General Electric LC9 Series Basic Service Manual English Version_SM_5482298-100_5 LOGIQ C9 Series Basic Service Manual

GE

Technical Publication

LOGIQ C9 Series

Basic Service Manual

Direction Number: 5482298-100 English

Rev. 5

All Material Copyright © 2014-2017 by General Electric Company Inc.

All Rights Reserved.

Product Information

This Manual covers the software version of R1.x.x for LOGIQ C9 Series ultrasound

system.

GE

Copyright © 2014-2017, General Electric Company.

GE Medical Systems, a General Electric Company, going to

market as GE

Manufacturer:

GE Medical Systems (China) Co., Ltd.

No. 19, Changjiang Road

WuXi National Hi-Tech Development Zone

Jiangsu, P.R. China 214028

TEL: +86 510 85225888; FAX: +86 510 85226688

www.gehealthcare.com

Revision history

Revision History

Date

Revision

Rev.1 2014/01/09 Initial Release

Rev.2 2014/03/11 Update for transportation box

Rev.3 2016/06/30 Update spare part list

Rev.4 2016/11/18 Update spare part list

Rev.5 2017/08/23 Update spare part list

Pages Revision Pages Revision

Front Rev. 5 Chapter 6 Rev. 5

Front matter Rev. 5 Chapter 7 Rev. 5

TOC Rev. 5 Chapter 8 Rev. 5

(YYYY/MM/DD) Reason for change

List of Effected Pages (LOEP)

Chapter 1 Rev. 5 Chapter 9 Rev. 5

Chapter 2 Rev. 5 Chapter 10 Rev. 5

Chapter 3 Rev. 5 Index Rev. 5

Chapter 4 Rev. 5 Rear Cover Rev. 5

Chapter 5 Rev. 5

Please verify that you are using the latest revision of this document. Information

pertaining to this document is maintained on MyWorkshop/ePDM (GE electronic Product

Data Management). If you need to know the latest revision, contact your distributor, local

GE Sales Representative or in the USA call the GE Ultrasound Clinical Answer Center at

1 800 682 5327 or 1 262 524 5698.

LOGIQ C9 Series – Basic Service Manual i-1

5482298-100 English Rev. 5

Important precautions

Translation policy

i-2 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series – Basic Service Manual i-3

5482298-100 English Rev. 5

i-4 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series – Basic Service Manual i-5

5482298-100 English Rev. 5

i-6 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series – Basic Service Manual i-7

5482298-100 English Rev. 5

i-8 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series – Basic Service Manual i-9

5482298-100 English Rev. 5

i-10 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series – Basic Service Manual i-11

5482298-100 English Rev. 5

Damage in transportation

All packages should be closely examined at time of delivery. If

damage is apparent, write “Damage In Shipment” on ALL copies

of the freight or express bill BEFORE delivery is accepted or

“signed for” by a GE representative or hospital receiving agent.

Whether noted or concealed, damage MUST be reported to the

carrier immediately upon discovery, or in any event, within 14

days after receipt, and the contents and containers held for

inspection by the carrier. A transportation company will not pay a

claim for damage if an inspection is not requested within this 14

day period.

Certified electrical contractor statement - For USA Only

All electrical Installations that are preliminary to positioning of

the equipment at the site prepared for the equipment shall be

performed by licensed electrical contractors. Other connections

between pieces of electrical equipment, calibrations and testing

shall be performed by qualified GE personnel. In performing all

electrical work on these products, GE will use its own specially

trained field engineers. All of GE’s electrical work on these

products will comply with the requirements of the applicable

electrical codes.

The purchaser of GE equipment shall only utilize qualified

personnel (i.e., GE’s field engineers, personnel of third-party

service companies with equivalent training, or licensed

electricians) to perform electrical servicing on the equipment.

i-12 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Omission and errors

If there are any omissions, errors or suggestions for improving

this documentation, contact the GE Global Documentation

Group with specific information listing the system type, manual

title, part number, revision number, page number and

suggestion details.

Mail the

information to:

GE Medical Systems (China) Co., Ltd.

No. 19 Changiang Road

Wuxi National Hi-Tech Dev. Zone

Jiangsu

P.R.China 214028

GE employees should use TrackWise to report service

documentation issues.

These issues will then be in the internal problem reporting tool

and communicated to the writer.

LOGIQ C9 Series – Basic Service Manual i-13

5482298-100 English Rev. 5

Service Safety Considerations

WARNING

DANGER DANGEROUS VOLTAGES, CAPABLE OF CAUSING DEATH,

ARE PRESENT IN THIS EQUIPMENT. USE EXTREME

CAUTION WHEN HANDLING, TESTING AND ADJUSTING.

Use all Personal Protection Equipment (PPE) such as gloves,

safety shoes, safety glasses, and kneeling pad, to reduce the

risk of injury.

For a complete review of all safety requirements, refer to

Chapter 1 in the Service Manual.

i-14 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Legal notes

Trademarks

Copyrights

The contents of this publication may not be copied or duplicated

in any form, in whole or in part, without prior written permission

of GE.

GE may revise this publication from time to time without written

notice.

All products and their name brands are trademarks of their

respective holders.

All Material Copyright © 2014-2017 by

General Electric Company Inc. All Rights Reserved.

LOGIQ C9 Series – Basic Service Manual i-15

5482298-100 English Rev. 5

i-16 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Translation policy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-2

Damage in transportation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-12

Certified electrical contractor statement - For USA Only - - - - - - - - - - - - i-12

Omission and errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-13

Service Safety Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-14

Legal notes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-15

Trademarks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-15

Copyrights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i-15

Table of Contents

Chapter 1 — Introduction

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Manual Overview

Contents in this manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

LOGIQ C9 Series models covered by this manual - - - - - - - - - - - - - - - - 1-5

Important conventions

Conventions used in book - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

Standard hazard icons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Product icons

Labels locations

Safety considerations

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

Human Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-12

Mechanical safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-15

Electrical safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-18

Dangerous procedure warnings

Lockout/Tagout (LOTO) requirements

Returning probes and repair parts

EMC, EMI and ESD

What is EMC? - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-23

CE Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-23

Electrostatic discharge (ESD) prevention - - - - - - - - - - - - - - - - - - - - - 1-24

Customer assistance

Contact information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-25

Phone numbers for Customer Assistance - - - - - - - - - - - - - - - - - - - - - 1-26

System manufacturer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-26

Authorized Representative- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-27

Table of Contents

LOGIQ C9 Series – Basic Service Manual i-17

5482298-100 English Rev. 5

Chapter 2 — Site Preparations

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

General Ultrasound system requirements

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Ultrasound system environmental requirements- - - - - - - - - - - - - - - - - - 2-3

Electrical requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

EMI limitations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

Probes environmental requirements - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

Time and manpower requirements - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

Facility needs

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

Purchaser responsibilities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

Required facility needs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

Desirable features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15

Minimal floor plan suggestion- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-16

Recommended floor plan suggestion - - - - - - - - - - - - - - - - - - - - - - - - 2-17

Suggested floor plan, Ultrasound system, and EchoPAC PC in same

room - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18

Networking setup requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-18

Environmental Dangers

Patient Vicinity UL60601-1 (USA) - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22

Patient Environment IEC60601-1 and ANSI AAMI ES60601-1 - - - - - - 2-23

Chapter 3 — System Setup

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Setup reminders

Average setup time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Setup warnings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

Receiving and unpacking the equipment

Purpose of this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Warnings for receiving and unpacking - - - - - - - - - - - - - - - - - - - - - - - - 3-6

The Tilt indicator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

Receiving the LOGIQ C9 Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

Unpacking the LOGIQ C9 Series - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-12

Packing the Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-16

Packing materials - recycling information

Preparing for setup

Verify customer order - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

Physical inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

EMI protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

Completing the setup

Purpose of this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

System specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

i-18 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Electrical specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-20

Connections on the I/O Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - 3-21

Connecting probes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-21

Powering the system - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-21

System Configuration

Purpose of this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-22

Contents in this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-22

LOGIQ C9 Series configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-22

Peripherals Installation

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-23

Furnished materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-24

Peripherals Installation Instructions - - - - - - - - - - - - - - - - - - - - - - - - - 3-26

