Fresh Food Panel 3/16" 1/4"Backer

1/4" Backer Panel 22-5/16" 67-7/8"

3/4" Overlay Panel 21-15/16" 67-1/4"

I/4" Backer Panel 26-7/16" 67-7/8"

3/4" Overlay Panel 26-I/16" 67-I/4"

B

27

Page 28

Installation Instructions

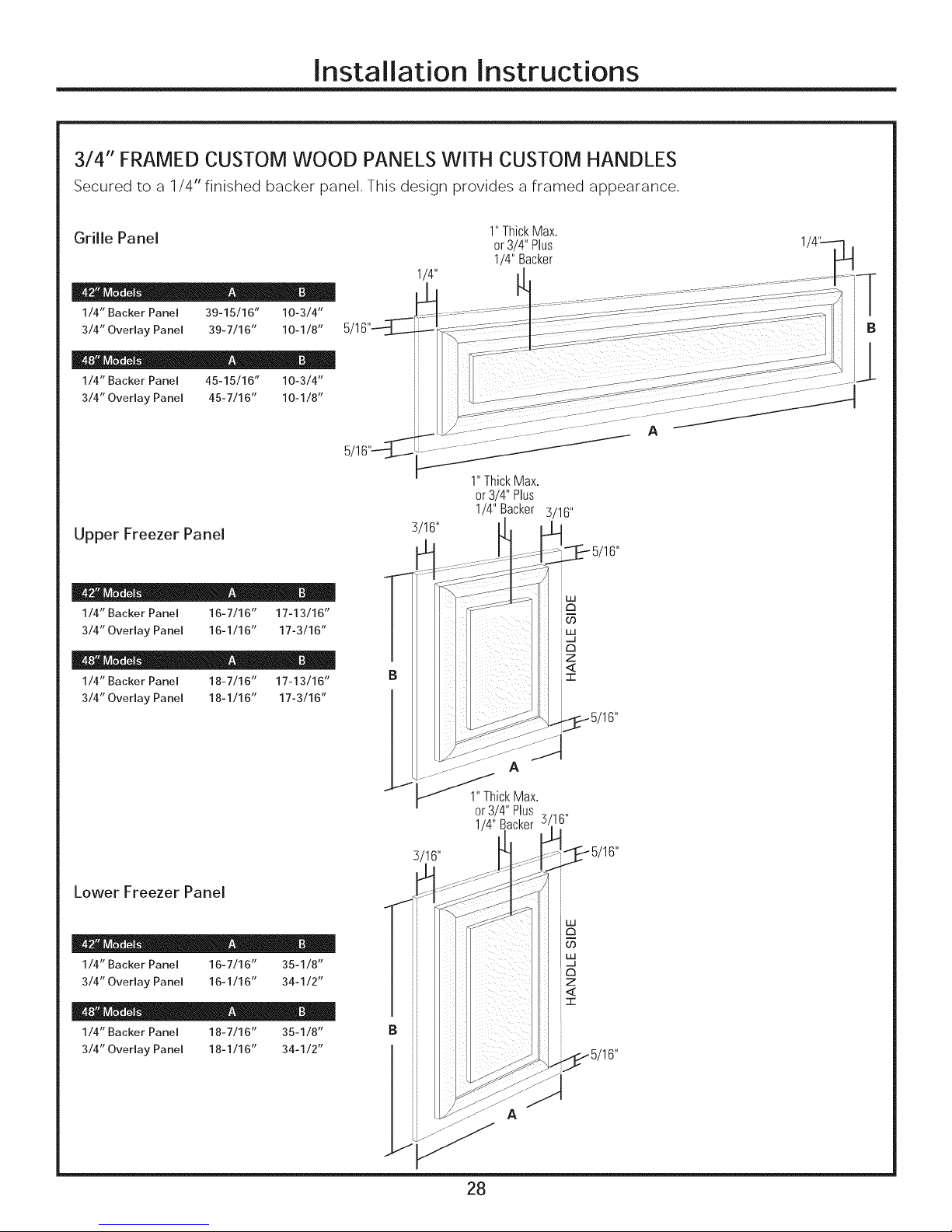

3/4" FRAMED CUSTOM WOOD PANELSWITH CUSTOM HANDLES

Secured to a 1/4" finished backer panel. This design provides a framed appearance.

