Page 1

Installation

Above the

Instructions

Cooktop Oven

PVM1790, PSA1200, PSA2200

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT

instructions for local inspector’s use.

•

IMPORTANT

governing codes and ordinances.

• Note to Installer

instructions with the Consumer.

Save these

–

Observe all

–

Be sure to leave these

–

• Note to Consumer

for future reference.

• Skill level – Installation of this appliance requires basic

mechanical and electrical skills.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

Keep these instructions

–

LA SECCIÓN EN ESPAÑOL EMPIEZA

EN LA PÁGINA 25.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS

.

Page 2

Installation Instructions

CONTENTS

General information

Important Safety Instructions ...................................... 3

Electrical Requirements .................................................. 3

Hood Exhaust ................................................................ 4, 5

Damage – Shipment/Installation .................................. 6

Parts Included .................................................................. 6

Tools You Will Need.......................................................... 7

Mounting Space ................................................................ 7

Step-by-step installation guide

Placement of Mounting Plate .................................. 8–10

Removing the Mounting Plate ............................ 8

ecirculating ................................................ 19–22

R

C

Attach Mounting Plate to Wall ................19

Preparation of Top Cabinet ......................19

Adapting Blower

for Recirculation ..................................20, 21

Mount the Oven ..................................21, 22

Installing the Charcoal Filter ....................22

Before You Use Your Oven .......................................... 23

Sección en Español ................................................ 25–47

Finding the Wall Studs.......................................... 8

Determining Wall Plate Location ........................ 9

Aligning the Wall Plate ...................................... 10

Installation Types .................................................... 11–22

Outside Top Exhaust .................................... 12–14

A

Attach Mounting Plate to Wall ................12

Preparation of Top Cabinet ......................13

Assemble and Install Adaptor ..................13

Mount the Oven ..................................13, 14

Adjust the Exhaust Adaptor ......................14

Connecting Ductwork................................14

Outside Back Exhaust .................................. 15–18

B

Preparing Rear Wall for

Outside Back Exhaust................................15

Attach Mounting Plate to Wall ..........15, 16

Preparation of Top Cabinet ......................16

Adapting Blower for Outside

Back Exhaust ..........................................16, 17

Mount the Oven..........................................18

2

Page 3

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

ee Electrical Requirements for proper outlet installation

S

requirements. The installer must perform a ground

continuity check on the power outlet box before beginning

the installation to ensure that the outlet box is properly

grounded. If not properly grounded, or if the outlet box does

not meet electrical requirements noted (under ELECTRICAL

REQUIREMENTS), a qualified electrician should be employed

to correct any deficiencies.

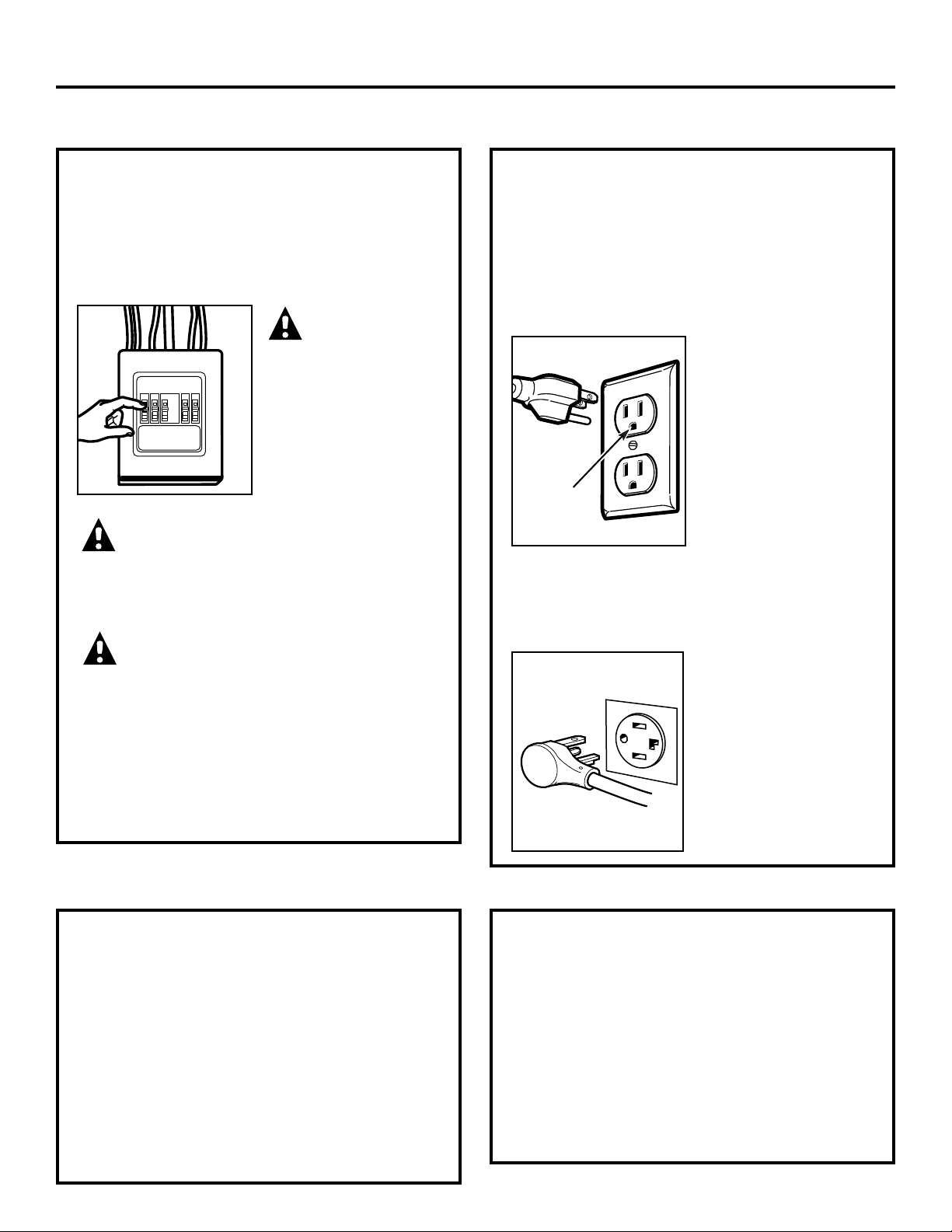

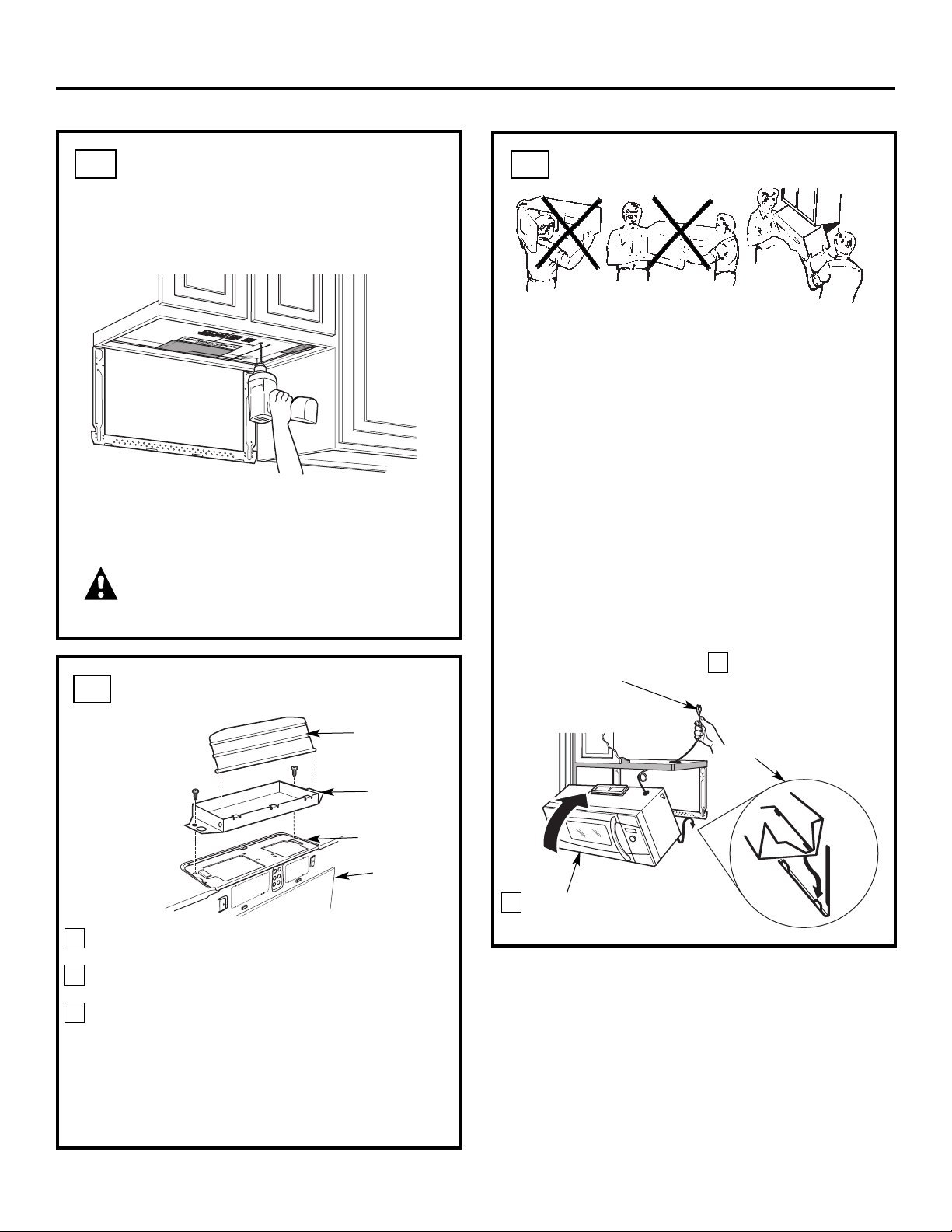

CAUTION:

For personal safety, remove

house fuse or open circuit

breaker before beginning

installation to avoid severe

or fatal shock injury.

CAUTION:For personal safety, the

mounting surface must be capable of supporting the

cabinet load, in addition to the added weight of this

63-85 pound product, plus additional oven loads of

up to 50 pounds or a total weight of 113–135 pounds.

CAUTION: For personal safety, this

product cannot be installed in cabinet arrangements

such as an island or a peninsula. It must be mounted

to BOTH a top cabinet AND a wall.

NOTE: For easier installation and personal safety, it is

recommended that two people install this product.

IMPORTANT—PLEASE READ CAREFULLY. FOR PERSONAL

SAFETY, THIS APPLIANCE MUST BE PROPERLY GROUNDED

TO AVOID SEVERE OR FATAL SHOCK.

ou should have the wall receptacle and circuit checked

Y

by a qualified electrician to make sure the receptacle is

properly grounded.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT, DEFORM, OR

REMOVE ANY OF THE PRONGS FROM THE POWER CORD.

DO NOT USE WITH AN EXTENSION CORD.

120 V Models

The power cord of this appliance is equipped with

a three-prong (grounding)

plug which mates with

a standard three-prong

(grounding) wall receptacle

to minimize the possibility

of electric shock hazard

from this appliance.

Where a standard

Ensure proper

ground exists

before use.

two-prong wall receptacle

is encountered, it is very

important to have it

replaced with a properly

grounded three-prong wall

receptacle, installed by a

qualified electrician.

240 V Models

The wall outlet receptacle recommended for this

NEMA 14–30R

Wall Receptacle

Ensure proper

ground exists

before use.

appliance is NEMA #14–30R

and accepts the four-prong

grounded plug of this

appliance.

ELECTRICAL REQUIREMENTS

120 V Models

This product requires a three-prong grounded outlet .

Product rating is 120 volts AC, 60 Hertz, 15 amps,

and 1.70 kilowatts. This product must be connected

to a supply circuit of the proper voltage and frequency.

Wire size must conform to the requirements of the

National Electrical Code or the prevailing local code

for this kilowatt rating. The power supply cord and

plug should be brought to a separate 15 to 20 ampere

branch circuit single grounded outlet. The outlet box

should be located in the cabinet above the oven.

The outlet box and supply circuit should be installed

by a qualified electrician and conform to the National

Electrical Code or the prevailing local code.

240 V Models

This product requires a four-prong grounded outlet .

Product rating is 120/208 or 120/240 volts, 60 Hertz,

30 amps and 6.5 kilowatts. This product must be

connected to an individual properly grounded branch

circuit, protected by circuit breakers or time-delay

fuses. Wire size must conform to the requirements of

the National Electrical Code or the prevailing local code

for this kilowatt rating. The outlet box should be located

in the cabinet above the oven. The outlet box and

supply circuit should be installed by a qualified

electrician and conform to the National Electrical Code

or the prevailing local code.

