General Electric DSXH47EGWW Installation Manual

175D1807P643 49-90381 04-09 JR

GEAppliances.com

Dryers

Safety Instructions . . . . . . . . . . . . . 2–5

Operating Instructions

Care and Cleaning . . . . . . . . . . . . . . . . . . . . .8

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Loading and Using the Dryer . . . . . . . . . . .8

Installation Instructions . . . . . . 9–18

Electrical Installation for

Electric Dryer . . . . . . . . . . . . . . . . . . . . 16, 17

Electrical Requirements . . . . . . . . . . . . . . .11

Exhausting the Dryer . . . . . . . . . . . . .12, 13

Gas Connection for Gas Dryer . . . . . . . .18

Gas Supply Requirements . . . . . . . . . . . .13

Location of Your Dryer . . . . . . . . . . . . . . . .14

Mobile Home Installation . . . . . . . . . . . . .15

Preparing to Install Your Dryer . . . . . .9, 10

Reversing the Door Swing . . . . . . . . . . . .18

Troubleshooting Tips . . . . . . . . .19–21

Consumer Support

Consumer Support . . . . . . . . . . . . . . . . . . . 24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Spacemaker

DSXH47

Owner’s Manual &

Installation Instructions

®

Printed in Mexico

2

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

California Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires businesses to warn customers of potential exposure

to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be

minimized further by properly venting the dryer to the outdoors.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or death.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light a match, or cigarette, or

turn on any gas or electrical appliance.

Do not touch any electrical switch; do not

use any phone in your building.

Clear the room, building or area of all

occupants.

Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions carefully.

If you cannot reach your gas supplier, call

the fire department.

5

4

3

2

1

■

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

■

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

■ Properly ground dryer to conform with all

governing codes and ordinances. Follow

details in Installation Instructions.

■ Install or store where it will not be exposed to

temperatures below freezing or exposed to the

weather.

■ Connect to a properly rated, protected and

sized power supply circuit to avoid electrical

overload.

■ Remove all sharp packing items and dispose of

all shipping materials properly.

Exhaust/Ducting:

This dryer

MUST

be exhausted to the outside.

Use only rigid metal 4″ diameter ductwork

inside the dryer cabinet. Use only rigid metal

or flexible metal 4″ diameter ductwork for

exhausting to the outside.

USE OF PLASTIC OR

OTHER COMBUSTIBLE DUCTWORK CAN CAUSE

A FIRE. PUNCTURED DUCTWORK CAN CAUSE A

FIRE IF IT COLLAPSES OR BECOMES OTHERWISE

RESTRICTED IN USE OR DURING INSTALLATION.

For complete details, follow the Installation

Instructions.

2

1

PROPER INSTALLATION

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used.

3

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions Installation Instructions

4

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

YOUR LAUNDRY AREA

■ Keep the area underneath and around your

appliances free of combustible materials, such

as lint, paper, rags and chemicals.

■ Keep the floor around your appliances clean and

dry to reduce the possibility of slipping.

■ Keep area around the exhaust opening and

surrounding areas free from the accumulation

of lint, dust and dirt.

■ Do not obstruct the flow of ventilating air. Do not

stack or place laundry or throw rugs against the

front or back of the dryer.

■ Close supervision is necessary if this appliance is

used by or near children. Do not allow children

to play on, with or inside this or any other

appliance.

■ Keep all laundry aids (such as detergents,

bleaches, etc.) out of the reach of children,

preferably in a locked cabinet. Observe all

warnings on container labels to avoid injury.

■ Never climb on or stand on the dryer top.

WHEN USING YOUR DRYER

■ Never reach into the dryer while the drum is

moving. Before loading, unloading or adding

clothes, wait until the drum has completely

stopped.

■

Clean the lint filter before each load

to prevent lint

accumulation inside the dryer or in the room.

DO NOT OPERATE THE DRYER WITHOUT THE LINT

FILTER IN PLACE, UNLESS THE DRYING RACK IS IN

USE.

Always replace the lint screen when finished

using the drying rack.

■ Do not wash or dry articles that have been

cleaned in, washed in, soaked in or spotted

with combustible or explosive substances (such as

wax, oil, paint, gasoline, degreasers, dry-cleaning

solvents, kerosene, etc.). These substances give

off vapors that may ignite or explode. Do not add

these substances to the wash water. Do not use or

place these substances around your washer or

dryer during operation.

■ Any article on which you have used a cleaning

solvent or that contains flammable materials

(such as cleaning cloths, mops, towels used in

beauty salons, restaurants or barber shops, etc.)

must not be placed in or near the dryer until

solvents or flammable materials have been

removed. There are many highly flammable

items used in homes such as acetone, denatured

alcohol, gasoline, kerosene, some household

cleaners, some spot removers, turpentines,

waxes, wax removers and products containing

petroleum distillates.

■ The laundry process can reduce the flame

retardancy of fabrics. To avoid such a result,

carefully follow the garment manufacturer’s

care instructions.

■ Do not dry articles containing rubber, plastic

or similar materials such as padded bras, tennis

shoes, galoshes, bath mats, rugs, bibs, baby pants,

plastic bags and pillows that may melt or burn.

Some rubber materials, when heated, can under

certain circumstances produce fire by

spontaneous combustion.

■ Do not store plastic, paper or clothing that may

burn or melt on top of the dryer during

operation.

■ Garments labeled

Dry Away from Heat orDo

Not Tumble Dry

(such as life jackets containing

kapok) must not be put in your dryer.

■ Do not dry fiberglass articles in your dryer.

Skin irritation could result from the remaining

particles that may be picked up by clothing

during subsequent dryer uses.

■ To minimize the possibility of electric shock,

unplug this appliance from the power supply

or disconnect the dryer at the household

distribution panel by removing the fuse or

switching off the circuit breaker before

attempting any maintenance or cleaning

(except the removal and cleaning of the lint

filter).

NOTE:

Pressing the

PAUSE

button does

NOT

disconnect the appliance from the power

supply.

■ Do not spray any type of aerosol into, on or near

dryer at any time.

■ Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a clothes load to catch fire.

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

WHEN NOT USING YOUR DRYER

■ Grasp the plug firmly when disconnecting this

appliance to avoid damage to the cord while

pulling. Place the cord away from traffic areas so

it will not be stepped on, tripped over or

subjected to damage.

■ Do not attempt to repair or replace any part of

this appliance or attempt any servicing unless

specifically recommended in this Owner’s Manual

or in published user-repair instructions that you

understand and have the skills to carry out.

■ Before discarding a dryer, or removing it from

service, remove the dryer door to prevent

children from hiding inside.

■ Do not tamper with controls.

■ Never attempt to operate this appliance if

it is damaged, malfunctioning, partially

disassembled or has missing or broken parts,

including a damaged cord or plug.

■ The interior of the machine and the exhaust

duct connection inside the dryer should be

cleaned at least once a year by a qualified

technician. See the

Loading and Using the Dryer

section. Do not use any type of spray cleaner

when cleaning dryer interior. Hazardous fumes

or electrical shock could occur.

■ If yours is a gas dryer, it is equipped with an

automatic electric ignition and does not have a

pilot light.

DO NOT ATTEMPT TO LIGHT WITH A

MATCH.

Burns may result from having your hand

in the vicinity of the burner when the automatic

ignition turns on.

■ You may wish to soften your laundered fabrics

or reduce the static electricity in them by using

a dryer-applied fabric softener or an antistatic

conditioner. We recommend you use either a

fabric softener in the wash cycle, according to the

manufacturer’s instructions for those products,

or try a dryer-added product for which the

manufacturer gives written assurance on the

package that their product can be safely used in

your dryer. Service or performance problems

caused by use of these products are the

responsibility of the manufacturers of those

products and are not covered under the warranty

to this appliance.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

5

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

WARNING!

