GENERAL ELECTRIC 100 AMP AUTOMATIC TRANSFER SWITCH, 200 AMP AUTOMATIC TRANSFER SWITCH User Manual

Page 1

Installation & Operator’s Manual

Not

for

Reproduction

100/200 Amp Automatic

Transfer Switch

with Service Disconnect and

Symphony™ II Power Management System

Questions?

Help is just a moment away!

Call: Transfer Switch Helpline

800-743-4115 M-F 8-5 CT

Page 2

Thank you for your purchase of this Briggs & Stratton® Power Products automatic transfer switch. This product is designed

Not

for

Reproduction

for use with specific home standby generators and may not function with generators or remote modules produced by other

manufacturers. Seek a qualified electrical professional to determine applicability of this equipment to equipment manufactured

by others. When operated and maintained according to the instructions in this manual, your system will provide many years of

dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with this system and how to

avoid them. We have made every effort to provide for a safe, streamlined and cost-effective installation. As each installation

is unique, it is impossible to know of and advise of all conceivable procedures and methods by which installation might be

achieved. We do not know all possible hazards and/or the results of each possible method or procedure. It is important that

you read and understand these instructions thoroughly before attempting to install or operate this equipment. Save these

original instructions for future reference.

This transfer switch and optional remote modules require professional installation before use. Refer to the Installation section

of this manual and the installation instructions packaged with the remote modules for instructions on installation procedures.

Only licensed electrical contractors should install transfer switches and remote modules. Installations must strictly comply with

all applicable federal, state and local codes, standards and regulations. Your installer should follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your system. Consult your Yellow Pages. There

are many authorized service dealers who provide quality service. You can also contact Technical Service by phone at

800-743-4115 between 8:00 AM and 5:00 PM CT, or click on Find a Dealer at BRIGGSandSTRATTON.COM, which provides

a list of authorized dealers.

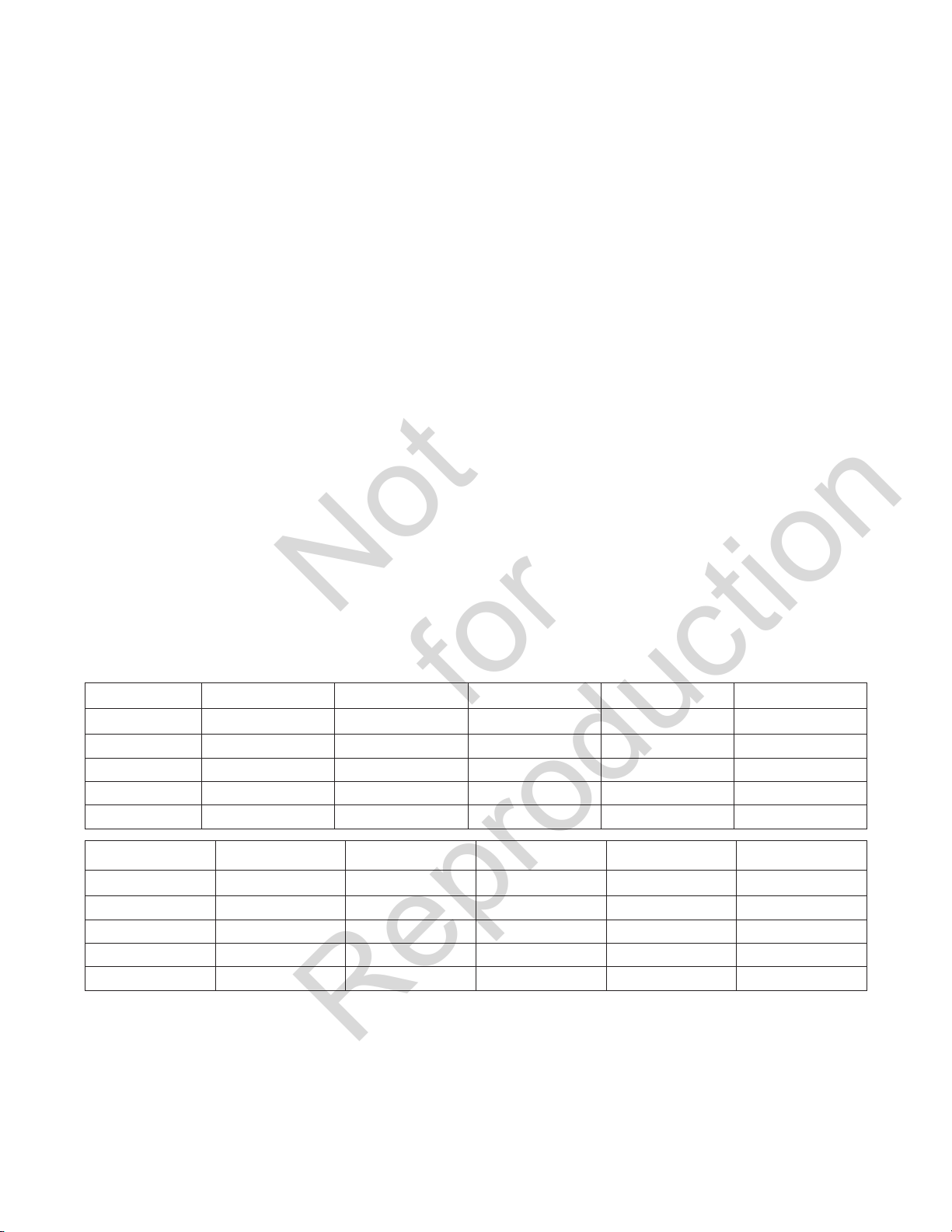

For Future Reference

Please fill out the information below and keep with your receipt to assist in unit identification for future purchase issues.

Transfer Switch Remote Module Remote Module Remote Module Remote Module

Model Number

Revision

Serial Number

Date Purchased

PRIORITY N/A

Remote Module Remote Module Remote Module Remote Module Remote Module Remote Module

Copyright © 2011. Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, USA. All rights reserved.

Briggs & Stratton Power Products is a registered

trademark of Briggs & Stratton Corporation

Milwaukee, WI, USA

2 BRIGGSandSTRATTON.COM

Page 3

Table of Contents

Not

for

Reproduction

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Home Owner Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Owner Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing Dealer/Contractor Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . 5

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Delivery Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Wiring Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Supervisory Control Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remote Module Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Testing the Automatic Transfer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Te sting the Symphony™ II Power Management System . . . . . . . . . . . . . . 14

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Symphony™ II Power Monitor (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Enclosure Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Status LED’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Remote Module LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

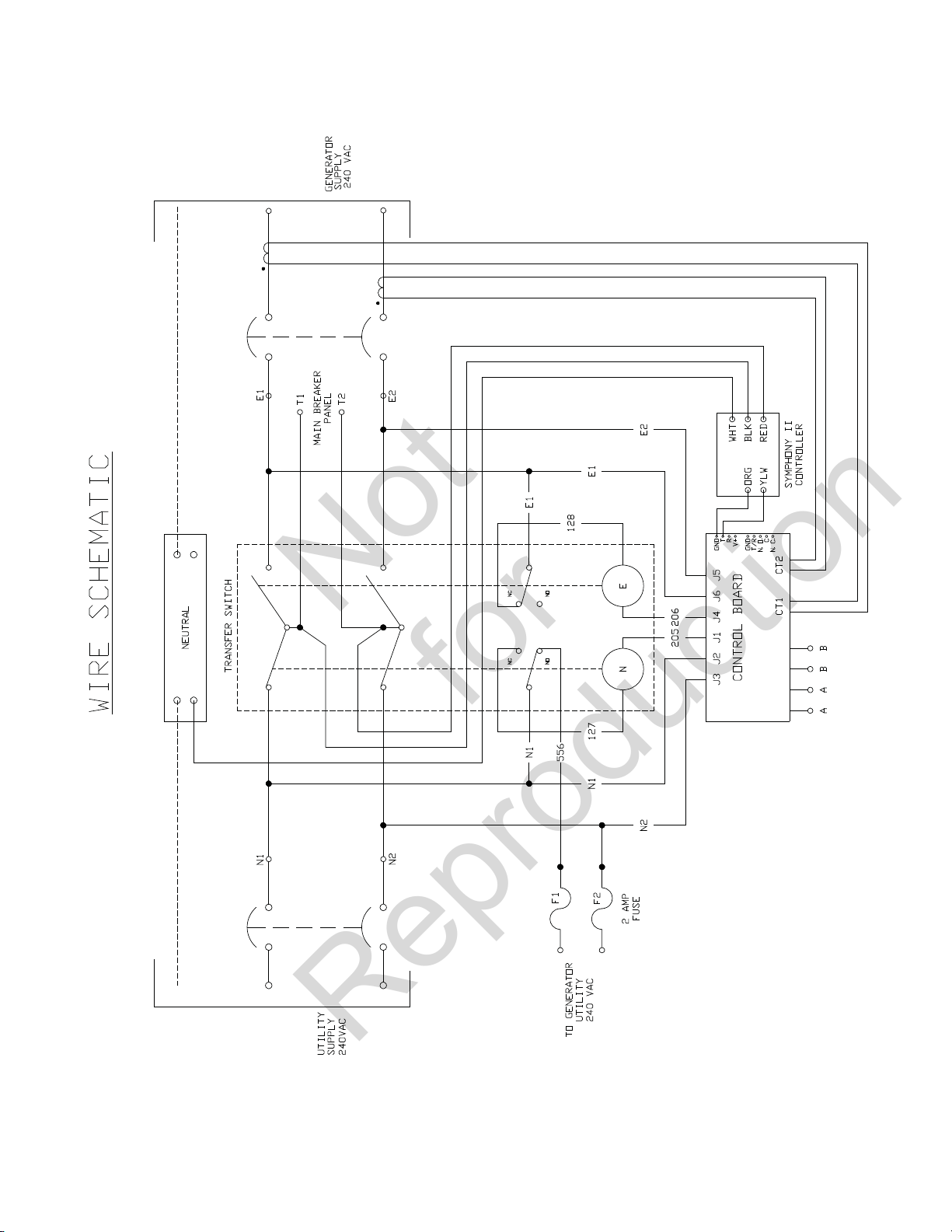

Transfer Switch Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

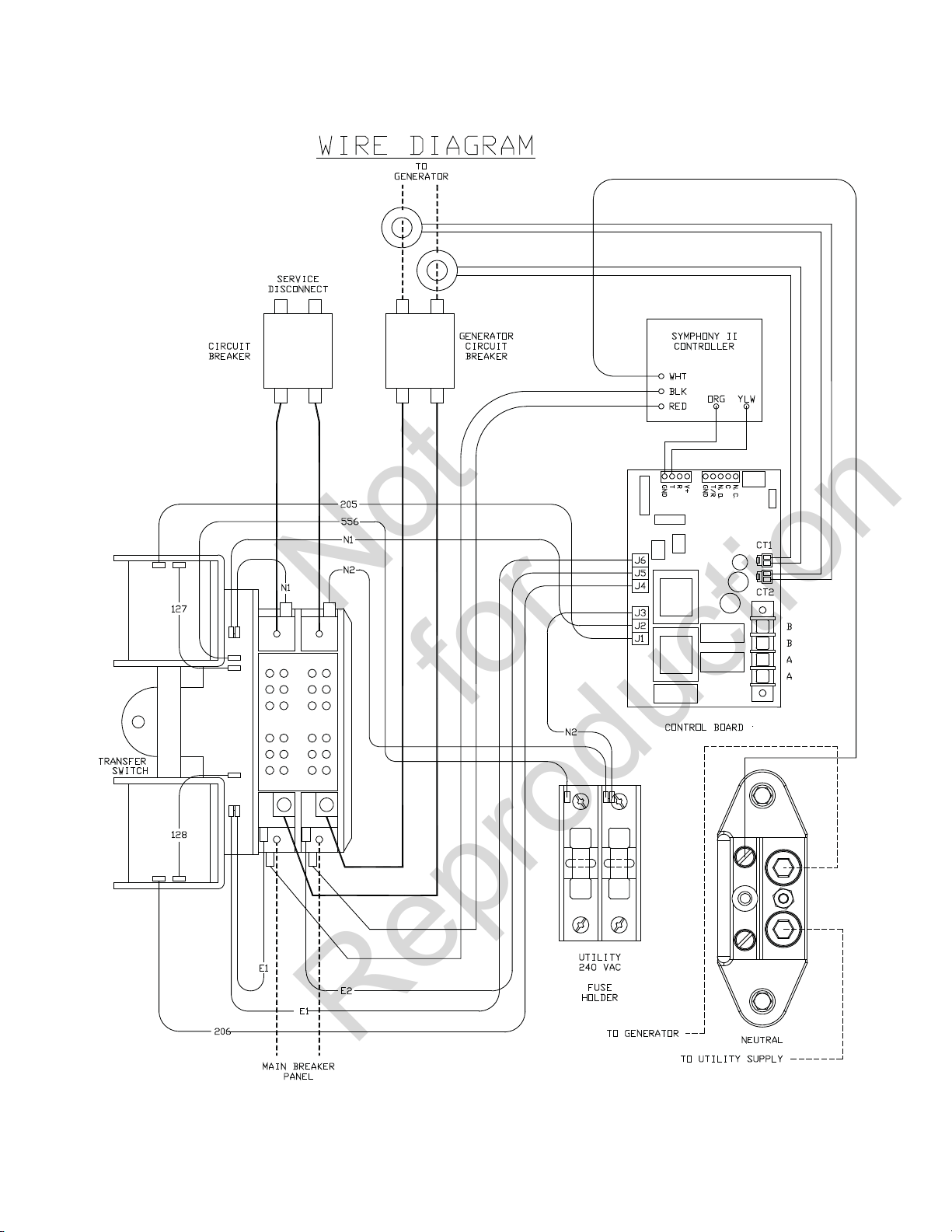

Transfer Switch Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3

Page 4

Save These Instructions

Not

for

Reproduction

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation and maintenance of the equipment.

Safety Symbols and Meanings

Electrical Shock Read Manual

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a

degree or level of hazard seriousness. A safety symbol

may be used to represent the type of hazard. The signal

word NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings in

this manual, and the tags and decals affixed to the unit are,

therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that

it is safe for you and others. You must also make sure that

the procedure, work method or operating technique that you

choose does not render the equipment unsafe.