Connectivity setup

Setup the LOGIQ C9 Series for DICOM Communications- - - - - - - - - - 3-34

How to get the LOGIQ C9 Series to recognize another Device on the

Network - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-36

How to Setup and Use a DICOM Image Storage Service - - - - - - - - - - 3-37

Option Setup

Software Option Installation Procedure - - - - - - - - - - - - - - - - - - - - - - - 3-38

Paperwork after setup

Contents in this Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-40

User’s Manual(s) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-40

Product Locator Installation Card - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-41

Chapter 4 — General Procedures and Functional Checks

Overview

Purpose of this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Special Equipment required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

General procedures

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

Power ON/Boot Up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

Power off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

LCD Monitor position adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-10

Logging on to LOGIQ C9 Series as “ADM” - - - - - - - - - - - - - - - - - - - - 4-10

Service Key (Dongle, HASP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

Exit to Windows Desktop from the LOGIQ C9 Series application

software - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

Removable media - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

Archiving and loading presets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-16

Download/Upload of System Presets via InSite ExC - - - - - - - - - - - - - 4-17

Data Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17

Backup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17

Installation and Setup Procedure for Peripherals - - - - - - - - - - - - - - - - 4-17

Moving and transporting the LOGIQ C9 Series - - - - - - - - - - - - - - - - - 4-17

Recording important settings and parameters - - - - - - - - - - - - - - - - - - 4-17

Where are the User Manuals and the Service Manual? - - - - - - - - - - - 4-18

How to display or print the PDF files from the Manual CD-ROM? - - - - 4-18

LOGIQ C9 Series – Basic Service Manual i-19

5482298-100 English Rev. 5

Cleaning the Tracball - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-19

Functional checks

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

Contents in this Section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

Basic Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-22

Operator Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-22

Touch panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

Probe/Connectors Check- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-24

Peripheral checks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-25

Pedals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-25

Power supply test & adjustments

Power Supply Test Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

Power Supply Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

Application Turnover Check List

Software Configuration Checks - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-27

Site Log

Chapter 5 — Components and Functions (Theory)

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Block Diagram and Theory

General Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Top Console- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Software Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

Power Diagram

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

AC Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

Common Service Platform

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

Chapter 6 — Service Adjustments

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

LCD Monitor adjustments

Purpose of this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Monitor Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

Touch Panel

Touch Panel Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

Control Panel adjustment

Chapter 7 — Diagnostics/Troubleshooting

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

Gathering Trouble Data

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

Collect Vital System Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

Collect a Trouble Image with Logs - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

i-20 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Screen Capture

Check and Record the P1 Key Function - - - - - - - - - - - - - - - - - - - - - - - 7-7

Setting the P1 Key to Screen Capture- - - - - - - - - - - - - - - - - - - - - - - - - 7-7

Capturing a Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

Reset the P1 Key to Customer’s Functionality - - - - - - - - - - - - - - - - - - 7-10

Common Diagnostics

Utilities- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

PC Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-12

PC Diagnostics (Interactive Tests) - - - - - - - - - - - - - - - - - - - - - - - - - - 7-12

Restart LOGIQ C9 Series After Diagnostics - - - - - - - - - - - - - - - - - - - 7-12

Network Configuration

Network Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-13

Chapter 8 — Replacement Procedures

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

Warnings and important information

Warnings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

Returning/shipping probes and repair parts - - - - - - - - - - - - - - - - - - - - - 8-4

Disassembly/Re-assembly

Warning and Caution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

Tools needed for servicing LOGIQ C9 Series - - - - - - - - - - - - 8-6

Overview of LOGIQ C9 Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

Body Assy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-9

Air Filter Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-10

Trackball Roller Cleaning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-12

Loading the software

Purpose of this section - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-13

Customer provided prerequisite - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-13

Data Management - moving all images - - - - - - - - - - - - - - - - - - - - - - - 8-13

Backing up the Patient Archive and System Configurations - - - - - - - - 8-14

Recording important settings and parameters - - - - - - - - - - - - - - - - - - 8-14

Loading the System Software - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-15

Option strings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-22

Chapter 9 — Renewal Parts

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

List of Abbreviations

Renewal Parts Lists

ACDC Power Pack - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

Operator Console Assy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

Probe - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

Peripheral - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

Manuals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

Accessories and Kits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

LOGIQ C9 Series – Basic Service Manual i-21

5482298-100 English Rev. 5

Chapter 10 — Care and Maintenance

Overview

Contents in this chapter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

Warnings

Why do maintenance

Periodic maintenance inspections - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

Keeping records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

Quality assurance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-5

Maintenance task schedule

How often should maintenance tasks be performed? - - - - - - - - - - - - - 10-6

Tools required

Standard GE tool kit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-8

GE-2 tool kit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-10

Special tools, supplies and equipment used for maintenance - - - - - - 10-11

System maintenance

Preliminary checks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-12

Functional checks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-13

Physical inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15

Optional Diagnostic Checks- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-16

Probe maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-17

Electrical safety tests

Safety test overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-19

Leakage current limits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-21

Outlet test - wiring arrangement - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-23

Grounding continuity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-24

Chassis leakage current test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-25

Probe leakage current test- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-27

When there's too much leakage current …

AC/DC Fails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-30

Chassis Fails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-30

Probe Fails- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-31

Peripheral Fails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-31

Still Fails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-31

New Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-31

ECG Fails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-31

Inspection Paperwork

Ultrasound Inspection Forms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-32

Electrical Safety Tests Log

Index

i-22 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Chapter 1

Introduction

This chapter describes important issues related to

safely servicing the Ultrasound system. The service

provider must read and understand all the information

presented here before installing or servicing the units.

LOGIQ C9 Series – Basic Service Manual 1-1

5482298-100 English Rev. 5

Introduction

Contents in this chapter

• ‘Overview’ on page 1-2

• ‘Manual Overview’ on page 1-3

• ‘Important conventions’ on page 1-6

• ‘Product icons’ on page 1-10

• ‘Labels locations’ on page 1-11

• ‘Safety considerations’ on page 1-12

• ‘Dangerous procedure warnings’ on page 1-20

• ‘Lockout/Tagout (LOTO) requirements’ on page 1-21

• ‘Returning probes and repair parts’ on page 1-22

• ‘EMC, EMI and ESD’ on page 1-23

• ‘Customer assistance’ on page 1-25

Overview

1-2 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

This manual provides installation and service information for the

LOGIQ C9 Series Ultrasound system. It is divided in ten

chapters as shown below.

Contents in this manual

The manual is divided into ten chapters.

In the beginning of the manual, before chapter 1, you will find

the Revision overview, the Important precautions including

Translation policy, Damage in transportation, Certified electrical

contractor statement, Omission & errors, Service safety

considerations and Legal notes, and the Table of Contents

(TOC).