3

Page 4

Installation Instructions

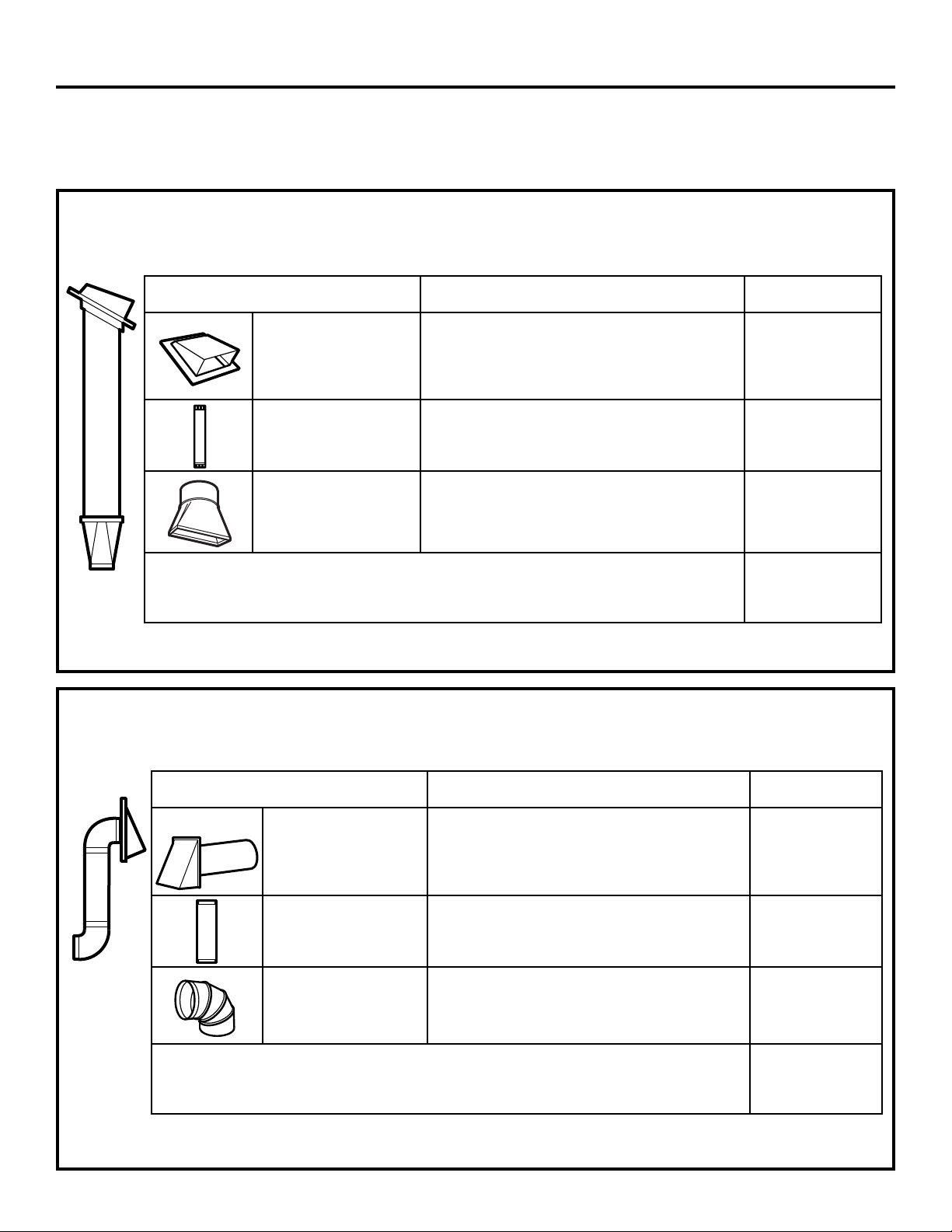

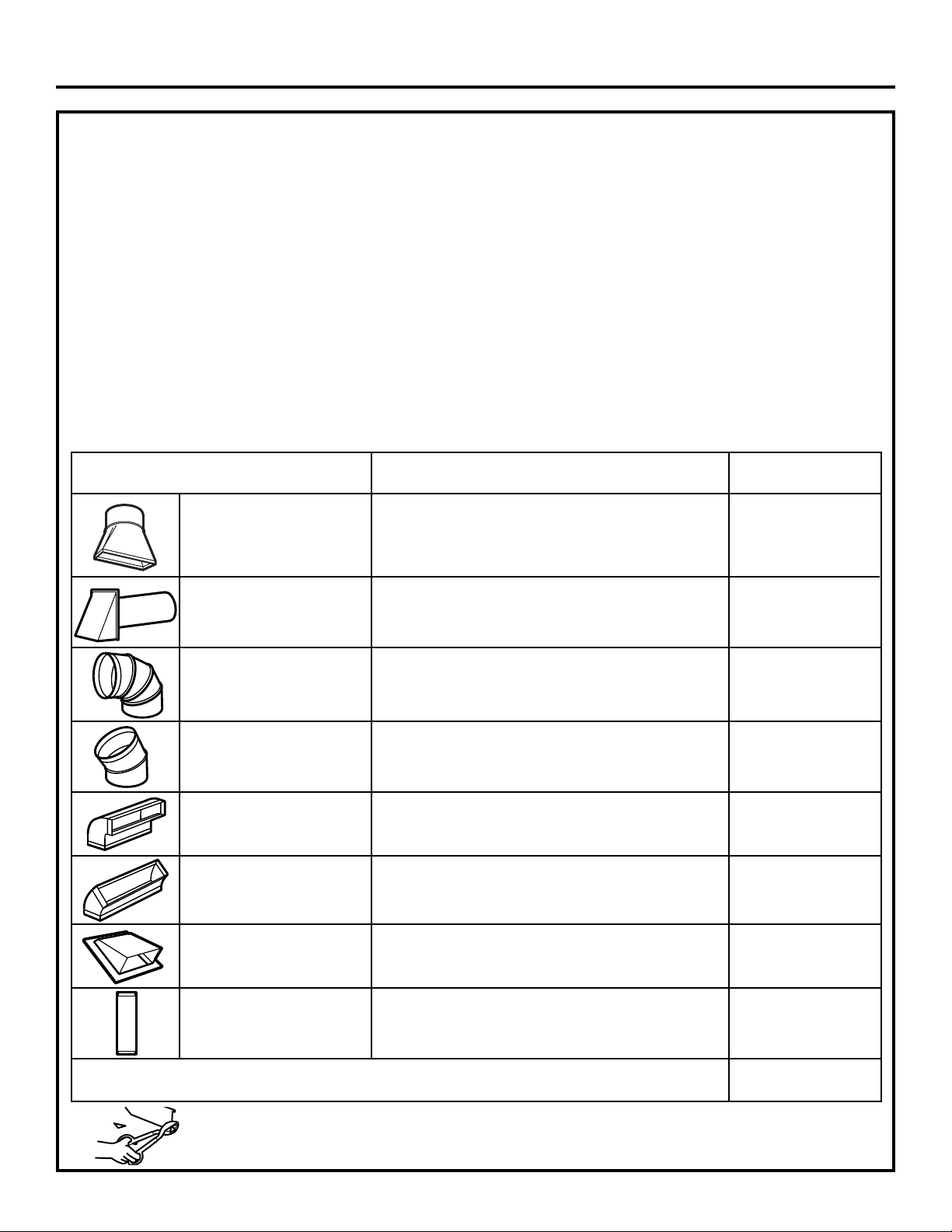

HOOD EXHAUST

OTE: Read these next two pages only if you plan to vent your exhaust to the outside.

N

If you plan to recirculate the air back into the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Roof Cap 24 Ft. x (1) = 24 Ft.

12 Ft. Straight Duct 12 Ft. x (1) = 12 Ft.

(6″ Round)

Rectangular-to-Round 5 Ft. x (1) = 5 Ft.

Transition Adaptor*

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent hood.

*IMPORTANT: If a rectangular-to-round transition adaptor is used, the bottom corners of the damper will

have to be cut to fit, using the tin snips, in order to allow free movement of the damper.

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH* x USED = LENGTH

Wall Cap 40 Ft. x (1) = 40 Ft.

3 Ft. Straight Duct 3 Ft. x (1) = 3 Ft.

(31⁄4″ x 10″ Rectangular)

90° Elbow 10 Ft. x (2) = 20 Ft.

Total Length = 41 Ft.

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent hood.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall should be prepared

at the time it is constructed by leaving enough space between the wall studs to accommodate exhaust.

Total Length = 63 Ft.

4

Page 5

Installation Instructions

NOTE: If you need to install ducts, note that the total duct

length of 31⁄4″ x 10″ rectangular or 6″ diameter round duct

should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the following carefully.

NOTE: It is important that venting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely

and nothing is blocking the ducts.

Exhaust connection:

The hood exhaust has been designed to mate with

a standard 31⁄4″ x 10″ rectangular duct.

If a round duct is required, a rectangular-to-round

transition adaptor must be used. Do not use less than

a 6″ diameter duct.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Rectangular-to-Round 5 Ft. x ( ) = Ft.

Transition Adaptor*

Maximum duct length:

For satisfactory air movement, the total duct length of

31⁄4″ x 10″ rectangular or 6″ diameter round duct should

ot exceed 140 equivalent feet.

n

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equivalent

to a section of straight duct which is longer than their actual

physical size. When calculating the total duct length, add

the equivalent lengths of all transitions and adaptors plus

the length of all straight duct sections. The chart below

shows you how to calculate total equivalent ductwork

length using the approximate feet of equivalent length

of some typical ducts.

Wall Cap 40 Ft. x ( ) = Ft.

90° Elbow 10 Ft. x ( ) = Ft.

45° Elbow 5 Ft. x ( ) = Ft.

90° Elbow 25 Ft. x ( ) = Ft.

45° Elbow 5 Ft. x ( ) = Ft.

Roof Cap 24 Ft. x ( ) = Ft.

Straight Duct 6″ Round or 1 Ft. x ( ) = Ft.

31⁄4″ x 10″ Rectangular

* IMPORTANT: If a rectangular-to-round transition

adaptor is used, the bottom corners of the damper

will have to be cut to fit, using the tin snips, in order

to allow free movement of the damper

.

Total Ductwork = Ft.

Equivalent lengths of duct pieces are based on actual tests and

reflect requirements for good venting performance with any vent

hood.

5

Page 6

Installation Instructions

12″

4″

REAR WALLTEMPLATE

1

/4″TOEDGE

F

. CUT OUT FOR HORIZONTAL

OUTSIDE EXHAUST

DAMAGE – SHIPMENT/ INSTALLATION

• If the unit is damaged in shipment, return

the unit to the store in which it was bought for

repair or replacement.

• If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

• If the unit is damaged by the installer (if other than

the customer), repair or replacement must

be made by arrangement between customer

and installer.