WARNING Certain components in this product and

related accessories contain chemicals known to the

State of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after handling.

NOTICE Only qualified electricians should attempt

installation of this equipment, which must strictly comply

with applicable codes, standards and regulations.

WARNING Shock Hazard. Installing low and high

voltage wire in same conduit could result in death,

serious injury and/or property damage.

• Do not run low and high voltage wire in the same conduit

unless the insulation rating on ALL wiring is rated for

600V. See NEC for more information.

WARNING Failure to properly ground equipment

could cause electrocution resulting in death or

serious injury.

• Do not touch bare wires.

• Do not use equipment with worn, frayed, bare or

otherwise damaged wiring.

• Do not handle electrical cords while standing in water,

while barefoot, or while hands or feet are wet.

• If you must work around a unit while it is operating, stand

on an insulated dry surface to reduce shock hazard.

• Do not allow unqualified persons or children to operate or

service equipment.

• In case of an accident caused by electrical shock,

immediately shut down all sources of electrical power

and contact local authorities. Avoid direct contact with

the victim.

WARNING Equipment contains high voltage that

could cause electrocution resulting in death or

serious injury.

• Despite the safe design of the system, operating this

equipment imprudently, neglecting its maintenance or

being careless could result in death or serious injury.

NOTICE Improper treatment of equipment could damage

it and shorten its life.

• Use equipment only for intended uses.

• If you have questions about intended use, ask dealer or

contact Briggs & Stratton Power Products.

• Do not expose equipment to excessive moisture, dust,

dirt, or corrosive vapors.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• If connected devices overheat, turn them off and turn off

their circuit breaker/fuse.

4 BRIGGSandSTRATTON.COM

Page 5

Installation

Not

for

Reproduction

We sincerely appreciate your patronage and have made

significant effort to provide for a safe, streamlined and costeffective installation. Because each installation is unique, it is

impossible to know of and advise the trade of all conceivable

procedures and methods by which installation might be

achieved. Neither could we know of possible hazards and/or

the results of each method or procedure.

For these reasons, only current licensed electrical

professionals should attempt system installations.

Installations must strictly comply with all applicable

codes, industry standards and regulations.

Your equipment is supplied with this combined “Installation

and Operator’s Manual”. This is an important document and

should be retained by the owner after the installation has

been completed.

Every effort has been made to make sure that the information

in this manual is both accurate and current. However, the

manufacturer reserves the right to change, alter or otherwise

improve the system at any time without prior notice.

Home Owner Responsibilities

To help you make informed choices and communicate

effectively with your installation contractor(s), read and

understand Owner Orientation before contracting or

starting your equipment installation.

To arrange for proper installation, contact the store at which

you purchased your equipment, your dealer, or your utility

power provider.

The equipment warranty is VOID unless the system is

installed by licensed electrical professionals.

Owner Orientation

The illustrations provided are for typical circumstances and

are meant to familiarize you with the installation options

available with your system.

Local codes, appearance, and distances are the factors that

must be considered when negotiating with an installation

professional. As the distance from the existing electrical

service increases, compensation in wiring materials must be

allowed for. This is necessary to comply with local codes and

overcome electrical voltage drops.

These factors will have a direct effect on the overall

price of your equipment installation.

Your installer must check local codes AND obtain permits

before installing the system.

• Read and follow the instructions given in this manual.

• Follow a regular schedule in caring for and using your

equipment, as specified in this manual.

Installing Dealer/Contractor Responsibilities

• Read and observe the Important Safety Instructions.

• Read and follow the instructions given in this manual.

• The installer may need to provide appropriate rated

• Discuss with owner their load priority preferences to

• Check federal, state and local codes and authority

• Ensure generator is not overloaded with selected loads.

If you need more information about the transfer switch, call

800-743-4115, between 8:00 AM and 5:00 PM CT.

Equipment Description

The transfer switch is designed to transfer selected loads

found in normal residential installations to standby power in

the event of a primary power outage. The load is connected

either to utility power (normal) or home standby power

(generator). The transfer switch monitors utility and generator

voltages and will automatically connect loads to the

appropriate source of power.

The Symphony™ II Power Management System is highly

flexible and utilizes individual high and low voltage modules

that can be mounted anywhere between the home’s main

distribution panel and the managed appliance. Designed

to communicate via your home’s existing power wiring, the

power demand and priority sequence of up to 8 appliance

loads are relayed back to the standby generator, effectively

preventing generator overload while expanding power range

and performance. The system is scalable and additional

relays can be added as a homeowner’s power management

needs change over time.

Only a licensed electrician should complete a home standby

installation. Service conduit and conductors can be wired

directly from the watt-hour meter to the transfer switch. A

separate service entrance disconnect and associated wiring

is not required when installed per applicable federal, state

and local codes, standards and regulations.

Major components of the transfer switch are a 2 pole utility

disconnect circuit breaker, a 2 pole generator disconnect

circuit breaker, a 2 pole double throw transfer switch, transfer

switch control circuit board, Symphony II power management

system control circuit board, fused utility terminals and

interconnecting wiring. All of these components are housed

in a NEMA 3R enclosure that is suitable for both indoor and

outdoor installations.

The transfer switch is solenoid-operated from utility or

generator inputs and contain suitable mechanical and

electrical interlock switches to eliminate the possibility of

connecting the utility service to the generator output. It

has ratings capable of switching full utility power into the

residence. In addition, a manual override lever is provided for

the transfer function.

contactors based on loads to be controlled.

decide on remote module priority settings.

having jurisdiction, for questions on installation.

5

Page 6

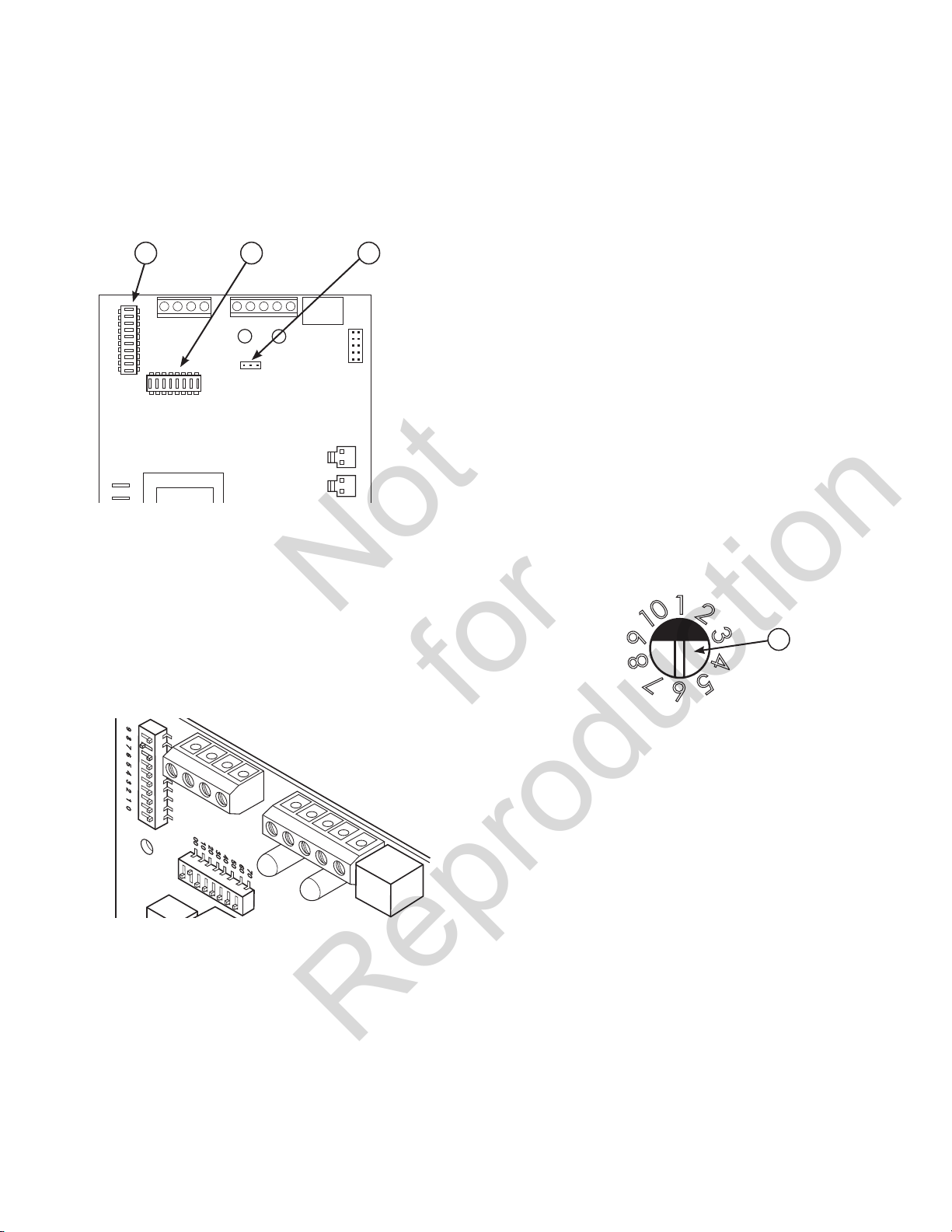

The transfer switch control board has active circuits sensing

Not

for

Reproduction

utility and generator voltages. It creates a signal for generator

start-up, switch transfer and retransfer when utility is

restored. The transfer switch control board provides status

LED’s to indicate the power source available.

The Symphony™ II power management system control

board contains a test button, a status LED and eight priority

load LED’s. It creates and sends signals to optional remote

modules, instructing them when to add (turn power on) or

shed (turn power off) the managed load.

The Symphony II system power line carrier technology has

been rigorously tested and has proven to be very robust.

However, certain types of devices and appliances in the

home generate ‘noise’ on the power line. Such devices

may include non-residential fluorescent ballasts, dimmers,

speed controls (lighting and fans), bathroom equipment,

kitchen equipment, power tools, phone chargers, and power

supplies. These types of devices have the greatest impact on

power line communication when located close to a remote

module.

AM broadcast radio, X10, power line carrier (PLC),

uninterrupted power supply (UPS), transient voltage surge

suppression (TVSS) systems, and power filter technology

may also cause the Symphony II system to not operate as

intended. They may cause interference with the Symphony II

system during standby power operation.

If it is determined that power line noise is causing a

communication issue with the Symphony II system, the

following changes may remedy the issue.

• Have commercial (non consumer use) fluorescent

ballasts replaced with residential use ballasts.

• Have a EMI/RFI filter installed in series and near the

problematic device.

• Have the remote module rewired to the opposite power

line (Line 1 or Line 2) from that of the problematic

device.

• Refer to Troubleshooting section.

The optional 50 Amp remote module is designed for control

by the Symphony II system to add or shed appliance loads

connected to it based on a user-defined priority setting.

This remote module manages 120VAC or 240VAC, single

or double pole loads up to 50 amperes. The remote

module’s relay state is normally open. Its components are

housed in a NEMA 4 enclosure suitable for indoor and

outdoor installations.

The optional low voltage remote module is designed for

control by the Symphony II system to add or shed an air

conditioner, heat pump, or low voltage contactor controlled

loads based on a user-defined priority setting. The remote

module is housed in a NEMA 4 enclosure suitable for indoor

and outdoor installations.

Delivery Inspection

After opening the carton, carefully inspect the transfer

switch components for any damage that may have occurred

during shipment.

If loss or damage is noted at time of delivery, have the

person(s) making delivery note all damage on the freight bill

and affix his signature under the consignor’s memo of loss or

damage. If loss or damage is noted after delivery, contact the

carrier for claim procedures. Missing or damaged parts are

not warranted.

Shipment contents:

• Automatic transfer switch

• Installation and operator’s manual

• Current transformers (2)

Optional components:

• 50 Amp module

• Low voltage module (single or dual models)

• Symphony™ II power monitor

To be supplied by installer:

• Connecting wire and conduit

• Various specialty tools/equipment

Mounting Guidelines

The transfer switch system circuitry is enclosed in a

NEMA Type 3R enclosure suitable for indoor/outdoor use.

Guidelines for mounting the enclosure include:

• Install enclosure on a firm, sturdy supporting structure.