Manual Overview

Manual Overview

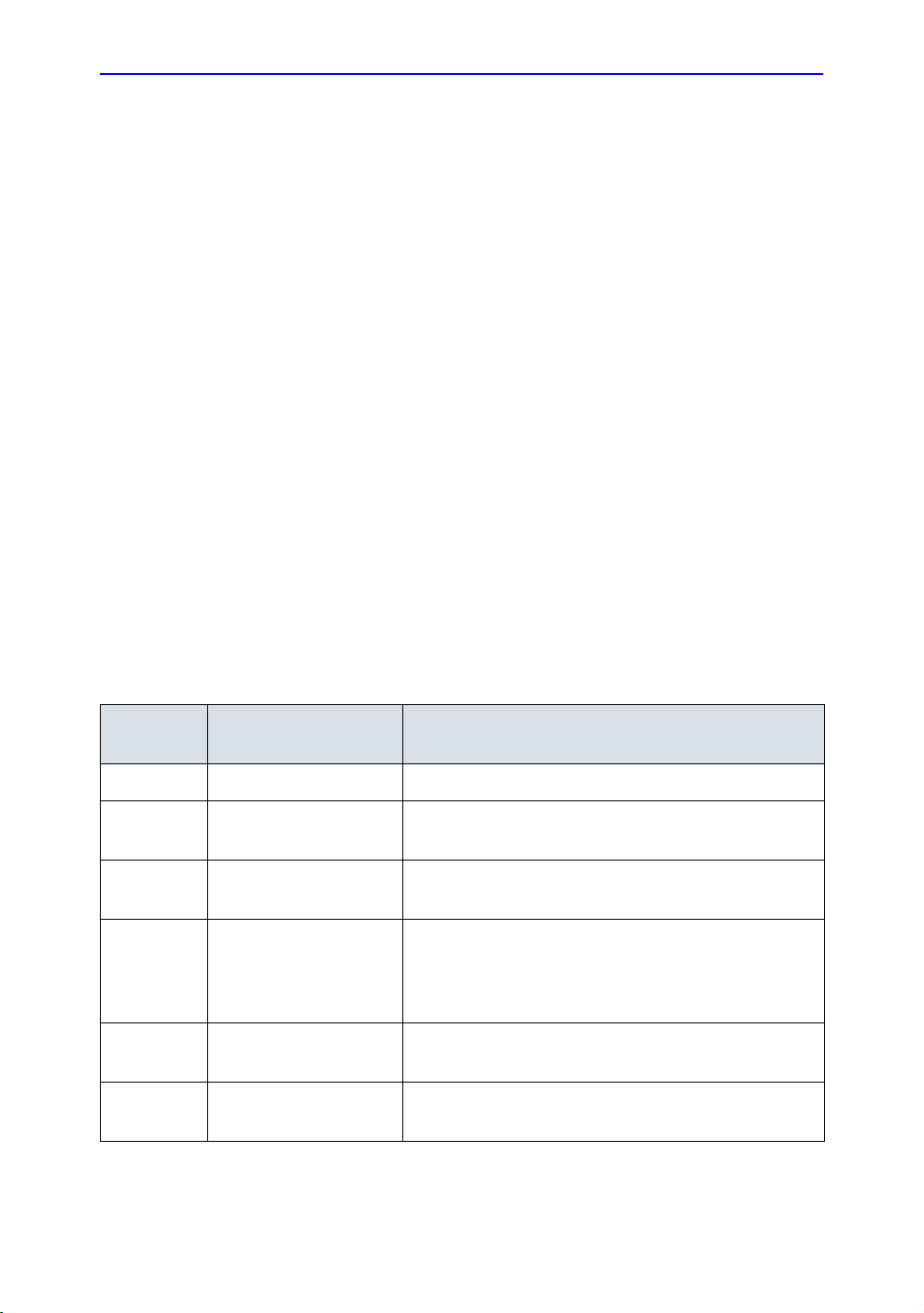

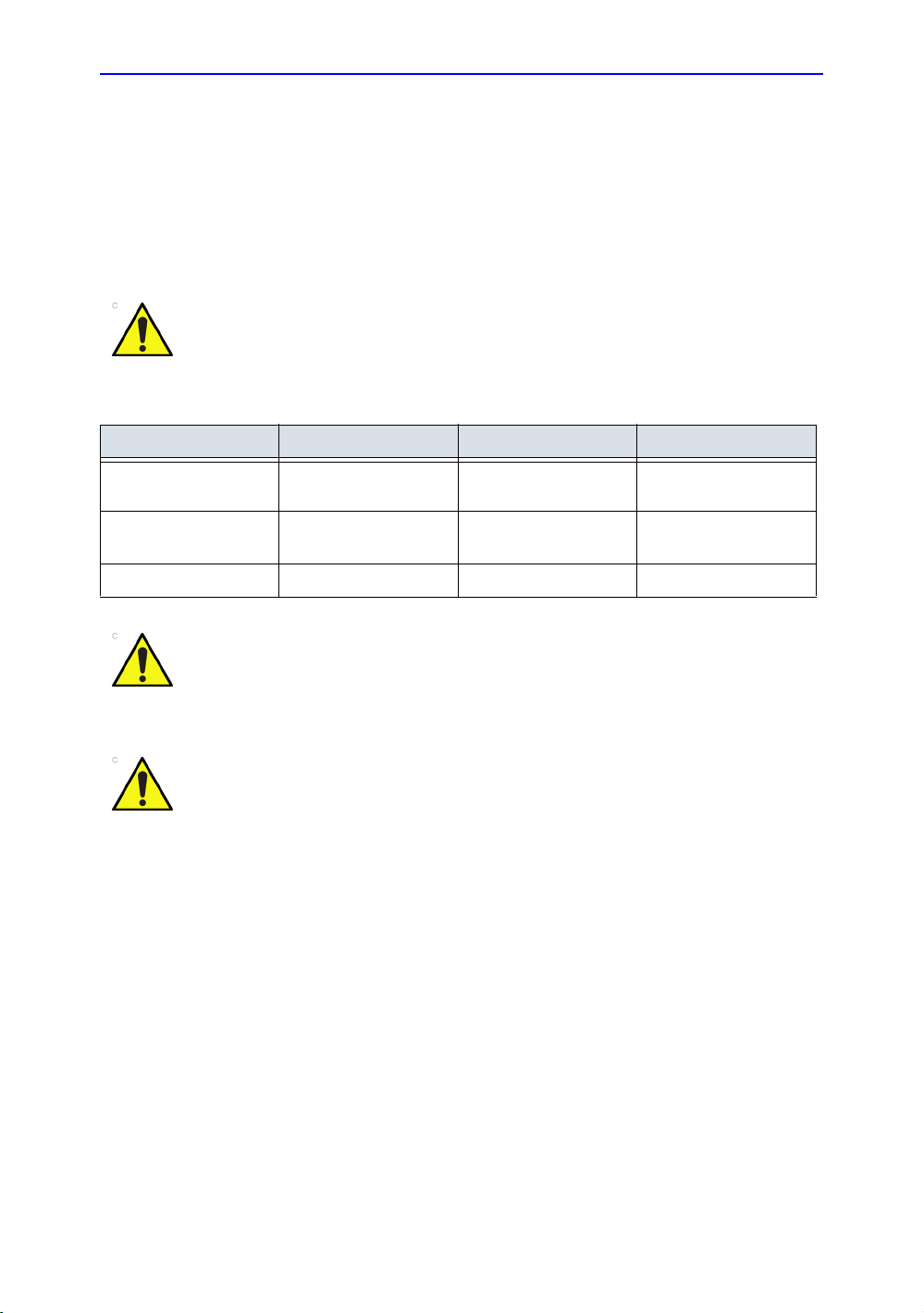

Chapter

number

1.

2.

3.

4.

5.

6.

An Index has been included after Chapter 10.

Table 1-1: Contents in this manual

Chapter title Description

Introduction Contains a content summary and warnings.

Site preparations Contains pre-setup requirements for the LOGIQ

C9 Series.

System Setup Contains setup procedure with procedure

checklist for the system.

General Procedures

and Functional

Checks

Components and

Functions (Theory)

Service Adjustments Contains instructions on how to make any

Contains functional checks that must be

performed as part of the installation, or as

required during servicing and periodic

maintenance.

Contains block diagrams and functional

explanations of the electronics.

available adjustments to the LOGIQ C9 Series.