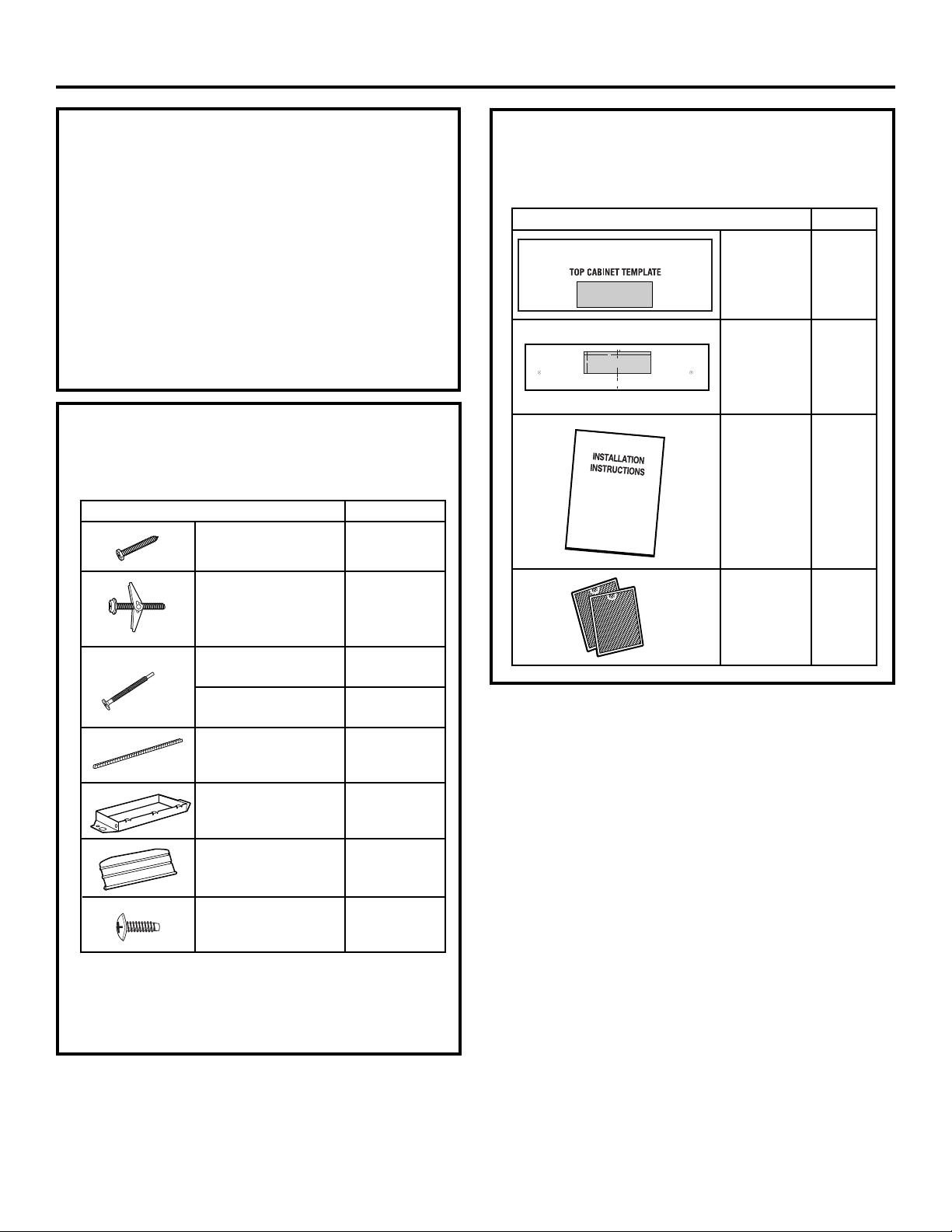

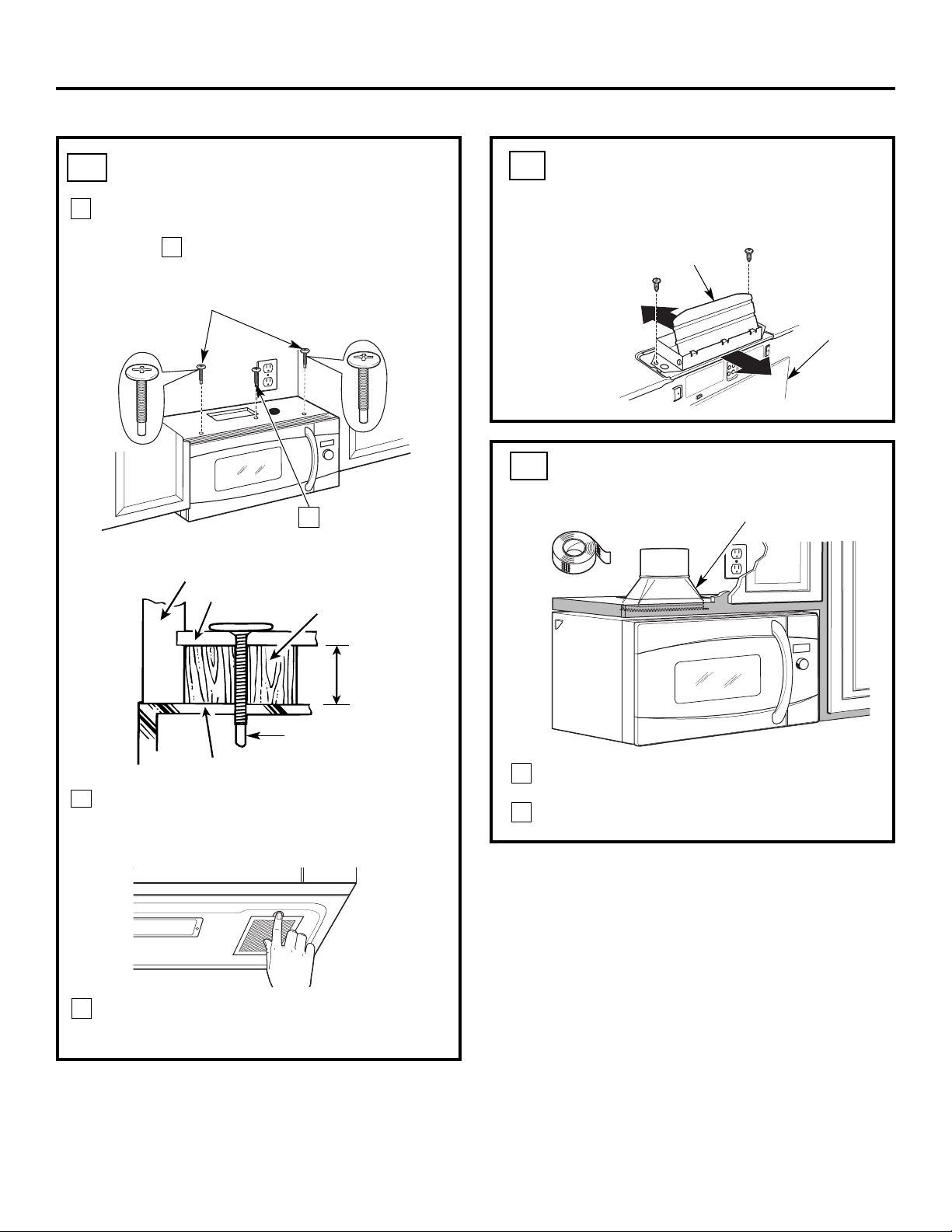

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

Wood Screws 2

(1⁄4″ x 2″)

Toggle Bolts (and 4

wing nuts) (1⁄4″ x 3″)

Self-aligning Machine 3

Screws (1⁄4″-28 x 31⁄4″)

Self-aligning Machine

Screw (1⁄4″-28 x 25⁄8″)

Nylon Grommet 2

(for metal cabinets)

2 (JVM1790 only)

1 (JVM1790 only)

PARTS INCLUDED

ADDITIONAL PARTS

PART

Top Cabinet 1

Template

Rear Wall 1

Template

Installation 1

Instructions

Separately 2

Packed

Grease

Filters

QUANTITY

Exhaust Adaptor 1

Damper 1

Metal Screws 1 black

(1⁄8″ x1⁄2″) 2 bronze

You will find the installation hardware contained

in a packet with the unit. Check to make sure you

have all these parts.

NOTE: Some extra parts are included.

6

Page 7

Installation Instructions

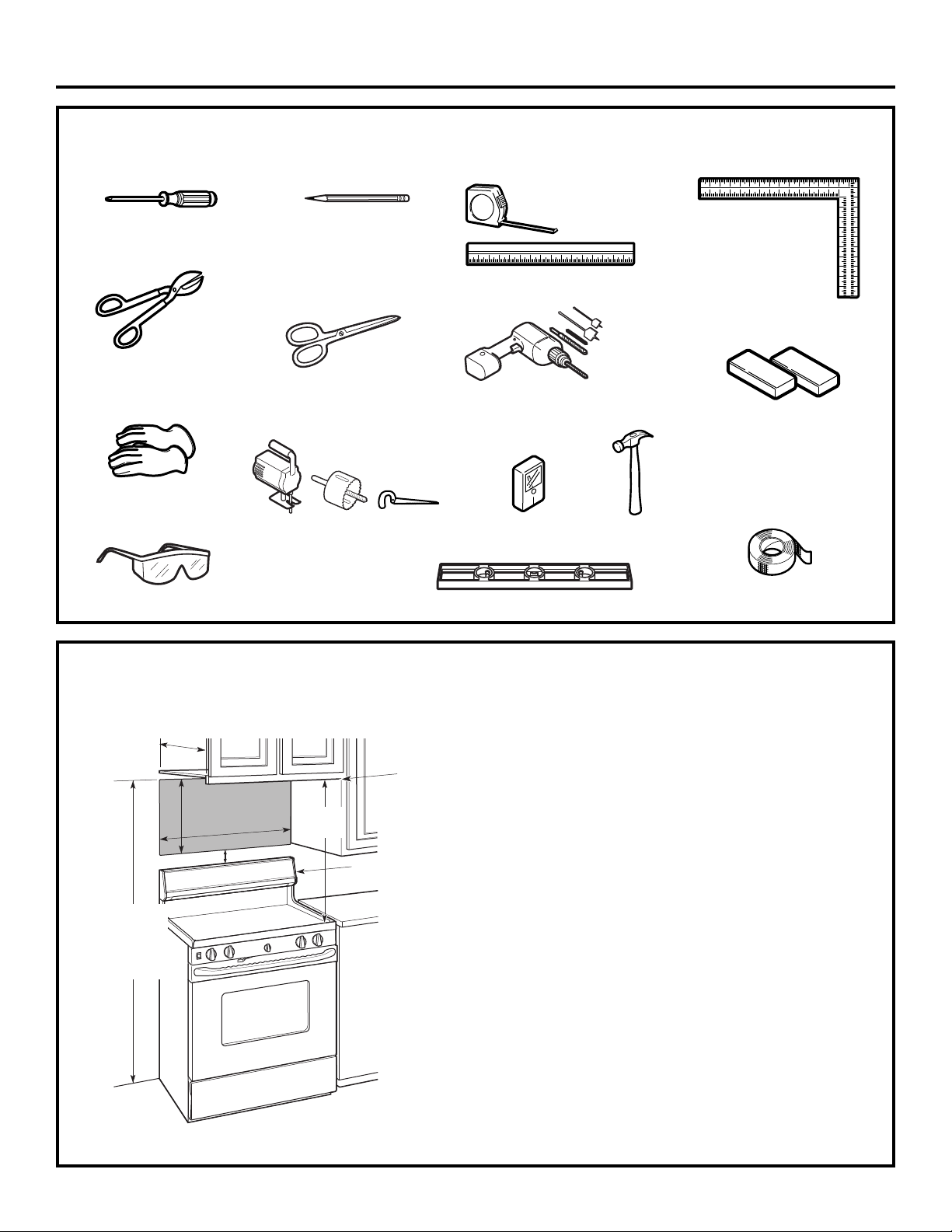

TOOLS YOU WILL NEED

# 1 and #2 Phillips screwdriver

Tin snips (for cutting

damper, if required)

Gloves

Scissors

(to cut template, if necessary)

Pencil

Ruler or tape measure

nd straight edge

a

Electric drill with

1

⁄2″ and5⁄8″ drill bits

3

⁄16″,7⁄16″,

Carpenter square

(optional)

Filler blocks or scrap

wood pieces, if needed

for top cabinet spacing

(used on recessed bottom

cabinet installations only)

Saw (saber, hole or keyhole)

Safety goggles

MOUNTING SPACE

13″ max.

1

⁄4″

16-

30″

2″

66″ or more

from the floor

to the top of

the oven

30″

min.

Backsplash

Bottom edge of

cabinet needs to

be 30″ or more

from the cooking

surface

Stud finder or

Level

Hammer (optional)

Duct and masking tape

NOTES:

• The space between the cabinets must be 30″ wide

and free of obstructions.

• If the space between the cabinets is greater than

30″, a Filler Panel Kit may be used to fill in the gap

between the oven and the cabinets. Your Owner’s

Manual contains the kit number for your model.

• This oven is for installation over ranges up to

36″ wide.

• If you are going to vent your oven to the outside,

see Hood Exhaust Section for exhaust duct

preparation.

• When installing the oven beneath smooth, flat

cabinets, be careful to follow the instructions

on the top cabinet template for power cord

clearance.

• The depth of the opening cannot be more than

13″.

• The product should not be installed over any

cooktop or range with a combined BTU greater

than 60000 BTU.

