Page 1

Page 1

GE Healthcare

Pre-Installation Manual

Discovery RF180

Discovery RF180

Pre-Installation Manual

5793724-1EN

Revision 6

© 2020 General Electric Company

All rights reserved.

Page 2

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 2

This page is blank.

Page 3

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 3

Revision

Hist

ory

Revision Date

Reason for change

01

May 2018

First Version, changes from draft. Base plate torque values and drawing, Wall

stand dimensions, overvoltage image translation, materials and tools review.

Underfloor drawings update, RSVP requirements, information for room layout,

torque values for wall stand.

Critical components data, base plate installation, room height requirements, wifi

detector, details in base plate installation.

02

November 2018

July 2018

Small room packaging, access point, OTS bridge dimension.

September 2018

Base plate installation, dimensions and weights, doors requirements, ducts

dimension, in-room secondary console.

November 2018

Wall stand center of gravity, door sizes, 4” floor example, OTS fixation example,

in-room package, door sizes.

03

April 2019

Par. 4.3.3.2: added grout pad note. Par. 4.3.3.3 note added.

OTS drawings, notes for UPS and MSP for US.

04

July 2019

Floor flatness requirements. Base plate dolly.

05

October 2019

Correction drawing 40833.A page 29.

Addition of Advantech monitor.

Added overall dimensions for monitor suspension

06

March 2020

Par. 5.3.5 service area correction; par. 4.3.1 added a note; added subparagraph to

par. 4.3.3.4 , modified par. 5.2.1 and par. 5.3.1. for Monitor Suspension and OTS

data.

Manufacturer: GENERAL MEDICAL MERATE S.p.A.

Via Partigiani, 25

24068 Seriate (BG) – Italy

Tel. +39 035 45 25 311

Fax +39 035 29 77 87 / 29 95 37

www.gmmspa.com

Distributor: GE Medical Systems, SCS

283, rue de la Miniére,78530 Buc, France

The original version of this publication was drafted in English and will be referred to for any

controversy regarding interpretation of the eventual corresponding versions, translated into other

languages.

The contents of this publication may not be reproduced in any manner with any electronic or

mechanical means. It cannot be distributed in any manner without written authorization issued by

the manufacturer. The manufacturer reserves the right to modify/update this document without

notice.

Page 4

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 4

Table of Contents

1. General Notes ........................................................................................................................ 7

1.1. Damage in transportation ......................................................................................................... 7

1.2. Certified electrical contractor statement .................................................................................. 7

1.3. Important X-Ray protection....................................................................................................... 8

1.4. Omissions & Errors .................................................................................................................... 8

2. Preface .................................................................................................................................. 9

2.1. Typographic conventions .......................................................................................................... 9

2.2. Warning symbols on the equipment ......................................................................................... 9

3. Introduction ......................................................................................................................... 11

3.1. Objective and Scope of pre-installation .................................................................................. 11

3.2. Responsibilities of the Purchaser ............................................................................................ 11

3.3. What You Will Receive (System Components) ........................................................................ 12

4. Room requirements ............................................................................................................. 15

4.1. Environmental ......................................................................................................................... 15

4.2. Magnetic/Electrical Field Sensitivity and Electromagnetic Emissions .................................... 18

4.3. Structural ................................................................................................................................. 18

4.3.1. Doors requirements ............................................................................................................. 18

4.3.2. Room height requirement ................................................................................................... 23

4.3.3. Floors, Ceilings and Walls .................................................................................................... 25

4.3.3.1. Seismic Requirements .................................................................................................... 25

4.3.3.2. Floor Flatness Requirements .......................................................................................... 25

4.3.3.3. Floor Requirements when using provided Table Floor Anchors .................................... 26

4.3.3.4. Ceiling requirement for OTS and/or Monitor suspension installation ........................... 26

4.3.3.4.1. In-room Ceiling suspension – Single monitor on fixed point ...................................... 27

4.3.3.4.2. Substructure for ceiling fixation of the In-room monitor suspension fixed point ...... 27

4.3.3.4.3. Substructure for ceiling fixation of the In-room monitor suspension fixed point ...... 30

4.3.3.5. Walls ............................................................................................................................... 31

5. System Physical Characteristics ............................................................................................ 32

5.1. Ceiling rails (for OTS and / or Monitor suspension) - option .................................................. 33

5.1.1. Maximum flexion between 2 anchoring points ................................................................... 35

5.1.2. Rail mounting ....................................................................................................................... 36

5.2. Overhead Tube Suspension ..................................................................................................... 37

5.2.1. Packaging ............................................................................................................................. 37

5.2.2. Dimensions .......................................................................................................................... 38

5.3. Monitor suspension (single / double) - option ........................................................................ 41

Page 5

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 5

5.3.1. Packaging ............................................................................................................................. 41

5.3.2. Dimensions ........................................................................................................................... 42

5.3.3. Packaging – table delivered in one piece ............................................................................. 46

5.3.4. Packaging – table delivered in two pieces ........................................................................... 47

5.3.5. Dimensions ........................................................................................................................... 48

5.4. Base plate installation .............................................................................................................. 53

5.4.1. Use of the under floor installation plate.............................................................................. 55

5.4.2. Use of the over floor installation plate ................................................................................ 56

5.5. Table main control console ...................................................................................................... 60

5.5.1. Packaging ............................................................................................................................. 60

5.5.2. Dimensions ........................................................................................................................... 60

5.6. In-room secondary console (option) ....................................................................................... 61

5.6.1. Packaging ............................................................................................................................. 61

5.6.2. Dimensions ........................................................................................................................... 61

5.7. Generator Cabinet ................................................................................................................... 62

5.7.1. Packaging ............................................................................................................................. 62

5.7.2. Dimensions ........................................................................................................................... 62

5.8. Digital system ........................................................................................................................... 63

5.8.1. Packaging ............................................................................................................................. 63

5.8.2. Dimensions ........................................................................................................................... 64

5.9. Monitor .................................................................................................................................... 65

5.9.1. Packaging ............................................................................................................................. 65

5.9.2. Dimensions ........................................................................................................................... 65

5.10. Monitor Advantech .................................................................................................................. 66

5.10.1. Packaging ............................................................................................................................. 66

5.10.2. Dimensions ........................................................................................................................... 66

5.11. Monitor cart ............................................................................................................................. 67

5.11.1. Packaging ............................................................................................................................. 67

5.11.2. Dimensions ........................................................................................................................... 67

5.12. Wall Stand - option .................................................................................................................. 70

5.12.1. Packaging ............................................................................................................................. 70

5.12.2. Dimensions ........................................................................................................................... 71

5.12.3. Wall Stand Base Plate and Wall Bracket .............................................................................. 73

5.13. Wall stand and Table Layout ................................................................................................... 74

5.14. Detector ................................................................................................................................... 75

5.14.1. Packaging ............................................................................................................................. 75

5.14.2. Dimensions ........................................................................................................................... 76

5.15. Access Point ............................................................................................................................. 77

5.15.1. Packaging ............................................................................................................................. 77

5.15.2. Dimensions ........................................................................................................................... 77

6. Planning Electrical Connections ............................................................................................ 78

6.1. Routing Cables ......................................................................................................................... 78

6.1.1. General ................................................................................................................................. 78

Page 6

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 6

6.1.2. Conduit................................................................................................................................. 78

6.1.3. Floor Ducts ........................................................................................................................... 78

6.1.4. Power Distribution ............................................................................................................... 78

6.1.5. Emergency Power ................................................................................................................ 78

6.2. Master Interconnect System (MIS) ......................................................................................... 79

6.3. Hospital Network Connections ................................................................................................ 79

6.3.1. Remote services broadband pre-installation requirements for Europe ............................. 79

6.3.2. RSVP Network requirements ............................................................................................... 79

6.3.3. DICOM hospital Network ..................................................................................................... 80

7. Laying Out the Room ............................................................................................................ 81