• The transfer switch enclosure must be installed with

• To prevent switch contact distortion, level and plumb

• NEVER install the switch or remote modules where any

• Protect the switch at all times against excessive

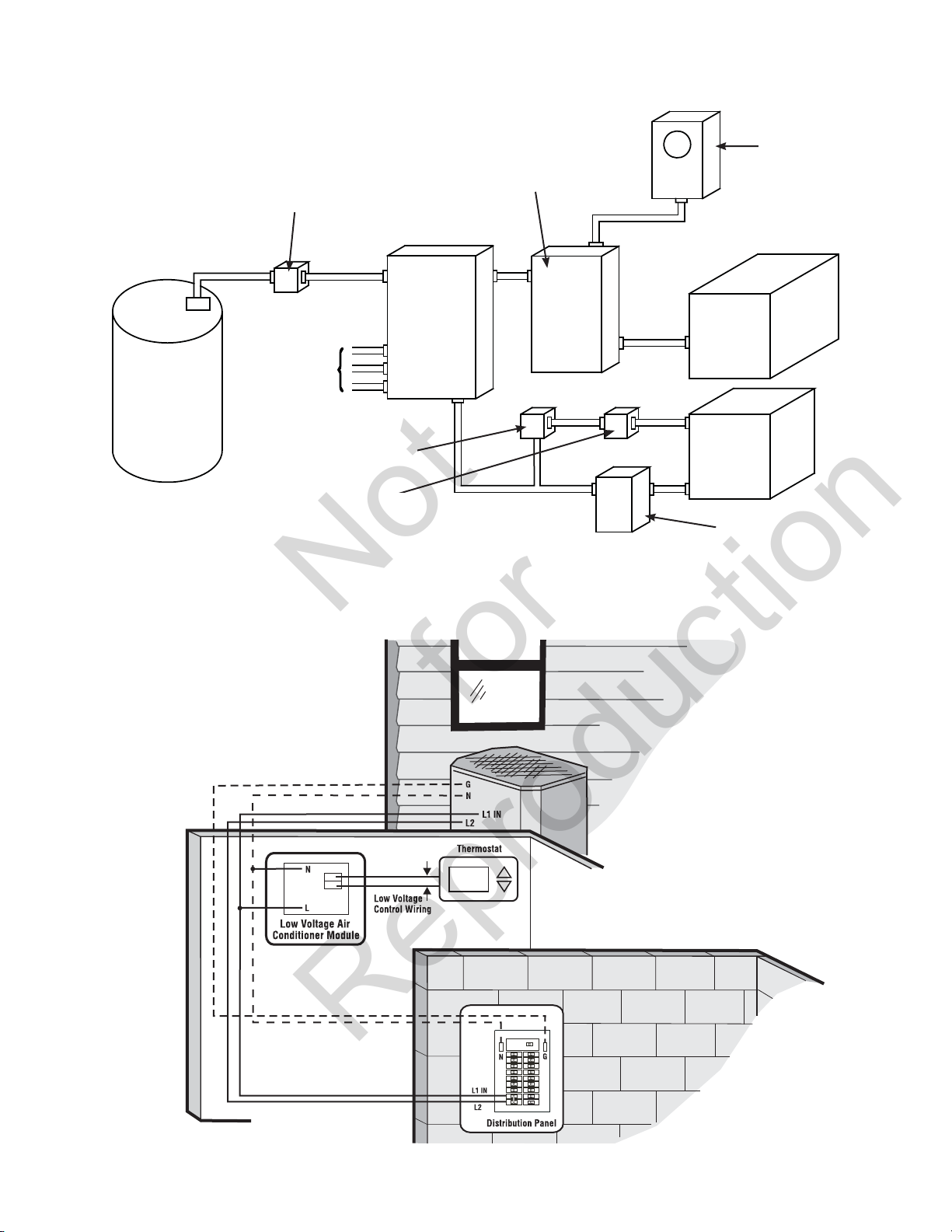

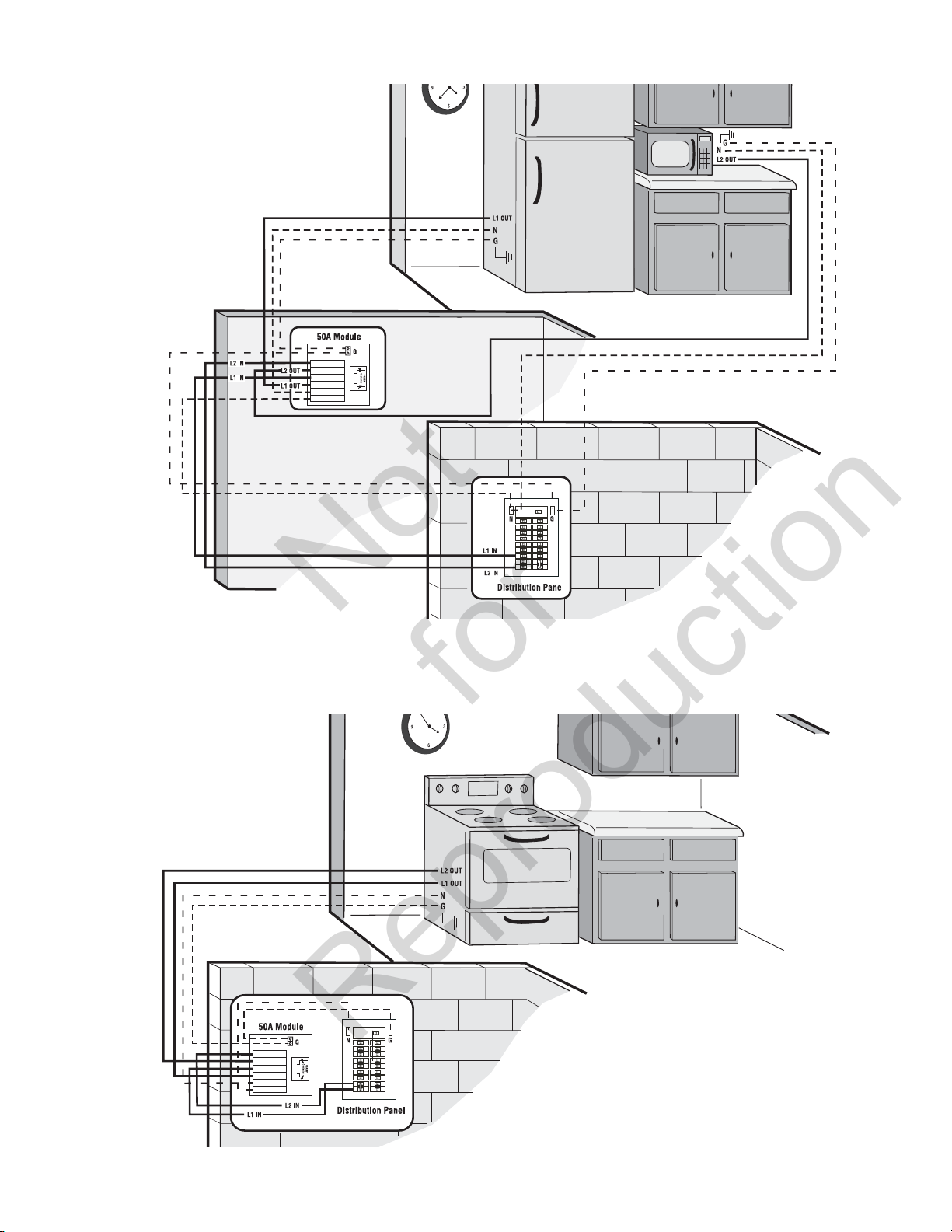

A typical automatic transfer switch installation is depicted on

the next page. Examples of remote module installations are

also shown. It is best if the transfer switch is mounted near

the utility meter, either inside or outside. The remote module

can be located anywhere between the main distribution panel

and its connected load, either inside or outside. The remote

module must be accessible for service. Discuss layout

suggestions/ changes with the owner before beginning the

system installation process.

minimum NEMA 3R hardware for conduit connections.

the enclosure. This can be done by placing washers

between the enclosure and the mounting surface.

corrosive substance might drip onto the enclosure.

moisture, dust, dirt, lint, construction grit and

corrosive vapors.

6 BRIGGSandSTRATTON.COM

Page 7

Hot Water

Not

for

Reproduction

Heater

Optional

50A Remote

Module

Branch

Circuits

Main

Distribution

Panel

Transfer Switch

w/ Service

Disconnect

and Symphony

System

Watt -

Hourmeter

Generator

Example of 240VAC air

conditioner load controlled by

thermostat. Thermostat controlled

by low voltage remote module.

Optional

LV Remote

Module

A/C

Thermostat

Air

Conditioner

Service Disconnect

7

Page 8

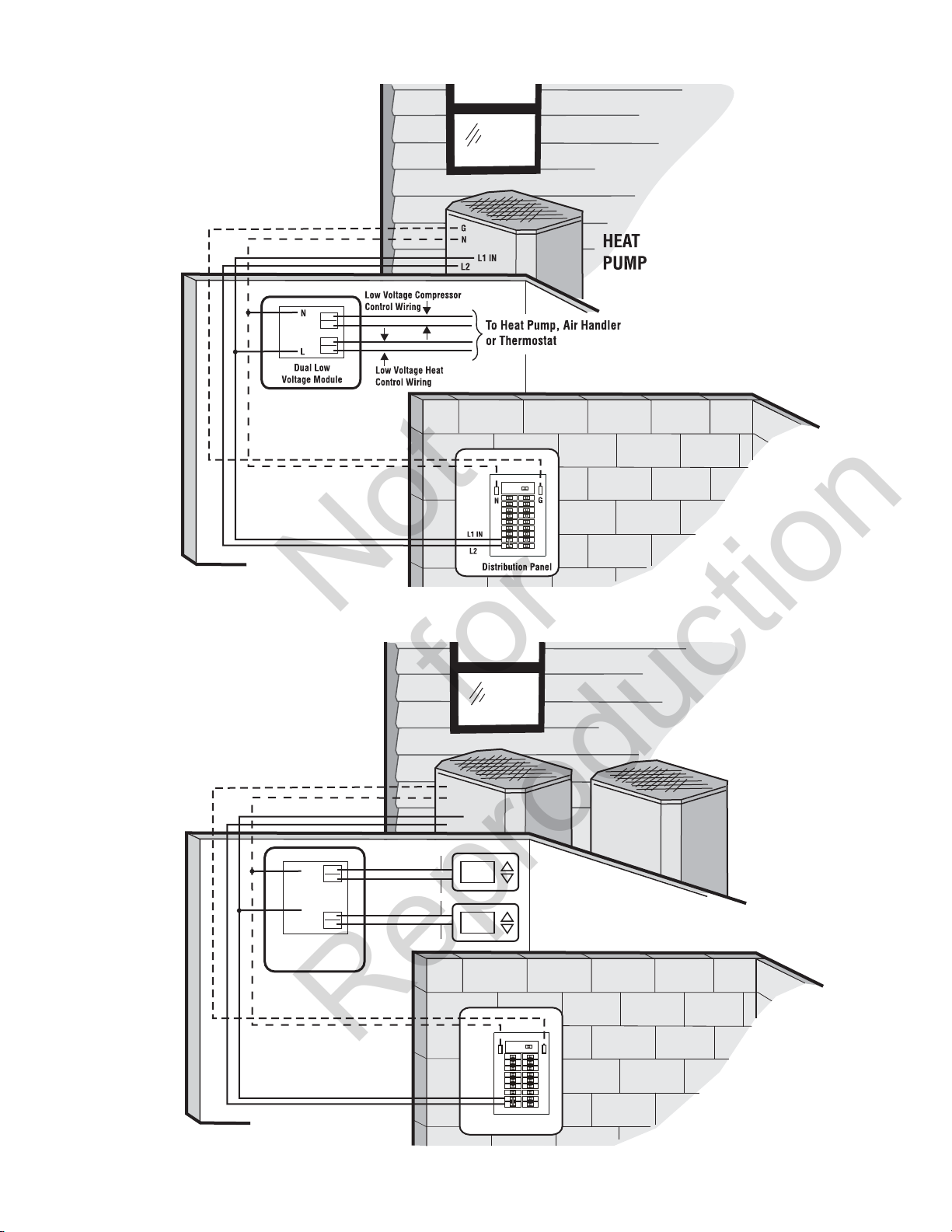

Example of 240VAC heat pump

Not

for

Reproduction

load controlled by a dual low

voltage remote module.

Example of two 240VAC air

conditioner loads controlled by

thermostat. Thermostats controlled

by dual low voltage remote module.

N

L

Dual Low

Voltage Module

Low Voltage

Control Wiring

G

N

L1 IN

L2

Thermostat

#1

#2

L1 IN

L2

Distribution Panel

#1

N

#2

G

8 BRIGGSandSTRATTON.COM

Page 9

Example of two 120VAC loads

Not

for

Reproduction

controlled by 50 Amp remote

module.

L2 IN

L2 OUT

L1 IN

L1 OUT

Neutral IN

Neutral OUT

Example of one 240VAC load

controlled by 50 Amp remote

module.

L2 IN

L2 OUT

L1 IN

L1 OUT

Neutral IN

Neutral OUT

9

Page 10

Power Wiring Interconnections

Not

for

Reproduction

NOTICE Improper installation could cause damage to the

circuit boards and shorten their life. Installing circuit boards

in live circuits will damage the board and is not covered by

warranty. ALWAYS disconnect ALL sources of power prior

to servicing.

• Remove all power prior to installing this equipment. Failure

to do so could cause internal damage to the board when

making electrical connections.

• Turn generator to OFF position.

• Turn off utility power to the standby generator and

transfer switch.

All wiring must be the proper gauge, properly supported

and protected by conduit. All wiring should be done per

applicable federal, state and local codes, standards and

regulations. Obey wire type and torque specifications printed

on the terminal blocks, neutral/ground connectors, and

installation instructions.

WARNING Shock Hazard. Installing low and high

voltage wire in same conduit could result in death,

serious injury and/or property damage.

• Do not run low and high voltage wire in the same conduit

unless the insulation rating on ALL wiring is rated for

600V. See NEC for more information.

Use installer supplied 300VAC or greater copper wire of a

gauge that complies with the latest version of the National

Electric Code to complete the following connections between

utility power, transfer switch, generator, main distribution

panel, and optional remote modules. Apply the necessary

correction factors and wire size calculations.

1. Set generator’s circuit breaker to OFF (open) position.

2. Set generator’s system switch to OFF position.

3. Remove 15 Amp fuse from generator control panel.

4. Turn off utility power to the standby generator and

transfer switch.

5. Connect utility service to transfer switch’s utility

service disconnect circuit breaker terminals marked

“UTILITY CONNECTION”.

6. Connect utility service neutral to transfer switch

neutral terminal.

7. Connect main distribution panel feeder

conductors to transfer switch terminals marked

“LOAD CONNECTION”.

8. NOTICE Connect main distribution panel neutral to

transfer switch neutral terminal.

9. Connect main distribution panel ground to transfer

Assure grounding electrode conductor is connected

10. Connect feeder conductors from transfer switch

11. Plug current transformer leads into “CT1” and “CT2”

switch “GND” terminal.

44

Generator

0

Ground

Ground

and bonded per applicable federal, state and local

codes, standards and regulations.

breaker “GENERATOR CONNECTION” terminals to

generator circuit breaker LINE1 and LINE2 terminals.

Each conductor must pass through hole of current

transformer before making connection.

terminals (C) on transfer switch control board.

Circuit

Breaker

Line 1 Neutral

To Transfer Switch

11

22

Neutral

Line 2

C

10 BRIGGSandSTRATTON.COM

Page 11

12. Connect conductor from transfer switch neutral terminal

Not

for

Reproduction

to generator NEUTRAL terminal. Observe generator

control panel labeling for terminal identification.

13. Connect conductor from transfer switch “GND” terminal

to generator control panel “GROUND” terminal.

Assure generator equipment grounding conductor is

connected per applicable federal, state and local codes,

standards and regulations.

14. Using minimum #14 AWG conductors, connect

the transfer switch “UTILITY 240 VAC” terminals to

generator’s “240 VAC” terminals via two-pole connector

supplied with generator.