7

Page 8

Installation Instructions

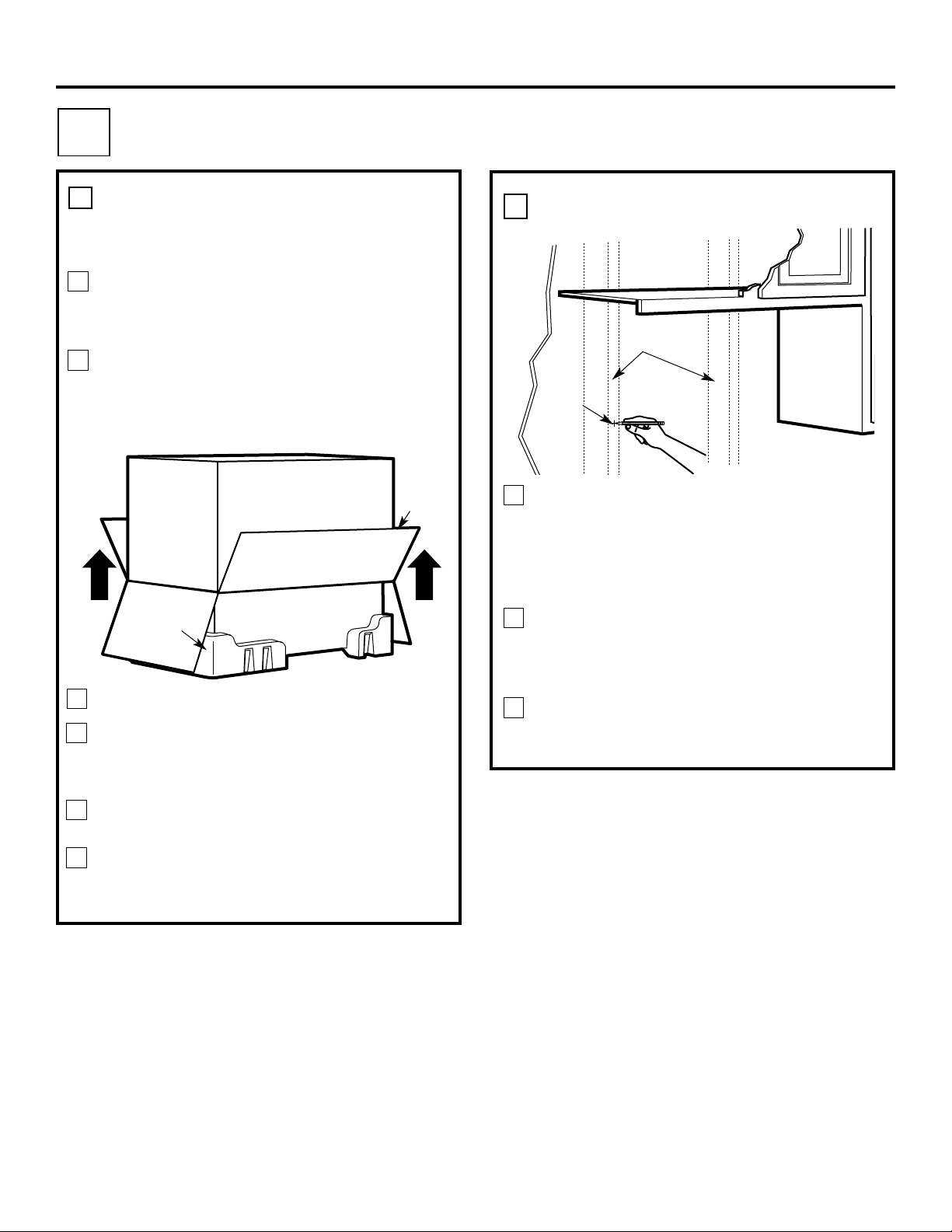

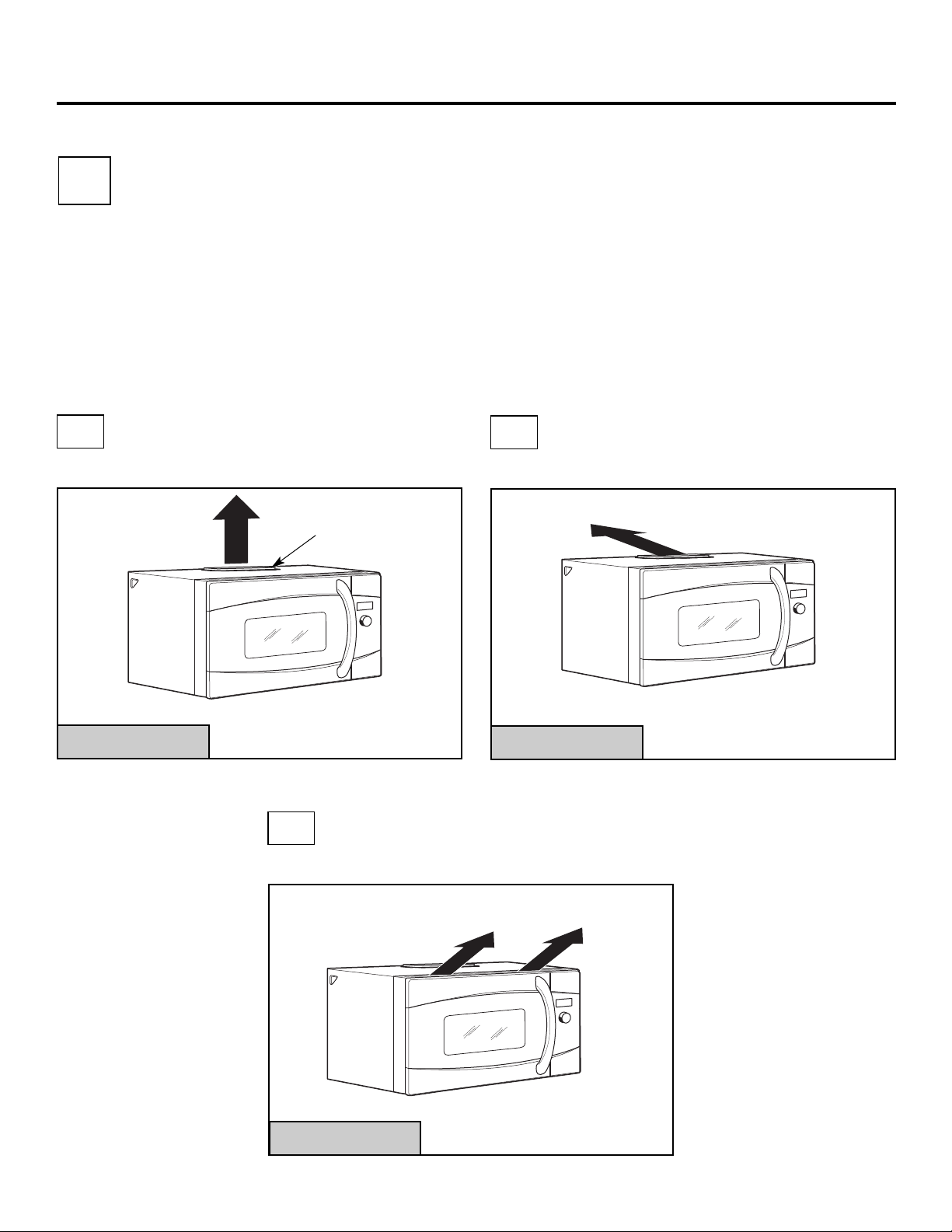

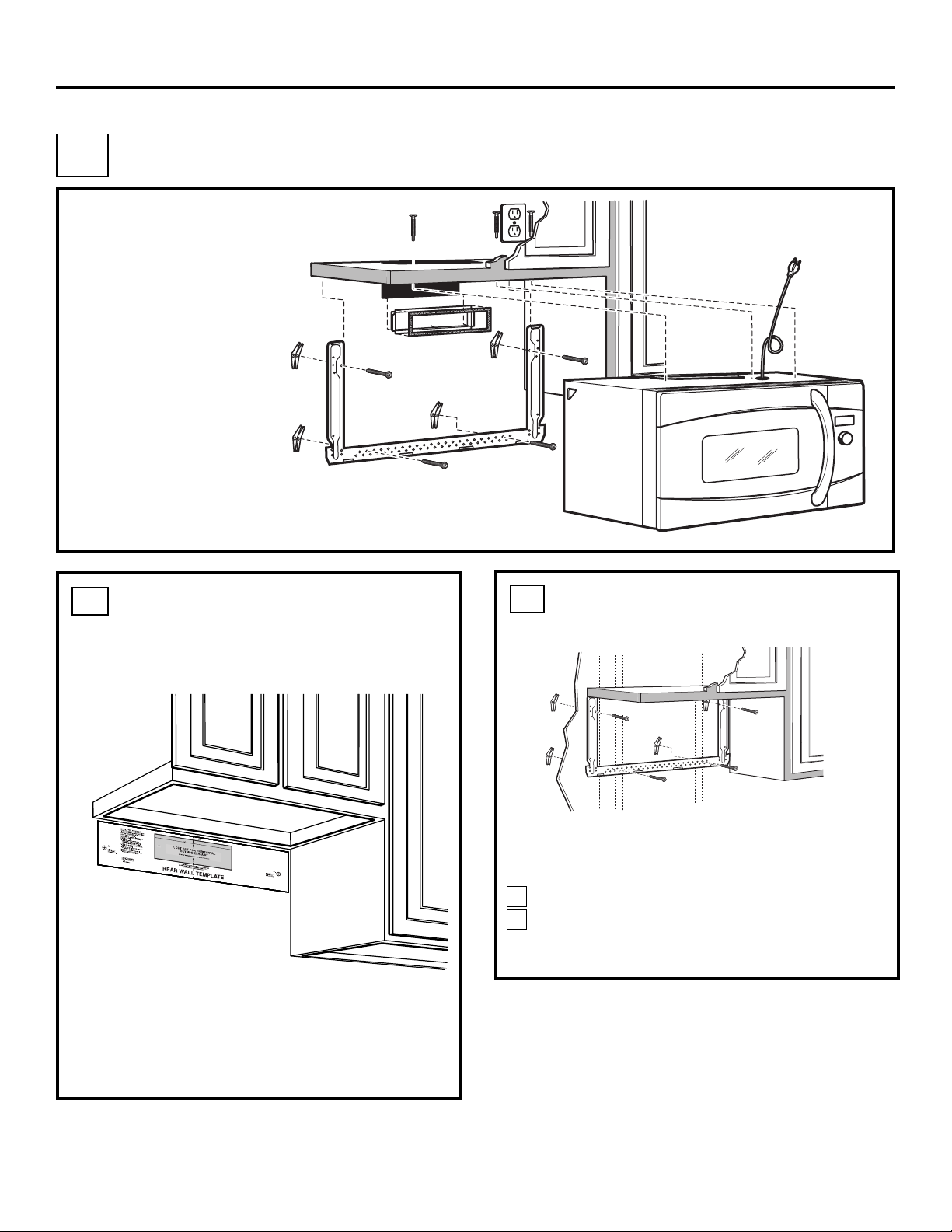

PLACEMENT OF THE MOUNTING PLATE

1

A

REMOVING THE OVEN FROM

THE CARTON/REMOVING

THE MOUNTING PLATE

1

Remove the box containing the installation

instructions, filters, exhaust adaptor, damper

and the small hardware bag. Do not remove

the Styrofoam protecting the front of the oven.

2

Fold back all 4 carton flaps fully against carton sides.

Then carefully roll the oven and carton over onto

the top side. The oven should be resting in the

Styrofoam.

Styrofoam

3

Pull the carton up and off the oven.

4

The mounting plate is attached to the back of the

oven. Remove the two screws holding it to the oven.

The plate will be used as the rear wall template and

for mounting the oven to the wall.

5

Set the oven upright. Remove and properly discard

plastic bags and Styrofoam.

Carton

FINDING THE WALL STUDS

B

1

Find the studs, using one of the following methods:

A. Stud finder – a magnetic device which locates nails.

B. Use a hammer to tap lightly across the mounting

After locating the stud(s), find the center by probing

2

the wall with a small nail to find the edges of the stud.

Then place a mark halfway between the edges.

The center of any adjacent studs should be 16″ or 24″

from this mark.

Draw a line down the center of the studs.

3

THE OVEN MUST BE CONNECTED TO AT LEAST ONE

WALL STUD.

Wall

Studs

Center

OR

surface to find a solid sound. This will indicate

a stud location.

Open the oven door and remove the styrofoam

6

pack from inside the oven. Remove the tape

covering the turntable hub.

8

Page 9

Installation Instructions

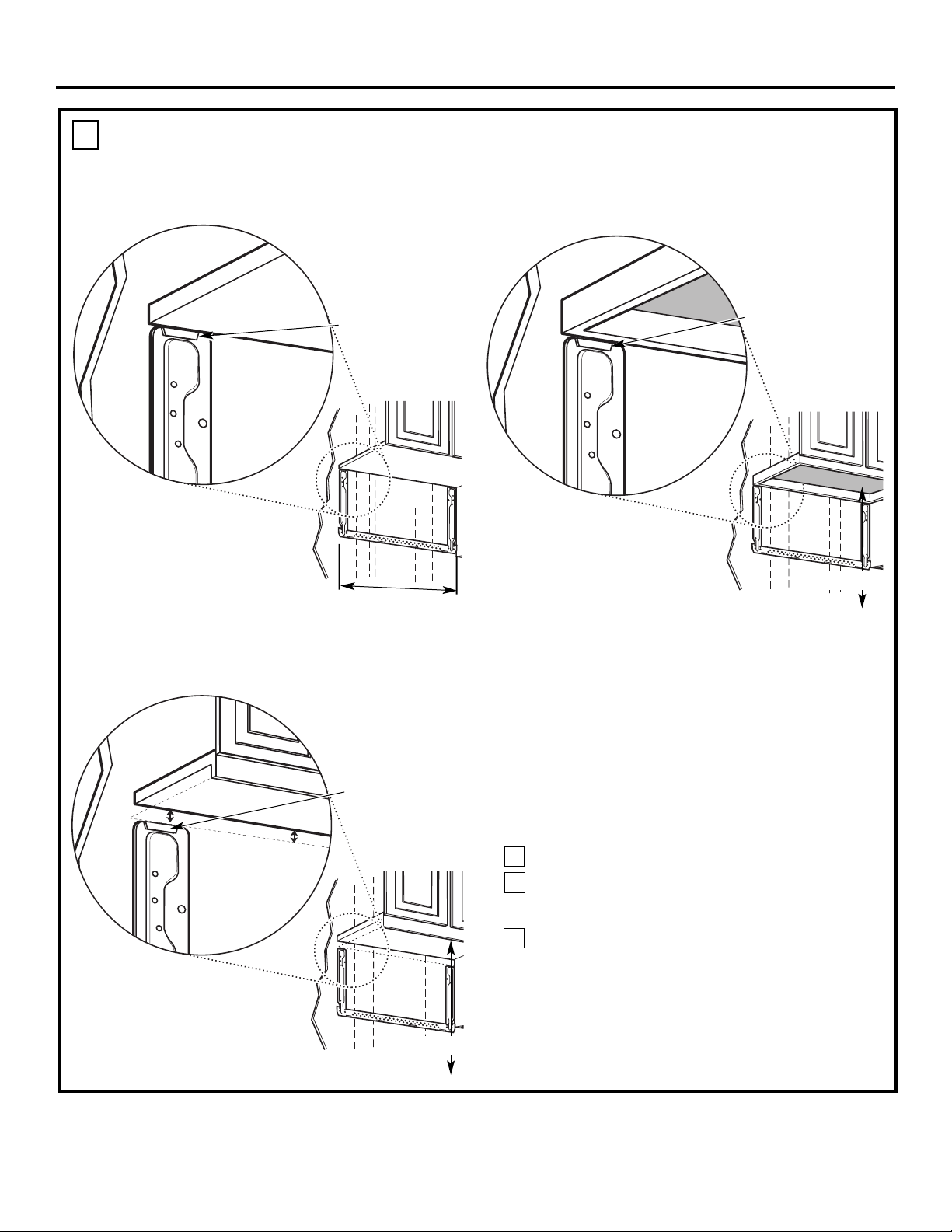

DETERMINING WALL PLATE LOCATION UNDER YOUR CABINET

C

Plate position – beneath flat bottom

cabinet

Mounting Plate Tabs

Touching the Cabinet Bottom

At

le

Plate position – beneath framed recessed

cabinet bottom

Mounting Plate Tabs

ouching the Back

T

Frame

30″ to Cooktop

a

s

t

3

0

″, u

p

t

o

3

6

″

Plate position – beneath recessed bottom

cabinet with front overhang

Mounting Plate with

Tabs Below Cabinet

Bottom the Same

Distance as the Front

Overhang Depth

30″ to Cooktop

Your cabinets may have decorative trim that interferes

with the oven installation. Remove the decorative trim

to install the oven properly and to make it level.

THE OVEN MUST BE LEVEL.

Use a level to make sure the cabinet bottom is level.

If the cabinets have a front overhang only, with no back

or side frame, install the mounting plate down the same

distance as the front overhang depth. This will keep

the oven level.

Measure the inside depth of the front overhang.

1

Draw a horizontal line on the back wall an equal

2

distance below the cabinet bottom as the inside depth

of the front overhang.

For this type of installation with front overhang only,

3

align the mounting tabs with this horizontal line, not

touching the cabinet bottom as described in Step D.