LOGIQ C9 Series – Basic Service Manual 1-3

5482298-100 English Rev. 5

Introduction

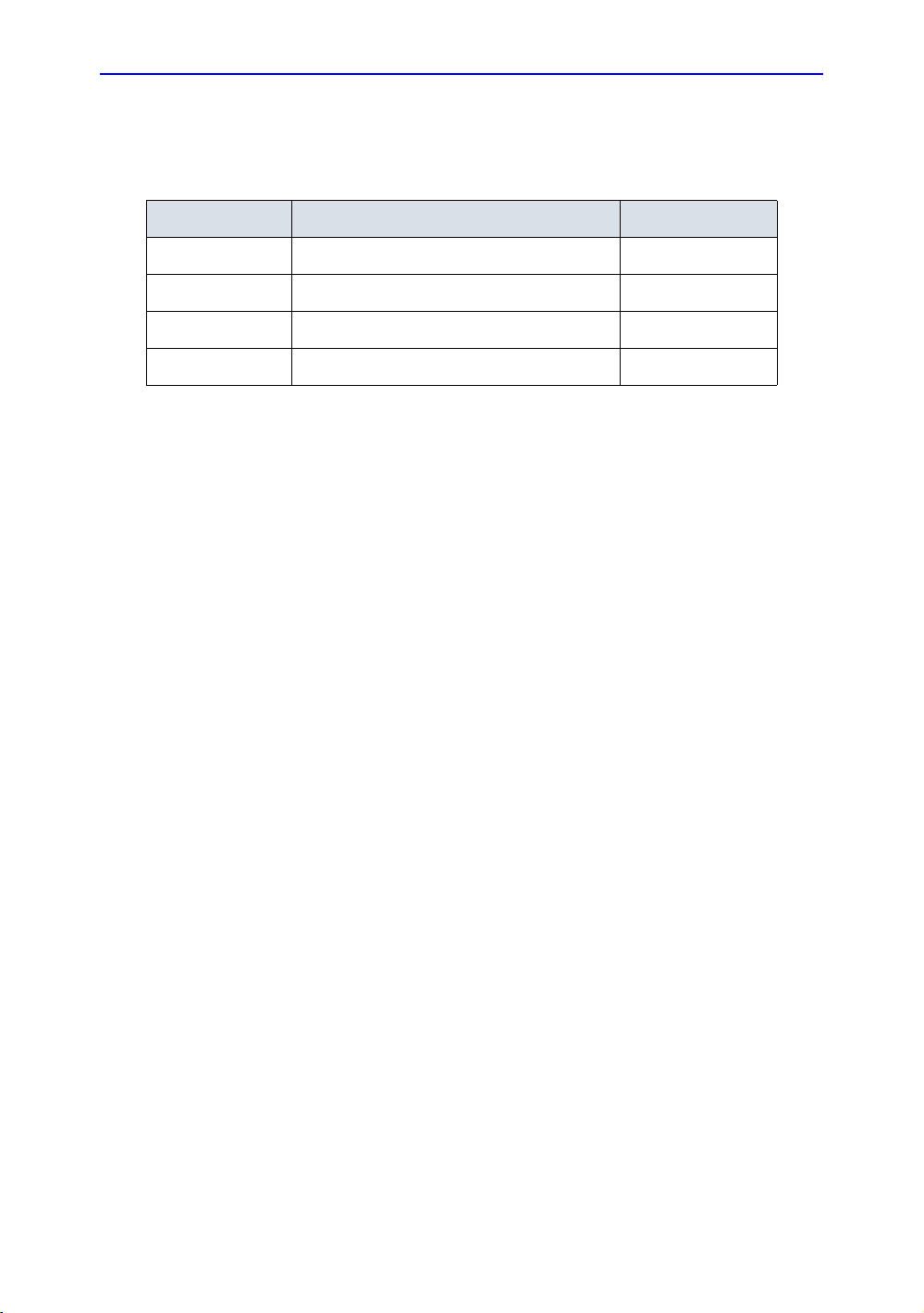

Table 1-1: Contents in this manual (Continued)

Chapter

Chapter title Description

number

7.

8.

9.

Diagnostics/

Troubleshooting

Replacement

procedures

Provides procedures for running diagnostic or

related routines for the LOGIQ C9 Series.

Provides disassembly procedures and

reassembly procedures for all changeable FRU.

Renewal Parts Contains a complete list of replacement parts for

LOGIQ C9 Series.

10.

Care & Maintenance Provides periodic maintenance procedures for

LOGIQ C9 Series.

N/A Index A quick way to the topic you’re looking for.

1-4 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

LOGIQ C9 Series models covered by this manual

Table 1-2: LOGIQ C9 Series Model Designations

Model Number Description System SW

5489329 LOGIQ C9 Premium for China R1.x.x

5489330 LOGIQ C9 Expert for China (with 4D) R1.x.x

5489331 LOGIQ C9 Expert for China R1.x.x

5489332 LOGIQ C9 Expert for India R1.x.x

NOTE: When not otherwise specified, the contents of this manual

applies to all LOGIQ C9 Series models.

Manual Overview

LOGIQ C9 Series – Basic Service Manual 1-5

5482298-100 English Rev. 5

Introduction

Conventions used in book

Important conventions, used in this document, are described

next.

Model designations

This manual covers the LOGIQ C9 Series Ultrasound systems

listed in:

‘LOGIQ C9 Series models covered by this manual’ on page 1-5.

Icons

Important conventions

Pictures, or icons, are used wherever they will reinforce the

printed message. The icons, labels, and conventions used on

the product and in the service information are described in this

chapter.

1-6 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Safety precaution messages

DANGER

WARNING

CAUTION

Various levels of safety precaution messages may be found on

the equipment and in the service information. The different

levels of concern are identified by a flag word that precedes the

precautionary message. Known or potential hazards to

personnel are labeled in one of three ways:

• DANGER

• WARNING

• CAUTION

Danger is used to indicate the presence of a hazard that will

cause severe personal injury or death if the instructions are

ignored.

Warning is used to indicate the presence of a hazard that can

cause severe personal injury and property damage if

instructions are ignored.

Important conventions

Caution is used to indicate the presence of a hazard that will or

can cause minor personal injury and property damage if

instructions are ignored. Equipment damage possible.

NOTE: Notes are used to provide important information about an item

or a procedure.

NOTE: Be sure to read the notes; the information contained in a note

can often save you time or effort.

LOGIQ C9 Series – Basic Service Manual 1-7

5482298-100 English Rev. 5

Introduction

Standard hazard icons

Important information will always be preceded by either the

exclamation point (!) contained within a triangle, or the symbols

for “Danger”, “Warning” or “Caution”, as seen throughout this

chapter. In addition to text, several different graphical icons

(symbols) may be used to make you aware of specific types of

hazards that could possibly cause harm. Even if a symbol isn’t

used in this manual, it may be included for your reference.

Table 1-3: Standard hazard icons

ELECTRICAL

MECHANICAL

RADIATION

LASER

HEAT

PINCH

NOTE: Even if a symbol isn’t used on the product or in this manual, it

may be included for your reference.

1-8 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Important conventions

Standard Icons that indicate that a special procedure is to be used

Some others icons make you aware of specific procedures that

should be followed.

Table 1-4: Standard Icons that indicates that a special procedure is to be used

Avoid Static Electricity Tag and Lock Out Wear Eye Protection

Hand Protection Foot Protection Wear Eye Protection

Be sure to read the notes; the information contained in a note

can often save you time or effort.

LOGIQ C9 Series – Basic Service Manual 1-9

5482298-100 English Rev. 5

Introduction

Product icons

It is important to refer to the current revision of the Ultrasound

system’s User Manual for a full list of product labels prior to

servicing the system.

1-10 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Labels locations

Labels locations

It is important to refer to the current revision of the Ultrasound

system’s User Manual for a full list of product labels prior to

servicing the system.

LOGIQ C9 Series – Basic Service Manual 1-11

5482298-100 English Rev. 5

Introduction

DANGER

WARNING

Contents in this section

• ‘Introduction’ on page 1-12

• ‘Human Safety’ on page 1-12

• ‘Mechanical safety’ on page 1-15

• ‘Electrical safety’ on page 1-18

Introduction

The following safety precautions must be observed during all

phases of operation, service and repair of this equipment.

Failure to comply with these precautions or with specific

warnings elsewhere in this manual, violates safety standards of

design, manufacture and intended use of the equipment.

Safety considerations

Human Safety

• Operating personnel must not remove the system covers.

• Servicing should be performed by authorized personnel

only.

Only personnel who have participated in a LOGIQ C9 Series

Training Seminar are authorized to service the equipment.

DANGEROUS VOLTAGES, CAPABLE OF CAUSING

DEATH, ARE PRESENT IN THIS EQUIPMENT. USE

EXTREME CAUTION WHEN HANDLING, TESTING

AND ADJUSTING.

If the covers are removed from an operating LOGIQ C9 Series,

some metal surfaces may be warm enough to pose a potential

heat hazard if touched, even while in shutdown mode.

1-12 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Human Safety (continued)

WARNING

WARNING

WARNING

WARNING

WARNING

Because of the limited access to cabinets and equipment in the

field, placing people in awkward positions, GE has limited the

lifting weight for one person in the field to 16 KG (35 LBS).

Anything over 16 KG (35 LBS) requires 2 people.

Have two people available to deliver and unpack the LOGIQ

C9 Series.