6

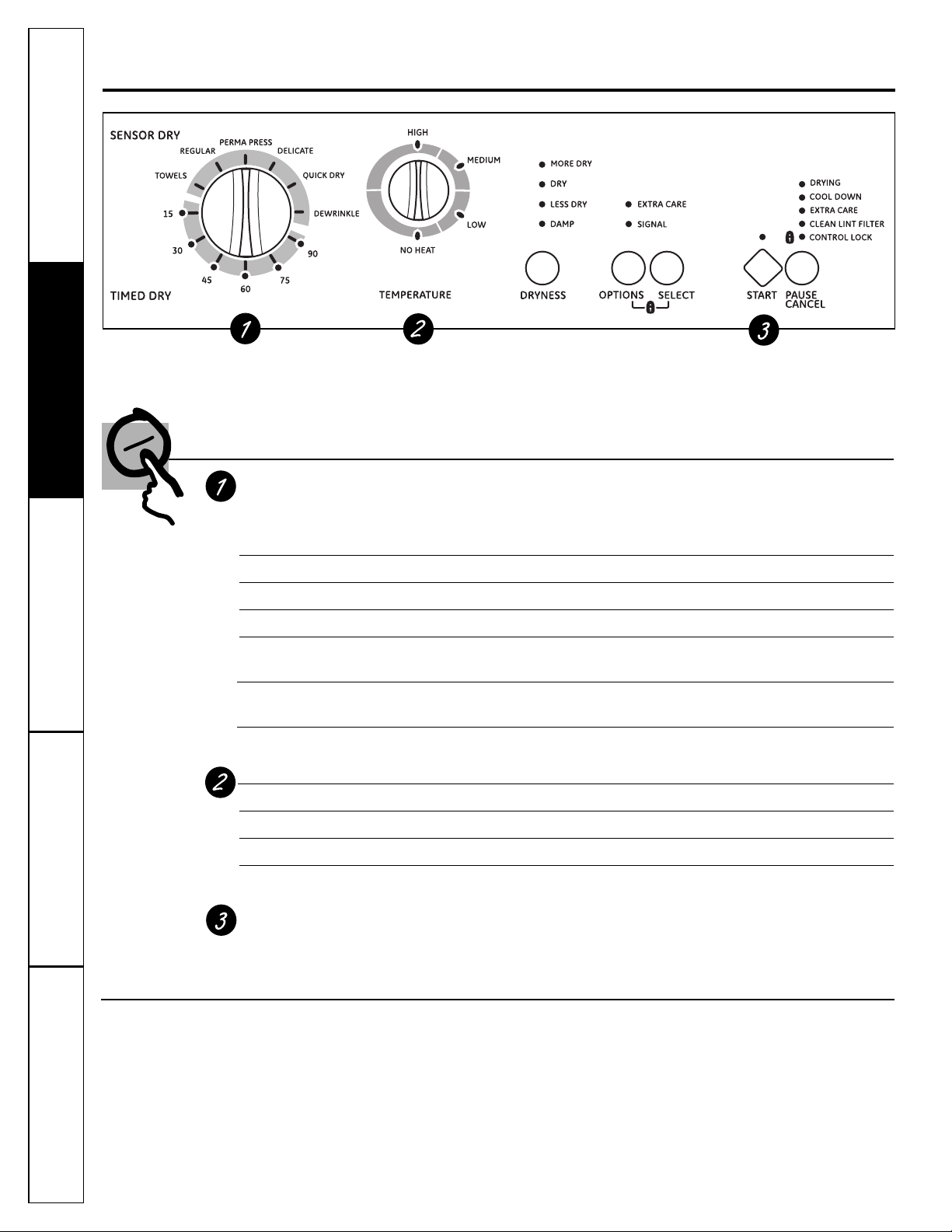

About the dryer control panel.

Control Settings

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Drying Cycles

The

REGULAR, PERMA PRESS

and

DELICATE

cycles automatically sense fabric dryness. Select

MORE

DRY

for heavier fabrics,

LESS DRY

for lighter fabrics. The

TIMED DRY

cycle will run for a selected time.

TOWELS For towels and heavy cottons.

REGULAR For regular to heavy cottons.

PERM PRESS For wrinkle-free, permanent press and delicate items.

DELICATES For lingerie and special-care fabrics.

QUICK DRY For small loads that are needed in a hurry, such as sports and school uniforms. Can also be used if the

previous cycle left some items damp, such as collars or waistbands.

DEWRINKLE For removing wrinkles from items that are dry or slightly damp. This cycle is not recommended for

delicate fabrics.

TIMED DRY Set the Cycle Selector at the desired drying time.

Fabric Care

HIGH For regular to heavy cottons.

MEDIUM For synthetics, blends and items labeled

permanent press

or

tumble dry medium heat.

LOW For knits, delicates, synthetics and items labeled

tumble dry low heat.

NO HEAT For

fluffing

items without heat. Use the

TIMED DRY

cycle.

Start

Close the dryer door. Select

START

. Opening the door during operation will stop the dryer. To restart

the dryer, close the door and select

START

to complete the cycle.

Control Lock

To prevent accidentally starting or

stopping the dryer, press

OPTIONS

and

SELECT

at the same time until the Control

Lock indicator is lighted. To unlock the

controls, press

OPTIONS

and

SELECT

again.

About your dryer features.

Signal Option

When the signal is on it will sound just

before the end of the cycle to remind

you to remove the clothes.

If the dried load cannot be removed

promptly during the cycle, the Cycle

Selector will advance to the

EXTENDED

COOL DOWN

setting. Unheated tumbling

continues during

EXTENDED COOL DOWN

and

WRINKLE CARE

(on some models)

for 40 minutes to help reduce wrinkling.

When the

CYCLE SIGNAL

is on, it will

sound briefly every five minutes as a

reminder to remove the load.

NOTE:

■

If items are removed before the end of

the cycle, press the CANCEL button twice

.

■

Remove garments promptly at the sound

of the signal. Place clothes on hangers

so wrinkles won’t set in.

■

Use the Cycle Signal especially when

drying fabrics like polyester knits and

permanent press. These fabrics should

be removed so wrinkles won’t set in.