9

Page 10

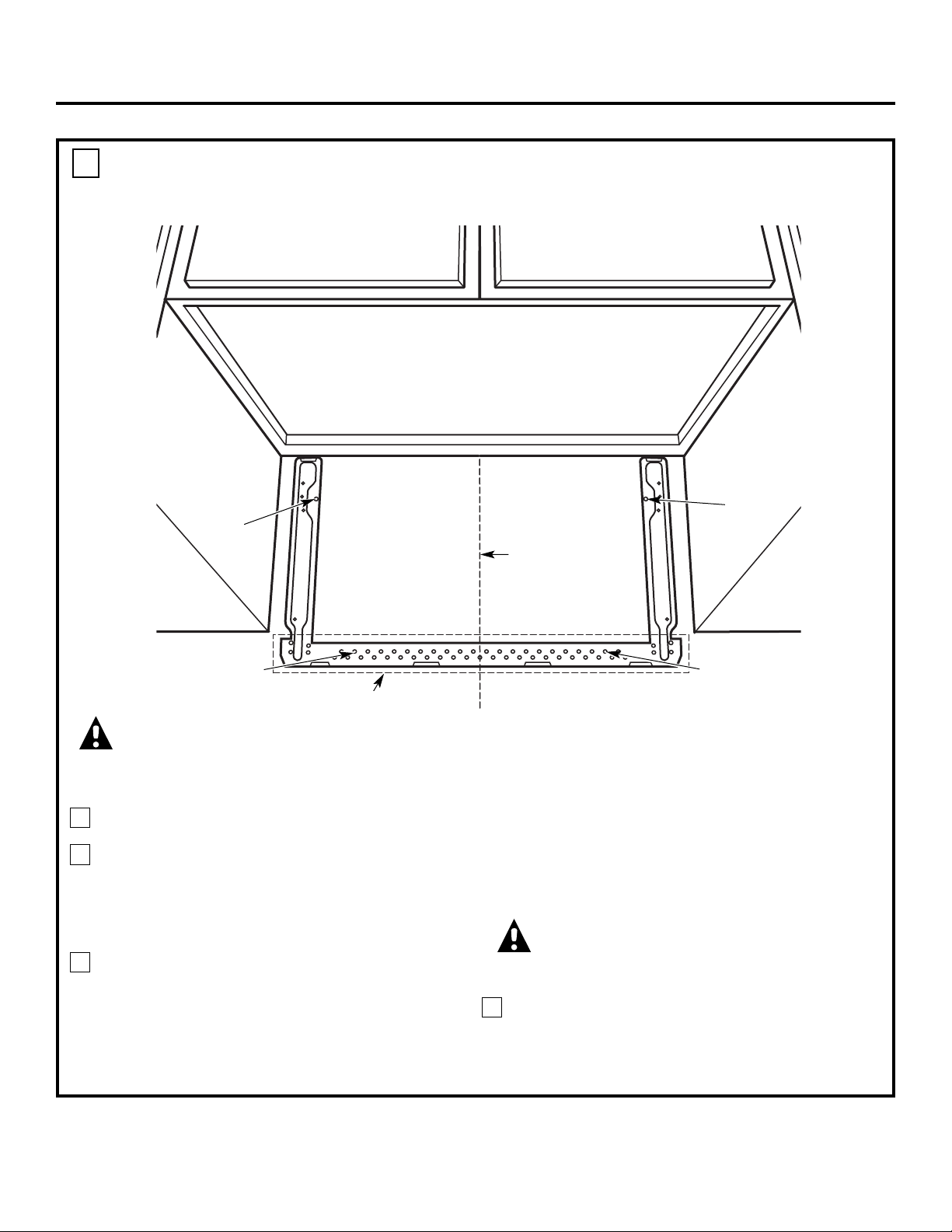

ALIGNING THE WALL PLATE

D

Hole A

Installation Instructions

Hole B

Draw a Vertical

Line on Wall

from Center of

Top Cabinet

Hole C

Area E

CAUTION:

Wear gloves to avoid cutting

fingers on sharp edges.

Draw a vertical line on the wall at the center of the 30″

1

wide space.

Use the mounting plate as the template for the rear wall.

2

Place the mounting plate on the wall, making sure that

the tabs are touching the bottom of the cabinet or

the level line drawn in Step C for cabinets with front

overhang. Line up the notch and center line on

the mounting plate to the center line on the wall.

While holding the mounting plate with one hand, draw

3

circles on the wall at holes A, B, C and D (see illustration

above/actual plate marked with arrows). Four holes

must be used for mounting.

Hole D

NOTE: Holes C and D are inside area E. If neither C nor D

is in a stud, find a stud somewhere in area E and draw a

fifth circle to line up with the stud. It is important to use

at least one wood screw mounted firmly in a stud

to support the weight of the oven.

Set the mounting plate aside.

WARNING:Risk of electric shock. Can

cause injury or death. Take care to not drill into electrical

wiring inside walls or cabinets.

Drill holes on the circles. If there is a stud, drill a3⁄16″ hole

4

for wood screws. For holes that don’t line up with a stud,

drill a5⁄8″ hole for toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

10

Page 11

Installation Instructions

INSTALLATION TYPES (Choose A, B or C)

2

This oven is designed for adaptation to the following

3 types of ventilation:

A. Outside Top Exhaust (Vertical Duct)

B. Outside Back Exhaust (Horizontal Duct)

C. Recirculating (Non-Vented Ductless)

A

OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

Adaptor in Place for

Outside Top Exhaust

NOTE: This oven is shipped assembled for Outside Top

Exhaust. Select the type of ventilation required for your

installation and proceed to that section.

B

OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

See page 12

RECIRCULATING

C

(NON-VENTED DUCTLESS)

See page 19

See page 15

A Charcoal Filter Accessory Kit

is required for the non-vented

exhaust. (See your Owner’s

Manual for the kit number.)

11

Page 12

Installation Instructions

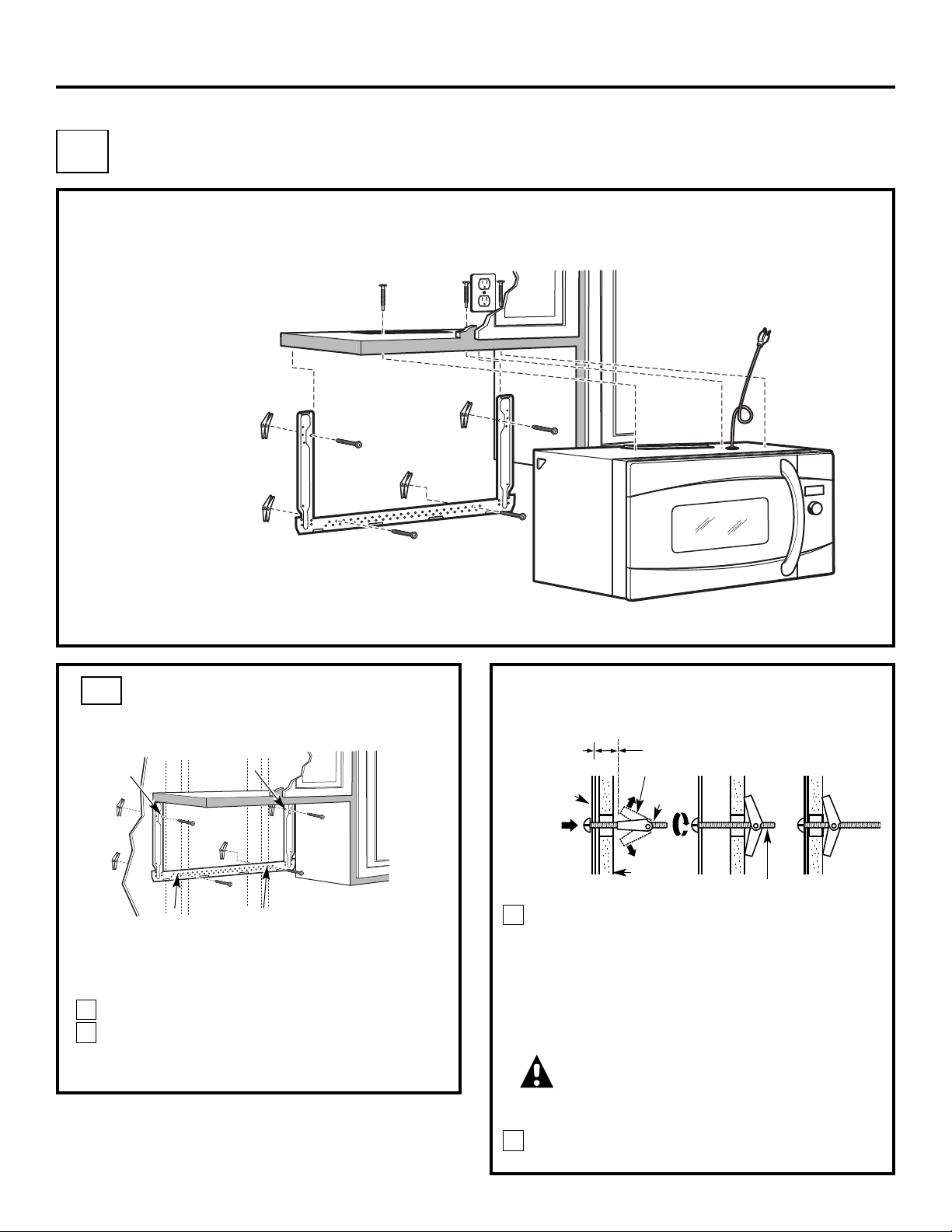

A

OUTSIDE TOP EXHAUST (Vertical Duct)

INSTALLATION OVERVIEW

A1. Attach Mounting Plate to Wall A2. Prepare Top Cabinet A3. Install Adaptor A4. Mount Oven A5. Adjust Exhaust Adaptor A6. Connect Ductwork

A1

ATTACH THE MOUNTING PLATE

TO THE WALL

A

C

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to

a wall stud. Recommended locations on the mounting

plate are indicated by A, B, C and D.

1

Remove the toggle wings from the bolts.

2

Insert the bolts into the mounting plate through

the holes designated to go into drywall and reattach

the toggle wings to3⁄4″ onto each bolt.

B

D

To use toggle bolts:

Spacing for Toggles

More Than Wall

Thickness

Mounting

Plate

Place the mounting plate against the wall and insert

3

the toggle wings into the holes in the wall to mount

the plate.

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch

the bottom of the cabinet when pushed flush against

the wall and that the plate is properly centered under

the cabinet.

Toggle Wings

Toggle

Bolt

Wall

Bolt End

CAUTION: Be careful to avoid

pinching fingers between the back of the mounting

plate and the wall.

4

Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

12

Page 13

Installation Instructions

USE TOP CABINET TEMPLATE FOR

A2

PREPARATION OF TOP CABINET

You need to drill holes for the top support screws,

a hole large enough for the power cord to fit through,

and a cutout large enough for the exhaust adaptor.

• Read the instructions on the TOP CABINET TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

CAUTION:Wear safety goggles when

drilling holes in the cabinet bottom.

ASSEMBLE AND INSTALL ADAPTOR

A3

Damper

A4

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY, WE

RECOMMEND THAT TWO PEOPLE INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the cabinet

front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting

the oven, thread power

cord through hole in bottom

of top cabinet. Keep it tight

throughout Steps 1–3.

Do not pinch cord or

lift oven by pulling cord.

1

Lift oven, tilt it

forward, and hook

slots at back bottom

edge onto two lower

tabs of mounting

plate.

Exhaust

Adaptor

Blower Plate

Back of

1

Place the oven in its upright position, with the top

of the unit facing up.

2

Insert the tabs on each side of the damper into

the holes at the inside rear of the adaptor.

3

Attach the exhaust adaptor to the blower plate with

the two bronze metal screws provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make adjustments to assure proper

alignment with your house exhaust duct after the

oven is installed.

Oven

13

Rotate front of oven up

2

against cabinet bottom.

Page 14

MOUNT THE OVEN (continued)

A4

Installation Instructions

ADJUST THE EXHAUST ADAPTOR

A5

3

ttach the oven to the top cabinet .

A

4

Insert 2 self-aligning screws

(1⁄4″-28 x 31⁄4″) through outer

top cabinet holes. Turn two full

turns on each screw.

Cabinet Front

Cabinet Bottom Shelf

5

Tighten center

screw completely.

Filler Block

Equivalent to

Depth of Cabinet

Recess

Open the top cabinet and adjust the exhaust adaptor

to connect to the house duct .

Damper

Back of

Oven

A6

CONNECTING DUCTWORK

House Duct

Self-Aligning Screw

Oven Top

6

Tighten the outer two screws to the top of the oven.

(While tightening screws, hold the oven in place

against the wall and the top cabinet .)

Install grease filters. See the Owner’s Manual

7

packed with the oven.

Extend the house duct down to connect to

1

the exhaust adaptor.

Seal exhaust duct joints using duct tape.

2

14

Page 15

Installation Instructions

OUTSIDE BACK EXHAUST (Horizontal Duct)

B

INSTALLATION OVERVIEW

B1. Prepare Rear Wall B2. Attach Mounting Plate to Wall B3. Prepare Top Cabinet B4. Adjust Blower B5. Mount the Oven

PREPARING THE REAR WALL

B1

FOR OUTSIDE BACK EXHAUST

You need to cut an opening in the rear wall for outside

exhaust.

• Read the instructions on the REAR WALL TEMPLATE.

• Tape it to the rear wall, lining up with the holes

previously drilled for holes A and B in the wall plate.

• Cut the opening, following the instructions of the

REAR WALL TEMPLATE.

ATTACH THE MOUNTING PLATE

B2

TO THE WALL

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to

a wall stud.

Remove the toggle wings from the bolts.

1

Insert the bolts into the mounting plate through

2

the holes designated to go into drywall and reattach

the toggle wings to3⁄4″ onto each bolt.

15

Page 16

Installation Instructions

To use toggle bolts:

pacing for Toggles More

S

Than Wall Thickness

Mounting

Plate

3

Place the mounting plate against the wall and insert

the toggle wings into the holes in the wall to mount

the plate.

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch

the bottom of the cabinet when pushed flush against

the wall and that the plate is properly centered under

the cabinet.

Toggle Wings

Toggle

Bolt

Wall

Bolt End

CAUTION:Be careful to avoid pinching

fingers between the back of the mounting plate and

the wall.

Tighten all bolts. Pull the plate away from the wall

4

to help tighten the bolts.

ADAPTING BLOWER FOR

B4

OUTSIDE BACK EXHAUST

Remove the three screws that hold the blower

1

plate to the oven. Slide blower plate from under

its retaining flange. Remove and save the screw

that holds blower motor to oven.

Retaining

lange

F

Blower Motor

Screw

Carefully pull out the blower unit. The wires

2

will extend far enough to allow you to adjust

the blower unit.

BEFORE: Fan Blade

Openings Facing Up

End A

Blower Plate

End B

USE TOP CABINET TEMPLATE

B3

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws and

a hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

Rotate blower unit counterclockwise 180°.

3

Before Rotation After Rotation

Back of

Oven

Gently remove the wires from the grooves.

4

Reroute the wires through grooves on other side

of the blower unit.

Before Rerouting After Rerouting

Wires Routed Through Right Side

Wires Routed Through Left Side

Back of

Oven

CAUTION:Wear safety goggles when

drilling holes in the cabinet bottom.

16

Page 17

Installation Instructions

Roll the blower unit 90° so that fan blade openings

5

re facing out the back of the oven.

a

Before Rolling

Back of

Oven

Locate the two “knockout” plates, on the rear oven

6

panel, near the top of the oven.

Using tin snips, carefully cut the web area from the

two holes side-by-side (that secure the knockouts to

the oven). Cut all four webs on both rear knockouts;

this will allow the ventilation fan airflow to exhaust

out the rear of the oven.

After Rolling

Back of

Oven

Replace the blower plate in the same position

8

s before with the screws.

a

Insert the tabs on each side of the damper

9

Blower Plate Screws

Blower Plate

Back of Oven

into the holes at the inside rear of the adaptor.