7.1. Considerations ......................................................................................................................... 81

7.1.1. Privacy and security ............................................................................................................. 81

7.1.2. Radiation Protection ............................................................................................................ 81

7.1.3. Service Access ...................................................................................................................... 81

7.1.4. Clinical Access ...................................................................................................................... 81

7.1.5. Peripheral Equipment .......................................................................................................... 82

7.2. Typical Room Layout ............................................................................................................... 83

8. System Facility Power and Grounds ...................................................................................... 89

8.1. Introduction ............................................................................................................................. 89

8.2. Electrical Requirements ........................................................................................................... 89

8.2.1. Power quality and System Power Specifications ................................................................. 89

8.2.2. Table Electrical requirements .............................................................................................. 95

8.2.3. Generator Electrical Requirements ..................................................................................... 96

8.3. UPS Electrical Requirements ................................................................................................... 97

8.4. Electrical Grounds .................................................................................................................... 98

9. Materials and Tools ............................................................................................................ 102

10. System Cable Information .................................................................................................. 103

Page 7

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 7

1. General Notes

Important note

THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER THAN ENGLISH, IT IS THE

CUSTOMER’S RESPONSIBILITY TO PROVIDE TRANSLATION SERVICES.

DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE MANUAL HAS BEEN

CONSULTED AND UNDERSTOOD.

FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO THE SERVICE PROVIDER, OPERATOR OR

PATIENT FROM ELECTRIC SHOCK, MECHANICAL OR OTHER HAZARDS.

1.1. Damage in transportation

All packages should be closely examined at time of delivery. If damage is apparent, write “Damage in

Shipment” on ALL copies of the freight or express bill BEFORE delivery is accepted or “signed for” by a

distributor representative or hospital receiving agent. Whether noted or concealed, damage MUST

be reported to the carrier immediately upon discovery, or in any event, within 14 days after receipt,

and the contents and containers held for inspection by the carrier.

A transportation company will not pay a claim for damage if an inspection is not requested within this

14 day period. Call the distributor service department, immediately after damage is found. At this

time be ready to supply name of carrier, delivery date, consignee name, freight or express bill

number, item damaged and extent of damage.

1.2. Certified electrical contractor statement

All electrical Installations that are preliminary to equipment positioning shall be performed by

licensed electrical contractors. In addition, electrical feeds into the Power Distribution Unit shall be

performed by licensed electrical contractors. Other connections between pieces of electrical

equipment, calibrations and testing shall be performed by qualified Systems personnel. The products

involved (and the accompanying electrical installations) are highly sophisticated, and special

engineering competence is required.

In performing all electrical work on these products, the distributor shall use their own specifically

trained field engineers. All of distributor’s electrical work on these products shall comply with the

requirements of the applicable electrical codes.

The purchaser of the equipment shall only use qualified personnel (i.e., distributor’s field engineers,

personnel of third party service companies with equivalent training, or licensed electricians) to

perform electrical servicing on the equipment.

Page 8

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 8

1.3. Important X-Ray protection

X-RAY EQUIPMENT AND DEVICES CAN BE DANGEROUS FOR THE HEALTH OF BOTH

PATIENTS AND OPERATORS UNLESS PROPER SAFETY MEASURES ARE STRICTLY OBSERVED.

Although this equipment was designed and manufactured according to the most up-to-date safety

standards, the source of X-rays is always dangerous when the operator is not properly qualified or

trained. Excessive exposure to X-rays damages the human body.

Therefore, all the necessary precautions must be taken to prevent unauthorized or unskilled

personnel from operating this equipment, thus jeopardizing themselves and other people. Do not use

the equipment if you have not received appropriate training in the correct and safe use of the

equipment itself by the manufacturer or any of his appointed instructors.

Before executing any operation, the persons qualified and authorized to operate this equipment

must be informed about the protection and safety measures established by the International

Committee for Radiological Protection, as well as any other relevant national Standards.

1.4. Omissions & Errors

The manufacturer declines all responsibility with regard to the proper functioning of the equipment,

should the installation or the maintenance of it be executed by unauthorized personnel.

The X-ray system’s installation instructions are included in the service manual, which is a separate

item from the Operator’s manual.

Page 9

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 9

2. Preface

2.1. Typographic conventions

In order to facilitate the reading of the manual, different styles and types were used.

The text identified by bullets indicates:

• Instructions to be executed according to the sequence specified.

The text in italics inside a frame indicates:

Useful supplementary information for the technician.

The following icons are also used:

Important information

It is advisable that extra attention be paid in reading the topics identified with

this symbol.

WARNING

The topics identified with this icon regard aspects of safety for the patient

and/or operator.

2.2. Warning symbols on the equipment

Warning symbol that indicates potential generic danger for the equipment or

the operator. It invites the operator to check the equipment documentation for

further details.

Warning symbol that invites operators to follow the instructions for using the

device on which the symbol itself is applied.

Hazard symbol that indicates X-ray radiation exposure.

Warning symbol that indicates electrical components which are sensitive to

electrostatic discharge.

Page 10

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 10

Warning symbol that indicates live electrical parts with a possible risk of electric

shock.

Warning symbol that indicates that fingers may be crushed.

Symbol of protective earth (ground).

“ON” symbol (power).

“OFF” symbol (power).

“ON” / “OFF” symbol (push-push).

Symbol of applied part B type.

Symbol of filtration.

Symbol that indicates electrical and electronic components which must be

collected separately.

Fluoroscopy and radiography foot pedal connector fitting

The screws labelled with ETS symbol (Essential To Safety) are involved in safety

during installation or parts replacement.

The technician is asked to label with a red marker each of these screws.

Page 11

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 11

3. Introduction

3.1. Objective and Scope of pre-installation

This document is intended as a guide and informational resource for planning and properly preparing

a location for the system installation. This document is intended to assist the customer and installer

in properly preparing a site for product installation.

3.2. Responsibilities of the Purchaser

The purchaser is responsible for the completion of the “pre-installation” requirements. This includes

the procurement and installation of all required materials and services to get the room ready for the

product installation.

This responsibility includes providing:

• A clean and safe work environment for the product installation (finished floor, ceiling, walls,

and proper room lighting).

• A location suitable for the product installation. See Chapter 2 - Suite/Room Requirements.

• Suitable support structures in the floor, walls, or ceiling necessary for the mounting of the

product and/or its components. Installation of conduit ducts and/or raceways necessary to

route cables safely. System Physical Characteristics and Chapter 6 – Planning Electrical

Connections.

Note: Unistrut / halfen / equivalent rails and means necessary to anchor of the Mavig Substructure

and the Mavig mounting plate for the “in room ceiling suspension on fixed point” (rails, anchors,

bolts, screws, etc.) are not delivered with the kit and should be provided and designed under

customer responsibility.

• Electrical power and grounds of specified quality and reliability. See Chapter 8 – System

Facility Power and Grounds.

• Electrical power of the required voltage, including an emergency-off safety switch in the

room. Power and ground cables to the PDU.

• Properly installed and sized junction boxes, including covers and fittings at locations

required and called out in the architectural drawings.

Page 12

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 12

3.3. What You Will Receive (System Components)

Table assembly with table cabinet

Table main control console

Digital system (with UPS*)

*UPS provided by GMM except for US

(specific version for US available with CAT Number S13411PS)

H.V. Indico IQ Generator

Single / Double monitor suspension (option)

S13441MM – Single Monitor Suspension

S13441RF – Radshield on fixed point (option)

Page 13

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 13

S13441MF – Substructure for ceiling fixation of

the in-room monitor suspension fixed point. In

case of installation on concrete ceiling preferred.

S13441MP – Mounting Plate for ceiling fixation

of the In-room monitor suspension fixed point

(including the items 1, 2, 3 and 4) In case of

installation on Unistrut / Halfen / equivalent

rails preferred.