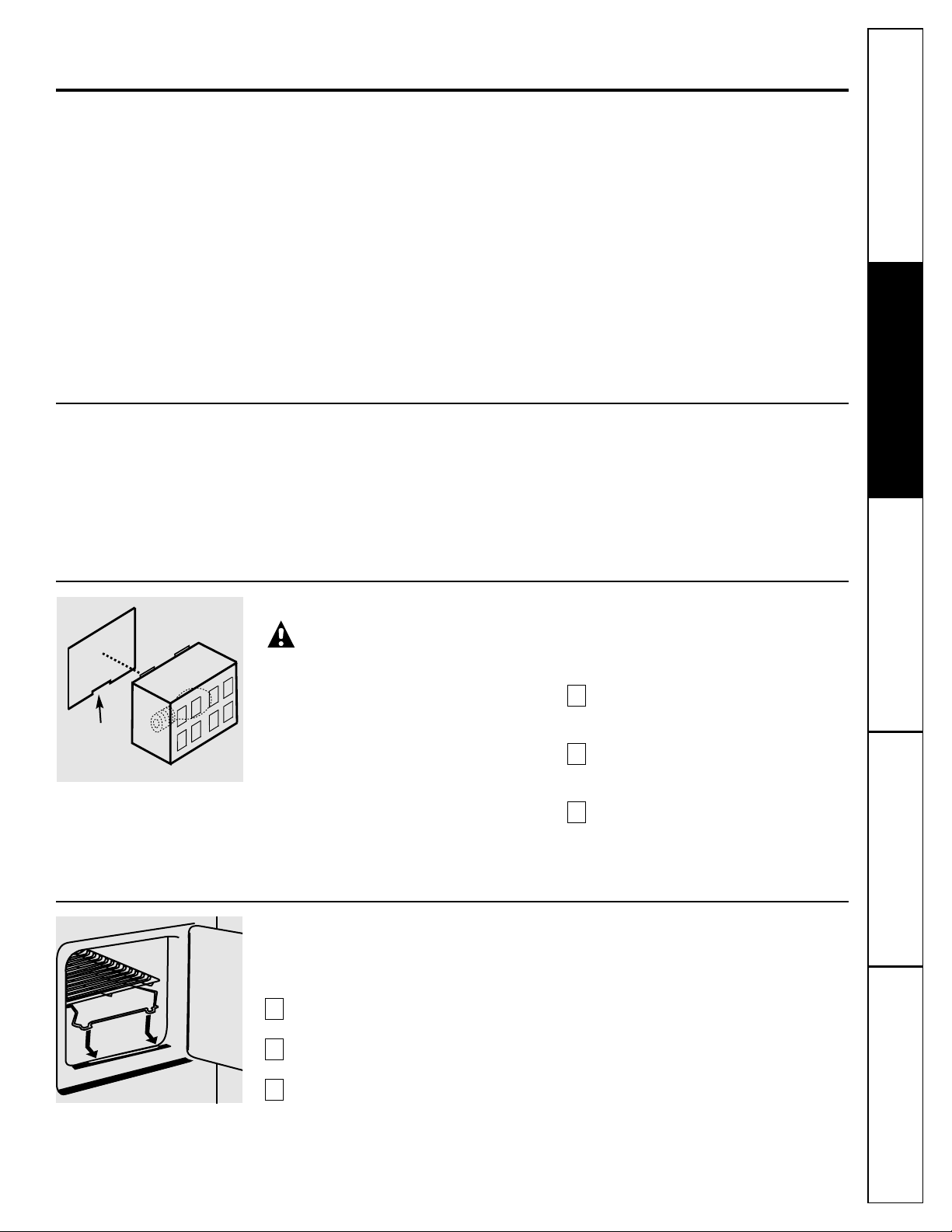

Replacing the Dryer Light Bulb

WARNING:

To reduce the

risk of electric shock, disconnect this

appliance from the power supply

before attempting any user

maintenance. Turning the controls

to the

OFF

position does not

disconnect this appliance from the

power supply.

The dryer light is located above the dryer

door opening.

Before replacing the light bulb, be sure to

unplug the dryer power cord or disconnect

the dryer at the household distribution

panel by removing the fuse or switching

off the circuit breaker.

To replace the dryer light:

Using a small flat blade screwdriver,

pry the bottom of the

light cover

out

and off the

light housing.

Unscrew the bulb when cool and

replace it with an appliance bulb of

the same or lower wattage.

Snap the

light cover

back on the

light

housing.

3

2

1

Drying Rack (on some models)

A handy drying rack may be used for drying

articles such as stuffed toys, pillows or

washable sweaters.

Remove the lint screen.

Place the front bar under the lip of the

lint screen opening.

When items are dry, remove the rack

and replace the lint screen.

DO NOT

OPERATE THE DRYER WITHOUT THE LINT

SCREEN IN PLACE UNLESS THE DRYING

RACK IS IN PLACE.

NOTE:

■ The drying rack must be used with the

TIMED DRY

cycle.

■ Do not use this drying rack when there

are other clothes in the dryer.

3

2

1

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Installation Instructions

Pry with

flat blade

screwdriver

Light

housing

Light

cover

Wrinkle Care

Use this option to minimize the wrinkles

in clothes. It provides approximately 15

minutes of no-heat tumbling after the

clothes are dry.

This option can only be used with the

PERMA PRESS

and

DELICATE

cycles.

7

As a general rule, if clothes are sorted properly for the washer, they are sorted properly for the dryer.

Do not add fabric softener sheets once the load has become warm. They may cause fabric softener stains.

Bounce®Fabric Conditioner Dryer Sheets have been approved for use in all GE Dryers when used in accordance

with the manufacturer’s instructions.

Do not overload. This wastes energy and causes wrinkling.

Do not dry the following items: fiberglass items, woolens, rubber-coated items, plastics, items with plastic trim and

foam-filled items.

8

Loading and using the dryer.

Always follow the fabric manufacturer’s care label when laundering.

Sorting and Loading Hints

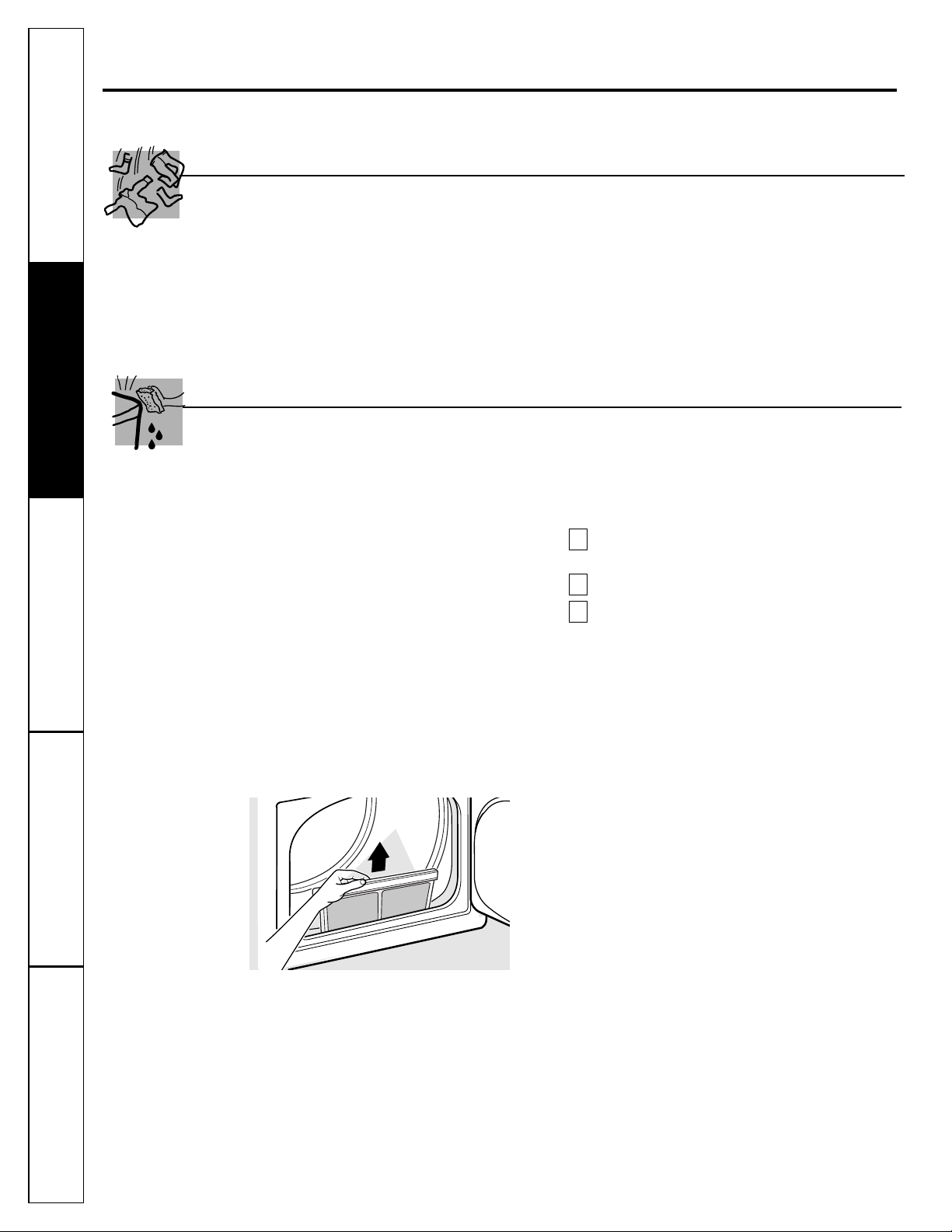

The Exterior:

Wipe or dust any spills or washing

compounds with a damp cloth. Dryer control panel

and finishes may be damaged by some laundry

pretreatment soil and stain remover products.

Apply these products away from the dryer. The

fabric may then be washed and dried normally.

Damage to your dryer caused by these products is

not covered by your warranty.