Exhaust

Adaptor

CAUTION:Be sure to trim the sharp

edges from the openings after removing the

knockout plates.

Oven Rear Panel

Snip all 4 webs

on each knockout

panel and remove

the metal knockouts

for rear airflow.

7

Place the blower unit back into the opening.

AFTER: Fan Blade

Openings Facing

Back

End B

End A

CAUTION:Do not pull or stretch

the blower unit wiring. Make sure the wires

are not pinched.

NOTE: The blower unit exhaust openings should

match exhaust openings on rear of oven.

Attach the exhaust adaptor to the rear of the oven

10

by sliding it into the guides at the top center of the

back of the oven.

Exhaust Adaptor

Slide exhaust

adaptor into

guides on

oven rear.

Locking

Tabs

Damper

(hinge side up)

Back of Oven

Guides

Push in securely until it is in the lower locking tabs.

Take care to assure the damper hinge is installed

so that it is at the top and that the damper swings

freely.

Secure the exhaust adaptor to the oven with

11

the two bronze metal screws provided.

Screws

17

Page 18

Installation Instructions

B5

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY, WE

RECOMMEND THAT TWO PEOPLE INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon grommet

around the power cord hole to prevent cutting of the

cord.

NOTE: We recommend using filler blocks if the cabinet

front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used,

case damage may occur from over

tightening screws.

NOTE: When mounting

the oven, thread power

cord through hole in

bottom of top cabinet.

Keep it tight throughout

Steps 1–3. Do not pinch

cord or lift oven by

pulling cord.

1

Lift oven, tilt it

forward, and hook

slots at back bottom

edge onto two lower

tabs of mounting plate.

Cabinet Front

abinet Bottom Shelf

C

Filler Block

Self-Aligning Screw

Oven Top

4

Attach the oven to the top cabinet .

Insert 2 self-aligning screws

5

(1⁄4″-28 x 31⁄4″) through outer

top cabinet holes. Turn two full

turns on each screw.

Tighten center

6

screw completely.

NOTE: Use self-aligning screw,1⁄4″-28 x 25⁄8″, on

PVM1790 and self-aligning screws,1⁄4″-28 x 31⁄4″,

on PSA1200 and PSA2200.

Equivalent

to Depth

of Cabinet

Recess

Rotate front of oven up

2

against cabinet bottom.

3

Insert a self-aligning screw through top center

cabinet hole. Temporarily secure the oven by

turning the screw at least two full turns after the

threads have engaged. (It will be completely tightened

later.) Be sure to keep power cord tight. Be careful

not to pinch the cord, especially when mounting

flush to bottom of cabinet.

18

7

Tighten the outer two screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

8

Install grease filters. See the Owner’s Manual

packed with the oven.

Page 19

Installation Instructions

RECIRCULATING (Non-Vented Ductless)

C

INSTALLATION OVERVIEW

C1. Attach Mounting Plate to Wall C2. Prepare Top Cabinet C3. Adjust Blower C4. Mount the Oven C5. Install Charcoal Filter (not supplied)

C1

ATTACH THE MOUNTING PLATE

TO THE WALL

Place the mounting plate against the wall and insert

3

the toggle wings into the holes in the wall to mount

the plate.

NOTE: Before tightening toggle bolts and wood screw,

make sure the tabs on the mounting plate touch the

bottom of the cabinet when pushed flush against the

wall and that the plate is properly centered under the

cabinet.

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to

a wall stud.

Remove the toggle wings from the bolts.

1

Insert the bolts into the mounting plate through

2

the holes designated to go into drywall and reattach

the toggle wings to3⁄4″ onto each bolt.

To use toggle bolts:

Spacing for Toggles

More Than Wall

Thickness

Mounting

Plate

Toggle Wings

Toggle

Bolt

Wall

Bolt End

CAUTION:Be careful to avoid pinching

fingers between the back of the mounting plate and

the wall.

Tighten all bolts. Pull the plate away from the wall

4

to help tighten the bolts.

C2

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP CABINET

You need to drill holes for the top support screws and

a hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the TOP

CABINET TEMPLATE.

CAUTION:Wear safety goggles when

drilling holes in the cabinet bottom.

19

Page 20

Installation Instructions

C3

ADAPTING BLOWER FOR RECIRCULATION

NOTE: The exhaust adaptor with damper is not

needed for recirculating models. You may want

to save them for possible future use.

Remove and save screws that hold blower plate

1

to the oven.

Blower Plate Screws

Carefully pull out the blower unit. The wires

3

ill extend far enough to allow you to adjust

w

the blower unit.

4

Roll the blower unit 90° so that fan blade openings

are facing toward the front of the oven.

Back of

Oven

Slide the blower plate from under its retaining

2

flange and lift it off. Remove and save screw that

holds the blower motor to oven.

Retaining

Flange

Blower Motor

Screw

Blower Plate

BEFORE: Fan Blade

Openings Facing Up

Roll

AFTER: Fan Blade

Openings Facing

Forward

20

NOTE: Make sure wires remain routed in the grooves

of the motor frame.

Page 21

Installation Instructions

ADAPTING BLOWER FOR

C3

RECIRCULATION

Place the blower unit back into the opening.

5

(continued)

CAUTION:Do not pull or stretch the

blower unit wiring. Make sure the wires are not

pinched.

Secure blower unit to oven with the screw removed

6

in Step 2. Insert the screw in bottom right screw

hole on the back of the oven.

Replace blower plate with the screws removed in

7

Step 1.

Blower Plate Screws

Back of Oven

Blower Motor

Screw

NOTE: When mounting the

oven, thread power cord

through hole in bottom of

op cabinet. Keep it tight

t

throughout Steps 1–3. Do

not pinch cord or lift oven

by pulling cord.

2

Rotate front of oven up

against cabinet bottom.

3

Insert a self-aligning screw through top center

cabinet hole. Temporarily secure the oven by

turning the screw at least two full turns after the

threads have engaged. (It will be completely tightened

later.) Be sure to keep power cord tight. Be careful

not to pinch the cord, especially when mounting

flush to bottom of cabinet.

1

Lift oven, tilt it forward,

and hook slots at back

bottom edge onto two

lower tabs of mounting

plate.

C4

MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL SAFETY, WE

RECOMMEND THAT TWO PEOPLE INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle during

installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used,

case damage may occur from overtightening

screws.

Cabinet Front

Cabinet Bottom Shelf

Self-Aligning Screw

Oven Top

Attach the oven to the top cabinet .

4

Filler Block

Equivalent to Depth

of Cabinet Recess

21

Page 22

C4

MOUNT THE OVEN

5

Insert 2 self-aligning screws

(1⁄4″-28 x 31⁄4″) through outer

top cabinet holes. Turn two full

turns on each screw.

Installation Instructions

C5

(continued)

6

Tighten center

screw completely.

INSTALLING THE CHARCOAL FILTER

1

Remove 2 screws on top of oven, just above

the grille panel, using a Phillips screwdriver.

2

Open the door.

3

Remove the grille.

Grille

Screws

NOTE: Use self-aligning screw,1⁄4″-28 x 25⁄8″, on

PVM1790 and self-aligning screws,1⁄4″-28 x 31⁄4″,

on PSA1200 and PSA2200.

7

Tighten the outer two screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

Install grease filters. See the Owner’s Manual

8

packed with the oven.

4

Insert the filter into the oven as shown until it fits

squarely into place. It will rest at an angle behind

the front lower tabs. When properly installed,

the wire mesh of the filter should be visible

from the front.

Front lower tabs

Charcoal filter

Charcoal filter installed

5

Replace the grille and the 2 top screws.

22

6

Close the door and replace left side screw.

Page 23

Installation Instructions

BEFORE YOU USE YOUR OVEN

Make sure the oven has been installed

1

according to instructions.

Remove all packing material from the oven.

2

Install turntable and wheeled ring in cavity.

3

(continued)

5

240 V Models: The wall outlet receptacle

recommended for this appliance is NEMA

#14–30R and accepts the four-prong grounded

plug of this appliance.

NEMA 14–30R

Wall Receptacle

Ensure proper

ground exists

before use.

Read the Owner’s Manual.

6

Replace house fuse or turn breaker back on.

4

120 V and 1790 Models: Plug power cord into

5

a dedicated 15- to 20-amp electrical outlet .

Ensure proper

ground exists

before use.

Where a standard two-prong wall receptacle

is encountered, it is very important to have it

replaced with a properly grounded three-prong

wall receptacle, installed by a qualified

electrician.

23

KEEP INSTALLATION INSTRUCTIONS

7

FOR THE LOCAL INSPECTOR’S USE.

Page 24

49-40611

(06-09 JR)

Printed in Korea

24

Page 25

Instrucciones

Horno para colocar

de instalación

encima de la estufa

PVM1790, PSA1200 y PSA2200

¿Preguntas? Llame 800.GE.CARES (800.432.2737) o visite nuestra página en la reden: GEAppliances.com

ANTES DE EMPEZAR

Lea estas instrucciones completa y cuidadosamente.

•

IMPORTANTE

instrucciones para el uso del inspector local.

•

IMPORTANTE

códigos y ordenanzas gubernamentales.

• Nota para el instalador

estas instrucciones con el consumidor.

Guarde estas

–

Cumpla con todos los

–

Asegúrese de dejar

–

• Nota para el consumidor

instrucciones para futura referencia.

• Nivel de destrezas – La instalación de este aparato

requiere de destrezas básicas de mecánica y electricidad.

• La instalación apropiada es responsabilidad

del instalador.

• La falla del producto debido a una instalación

inapropiada no está cubierta por la garantía.

Guarde estas

–

25

LEA CUIDADOSAMENTE.

GUARDE ESTAS INSTRUCCIONES.

Page 26

Instrucciones de instalación

CONTENIDO

Información general

Instrucciones de seguridad importantes .................. 27

Requisitos eléctricos...................................................... 27

Campana de escape ................................................ 28, 29

Daños – Envío / Instalación .......................................... 30

Partes incluidas .............................................................. 30

Herramientas que necesitará ...................................... 31

Espacio de montaje........................................................ 31

Guía de instalación paso por paso

Cómo colocar el plato de montaje........................ 32–34

Cómo remover el plato de montaje.................. 32

ecirculación ................................................ 43–46

R

C

Cómo adherir la placa de

ontaje a la pared....................................43

m

Preparación del gabinete superior ..........43

Cómo adaptar el calefactor

para la recirculación ..........................44, 45

Cómo montar el horno............................45, 46

Cómo instalar el filtro de carbonilla ........46

Antes de comenzar a usar su horno ........................ 47

Cómo encontrar madera sólida

en la pared .......................................................... 32

Cómo determinar la localización

de las placas de la pared .................................. 33

Cómo alinear la placa de la pared .................. 34

Tipos de instalación ................................................ 35–46

Escape superior exterior.............................. 36–38

A

Cómo adherir la placa de

montaje a la pared ....................................36

Preparación del gabinete superior ..........37

Ensamblaje e instalación

del adaptador ............................................37

Cómo montar el horno........................37, 38

Cómo ajustar el adaptador de escape....38

Cómo conectar el conducto ....................38

Escape posterior externo ............................ 39–42

B

Cómo preparar la pared posterior

para el escape posterior exterior ............39

Cómo adherir el plato de

montaje a la pared ..............................39, 40

Preparación del gabinete superior ..........40

Cómo adaptar el calefactor para

el escape posterior exterior ................40, 41

Cómo montar el horno ..............................42

26

Page 27

Instrucciones de instalación

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Ver Requisitos Eléctricos para los requisitos de instalación de

tomacorriente apropiados. El instalador debe llevar a cabo una

inspección de continuidad a tierra en la caja eléctrica antes de

comenzar la instalación para asegurar que la caja tomacorriente

está conectada a tierra de manera apropiada. Si no lo está, o si el

tomacorriente no cumple con los requisitos eléctricos indicados

(bajo la sección REQUISITOS ELÉCTRICOS), se deberá recurrir a un

técnico calificado paracorregir cualquier deficiencia.

PRECAUCIÓN:

Para seguridad personal, remueva

el fusible de la casa o abra el

interruptor de circuito antes de

comenzar la instalación para evitar

descargas eléctricas severas o

fatales.

PRECAUCIÓN:En pos de la seguridad

personal, la superficie de montaje debe ser capaz de soportar

la carga del gabinete, además del peso adicional (de 63 a 85

libras) de este producto, más las cargas adicionales del horno

de hasta 50 libras o un peso total entre 113 y 135libras.

PRECAUCIÓN:En pos de la seguridad

personal, este producto no puede serinstalado en sistemas de

gabinetes tales como los llamados “islas” o “penínsulas”. Éste

debe ser montado tanto a un gabinete superior como a una

pared.

NOTA:Para unainstalación más fácily en pos delaseguridad

personal,serecomienda que dos personasinstalen este producto.

IMPORTANTE:POR FAVOR,LEACUIDADOSAMENTE. EN POSDE

LASEGURIDADPERSONAL, ESTE APARATODEBE SERCONECTADO

A TIERRA APROPIADAMENTE PARAEVITARDESCARGAS SEVERAS

O FATALES.

Deberá hacer que un técnico calificado inspeccione el

tomacorriente de pared y el circuito para asegurarse de que el

tomacorriente esté conectado a tierra de manera apropiada.

AJO NINGUNA CIRCUNSTANCIA NO CORTE, DEFORME,

B

O REMUEVA NINGUNA DE LAS PATAS DELCABLE ELÉCTRICO.

NO LO USE CON UNA EXTENSIÓN ELÉCTRICA.

Modelos de 120 V

El cable eléctrico de este aparato está equipado con un enchufe

de tres patas (con conexión

a tierra), lo cual requiere que

el mismo encaje con un

tomacorriente para tres

patas (con conexión a tierra)

de pared para minimizar

la posibilidad de descargas

eléctricas.

Asegúrese de

que existe una

conexión a tierra

apropiada antes

del uso.

a tierra, instalado por un electricista calificado.