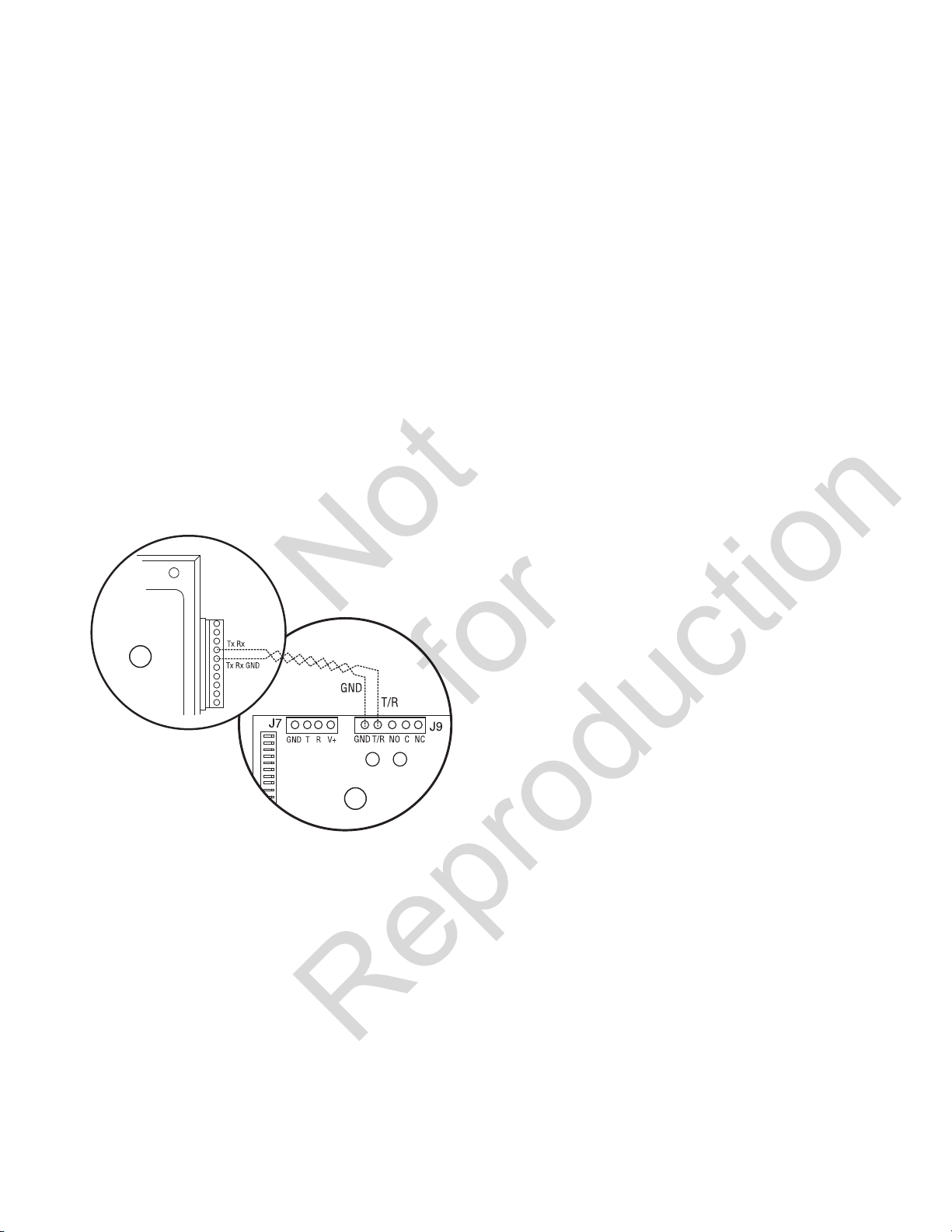

NOTICE TxRx and TxRx GND communication wiring

must be connected for the Synphony II System to operate

properly.

15. Using #18 AWG twisted pair copper conductors, no

greater than 200 ft. in length, 300 volt 75°C-90°C,

connect “T/R” and “GND” terminals on transfer switch

control board (B) to the generator’s control panel (A)

“TxRx” and “TxRx GND” terminals via ten pin connector

supplied with generator. Count down to the proper pin

location on the generator control board since visual

alignment with its decal can be misleading:

A

B

Supervisory Control Terminals

To avoid undesirable operation, we recommend loads be

managed only with low voltage or 50 Amp remote modules.

Do not use the transfer switch control board supervisory

control terminals (if present).

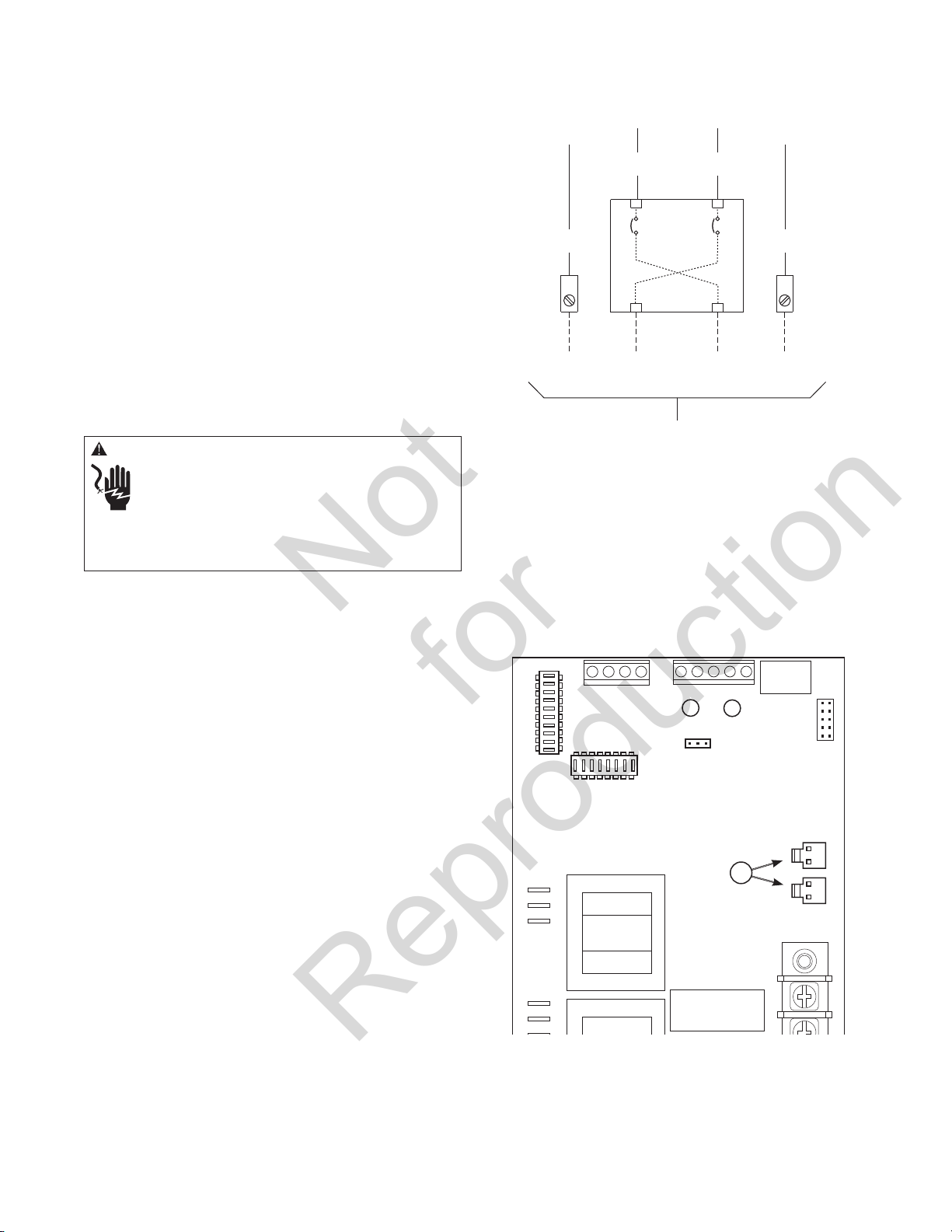

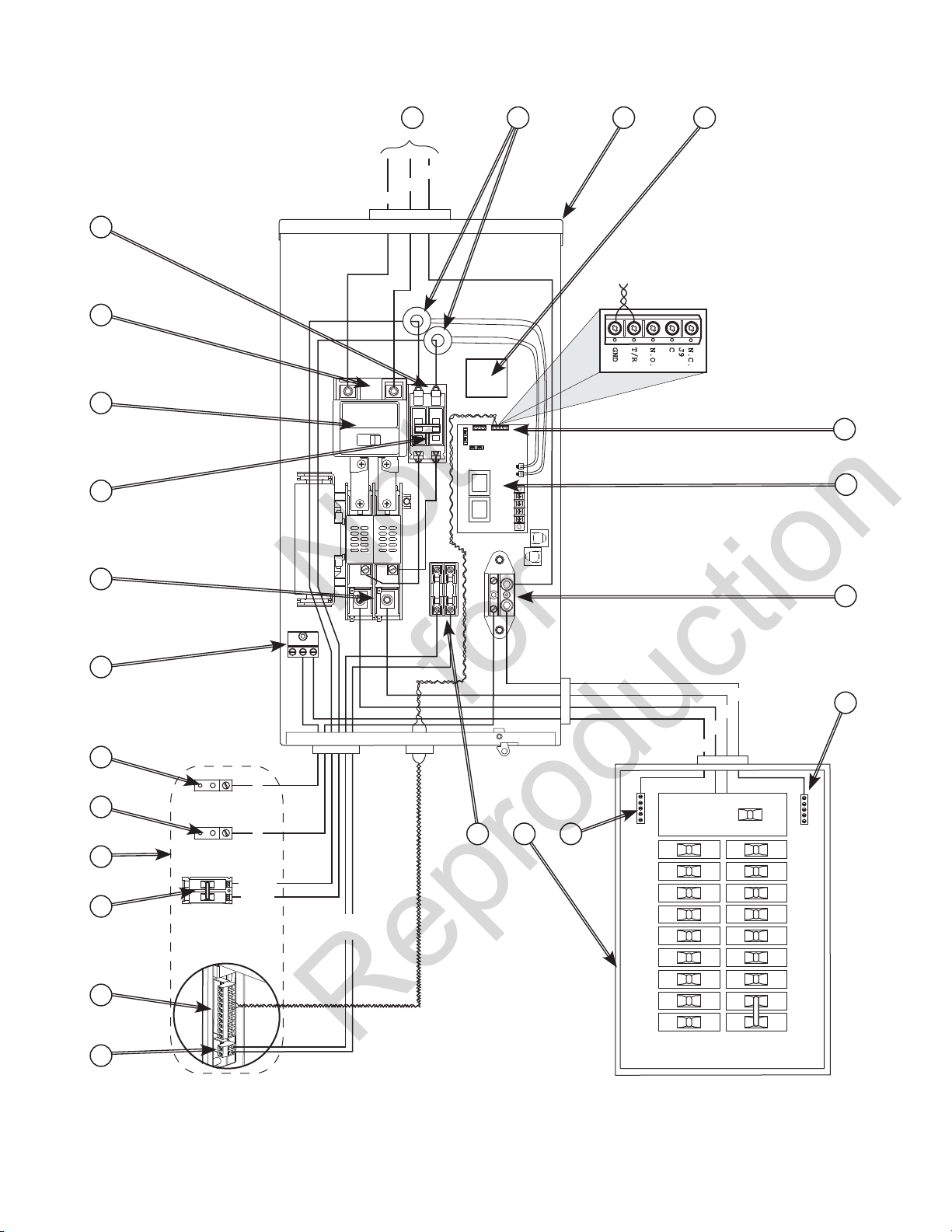

The illustration on the following page shows a completed

transfer switch installation. Your actual layout will vary.

Illustration callouts are:

A - From utility watt-hour meter

B - Current transformers

C - Transfer switch

D - Symphony™ II system control board

E - T/R and GND to Generator

F - Transfer switch control board

G - Neutral terminal

H - Neutral bus

J - Ground bus

K - Main distribution panel

L - UTILITY 240VAC to Generator

M - Two pin connector

N - Ten pin connector

P - Generator circuit breaker

R - Generator

S - Generator Neutral terminal

T - Generator Ground terminal

U - Transfer switch ground terminal

V - Load connection to distribution panel

W - Generator disconnect circuit breaker

X - Utility disconnect circuit breaker

Y - Utility connection

Z - Generator connection

16. Install optional remote modules using the installation

instructions provided with each module. Set each

module to the agreed-upon priority setting.

17. Tighten all wire connections/fasteners to proper torque.

See label inside transfer switch enclosure or values

listed in remote module installation instructions for

proper torque values.

11

Page 12

A D

Not

for

Reproduction

N

L2

L1

Z

Y

X

B

C

E

W

R

F

V

G

U

N

L2

L1

T

G

S

N

LINE1

P

LINE2

K

L

240

VAC

J

G

H

N

M

Typical Transfer Switch shown

12 BRIGGSandSTRATTON.COM

Page 13

System Setup

Not

for

Reproduction

You must perform the following before operating the system:

• If generator is installed in an area regularly subjected

to temperatures below 40°F (4°C), select a 50 second

warm up time by moving jumper JP2 (C) installed

on transfer switch control board from ‘20’ position to

‘50’ position.

B

• Set the DPSW1 (A) and DPSW2 (B) dipswitches on

the transfer switch control board to match the kW

rating of the home standby generator, as described in

Setting Dipswitches.

Setting Dipswitches

Dipswitches are used to adjust control board operation

based on generator capacity. DPSW1 and DPSW2 switches

are set to correspond to total system kW rating. Dipswitch

DPSW1 (A) has units of 1,000 watts; Dipswitch DPSW2 (B)

has units of 10,000 watts.

CA

NOTICE Use extreme caution when setting dipswitches or

damage to control board will result.

• Use a pencil or small piece of plastic to set the dipswitch.

• NEVER use a screwdriver or any type of metal object to

set dipswitches.

The “On” position for the dipswitches is the switch number ON

THE TRANSFER SWITCH CONTROL BOARD, not on the

switch. For example, for an 18,000 watt generator, set DPSW2

dipswitch 10 to “On” position. Set DPSW1 dipswitch 8 to “On”

position. 10,000 plus 8000 equals 18,000 watts.

switch to “On” position on DPSW1 and DPSW2.