Attempts to move the Ultrasound system considerable

distances or on an incline by one person could result in injury

or damage or both.

Explosion Warning

DO NOT operate the equipment in an explosive atmosphere.

Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

Safety considerations

DO NOT substitute parts or modify equipment

Because of the danger of introducing additional hazards, ONLY

install GE approved parts. DO NOT perform any unauthorized

modification of the equipment.

Ensure that the Ultrasound system is turned off and unplugged

Wait for at least 20 seconds for capacitors to discharge as

there are no test points to verify isolation. The amber light on

the OP panel ON/OFF button will turn off.

Ultrasound system components may be energized. Always

refer to the Ultrasound system's Proprietary Service Manual for

LOTO warnings and cautions

LOGIQ C9 Series – Basic Service Manual 1-13

5482298-100 English Rev. 5

Introduction

WARNING

WARNING

WARNING

WARNING

Human Safety (continued)

Risk of electrical shock, Ultrasound system must be turned off

and disconnected from power source. Cord must be controlled

at all times.

Wait for at least 20 seconds for capacitors to discharge as

there are no test points to verify isolation. The amber light on

the OP panel on/off button will turn off.

Ultrasound System components may be energized. Always

refer to the Ultrasound system's Proprietary Service Manual for

LOTO warnings and cautions

Use all Personal Protection Equipment (PPE) such as gloves,

safety shoes, safety glasses, and kneeling pad, to reduce the

risk of injury.

Beware of possible sharp edges on all mechanical parts. If

sharp edges are encountered, the appropriate PPE should be

used to reduce the risk of injury.

Wear all PPE including gloves as indicated in the chemical

MSDS.

1-14 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Mechanical safety

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

Safety considerations

While the software install procedure is designed to preserve

data, you should save any patient data, images, system setups

to removable media or hardcopy before doing a software

upgrade.

Ultrasound probes are highly sensitive medical instruments

that can easily be damaged by improper handling. Use care

when handling and protect from damage when not in use. Do

NOT use a damaged or defective probe. Failure to follow these

precautions can result in serious injury and equipment

damage.

Never use a probe that has fallen to the floor. Even if it looks

OK, it may be damaged.

When the Ultrasound system is raised for a repair or moved

along any incline, use extreme caution since it may become

unstable and tip over.

Take extra care when moving the system.

The LOGIQ C9 Series weighs approximately 130 kg (287 lbs)

or more, depending on installed peripherals, when ready for

use. To avoid possible injury and equipment damage when

transporting from one area of use to another:

• Be sure the pathway is clear.

• Limit movement to a slow careful walk.

• Use two or more persons to move the equipment on

inclines or long distance.

Before you move or transport the Ultrasound system, make

sure to lock the LCD monitor arm firmly and flip down the

monitor to prevent damage to the Ultrasound system.

LOGIQ C9 Series – Basic Service Manual 1-15

5482298-100 English Rev. 5

Introduction

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Mechanical safety (continued)

To avoid injury when you move the LCD monitor and the

monitor arm, do not put your finger, hand, or object on the joint

of the monitor or the monitor arm.

Ensure that nobody touches the console arm when moving the

operator panel.

Do not move the Ultrasound system if the Operator Panel is in

unlocked position.

Do not transport LOGIQ C9 Series in a vehicle without locking

the casters (wheels) and securing it as described in chapter 4.

Use protective glasses during drilling, filing smooth surfaces,

and during all other work where eyes need protection.

Use safety shoes when doing work where there is any chance

of foot injury.

1-16 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Mechanical safety (continued)

CAUTION

CAUTION

Use protective gloves when working with sharp edges or when

directed to wear PPE during a removal/replacement procedure.

Be careful not to pinch any of the cables.

NOTE: Special care should be taken when transporting the Ultrasound

system in a vehicle:

• Before transporting, place the system in its special storage

case.

• Lock the wheels (brake)

• Ensure that the system is firmly secured while inside the

vehicle.

• Secure system with straps or as directed otherwise to

prevent motion during transport.

• Prevent vibration damage by driving cautiously. Avoid

unpaved roads, excessive speeds, and erratic stops or

starts.

Safety considerations

LOGIQ C9 Series – Basic Service Manual 1-17

5482298-100 English Rev. 5

Introduction

WARNING

Electrical safety

Safe practices

Follow these guidelines to minimize shock hazards whenever

you are using the Ultrasound system:

• To minimize shock hazard, the equipment chassis must be

connected to an electrical ground.

• The Ultrasound system is equipped with a three-conductor

AC power cable. This must be plugged into an approved

electrical outlet with safety ground.

• The power outlet used for this equipment should not be

shared with other types of equipment.

• Both the system power cable and the power connector must

meet international electrical standards

Connecting a LOGIQ C9 Series to the wrong voltage level will

most likely destroy it.

1-18 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Probes

Safety considerations

Follow these guidelines before connecting a probe to the

Ultrasound system:

• Inspect the probe prior to each use for damage or

degradation to the:

• housing

• cable strain relief

• lens

• seal

• connector pins

• locking mechanism

• Do not use a damaged or defective probe.

• Never immerse the probe connector or adapter into any

liquid.

• The system has more than one type of probe port. Use the

appropriate probe port designed for the probe you are

connecting.

Peripherals

Refer to the Patient Safety Environment section of the User’s

Manual for peripheral isolation information.

LOGIQ C9 Series – Basic Service Manual 1-19

5482298-100 English Rev. 5

Introduction

DANGER

WARNING

WARNING

WARNING

WARNING

Dangerous procedure warnings

Warnings, such as the example below, precede potentially

dangerous procedures throughout this manual. Instructions

contained in the warnings must be followed.

DANGEROUS VOLTAGES, CAPABLE OF CAUSING

DEATH, ARE PRESENT IN THIS EQUIPMENT. USE

EXTREME CAUTION WHEN HANDLING, TESTING

AND ADJUSTING.

If the covers are removed from an operating LOGIQ C9 Series,

some metal surfaces may be warm enough to pose a potential

heat hazard if touched, even while in shutdown mode.

Explosion Warning

DO NOT operate the equipment in an explosive atmosphere.

Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

DO NOT substitute parts or modify equipment

Because of the danger of introducing additional hazards, ONLY

install GE approved parts. DO NOT perform any unauthorized

modification of the equipment.

SHUT DOWN FORCEDLY OR PLUG IN/OUT ACDC

INVALID MAY CAUSE THE DAMAGE OF SYSTEM

FILES.

1-20 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Lockout/Tagout (LOTO) requirements

WARNING

Lockout/Tagout (LOTO)

requirements

Follow Lockout/Tagout requirements by ensuring you are in total

control of the AC power plug at all times during the service

process.

To apply Lockout/Tagout (LOTO):

1. Plan and prepare for shutdown.

2. Shutdown the equipment.

3. Isolate the equipment.

4. Remove/disconnect the battery, if present.

5. Apply Lockout/Tagout Devices.

6. Control all stored and residual energy.

7. Verify isolation.

All potentially hazardous stored or residual energy is relieved.

Energy Control and Power Lockout for LOGIQ C9 Series.

When servicing parts of the Ultrasound system where there is

exposure to voltage greater than 30 volts:

1. Follow LOCK OUT/TAG OUT procedures.

2. Turn off the breaker.

3. Unplug the Ultrasound system.

4. Maintain control of the Ultrasound system power plug.

5. Wait for at least 30 seconds for capacitors to discharge as

there are no test points to verify isolation.

6. Remove/disconnect the battery, if present.

Ultrasound System components may be energized.

LOGIQ C9 Series – Basic Service Manual 1-21

5482298-100 English Rev. 5

Introduction

Returning probes and repair parts

Equipment being returned must be clean and free of blood and

other infectious substances. GE policy states that body fluids

must be properly removed from any part or equipment prior to

shipment. GE employees, as well as customers, are responsible

for ensuring that parts/equipment have been properly

decontaminated prior to shipment. Under no circumstance

should a part or equipment with visible body fluids be taken or

shipped from a clinic or site (for example, body coils or an

ultrasound probe).

The purpose of the regulation is to protect employees in the

transportation industry, as well as the people who will receive or

open this package.