OTS (option)

Wall stand (option)

In-room secondary Console (option)

Single / Double monitor cart (option)

Page 14

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 14

Product Name

Catalog Number

Discovery RF180 system

S13441RS

Digital system (RF4343 detector + Monitor)

S13431AB

Digital system (RF4343FL detector + Monitor) (not for US)

S13431AC

DIN Monitor (Option)

S13441GM

RAD Wifi detector (Gadox) 3543EZ and access point (not for US)

S13431FG

RAD Wifi detector (CSI) 3543EZ and access point

S13431FH

RAD Wifi detector (CSI) 2430EZ and access point

S13431FK

High Voltage Generator (65kW – 1 tube) (not for US)

S13431BR

High Voltage Generator (80kW – 1 tube) (not for US)

S13431BT

High Voltage Generator (65kW – 2 tube)

S13431E

High Voltage Generator (80kW – 2 tube)

S13431EA

Single Monitor Suspension

Radshield on fixed point (option)

S13441MM

S13441RF

Substructure for ceiling fixation of the in-room monitor suspension

fixed point.

S13441MF

Mounting Plate for ceiling fixation of the In-room monitor

suspension fixed point.

S13441MP

(Option)

Single Monitor Ceiling Suspension including Bridge & Carriage

S13431NG

(Option)

Dual Monitor Ceiling Suspension including Bridge & Carriage

S13431NH

Radshield for ceiling suspension (Option)

S13441SR

In-Room single monitor on Cart (option)

S13431DG

UPS unit (Version provided by GMM except for US)

S13441PE

Wall Stand (option) Tilting Left hand (not for US)

S13441TL

Wall Stand (option) Tilting Right hand (not for US)

S13441TR

Wall Stand (option) NON tilting Left hand

S13441WL

Wall Stand (option) NON tilting Right hand

S13441WR

Overhead Tube Suspension OTS (option)

S13411EB

In-room secondary console (option)

S13441RC

UPS (US SYSTEM ONLY not provided by GMM)

S13441PS

MDP (US SYSTEM ONLY not provided by GMM)

S13411MD

Page 15

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 15

4. Room requirements

4.1. Environmental

The unit has been designed to operate in a room respecting the following environmental conditions:

Device

Storage

temperature

Operating

Temperature

Digital system (PU included)

-20 … +60°C

+10 … +40 °C

Detector Pixium 4343FL

-25 … +55 °C

+15 … +35 °C

Detector Pixium RF4343

-25 … +55 °C

+15 … +35 °C

Detector Pixium 3543EZ

-10 … +55 °C

+15 … +35 °C

Detector Pixium 2430EZ

-10 … +55 °C

+15 … +35 °C

Generator

-20 … +50 °C

+10 … +40 °C

Table

-20 … +60 °C

+15 … +40 °C

Monitor (Eizo)

-20 … +60 °C

+5 … +35 °C

Monitor (Advantech)

-20 … +60 °C

+0 … +40 °C

UPS (not valid for US)

-15 … +50 °C

+0 … +40 °C

Monitor suspension (option)

-20 … +70 °C

+10 … +40 °C

OTS (option)

-20 … +60 °C

+15 … +40 °C

Wall Stand

-20 … +70 °C

+10 … +40 °C

Wall Stand (tilting)

-20 … +70 °C

+10 … +40 °C

Vacutec DAP (Dose Area Product)

-20 … +60 °C

+10 … +40 °C

Access Point

-20 … +65 °C

+0 … +40 °C

UPS (US ONLY, not provided by GMM)

-25 … +55 °C

+0 … +40 °C

MDP (US ONLY, not provided by GMM)

-25 … +70 °C

+0 … +40 °C

Device

Storage

Humidity

Operating

Humidity

(non cond.)

Digital system

(PU included)

10 … 90%

30 … 75%

Detector Pixium 4343FL

5 … 95%

20 … 75%

Detector Pixium RF4343

5 … 95%

20 … 75%

Detector Pixium 3543EZ

5 … 95%

20 … 80%

Detector Pixium 2430EZ

5 … 95%

20 … 80%

Generator

5 … 85%

20 … 80%

Table

10 … 80%

20 … 80%

Monitor (Eizo)

10 … 90%

20 … 80%

Monitor (Advantech)

5 … 90%

Ta = 40 °C, 90% RH

UPS (not valid for US)

10 … 90%

0 … 95%

Monitor suspension (option)

10 … 95%

20 … 75%

OTS (option)

10 … 80%

20 … 80%

Wall Stand

10 … 90%

30 … 75%

Page 16

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 16

Device

Storage

Humidity

Operating

Humidity

(non cond.)

Wall Stand (tilting)

10 … 90%

30 … 75%

Vacutec DAP (Dose Area Product)

10 … 80%

10 … 80%

Access Point

5 … 95%

10 … 90%

UPS (US ONLY, not provided by GMM)

0 … 95%

0 … 96%

MDP (US ONLY, not provided by GMM)

5 … 95%

0 … 95%

Device

Storage

Pressure

Operating

Pressure

Digital system

(PU included)

700 … 1060hPa

700 … 1060hPa

Detector Pixium 4343FL

500 … 1060hPa

700 … 1060hPa

Detector Pixium RF4343

500 … 1060hPa

700 … 1060hPa

Detector Pixium 3543EZ

500 … 1100hPa

700 … 1100hPa

Detector Pixium 2430EZ

500 … 1100hPa

700 … 1100hPa

Generator

700 … 1060hPa

700 … 1060hPa

Table

500 … 1060hPa

500 … 1060hPa

Monitor (Eizo)

200 … 1060hPa

700 … 1060hPa

Monitor (Advantech)

500 … 1013hPa

500 … 1013hPa

Monitor suspension (option)

500 … 1060hPa

700 … 1060hPa

OTS (option)

500 … 1060hPa

700 … 1060hPa

Wall Stand

700 … 1060hPa

700 … 1060hPa

Wall Stand (tilting)

700 … 1060hPa

700 … 1060hPa

Vacutec DAP (Dose Area Product)

800 … 1060hPa

800 … 1060hPa

UPS (US ONLY, not provided by GMM)

700 … 1060hPa

700 … 1060hPa

MDP (US ONLY, not provided by GMM)

794 … 1060hPa

794 … 1060hPa

Device

Supply

Voltage

Mains

Frequency

Momentary

Current

Operating

Current

Operating

Power

Digital system

(PU and detector

included)

230Vac

10 %

50/60 Hz

1.5A

1.3A

350 VA

Generator IQ

(65kW)

400Vac

3-phase

10 %

50/60 Hz

2 %

135A/phase

---

300 VA

stand-by

95 kVA

peak

Page 17

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 17

Device

Supply

Voltage

Mains

Frequency

Momentary

Current

Operating

Current

Operating

Power

480Vac

3-phase

10 %

50/60 Hz

2 %

110A/phase

---

300 VA

stand-by

95 kVA

peak

Generator IQ

(80kW)

400Vac

3-phase

10 %

50/60 Hz

2 %

168A/phase

---

300 VA

stand-by

115 kVA

peak

480Vac

3-phase

10 %

50/60 Hz

2 %

140A/phase

---

300 VA

stand-by

115 kVA

peak

Monitor

(for all the

devices)

200Vac

240Vac

50/60 Hz

---

0.5A

21 W typ.

57 W max.

Monitor

(Advantech)

100 – 240 Vac

(power supply)

50/60 Hz

---

---

65 W max

OTS

220/230/240Vac

(10%)

Single phase

50/60 Hz

3 %

---

---

100 VA

stand-by

1370 VA

peak

Table

400V

3-phase

10 %

50/60 Hz

2 %

3.5A phase

N.A.

600 VA

stand-by

4000 VA

peak

Device

Heat dissipation

W

BTU/hour

Digital system (PU and detector included)

320

1092

Generator (IQ)

22 (standby)

1026 (during fluoro)

75 (standby)

3500 (during fluoro)

UPS (average)

(not valid for US)

50

171

Monitor (single)

57

149

Monitor (single Advantech)

65 max

222 max

OTS (option)

350

1190

Table

700 (average)

2388 (average)

Wall Stand

N.A.