Grille Panel

1/4" Backer Panel 39-15/16" 10-3/4"

3/4" Overlay Panel 39-7/16" 10-1/8"

I/4" Backer Panel 45-15/16" 10-3/4"

3/4" Overlay Panel 45-7/16" 10-I/8"

Upper Freezer Panel

1/4" Backer Panel 16-7/16" 17-13/16"

3/4" Overlay Panel 16-1/16" 17-3/16"

1/4" Backer Panel 18-7/16" 17-13/16"

3/4" Overlay Panel 18-1/16" 17-3/16"

I/4"

3/16"

1" ThickMax.

or 3/4" Plus

1/4"Backer

i

1"ThickMax.

or3/4"Plus

1/4"Backer 3/16"

A

Lower Freezer Panel

1/4" Backer Panel 16-7/16" 35-1/8"

3/4" Overlay Panel 16-1/16" 34-1/2"

1/4" Backer Panel 18-7/16" 35-1/8"

3/4" Overlay Panel 18-1/16" 34-1/2"

3/16"

qB"

'16"

28

Page 29

Installation Instructions

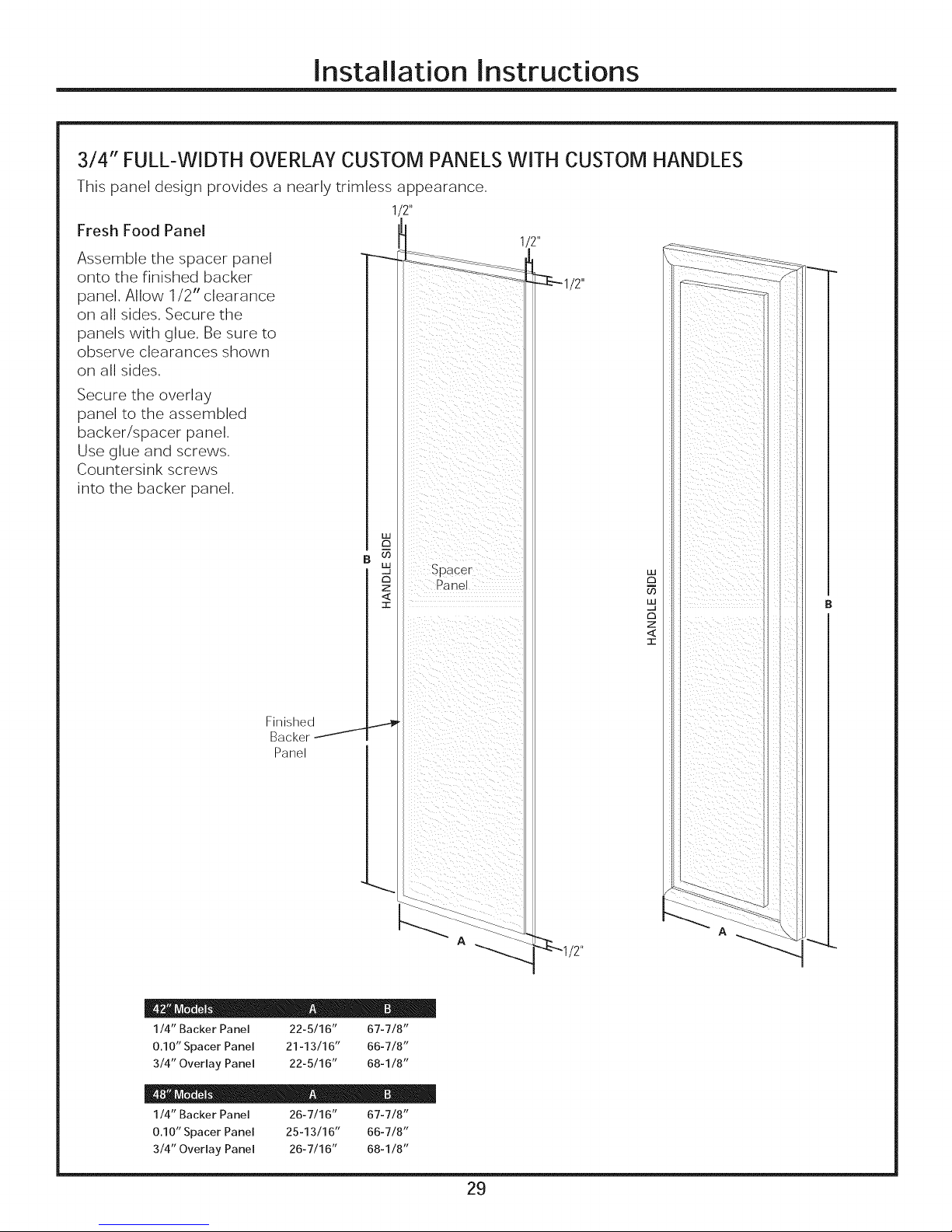

3/4" FULL-WIDTH OVERLAY CUSTOM PANELS WITH CUSTOM HANDLES

This panel design provides a nearly trimless appearance.