Donde usted encuentre

un tomacorriente estándar de

dos patas, es muy importante

que haga que el mismo se

cambie por uno de tres patas

apropiadamente conectado

Modelos de 240 V

El tomacorriente de pared recomendado para este aparato es

Tomacorriente de

pared NEMA 14–30R

Asegúrese de que

existe una conexión a tierra

apropiada antes del uso.

NEMA #14– 30R y puede usarse

con el enchufe de 4 clavijas

con conexión a tierra de

este aparato.

REQUISITOS ELÉCTRICOS

Modelos de 120 V

Este producto requiere un tomacorriente eléctrico de tres

patas conectado a tierra. La clasificación del producto es

de 120 voltios CA (AC), 60 hercios,15 amperios y 1.70

kilovatios. Este producto debe estar conectado a un circuito

de suministro del voltaje y frecuencia apropiados. El tamaño

del alambre debe conformarse a los requisitos del National

Electric Code o al código local en efecto para este índice de

kilovatios. El cable eléctrico de alimentación y el interruptor

deberán llevarse a un tomacorriente único conectado a

tierra de 15 a 20 amperios. La caja del tomacorriente deberá

estar localizada en el gabinete encima del horno. La caja

del tomacorriente debe ser instalada por un electricista

calificado y debe conformarse al National Electrical Code

o al código local en efecto.

Modelos de 240 V

Este producto requiere un tomacorriente eléctrico

de cuatro patas conectado a tierra. La clasificación del

producto es de 120/208 o 120/240 voltios, 60 hercios,

30 amperios y 6.5 kilovatios. Este producto debe conectarse

a un circuito derivado individual conadecuada conexión a

tierra, protegido por interruptores de circuito y fusibles con

retraso. El tamaño del cable debe cumplir con los requisitos

del Código Eléctrico Nacional o con el código local vigente

para esta clasificación de kilovatios. La caja de distribución

debe estar ubicada en el gabinete sobre el horno. Un

electricista calificado debe instalar la cajade distribución

y el circuito de suministro y éstos deben cumplir con el

Código Eléctrico Nacionalo con el código local vigente.

27

Page 28

Instrucciones de instalación

CAMPANA DE ESCAPE

OTA: Lea las siguientes dos páginas solamente si planea ventilar el escape hacia el exterior.

N

Si por el contrario planea recircular el aire de vuelta hacia el salón, continúe en la página 30.

ESCAPE SUPERIOR EXTERNO (EJEMPLO SOLAMENTE)

La siguiente tabla describe un ejemplo de una posible

instalación de red de conductos.

LONGITUD NÚMERO LONGITUD

PARTES DEL CONDUCTO EQUIVALENTE x USADO = EQUIVALENTE

Tapa del techo 24 pies x (1) = 24 pies

Conducto recto de 12 pies 12 pies x (1) = 12 pies

(redondo de 6″)

Adaptador de transición 5 pies x (1) = 5 pies

de rectángulo a redondo*

La longitud de las partes de los conductos equivalentes está basada en pruebas reales y reflejan

los requisitos para lograr una buena ventilación con cualquier campana de escape.

*IMPORTANTE: Si se usa un adaptador de transición de rectángulo a redondo, las esquinas del fondo

del regulador de tiros deberán cortarse para que encajen, usando las tijeras de corte, para permitir

el movimiento libre del regulador de tiros.

ESCAPE POSTERIOR EXTERNO (EJEMPLO SOLAMENTE)

La siguiente tabla describe un ejemplo de una posible

instalación de red de conductos.

LONGITUD NÚMERO LONGITUD

PARTES DEL CONDUCTO EQUIVALENTE x USADO = EQUIVALENTE

Tapa de pared 40 pies x (1) = 40 pies

Conducto recto de 3 pies 3 pies x (1) = 3 pies

(rectangular de 31⁄4″ x 10″)

Longitud total = 41 pies

Codo de 90° 10 pies x (2) = 20 pies

La longitud de las partes de los conductos equivalentes está basada en pruebas reales y reflejan los

requisitos para lograr una buena ventilación con cualquier campana de escape.

NOTA: Para el escape posterior, se debetenercuidado al alinear el escape entre los espacios de los postes de viga de la pared, o la pared debería ser

preparada en el momento de su construcción dejando suficiente espacio entre los postes de viga de la pared para acomodar el escape.

Longitud total = 63 pies

28

Page 29

Instrucciones de instalación

NOTA: Si usted necesita instalar conductos, tenga pendiente

que la longitud total del conducto rectangular de 31⁄4″ x 10″

o el conducto redondo de 6″ de diámetro no debe sobrepasar

40 pies equivalentes.

1

La ventilación externa requiere un CONDUCTO DE CAMPANA

DE ESCAPE. Lea lo siguiente cuidadosamente.

NOTA: Es importante que la ventilación sea instalada usando

la ruta más directay con la menor cantidad de codos posible.

Esto asegura la ventilación del escape y ayuda a prevenir

bloqueos. También,cerciórese de que el regulador de tiro

pende librementey nada bloquea los conductos.

Conexiones de escape:

La campana de escape ha sido diseñada para encajar con

un conducto rectangular de 31⁄4″ x 10″ estándar.

Si un conducto redondo es necesario, se debe usar

un adaptador de transición de rectangular a redondo.

No use un conducto menor de 6″ de diámetro.

LONGITUD NÚMERO LONGITUD

PARTES DE CONDUCTO EQUIVALENTE x USADO = EQUIVALENTE

Adaptador de transición de 5 pies x ( ) = pies

rectángulo a redondo*

Longitud máxima del conducto:

Para lograr un movimiento satisfactorio del aire, la

longitud total del conducto rectangular de 31⁄4″ x 10″

o el conducto redondo de 6″ de diámetro no debe

obrepasar 140 pies equivalentes.

s

Los codos, transiciones, paredes y tapas

de techo, etc.,

de aire y son equivalentes a una sección de conducto

recto el cual es más largo que su tamaño físico real.

Cuando calcule la longitud total del conducto, agregue

las longitudes equivalentes de todas las transiciones

y adaptadores, más la longitud de todas las secciones

de conducto rectas. La tabla más adelante muestra cómo

puede calcular la longitud aproximada de la red de

conductos usando pies aproximados de longitudes

equivalentes de algunos conductos típicos.

presentan resistencia adicional al flujo

Tapa de pared 40 pies x ( ) = pies

Codo de 90° 10 pies x ( ) = pies

Codo de 45° 5 pies x ( ) = pies

Codo de 90° 25 pies x ( ) = pies

Codo de 45° 5 pies x ( ) = pies

Tapa de techo 24 pies x ( ) = pies

Conducto recto de 6″ redondo 1 pies x ( ) = pies

o rectangular de 31⁄4″ x 10″

* IMPORTANTE: Si se usa un adaptador de transición de

rectángulo a redondo, las esquinas del fondo del regulador

de tiros deberán ser cortadas para que encajen, usando

las tijeras de corte, para permitir el movimiento libre del

regulador de tiros.

29

Total red de conductos = pies

La longitud de las partes de conductos equivalentes está basada

en pruebas reales y reflejan los requisitos para lograr una buena

ventilación con cualquier campana de escape.

Page 30

Instrucciones de instalación

12″

4″

R

EAR WALLTEMPLATE

1

/4″TOEDGE

F. CUT OUT FOR HORIZONTAL

O

UTSIDE EXHAUST

DAÑOS – ENVÍO / INSTALACIÓN

• Si la unidad se daña durante el envío, devuelva

la unidad al almacén donde la adquirió para

su reparación o reemplazo.

• Si el cliente daña la unidad, la reparación

o el reemplazo es responsabilidad del cliente.

• Si el instalador daña la unidad (si no es el cliente),

la reparación o reemplazo se debe hacer por medio

de un arreglo entre el cliente y el instalador.

PARTES INCLUIDAS

PAQUETE DE ELEMENTOS

PARTE CANTIDAD

Tornillos de madera 2

(1⁄4″ x 2″)

Tornillos basculantes 4

(y tuercas de mariposa)

(1⁄4″ x 3″)

Tornillos de máquina 3

autoalineables

(1⁄4″-28 x 31⁄4″)

2 (JVM1790 Sólo)

PARTES INCLUIDAS

PARTES ADICIONALES

PART

Plantilla para 1

el gabinete

superior

Plantilla para 1

la pared

posterior

Instrucciones 1

de instalación

Filtros de 2

grasa

empacados

por separado

CANTIDAD

Tornillos de máquina

1 (JVM1790 Sólo)

autoalineables

(1⁄4″-28 x 25⁄8″)

Arandela aislante de 2

nilón (para gabinetes

metálicos)

Adaptador del escape 1

Regulador de tiro 1

Tornillos para metal 1 negro

(1⁄8″ x1⁄2″) 2 de bronce

Usted encontrará los elementos de instalación en

un paquete junto con la unidad. Inspeccione para

cerciorarse de que tiene todas las partes.

NOTA: Se incluyen algunas partes adicionales.

30

Page 31

Instrucciones de instalación

HERRAMIENTAS QUE NECESITARÁ

Regla recta y cinta métrica

Destornilladores de estrella

# 1 y # 2

Tijeras para cortar latón

(para cortar el regulador

de tiro, si es necesario)

Guantes

Tijeras (para cortar la

plantilla, si es necesario)

Sierra (de sable, agujero, o de

ojo de cerradura)

Lápiz

Taladro eléctrico con brocas

3

de

⁄16″,7⁄16″,1⁄2″ y5⁄8″

Detector de

postes de viga o

Escuadra de

carpintero

(opcional)

Bloques de relleno o

pedazos de madera, si son

necesarios para rellenar el

gabinete (usados solamente

en la instalación de

gabinetes apoyados)

un martillo (opcional)

Gafas de seguridad

ESPACIO DE MONTAJE

13″ max.

66″ o más

desde el

piso hasta

la parte

superior

del horno

16-

1

⁄4″

30″

2″

30″

min.

Protector posterior

de salpicaduras

El extremo del

fondo del gabinete

necesita estar a

30″ o más a partir

de la superficie de

la estufa

Nivel

Cinta de conductos o

cinta adhesiva protectora

NOTAS:

• El espacio entre los gabinetes debe ser de 30″

de ancho y debe estar libre de obstrucciones.

• Si el espacio entre los gabinetes es mayor de

30″, un “Filler Panel Kit” podría ser necesario para

rellenar las brechas entre el horno y los gabinetes.

Su Manual del Propietario contiene

el número de kit para su modelo.

• Este horno es para ser instalado por encima

de estufas hasta 36″ de ancho.

• Si usted se dispone a ventilar su horno hacia el

exterior, ver la Sección de Campana de Escape

para la preparación del conducto de escape.

• Cuando se instale el horno debajo de gabinetes

de fondos lisos y planos, tenga cuidado de

seguir cuidadosamente las instrucciones en

la plantilla del gabinete superior para el espacio

de tolerancia del cable eléctrico.

• La profundidad de la abertura no puede ser

superior a 13″.

• El producto no debe instalarse sobre ninguna

estufa o cocina con una combinación superior

a 60000 BTU.

31

Page 32

Instrucciones de instalación

CÓMO COLOCAR EL PLATO DE MONTAJE

1

A

CÓMO REMOVER EL HORNO

DEL EMBALAJE / CÓMO REMOVER

EL PLATO DE MONTAJE

1

Remueva la caja que contiene las instrucciones

de instalación, los filtros, el adaptador de escape,

el regulador de tiro y la pequeña bolsa con los

elementos de instalación. No remueva la espuma

de poliestireno que protege el frente del horno.

2

Pliegue hacia atrás las alas de la caja. Luego,

cuidadosamente ruede el horno hasta que quede

apoyado sobre la parte superior. El horno deberá

descansar sobre la espuma de poliestireno.

B

CÓMO ENCONTRAR LOS POSTES

DE VIGA EN LA PARED

Centro

Postes de viga

en la pared

Poliestireno

3

Tire de la caja hacia arriba y retírela del horno.

4

El plato de montaje está pegado a la parte posterior

del horno. Remueva los dos tornillos que lo sostienen

pegado al horno. El plato será usado como la plantilla

de la pared posterior y para montar el horno a la

pared.

5

Pare el horno. Remueva y descarte de manera

apropiada las bolsas plásticas y el poliestireno.

Abra la puerta del horno y remueva el paquete de

6

espuma de poliestireno del interior. Remueva la

cinta adhesiva que cubre el aro giratorio.

Caja

1

Encuentre los postes, usando uno de los

métodos siguientes:

A. Use un detector de postes – un dispositivo

magnético que localiza clavos.

O

B. Use un martillo para golpear ligeramente a través

de la superficie de montaje hasta encontrar un

sonido sólido. Esto indicará que hay un poste de

viga en ese lugar.

Después de localizar el poste o los postes de viga,

2

encuentre el centro mediante el análisis de la pared

usando un clavo pequeño para darse cuenta de

dónde están los bordes del poste. Luego coloque

una marca en el centro de los bordes. El centro de

cualquier poste adyacente deberá ser entre 16″ ó

24″ desde esta marca.

Trace una línea hacia abajo indicando el centro

3

del poste.

EL HORNO DEBE CONECTARSE POR LO MENOS

A UN POSTE DE LA PARED.

32

Page 33

Instrucciones de instalación

CÓMO DETERMINAR LA LOCALIZACIÓN DEL PLATO DE MONTAJE DEBAJO

C

DE SU GABINETE

Posición del plato – debajo de gabinetes

de fondo plano

Las orejillas del plato de

montaje tocan el fondo

del gabinete

P

o

r

lo

m

e

n

o

s

3

0

Posición del plato – debajo de gabinetes

de fondo apoyado en un marco

as orejillas del plato

L

de montaje tocan

el marco posterior

30″ hasta la estufa

″

, h

a

s

ta

3

6

″

Posición del plato – debajo de gabinetes

de fondo apoyado con frente saliente

Plato de montaje con

orejillas por debajo

del fondo del gabinete

a la misma distancia

que la profundidad

del saliente

30″ hasta la estufa

Sus gabinetes podrían tener marcos de decoración

que interfieran con la instalación del horno. Remueva

los marcos decorativos para instalar el horno

apropiadamente y para hacer que quede nivelado.