NOTICE

less available engine power. Specifically, engine power will

decrease 3.5% for each 1,000 feet (300 meters) above sea

level and 1% for each 10° F (5.6°C) above 77°F (25°C).

Generators located in these conditions must have the transfer

switch programmed appropriately for this power decrease.

Remote Module Setup

Each remote module features a priority selector (D) that

permits control of load-add or load-shed sequence. Priority

number is identified on clear protective barrier. Diagrams of

each module are shown in Status LED’s, later in this manual.

Priority 1 is the highest priority - devices set to this priority

will be the first load(s) added or last load(s) shed in a load

management situation. Priority 8 is the lowest priority.

Priority 9 and 10 are lockouts. Remote module(s) set to

these priorities will remain unpowered during any utility

power outage. An unlimited amount of remote modules can

be assigned to priority 9 or 10.

In consultation with the homeowner, set each remote

module’s priority selector switch to the desired priority

position. Assign a different priority to each remote module for

optimum operation.

Air density is less at high altitudes, resulting in

Set only one

D

13

Page 14

Testing the Automatic Transfer Switch

Not

for

Reproduction

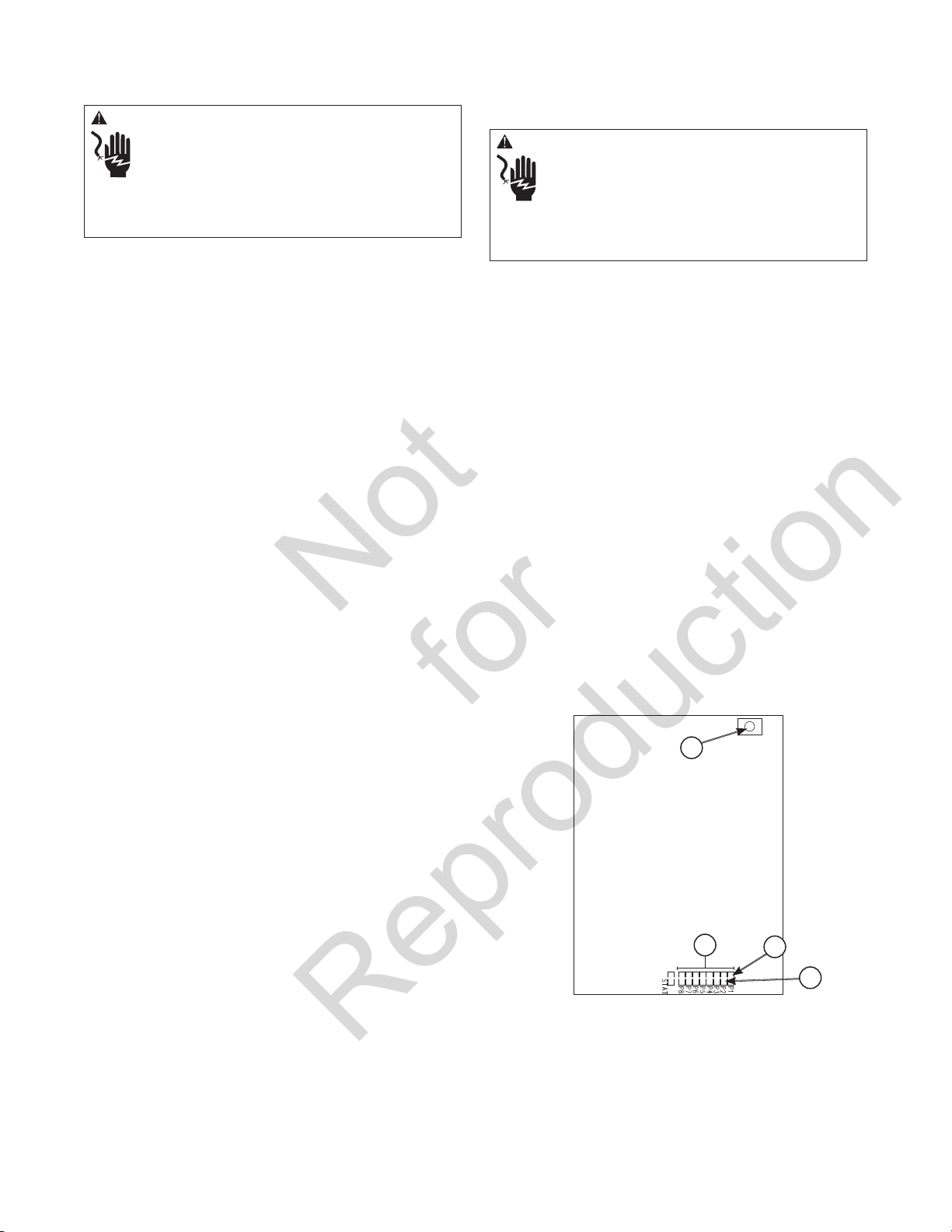

WARNING Testing must only be performed by

qualified personnel. Equipment contains high

voltage that can cause personal injury or death.

• Despite the safe design of the system, operating this

equipment imprudently, neglecting its maintenance or

being careless can cause possible injury or death.

Turn the utility service disconnect circuit breaker feeding the

transfer switch contactor to the “OFF” position. The system’s

automatic sequence described below will initiate. To return to

utility power, turn the utility service disconnect circuit breaker

to the “ON” position.

Utility Fail

The generator senses when utility voltage is below

70 percent of nominal. Engine start sequence is initiated after

6 second time delay.

Engine Warm-Up

Time delay to allow for engine warm-up before transfer. Use

jumper on transfer switch control board to select delay of

20 seconds or 50 seconds.

Transfer

Transfer from utility to generator supply occurs after voltage

is above set levels. The transfer switch control board LED

lights will change from green (utility) to red (generator)

and the Symphony II status light will change blink status

from Blink Blink_Pause_Blink Blink to Blink_Pause_Blink.

Minimum engine run time is 5 minutes after transfer.

Load Management

Five minutes after transfer to generator power, the remote

modules energize connected load(s) if generator power is

available, starting with the highest priority (1) through the

lowest priority (8). There is a 10 second delay between each

sequential activation.

The P1 through P8 LED’s (A) on the Symphony II control

board will illuminate to show loads being added.

Loads connected to remote modules set to priorities 9 and

10 remain off for the duration of a utility power outage.

Te sting the Symphony™ II Power

• Despite the safe design of the system, operating this

The Symphony II system can be tested under either utility

power or generator power. Only one priority LED and

associated remote module will be powered (ON) at a time

during test mode.

• If TEST is not pressed again within 4 minutes AND

• If TEST is not pressed again within 4 minutes AND

The test procedure in generator mode is as follows:

1. Turn the utility service disconnect circuit breaker

2. After transfer to generator power, verify communication

3. Press the TEST button (B) on the Symphony II system

Management System

WARNING Testing must only be performed by

qualified personnel. Equipment contains high

voltage that can cause personal injury or death.

equipment imprudently, neglecting its maintenance or

being careless can cause possible injury or death.

testing is being done under utility power, all managed

loads will resume operation under utility power after a

five minute delay.

testing is being done under generator power, managed

loads will be added in the priority order set for

each load.

feeding the transfer switch contactor to the

“OFF” position.

LED is green on each remote module.

control board. The Symphony II system control board

priority 1 LED (C) and load connected to remote

module set to priority 1 will turn ON.

B

Utility Pickup

Voltage pickup level is 80 percent of nominal voltage.

A

Retransfer

Retransfer from generator to utility power is approximately 10

seconds after utility voltage supply is above pickup level and

minimum run time is completed. All remote module(s) will

remain OFF for five minutes after the power transfer.

Engine Cool Down

Engine will run for 60 seconds after retransfer.

14 BRIGGSandSTRATTON.COM

LED

LED

LED

LED

LED

LED

LED

LED

C

LED

D

Page 15

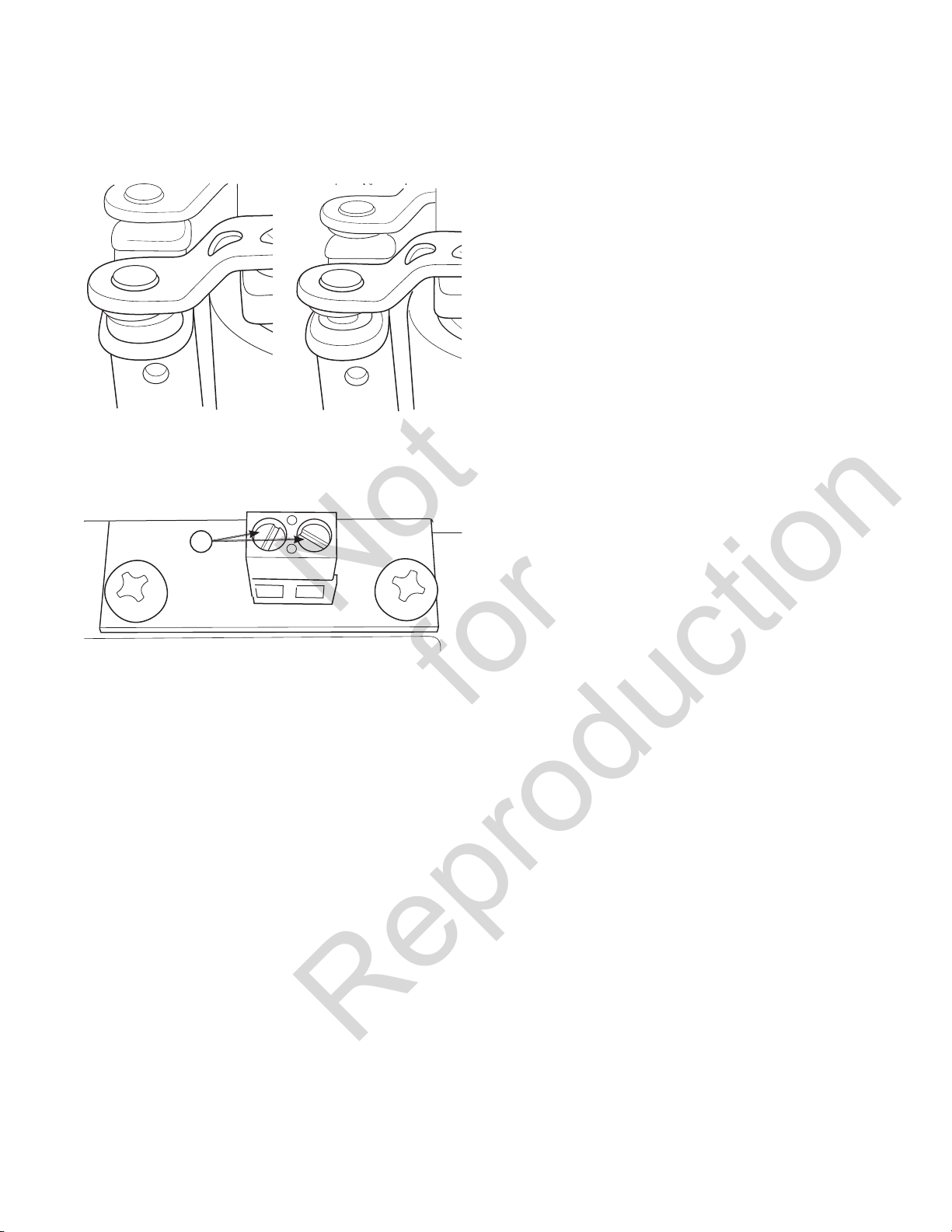

4. Verify signal was received by remote module set to

Not

for

Reproduction

priority one. Follow the test guidelines for each module:

50 Amp Module: Relay contacts will be closed. Relay

and communication LED’s will be green. Appliance/load

will have power.

Closed Open

Low Voltage Module (Single or Dual): Verify

continuity across low voltage control wiring contacts

(A). Communication LED will be green. Appliance/load

will have power.

5. Press the TEST button on the Symphony II system

control board. The priority 1 LED and load connected to

remote module set to priority 1 will turn OFF.

50 Amp Module: If off, relay LED status is off.

Communication LED status is green.

Low Voltage Module (Single or Dual): If off, low

voltage communication LED status is green. Continuity

will not be measured across low voltage contacts.

The priority 2 LED (D) and load connected to remote

module set to priority 2 will turn ON. Repeat step 4 for

each priority number being managed.

6. Each subsequent press of the TEST button cycles to

the next lower priority, through priority 8. After priority

8, press TEST button one time to exit test mode.

The system will reset and be ready to add loads in 5

minutes.

7. To return to utility power, turn the utility disconnect

circuit breaker to the “ON” position. All managed loads

will be turned off and turn back on after 5 minutes.

A

15

Page 16

Controls

Not

for

Reproduction

Other than a Manual Override lever, there are no operator

controls because this is an automatic transfer switch. The

manual override is to be used only by licensed professionals.

Information on handle use can be obtained by calling

Technical Service at 800-743-4115.

Operation

To select automatic transfer operation, do the following:

1. In transfer switch, set utility disconnect circuit breaker to

“ON” position.

2. In transfer switch, set generator disconnect circuit

breaker to “ON” position.

3. Install 15 Amp fuse in generator’s control panel.

4. Set generator’s circuit breaker to “ON” position.

5. Set generator’s system switch to “AUTO” position.

The system will now be in automatic operation mode.

When the generator is providing power to the transfer switch,

the transfer switch control board is constantly monitoring

generator power and communicating with the Symphony II

system control board.

The Symphony II system will control up to 8 priorities, with

priority 9 and 10 as lockouts. When total generator load

meets a preset value, the Symphony II system control board

will start shedding loads, starting with the lowest priority

(highest number) load. The Symphony II system will add or

shed managed loads based on the generator output capacity

and priority settings.

The Symphony II system waits 10 seconds between adding

or shedding each load to permit the system to stabilize. If

too much load demand is seen, the Symphony II system will

shed all managed loads quickly to prevent the generator

from overloading. Once the load demand has stabilized,

the Symphony II system will re-load the generator after a

5 minute delay, as described above.

There is a minimum five minute delay between the time

utility power is lost and priority 1 loads are energized by the

Symphony II system.