I/2"

Fresh Food Panel

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2" clearance

on all sides, Secure the

panels with glue, Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel,

1/2"

_1/2"

Finished

Backer /

Panel

w

tm

c_

Z

<

-r

Spacer

Panel

LU

a

a

z

<

-I-

114" Backer Panel 22-5116" 67-7/8"

0.10" Spacer Panel 21-13/16" 66-7/8"

3/4" Overlay Panel 22-5/16" 68-1/8"

1/4" Backer Panel 26-7/16" 67-7/8"

0.10" Spacer Panel 25-13/16" 66-7/8"

3/4" Overlay Panel 26-7/16" 68-1/8"

29

Page 30

Installation Instructions

3/4" FULL-WIDTH OVERLAY CUSTOM PANELS WITH CUSTOM HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2" clearance on all four sides of the grille spacer

panel. Allow 1/2" clearance on the top, hinge side and handle side, and 15/1 6" on the bottom of the upper

freezer door panel. Allow 15/1 6" on the top and 1/2" clearance on the bottom, hinge side and handle side

of the lower freezer door panel. Secure the panels with glue. Be sure to observe clearances on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

I/4" Backer Panel 39-15/16" 10-3/4"

0.10" Spacer Panel 38-15/16" 9-3/4"

3/4" Overlay Panel 40-3/16" 11"

1/4" Backer Panel 45-15/16" 10-3/4"

0.10" Spacer Panel 44-15/16" 9-3/4"

3/4" Overlay Panel 46-3/16" 11"

Upper Freezer Panel

I/4" Backer Panel 16-7/16" 17-13/16"

0.I0" Spacer Panel 15-7/16" 16-3/8"

3/4" Overlay Panel 16-7/16" 17-5/8"

1/4" Backer Panel 18-7/16" 17-13/16"

0.10" Spacer Panel 17-7/16" 16-3/8"

3/4" Overlay Panel 18-7/16" 17-5/8"

Lower Freezer Panel

1/4" Backer Panel 16-7/16" 35-1/8"

0.10" Spacer Panel 15-7/16" 33-11/16"

3/4" Overlay Panel 16-7/16" 34-15/16"

1/4" Backer Panel 18-7/16" 35-1/8"

0.10" Spacer Panel 17-7/16" 33-11/16"

3/4" Overlay Panel 18-7/16" 34-15/16"

Upper Freezer Panel

Spacer Assembly

1/2"

112"

5/16"

5/16"

c_

z

=<

Lower Freezer Panel

Spacer Assembly

1/2"

1/2"

F_nished Finished

Ba ;kerr Racker

Panel Panel

30

Page 31

Installation Instructions

SIDE PANELS

Side panels (not

supplied) must be used

whenever the sides of

the refrigerator will be

exposed. The 1/4" side

panels will slip into the

side case trim, Order

side panels from your

cabinet manufacturer,

* Depending on

installation height.

_24'_

_84"

-]_'3" to 4"

1-1/2"

FLOORING

For proper installation, this refrigerator must be

placed on a level surface of hard material that is

at the same height as the rest of the flooring. This

surface should be strong enough to support a fully

loaded refrigerator, or approximately 1500 lb.

NOTE: Protect the finish of the flooring. Cut a large

section of the cardboard carton and place under

the refrigerator where you are working.

GROUNDING THE REFRIGERATOR

IMPORTANT--Please read carefully

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED.

The power supply cord of this appliance is

equipped with a three-prong (grounding) plug

which mates with a standard three-prong

(grounding) wall receptacle to minimize the

possibility of electric shock hazard from this

appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet

is encountered, it is your personal responsibility

and obligation to have it replaced with a properly

grounded 3-prong wall outlet.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

(GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER

PLUG TO CONNECT THE REFRIGERATOR

TO A 2-PRONG OUTLET.

DO NOT USE AN EXTENSION CORD WITH

THIS APPLIANCE.