NOTE: The US Department of Transportation (DOT) has ruled that

“items that were saturated and/or dripping with human blood

that are now caked with dried blood; or which were used or

intended for use in patient care” are “regulated medical waste”

for transportation purposes and must be transported as a

hazardous material.

NOTE: The USER/SERVICE staff should dispose of all the waste

properly, per federal, state, and local waste disposal regulations.

The Ultrasound system is not meant to be used for long-term

storage of patient data or images. The user is responsible for the

data on the system and a regular backup is highly

recommended.

If the system is sent for repair, please ensure that any patient

information is backed up and erased from the system before

shipping. It is always possible during system failure and repair to

lose patient data. GE is not responsible for the loss of this data.

If PHI (Patient Healthcare Information) data needs to be sent to

GE employees for service purposes, GE will ascertain

agreement from the customer. Patient information shall only be

transferred by approved service processes, tools and devices

restricting access, protecting or encrypting data where required,

and providing traceability in the form of paper or electronic

documents at each stage of the procedure while maintaining

compliance with cross-border restrictions of patient information

transfers.

1-22 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

What is EMC?

EMC, EMI and ESD

EMC, EMI and ESD

Electromagnetic compatibility describes a level of performance

of a device within its electromagnetic environment. This

environment consists of the device itself and its surroundings

including other equipment, power sources and persons with

which the device must interface. Inadequate compatibility results

when a susceptible device fails to perform as intended due

interference from its environment or when the device produces

unacceptable levels of emission to its environment. This

interference is often referred to as radio–frequency or

electromagnetic interference (RFI/EMI) and can be radiated

through space or conducted over interconnecting power of

signal cables. In addition to electromagnetic energy, EMC also

includes possible effects from electrical fields, magnetic fields,

electrostatic discharge and disturbances in the electrical power

supply.

CE Compliance

LOGIQ C9 Series conforms to all applicable conducted and

radiated emission limits and to immunity from electrostatic

discharge, radiated and conducted RF fields, magnetic fields

and power line transient requirements.

For applicable standards, refer to the Safety Chapter of the

Ultrasound system’s User’s Manual.

NOTE: For CE Compliance, it is critical that all covers, screws,

shielding, gaskets, mesh, clamps, are in good condition,

installed tightly without skew or stress. Proper installation

following all comments noted in this service manual is required

in order to achieve full EMC performance.

LOGIQ C9 Series – Basic Service Manual 1-23

5482298-100 English Rev. 5

Introduction

WARNING

WARNING

Electrostatic discharge (ESD) prevention

DO NOT touch any boards with integrated circuits prior to

taking the necessary ESD precautions.

Always connect yourself, via an arm-wrist strap, to the advised

ESD connection point located on the rear of the Ultrasound

system (near the power connector).

Follow general guidelines for handling of electrostatic sensitive

equipment.

Risk of electrical shock, Ultrasound system must be turned off.

Avoid all contact with electrical contacts, conductors and

components. Always use non-conductive handles designed for

the removal and replacement of ESD sensitive parts. All parts

that have the potential for storing energy must be discharged or

isolated before making contact.

1-24 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Contact information

Customer assistance

Customer assistance

If this equipment does not work as indicated in this service

manual or in the user manual, or if you require additional

assistance, please contact the local distributor or appropriate

support resource, as listed below.

Before you call, identify the following information, and acquire

image (Alt+D) to send to the Customer Care team:

1. System ID serial number.

2. Software version.

3. Date and time of occurrence.

4. Sequence of events leading to issue.

5. Is the issue repeatable?

6. Imaging mode, probe, preset/application.

7. Media brand, speed, capacity, type.

8. Save secondary image capture, cine loop, 4D multi-volume

loop.

NOTE: Restart the application before resuming clinical scanning.

LOGIQ C9 Series – Basic Service Manual 1-25

5482298-100 English Rev. 5

Introduction

Phone numbers for Customer Assistance

Table 1-5: Phone numbers for Customer Assistance

LOCATION PHONE NUMBER

USA

GE Healthcare - GE Medical Systems

Ultrasound Service Engineering

9900 Innovation Drive

Wauwatosa, WI 53226

Canada Phone: 1-800-668-0732

Latin America Service

Europe (OLC-EMEA)

GE Ultraschall Deutschland Gmbh & Co. KG

Beethovenstraße 239

Postfach 11 05 60, D-42655 Solingen

Germany

Online Services Ultrasound Asia Phone:

Service: On-site 1-800-437-1171

Service Parts 1-800-558-2040

Application Support 1-800-682-5327 or

1-262-524-5698

Application Support

OLC - EMEA

Phone:

Fax: +49 (0) 2122-8024-31

• Australia

• China

• India

• Japan

• Korea

• Singapore

1-800-321-7937

1-262-524-5698

+49 (0) 212 2802 - 652

+33 1 3083 1300

+(61) 1-800-647-855

+(86) 800-810-8188

+(91) 1800-425-8025

+(81) 42-648-2940

+(82) 2620 13585

+(95) 6277-3444

System manufacturer

Table 1-6: System manufacturer

MANUFACTURER PHONE NUMBER FAX NUMBER

GE Medical Systems (China) Co., Ltd.

No.19 Changjiang Road

WuXi National Hi-Tech Development Zone

Jiangsu

P.R.China 214028

+86 510 85225888 +86 510 85226688

1-26 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Authorized Representative

Table 1-7: Authorized Representative

AUTHORIZED REPRESENTATIVE

Customer assistance

TELEPHONE / FAX

NUMBER

The location of the CE marking is shown in the Safety chapter of the User

manual.

Authorized EU Representative/European registered place of business:

GE Medical Systems Information Technologies GmbH (GEMS IT GmbH)

Munzinger Strasse 5, D-79111 Freiburg, GERMANY

+49 761 45 43 -0 /

+49 761 45 43 -233

LOGIQ C9 Series – Basic Service Manual 1-27

5482298-100 English Rev. 5

Introduction

1-28 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Chapter 2

Site Preparations

This chapter provides the information required to plan

and prepare for the setup of an Ultrasound system.

Included are descriptions of the facility and electrical

needs to be met by the purchaser of the units.

LOGIQ C9 Series – Basic Service Manual 2-1

5482298-100 English Rev. 5

Site Preparations

Contents in this chapter

• ‘Overview’ on page 2-2

• ‘General Ultrasound system requirements’ on page 2-3

• ‘Facility needs’ on page 2-12

• ‘Environmental Dangers’ on page 2-22

Overview

2-2 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

General Ultrasound system

CAUTION

Contents in this section

• ‘Ultrasound system environmental requirements’ on

page 2-3

• ‘Electrical requirements’ on page 2-6

• ‘EMI limitations’ on page 2-9

• ‘Probes environmental requirements’ on page 2-11

• ‘Time and manpower requirements’ on page 2-11

General Ultrasound system requirements

requirements

Ultrasound system environmental requirements

If the Ultrasound system is very cold or hot

When unpacking the Ultrasound system, allow the temperature

of the Ultrasound system to stabilize before powering up. The

following table describes guidelines for reaching operational

temperatures from storage or transport temperatures.

If the Ultrasound system is very cold or hot, do not turn on its

power until it has had a chance to acclimate to its operating

environment.

Table 2-1: System Acclimation Time Chart

Degree C 50 45 40 35 30 25 20 15 10 5 0 -5

Degree F 122 113 104 95 86 77 68 59 50 41 32 23

hours 4 2 0 000000246

LOGIQ C9 Series – Basic Service Manual 2-3

5482298-100 English Rev. 5

Site Preparations

CAUTION

CAUTION

Environmental specifications for Ultrasound system

The system should be operated, stored, or transported within

the parameters outlined below. Either its operational

environment must be constantly maintained or the unit must be

turned off.

Table 2-2: System Environmental Requirements

Operational Storage Transport (<16hrs.)

Temperature 10° - 40°C

50° - 104°F

Humidity 30 - 80%

non-condensing

Pressure 700 - 1060hPa 700 - 1060hPa 700 - 1060hPa

Ensure that the probe face temperature does not exceed the

normal operation temperature range.

The LOGIQ C9 Series system and probe connector is not

waterproof. Do not expose the device to water or any kind of

liquid.