Be aware that managed heating element energy loads

(such as electric range burners, oven, or space heaters)

that were ON when utility power was lost, will be ON when

the generator begins supplying power. It is advised that the

owner check all such managed devices to ensure they are

turned OFF before generator power appears.

Managed devices like clothes dryers that require pressing a

START button will not resume operation unless the START

button is pressed after generator power begins.

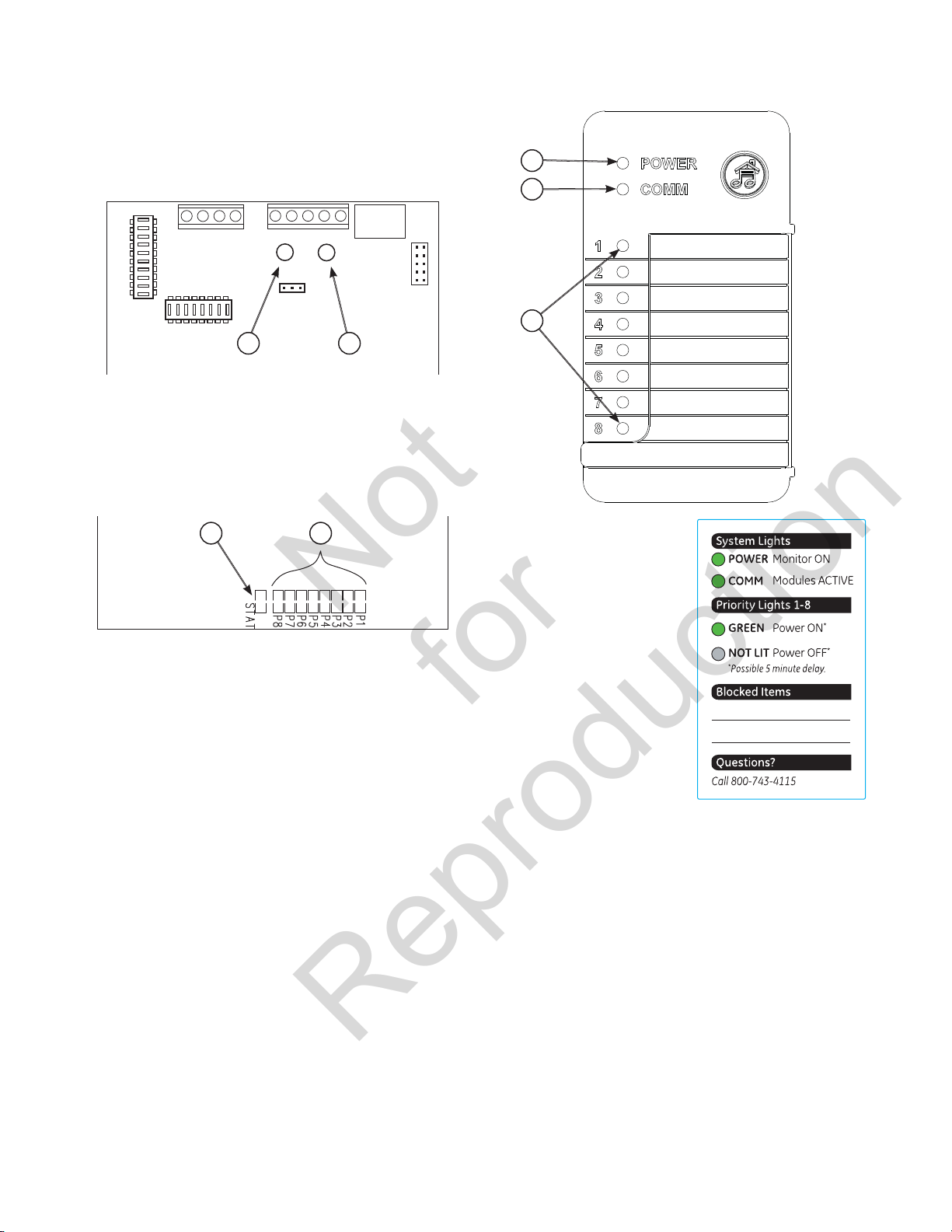

Symphony™ II Power Monitor (Optional)

For your convenience, a Symphony II Power Monitor is

available, which provides a visual “on/off” status of each

managed appliance/load. A series of LED lights are ON

when an appliance has generator power and OFF when the

appliance is in a shed mode or does not have power. When

on generator power, the consumer can see which appliances

are being managed.

A decal is provided that can be labeled with the managed

appliances/loads and placed next to each priority LED.

The monitor is plugged into any convenient standard outlet

within the home and constantly receives system status via

the power line communication technology utilized by the

Symphony II Power Management System during generator

power.

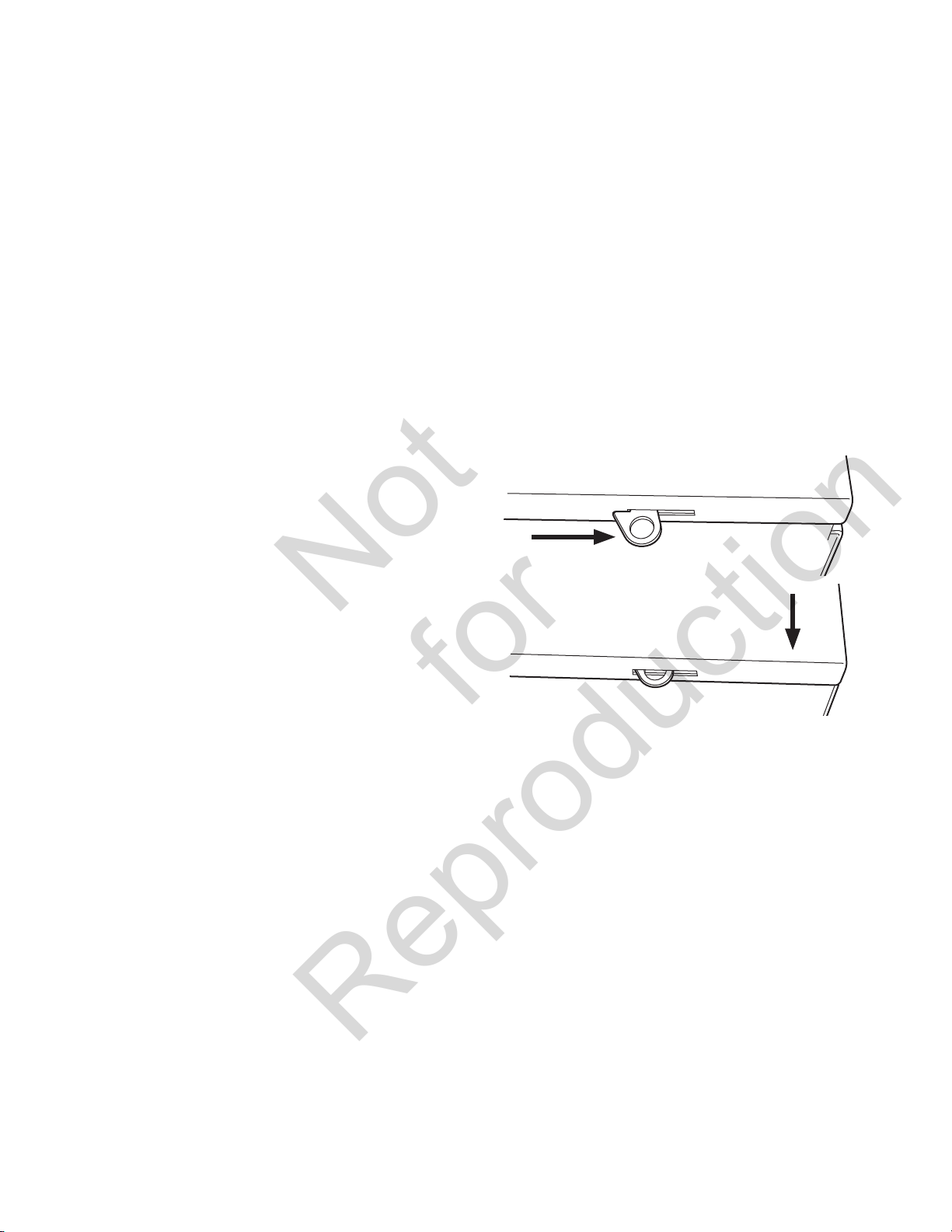

Enclosure Door

To open transfer switch door, press the spring-load door lock

to the right and pull down on the door.

To close and latch door, push door closed against enclosure.

While in this position, push door upwards. This will cause

spring-load door lock to engage and latch door in place.

Enclosure door MUST be closed and latched at all times

except when system is being serviced.

16 BRIGGSandSTRATTON.COM

Page 17

Status LED’s

Not

for

Reproduction

Described below are the system’s LED indicators and the

conditions each LED color represents:

Symphony II Power Monitor (Optional)

Transfer Switch Control Board

A

STATUS LED

RED (A) means GENERATOR power is present.

GREEN (B) means UTILITY power is present.

Symphony II System Control Board

C

LED

LED

LED

B

D

LED

LED

LED

LED

LED

LED

E

F

G

POWER LIGHT (E)

When lit, indicates that monitor

detects outlet power.

When not lit, indicates that no

power is present at outlet.

STATUS LED (C)

Single Blink-Pause means unit is operating on

GENERATOR power.

Double Blink–Pause means unit is operating on

UTILITY power.

PRIORITY LIGHTS/LED’s (D & G)

When green LED is lit, indicates that optional remote module

set to that priority is supplying power to connected load

during generator power.

When not lit, indicates that optional remote module set to

that priority is set to OFF (being managed and Symphony II

System is not allowing power to the unit).

All lights/LED’s are OFF when utility power is present.

COMM (communication

status) LIGHT (F)

When lit, indicates that unit

is receiving signals from the

Symphony II controller.

When not lit, indicates that

utility power is present or a

fault in Symphony II controller.

312113

17

Page 18

Remote Module LED Status Indicators

Not

for

Reproduction

Symphony II System does not communicate or manage

appliances/loads when utility power is present.

NOTICE When looking at LED’s, make sure you look

straight on and not at an angle.

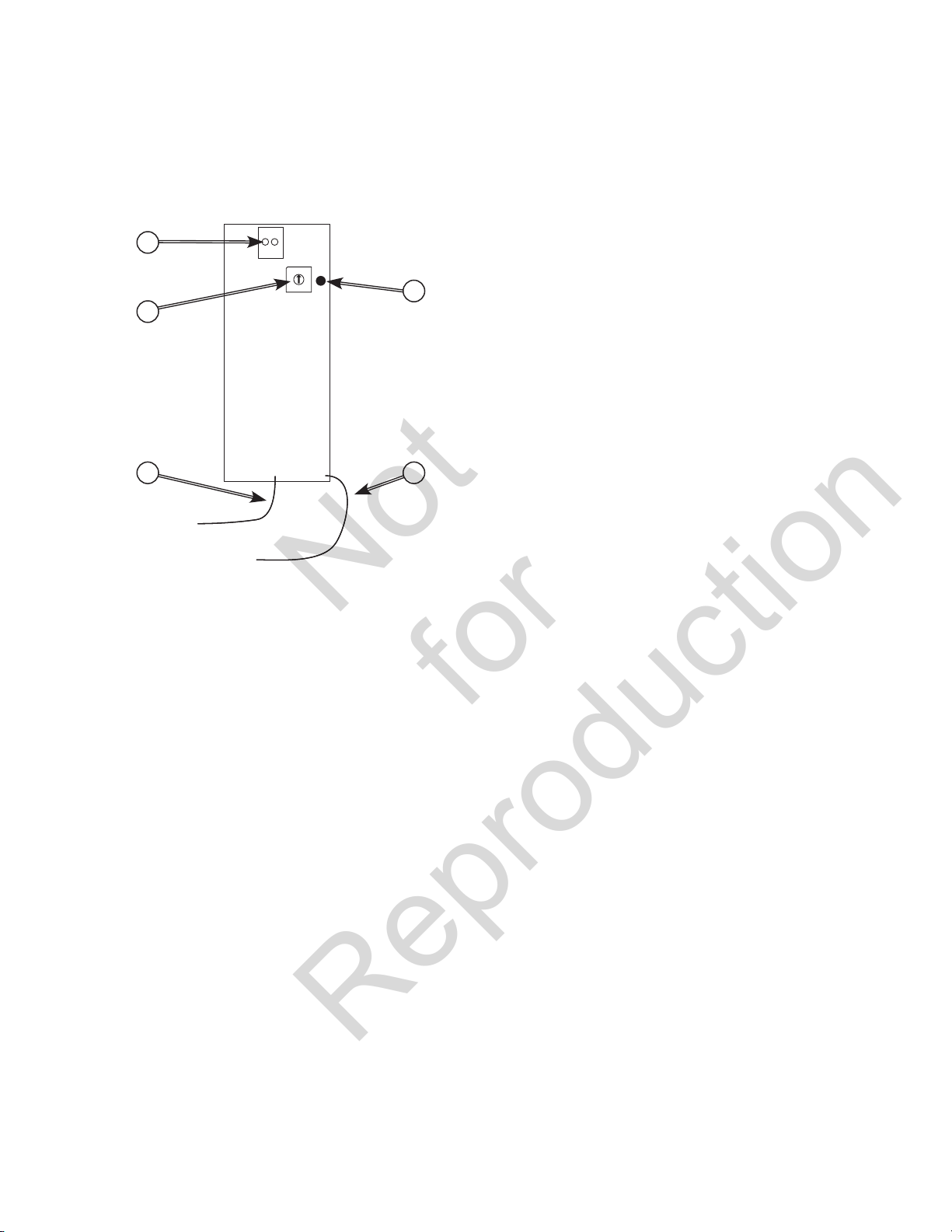

Low Voltage (Single and Dual) Models

A

C

B

DE

A - Low Voltage Control Wiring Terminal Contacts

B - Priority Selector

C - Communication LED

D - Neutral Connection

E - Power/Line Connection

LED is for signal communication status (C).