31

Page 32

Installation Instructions

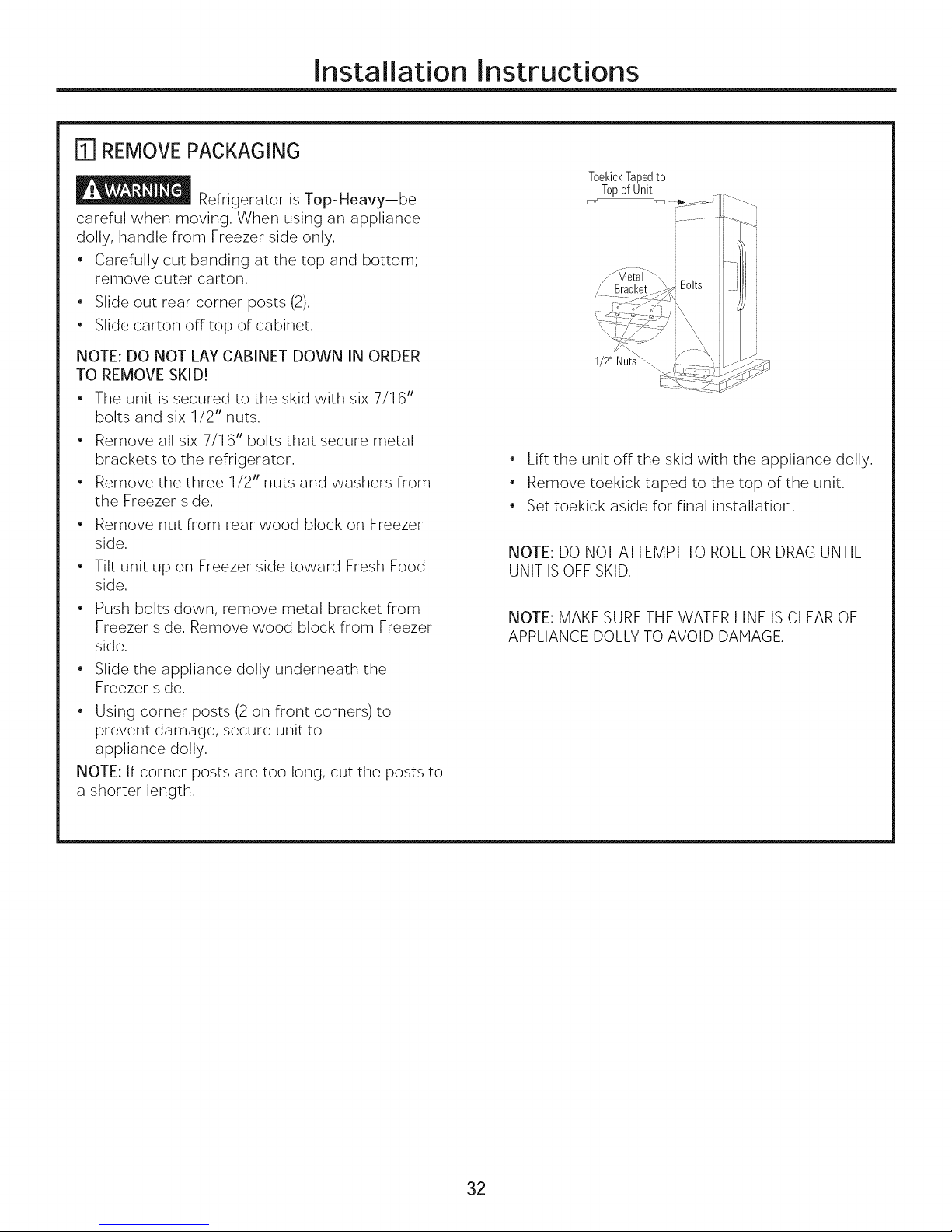

[] REMOVEPACKAGING

Refrigerator is Top-Heavy-be

careful when moving. When using an appliance

dolly, handle from Freezer side only.

• Carefully cut banding at the top and bottom;

remove outer carton.

• Slide out rear corner posts (2).

• Slide carton off top of cabinet.

Toel(icl(Tapedto

Topof Unit

NOTE: DO NOT LAY CABINET DOWN IN ORDER

TO REMOVE SKID!

• The unit is secured to the skid with six 7/16"

bolts and six 1/2" nuts.

• Remove all six 7/16" bolts that secure metal

brackets to the refrigerator.

• Remove the three 1/2" nuts and washers from

the Freezer side.

• Remove nut from rear wood block on Freezer

side.

• Tilt unit up on Freezer side toward Fresh Food

side.

• Push bolts down, remove metal bracket from

Freezer side. Remove wood block from Freezer

side.

• Slide the appliance dolly underneath the

Freezer side.

• Using corner posts (2 on front corners) to

prevent damage, secure unit to

appliance dolly.

NOTE: If corner posts are too long, cut the posts to

a shorter length.

1/2" Nuts_--.

• Lift the unit off the skid with the appliance dolly.

• Remove toekick taped to the top of the unit.

• Set toekick aside for final installation.

NOTE: DO NOT ATTEMPTTO ROLL OR DRAG UNTIL

UNIT IS OFF SKID.