The Lint Screen:

Clean the lint screen before each

use. Lint buildup in the screen restricts air flow,

which causes longer drying times. The screen is

located at the bottom of the door opening. Remove

by pulling straight up. Remove the lint and replace

the screen.

A waxy buildup may form on the lint screen from

using dryer-added fabric softener sheets. To remove

this buildup, wash the lint screen in warm, soapy

water. Dry thoroughly and replace. Do not operate

the dryer without the lint screen in place.

The Exhaust Duct:

Inspect and clean the exhaust

ducting at least once a year to prevent clogging. A

partially clogged exhaust can lengthen the drying

time.

Follow these steps:

Turn off electrical supply by disconnecting the

plug from the wall socket.

Disconnect the duct from the dryer.

Vacuum the duct with the hose attachment and

reconnect the duct.

The Exhaust Hood:

Check from the outside that the

flaps of the hood move freely when operating. Make

sure that there is no wildlife (birds, insects, etc.)

nesting inside the duct or hood.

3

2

1

Care and Cleaning of the Dryer

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

9

If you have any questions, call 800.GE.CARES (800.432.2737)

or

visit our Website at:

GEAppliances.com

Installation

Spacemaker Dryer

Instructions

Model DSXH47

CALIFORNIA SAFE DRINKING WATER

AND TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish

a list of substances known to the state to cause cancer,

birth defects or other reproductive harm and requires

businesses to warn customers of potential exposure to

such substances. Gas appliances can cause minor

exposure to four of these substances, namely benzene,

carbon monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of natural

gas or LP fuels. Properly adjusted dryers will minimize

incomplete combustion. Exposure to these substances

can be minimized further by properly venting the dryer

to the outdoors.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these

instructions for local inspector’s use.

•

IMPORTANT – Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

•

Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance requires

basic mechanical and electrical skills.

• Completion time – 1–3 hours

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Remove and discard existing plastic or metal foil

duct and replace with UL-listed duct.

WARNING

• To reduce the risk of severe injury or death, follow all

installation instructions.

• Clothes dryer installation must be performed by a

qualified installer.

• Install the clothes dryer according to these instructions

and in accordance with local codes.

• This dryer must be exhausted to the outdoors.

• Use only 4″ (10 cm) rigid metal ducting for exhausting

the clothes dryer to the outdoors.

• DO NOT install a clothes dryer with flexible plastic

ducting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found in

“Connecting the Dryer to House Vent” on page 12 of

this manual. Flexible ducting materials are known to

collapse, be easily crushed, and trap lint. These

conditions will obstruct dryer airflow and increase the

risk of fire.

• Do not install or store this appliance in any location

where it could be exposed to water and or weather.

• Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

• The National Fuel Gas code restricts installations of

gas appliances in garages. They must be 18″ (45.7 cm)

off the ground and protected from vehicles by a

barrier. See

Location of Your Dryer

section.

• The electrical service to the dryer must conform with

local codes and ordinances and the latest edition of the

National Electrical Code, ANSI/NFPA 70 or in Canada,

CSA C22.1 Canadian Electrical Code Part 1.

• The gas service to the dryer must conform with local

codes and ordinances or the latest edition of the

National Fuel Gas Code ANSI Z223.1 or in Canada,

CAN/CGA B149.12. The gas dryer is designed under

ANSI Z 21.5.1 or ANSI/UL2158–CAN/CSA C22.2

(latest editions) for home use only. This dryer is not

recommended for commercial applications such as

restaurants or beauty salons.

FOR YOUR SAFETY:

IN THE COMMONWEALTH OF

MASSACHUSETTS

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

1. Prepare the area and exhaust for installation

of the new dryer.

2. Check to be sure that the existing external

exhaust is clean and that it meets attached

installation specifications.

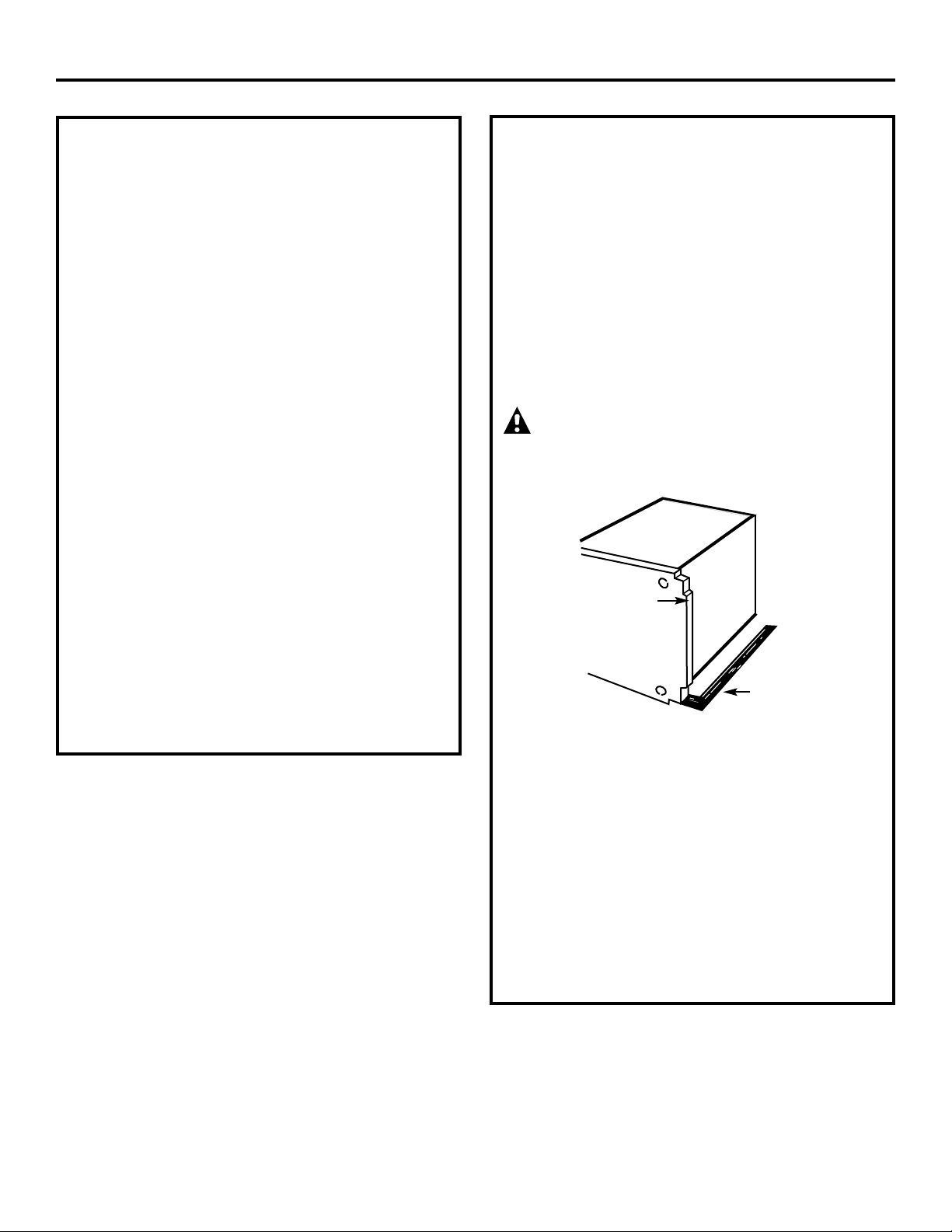

3. Place the four corner posts from the shipping

carton on the floor, parallel to each other, 2–3″

apart. Carefully lay the dryer on its left side on

top of the corner posts. Remove the foam

shipping pad.

CAUTION: To prevent damage, do

not use the control panel as a means to pick up

or move the dryer.

4. Return the dryer to an upright position.

5. Move the dryer to the desired location.

6. Connect the external exhaust.

7. Adjust the leveling legs to match the washer

height. The dryer must be level and rest firmly

on all four leveling legs.

8. Connect the power supply.

9. Check the operation of the power supply and

venting.