N.A.

System noise in stand-by: < 45 dB

System noise in working conditions: < 65 dB

Page 18

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 18

4.2. Magnetic/Electrical Field Sensitivity and Electromagnetic Emissions

All the products or components of the system meet EMI and EMC requirements and IEC 60601-1-2

(International). Because X-ray equipment produces radiation, special precautions may need to be

taken or special site modifications may be required. This manual does not make recommendations

regarding radiation protection. It is the purchaser’s responsibility to consult a radiation physicist for

advice on radiation protection in X-ray rooms.

4.3. Structural

4.3.1. Doors requirements

Make reference to the following examples pictures.

Component

Minimum Doors size requirements

(using provided dollies, pallets, etc)

Minimum

corridor depth

Height

Width

Table delivered in

cm

inches

cm

inches

One piece

Two pieces

Table

185

73

120

47.2

>= 120 cm

(47.2 inches)

>= 115 cm

(45.3 inches)

117

46

>= 122 cm

(48 inches)

>= 117 cm

(46 inches)

102

40.2

>=160 cm

(63 inches)

>= 130 cm

(51.2 inches)

95

37.4

NO

>= 135 cm

(53.1 inches)

In case the doorway is between 102 - 105 cm, be aware that the Spot Film Device (SFD) has to be

removed temporarily from the table beam during maneuvered thru the doorway. Refer to the

Installation Manual, section 10.2.1. (P/N 5793725-1EN).

Component

Minimum Doors size requirements

(using provided dollies, pallets, etc)

Minimum

corridor depth

Height

Width

cm

inches

cm

inches

inches

cm

Overhead Tube

Suspension

(and Monitor

suspension

transversal

bridge)

180

71

90

35

>= 102.4

>= 260

140

55

>= 71

>= 180

Generator

132

52

71

28

---

---

Digital system

---

---

80

31.5

---

---

Wall stand

---

---

80

31.5

---

---

Page 19

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 19

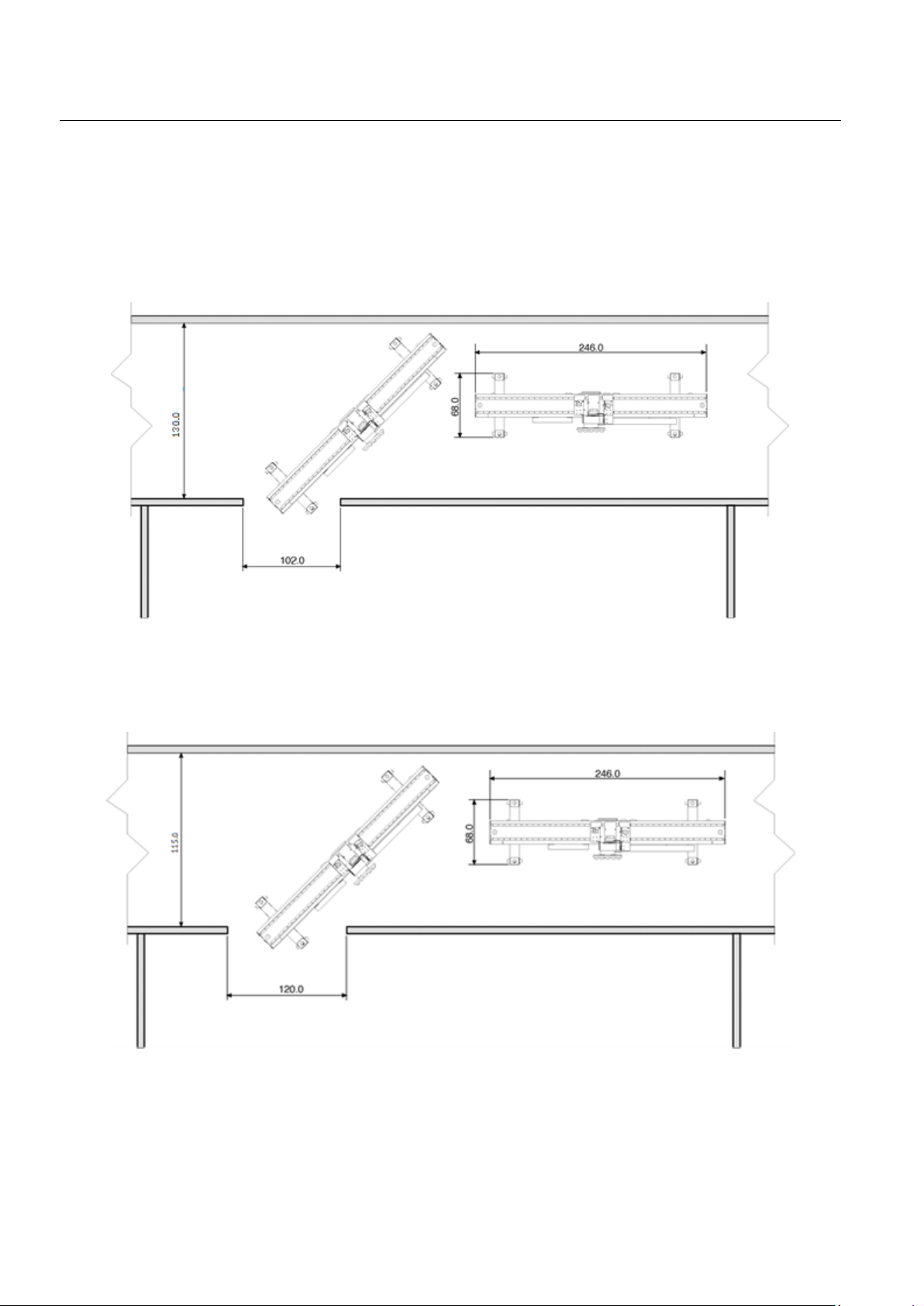

Table – delivered in one piece

The unit can be shipped in a whole lot that can be maneuvered through a 102 – 120-cm doorway.

In case of 102cm doorway, the table main frame will require about 1.60 m minimum hallway width to

allow negotiating turns.

In case of 120-cm doorway the table main frame will require about 1.20-mt. minimum hallway width

to allow negotiating turns.

(Measure in cm)

Page 20

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 20

Table – delivered in two pieces

The unit can be divided into few assemblies, in most cases the two major assemblies could be

maneuvered through a 102-cm doorway.

The most limiting item is the table main frame that will require about 1.30-mt. minimum hallway

width to allow negotiating turns.

Measure in cm.

In case of 120cm doorway, the table main frame will require about 1.15 m minimum hallway width to

allow negotiating turns.

Measure in cm.

In case the unit is shipped into two pieces, please find sizes and weight in the following pictures:

Page 21

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 21

Measures in mm.

Measures in mm.

Weight = 680 kg

1630

Page 22

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 22

OTS

The same constraints can be considered valid also for monitor suspension transversal bridge.

Measures in mm

Measures in mm

Page 23

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 23

4.3.2. Room height requirement

The minimum room height for the table must take into consideration the most protruding object

from the ceiling that is in the system area (for example the rails for OTS).

The minimum room height for the table is 260 cm (103”). In any case, the recommended room height

to move the system with software limitations is 300 cm (118”).

However, for a system with OTS and wall stand, full range of wall stand use is achieved with a ceiling

height of 292 cm . A higher height will limit the lower end of the useful travel range of the wall stand.

For all OTS dimensions and travels make reference to par. 5.2, page 37.

Parameter value

Minimum ceiling

height [cm]

Table constrains

Value of the ceiling

height.

From 260 to 269

WARNING! Tilting limitation! It is not possible to reach

a complete tilting. The tilting angulation will be limited

to a value less than +90° and -90°.