Utility power present:

• Normal State

- Orange LED - No communication and appliances/

loads cannot be managed by Symphony II System

• Problem State (see Troubleshooting)

- No LED - No power to low voltage control board;

verify correct wiring

- Green LED - Broken LED; replace low voltage

module

- Red LED - Fault in system; verify current

transformer connections, verify terminations on

orange and yellow communication wires

Generator power present:

• Normal State

- Green LED - Signal communication detected and

appliances/loads can be managed after 5 minute

delay

• Problem State (see Troubleshooting)

- No LED - No power to low voltage control board;

verify correct wiring

- Orange LED - Signal communication not detected;

verify correct wiring

- Red LED - Fault in system; verify current

transformer connections, verify terminations on

orange and yellow communication wires

18 BRIGGSandSTRATTON.COM

Page 19

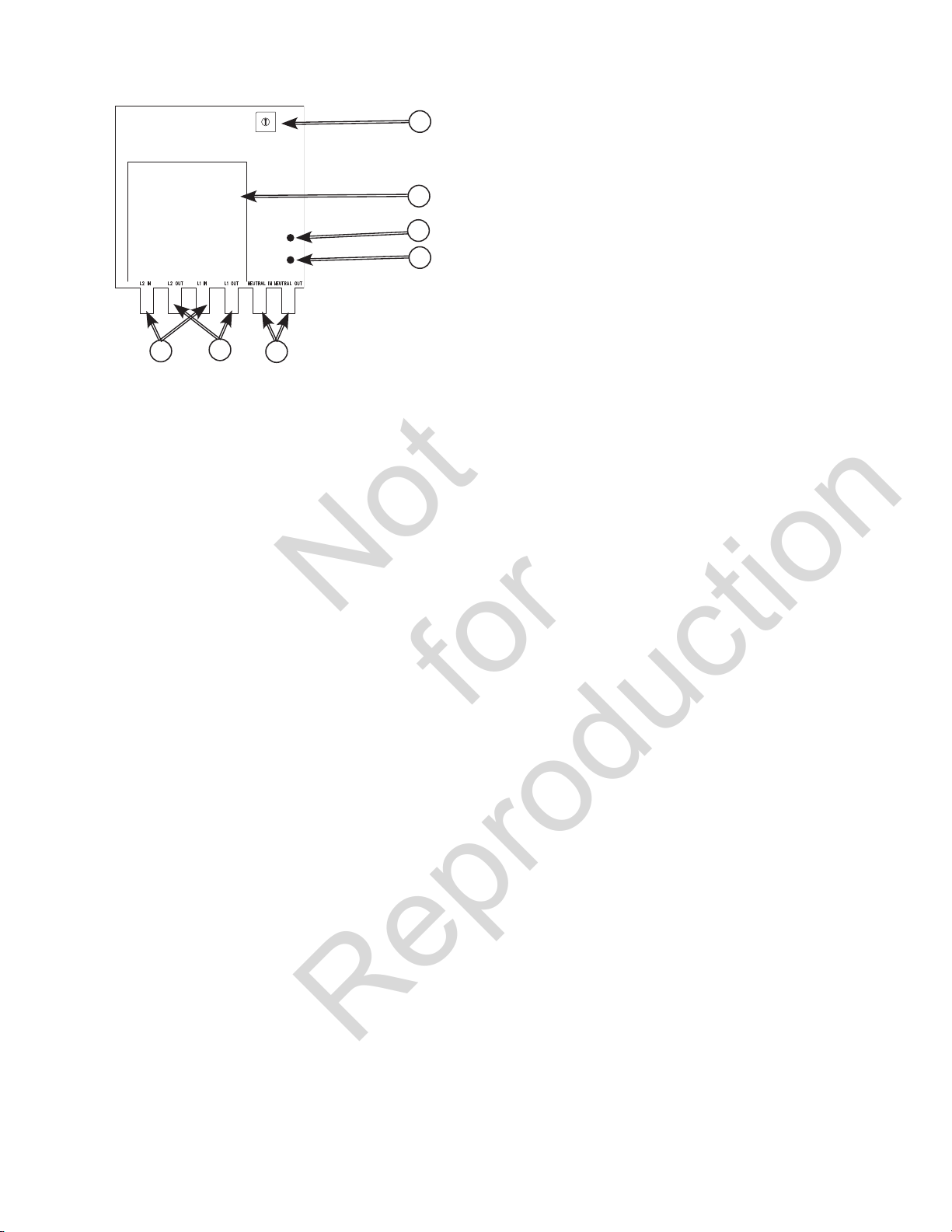

50 Amp Model

Not

for

Reproduction

A

B

C

D

G

A - Priority Selector

B - 50 Amp Relay

C - Relay Status LED

D - Signal Communication LED

E - Neutral Connection

F - Load Connection

G - Power/Line Connection

LED’s are for signal communication status and relay position

status.

Utility power present:

• Normal State

Relay Position Status LED (C)

- Green LED - Relay is closed; power available to

appliance/load

Signal Communication Status LED (D)

- Orange LED - No communication and appliances/

loads cannot be managed by Symphony II System

• Problem State (see Troubleshooting)

Relay Position Status LED (C)

- No LED - Power not available to managed

appliance/load; 5 minute delay has not expired,

verify correct wiring

- Red LED - 50 Amp relay contacts in incorrect state;

replace 50 Amp module

Signal Communication Status LED (D)

- No LED - No power to 50 Amp control board; verify

correct wiring

- Green LED - Broken LED; replace 50 Amp module

- Red LED - Fault in system; verify current

transformer connections, verify terminations on

orange and yellow communication wires

F

E

Generator power present:

• Normal State

Relay Position Status LED (C)

- Green LED - Relay is closed; power available to

appliance/load

- No LED - Relay open, no power, Symphony II is

managing load

Signal Communication Status LED (D)

- Green LED - Signal communication detected and

appliances/loads are being managed after 5 minute

delay

• Problem State (see Troubleshooting)

Relay Position Status LED (C)

- No LED - Power not available to managed

appliance/load; 5 minute delay has not expired,

verify correct wiring

- Red LED - 50 Amp relay contacts in incorrect state;

replace 50 Amp module

Signal Communication Status LED (D)

- No LED - No power to 50 Amp control board; verify

correct wiring

- Orange LED - Signal communication not detected;

verify correct wiring

- Red LED - Fault in system; verify current

transformer connections, verify terminations on

orange and yellow communication wires

19

Page 20

Maintenance

Not

for

Reproduction

The transfer switch is designed to be maintenance free under

normal usage. However, inspection and maintenance checks

should be made on a regular basis. Maintenance will consist

mainly of keeping the transfer switch clean.

Visual inspections should be done at least three times each

year. Access to the transfer switch and optional remote

modules must not be obstructed. Keep 3 feet (92 cm)

clearance around transfer switch. Check for an accumulation

of dirt, moisture and/or corrosion on and around the

enclosure, loose parts/hardware, cracks and/or discoloration

to insulation, and damaged or discolored components.

Exercise the transfer switch and Symphony II system at

least once every three months as described in Testing the

Automatic Transfer Switch and in Testing the Symphony II

Power Management System unless a power outage occurs

and the entire home generator system has gone through

an automatic sequence. Allow generator to run for at least

10 minutes during exercise cycle.

Contact a licensed electrical professional to inspect and

clean the inside of the enclosure and other components of

your home generator system at least once a year.

When Calling for Assistance

You must have the Model Number and Serial Number from

each transfer switch or remote module ID label at hand if it is

necessary to contact a local service center regarding service

or repair. Obtain this information from the unit ID labels

located on or inside device. For convenience, record the

information on the inside front cover of this manual.

To contact Briggs & Stratton call 800-743-4115, between

8:00 AM and 5:00 PM CT.

Installation Inspection

Before placing the system into service, inspect the entire

installation carefully.

Complete the ”Installation Checklist” supplied with the

generator as you make the inspection. Ensure all items have

been filled-in and all signatures have been obtained. Instruct

the owner to mail the white copy to the address shown on

the checklist.

20 BRIGGSandSTRATTON.COM

Page 21

Troubleshooting

Not

for

Reproduction

Problem Cause Correction

Au tomatic transfer switch does

not transfer to generator

Au tomatic transfer switch does

not transfer to utility

Ge nerator is still running after

switch transfers to utility

power

Ge nerator or supervised loads

(air conditioner, etc.) are

operating improperly when

generator is supplying power

1. Generator breaker open.

2. Generator voltage not acceptable.

3. Generator disconnect circuit breaker open

in transfer switch.

1. Utility disconnect circuit breaker open in

transfer switch.

2. Utility voltage not acceptable.

Engine cool down period. Engine should stop after 1 minute.

1. Remote modules are not

operating correctly.

2. Too much load on generator.

3. Current transformer not connected.

4. Broken current transformer.

5. Communication lost due to power line

noise.

6. Communication lost between transfer

switch and Symphony II control boards.

1. Reset generator circuit breaker.

2. Refer to generator manual.

3. Reset generator disconnect circuit

breaker in transfer switch.

1. Reset utility disconnect circuit breaker

in transfer switch.

2. Wait for utility voltage to return

to normal.

1. Five minute delay timer has

not expired.

2. Decrease load to generator.

3. Contact local authorized service center.

4. Contact local authorized service center.

5. Verify fluorescent ballasts are rated for

residential use only. If not, replace

with residential ballast.

Install noise filter in series and close

to problematic device.

Rewire remote module to opposite

power line (L1 or L2) from that of

problematic device.

6. Contact local authorized service center.

Ge nerator is still running after

utility power is restored

Re lay modules do not close after

five minutes

Re lay modules do not open during

transfer and retransfer

Sy mphony II system control board

status LED does not change

illumination blinking pattern

for utility or generator power.

1. Minimum engine run time has not elapsed.

2. Fuse(s) in transfer switch is defective.

1. Too much load on generator.

2. Communication interruption.

3. Priority set to 9 or 10.

Communication interruption. Contact local authorized service center.

1. TxRx and TxRx GND communication

2. TxRx and TxRx GND communication wires

3. TxRx and TxRx GND communication

1. Wait five minutes for transfer switch to

2. Contact local authorized service center.

1. Decrease load to generator.

2. Reset utility disconnect circuit breaker

3. Appliance will not turn on during

1. Contact local authorized service center.

wires are not connected between the

generator and transfer switch.

2. Contact local authorized service center.

are connected incorrectly between the

generator and transfer switch.

3. Contact local authorized service center.

wires affected by electrical noise

interference.

retransfer to utility power.

in transfer switch and wait five

minutes (turn OFF breaker for ten

seconds then turn it back ON).

standby power. Contact local

authorized service center to change

priority setting.

21

Page 22

Transfer Switch Schematic Diagram

Not

for

Reproduction

22 BRIGGSandSTRATTON.COM

Page 23

Transfer Switch Wiring Diagram

Not

for

Reproduction

23

Page 24

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC TRANSFER SWITCH OWNER WARRANTY POLICY

Not

for

Reproduction

Effective November 1, 2005 replaces all undated Warranties and all Warranties dated before November 1, 2005

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the equipment that is defective in material or

workmanship or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for the time periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in

our dealer locator map at BRIGGSandSTRATTON.COM.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW. ANY AND ALL IMPLIED

WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS

PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which vary from state to state or country to country.

WARRANTY PERIOD

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the

table above. “Consumer use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for

commercial, income producing or rental purposes. Once equipment has experienced commercial use, it shall thereafter be considered as commercial use for

purposes of this warranty. Equipment used for prime power in place of utility are not applicable to this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF

PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED,

THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most warranty

repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For example, warranty service would not apply if

equipment damage occurred because of misuse, lack of routine maintenance, shipping, handling, warehousing or improper installation. Similarly, the warranty

is void if the manufacturing date or the serial number on the equipment has been removed or the equipment has been altered or modified. During the warranty

period, the Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal use and

service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This warranty does not cover

repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation

or alteration and modification, misuse, negligence, accident, overloading, improper maintenance, repair or storage so as, in our judgment, to adversely

affect its performance and reliability. This warranty also does not cover normal maintenance such as adjustments, cleaning and fuse replacement.

• Other Exclusions: This warranty excludes wear items or damage or malfunctions resulting from accidents, abuse, modifications, alterations, or

improper servicing. Accessory parts are excluded from the product warranty. This warranty excludes failures due to acts of God and other force

majeure events beyond the manufacturers control. Also excluded is used, reconditioned, and demonstration equipment. 198180E, Rev. C, 12/31/2006

3 years

None

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

MILWAUKEE, WI, USA

24 BRIGGSandSTRATTON.COM

Page 25

Reserved

Not

for

Reproduction

25

Page 26

Automatic Transfer Switch

Not

for

Reproduction

Product Specifications

Model 071048

Rated Maximum Load Current

(at 25°C/77°F) ....................................................... 100 Amps

Rated AC Voltage ................................................... 250 Volts

Poles .................................................................................... 2

Frequency .....................................................................60 Hz

Fault Current Rating ...... 25,000 RMS Symmetrical Amperes

Normal Operating Range .....-20°F (-28.8°C) to 104°F (40°C)

Weight .............................................................59 lbs. (27 kg)

Model 071049

Rated Maximum Load Current

(at 25°C/77°F) ....................................................... 200 Amps

Rated AC Voltage ................................................... 250 Volts

Poles .................................................................................... 2

Frequency .....................................................................60 Hz

Fault Current Rating ...... 25,000 RMS Symmetrical Amperes

Normal Operating Range .....-20°F (-28.8°C) to 104°F (40°C)

Weight .............................................................63 lbs. (28 kg)

Model 071054

Rated Maximum Load Current

(at 25°C/77°F) ....................................................... 200 Amps

Rated AC Voltage ................................................... 250 Volts

Poles .................................................................................... 2

Frequency .....................................................................60 Hz

Fault Current Rating ...... 25,000 RMS Symmetrical Amperes

Normal Operating Range .....-20°F (-28.8°C) to 104°F (40°C)

Weight .............................................................63 lbs (27 kg).

This transfer switch is a UL Listed device

26 BRIGGSandSTRATTON.COM

Page 27

Manual de instalación y del operario

Not

for

Reproduction

100/200 Amperios Interruptor

de transferencia automática

con seccionador de servicio y sistema

de gestión de energía Symphony™ II

Preguntas?

La ayuda es justa un momento lejos!