NOTE: MAKE SURE THE WATER LINE IS CLEAR OF

APPLIANCE DOLLY TO AVOID DAMAGE.

32

Page 33

Installation Instructions

[] INSTALL WATER LINE

• A cold water supply is required for automatic

icemaker operation, The water pressure must

be between 40 and 120 psi.

• Route 1/4" O,D, copper tubing or GE

SmartConnect TMtubing between cold water

line and the water connection location,

• Tubing should be long enough to extend to the

front of the refrigerator, Allow enough tubing to

accommodate bend leading into the water line

connection,

NOTE; The only GE approved plastic tubing is

supplied in the GE SmartConnect TMRefrigerator

Tubing kits, Do not use any other plastic water

supply line; the line is under pressure at all times,

Certain types of plastic may crack or rupture with

age and cause water damage to your home,

GE SmartConnect TMrefrigerator tubing kits are

available in the following lengths:

2" (0.6m) WXOSX10002

6" (1.8m) WXO8X10006

15" (4.6m) WXOSX10015

25" (7.6m) WXOSX10025

Shut off the main water supply.

Turn on the nearest faucet long enough

to purge all the water from the line.

• Install a shutoff valve between the icemaker

water valve and cold water pipe in a basement

or cabinet. The shutoff valve should be located

where it will be easily accessible.

NOTE: It is best to install the valve into a vertical

water pipe. If you install the valve into a horizontal

water pipe, make the connection at the top

or side to avoid drawing off any sediment

from the water pipe.

• Drill a 1/4" hole in the water pipe.

• Fasten the shutoff valve to the pipe with pipe

clamp.

• Tighten the clamp screws until the sealing

washer begins to swell. Do not OVERTIGHTEN.

• Place a compression nut and ferrule (sleeve) for

copper tubing onto the end of the tubing and

connect it to the shutoff valve. Make sure the

tubing is fully inserted into the valve and ferrule

is tightened.

CopperTubingJ

orGESmartC0nnectTMTubing

SaddleType

Shut0_ve _

Pacl<in_

OutletValve

CompressionNut

_ /,////"/

/

\

Ferrule

(Sleeve)

For plastic tubing from a GESmartConnect TM

refrigerator tubing kit, insert the molded end of

the tubing into the shutoff valve and tighten the

compression nut until it is hand tight, and then

tighten an additional turn with a wrench.

Turn on the main water supply and

flush debris. Run about a quart of water

through the tubing into a bucket. Shut

off water supply at the shutoff valve.

NOTE: Saddle type shutoff valves are included in

many water supply kits. Before purchasing, make

sure a saddle type valve complies with your local

plumbing codes.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR must be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

33

Page 34

Installation Instructions

_WATER LINE INSTALLATION WITH

A REVERSE OSMOSIS SYSTEM

SKIP THIS STEP WHEN NOT USING AN RO SYSTEM

NOTE: If the water supply to the refrigerator

is from a Reverse Osmosis Water System, use

the refrigerator's filter bypass plug. Using the

refrigerator's water filtration cartridge with

the RO filter can result in hollow ice cubes.

Master Power Switch Water Filter

Rotate Counterclockwise To Remove

• Open the top grille to view the filtration cartridge.

Rotate the filtration cartridge counterclockwise

until removed.

• Insert filter bypass plug. Rotate the filter bypass

plug clockwise until tightly secured in place.

[] INSTALLANTI-TIP BRACKETS(cant,)

Screws

must Required

penetrate

at least 1"

into vertical

wall studs•

Brackets

Height

From

Floor

to

Bottom

of Wooc

Block

Side View

ALTERNATE ANTI-TIP

PRECAUTIONS

The refrigerator must be secured to prevent tipping.

The anti-tip brackets cannot be used on metal wall

studs. Use this Alternate Procedure to secure the

refrigerator against tip-over whenever metal wall

studs are encountered and there is not soffit.

r3] INSTALL SIDE PANELS

SKIPTHIS STEPWHEN NOT USINGSIDEPANELS

If you are using 1/4" side panels, they should be

inserted into the case trim. Fasten the panels to the

refrigerator with the 3M Dual Lock adhesive strips

before setting refrigerator in place.