It is not possible to reach the maximum focal distance

and the maximum table elevation together. It means

that if you need the maximum focal distance you

cannot use the maximum table elevation and vice

versa.

From 270 to 299

A complete table tilting is always possible but with

some software limitations.

It means that during the tilting movement the focal

distance is automatically reduced. The tilting

movement is automatically stopped if the longitudinal

position of the column introduces a collision risk with

the ceiling. In this case it is necessary to manually

move the column to place it in the middle of the

longitudinal area.

Because the maximum table height is 295 cm when it

is in horizontal position, it is not possible to reach the

maximum focal distance and the maximum table

elevation at the same time.

The recommended room height is 300 cm.

NOTE: IF AN OTS KALOS OTS HAVE TO BE INSTALLED

IN THE ROOM WITH FIXATION RAILS ABOVE THE

RF180 SYSTEM, THE MIN CEILING HEIGHT TO HAVE

THE COMPLETE TABLE TILTING IS 293cm (9.6 feet).

From 300 to 319

As in the previous condition a complete table tilting is

always possible with software limitations.

With this ceiling height it is possible tilt the table with

the column in the middle of the longitudinal area but

with the maximum focal distance and maximum table

elevation.

Page 24

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 24

Parameter value

Minimum ceiling

height [cm]

Table constrains

From 320 to 359

With the minimal focal distance, it is always possible

to tilt the table with the column in any longitudinal

position.

From 360 to ∞

Table without limited movements.

It is possible to tilt the table in every condition,

maximum elevation and focal distance with the

column in every longitudinal position.

Minimum ceiling

height [cm]

Wall Stand constrains

Tilting wall stand

From 260 to 264

Wall Stand Arm Support option not applicable

From 265 to ∞

Wall Stand Arm Support option applicable

Not tilting wall stand

From 240 to 279

Wall Stand Arm Support option not applicable

From 280 to ∞

Wall Stand Arm Support option applicable

Minimum ceiling

height [cm]

Monitor suspension

From 260 to 320

Complete vertical travel is possible

From 320 to ∞

For rooms higher than 320 cm / 126 in, we strongly

suggest a ceiling construction between structural

ceiling and vertical column.

Minimum ceiling

height [cm]

Overhead Tube Suspension constrains

From 260 to 292

The vertical travel must be manually reduced because

the ceiling height is not enough.

From 292 to 300

OTS can use the complete vertical travel.

From 300 to ∞

OTS with limited lower end of the useful travel range of

the wall stand is possible.

Page 25

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 25

4.3.3. Floors, Ceilings and Walls

4.3.3.1. Seismic Requirements

Seismic requirements are determined and specified by the hospital structural engineer of record and

approved by the specific state or country agency.

4.3.3.2. Floor Flatness Requirements

See below figure for graphical definition of “flatness”. To insure a sufficient contact surface with the

floor, the below shaded region under the base plate must be within 1.5mm or 1/16” flatness (i.e. no

local concave or convex regions >1.5mm from flat). The critical region of flatness is:

- 1000mm wide and centered longitudinally under base

- 600mm deep against the rear of the base plate

Outside this region, shims may be used along the perimeter of the base plate to improve surface

contact.

Floor Levelness Requirement

See below figure for graphical definition of “levelness”. Discovery RF180 requires a floor levelness of

6mm or ¼”: the maximum height difference between any two points on the floor under the baseplate

with respect to perfect level measured via self-leveling laser, may not exceed 6mm or ¼”.

Page 26

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 26

Grout Pad Concession

In case of any violations of the above flatness/levelness requirements, it is STRONGLY recommended

the floor be leveled by the contractor to insure proper contact of base plate. This will greatly improve

the overall install quality and timing.

In the event this is not possible, a concession will be required. Self-levelling products may be an

option, including:

• Keratech Eco Flex (Kerakoll S.p.A.)

• “Ardex K15”, available at GE, orderable with SCAT S0915SW – reference installation

procedure GE DOC2242533

• Henry 565 which may be locally available

However, a concession will be required to review the specifics of the room and whether grout will be

a viable solution.

Strictly follow the instructions provided in the products’ technical data sheets.

It is recommended to entrust this job to field professionals who will be able to suitably prepare the

floor surface and to set up the containment structures for the solidification of these materials.

Upon solidifying, these products can usually be drilled with low speed drills until reaching the slab or

by performing a sequence of drilling, starting from smaller diameter drills and increasing up to the

diameter desired. Please ask the permission to the installation responsible team before drilling.

4.3.3.3. Floor Requirements when using provided Table Floor Anchors

The maximum pullout force per provided anchor was calculated assuming:

• A regular weight concrete having a minimum of 28-day compression, class min C20/C25

(UNI EN 206-1).

• Concrete thickness should be at least 200mm. For 100 and 140mm thickness refer to 5.4.2.

• Anchors installed to the required hole depth of 130mm. Refer to 5.4.2 for others examples.

• Center of anchor hole to concrete edge distance 106.5 mm (valid for all the examples).

Make sure to obtain concrete compression strength data before using floor anchors.

NOTE: make reference to par. 5.4.2 for 140mm or 100mm concrete thickness examples.

4.3.3.4. Ceiling requirement for OTS and/or Monitor suspension installation

The construction and load capability of the ceiling must be sufficient for the installation of the unit.

It is the responsibility of the customer or structural engineer to evaluate the best fixation system to

be used for the ceiling rails/mounting systems as described in the following layout example under

consideration of the options to be installed.

A good ceiling levelness is required. For OTS, a maximum of 7 mm height displacement along the

ceiling longitudinal rails is allowed and can be corrected with the use of shims to ensure the rails are

as close to perfect level as possible.

Page 27

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 27

Aluminum rails support the Overhead Tube Suspension and the in-room LCD Monitor bridge used in

X-ray rooms.

Monitor Suspension, that will be included:

measured in mm

The installation of the single/double Monitor option is to be installed to the upper mounting point of

the suspension.

An optional Radshield has to be mounted to the lower mounting point.

Reference - For details on ceiling requirements for stationary rails, refer to Chapter 5 System Physical

Characteristics.

4.3.3.4.1. In-room Ceiling suspension – Single monitor on fixed point

The In-room Ceiling monitor suspension on fixed point can be attached to the solid ceiling using one

of the two following options:

- attached to the substructure: the substructure is used as the bridging element between the

solid ceiling and the ceiling flange (top plate of the monitor suspension). The means required

for the fixation of the suspension to the substructure are delivered with the substructure.

- attached to the mounting plate: the mounting plate is installed to the hardware defined by

the structural engineer (It could be Unistrut / Halfen or equivalent rails). The ceiling flange

(top plate of the monitor suspension) is fixed to the mounting plate. The means required for

the fixation of the suspension to the mounting plate are delivered with the substructure.

4.3.3.4.2. Substructure for ceiling fixation of the In-room monitor suspension fixed point

The used mounting of the Monitor Suspension can be realized in three different ways:

- Fixed Monitor Suspension, direct to the ceiling

Standard Installation of MAVIGs Portegra2 System. Refer to the GE DOC 5849374-1EN for

MAVIGs Portegra2 Installation Manual - POR03Oxx (where xx stands for the latest revision,

12 or higher).

Page 28

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 28

- Fixed Monitor Suspension to the ceiling with Substructure.

The Substructure is mandatory to install the MAVIG suspension with fixed point directly to

the solid ceiling for Non-seismic Zones. For Seismic Zone installations, refer to Structural

Engineer for appropriate design of the structure for installing the MAVIG suspension system.

For standard site configurations, the distance between the ceiling and the ceiling flange

should be in a range of minimum 100 mm and maximum 626 mm.

If the distance between the ceiling and the ceiling flange is more than 626 mm, Long

variation of the Substructure for could be proposed by MAVIG.