Llamada: Línea Directa de generador de hogar

800-743-4115 M-F 8-5 CT

Page 28

Gracias por comprar este conectador automático de Briggs & Stratton® Power Products. Este producto está diseñado para

Not

for

Reproduction

utilizarse con generadores de reserva domésticos específicos y puede no funcionar con generadores o módulos remotos

producidos por otros fabricantes. Recurra a un electricista profesional cualificado para determinar si este equipo se puede

utilizar con equipo fabricado por terceros. Si se utiliza y mantiene de acuerdo con las instrucciones de este manual, su sistema

le proporcionará muchos años de funcionamiento fiable.

Este manual contiene información de seguridad para que usted conozca los peligros y riesgos propios de este sistema y

cómo evitarlos. Se ha realizado el máximo esfuerzo para que la instalación resulte segura, sencilla y económica. Debido a que

cada instalación es única, es imposible conocer y recomendar todos los procedimientos y métodos posibles para efectuarla.

No conocemos todos los riesgos y/o resultados posibles de cada método o procedimiento existente. Es importante que lea y

comprenda perfectamente estas instrucciones antes de intentar instalar o utilizar este equipo. Guarde estas instrucciones

para futuras consultas.

Este conectador y los módulos remotos opcionales deben ser instalados por un profesional antes de utilizarlos.

Consulte la sección de instalación de este manual y las instrucciones de instalación que vienen con los módulos remotos. Los

conectadores y los módulos remotos sólo deben ser instalados por electricistas con licencia. Las instalaciones deben cumplir

estrictamente la totalidad de los códigos, estándares y regulaciones federales, estatales y locales vigentes. El instalador debe

seguir las instrucciones detalladamente.

Ubicación

Nunca debe ir demasiado lejos para encontrar el soporte y servicio de Briggs & Stratton para su sistema. Consulte las

Páginas Amarillas. Existen múltiples distribuidores de servicio autorizados que ofrecen un servicio de calidad. También puede

comunicarse con el Servicio Técnico por teléfono al 800-743-4115 entre 8:00 a. m. y 5:00 p. m. Hora del Centro; o bien,

busque un distribuidor en BRIGGSandSTRATTON.COM, donde se incluye una lista de distribuidores autorizados.

Para futuras consultas

Llene la siguiente información y conserve su factura para facilitar la identificación de la unidad en caso de que surjan

problemas relacionados con la compra en el futuro.

Conectador Módulo remoto Módulo remoto Módulo remoto Módulo remoto

Número de modelo

Versión

Número de serie

Fecha de compra

PRIORIDAD N/A

Módulo remoto Módulo remoto Módulo remoto Módulo remoto Módulo remoto Módulo remoto

Copyright © 2011. Briggs & Stratton Power Products Group, LLC

Milwaukee, WI, USA. Reservados todos los derechos.

Briggs & Stratton Power Products es una marca

registradas de Briggs & Stratton Corporation

Milwaukee, WI, USA

2 BRIGGSandSTRATTON.COM

Page 29

Tabla de contenido

Not

for

Reproduction

Instrucciones importantes de seguridad. . . . . . . . . . . . . . . . . .4

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Responsabilidades del propietario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Orientación al propietario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Re sponsabilidades del distribuidor / técnico instalador. . . . . . . . . . . . . . . . . 5

Descripción del equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspección en el momento de la entrega . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Directrices de montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interconexión de los cables de alimentación . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminales de control de supervisión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Configuración del sistema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuración del módulo remoto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Prueba del conectador automático . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pr ueba del sistema de gestión de energía Symphony II . . . . . . . . . . . . . . . 15

Controles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Funcionamiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Monitor de alimentación Symphony™ II (opcional) . . . . . . . . . . . . . . . . . . . 17

Puerta de la caja . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LED de estado. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Indicadores de estado de los LED del módulo remoto . . . . . . . . . . . . . . . . 19

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Especificaciones del producto . . . . . . . . . . . . . . . . . . . . . . . . .24

3

Page 30

Guarde estas instrucciones

Not

for

Reproduction

Instrucciones importantes

de seguridad

GUARDE ESTAS INSTRUCCIONES - Este manual contiene

instrucciones importantes que se deben seguir durante la

instalación y el mantenimiento del equipo.

Símbolos sobre la seguridad y significados

Descarga eléctrica

El símbolo de alerta de seguridad indica un posible

riesgo para su integridad física. Se utiliza una palabra de

señalización (PELIGRO, ADVERTENCIA o ATENCIÓN)

junto con el símbolo de alerta para designar un grado o nivel

de gravedad de riesgo. Se puede utilizar un símbolo de

seguridad para representar el tipo de riesgo. La palabra de

señalización AVISO se utiliza para hacer referencia a una

práctica no relacionada con una lesión física.

PELIGRO indica un riesgo que, de no evitarse, provocará

la muerte o lesiones de gravedad.

ADVERTENCIA indica un riesgo que, de no evitarse,

podría provocar la muerte o lesiones de gravedad.

ATENCIÓN indica un riesgo que, de no evitarse, podría

provocar lesiones leves o moderadas.

AVISO hace referencia a una práctica no relacionada con

una lesión física.

El fabricante no puede prever toda circunstancia que

conlleve un riesgo potencial. Por tanto, las advertencias

de este manual, así como las etiquetas y calcomanías

adheridas a la unidad, no incluyen todos los riesgos

posibles. Si utiliza un procedimiento, método de trabajo

o técnica de uso no recomendado específicamente por

el fabricante, deberá asegurarse de que es seguro tanto

para usted como para otras personas. También deberá

asegurarse de que el procedimiento, método de trabajo o

técnica de uso que elija no hace que el equipo sea inseguro.

ADVERTENCIA Determinados componentes en

este producto y los accesorios relacionados contienen

sustancias químicas declaradas cancerígenas, causantes

de malformaciones, y otros defectos congénitos por el

Estado de California. Lávese las manos después de

manipular estos elementos.

AVISO La instalación de este equipo debe cumplir

estrictamente la totalidad de los códigos, estándares y

regulaciones vigentes, por lo que sólo debe ser llevada a

cabo por un electricista cualificado.

Lea el manual

ADVERTENCIA Peligro de descarga. La instalación

de un cable de baja y alta tensión en el mismo

conducto podría provocar daños materiales,

lesiones graves o incluso la muerte.

• No tienda un cable de baja y alta tensión en el mismo

conducto a menos que el valor nominal de aislamiento

en TODO el cableado sea de 600 V. Para obtener más

información, consulte el NEC.

ADVERTENCIA Una conexión a tierra defectuosa del

equipo podría provocar electrocución, así como

lesiones graves o incluso la muerte.

• No toque los cables pelados.

• No utilice el equipo con cables desgastados,

deshilachados o deteriorados de cualquier otra forma.

• No manipule los cables eléctricos si se encuentra en

una zona húmeda, está descalzo o tiene las manos o los

pies mojados.

• Si tiene que trabajar junto a una unidad en

funcionamiento, manténgase en una superficie aislada y

seca para reducir el riesgo de descarga eléctrica.

• No permita que personas no cualificadas o niños utilicen

o reparen el equipo.

• En caso de accidente provocado por una descarga

eléctrica, desconecte inmediatamente todos los

suministros de energía eléctrica y póngase en contacto

con las autoridades locales. Evite el contacto directo con

la víctima.

ADVERTENCIA El equipo contiene alta tensión que

podría provocar electrocución, así como lesiones

graves o incluso la muerte.

• A pesar de la seguridad del diseño del sistema, si éste se

utiliza con imprudencia, ignorando su mantenimiento o sin

las debidas precauciones, se podrían provocar lesiones

graves o incluso la muerte.

AVISO Un tratamiento inadecuado del equipo podría

estropearlo y acortar su vida útil.

• Utilice el equipo sólo para los usos previstos.

• En caso de dudas sobre su uso, diríjase al distribuidor o a

Briggs & Stratton Power Products.

• No exponga el equipo a un exceso de humedad, polvo,

suciedad o vapores corrosivos.

• Manténgase alerta en todo momento cuando utilice este

equipo. Nunca lo utilice ni manipule en condiciones de

fatiga física o mental.

• Si se calientan excesivamente los dispositivos

conectados, apáguelos y abra sus interruptores o quite

sus fusibles.

4 BRIGGSandSTRATTON.COM

Page 31

Instalación

Not

for

Reproduction

Agradecemos sinceramente que nos haya elegido, por lo

que hemos realizado un esfuerzo importante para que la

instalación resulte segura, sencilla y económica. Debido

a que cada instalación es única, es imposible conocer y

recomendar todos los procedimientos y métodos posibles

para efectuarla. Tampoco conocemos todos los riesgos y/o

resultados posibles de cada método o procedimiento.

Por tanto, la instalación del sistema sólo puede ser

llevada a cabo por electricistas profesionales con

licencia vigente. Las instalaciones deben cumplir

estrictamente la totalidad de los códigos, estándares

de la industria y regulaciones vigentes.

Su equipo se suministra con este “Manual de instalación

y del operario” combinado. Se trata de un documento

importante que el propietario debe conservar después de

haber terminado la instalación.

Se ha realizado el máximo esfuerzo para reunir en este

manual la información más precisa y actualizada. No

obstante, el fabricante se reserva el derecho de modificar,

alterar o mejorar de cualquier otra forma el sistema en

cualquier momento y sin previo aviso.

Responsabilidades del propietario

Para tomar decisiones bien fundadas y comunicarse

eficazmente con el técnico instalador, lea y comprenda la

sección de Orientación al propietario antes de contratar

o iniciar la instalación del equipo.

Para solicitar la instalación, póngase en contacto con la

tienda en la que adquirió el equipo, con su distribuidor o con

la compañía eléctrica.

La garantía del equipo quedará ANULADA a menos que

electricistas profesionales con licencia instalen el sistema.

Orientación al propietario

Las ilustraciones incluidas corresponden a circunstancias

habituales y tienen por objeto familiarizarle con las opciones

de instalación del sistema.

La normativa local, la apariencia y las distancias son los

aspectos que deberán tenerse en cuenta al negociar la

instalación con un profesional. Al aumentar la distancia

desde el servicio eléctrico, se deberá prever una

compensación en cables y otros materiales necesarios

para cumplir la normativa local vigente y evitar caídas de

tensión eléctrica.

Estos factores tendrán un efecto directo en el precio

total de la instalación del equipo.

El instalador deberá comprobar la normativa local Y obtener

los permisos correspondientes antes de instalar el sistema.

• Lea y siga las instrucciones que se indican en

este manual.

• Siga un plan regular de cuidado y uso del equipo, como

se indica en este manual.

Re sponsabilidades del distribuidor /

técnico instalador

• Lea y siga las instrucciones importantes de seguridad.

• Lea y siga las instrucciones que se indican en

• Es posible que el instalador tenga que proporcionar

• Analice con el propietario la importancia de las

• Si tiene dudas sobre la instalación, consulte los

• Asegúrese de que las cargas seleccionadas no

Si necesita más información sobre el conectador, llame al

800-743-4115 entre 8:00 a. m y 5:00 p. m., Hora del Centro.

Descripción del equipo

El conectador está diseñado para transferir las cargas

seleccionadas de una instalación residencial normal al

suministro de reserva en caso de una interrupción de

alimentación primaria. La carga se conecta al suministro

de alimentación de la red pública (normal) o al suministro

doméstico de reserva (generador). El conectador

monitoriza las tensiones de la red pública y del generador

y conecta automáticamente las cargas a la fuente de

alimentación apropiada.

El sistema de gestión de energía Symphony™ II es muy

flexible y utiliza módulos de tensión alta y baja individuales

que se pueden montar en cualquier lugar entre el panel de

distribución principal doméstico y el aparato gestionado.

Dado que está diseñado para comunicarse a través del

cableado de alimentación doméstico existente, la demanda

de alimentación y la secuencia de prioridades de hasta 8

cargas de aparatos se transmiten de vuelta al generador

de reserva, lo que evita con eficacia que el generador

se sobrecargue y amplía el alcance y la eficiencia de la

alimentación. El sistema puede crecer y se pueden añadir

relés adicionales conforme cambien las necesidades de

gestión de alimentación del propietario doméstico con el

paso del tiempo.

Sólo un electricista con licencia debe realizar la instalación

doméstica de reserva. El conducto y los conductores de

servicio se pueden cablear directamente desde el contador

de vatios/hora hasta el conectador. No es necesario

instalar un seccionador de entrada de servicio distinto, con

su correspondiente cableado, para cumplir los códigos,

los estándares y las regulaciones federales, estatales y

locales correspondientes.

este manual.

contactores nominales adecuados con base en las

cargas que van a controlarse.

prioridades de carga para decidir qué ajustes se

realizarán en la prioridad de los módulos remotos.

códigos federales, estatales y locales, así como a la

autoridad competente.

sobrecarguen el generador.

5

Page 32

Los principales componentes del conectador son un

Not

for

Reproduction

disyuntor bipolar de desconexión de la red pública, un

disyuntor bipolar de desconexión del generador, un

conectador bipolar de 2 posiciones de contacto, la tarjeta

de circuito impreso de control del conectador, la tarjeta

de circuito impreso de control del sistema de gestión de

energía Symphony II, los terminales con fusibles de tensión

de la red pública y el cableado de interconexión. Todos

estos componentes se encuentran en una caja tipo 3R

según NEMA, que es adecuada para uso en interiores y a

la intemperie.

El conectador es accionado por un solenoide alimentado

desde entradas de la red pública o del generador y tiene

interruptores de enclavamiento mecánicos y eléctricos,

adecuados para eliminar la posibilidad de conectar la red

pública a la salida del generador. Sus valores nominales

son suficientes para conectar toda la alimentación de la

red pública a la residencia. Asimismo, para la función de

transferencia hay una palanca de cancelación manual.

La tarjeta de control del conectador tiene circuitos activos

que detectan las tensiones de la red pública y del generador.

Genera una señal para el arranque del generador, conectador

y retransferencia cuando se restablece la tensión en la red

pública. La tarjeta de control del conectador cuenta con LED

de estado que indican la fuente de energía disponible.

La tarjeta de control del sistema de gestión de energía

Symphony™ II contiene un botón de prueba, un LED de

estado y ocho LED de carga de prioridad. Este sistema

crea y envía señales a módulos remotos opcionales, para

indicarles cuándo añadir (encender la alimentación) o

eliminar (apagar la alimentación) la carga gestionada.

La tecnología de soporte de la línea de alimentación del