-5° - 50°C

23° - 122°F

10 - 90%

non-condensing

-5° - 50°C

23° - 122°F

10 - 90%

non-condensing

2-4 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Cooling

Lighting

General Ultrasound system requirements

The cooling requirement for a console Ultrasound system with

monitor and on board peripherals, is up to 3800 BTU/h. This

figure does not include cooling needed for lights, people, or

other equipment in the room.

NOTE: Each person in the room places an additional 300 BTU/h

demand on the cooling system.

Bright light is needed for Ultrasound system installation, updates

and repairs. However, operator and patient comfort may be

optimized if the room light is subdued and indirect. Therefore a

combination lighting system (dim/bright) is recommended. Keep

in mind that lighting controls and dimmers can be a source of

EMI which could degrade image quality. These controls should

be selected to minimize possible interference.

LOGIQ C9 Series – Basic Service Manual 2-5

5482298-100 English Rev. 5

Site Preparations

Electrical requirements

General requirements

NOTE: GE requires a dedicated power and ground for the proper

operation of its Ultrasound equipment. This dedicated power

shall originate at the last distribution panel before the Ultrasound

system.

Sites with a mains power system with defined Neutral and Live

The dedicated line shall consist of one phase, a neutral (not

shared with any other circuit), and a full size ground wire from

the distribution panel to the Ultrasound outlet.

Sites with a mains power system without a defined Neutral

The dedicated line shall consist of one phase (two lines), not

shared with any other circuit, and a full size ground wire from the

distribution panel to the Ultrasound outlet.

NOTE: Please note that image artifacts can occur, if at any time within

the facility, the ground from the main facility's incoming power

source to the Ultrasound system is only a conduit.

Electrical requirements for the Ultrasound system

In the table below, the electrical specifications for the Ultrasound

system includes monitor and on board peripherals.

Table 2-3: Electrical Specifications for LOGIQ C9 Series system

Vol tag e

To le r an c e Power Consumption Frequency

:

:

220-240 VAC

2-6 LOGIQ C9 Series – Basic Service Manual

±10% Max. 950VA 50/ 60HZ

5482298-100 English Rev. 5

Site circuit breaker

CAUTION

CAUTION

Site power outlets

General Ultrasound system requirements

Power outage may occur. The LOGIQ C9 Series requires a

dedicated single branch circuit. To avoid circuit overload and

possible loss of critical care equipment, make sure you do not

have any other equipment operating on the same circuit.

It is recommended that the branch circuit breaker for the

Ultrasound system be readily accessible.

POWER OUTAGE MAY OCCURE.

The LOGIQ C9 Series requires a dedicated single branch

circuit. To avoid circuit overload and possible loss of critical

care equipment, make sure you DO NOT have any other

equipment operating on the same circuit.

Unit power plug

A dedicated AC power outlet must be within reach of the

Ultrasound system without extension cords. Other outlets

adequate for the external peripherals, medical and test

equipment needed to support this Ultrasound system must also

be present within 1 m (3.2 ft.) of the Ultrasound system.

Electrical installation must meet all current local, state, and

national electrical codes.

If the Ultrasound system arrives without a power plug, or with

the wrong plug, you must contact your GE dealer or the

installation engineer must supply what is locally required.

LOGIQ C9 Series – Basic Service Manual 2-7

5482298-100 English Rev. 5

Site Preparations

Power stability requirement

Table 2-4: Power stability requirement

IEC 61000-4-11

Voltage dips, short

interruptions and

voltage variations

on mains supply

< 5%T (> 95% dip) for

0.5 cycle;

40%T (60% dip) for 5

cycles;

70%T (30% dip) for 25

cycles;

< 5%T (>95% dip) for 5

sec

< 5%T (> 95% dip) for

0.5 cycle;

40%T (60% dip) for 5

cycles;

70%T (30% dip) for 25

cycles;

< 5%T (>95% dip) for 5

sec

Mains power

quality should be

that of a typical

commercial or

hospital

environment.

2-8 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

EMI limitations

General Ultrasound system requirements

Ultrasound systems are susceptible to Electromagnetic

Interference (EMI) from radio frequencies, magnetic fields, and

transients in the air or wiring. They also generate EMI. The

Ultrasound system complies with limits as stated on the EMC

label. However there is no guarantee that interference will not

occur in a particular installation.

Possible EMI sources should be identified before the Ultrasound

system is installed.

Electrical and electronic equipment may produce EMI

unintentionally as the result of a defect. Some of these sources

include:

• medical lasers

• scanners

• cauterizing guns

• computers

• monitors

• fans

• gel warmers

• microwave ovens

• light dimmers

• mobile phones

• in-house wireless phones (DECT phones)

• wireless computer keyboard and mouse

• air conditioning system

• High Frequency (HF) surgery equipment

• general AC/DC adapters

The presence of a broadcast station or broadcast van may also

cause interference.

See: ‘EMI prevention/abatement’ on page 2-10 for EMI

prevention tips.

LOGIQ C9 Series – Basic Service Manual 2-9

5482298-100 English Rev. 5

Site Preparations

EMI prevention/abatement

Table 2-5: EMI prevention/abatement

EMI RULE DETAILS

Be aware of Radio

Frequency sources

Ground the

Ultrasound system

Replace all screws,

Radio Frequency

gaskets, covers,

cores

Replace broken

Radio Frequency

gaskets

Do not place labels

where Radio

Frequency gaskets

touch metal

Use GE specified

harnesses and

peripherals

Take care with

cellular phones

Properly route

peripheral cables

• Keep the Ultrasound system at least 5 meters (15 feet) away from other EMI

sources.

• Special shielding may be required to eliminate interference problems caused by

high frequency, high powered radio or video broadcast signals.

Poor grounding is the most likely reason an Ultrasound system will have noisy

images. Check grounding of the power cord and power outlet.

• After you finish repairing or updating the Ultrasound system, replace all covers

and tighten all screws.

• Any cable with an external connection requires a magnet wrap at each end.

• Install all covers. Loose or missing covers or Radio Frequency gaskets allow

radio frequencies to interfere with the ultrasound signals.

If more than 20% or a pair of the fingers on an Radio Frequency gasket are

broken, replace the gasket. Do not turn on the Ultrasound system until any loose

metallic part is removed.

Where applicable, never place a label where Radio Frequency gaskets meet the

Ultrasound system. Otherwise, the gap created will permit Radio Frequency

leakage. Or, if a label has been found in such a position, move the label.

The interconnect cables are grounded and require ferrite beads and other

shielding. Also, cable length, material, and routing are all important; do not change

from what is specified.

Cellular phones may transmit a 5 V/m signal; that could cause image artifacts.

Where applicable, do not allow cables to lie across the top of the Card Rack or

hang out of the peripheral bays. Loop the excess length for peripheral cables

inside the peripheral bays. Attach the monitor cables to the frame.

2-10 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

General Ultrasound system requirements

CAUTION

CAUTION

CAUTION

Probes environmental requirements

Operation, storage and transport temperatures for probes

Probes should be operated, stored, or transported within the

parameters outlined below.

Ensure that the probe face temperature does not exceed the

normal operation temperature range.

Table 2-6: Probe Environmental Requirements

Operational Storage Transport

Temperature 10° - 40° C

50° - 104° F

Humidity 5 - 85%

non-condensing

Pressure 700 - 1060hPa 700 - 1060hPa 700 - 1060hPa

0° - 55° C

32° - 131° F

5 - 85%

non-condensing

-40° - 55° C

-40° - 131° F

5 - 85%

non-condensing

Check the room temperature before you use the probe.

Ensure that the probe face temperature does not exceed the

normal operation temperature range.

NOTE: Refer to Table 2-1 on page 2-3 to determine the needed

settlement time.

Time and manpower requirements

Site preparation takes time. Begin site preparation checks as

soon as possible, if possible, six weeks before delivery, to allow

enough time to make any changes.