[_] INSTALL ANTI-TIP BRACKETS

ANTI-TIP PRECAUTIONS

The refrigerator isTop-Heavy and must besecured

to prevent the possibility of tipping forward•

• Cut a 2"x 4"wood block 36" long,

and secure the block ..........I', ! ,,

to the mounting _ _<-_- ;-._

brackets _' BI_-_ j

provided, using

#12 or #14 _f ]_I i Positioned

wood screws ..... _ ! _, . AntkHp

• Secure the brackets Mountedinto i i_ i

• Vertical i i ,

with wood block WoodStuds!s_ _Wall Stud

to the back wall so " #'_ I (Behind

that it is 82" (or the rear Drywall)

installation height) from the finished floor• Use

#12 or #14 wood screws•

• vv00a bcrews i ! i , Brac<et

/ _ j , ! A .T

(3/a ")

min.

i \ SideView

Top Case Trim

\

\

" H-o

.1,.. ','

• Adjust height of refrigerator to match

installation cutout opening 83-1/2" to 84-1/2".

The refrigerator must be level and plumb with

cabinets. The top case trim at the front is 2-1/8"

higher than the rear and will overlap upper

cabinets or cabinet trim.

• Open grille panel to access the top case trim.

• Use a 3/16"bit to drill 4 evenly spaced clearance

holes through the metal top case trim.

• Use a 1/16" bit to drill pilot holes through the

metal clearance holes and into wood soffit. The

holes should be centered in the soffit or a 3/4"

minimum wood brace. The brace spanning the

enclosure must be securely fastened to cabinets

on both sides.

• Install four 1-1/2" drywall screws into the pilot

holes.

or 3/4" Min, Wood Brace

34

Page 35

Installation Instructions

FS]CONNECT POWER

• Connect refrigerator power cord plug to

a properly grounded receptacle, Set the

Master Power switch to the I (ON) position.

o

x__i!!i_i!::i!jjiGrille j ;; "_i

Raise _ _cl

_Z_Panel IS J.{i

_" X

Master Water Filter

Power Switch

5,£

• Check to make sure power to refrigerator

is on by opening refrigerator door to see

if interior lights are on.

• After power has been established, turn the

Master Power switch to the 0 (OFF) position.

r6-]MOVE INTO INSTALLATION SPACE

[] LEVEL REFRIGERATOR

All models have 4-point leveling. The front and back

are supported by leveling legs. Both are accessible

from the front of the refrigerator.

• To level the back of the refrigerator, turn the 1/2"

hex nut located above the front wheels. Turn

clockwise to raise or counterclockwise to lower

the refrigerator.

• For front leveling, use a 7/16" open-end wrench.

• Adjust height of refrigerator to match

installation cutout opening 83-1/2" to 84-1/2".

The refrigerator should be level and plumb with

cabinets.

LevelingLeg

HexNutAdjusts

RearLevelingLegs

/

• Slide the unit into the installation space,

• Place excess slack in the power cord on top

of the refrigerator,

• Use care to ensure the power cord is not

pinched behind the unit.

Height

from

FI00rt0

Bottom

ofWood

Block

82"

IMPORTANT NOTE: The refrigerator must be level.

If it is not, the doors may not align evenly at

the top. See Step 16.

NOTE: The rear leveling legs and front leveling legs

are limited to a maximum height adjustment

of 1". If the installation requires more than 84-1/2"

height, the installer should elevate the refrigerator

on a sheet of plywood or runners. Cabinet trim

could be added across the top of the opening

to shorten the opening. If you attempt to raise

the refrigerator more than 1", you will damage

the front and rear leveling legs.

35

Page 36

Installation Instructions

1-81SECUREREFRIGERATOR

TO CABINETS

Whenever possible, perform this step for anti-tip

security or when anti-tip brackets cannot be used.

The refrigerator must be secured to prevent

tipping.

• Raise the grille panel to access case trim.

• Drill a hole in the trim and drive a screw through

the trim into the adjacent cabinet.

• Follow the same procedure on the opposite side.

;; Drive Screws , ,_

ThroughCaseTrimInt0

Adjacent Cabinets

\r\

rg-]ADJUST DOOR SWING

NOTE: This refrigerator has a 2-position door stop.

When space does not allow the door to swing open

fully to 130 °, you may change the door swing to

a 90 ° opening.

SKIP THIS STEP IF DOOR OPENING IS

SATISFACTORY FOR YOUR INSTALLATION

SITUATION.

• Open the door to view the bottom hinge.

Note the door stop pin location. The pin is factory

installed in the 130 ° position.

• Partially close the door. From above, use

a flat-head screwdriver to unscrew the door

stop pin and reinstall into the 90 ° position.

N-0"IINSTALL GRILLE PANEL

• Raise the grille panel to the stop position.

Grille

AA

• Remove 4 screws on bottom trim; retain

all screws.

• Remove bottom trim.

• NOTE: Stainless steel and acrylic panels are

covered with a protective film. Remove the film

before installing the panel.