EL HORNO DEBE QUEDAR NIVELADO.

Use un nivel para cerciorarse de que el fondo

del gabinete está nivelado.

Si los gabinetes tienen un saliente frontal solamente,

sin marco posterior o lateral, instale el plato de montaje

a la misma distancia de la profundidad del saliente.

Este mantendrá el horno nivelado.

1

Mida la profundidad interna del frente del saliente.

Trace una línea horizontal en la pared posterior

2

a una distancia debajo del fondo del gabinete igual

a la profundidad interna del frente saliente.

Para este tipo de instalación con saliente frontal

3

solamente, alinee las orejillas de montaje con la línea

horizontal, sin tocar el fondo del gabinete como

se describió en el Paso D.

33

Page 34

Instrucciones de instalación

CÓMO ALINEAR EL PLATO DE MONTAJE SOBRE LA PARED

D

Agujero A

Agujero C

Area E

PRECAUCIÓN:

Use guantes de protección

para evitar cortaduras en sus

dedos con los extremos filosos.

Trace una línea vertical en la pared en el centro

1

del espacio de 30″ de ancho.

Use el plato de montaje como la plantilla para la pared

2

posterior. Coloque el plato de montaje en la pared,

cerciorándose de que las orejillas se encuentran tocando

el fondo del gabinete o la línea marcada en el Paso C

para los gabinetes con salientes frontales. Alinee

la muesca y línea del centro en el plato de montaje

con la línea de centro en la pared.

Mientras sostiene el plato de montaje con una mano,

3

trace círculos en la pared en los agujeros A, B, C y D

(ver la ilustración anterior / la placa real está marcada

con flechas). Deben usarse cuatro agujeros para

el montaje.

Trace una línea vertical

en la pared a partir

del centro del gabinete

superior

NOTA: Los agujeros C y D van en el interior del área E.

Si ni el C ni el D están en un poste de viga, encuentre

un poste en algún otro lugar en el área E y marque

un quinto círculo para alinearse con el poste.

Es importante usar por lo menos un tornillo de madera

montado firmemente en un poste para apoyar el peso

del horno.

Agujero B

Agujero D

Aparte el plato de montaje.

ADVERTENCIA:Riesgo de descarga

eléctrica. Puede provocar lesiones o la muerte. Tenga

cuidado de no perforar el cableado eléctrico ubicado

dentro de las paredes o gabinetes.

4

Perfore agujeros en los círculos. Si hay un poste de

viga, perfore un agujero de 3/16″ para los tornillos de

madera. Para los agujeros que no quedaron alineados

con el poste de viga, perfore un agujero de 5/8″ para

los tornillos basculantes.

NOTA: TODAVÍA NO MONTE EL PLATO.

34

Page 35

Instrucciones de instalación

TIPOS DE INSTALACIÓN (Escoja A, B o C)

2

ste horno está diseñado para adaptarse a los siguientes

E

tres tipos de ventilación:

A. Escape superior exterior (Conducto vertical)

B. Escape posterior exterior (Conducto horizontal)

C. Recirculación (Sin conducto de ventilación)

ESCAPE SUPERIOR EXTERIOR

A

(CONDUCTO VERTICAL)

El adaptador está

en su lugar para

el escape superior

exterior

OTA: Este horno es enviado ya ensamblado para un escape

N

superior exterior. Seleccione el tipo de ventilación requerido

para su instalación y proceda a tal sección.

B

ESCAPE POSTERIOR EXTERIOR

(CONDUCTO HORIZONTAL)

Ver página 36

C

RECIRCULACIÓN

(SIN CONDUCTO DE VENTILACIÓN)

Ver página 43

Ver página 39

Un Kit de accesorios de filtro

de carbonilla es necesario para

el sistema sin ventilación.

(Consulte su Manual del

Propietario para obtener

el número del kit.)

35

Page 36

Instrucciones de instalación

ESCAPE SUPERIOR EXTERIOR (Conducto vertical)

A

PERSPECTIVA GENERAL

DE LA INSTALACIÓN

A1. Como adherir el plato de montaje

a la pared

A2. Prepare el gabinete superior

A3. Instale el adaptador

A4. Monte el horno

A5. Ajuste el adaptador

de escape

A6. Conecte el conducto

CÓMO ADHERIR LA PLACA

A1

DE MONTAJE A LA PARED

A

C

Pegue el plato a la pared usando los tornillos

basculantes. Por lo menos un tornillo de madera debe

ser usado para pegar el plato al poste de la pared. Las

ubicaciones recomendadas sobre la placa de montaje

se indican en A, B, C y D.

1

Remueva las mariposas del basculante de los

tornillos.

2

Inserte los tornillos en el plato de montaje a través

de los agujeros diseñados para ser insertados en

la pared de mampostería seca y pegue otra vez

las mariposas de3⁄4″ en cada tornillo.

B

D

36

Para usar los tornillos basculantes:

Espaciadores para los

basculantes mayores

que el ancho de la pared

Plato de

montaje

Coloque el plato de montaje contra la pared e inserte

3

las alas de mariposa en los agujeros de la pared

para montar el plato.

NOTA: Antes de apretar los tornillos basculantes

y los tornillos de madera, cerciórese de que las orejillas

en el plato de montaje toquen el fondo del gabinete

cuando son empujadas contra la pared y de que el plato

esté centrado apropiadamente debajo del gabinete.

PRECAUCIÓN:

pellizcar sus dedos entre la parte posterior del plato

de montaje y la pared.

Apriete todos los tornillos. Tire del plato

4

en dirección opuesta a la pared para ayudar

a apretar los tornillos.

Alas de mariposa

Tornillo de

mariposa

Pared

Extremo del tornillo

Tenga cuidado de evitar

Page 37

Instrucciones de instalación

USE LA PLANTILLA DEL GABINETE

A2

SUPERIOR PARA LA PREPARACIÓN

DEL GABINETE SUPERIOR

Deberá perforar agujeros para los tornillos de apoyo

superiores, un agujero suficientemente grande para que

el cable eléctrico quepa, y un recorte lo suficientemente

grande como para que el adaptador de escape pueda

ser introducido.

• Lea las instrucciones sobre la PLANTILLA

DEL GABINETE SUPERIOR.

• Péguelo debajo del gabinete superior.

• Taladre los agujeros, siguiendo las instrucciones

en la PLANTILLA DEL GABINETE SUPERIOR.

PRECAUCIÓN:

cuando perfore los agujeros en el fondo del gabinete.

ENSAMBLAJE E INSTALACIÓN

A3

DEL ADAPTADOR

Use gafas de seguridad

Regulador de tiro

A4

CÓMO MONTAR EL HORNO

PARA OBTENER UNA INSTALACIÓN MÁS FÁCIL Y EN POS

DE LA SEGURIDAD PERSONAL, SE RECOMIENDA QUE

DOS PERSONAS INSTALEN ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante la instalación.

NOTA: Si su gabinete es de metal, use la arandela

de nilón alrededor del cable eléctrico para evitar

que el mismo sea cortado.

NOTA: Recomendamos el uso de bloques de relleno

si el frente del gabinete cuelga por debajo del estante

del fondo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrían ocurrir daños por apretar

demasiado los tornillos.

NOTA: Cuando se encuentre

montando el horno, enrosque

el cable eléctrico a través del

agujero en el fondo del gabinete

superior. Manténgalo tenso

a través de los Pasos del 1–3.

No pellizque el cable ni tire

del horno por el cable.

Levante el horno,

1

inclínelo hacia

adelante, y enganche

las ranuras en

el extremo inferior

posterior en dos

orejillas inferiores

del plato de montaje.

Adaptador

de escape

Plato del

calefactor

posterior

del horno

Coloque el horno en su posición vertical, con la parte

1

superior hacia arriba.

Inserte las orejillas en cada lado del regulador de tiro

2

en los agujeros en el interior posterior del adaptador.

Pegue el adaptador de escape al plato calefactor con

3

los dos tornillos de bronce que le proporcionamos.

Cerciórese de que el regulador de tiro gira

fácilmente antes de montar el horno.

Deberá hacer ajustes para asegurarse de que existe

alineación apropiada con el sistema de conductos

de su casa después de la instalación del horno.

Parte

37

Gire el frente del horno contra

2

el fondo del gabinete.

Page 38

Instrucciones de instalación

CÓMO MONTAR EL HORNO

A4

(continuación)

Pegue el horno a la parte superior del gabinete.

3

nserte 2 tornillos (

I

4

autoalineables a través de los agujeros

exteriores superiores del horno. Gire

dos vueltas completas en cada tornillo.

Frente del gabinete

Estante del fondo del gabinete

1

-28 x 3

⁄4″

Apriete el tornillo del centro

5

completamente.

Bloque de relleno

CÓMO AJUSTAR EL ADAPTADOR

A5

DE ESCAPE

bra el gabinete superior y ajuste el adaptador

A

de escape para conectarlo al conducto de la casa.

1

)

⁄4″

A6

CÓMO CONECTAR EL CONDUCTO

Regulador de tiro

Parte posterior

del horno

Conducto de la casa

Equivalente a

la profundidad

del retroceso

del gabinete

Tornillo autoalineable

Parte superior del horno

Apriete los dos tornillos exteriores hacia la parte

6

de arriba del horno. (Mientras aprieta los tornillos,

mantenga el horno en su lugar contra la pared

y el gabinete superior.)

Instale los filtros de grasa. Ver el Manual del Propietario que

7

viene con el horno.

Extienda el conducto de la casa hacia abajo para

1

conectarlo con el adaptador de escape.

Selle las juntas del conducto de escape usando

2

cinta adhesiva de conductos.

38

Page 39

Instrucciones de instalación

ESCAPE POSTERIOR EXTERNO (Conducto horizontal)

B

PERSPECTIVA GENERAL

DE LA INSTALACIÓN

B1. Prepare la pared posterior

B2. Pegue el plato de montaje

a la pared

B3. Prepare el gabinete superior

B4. Ajuste el calefactor

B5. Monte el horno

CÓMO PREPARAR LA PARED

B1

POSTERIOR PARA EL ESCAPE

POSTERIOR EXTERIOR

Necesita cortar una abertura en la pared posterior para

el escape exterior.

• Lea las instrucciones en la PLANTILLA PARA

LA PARED POSTERIOR.

• Péguela con cinta adhesiva a la pared posterior,

alineándola con los agujeros previamente perforados

para los agujeros A y B en el plato de la pared.

• Corte la apertura, siguiendo las instrucciones

de la PLANTILLA PARA LA PARED POSTERIOR.

CÓMO ADHERIR EL PLATO

B2

DE MONTAJE A LA PARED

Pegue el plato a la pared usando los tornillos basculantes.

Por lo menos un tornillo de madera debe ser usado para

pegar el plato al poste de viga de la pared.

Remueva las mariposas de los tornillos.

1

Inserte los tornillos en el plato de montaje a través

2

de los agujeros diseñados para colocarse contra

la pared de mampostería seca y pegue otra vez

las mariposas de3⁄4″ a cada tornillo.

39

Page 40

Instrucciones de instalación

Para usar los tornillos basculantes:

spaciadores para los basculantes

E

mayores que el ancho de la pared

Plato de

montaje

3

Coloque el plato de montaje contra la pared

e inserte las alas de mariposa en los agujeros

de la pared para montar el plato.

NOTA: Antes de apretar los tornillos basculantes

y el tornillo de madera, cerciórese de que las orejillas

en el plato de montaje toquen el fondo del gabinete

cuando se empujen contra la pared y de que el plato

esté centrado apropiadamente debajo del gabinete.

PRECAUCIÓN:

pellizcar sus dedos entre la parte posterior del plato

de montaje y la pared.

Apriete todos los tornillos. Tire del plato en dirección

4

opuesta a la pared para ayudar a apretar los tornillos.

Alas de mariposa

Tornillo de

mariposa

Pared

Extremo del tornillo

Tenga cuidado de evitar

CÓMO ADAPTAR EL CALEFACTOR

B4

PARA EL ESCAPE POSTERIOR EXTERIOR

Remueva y guarde los tornillos que sostienen

1

el plato del calefactor en el horno. Deslice el plato

del calefactor de abajo de su reborde de retención.

Remueva y guarde los tornillos que sostienen el motor

del calefactor en el horno.

Reborde de

etención

r

Tornillo del motor

del calefactor

Cuidadosamente tire del calefactor. Los alambres

2

se extenderán lo suficiente como para permitirle

que usted ajuste la unidad del calefactor.

ANTES: LAS ABERTURAS DE

LA PALETA DEL VENTILADOR

ESTÁN ORIENTADAS

HACIA ARRIBA

Extremo A

Plato

calefactor

Extremo B

USE LA PLANTILLA DEL GABINETE

B3

SUPERIOR PARA PREPARAR

EL GABINETE SUPERIOR

Necesita perforar agujeros para los tornillos de apoyo

superiores y un agujero suficientemente grande para

que el cable eléctrico quepa.

• Lea las instrucciones sobre la PLANTILLA

DEL GABINETE SUPERIOR.

• Péguela debajo del gabinete superior.

• Taladre los agujeros, siguiendo las instrucciones

en la PLANTILLA DEL GABINETE SUPERIOR.

Rote la unidad 180° en sentido contrario

3

a las agujas del reloj.

Antes de la rotación

Parte posterior

del horno

Suavemente remueva los alambres de las ranuras.

4

Redirija los alambres a través de las ranuras

en el otro lado de la unidad del calefactor.

Antes de redirigirlos Después de redirigirlos

Después de la rotación

Parte posterior

del horno

PRECAUCIÓN:

cuando perfore los agujeros en el fondo del gabinete.

Use gafas de seguridad

40

Alambres dirigidos a través

del lado derecho

Alambres dirigidos a través

del lado izquierdo

Page 41

Instrucciones de instalación

Ruede la unidad del calefactor 90º de forma tal

5

ue las aberturas de la paleta del ventilador estén

q

orientadas hacia la parte posterior del horno.

Antes de la rotación

Parte posterior

del horno

Localice los dos platos removibles en el panel

6

posterior del horno, cerca de la parte superior

del horno.

Usando tijeras, cuidadosamente corte el área