Substructure (schematic)

1. Ceiling

2. Ceiling Plate - weight approx.4,9 kg

3. Threaded rods (8 pieces), M16 - 8.8,

length 495mm

4. Middle Plate - weight approx. 4,5 kg

5. Threaded rods (4 pieces), M16 - 8.8,

length 195mm

6. Interface Plate – weight approx. 2,3 kg

7. False Ceiling (not part of Delivery)

Page 29

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 29

Substructure Ceiling Plate for installation to the ceiling

The Substructure must be fastened to the ceiling using 8 suitable screws.

These screws must be dimensioned according to the conditions of the ceiling and provided by the

customer and must be checked by the structural engineer.

The Substructure ceiling plate must be seated flush to the ceiling in order to ensure optimum load

distribution.

Bolt Specifications:

Appropriate ceiling anchoring must withstand a maximum load of:

Normal Force: 1182,3 N

Momentum: 1148.51 Nm

The maximum pullout force shall be calculated in accordance with local building codes and it is part

of structural analysis done by customer.

Refer to GE Doc: 5849373-1-EN for MAVIGs Substructure Installation Manual - DBF02Oxx (where xx

stands for the latest revision, 04 or higher)

Page 30

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 30

4.3.3.4.3. Substructure for ceiling fixation of the In-room monitor suspension fixed point

The Mounting plate is mandatory to install the MAVIG suspension with fixed point to an existing

Unistrut / Halfen or equivalent rails for Non-seismic Zones. For Seismic Zone installations, refer to

Structural Engineer for appropriate design of the structure for installing the MAVIG suspension

system.

Mounting Plate for rails (Unistrut or Halfen)

Refer to the GE Doc: 5849374-1EN for MAVIGs Portegra2 Installation Manual - POR03Oxx (where xx

stands for the latest revision, 12 or higher).

Room layout

MAXIMUM SUGGESTED DISTANCE FROM FLOOR 3100mm

Page 31

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 31

Suggested position for Mavig 360° column installation (fixed on ceiling), in order to cover all clinical

scenario with no limitation of use.

Warning: the operator is responsible for the position and potential collision of the suspension in

relation to the position of the table. There are not safety interlocks which avoid table movements

depending from suspension position.

4.3.3.5. Walls

Precautionary measures have been taken to prevent scatter radiation from entering other rooms

and/or hallways and that all exposed walls are lead-lined.

In particular the hospital physicians should approve the room layout before the installation starts.

Under normal conditions, the wall at the installation site must be capable of supporting, minimally, a

110 lb. (490 N) pull from the wall at each anchor bolt.

Page 32

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 32

5. System Physical Characteristics

Refer to this section for the dimensional drawings of the components

Note: Drawings are not to scale. Dimensions are called out on each drawing

Component

Width

Height

Depth

Weight

Mounting comments

Table Assembly

246-414 cm

177-295cm

(not tilted)

201-221cm

1380kg

Mount on floor

Table main control

console

44cm

19cm

27cm

8kg

Placed on desk

Generator cabinet

51cm

106cm

41cm

91kg

Mount on floor

118kg packed

Digital system

56.8cm

90.1cm

73.7cm

110kg

Mount on wheels

UPS (not valid for US)

25.5cm

42.5cm

36cm

33,6kg

Mount on floor

Monitor

(for all the devices)

55.7cm

36.1cm

21.6cm

40.1cm (1)

6.6 kg

Mount on desk

Monitor

(Advantech)

57.8cm

40.3cm

68cm

9 kg (3)

---

Monitor suspension

mounting Plate

74cm

40cm

1.2cm

22kg

Mount to rails /

directly to the ceiling

Monitor suspension

substructure

62.6cm

30cm

30cm

22kg

Mount on ceiling

Single Monitor

suspension (2)

441cm

205cm

301cm

85 kg (4)

Monitor not

included

Double Monitor

suspension (2)

441cm

205cm

301cm

86 kg (4)

Monitors not

included

Overhead Tube

Suspension bridge

included (2)

441cm

291cm

301cm

300 kg

+ 78 kg

Mount on ceiling

rails

Wall Stand not

tilting

62cm

225cm

46cm

171kg

Mount on floor and

to wall

Wall Stand tilting

62cm

225cm

72cm max

200kg

Mount on floor and

to wall

UPS (ONLY FOR US)

203.2mm

(8.4inches)

330.2mm

(13.6inches)

406.4mm

(16.2inches)

34.9Kg

(77.2lbs)

(ONLY FOR US, NOT

PROVIDED BY GMM)

MDP (ONLY FOR US)

637.5mm

(25inches)

889mm

(35inches)

254mm

(10inches)

80Kg

(175lbs)

(ONLY FOR US, NOT

PROVIDED BY GMM)

(1). Make reference to par. 5.9.2.

(2). The dimensions refer to the maximum occupancy area.

(3). The weight includes the external power supply.

(4) The weight does not include the longitudinal rails.

Page 33

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 33

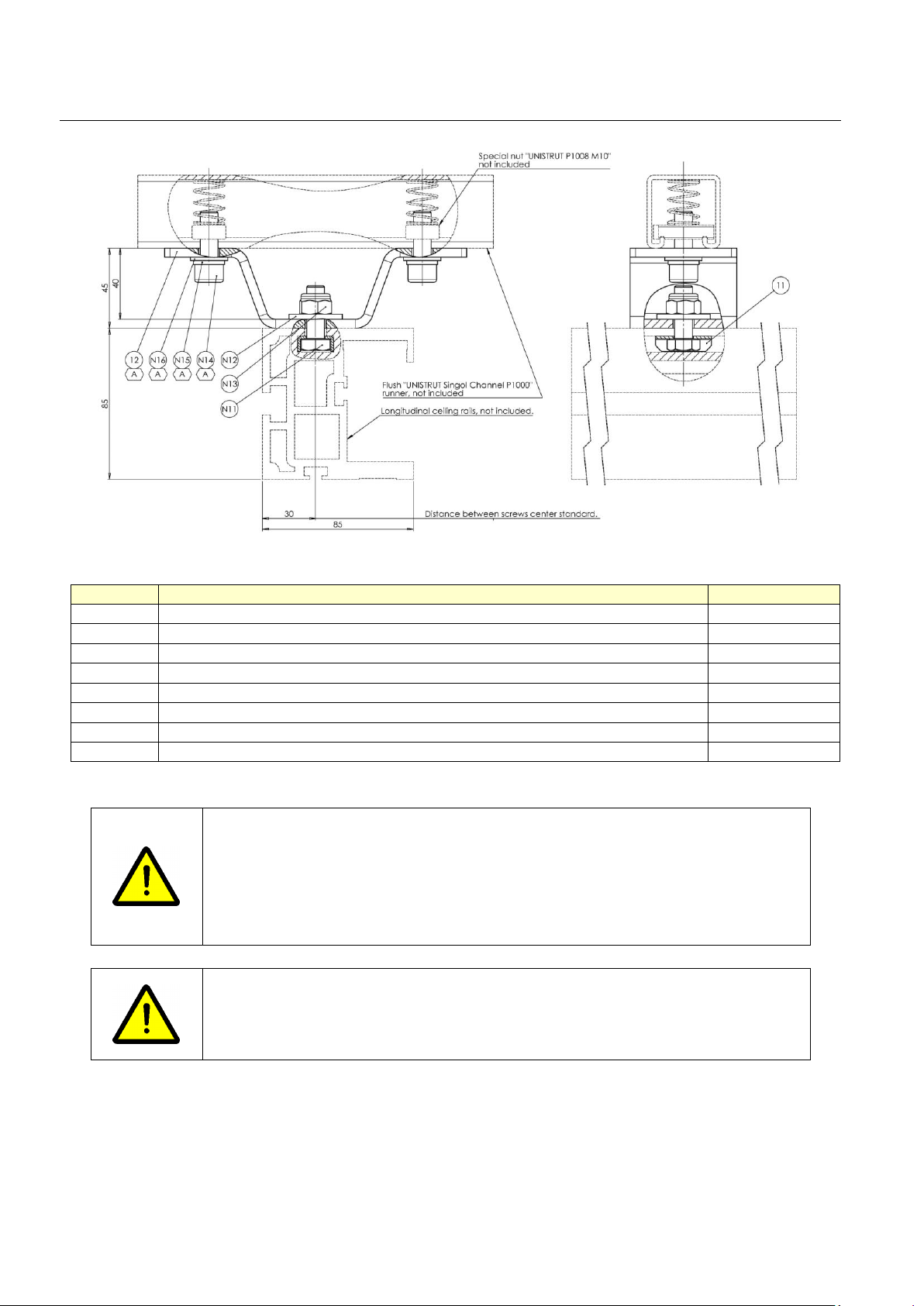

5.1. Ceiling rails (for OTS and / or Monitor suspension) - option

The stationary rails utilize extruded aluminum channels that are ceiling mounted and are 440cm in

length. The spacing between these stationary rails accommodates an overhead mounted bridge

structure. The bridge length is 301cm (or 361cm) and the bridge width is 61cm. The standard distance

between rails is 165cm.