• Slide panel over the metal backer panel and

under the trim.

& & & &

• If necessary, tap with a wood block until panel

slips under the top trim piece.

• Reassemble bottom trim. Tighten screws.

///

Interior

Hinge

00r

36

Page 37

Installation Instructions

INSTALL DOOR PANELS

WITH PRE-INSTALLED HANDLES

Handle_.

FreshFood

Refrigerator

Door

_\\\\\\\\\\\\\\\\\\\\]

3/4"CustomPanel

if Required

Install 1/4" Decorative Panels:

• Remove Handles

Open door to 90 °. Remove 5 Phillips head

screws from the Fresh Food and Freezer door

handles; retain all screws. Lift off door handles.

Install Door Panels

NOTE: Carefully push the Fresh Food panel in until

it slides into the slot behind the trim. Gently push

to opposite side. Repeat procedure for upper and

lower Freezer panels.

Reinstall Handles

Reinstall Fresh Food door handle with

the original 5 Phillips head screws, Tighten,

Repeat for Freezer door handle,

NOTE: Ensure that the edge of the handle does

not pinch the door gasket.

• 3/4" Custom Decorative Panels

If you choose to install custom wood panels,

they must be cut to dimensions shown on

pages 23-30. The panels will slide into the

frame on the doors and grille.

J

IMPORTANT NOTE: Maximum custom panel

thickness must not exceed 1-1/8" thick and 70

Ibs for the Fresh Food door, 45 Ibs total for the

Freezer door and 15 Ibs for the Grille panel.

37

Page 38

Installation Instructions

| INSTALL DOOR PANELS

Handle-

FreshFood

Refrigerator

Door

3/4"CustomPanel

if Required

Install 1/4" Decorative Panels:

• Remove Pre-lnstalled Handles

Open door to 90 °. Remove 5 Phillips head screws

from the Fresh Food and Freezer door handles;

retain all screws. Lift off pre-installed door handles.

Install Door Panels

NOTE: Carefully push the Fresh Food panel in until

it slides into the slot behind the trim. Gently push to

opposite side. Repeat procedure for upper and lower

Freezer panels.

Install Custom Trim

Install the custom trim with the original

5 Phillips head screws. Tighten. Repeat

for Freezer door.

NOTE: Ensure that the edge of the custom trim

does not pinch the door gasket.

• 3/4" Custom Decorative Panels

If you choose to install custom wood panels, they

must be cut to dimensions shown

on pages 23-30. The panels will slide

into the frame on the doors and grille.

If using custom handles, please see Door Handles

on page 20.

Custom Trirr_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

IMPORTANT NOTE: Maximum custom panel

thickness must not exceed 1-1/8" thick and 70 Ibs for

the Fresh Food door, 45 Ibs total for the Freezer door

and 15 Ibs for the Grille panel.

38

Page 39

Installation Instructions

CONNECT WATER SUPPLY

Check to make sure that Master Power switch

is in the 0 (OFF) position.

Ell

L

.-- - ..... •......... ----.

',, Refrigerator House

_ VVaterSupply Water Supplyj

"- _ ..................... °J ....

• Locate and bring GE Smart Connect TMtubing

to the front of the cabinet.

• Turn the water on to flush debris from line.

Run about a quart of water through tubing

into a bucket, then shut off water.

TURN ON THE POWER

• Set the Master Power switch to the I (ON}

position.

• Check to make sure power to refrigerator is on

by opening refrigerator door to see if interior

lights are on.

Water Fi

Power Switch

Master_ /_i

• The temperature controls are preset at 37°F

for the Fresh Food section and O°F for the

Freezer section.

• Allow 24 hours to stabilize before making

adjustments.

l

Copper Tubing

• Slip a 1/4" nut and ferrule onto end

of copper tubing. Insert tube into the union fitting

on the unit and tighten nut to union.

• Turn on the water to check for leaks.

GE SmartConnect '_Tubing

• Insert the molded end of the tubing

into the refrigerator connection. Tighten

the compression nut until it isjust hand tight.

• Tighten one additional turn with a wrench.

Overtightening can cause leaks.

• Turn on the water to check for leaks.

Note: Make sure excess tubing length does not

interfere with toekick installation.

39

Page 40

Installation Instructions

START ICE MAKER

Power Switch

Green Power Light

• Flip the switch to I (ON). The icemaker will begin

operation automatically.

• Make sure nothing interferes with the sweep

of the feeler arm.

• Discard the first full bucket of ice cubes.

• To turn the icemaker off, set the switch to

0 (OFF).

DOOR ALIGNMENT

• Stand back from the refrigerator to inspect

the door alignment.