10. Place the Owner’s Manual and the Installation

Instructions in a location where they will be

noticed by the owner.

Installation Instructions

TOOLS AND MATERIALS

YOU WILL NEED

Phillips head screwdriver

Adjustable pliers (adjust leveling legs)

Carpenter’s level

Flat or straight blade screwdriver (may be needed

for cord strain relief)

Duct tape

Rigid or UL-listed flexible metal 4″ (10.2 cm) duct

Vent hood

1/4″ nut driver (remove terminal block access

cover and install cord) (ELECTRIC DRYER)

Pipe thread sealer (GAS DRYER)

UL-listed strain relief (may be supplied

with cord)

UL-listed 30A, 240V, 3-wire, #10 AWG minimum

conductor power cord (existing structure)

UL-listed 30A, 240V, 4-wire, #10 AWG

minimum conductor power cord is required

(new construction)

Flexible stainless steel or plastic-coated brass

connnecting tube (if allowed by building code)

(GAS DRYER)

Open-end wrenches for flexible tube and

connector (GAS DRYER)

PREPARING THE INSTALLATION SITE

AND UNPACKING YOUR DRYER

Foam shipping pad

Back of

Dryer

10

Packing

ELECTRICAL CONNECTION

INFORMATION FOR

ELECTRIC DRYERS

Installation Instructions

WARNING –

To reduce the risk of

fire, electric shock or personal injury:

• DO NOT USE AN EXTENSION CORD WITH

THIS APPLIANCE.

• THIS APPLIANCE MUST BE PROPERLY

GROUNDED.

This dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70.

Electrical Requirements

• This dryer must be connected to a 208V or 240V

individual branch circuit, protected by 30-amp circuit

breakers or time-delay fuses.

• Power supply: 3-wire 240-volt, single-phase, 60-Hz,

Alternating Current.

• Use copper conductors only.

• If the electric supply does not meet the above

specifications, call a licensed electrician.

NOTE: A wiring diagram is located under the top panel.

ELECTRICAL CONNECTION

INFORMATION FOR GAS DRYERS

WARNING –

To reduce the risk of

fire, electric shock or personal injury:

• DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WITH THIS APPLIANCE.

•

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD GROUNDING PRONG FROM

THE POWER CORD.

This dryer

must be electrically grounded in accordance

with local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70.

Electrical Requirements

• This dryer must be supplied with 120V, 60-Hz,

and connected to a properly grounded branch

circuit, protected by a 15- or 20-amp circuit breaker

or time-delay fuse.

• If the electric supply provided does not meet the

above specifications, it is recommended that a licensed

electrician install an approved outlet.

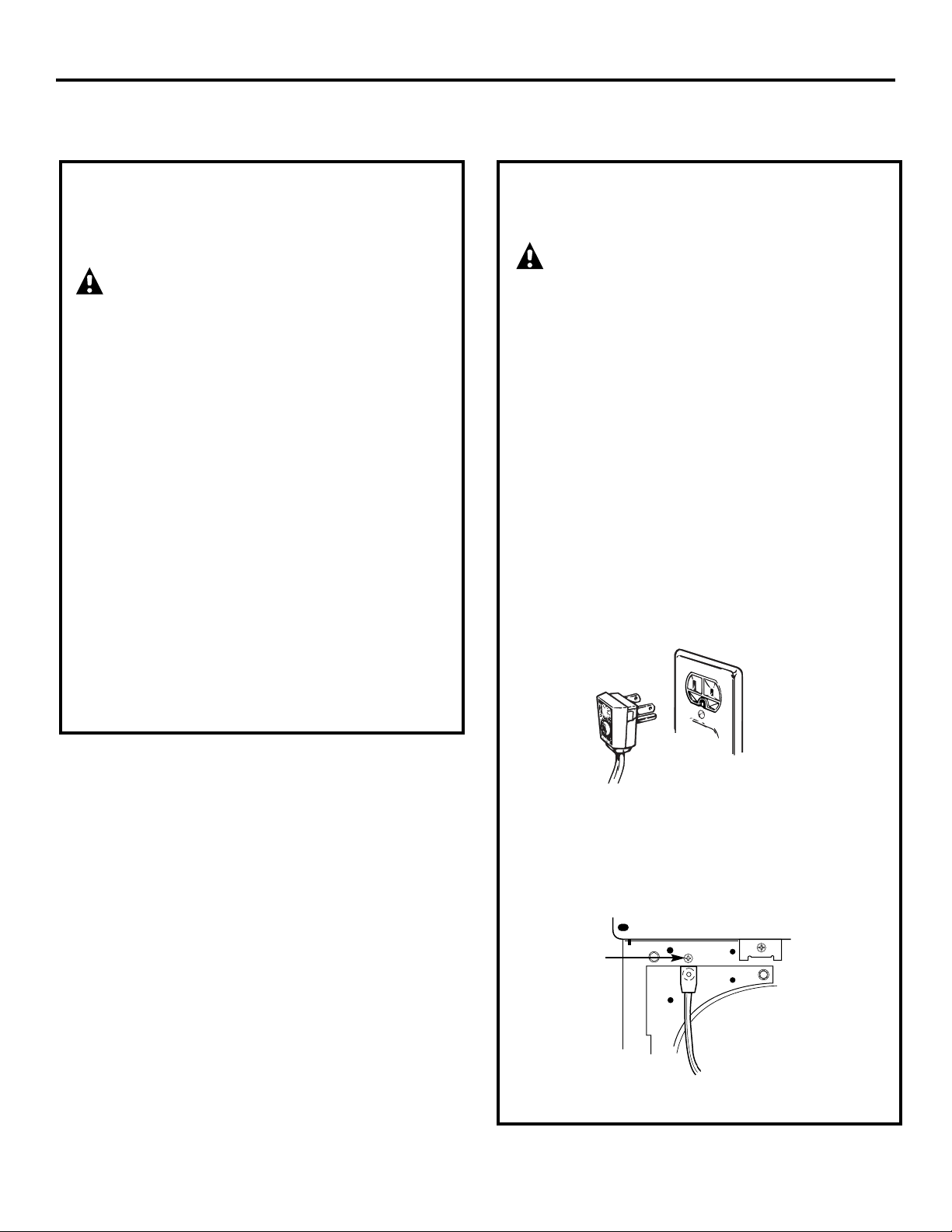

External Ground (if required)

An external ground wire (not provided), which meets local

codes, may be added by attaching it to the green ground

screw on the rear of the dryer in the upper left corner

above the cord, and to grounded metal cold water pipe

or other established ground.

NOTE: A wiring diagram is located under the top panel.

Attach ground wire

(obtain locally)

Ensure proper ground

exists before use

11

Read these instructions completely and carefully.

Installation Instructions

12

WARNING

•

Never terminate the exhaust into a common duct

with a kitchen exhaust system. A combination of

grease and lint creates a potential fire hazard.

•

Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

•

Never install a screen in or over the exhaust duct.

This will cause lint to accumulate, creating a potential

fire hazard.

•

Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

•

Do not obstruct incoming or exhausted air.

•

Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once a year.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

• Termination should present minimal resistance to the

exhaust airflow and should require little or no

maintenance to prevent clogging.

• Never install a screen in or over the exhaust duct.

• Wall caps must be installed at least 12″ above ground

level or any other obstruction with the opening pointed

down.

SEPARATION OF TURNS

• For best performance, separate all turns by at least 4 ft.

of straight duct, including distance between last turn

and dampened wall cap.

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male end

of each section of duct must point away from the dryer.

• Do not assemble the ductwork with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints should be made air- and moisture-tight by

wrapping the overlapped joints with duct tape or

aluminum tape.

• Horizontal runs should slope down towards the

outdoors 1/4″ per foot.

INSULATION

• Ductwork that runs through an unheated area or is

near air conditioning should be insulated to reduce

condensation and lint buildup.

WARNING

To reduce the risk of fire or

personal injury:

•

This clothes dryer must be exhausted to the outdoors.

•

Use only 4″ rigid metal ducting for the home exhaust

duct.