A proper iron beam has been immured in the ceiling in accordance with one of the solutions

suggested in the following figure:

Measures in mm

The calculation of the support structure of the ceiling stand depends exclusively on the designer,

who is responsible of the room preparation. Type and dimension of the T-irons, shown in these

drawings, are just an indication.

Page 34

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 34

Measures in mm

Code

Description

Quantity

11

CAGE FOR SCREW TE 10

14

12

UNISTRUCT BRACKET H=45

14

N11

SCREW TE 8.8 Z UNI 5739 M10x30

14

N12

PLAIN WASHER D10.5 D30 THICKNESS 3

14

N13

NUT M10 UNI7473 DIN9820

14

N14

SCREW TCEI M10x30 8.8Z UNI5931

28

N15

GROWER WASHER C72Z UNI1751 D10.5

28

N16

PLAIN WASHER B.R40Z D.10.5 UNI6592

28

WARNING:

THE SUSPENSION CEILING RAILS ARE MOUNTED ON THE IRON BEAM BY

MEANS OF A SET OF SCREWS DELIVERED WITH THE UNIT.

EACH FIXATION SCREW MUST RESIST A PULL OF 205 Kg AND IT IS UNDER THE

INSTALLER’S RESPONSIBILITY TO MAKE SURE THAT THE FIXATION METHOD

USED FOR THE IRON BEAM CAN WITHSTAND SUCH VALUE.

WARNING:

IT IS POSSIBLE THAT THE IRON BEAMS IMMURED IN THE CEILING ARE NOT

LEVELLED. THE INSTALLER MUST CAREFULLY VERIFY THAT AND, IF

NECESSARY, LEVEL THE CEILING RAILS USING PROPER SPACERS.

Page 35

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 35

5.1.1. Maximum flexion between 2 anchoring points

During the worst working equipment conditions, it is necessary to find out the working stress on each

equipment support. The stress force of each equipment part is split into the following items:

P1 = 1000 N Rails (4 of 14 points anchoring)

P2 = 600 N Bridge (it slides on 4 support bearings)

P3 = 1700 N Carriage (stand with tube, collimator, mechanical and electrical parts)

In order to find out rail flexures, the study must be related to a close rectangular shape that

reproduces the rails core dimensions.

If you work in this way, you will always be able to simplify job calculation and in addition we will

always be in a Safety situation

As a matter of fact, rails are more complex, ribs and cores (that in this study are not taken into

consideration) really add large stiffness to the rails

At the same way for the below calculation, the rail steel plate is not taken into consideration that it is

the guide for sliding bearings and as a matter of fact it does add stiffness to the rails too.

If you make reference to the attached drawing you can calculate rails flexure by taking into

consideration the main involved sizes.

P = 2000 N half suspension weight and transversal carriage weight

L = 700 mm distance between rail anchoring points

E = 60000 MPa aluminum modulus of elasticity

I = 365000 mm4 inertia module related to the rail section (make reference to the following

drawings).

As a result, the flexibility of beam rested between extreme sides is calculated by the beam deflection

formula.

Page 36

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 36

5.1.2. Rail mounting

Make reference to the 5780106-1EN Kalos Service manual par. 6.3.3 “Installation of the Ceiling Rails”.

Page 37

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 37

5.2. Overhead Tube Suspension

5.2.1. Packaging

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Single packaging in wooden case

(All inclusive)

455.4 cm

90.4 cm

166 cm

920 kg

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Overhead Tube Suspension

longitudinal rails (two packages)

442 cm

12 cm

12 cm

42 kg + 42 kg

Overhead Tube Suspension,

transversal bridge

301 cm

80 cm

140 cm

378 kg

Collimator

58 cm

36 cm

38 cm

25 kg

High voltage cables

65 cm

74 cm

32 cm

15 kg

H = High voltage cables; C = Collimator; R = Longitudinal Rails

Magnetic band

position: do not

cut on this side.

Page 38

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 38

5.2.2. Dimensions

ITEM

LENGTH

WIDTH

Rails area

441 cm

360 cm

The measures in this picture are in millimeters.

Page 39

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 39

The measures in this picture are in millimeters.

Page 40

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 40

The measures in this picture are in millimeters.

Page 41

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 41

5.3. Monitor suspension (single / double) - option

5.3.1. Packaging

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Mounting Plate (option)

79 cm

48 cm

10 cm

25 kg

Substructure for Ceiling Suspension

104 cm

49 cm

33 cm

43 kg

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Rails (only if OTS is not supplied)

450 cm

12 cm

22 cm

12 cm

31 kg +

41 kg

Longitudinal rails and lifting tool are present only if OTS is not supplied

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Monitor Suspension.

Transversal bridge included

455 cm

80 cm

75 cm

382 kg

Page 42

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 42

5.3.2. Dimensions

The provided device is equipped with only one arm. The following drawings show two arms in order

to have a complete mechanical documentation.

The ceiling suspension spring arm can be moved up and down by max 45°, but this range can be

adjusted/limited; for details, please refer to the monitor manufacturer’s manual. The downward

movement is limited by a lower stop. For upward movement, check clearance with ceiling and avoid

any collision. The extension arm has no up/down movement, but rotates on the column pins. Avoid

alignment of the extension arm and spring arm.

GD4210-L max load 9.5 kg GD4220-L max load 15.0 kg

* dimension for L version. Measures in mm.

Page 43

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 43

Measures in mm.

Measures in mm.

WARNING

The motion should always be smooth and easy, if any hard point is felt by

moving the system, please contact the manufacturer. If you encounter

damages such as bent ceiling columns, collision marks or cracks in the color

coating or the material of the system, broken plastic covers, loose connection

of parts, or similar, please contact the manufacturer without further delay.

Page 44

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 44

OVERALL DIMENSION MONITOR

SUSPENSION ON RAILS 1/3 [mm]

OVERALL DIMENSION MONITOR

SUSPENSION ON RAILS 2/3 [mm]

MAXIMUM SUGGESTED DISTANCE FROM FLOOR 3100mm

Page 45

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 45

OVERALL DIMENSION MONITOR

SUSPENSION ON RAILS 3/3 [mm]

Page 46

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 46

Table

5.3.3. Packaging – table delivered in one piece

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Table

267 cm

130 cm

232 cm

1500 kg

SFD

120 cm

130 cm

165 cm

220 kg

Table SFD and accessories

Page 47

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 47

5.3.4. Packaging – table delivered in two pieces

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

Main frame + tabletop

260 cm

130 cm

218 cm

1000 kg

Beam, SFD and

accessories

260 cm

130 cm

218 cm

773 kg

Main frame + tabletop

Beam, SFD and accessories

Page 48

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 48

5.3.5. Dimensions

Measures in [mm].