Shipping or the addition of heavy door panels

may have caused the doors to move slightly

out of alignment.

INSTALL TOEKICK

• Locate the supplied toekick (shipped taped

SuppliedT0ekick

3 .....

e

% %

to the top of the refrigerator). Install with

2 screws provided.

The vented toekick must remain unobstructed for

proper air flow.

Raise

Clockwise

• If necessary, the Fresh Food door

may be adjusted up or down to align

with the Freezer door.

• Loosen the leveling mechanism.

• Use a 7/32" wrench to adjust the hinge pin

as shown.

• Tighten the leveling mechanism.

IMPORTANT NOTE: After the unit has been leveled,

if the fresh food door is higher than the freezer

door, adjust the front right leveling leg lower

to align the doors and, if required, raise the left

leveling leg to level the unit side to side.

4O

Page 41

sounds.

Newer refrigerators sound different from older refrigerators.

Modern refrigerators have more features and use newer

technology.

Do you hear what I hear? These sounds are normal

GEAppliances.com

HUMMM...

--WHOOSH...

[]

The new high efficiency compressor may run faster and

longer than your old refrigerator and you may hear a high-

pitched hum or pulsating sound while

it is operating.

[]

You may hear a whooshing sound when the doors close.

This is due to pressure equalizing within

the refrigerator.

CLICKS,POPS,

CRACKSand CHIRPS

[] You may hear cracking or popping sounds when the

refrigerator is first plugged in. This happens as the

refrigerator cools to the correct temperature.

[] The compressor may cause a clicking or chirping sound

when attempting to restart (this could take

up to 5 minutes).

[] The electronic control board may cause a clicking sound

when relays activate to control refrigerator components.

[] Expansion and contraction of cooling coils during and

after defrost can cause a cracking or popping sound.

[] After an icemaking cycle, you may hear the ice cubes

dropping into the ice bucket.

WHIR!

[] You mayhearthe

fans spinning at high speeds.

This happens when the refrigerator is first plugged in,

when the doors are opened frequently or when a large

amount of food is added to the refrigerator or freezer

compartments. The fans are helping to maintain the

correct temperatures.

If either door is open for over 3 minutes, you may hear the

fans come on in order to cool the light bulbs.

The fans change speeds in order to provide optimal

cooling and energy savings.

WATERSOUNDS

6

[] The flow of refrigerant through the freezer cooling

coils may make a gurgling noise like boiling water.

[] Water dropping on the defrost heater can cause

a sizzling, popping or buzzing sound during the

defrost cycle.

[] A water dripping noise may occur during the defrost cycle

as ice melts from the evaporator and flows

into the drain pan.

[] Closing the door may cause a gurgling sound due

to pressure equalization.

41

Page 42

Troubleshooting Tips

Save time and money./Review the charts on the following

pages first and you may not need to call for service.

Possible Causes What To Do

Refrigerator does not Refrigerator in defrost cycle. , Wait about 30 minutes for defrost cycle to end,

operate Master power control set to OFF. • Set the control to an on setting,

Refrigerator is unplugged. , Push the plug completely into the outlet,

The fuse is blown/circuit , Replace fuse or reset the breaker,

breaker is tripped.

The refrigerator is in , Unplug the refrigerator and plug it back in,

showroom mode.

Vibration or rattling Refrigerator is not level. * See level refrigerntor,

(slight vibration , See Door alignment,

is normal)

Motor operates for Normal when refrigerator , Wait 24 hours for the refrigerator to completely

long periods or cycles is first plugged in. cool down,

on and off frequently, Often occurs when large * This is normal,

(Modern refrigerators amounts of food are

with more storage

space and a larger placed in refrigerator.

freezer require more Door left open. • Check to see if package is holding door open,

operating time, They

start andstop often Hot weather or frequent , This is normal,

to maintain even door openings.

Temperature controls , See About the temperature controls,

set at the coldest setting.

Refrigerator or freezer Temperature control not set * See About the temperature controls,

compartment too warm cold enough.

Warm weather or frequent • Set the temperature control one step colder,

door openings. See About the temperature controls,

Door left open. , Check to see if package is holding door open,

Frost or ice crystals Door left open. • Check to see if package is holding door open,

on frozen food Too frequent or too long

(frost within package door openings.

_ is normal)

Divider between Automatic energy saver , This helps prevent condensation on the outside,

refrigerator and freezer system circulates warm

compartments liquid around front edge

feels warm of freezer compartment.

Automatic icemaker [cemaker power switch , Set the power switch to the on position.

doesnot work is in the off position.

Water supply turned off or * See/nstnll wnter line,