•

Use only 4″ rigid metal or UL-listed flexible metal (semirigid or foil-type) duct to connect the dryer to the home

exhaust duct. It must be installed in accordance with the

instructions found in “Connecting the Dryer to House

Vent” on this page.

•

Do not terminate exhaust in a chimney, a wall, a ceiling,

gas vent, crawl space, attic, under an enclosed floor, or

in any other concealed space of a building.

Correct

Incorrect

Do

Don’t

Don’t

Don’t

CONNECTING THE DRYER TO

HOUSE VENT

RIGID METAL TRANSITION DUCT

• For best drying performance, a rigid metal transition

duct is recommended.

• Rigid metal transition ducts reduce the risk of crushing

and kinking.

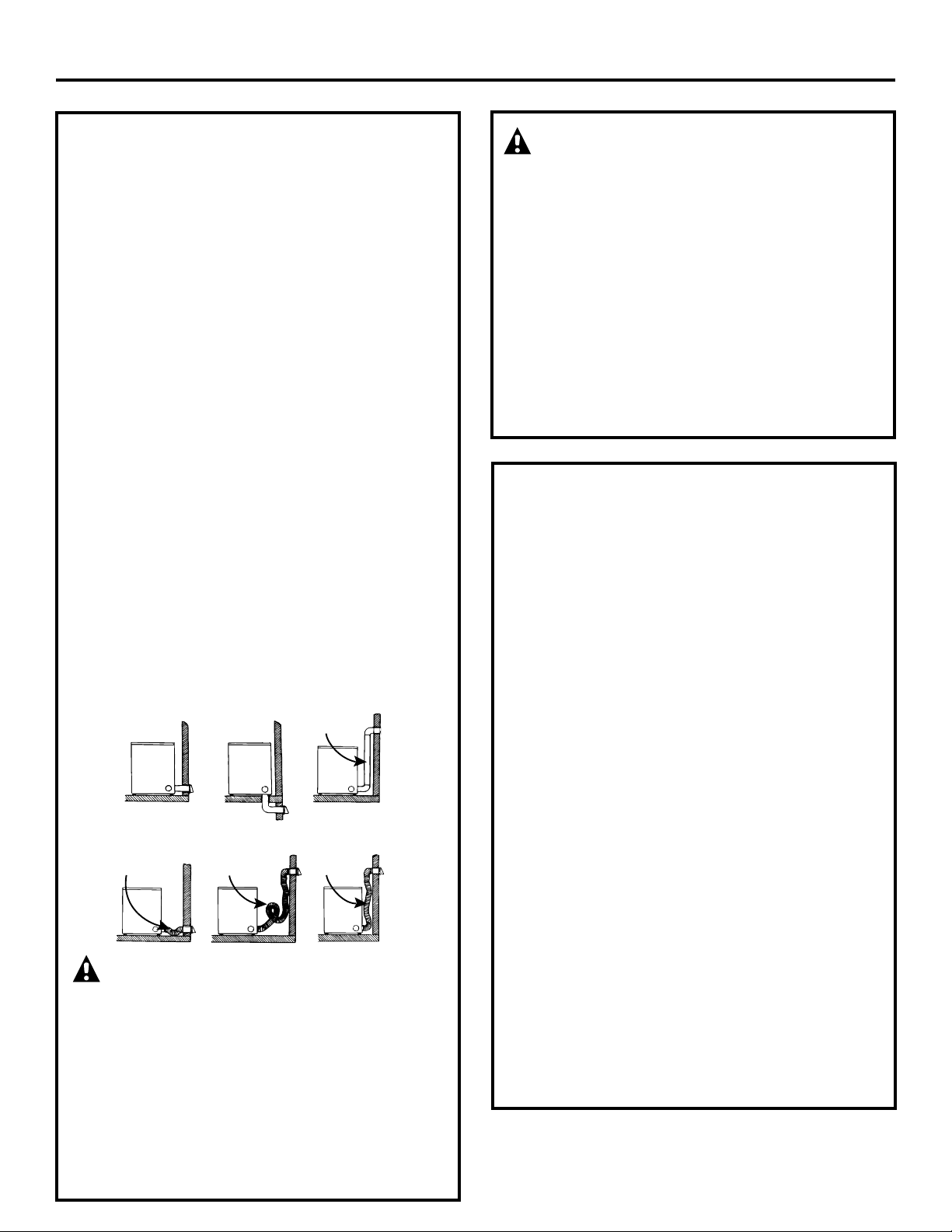

UL-LISTED FLEXIBLE METAL (SEMI-RIGID)

TRANSITION DUCT

• If rigid metal duct cannot be used, then UL-listed

flexible metal (semi-rigid) ducting can be used

(Kit WX08X10077).

• Never install flexible metal duct in walls, ceilings, floors

or other enclosed spaces.

• Total length of flexible metal duct should not exceed

8 feet (2.4 m).

• For many applications, installing elbows at both the dryer

and the wall is highly recommended (see illustrations at

right). Elbows allow the dryer to sit close to the wall

without kinking and/or crushing the transition duct,

maximizing drying performance.

• Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE)

TRANSITION DUCT

• In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal

(foil-type) duct. A UL-listed flexible metal (foil-type) duct

may be used ONLY in installations where rigid metal or

flexible metal (semi-rigid) ducting cannot be used AND

where a 4

″

diameter can be maintained throughout the

entire length of the transition duct.

• In Canada and the United States, only the flexible metal

(foil-type) ducts that comply with the “Outline for Clothes

Dryer Transition Duct, Subject 2158A” shall be used.

Installation Instructions

EXHAUST DIRECTION

All dryers are shipped set up for rear exhausting.

On electric dryers, exhausting can be on the cabinet right

or left side, or through the dryer bottom. Gas dryers can

exhaust on the cabinet right side or the dryer bottom. To

change exhaust direction you will need Exhaust Kit Pub.

No. 14-A018 and a rigid metal 4″ 90-degree elbow. The kit

is available through your GE retailer. Follow the

instructions supplied with the kit.

Same as

other side

EXHAUST DUCT LOCATING

DIMENSIONS

3 3/4″ (9.5 cm)

3 3/4″ (9.5 cm)

13 5/16″

(34 cm)

4 3/8″

(11 cm)

5 7/8″

(15 cm)

GAS SUPPLY REQUIREMENTS

Replace brass connecting pipe that is not plastic-coated.

Stainless steel or plastic-coated brass MUST be used.

WARNING: Never reuse old flexible

connectors. The use of old flexible connectors can cause

gas leaks and personal injury. Always use NEW flexible

connectors when installing a gas appliance.

1. Installation MUST conform with local codes, or in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (latest edition).

2. The gas supply line should be of 1/2″ (1.27 cm)

rigid pipe.

3. If codes allow, flexible metal tubing may be used

to connect your dryer to the gas supply line. The

tubing MUST be constructed of stainless steel or

plastic-coated brass.

4. The gas supply line MUST have an individual shutoff

valve.

5. A 1/8″ (0.32 cm) NPT plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures in excess of

1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping

system during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.45 kPa).