(*) NOTE: The recommended service area behind the table is 500mm. The minimum service area

behind the table must be 336 mm.

530 mm space left and right the table, represents the anti-collision escape area for operators and

patients.

500 (*) 336 (*)

Rear side

Front side

Page 49

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 49

To prevent collisions with accidental objects it is a good practice to maintain a clear-area around the

unit as suggested in the following figure. Refer to the dashed line around the table.

Measures in [mm].

Page 50

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 50

Rear side Front side

Measures in [mm].

Max patient weight on the platform with

vertical machine 266 kg

Page 51

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 51

Measures in [mm].

Page 52

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 52

Measures in [mm].

Page 53

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 53

5.4. Base plate installation

The responsibility for the base plate fixation belongs to the installer and to the pre-installation

team.

The installer must verify the room physical characteristics, in accordance with the information

provided by the pre-installation team in the pre-installation phase.

The method used to fix the base plate must follow the indications provided by the pre-installation

team. It’s on the installer charge to inform that the information received from the pre-installation

team is not suitable for the base plate fixing.

The remote tilting table can be fixed to the floor using one of the following two different methods:

fixation using the underfloor installation plate and fixation using the over floor installation plate.

Before starting the installation, the pre-installation team must verify that all accessories

or interface cables are available and delivered in the lengths defined during the room

layout design phase.

Page 54

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 54

It is the responsibility of the pre-installation to select the fixation method that grants the

correct unit anchoring in function of the constructive characteristics of the floor. The

team must provide this information regarding the fixation method and the room

physical characteristics to the installer.

WARNING FOR THE OVERFLOOR BASE PLATE

In case of over floor base plate, pay attention to the position of the base plate with the

right orientation. The hole has to be oriented as in the figure, with respect to the main

frame. Otherwise mismatches will occur between the two objects.

Check how the machine will be oriented during installation.

Page 55

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 55

5.4.1. Use of the under floor installation plate

With this base, the floor loading capability must be greater than 550 kg/m² (unit weight = 1025+80

Kg; patient weight= 323 Kg; loading area = 2,60 m²). In order to correctly install the base plate, the

installer will be responsible to:

• Remove the upper part of the floor for a minimum area of 2200 x 1700mm (x about

100mm):

• Make sure that the floor surface on the bottom side of the base plate is rugged enough to

grant a proper grip of the concrete (it is possible to use a welded mesh.)

• Make sure that the base plate is accurately leveled with the upper plate aligned with the

finished surface of the floor as detailed in the following drawing.

• If required, fix the base plate to the floor using M12 screws as detailed in the following

drawing.

• Insert M12 screws in the unit fixation holes to prevent the possibility that the concrete could

obstruct the eight-unit fixation holes.

• Pour the concrete between cement and sand in a 1:2.5 ratio.

Unit weight = 1025 kg

Patient weight = 323 kg

Plate weight = 80 kg

Loading area = 2.60 m2

Floor loading = 550 Kg/m2

Measures in mm.

The M12 screws are not supplied with the product. Use the same described in the figure or similar.

It is in charge of the structural engineer of the hospital to evaluate whether the floor characteristics

are suitable for this type of base plate.

Cable IN

duct

Rear

Front

Page 56

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 56

5.4.2. Use of the over floor installation plate

BEFORE INSTALL THE BASEPLATE ON THE FLOOR CHOOSE THE FIXAITION METHOD (three different

here below) IN ACCORDANCE WITH THE FLOOR THICKNESS AN WITH YOUR NEEDS.

This should be done during the PRE-INSTALLATION PHASE.

This fixation method is recommended when the floor characteristics are not suitable to allow the

installation of the under-floor plate (It is in charge of the structural engineer of the hospital to

evaluate whether the floor characteristics are suitable for the under floor base plate.). In this case,

the installer must use the optional over floor installation plate to distribute the weight on a larger

surface and to offer a better and easier fixation to the floor as detailed in the following figure.

It is responsibility of the installer to grant the correct anchoring of the base plate in

function of the constructive characteristics of the floor.

Unit weight = 1025 kg

Patient weight = 323 kg

Plate weight = 180 kg

Loading area = 1.90 m2

Floor loading = 805 kg/m2

Drilling hole depth = 130 mm

(5,1 inches)

Drilling hole diameter = 15 mm

(37/64 inches)

1 → N°1 anchor screw Bossong

2 → N°1 countersunk washer

3 → over-floor plate

Measures in mm

(*) Cable in point: cut the table cover at the predefined weakening point, in correspondence of the

plate hole.

(*)

Front

Rear

Page 57

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 57

WARNING

Be sure to have completely tightened the screws (torque value in the table below).

Reference to the critical

component on

Installation Manual

Description

Dimension

Number of

elements

According to and

material grade

Torque to apply

[Nm]

Loctite use

Nut size and washers

Embedment depth

[mm]

Material of the parent

to whitch the screw is

mounted on

Component

No

1 and 4

Anchor screw

for fixation of

the over floor

base plate

M10

8

Screw

8.8

55

No

Countersunk

Washer

115.5

Concrete

C20/25

not

cracked

The M10 screws and the washers are supplied with the system.

Remind to tight the screws/bolts using the cross rule.

Default fastening method

Page 58

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 58

Example of fastening on a 140 mm floor.

Reference to the critical

component on

Installation Manual

Description

Dimension

Number of elements

According to and

material grade

Torque to apply [Nm]

Loctite use

Nut size and washers

Embedment depth

[mm]

Material of the parent

to whitch the screw is

mounted on

Component

No

1 and 4

Anchor screw

for fixation of

the over floor

base plate

M10

8

Screw

8.8

55

No

Countersunk

Washer

90.5

Concrete

C20/25

not

cracked

The M10 screws and the washers are supplied with the system.

Remind to tight the screws/bolts using the cross rule.

The applicability verification of this example is under the responsibility of the room PMI Project

Manager Installation.

Page 59

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 59

Example of chemical fastening on a 100 mm floor.

(Example of approved chemical is Bossong BCR-300 V-Plus.)

Reference to the critical

component on

Installation Manual

Description

Dimension

Number of elements

According to and

material grade

Torque to apply [Nm]

Loctite use

Nut size and washers

Embedment de

pth

[mm]

Material of the parent

to whitch the screw is

mounted on

Component

No

1 and 4

Anchor screw

for fixation of

the over floor

base plate

M10

8

Screw

8.8

20

No

Nut M10 +

Washer

70

Concrete

C20/25

not

cracked

ANCHORAGE DIAGRAM MINIMUM THICKNESS 100 MILLIMETER MINIMUM

Screws type M10 (screws, nuts and the washers included in the shipment).

Remind to tight the screws/bolts using the cross rule.

Measure in millimeters.

NOTE: the hole must be perfectly clean.

The applicability verification of this example is under the responsibility of the room PMI Project

Manager Installation.

Not all fastening options are obtainable if customer site is in seismic / OSHPD regions. It is required

to work with regional guidelines for expectable floor thickness that is greater than the options

below to meet code.

WARNING

Install according the

screw manufacturer’s

instruction.

Page 60

Discovery RF180

Pre-Installation Manual

GE Healthcare

5793724-1EN, Rev. 6

Page 60

5.5. Table main control console

5.5.1. Packaging

The main control console is not shipped with a separate package. It is included in the Package 2,

referring to the Unpacking Procedure in the Installation Manual.

5.5.2. Dimensions

Measures in mm.

Page 61

GE Healthcare

5793724-1EN, Rev. 6

Discovery RF180

Pre-Installation Manual

Page 61

5.6. In-room secondary console (option)

5.6.1. Packaging

ITEM

LENGTH

WIDTH

HEIGHT

WEIGHT

In-room secondary console

shipping pack

130 cm

(51.2in)

47 cm

(18.5in)

50 cm

(19.7in)

50 kg

(110 lbs)

5.6.2. Dimensions

The measures are in millimeters.

Page 62