LOGIQ C9 Series – Basic Service Manual 2-11

5482298-100 English Rev. 5

Site Preparations

Contents in this section

• ‘Purchaser responsibilities’ on page 2-13

• ‘Required facility needs’ on page 2-14

• ‘Desirable features’ on page 2-15

• ‘Minimal floor plan suggestion’ on page 2-16

• ‘Recommended floor plan suggestion’ on page 2-17

• ‘Suggested floor plan, Ultrasound system, and EchoPAC PC

in same room’ on page 2-18

• ‘Networking setup requirements’ on page 2-18

Facility needs

2-12 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Purchaser responsibilities

The work and materials needed to prepare the site is the

responsibility of the purchaser. Delay, confusion, and waste of

manpower can be avoided by completing pre-installation work

before delivery. Purchaser responsibility includes:

• Procuring the materials required

• Completing the preparations before delivery of the

Ultrasound system

• Paying the costs for any alterations and modifications not

specifically provided in the sales contract

NOTE: All electrical installations that are preliminary to the positioning

of the equipment at the site prepared for the equipment must be

performed by licensed electrical contractors. Other connections

between pieces of electrical equipment, calibrations, and testing

must also be performed by qualified personnel. The products

involved (and the accompanying electrical installations) are

highly sophisticated and special engineering competence is

required. All electrical work on these products must comply with

the requirements of applicable electrical codes. The purchaser

of GE equipment must only utilize qualified personnel to perform

electrical servicing on the equipment.

Facility needs

The desire to use a non–listed or customer provided product or

to place an approved product further from the Ultrasound

system than the interface kit allows, presents challenges to the

installation team. To avoid delays during installation, such

variances should be made known to the individuals or group

performing the installation at the earliest possible date

(preferably prior to the purchase).

The ultrasound suite must be clean prior to delivery of the

Ultrasound system. Carpet is not recommended because it

collects dust and creates static. Potential sources of EMI

(electromagnetic interference) should also be investigated

before delivery. Dirt, static, and EMI can negatively impact

Ultrasound system reliability.

LOGIQ C9 Series – Basic Service Manual 2-13

5482298-100 English Rev. 5

Site Preparations

Required facility needs

NOTE: GE requires a dedicated power and ground for the proper

operation of its Ultrasound equipment. This dedicated power

shall originate at the last distribution panel before the Ultrasound

system.

Sites with a mains power system with defined Neutral and Live

The dedicated line shall consist of one phase, a neutral (not

shared with any other circuit), and a full size ground wire from

the distribution panel to the Ultrasound outlet.

Sites with a mains power system without a defined Neutral

The dedicated line shall consist of one phase (two lines), not

shared with any other circuit, and a full size ground wire from the

distribution panel to the Ultrasound outlet.

:

:

2-14 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Required facility needs (continued)

NOTE: Please note that image artifacts can occur, if at any time within

the facility, the ground from the main facility's incoming power

source to the Ultrasound unit is only a conduit.

• Dedicated single branch power outlet of adequate

amperage meeting all local and national codes which is

located less than 2.5 m (8 ft.) from the unit’s proposed

location

• Door opening is at least 76 cm (30 in) wide

• Proposed location for unit is at least 0.5m (1.5 ft.) from the

wall for cooling

• Power outlet and place for any external peripheral are within

2 m (6.5 ft.) of each other with peripheral within 1 m of the

unit to connect cables.

• Power outlets for other medical equipment.

• Power outlets for test equipment within 1 m (3.2 ft.) of

Ultrsound system.

• Clean and protected space to store probes (in their cases or

on a rack)

• Material to safely clean probes (done with a plastic

container, never metal)

Facility needs

Desirable features

For the amperage requirements, see: ‘Electrical requirements’

on page 2-6.

• Door is at least 92 cm (3 ft.) wide

• Circuit breaker for dedicated power outlet is easily

accessible

• Sink with hot and cold water

• Receptacle for bio–hazardous waste, like used probe

sheaths

• Emergency oxygen supply

• Storage for linens and equipment

• Nearby waiting room, lavatory, and dressing room

• Dual level lighting (bright and dim)

• Lockable cabinet ordered by GE for its software and

proprietary manuals

LOGIQ C9 Series – Basic Service Manual 2-15

5482298-100 English Rev. 5

Site Preparations

4

1

3

11

6

13

8

10

5

7

9

12

14

2

Minimal floor plan suggestion

CSI 8x10

Scale:

Each square equals one square

foot (app. 31 x 31 cm)

1. Door – at least 762 mm (30

inches)

2. Film Viewer

3. Counter Top, Sink with hot

and cold water and Supplies

Storage

4. Linen Supply

5. Probes/Supplies

6. Examination Table – 1930 x

610 mm (76 x 24 inches)

7. Footswitch

8. Stool

9. Ultrasound system

10. External Peripherals

11. Dedicated Power Outlet Circuit Breaker protected and

easily accessible

12. Network Interface

13. 457 mm (18 inches) distance

of Ultrasound system from

wall or objects

14. GE Cabinet for Software and

Manuals

Figure 2-1. Minimal floor plan, 2.5 m x 3 m (8 by 10 foot)

2-16 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Recommended floor plan suggestion

CSI 14x17

Facility needs

10

11

12

15

9

2

3

4

5

13 14

16

8

7

1

17

6

18

Scale: Each square equals one square foot (app. 31 x 31 cm)

1. Secretaries or Doctors Desk

2. File Cabinet

3. Film Viewer

4. Counter Top

5. Counter Top and Sink with

hot and cold water

6. Overhead Lights Dimmer Dual Level Lighting (bright

and dim)

7. Emergency Oxygen

8. Suction Line

9. Ultrasound system

10. Dedicated Power Outlet Circuit Breaker protected and

easily accessible

11. Network Interface

12. 457 mm (18 inches) distance

of Ultrasound system from

wall or objects

13. Stool

14. Footswitch

15. Storage for Linens and

Equipment

16. Examination Table – 1930 x

610 mm (76 x 24 inches)

17. Lavatory and Dressing Room

18. Door – at least 762 mm (30

inches)

Figure 2-2. A 14 by 17 foot recommended floor plan

LOGIQ C9 Series – Basic Service Manual 2-17

5482298-100 English Rev. 5

Site Preparations

Suggested floor plan, Ultrasound system, and EchoPAC PC in same

room

1. EchoPAC PC workstation

parts

2. UPS

3. Ethernet network wall outlet

4. 3x mains power outlets

5. Hot and Cold water

6. Dedicated mains power outlet

7. Ethernet network wall outlet

Figure 2-3. Suggested Room with EchoPAC PC workstation and Ultrasound Scanner

Networking setup requirements

Stand alone Ultrasound system (without network connection)

None.

Scanner connected to hospital’s network

Supported networks:

10/100 Mbit Ethernet/DICOM network (option)

InSite requirements

InSite requires an Ethernet connection via:

• 10/100 Mbit Interface

2-18 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

Purpose of the DICOM network function

DICOM services provide the operator with clinically useful

features for moving images and patient information over a

hospital network.

Examples of DICOM services include the transfer of images to

workstations for viewing or transferring images to remote

printers.

As an added benefit, transferring images in this manner frees up

the on-board monitor and peripherals, enabling viewing to be

done while scanning continues.

With DICOM, images can be archived, stored, and retrieved

faster, easier, and at a lower cost.

Facility needs

LOGIQ C9 Series – Basic Service Manual 2-19

5482298-100 English Rev. 5

Site Preparations

DICOM option setup requirements

To configure the Ultrasound system to work with other network

connections, the site’s network administrator must provide

information to complete the form “Worksheet for DICOM

Network Information”. Ensure that there are no spaces in any

field of the form.

See:

Entries must include:

• A host name, local port number, AE Title, IP address and

Net Mask for the Ultrasound system.

• The IP addresses for the default gateway and other routers

at the site for ROUTING INFORMATION.

• The host name, IP address, port and AE Title for each

device the site wants connected to the Ultrasound system

for DICOM APPLICATION INFORMATION. A field for the

make (manufacturer) and the revision of the device, is also

included. This information may be useful for error solving.

2-20 LOGIQ C9 Series – Basic Service Manual

5482298-100 English Rev. 5

DICOM option setup requirements (continued)

Facility needs

Figure 2-4. Worksheet for DICOM Network Information

LOGIQ C9 Series – Basic Service Manual 2-21

5482298-100 English Rev. 5

Site Preparations

Environmental Dangers

Commercial devices such as laser cameras, printers, VCRs and external monitors,

usually exceed allowable leakage current limits and, when plugged into separate AC

outlets, are in violation of patient safety standards. Suitable electrical isolation of such