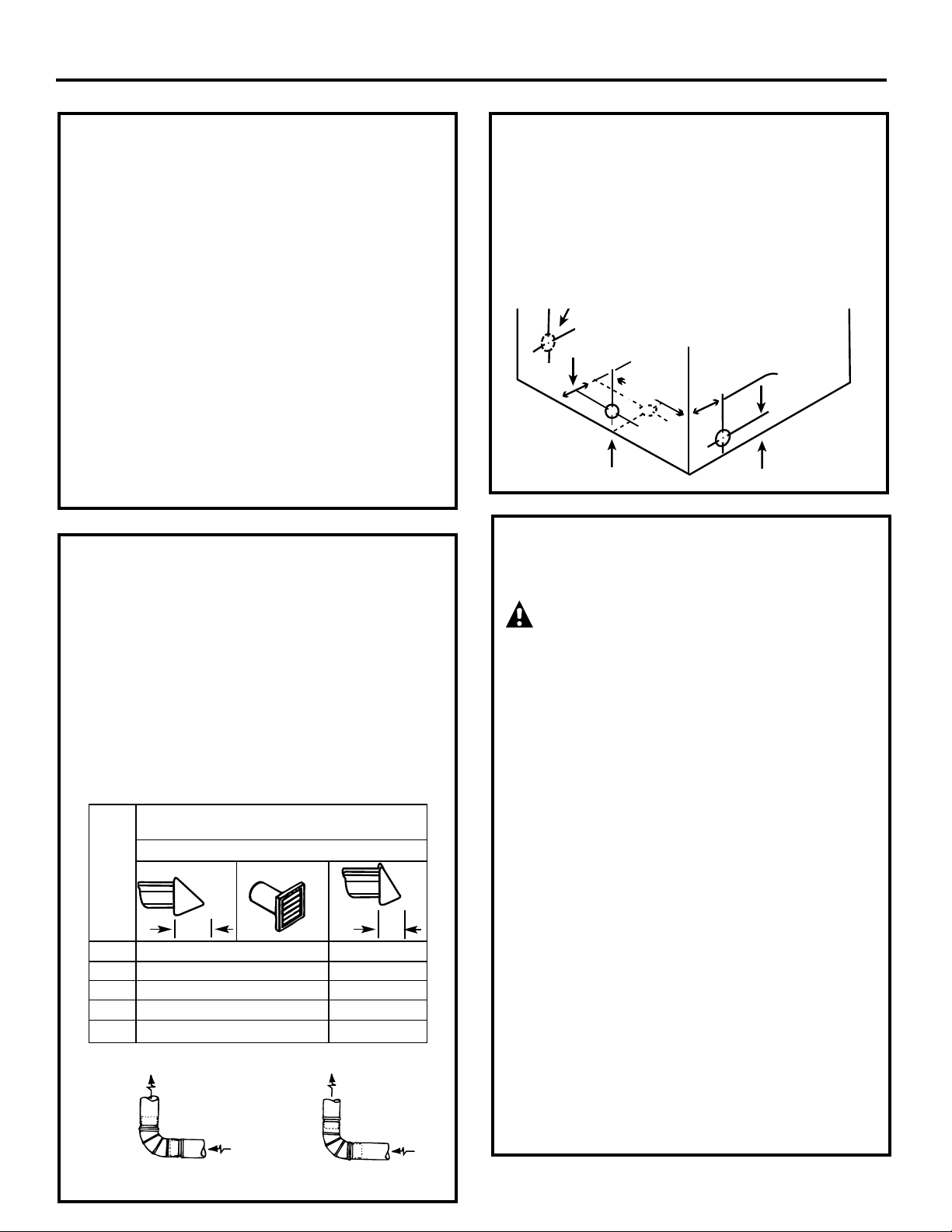

EXHAUST DUCTING LENGTH

The exhaust system should be inspected and cleaned a

minimum of every year with normal usage. The more the

dryer is used, the more often you should check the exhaust

system and vent hood for proper operation.

• DO NOT assemble the duct work with fasteners that

extend into the duct. They will serve as collection points

for lint.

• Insulation – Ductwork which runs through an unheated

area or is near an air conditioning duct should be

insulated to reduce condensation and lint buildup.

MAXIMUM LENGTH

of 4“ (10.2 cm) Dia. RIGID METAL DUCT

PREFERRED VENT HOOD TYPE

0 60’ (18.28 m) 48’ (14.63 m)

1 52’ (15.84 m) 40’ (12.19 m)

2 44’ (13.41 m) 32’ (9.75 m)

3 32’ (9.75 m) 24’ (7.31 m)

4 28’ (8.53 m) 16’ (4.87 m)

4” (10.2 cm) Louvered

4”

(10.2 cm)

Number

of 90°

turns

2.5”

(6.35

cm)

CORRECT

INCORRECT

INSTALL MALE FITTINGS IN CORRECT DIRECTION

CONNECTING THE DRYER TO

HOUSE VENT (CONT.)

• Never install flexible metal duct in walls, ceilings,

floors or other enclosed spaces.

• Total length of flexible metal duct should not

exceed 8 feet (2.4 m).

• Avoid resting the duct on sharp objects.

• For best drying performance:

1. Slide one end of the duct over the clothes

dryer outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position,

extend the duct to its full length. Allow 2

″

of duct to overlap the exhaust pipe. Cut off

and remove excess duct. Keep the duct as

straight as possible for maximum airflow.

4. Secure the duct to the exhaust pipe with

the other clamp.

13

Installation Instructions

14

LOCATION OF YOUR DRYER

Do Not Install the Dryer:

1. Do not install the dryer in an area exposed to dripping

water or outside weather conditions.

2. Do not install the dryer in an area where it will come

in contact with curtains, drapes or anything that will

obstruct the flow of combustion and ventilation air.

3. Do not install the dryer on carpet.

Floor MUST be solid with a maximum slope

of 1″ (2.54 cm).

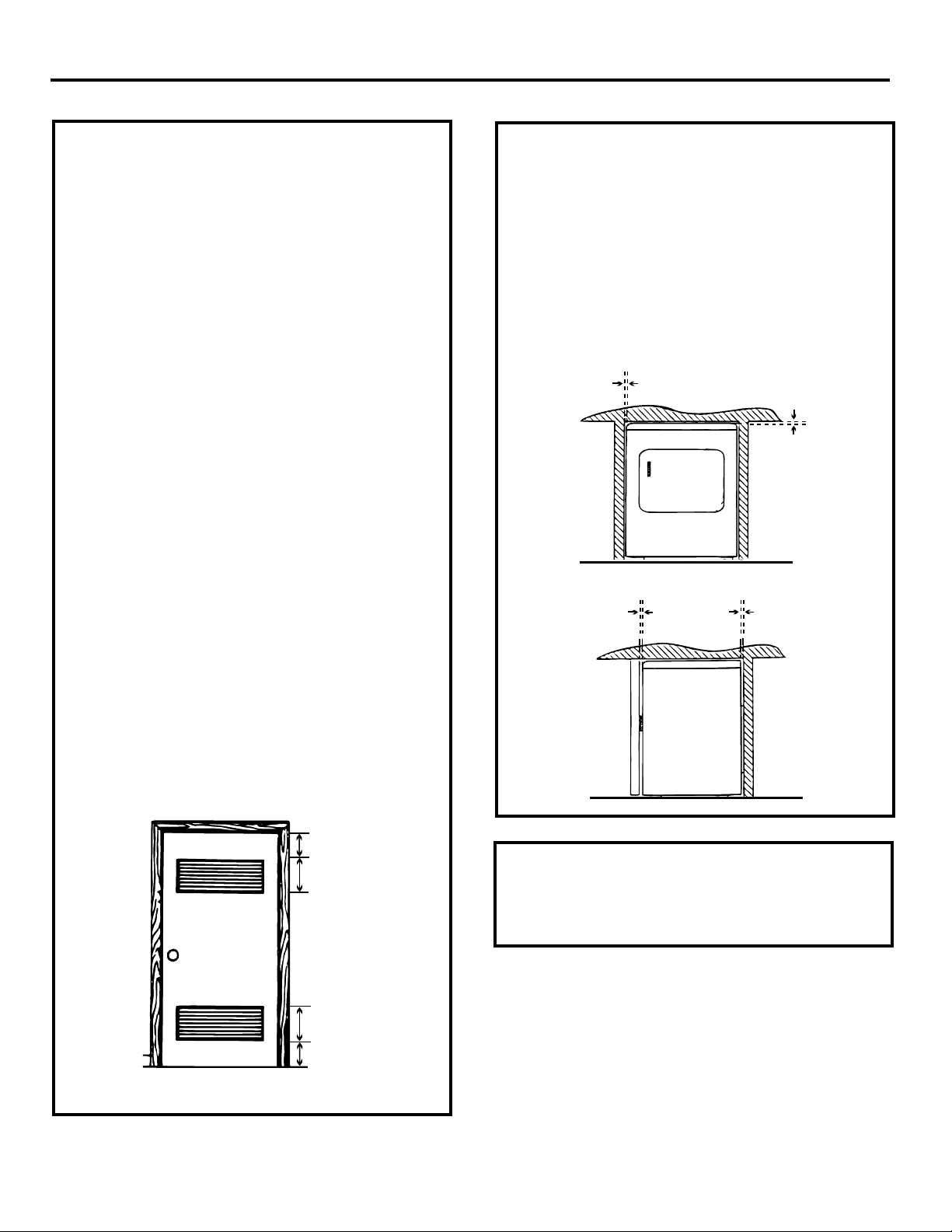

Undercounter Installation:

If an undercounter installation is desired, a custom-sized

countertop is required (36″ to the underside of the

countertop). No special dryer top is required.

Installation in Recess or Closet:

1. This dryer MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet as the GAS DRYER.

3. Your dryer needs the space around it for proper

ventilation. DO NOT INSTALL YOUR DRYER IN A

CLOSET WITH A SOLID DOOR.

4. Closet doors must be louvered or otherwise ventilated

and must contain a minimum of 60 sq. in. of open area

equally distributed. If the closet contains both a washer

and a dryer, doors must contain a minimum of 120 sq.

in. of open area equally distributed. Air openings are

required to be unobstructed when a door is installed.

A louvered door with equivalent air openings for the

full length of the door is acceptable.

60 sq. in.

(387.1 sq. cm)

60 sq. in.

(387.1 sq. cm)

Closet door

3 in.

(7.6 cm)

3 in.

(7.6 cm)

0″

(0 cm)

0″

(0 cm)

3″

(7.6 cm)

Allow the following clearances for ease of installation:

FRONT SIDES REAR TOP

Alcove, stack,

3” (7.6 cm) 0 (0 cm) 3” (7.6 cm) 0 (0 cm)

undercounter

or closet

THIS DRYER MUST BE EXHAUSTED OUTDOORS.

5. The following illustrations show minimum clearance

dimensions for proper operation in a recess or closet

installation.

3″

(7.6 cm)

STACKED INSTALLATION

If a stacked washer/dryer installation is desired, you MUST

use Stacking Kit WE25X10020. This kit is available through

your GE retailer.

Installation Instructions

15

MOBILE HOME INSTALLATION

1. Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting that will

not support combustion. Metal ducting must be 4″

(10.16 cm) in diameter with no obstructions. Rigid metal

duct is preferred.

2. If the dryer is exhausted through the floor, the exhaust

system MUST NOT terminate beneath the mobile

home. Termination MUST be securely fastened to the

mobile home structure.

3. When installing a gas dryer into a mobile home, a

provision must be made for outside make-up air. This

provision is to be not less than twice the area of the dryer

exhaust outlet.

4. Gas dryers MUST be fastened to the floor using Mobile

Home Installation Kit Pub. No. 14–D346–33.

5. See the

Exhaust System Checklist

section for other

important venting information.

6. Installation MUST conform to current Manufactured

Home Construction & Safety Standard (which is a

Federal Regulation Title 24 CFR—Part 32–80) or,

when such standard is not applicable, with American

National Standard for Mobile Homes, ANSI/NFPA No.

501B.

The dryer is designed under ANSI Z 21.5.1.

Correct

Incorrect

Do

Don’t

Don’t

Don’t

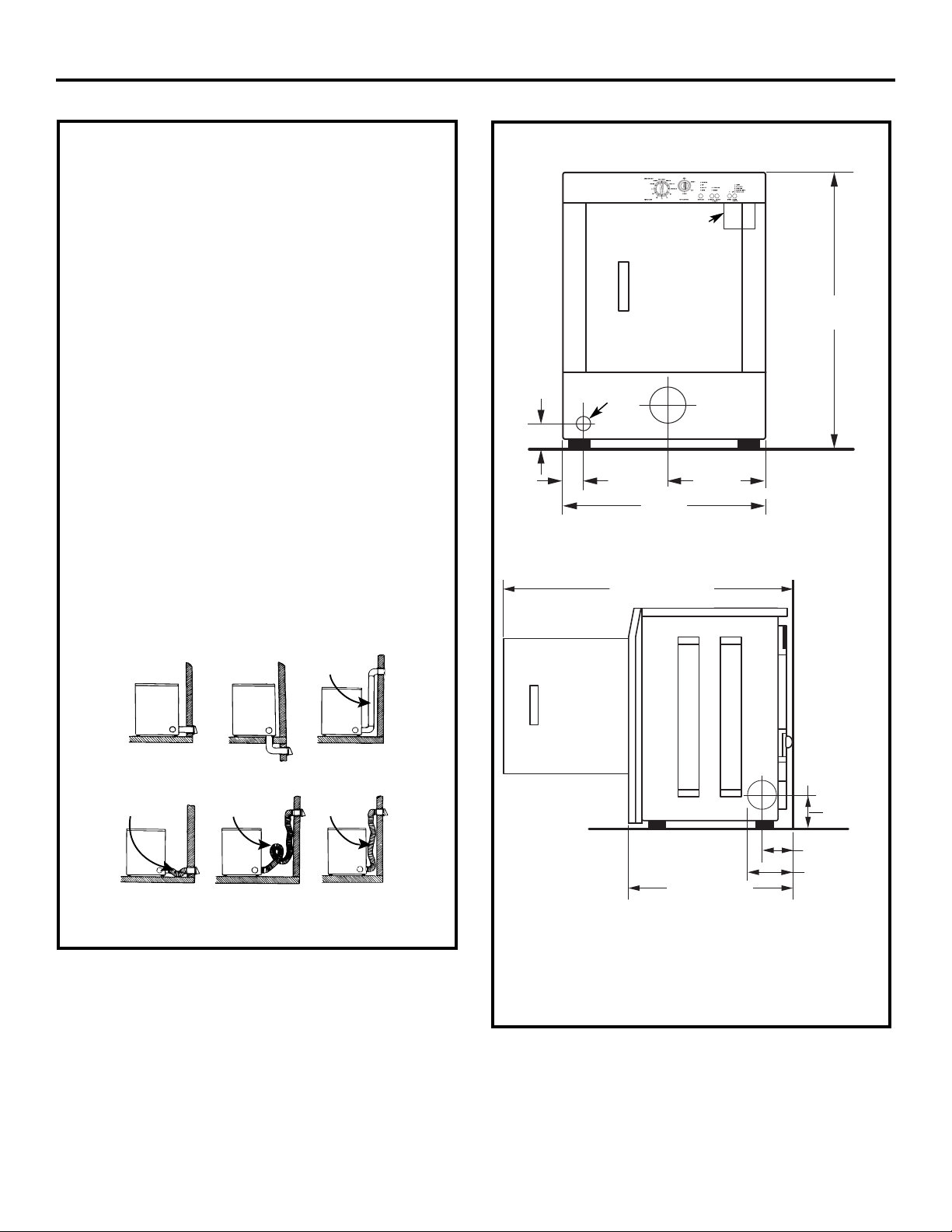

ROUGH-IN DIMENSIONS

48 1/2″ (123.2 cm)

to clear open door

27 1/4″ (69.2 cm) to front of cabinet

27 3/4″ (70.5 cm) to clear knobs

28 1/2″ (72.4 cm) to clear door handle

SIDE VIEW

36″

(91.4 cm)

Electrical supply

on rear of unit

FRONT VIEW

SERVICING – Consideration must be given to provide

adequate clearances for installation and servicing.

2 3/8″

(6.03 cm)

2 1/4″

(5.7 cm)

Gas supply pipe

on rear of unit

4 3/8″ (11.1 cm)

to side exhausts

5 7/8″ (14.9 cm)

to base exhaust

28 1/2″ (72.4 cm)

5″ (12.7 cm)

Center line

height for rear,

right, left vent

13 1/2″

(34.3 cm)

To rear and base exhausts

27″

(68.6 cm)

Loading...

Loading...